Germanium/carbon composite negative electrode material and preparation method thereof

A negative electrode material and carbon composite technology, applied in negative electrodes, battery electrodes, active material electrodes, etc., can solve problems such as low output and volume expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A preparation method of a germanium / carbon composite negative electrode material, comprising: ball milling and mixing germanium dioxide and polyvinylpyrrolidone, and then annealing in an argon-containing hydrogen atmosphere to obtain a germanium / carbon composite negative electrode material.

[0026] The inventors determined through in-depth research that the best effect can be achieved when the weight ratio of germanium dioxide to polyvinylpyrrolidone is in the range of 2:1-1:2. Below or above this range, germanium / carbon composite negative electrode materials can also be produced, and the prepared germanium / carbon composite negative electrode materials are also better. However, the effect obtained by the weight ratio of germanium dioxide to polyvinylpyrrolidone in the range of 2:1 to 1:2 is obviously better than that obtained outside this range, which is manifested in the more uniform particle size distribution of germanium nanocrystals, or the distribution of germanium...

Embodiment 1

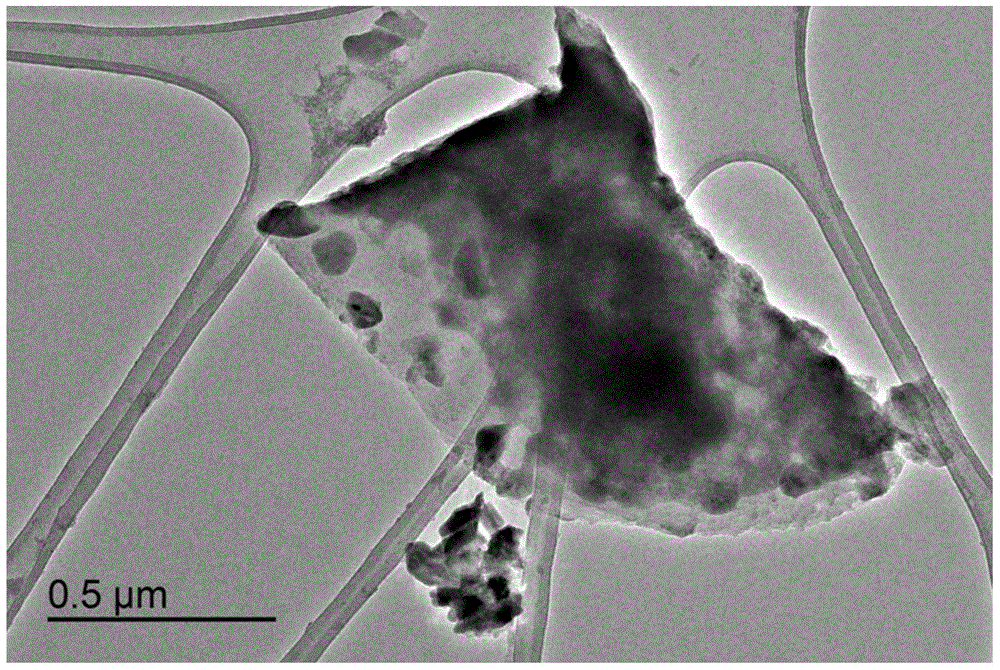

[0038] 60 grams of germanium dioxide and polyvinylpyrrolidone PVP-K10 with a weight ratio of 2:1 were mixed by ball milling for 1 hour, and then the mixture was heated in 5% Ar / H at 500°C. 2 Annealing in the atmosphere for 4 hours, the germanium / carbon composite material is obtained. Elemental analysis showed that the weight ratio of germanium: carbon: nitrogen was 68:30.55:1.45. figure 1 Transmission electron micrograph of the germanium / carbon composite material prepared in Example 1. Depend on figure 1 It can be seen that the germanium nanoparticles are uniformly wrapped in the carbon material.

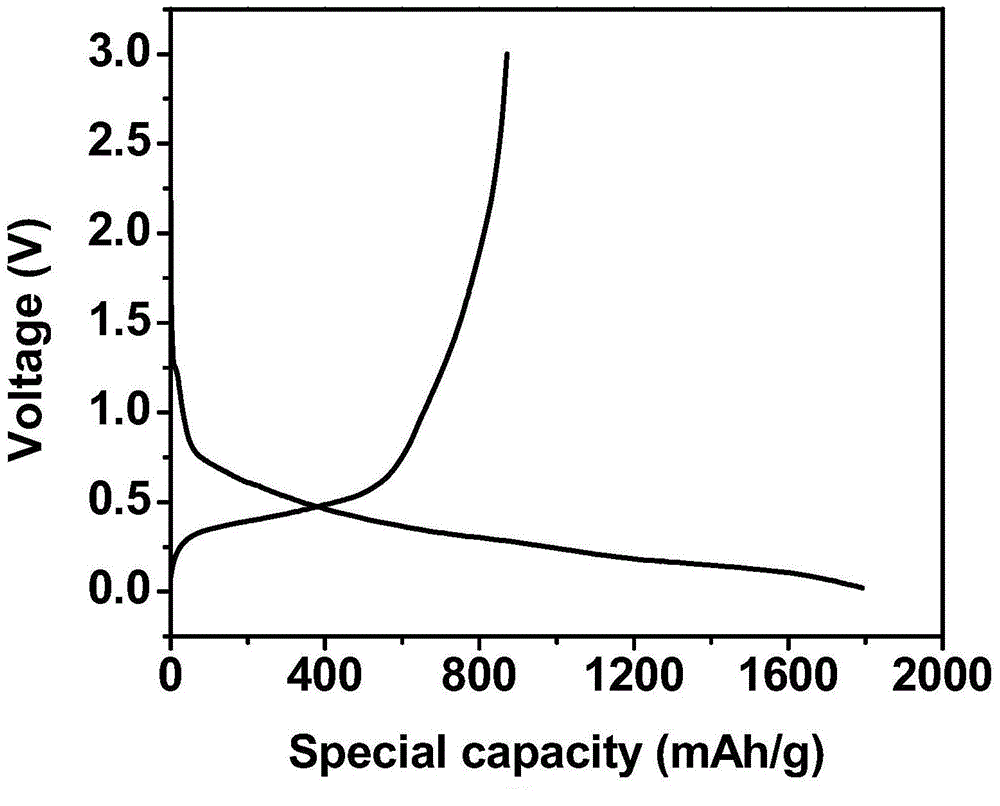

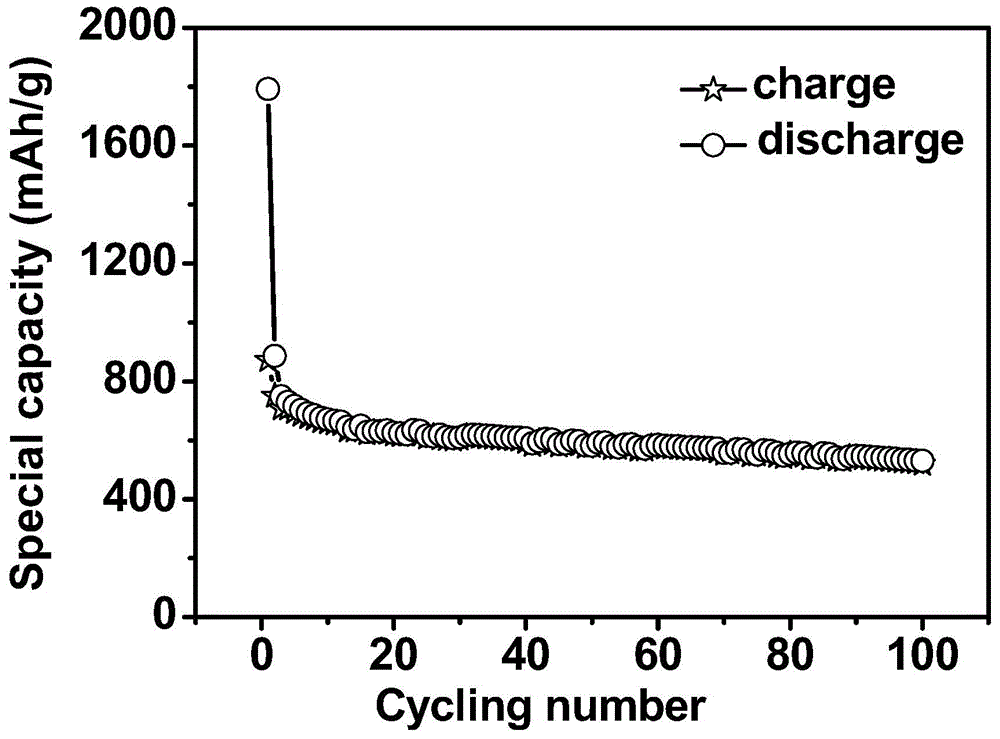

[0039] Mix the synthesized germanium / carbon composite material with conductive carbon black and CMC uniformly in the ratio of 80wt.%: 10wt.%: 10wt.%, and coat them on the copper foil. The electrochemical performance was tested by a button cell. The electrolyte uses 1mol / L LiPF 6 / EC-DEC-DMC (1:1:1, w / w). Discharging / charging were performed at 200mA / g, respectively, and the pot...

Embodiment 2

[0041] 60 grams of germanium dioxide and polyvinylpyrrolidone PVP-K10 with a weight ratio of 1:1 were mixed by ball milling for 1 hour, and the 5% Ar / H at 500 ° C 2 Annealing in the atmosphere for 4 hours, the germanium / carbon composite material is obtained. Elemental analysis showed a germanium:carbon:nitrogen weight ratio of 52:43:5. The transmission electron micrograph of the germanium / carbon composite material prepared in this example is similar to Example 1.

[0042] Mix the synthesized germanium / carbon composite material with conductive carbon black and CMC uniformly in the ratio of 80wt.%: 10wt.%: 10wt.%, and coat them on the copper foil. The electrochemical performance was tested by a button cell. The electrolyte uses 1mol / L LiPF 6 / EC-DEC-DMC (1:1:1, w / w). Discharging / charging were performed at 200mA / g, respectively, and the potential range was 0.01-3.0V. When charging and discharging at a current of 200mA / g, the charge specific capacity can reach 1680mAh / g in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com