Patents

Literature

66results about How to "Increased rate capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

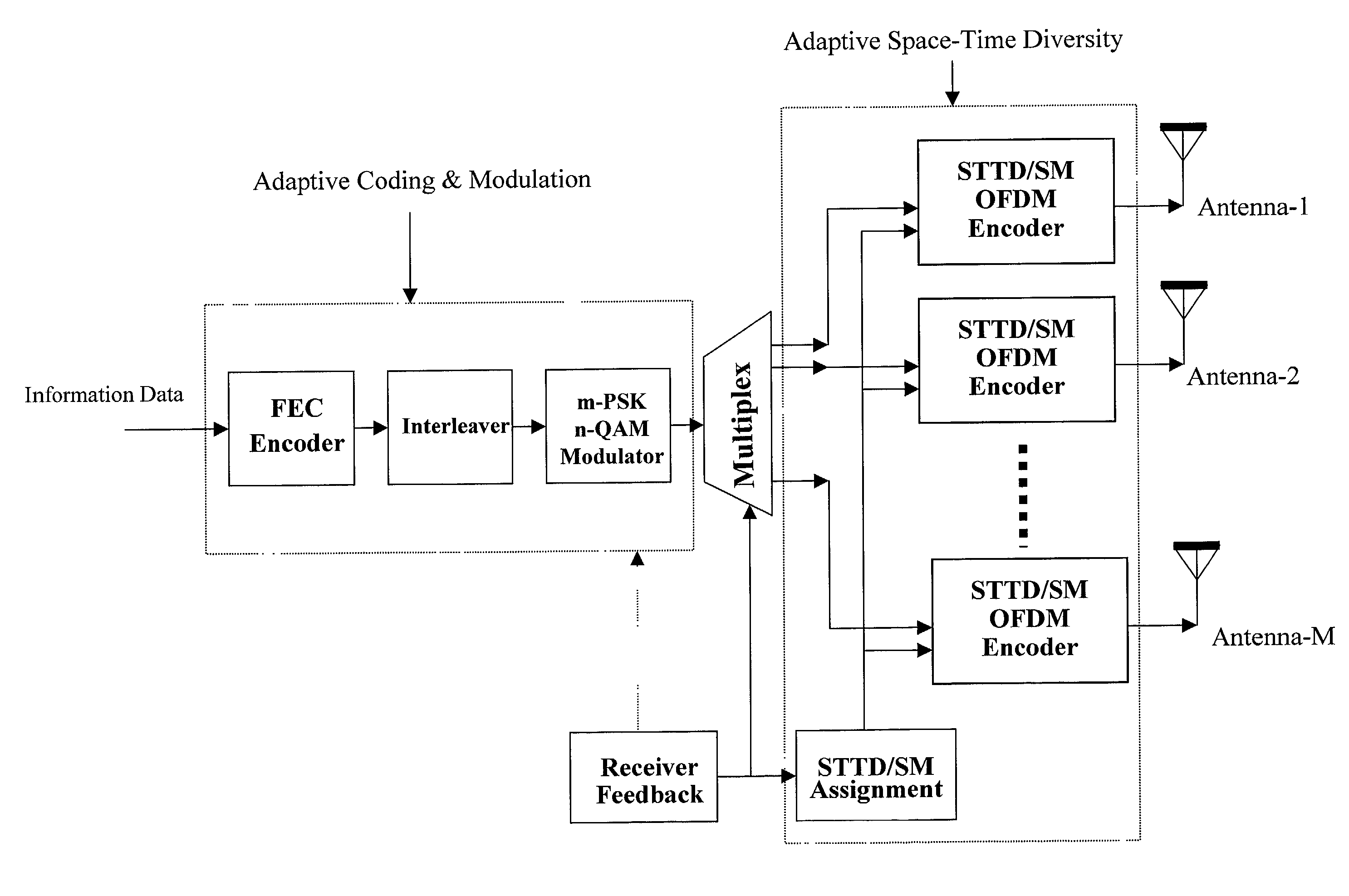

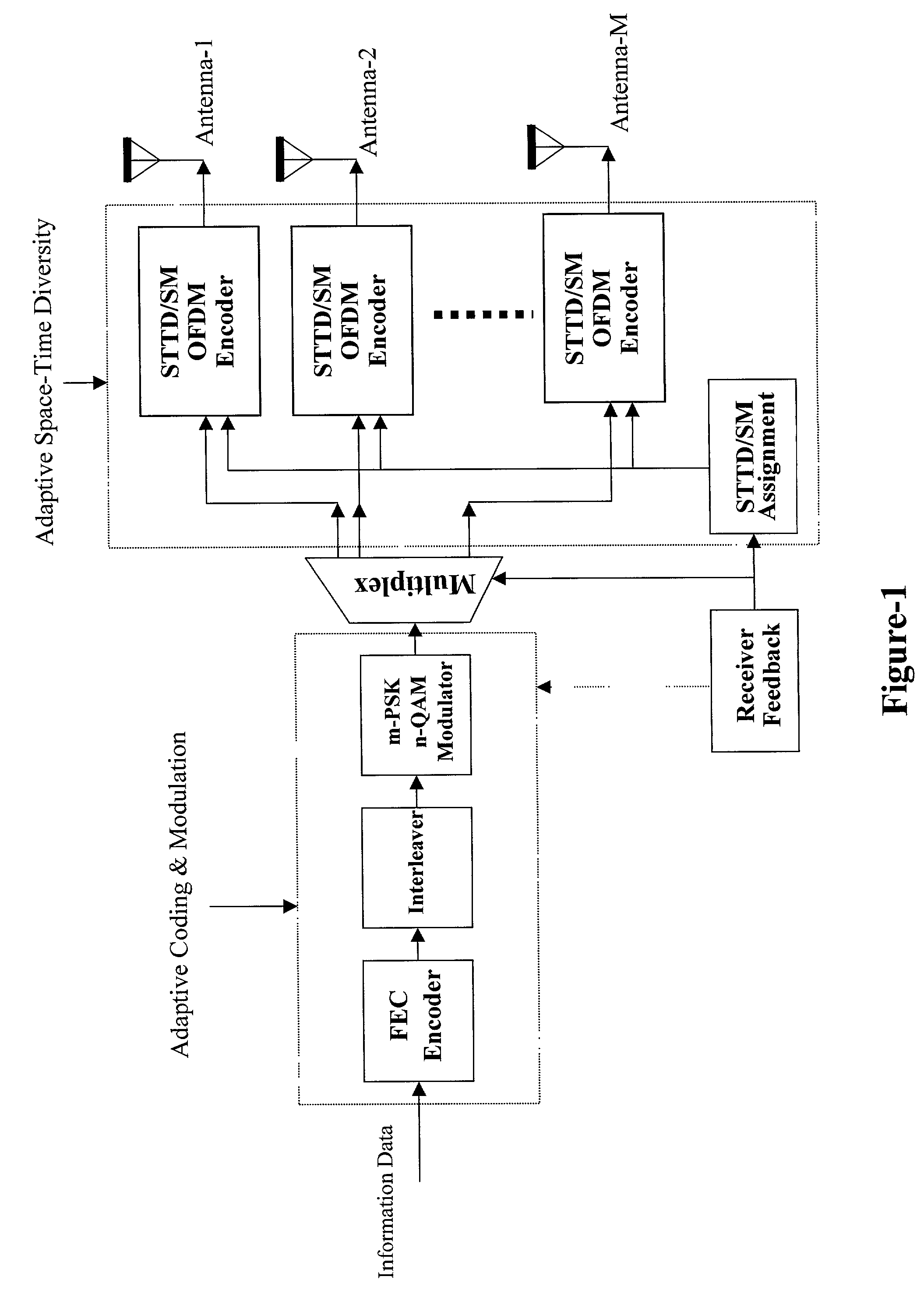

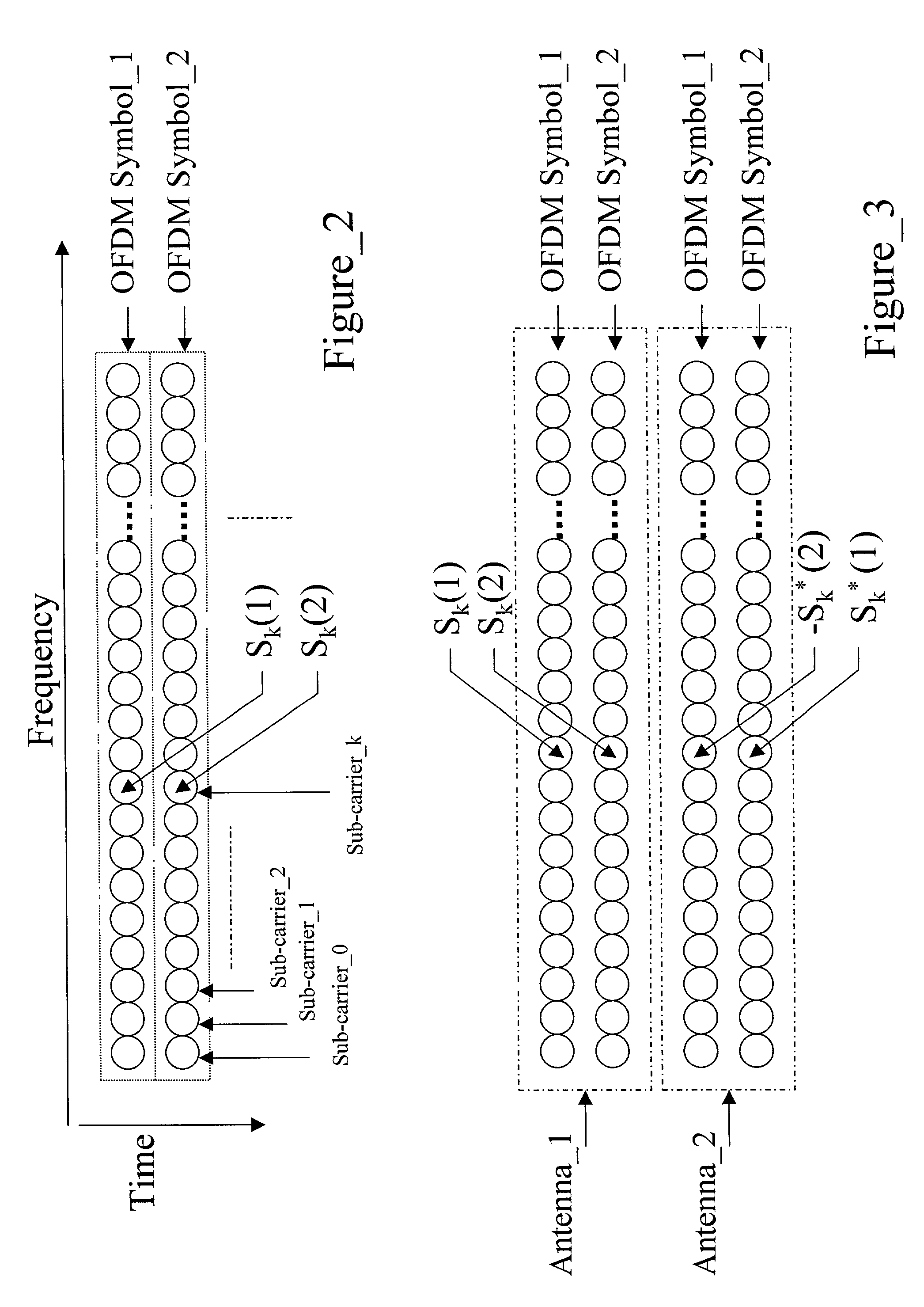

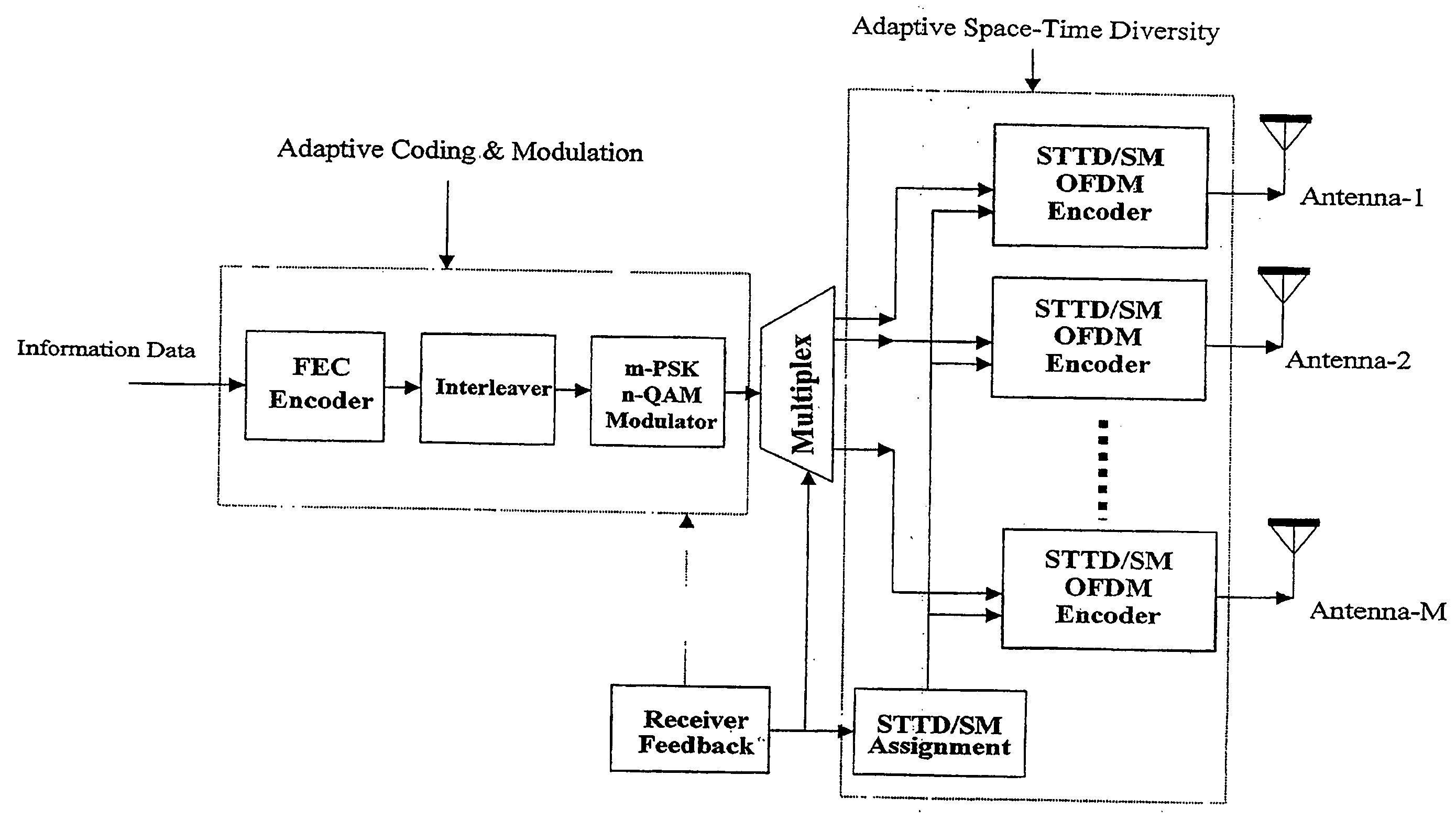

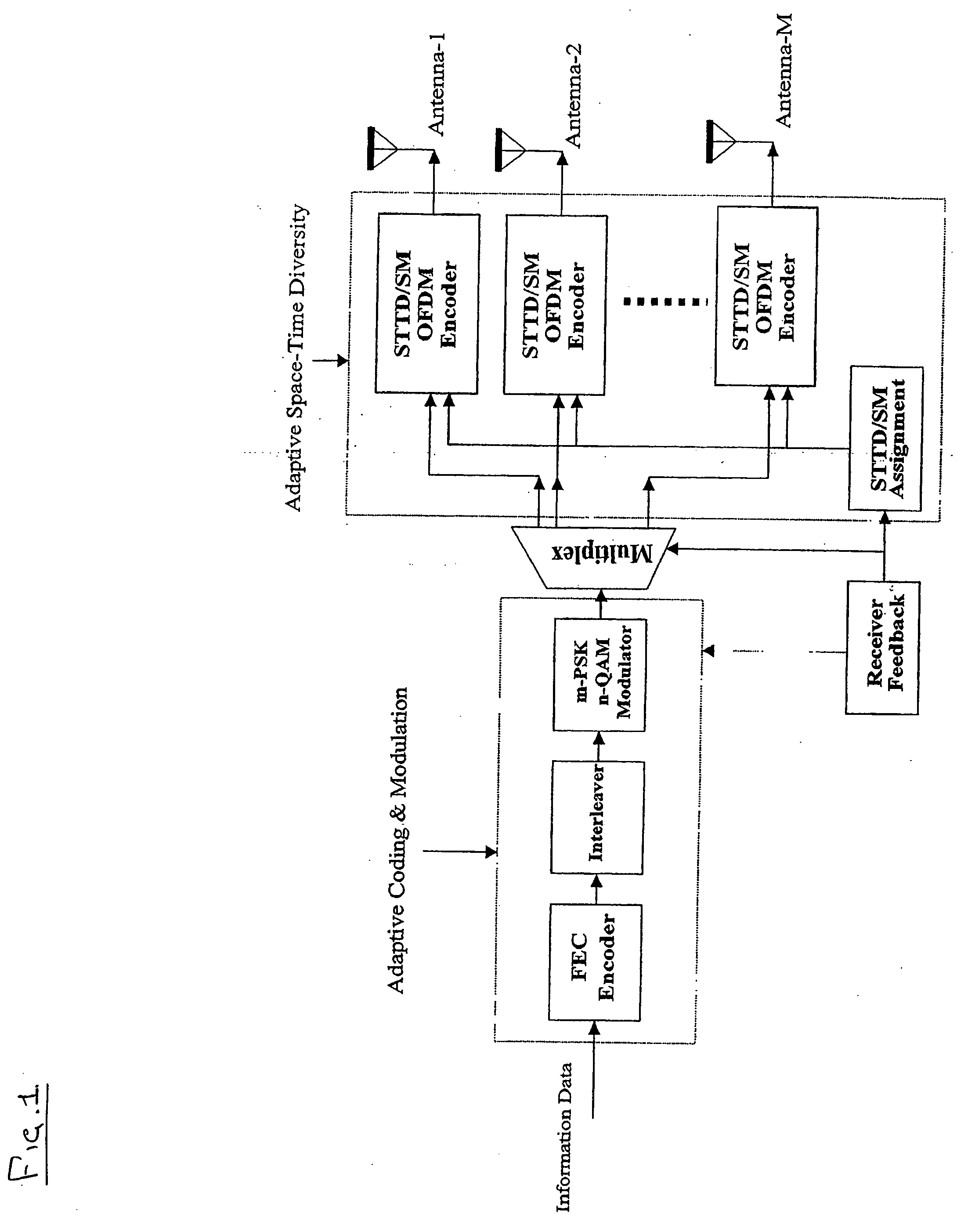

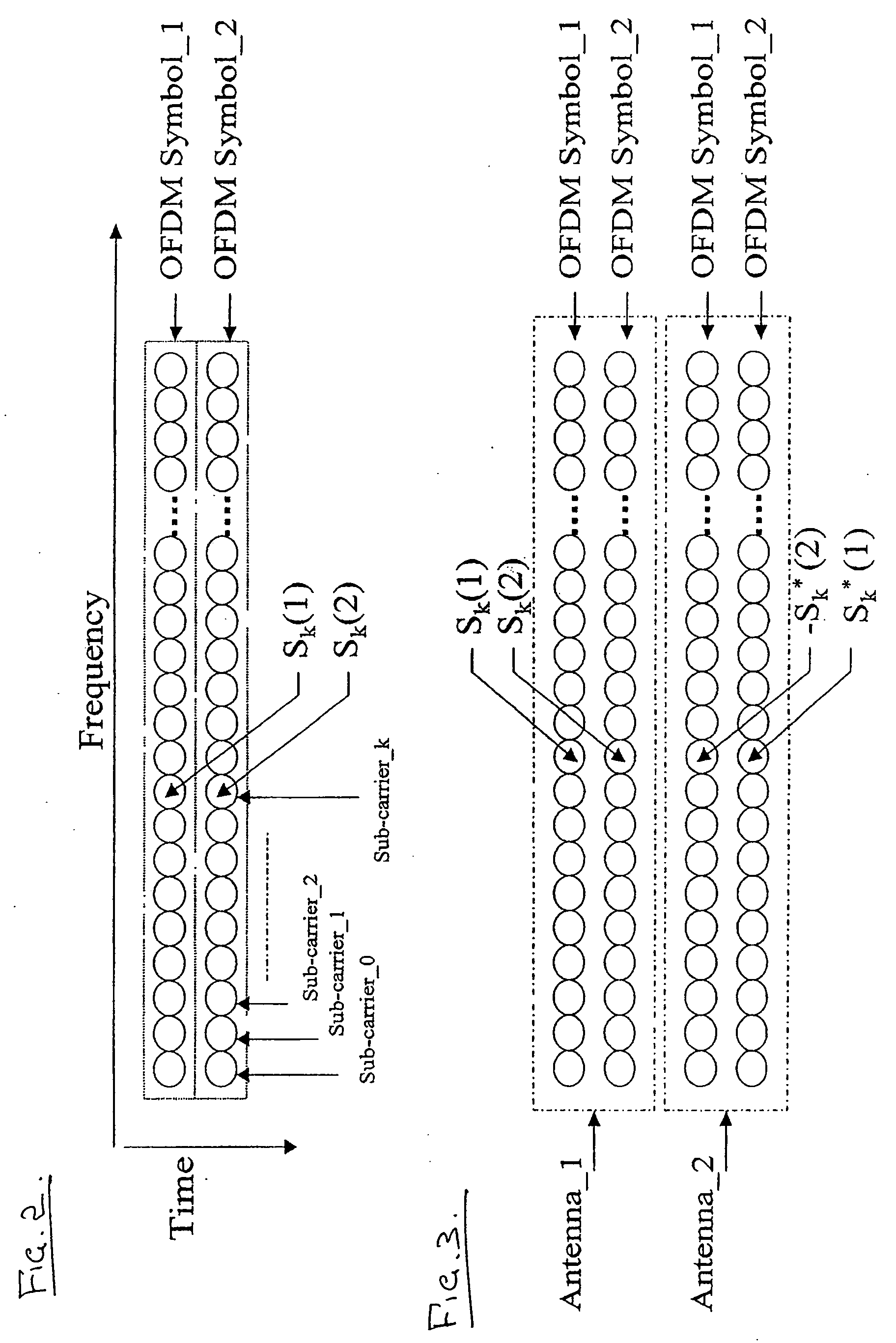

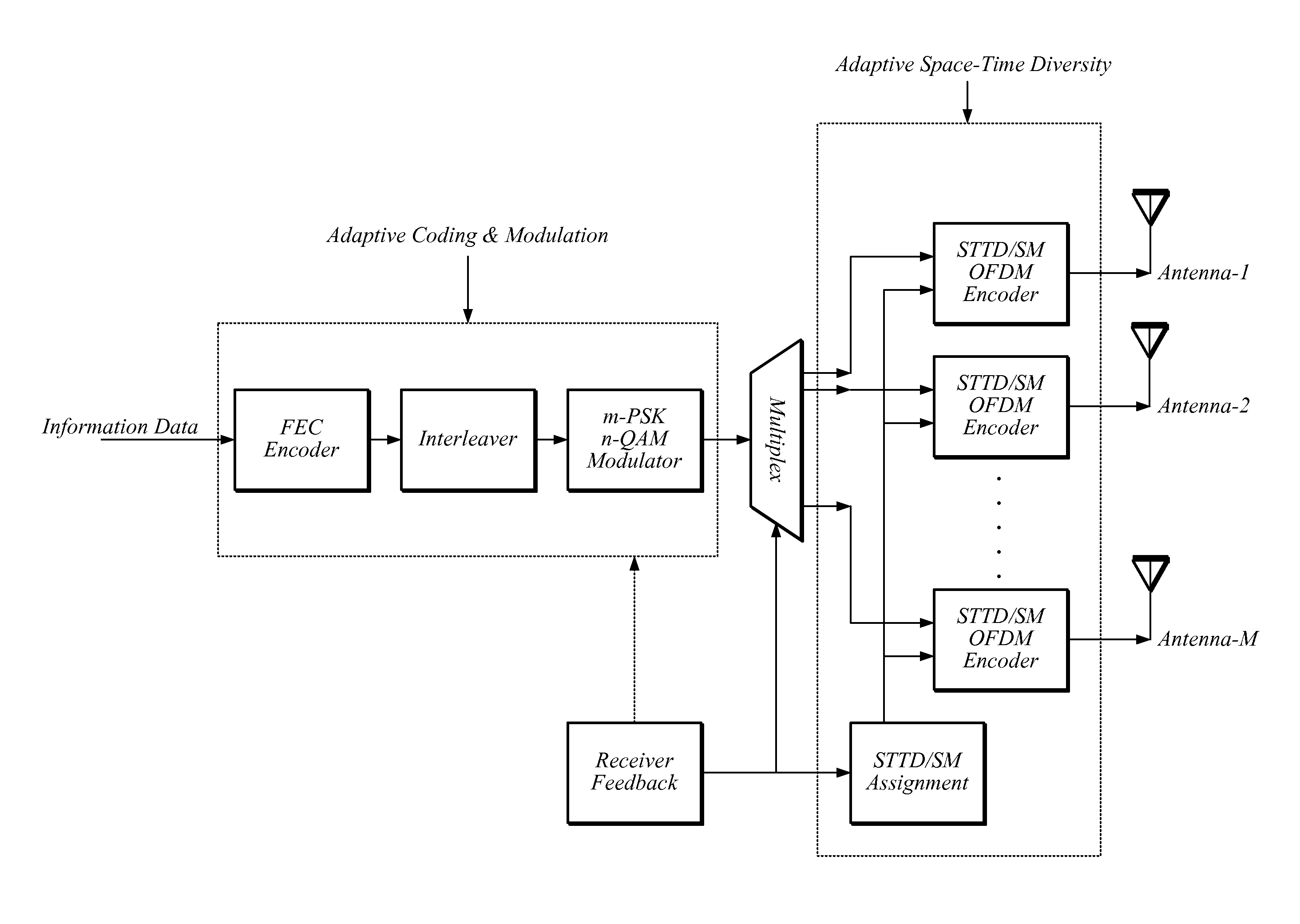

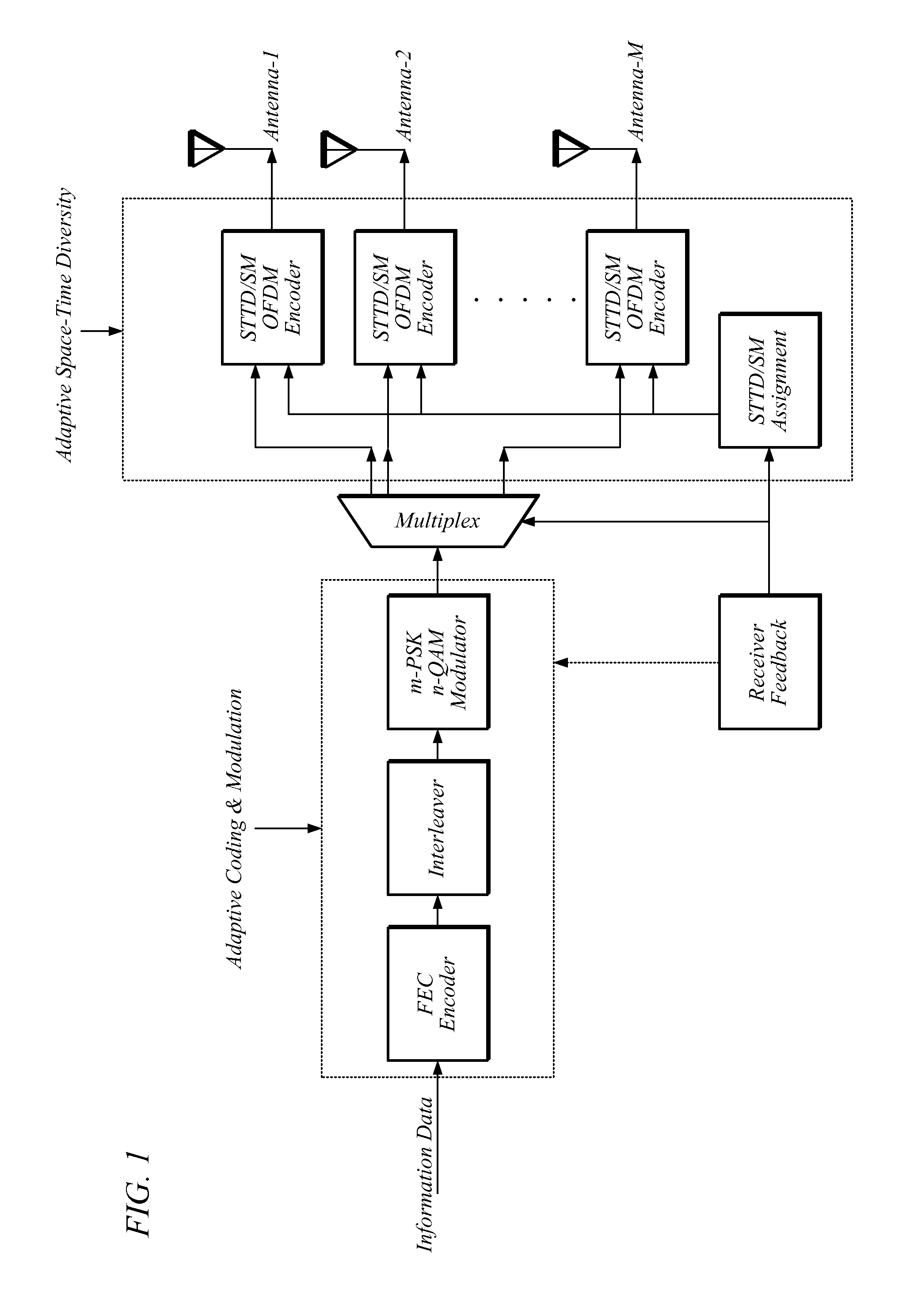

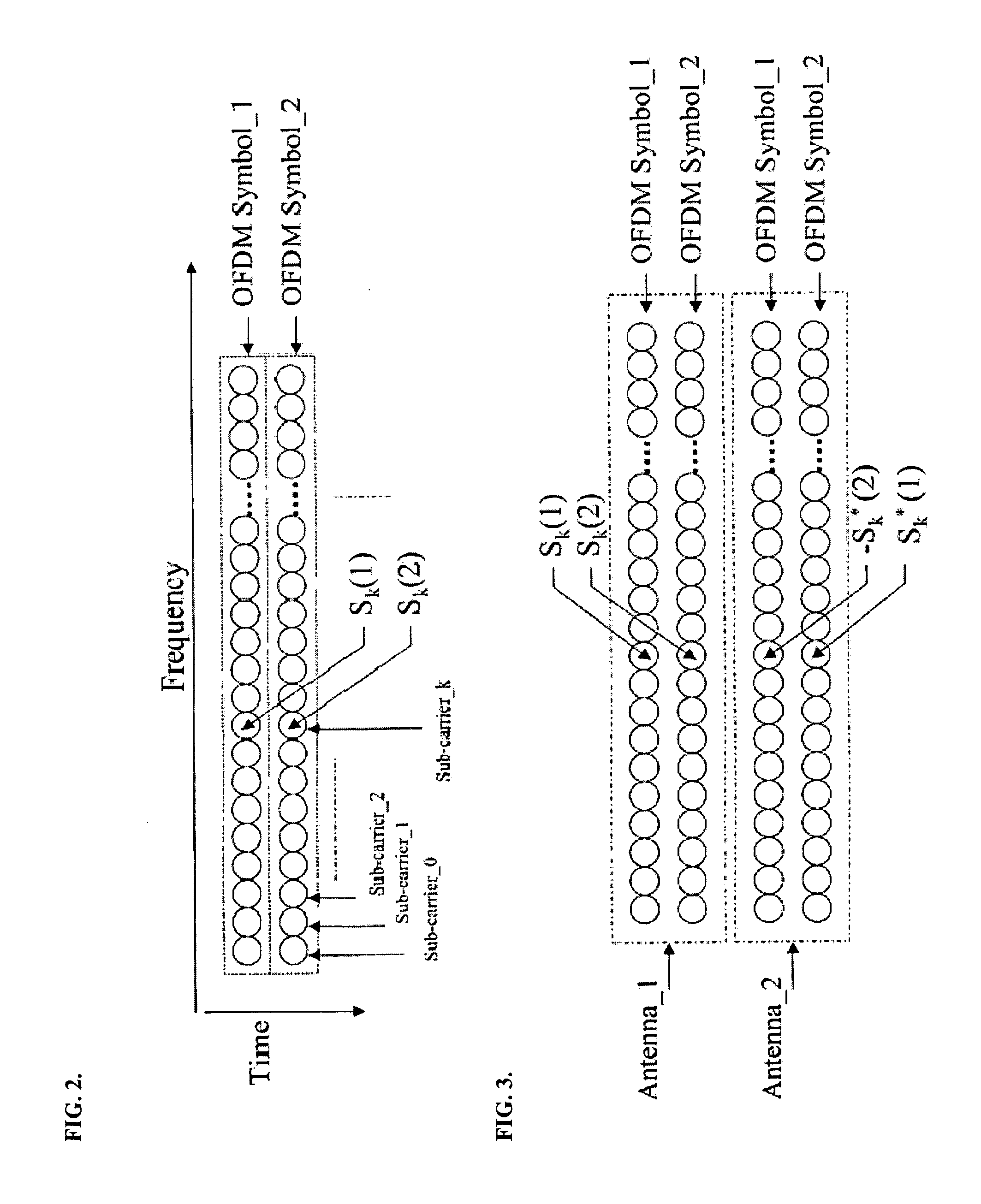

Adaptive time diversity and spatial diversity for OFDM

InactiveUS6985434B2Gain is assured with time diversityReduce signalingSpatial transmit diversityMultiple modulation transmitter/receiver arrangementsCarrier signalData rate

An adaptable orthogonal frequency-division multiplexing system (OFDM) that uses a multiple input multiple output (MIMO) to having OFDM signals transmitted either in accordance with time diversity to reducing signal fading or in accordance with spatial diversity to increase the data rate. Sub-carriers are classified for spatial diversity transmission or for time diversity transmission based on the result of a comparison between threshold values and at least one of three criteria. The criteria includes a calculation of a smallest eigen value of a frequency channel response matrix and a smallest element of a diagonal of the matrix and a ratio of the largest and smallest eigen values of the matrix.

Owner:APPLE INC

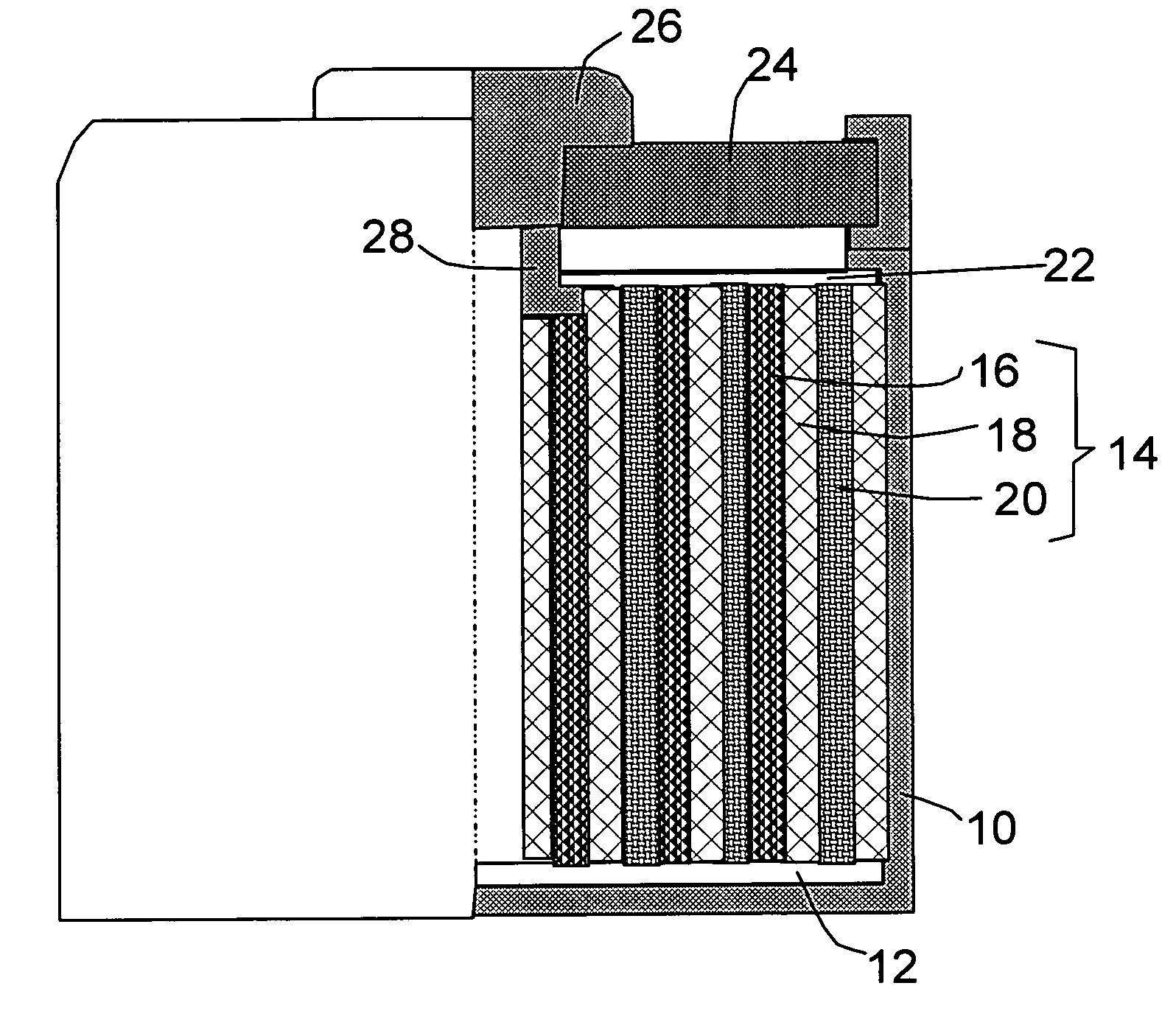

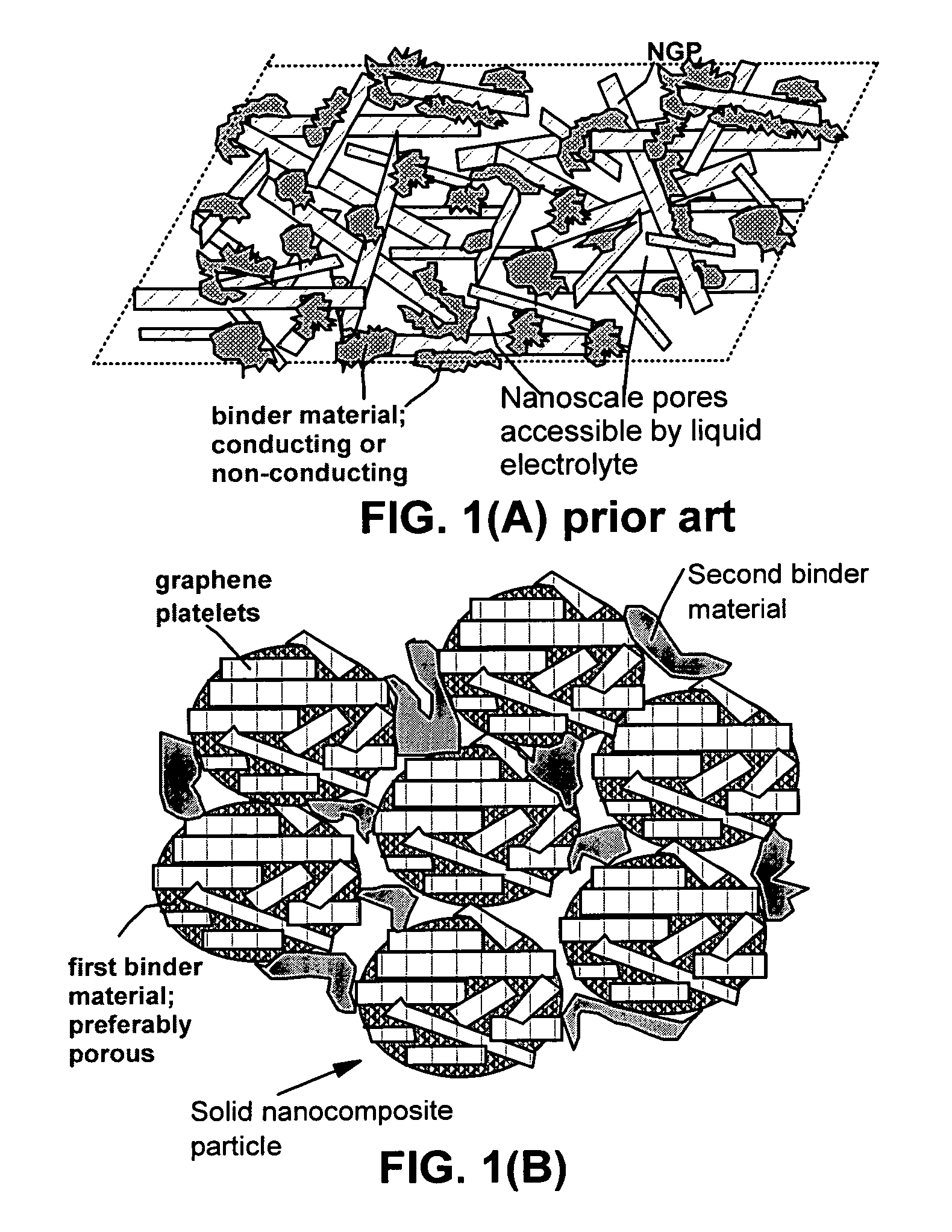

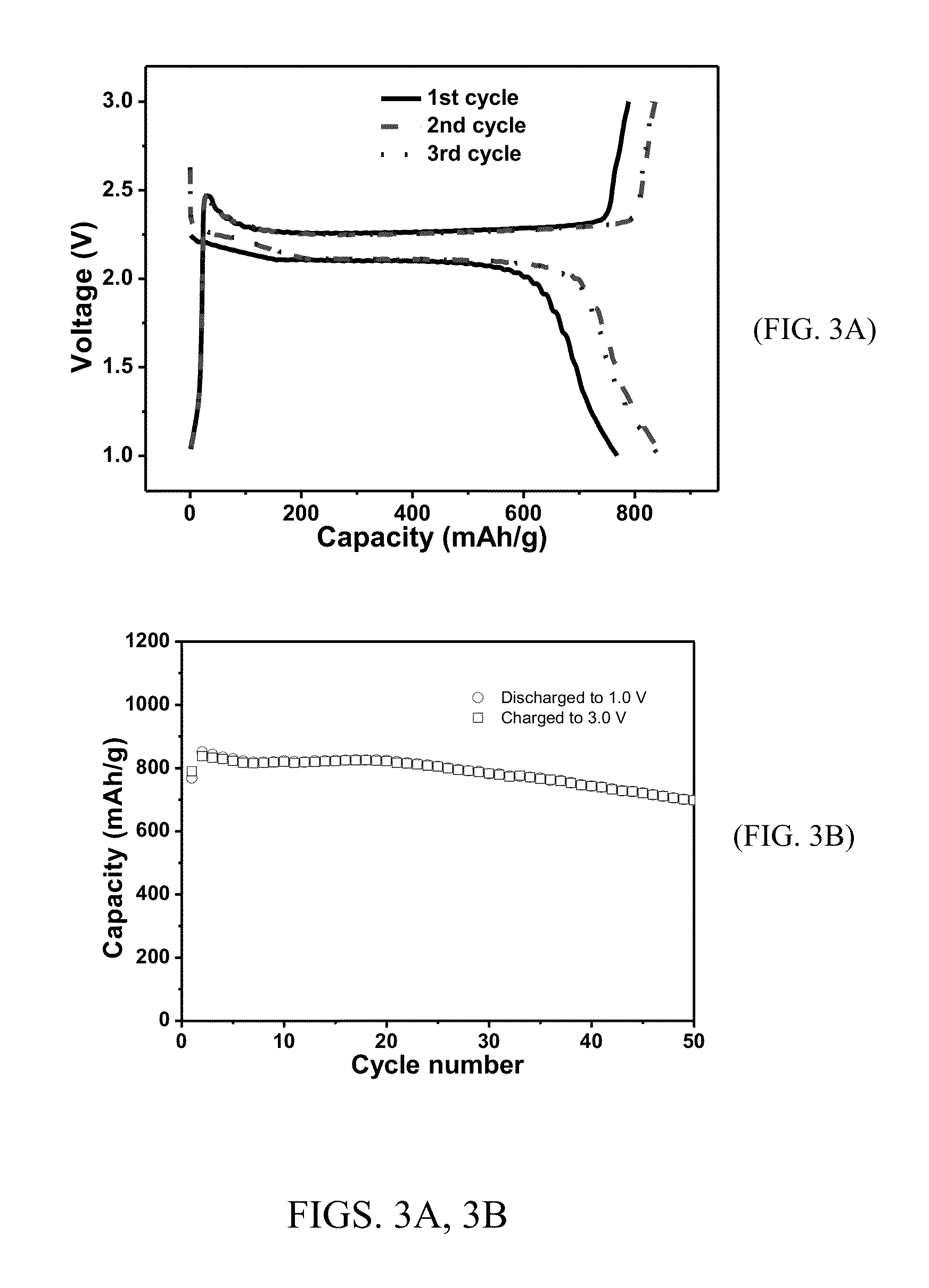

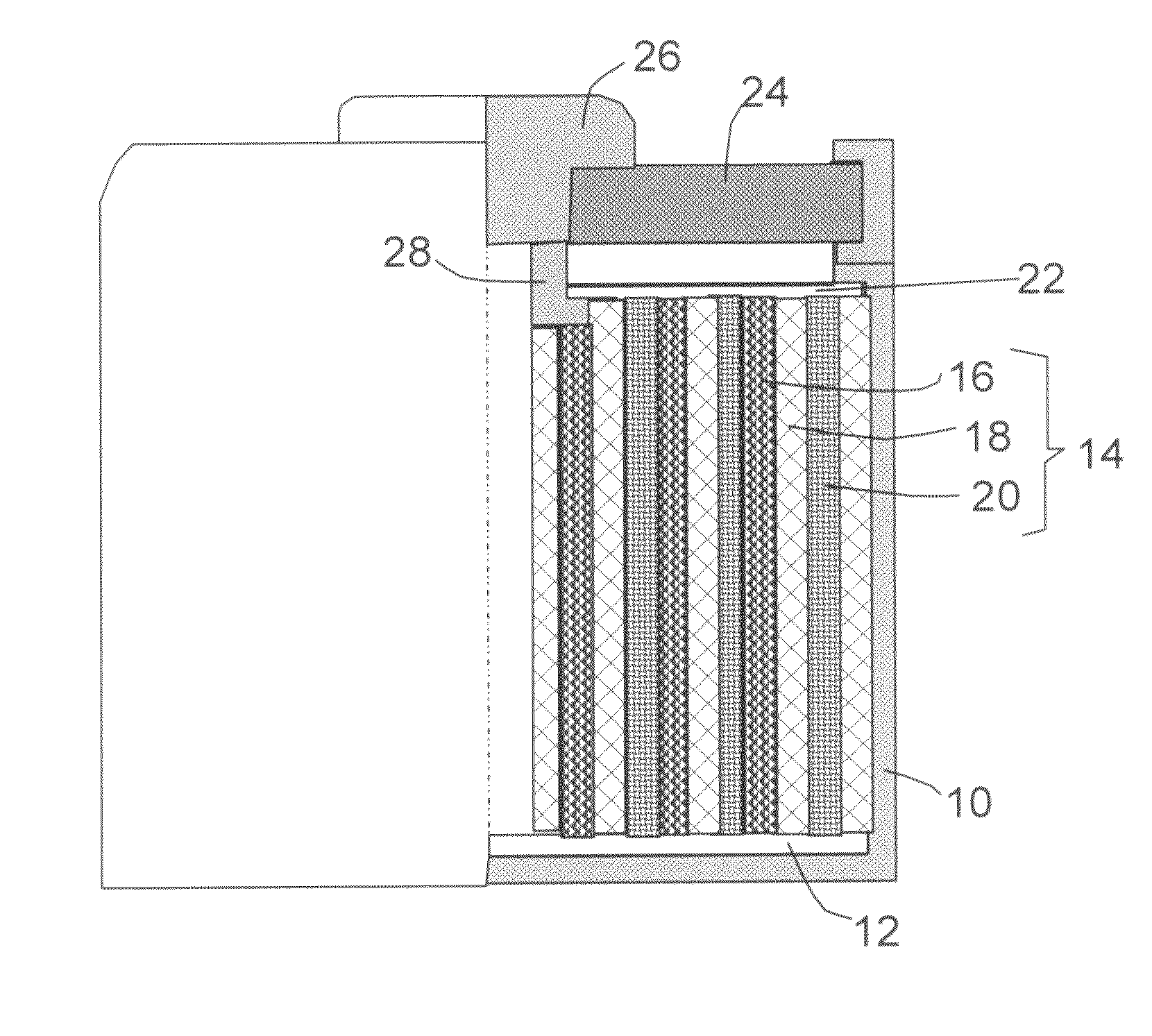

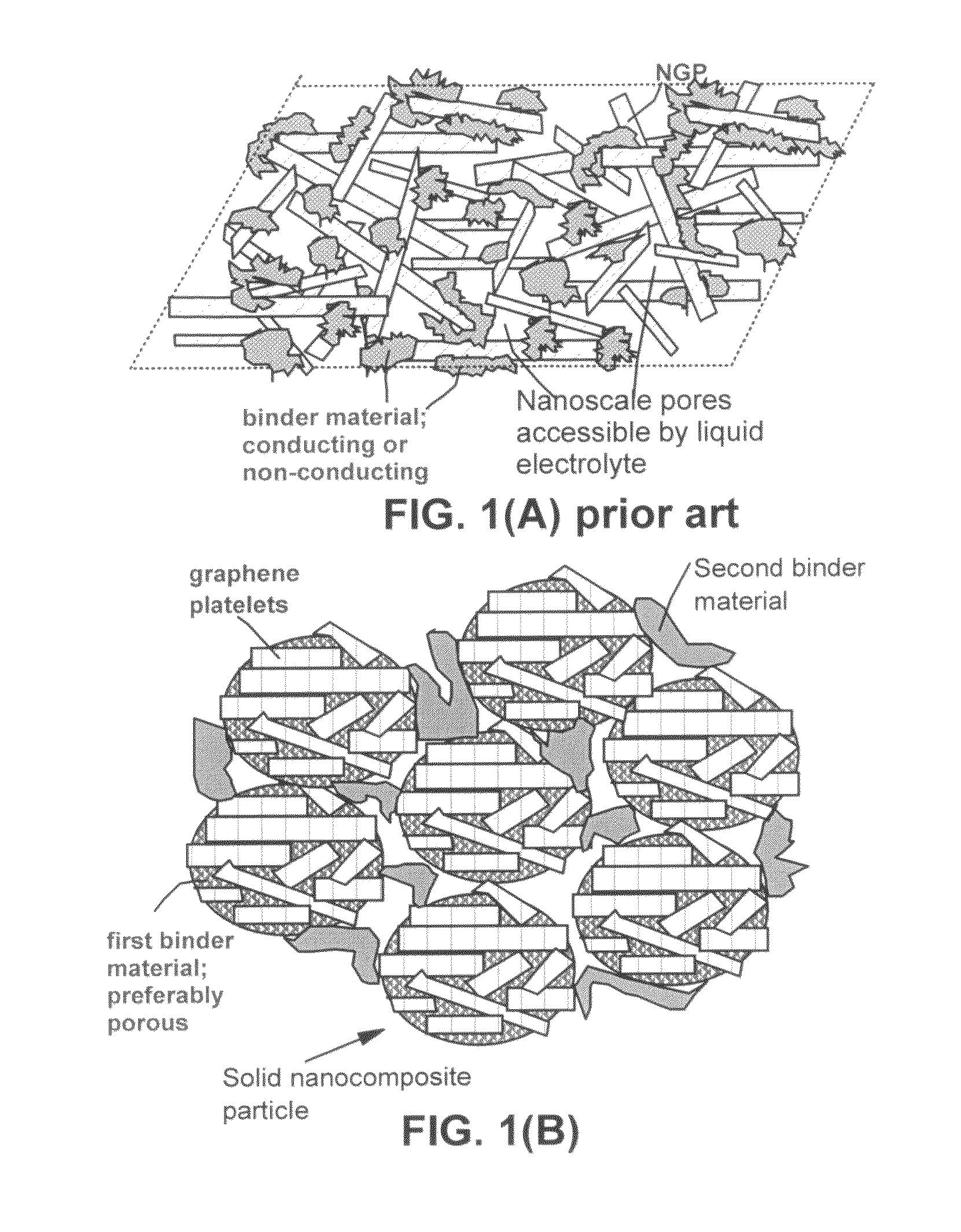

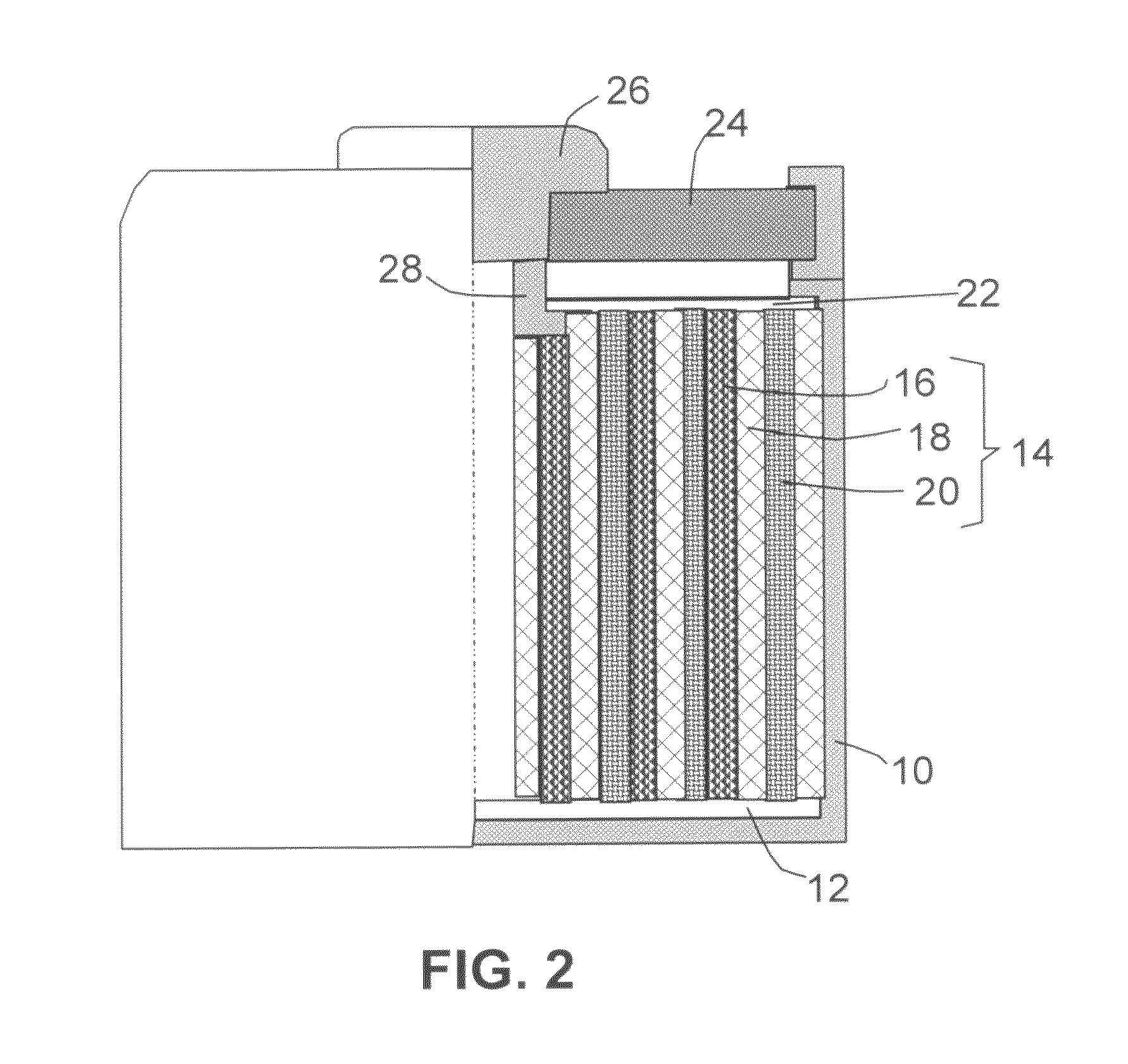

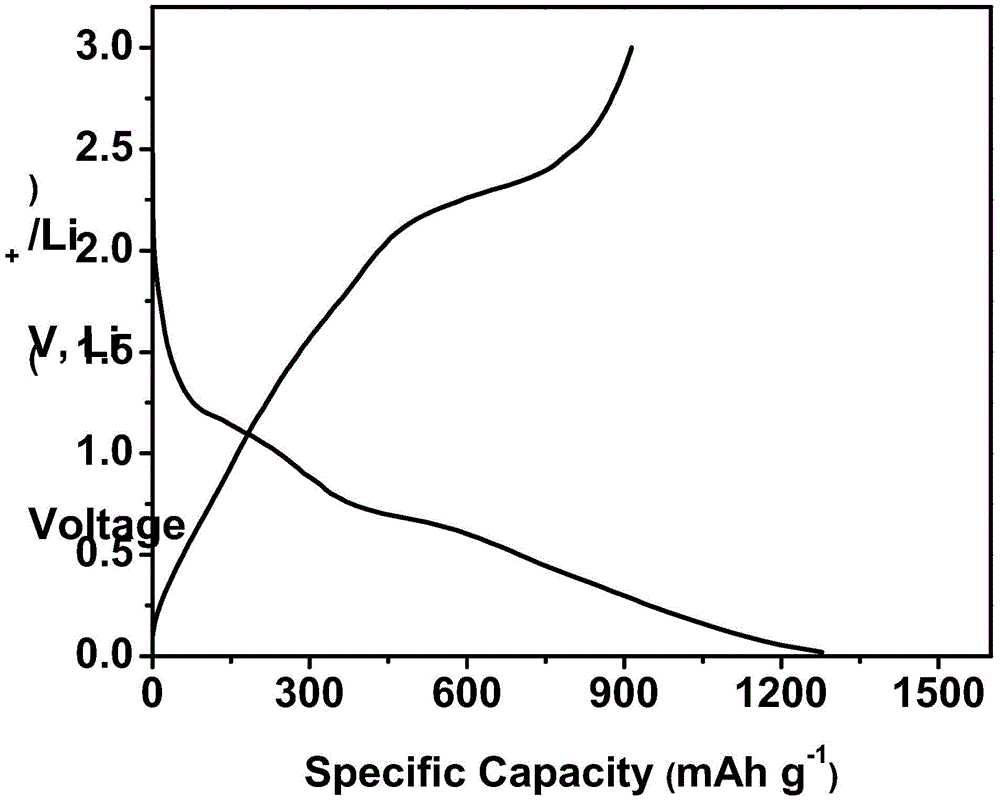

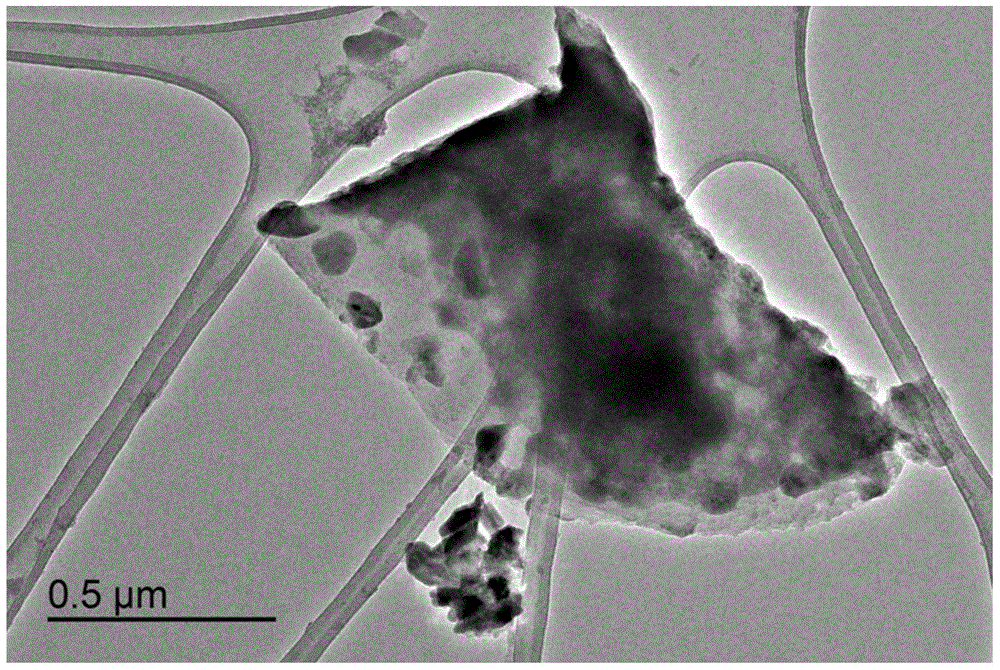

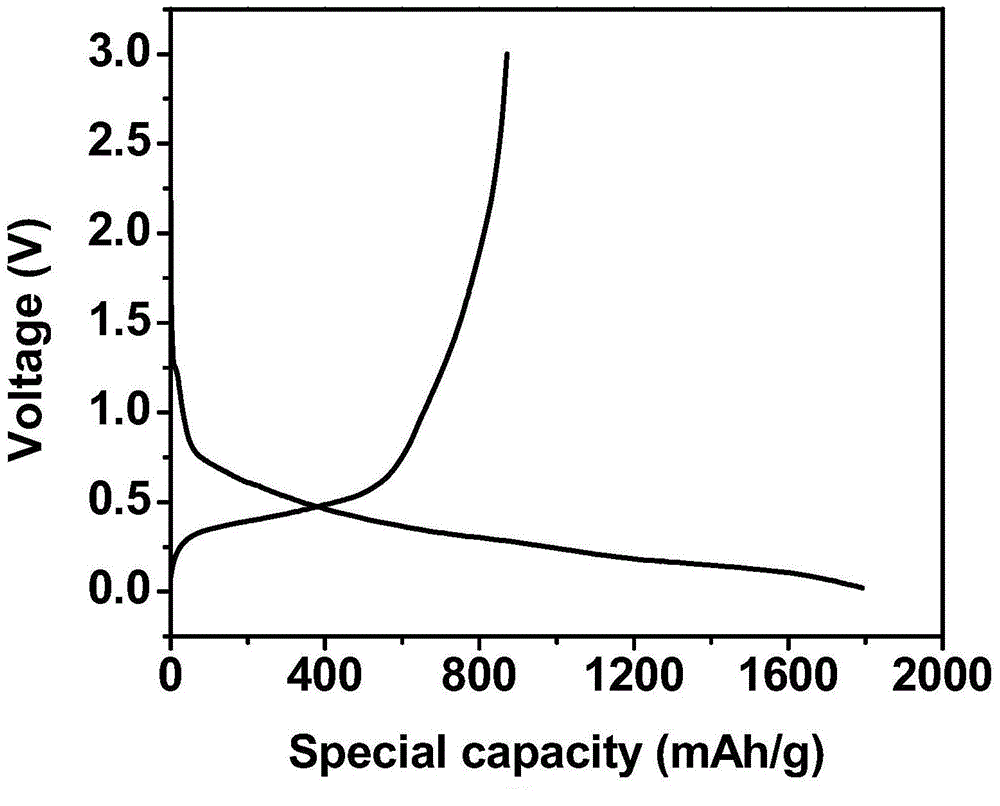

Graphene nanocomposites for electrochemical cell electrodes

ActiveUS20100021819A1High and reversible anode capacityTedious and energy-intensiveMicroscopic fiber electrodesHybrid capacitor electrodesGraphene nanocompositesSolid particle

A composite composition for electrochemical cell electrode applications, the composition comprising multiple solid particles, wherein (a) a solid particle is composed of graphene platelets dispersed in or bonded by a first matrix or binder material, wherein the graphene platelets are not obtained from graphitization of the first binder or matrix material; (b) the graphene platelets have a length or width in the range of 10 nm to 10 μm; (c) the multiple solid particles are bonded by a second binder material; and (d) the first or second binder material is selected from a polymer, polymeric carbon, amorphous carbon, metal, glass, ceramic, oxide, organic material, or a combination thereof. For a lithium ion battery anode application, the first binder or matrix material is preferably amorphous carbon or polymeric carbon. Such a composite composition provides a high anode capacity and good cycling response. For a supercapacitor electrode application, the solid particles preferably have meso-scale pores therein to accommodate electrolyte.

Owner:NANOTEK INSTR GRP LLC

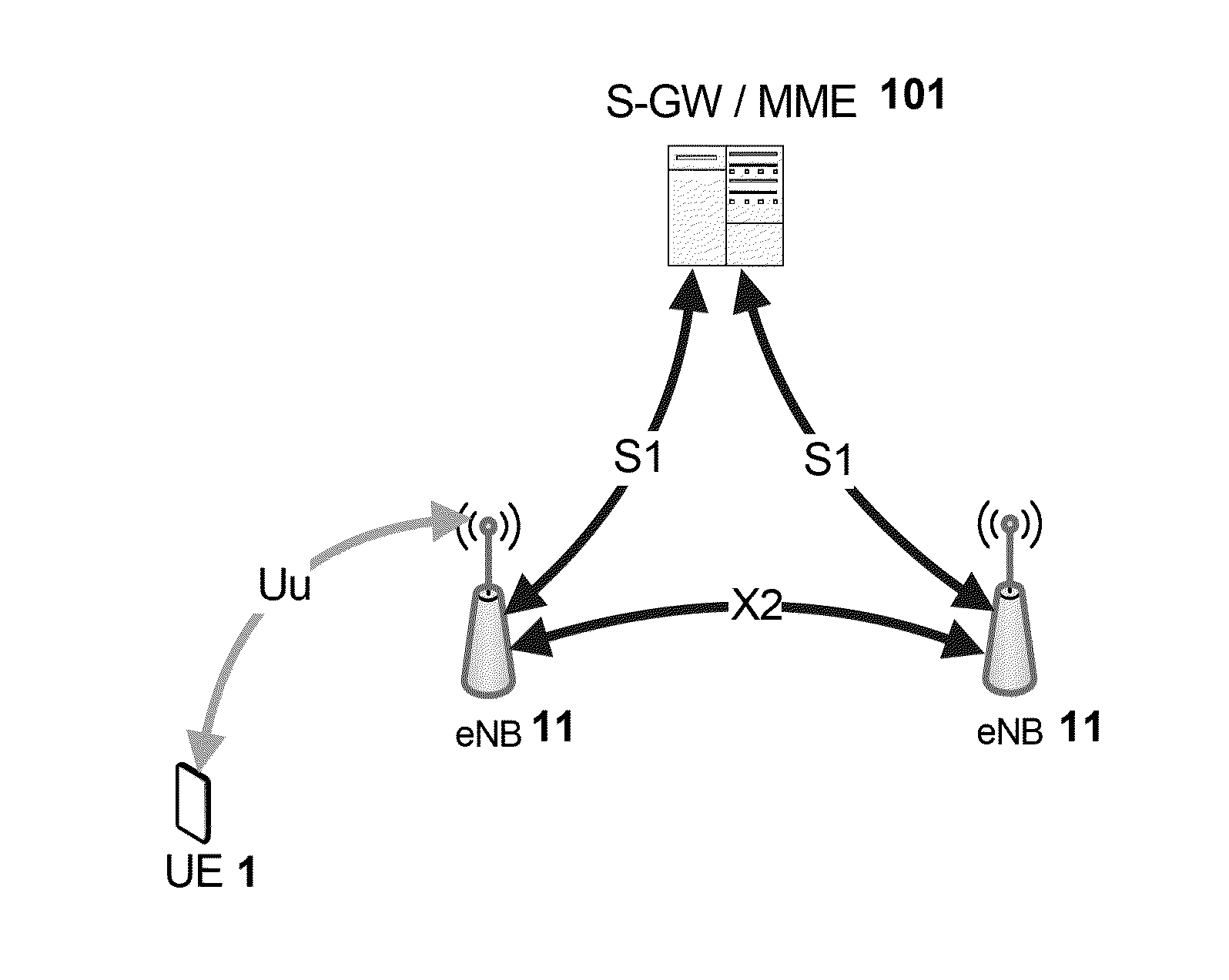

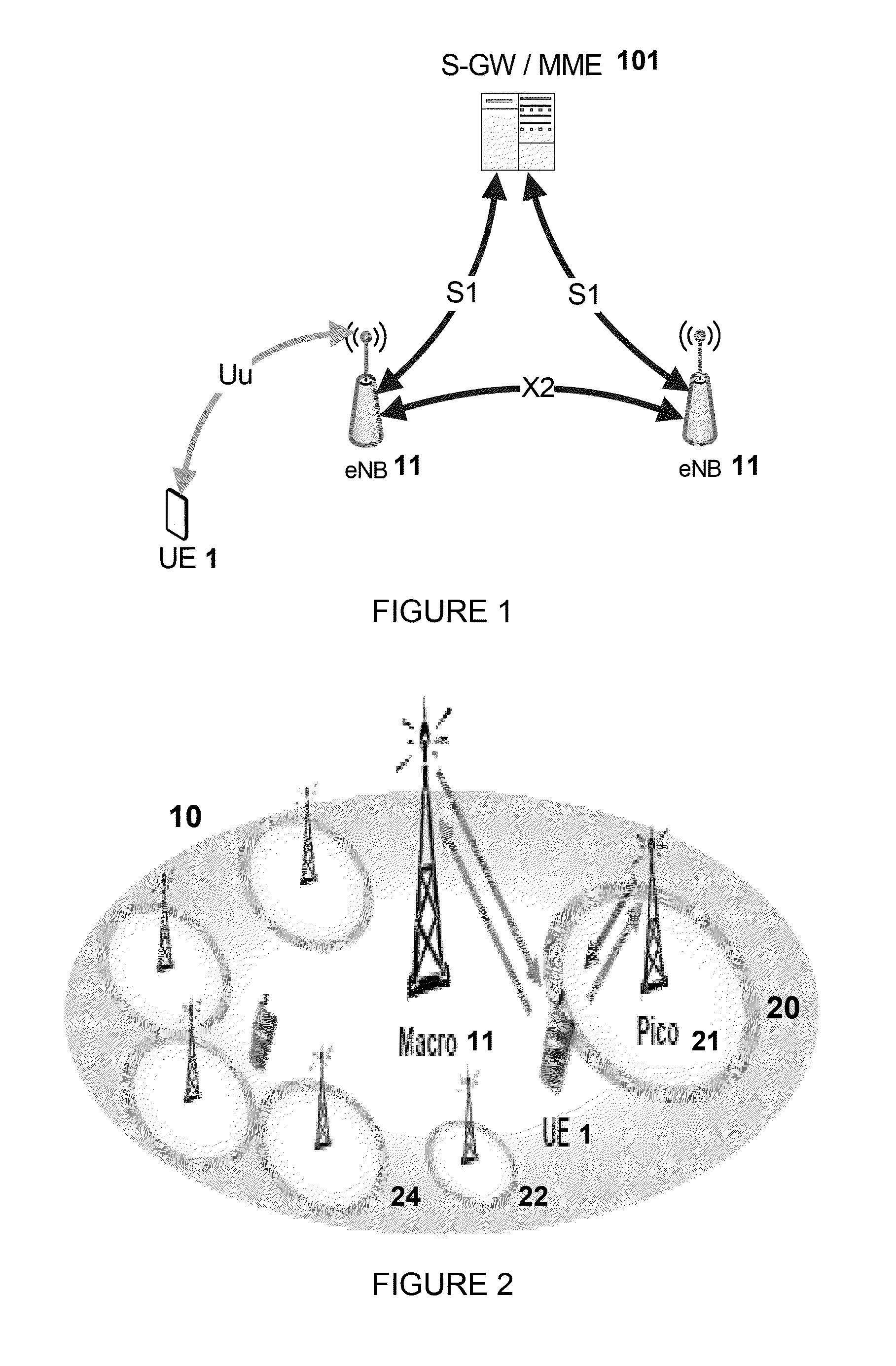

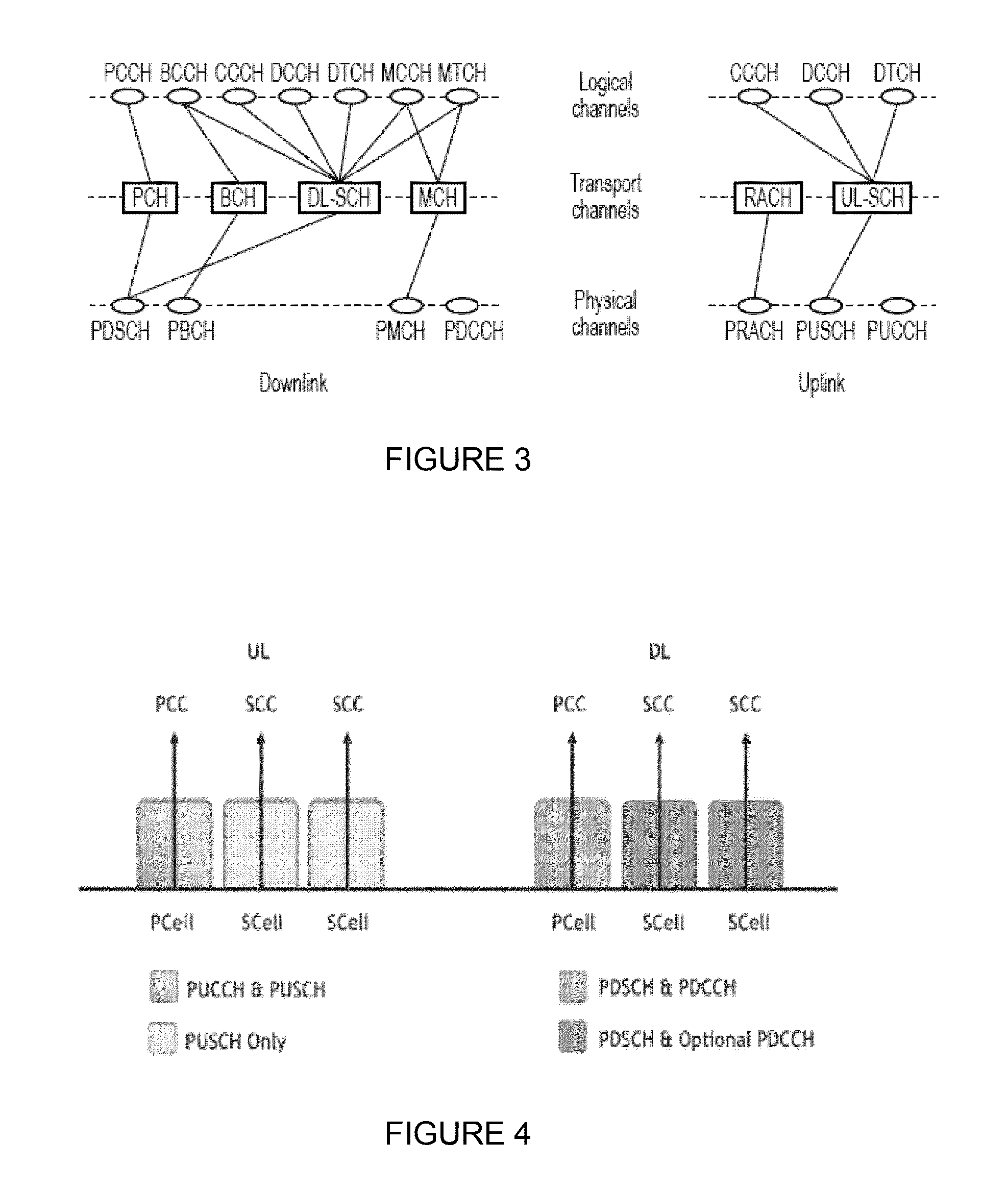

Resource requests in small cell networks

InactiveUS20150016350A1Improve achievable data rateIncreased rate capacityAssess restrictionNetwork topologiesSystem capacityRandom access

A Small Cell Network in which a terminal (1) is simultaneously served by a macro cell (10) and one or more small cells (20, 22, 24). When suitable uplink resources are not provided for data (PUSCH), the terminal (1) selects a cell and / or resource on which to transmit a scheduling request, or if no resource is allocated for scheduling requests (SR) the invention allows the terminal to select a suitable uplink cell and / or signature for a random access transmission (PRACH), and / or characteristic of a signal used to request such resources. A RACH transmission may also take place if SR has been transmitted more than a defined number of times without PUSCH resources being granted. Use of the most appropriate cell / resource for the request will improve the achievable data rate and system capacity.

Owner:FUJITSU LTD

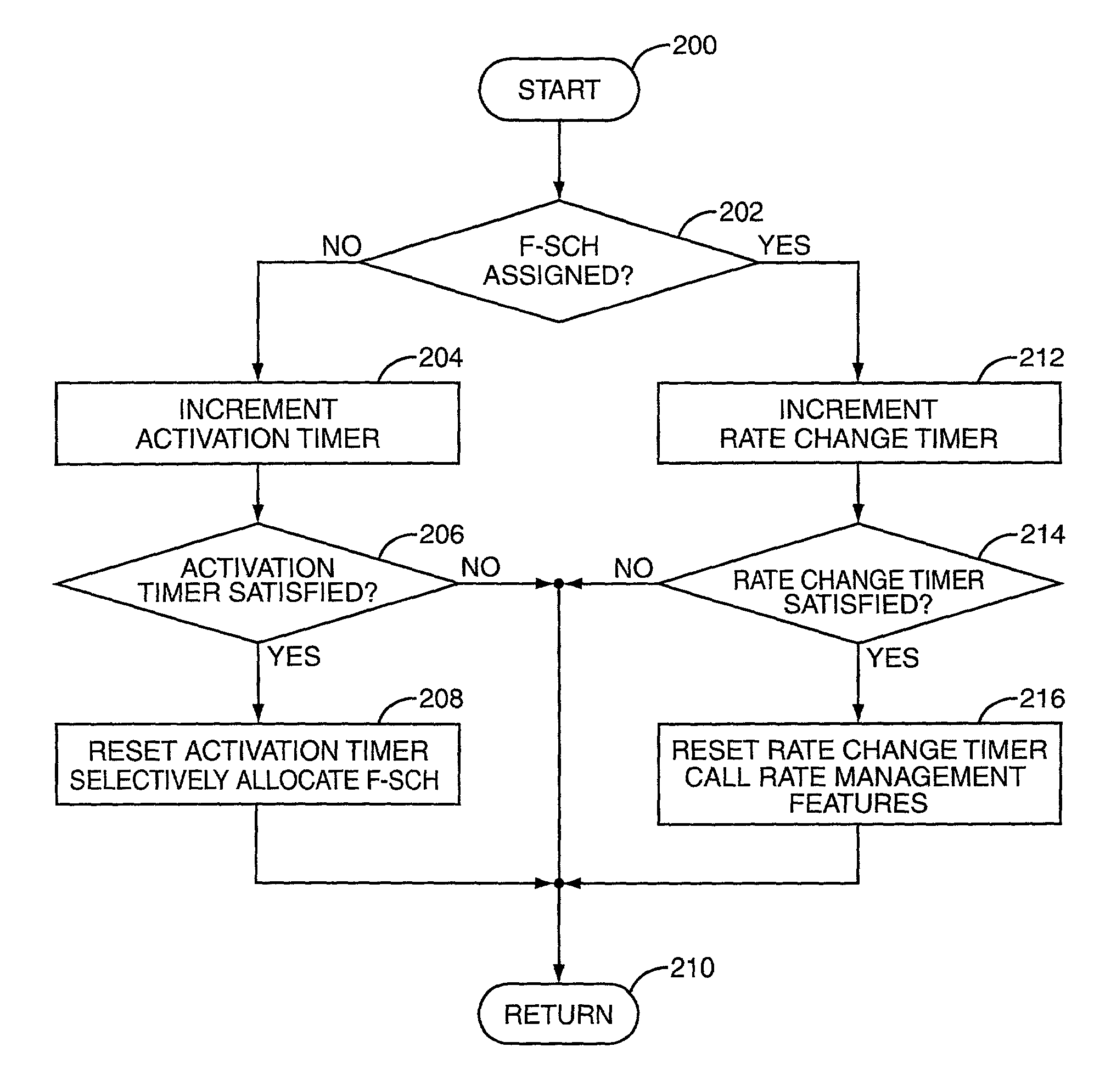

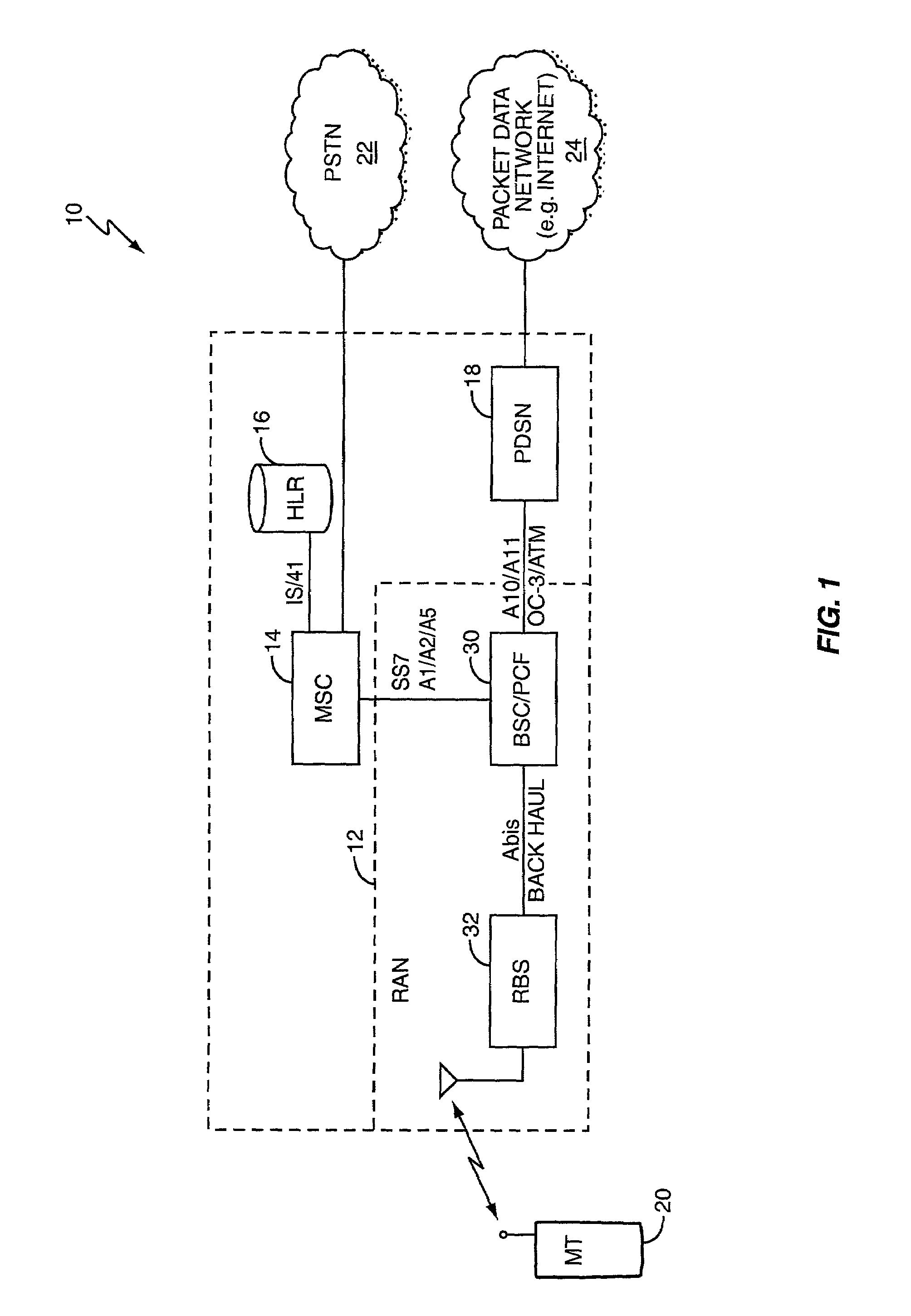

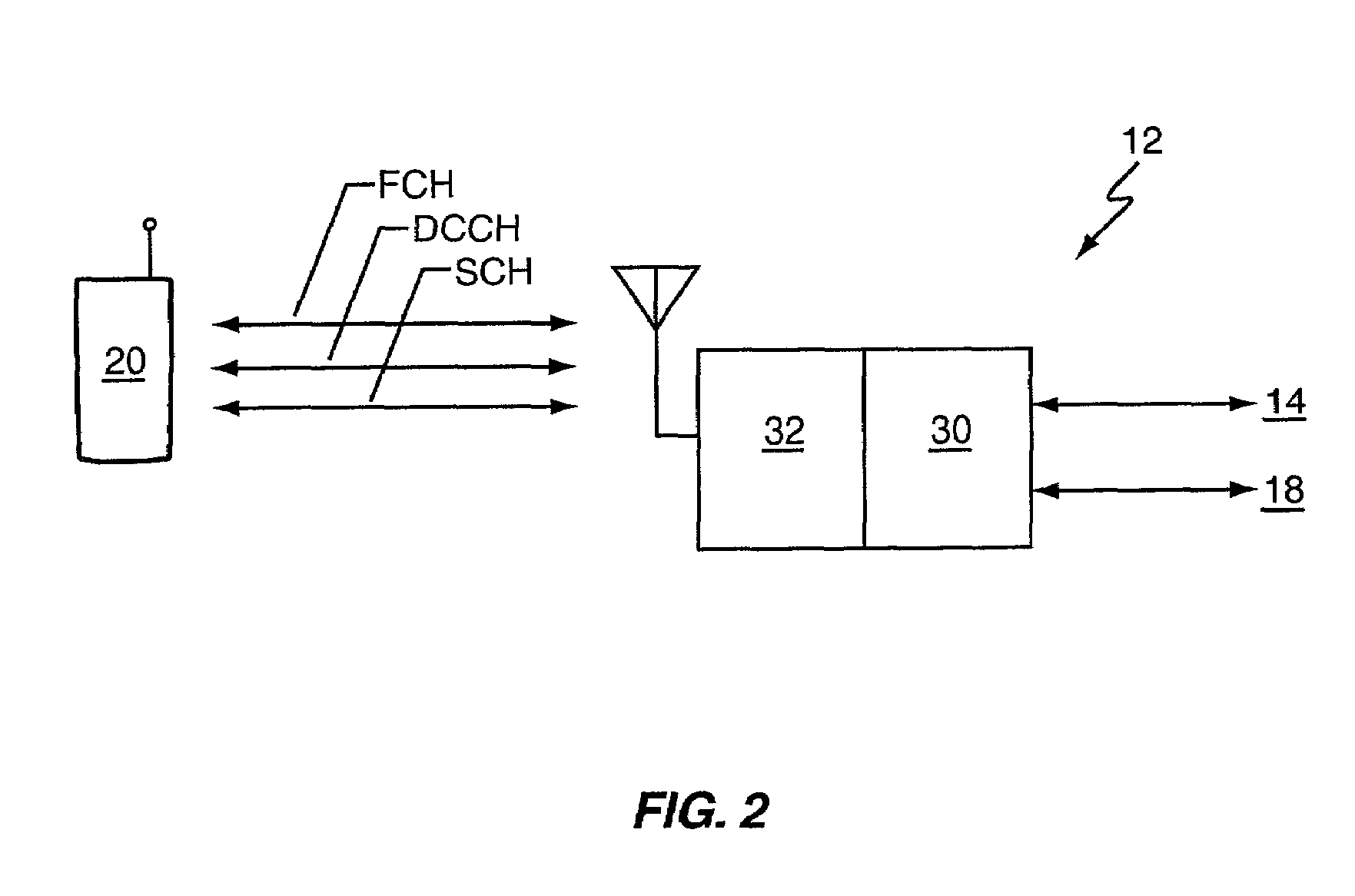

Triggered packet data rate change in a communication system

InactiveUS7193966B2Effective resourcesIncreased rate capacityTransmission systemsNetwork traffic/resource managementTraffic characteristicTraffic capacity

Communication traffic associated with one or more mobile terminals is monitored to efficiently manage allocated radio resources. A rate management technique dynamically adjusts allocated radio resources to increase or decrease the data rate capacity of allocated radio channels based on actual channel usage. In this manner, radio resources are more efficiently utilized because the amount of excess capacity allocated to individual subscribers is reduced. Monitoring communication traffic may also be used to determine whether additional radio channel resources are allocated to a given subscriber. For example, in a cdma2000 radio access network, subscribers are typically allocated fundamental radio channels and then assigned supplemental channels to access higher data rate services. By monitoring fundament channel traffic characteristics, such as the queue length or packet size of outgoing packet data, the radio access network can determine whether supplemental channel allocation is warranted.

Owner:TELEFON AB LM ERICSSON (PUBL)

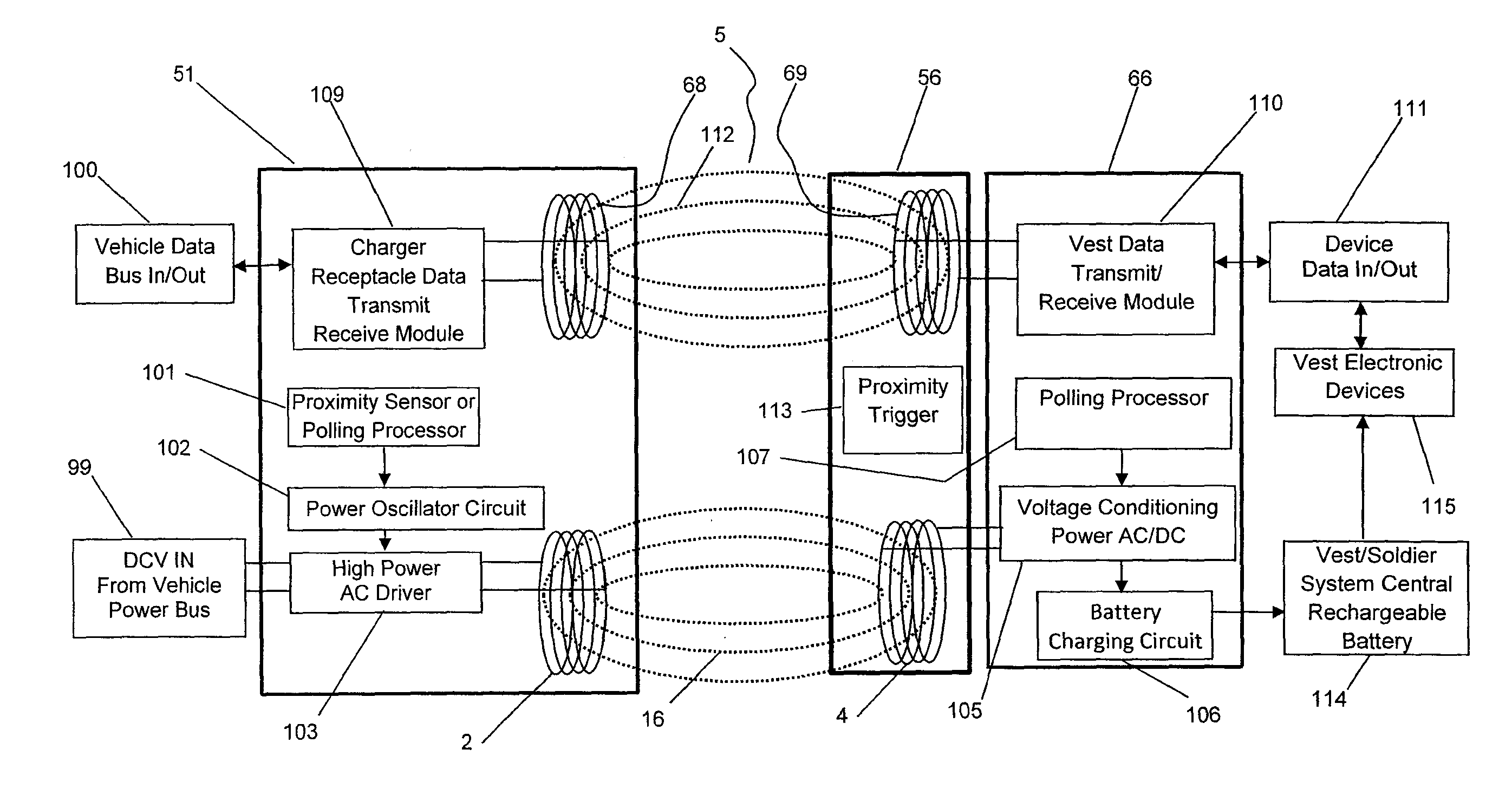

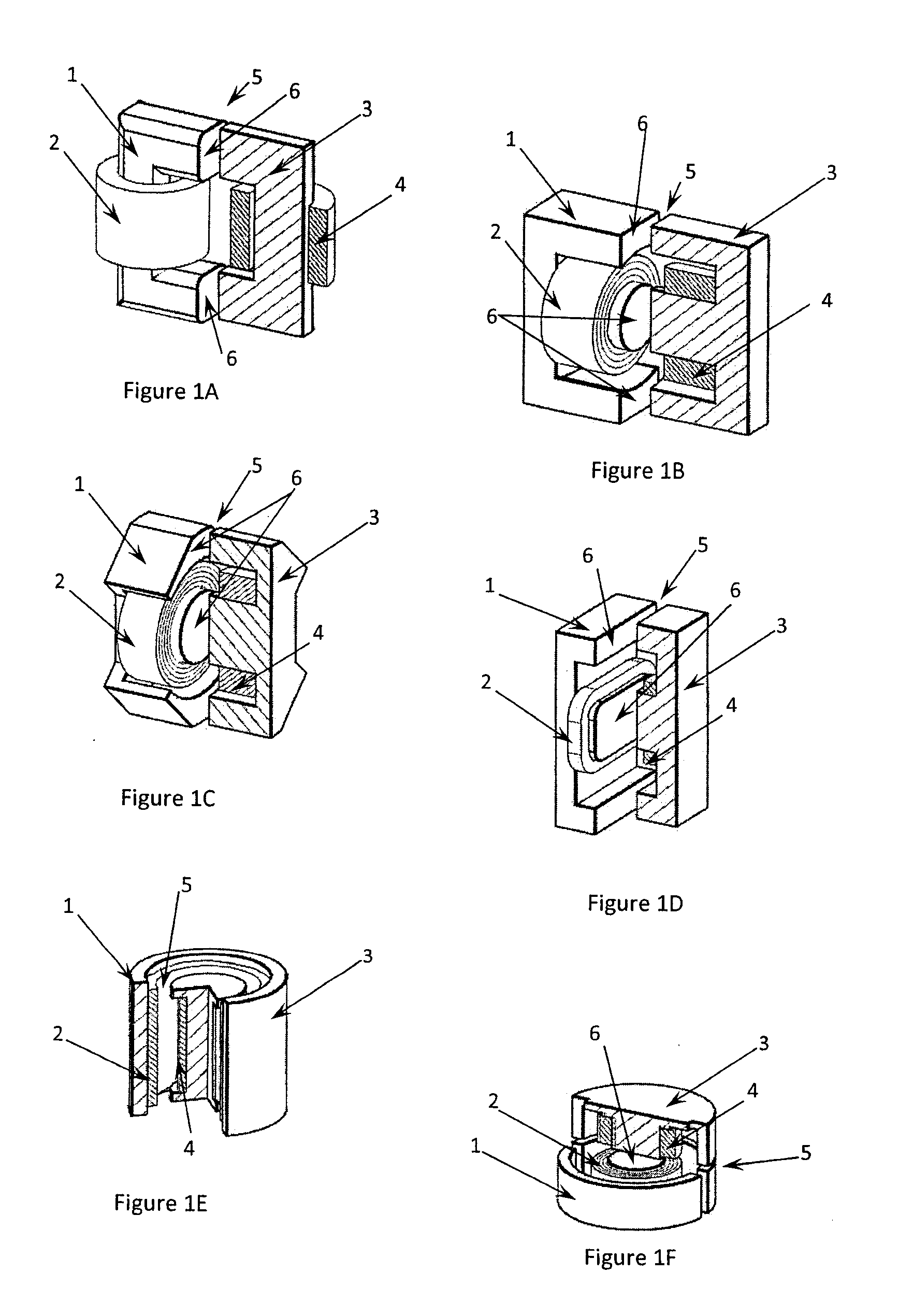

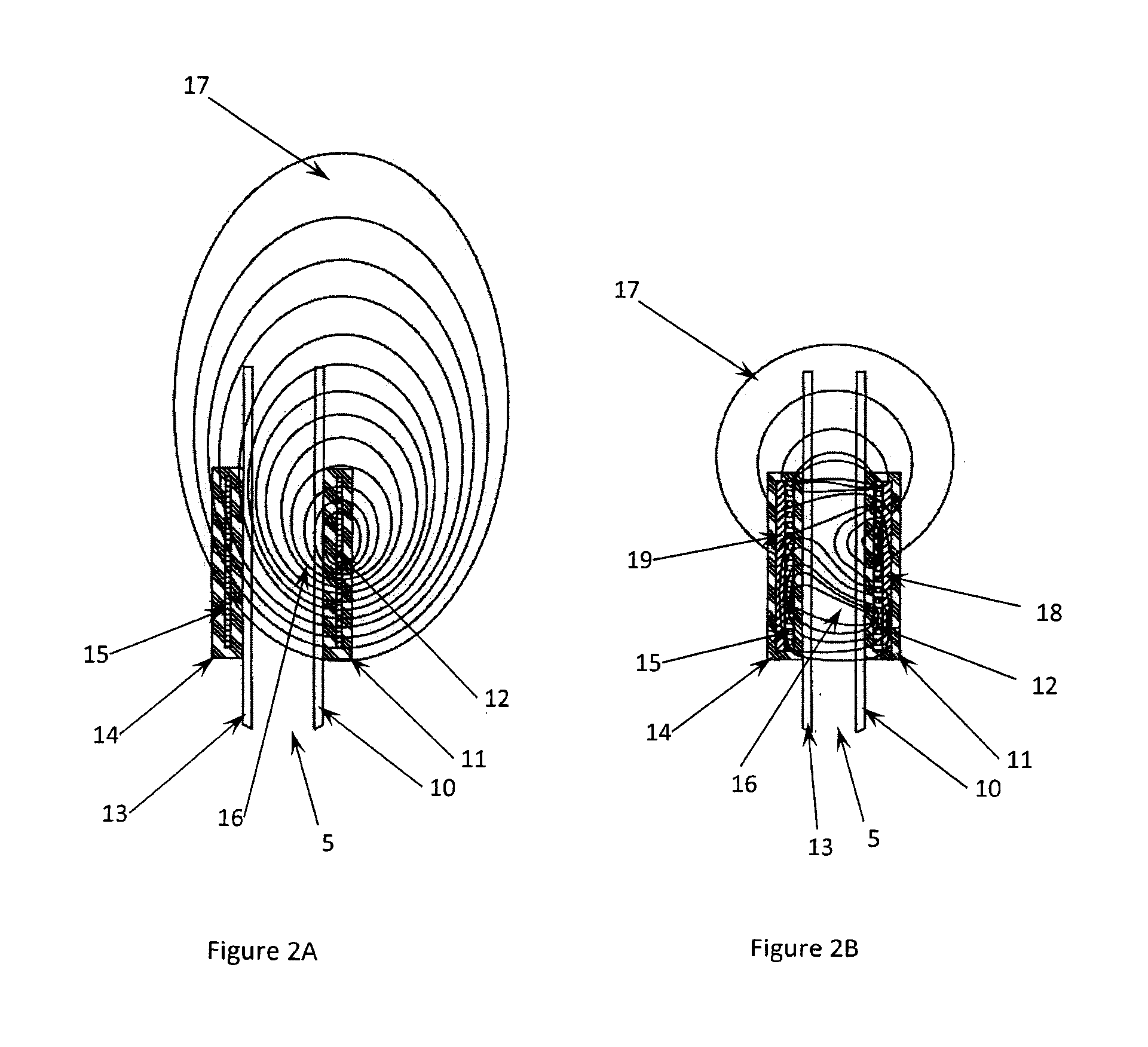

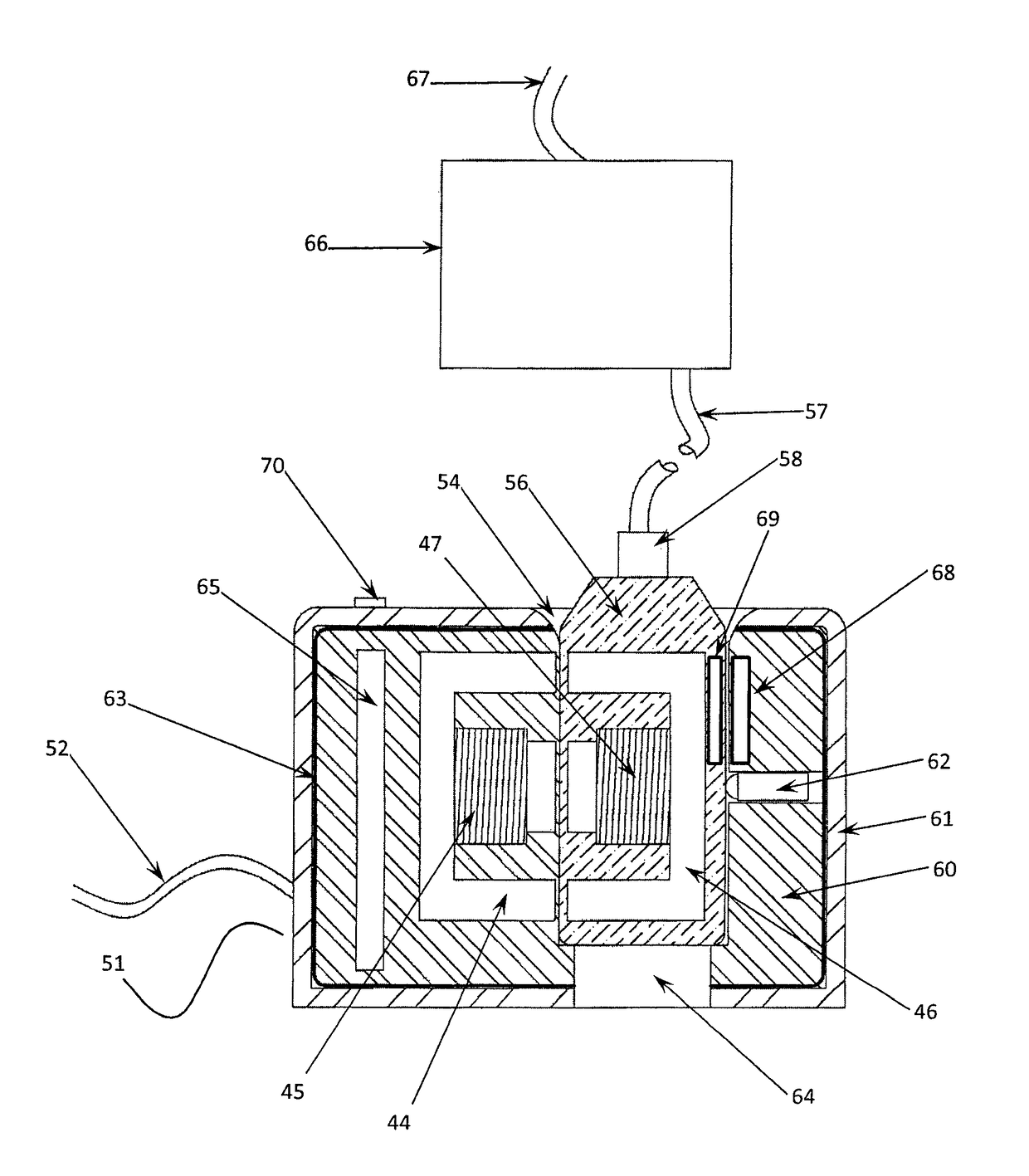

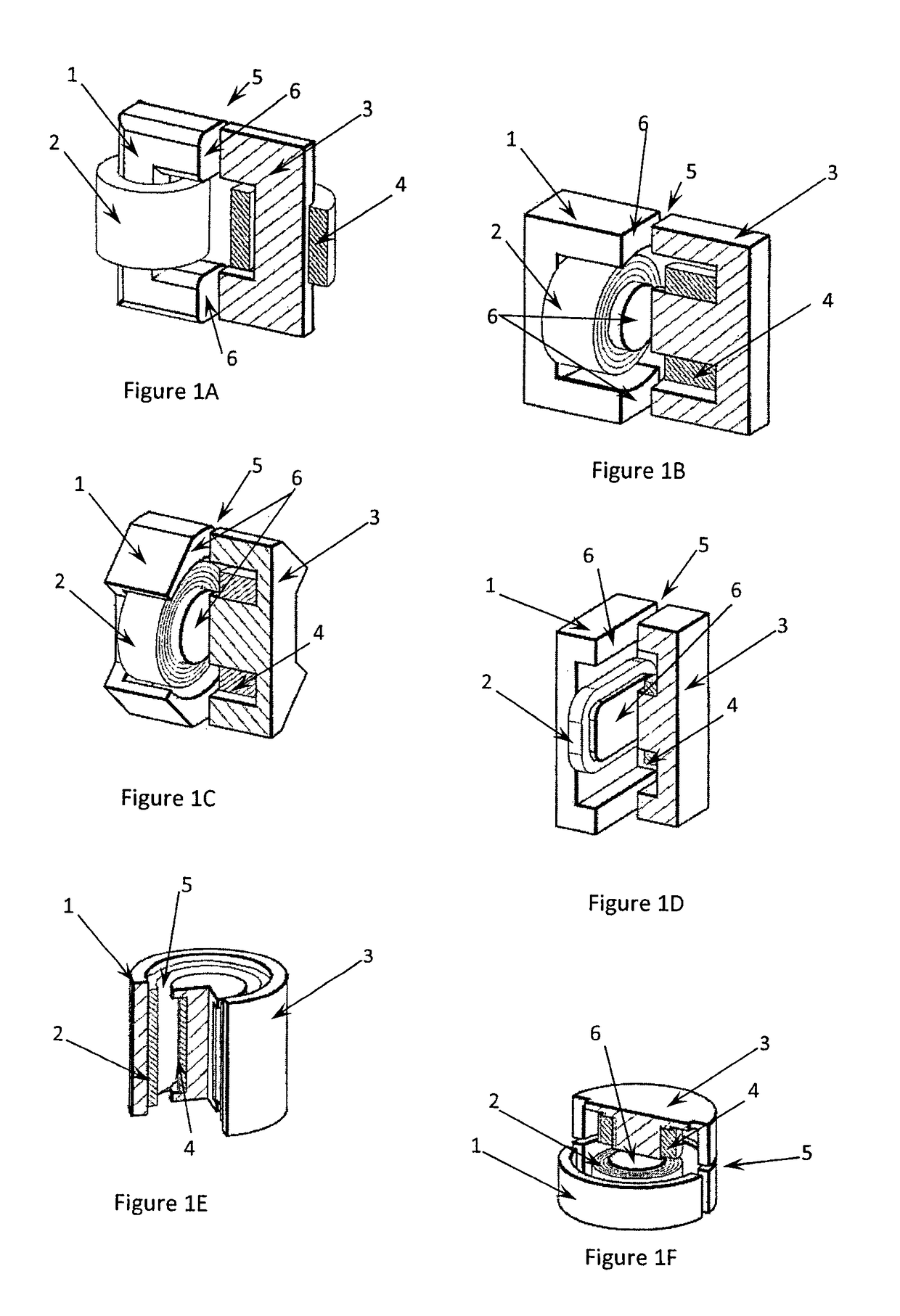

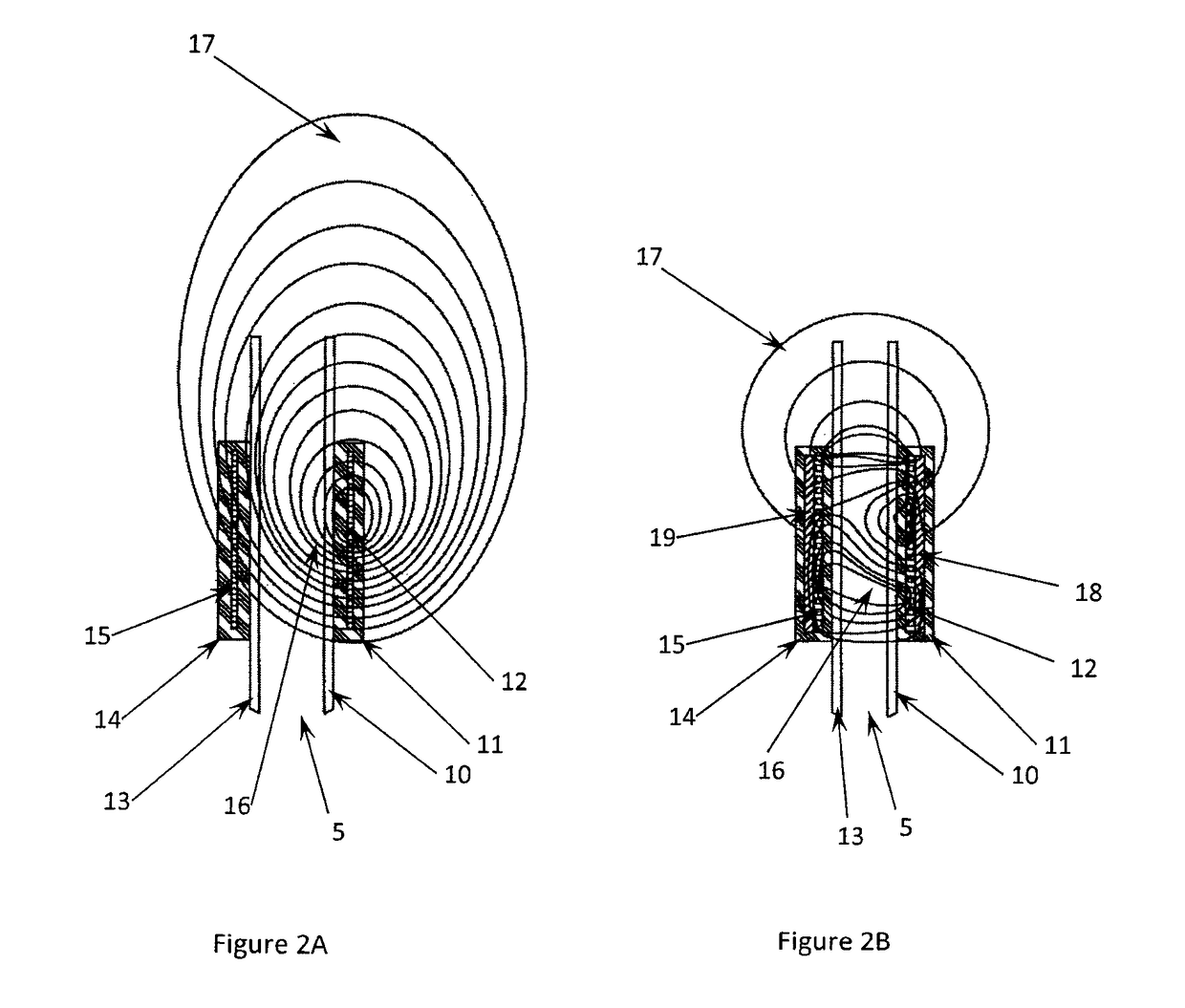

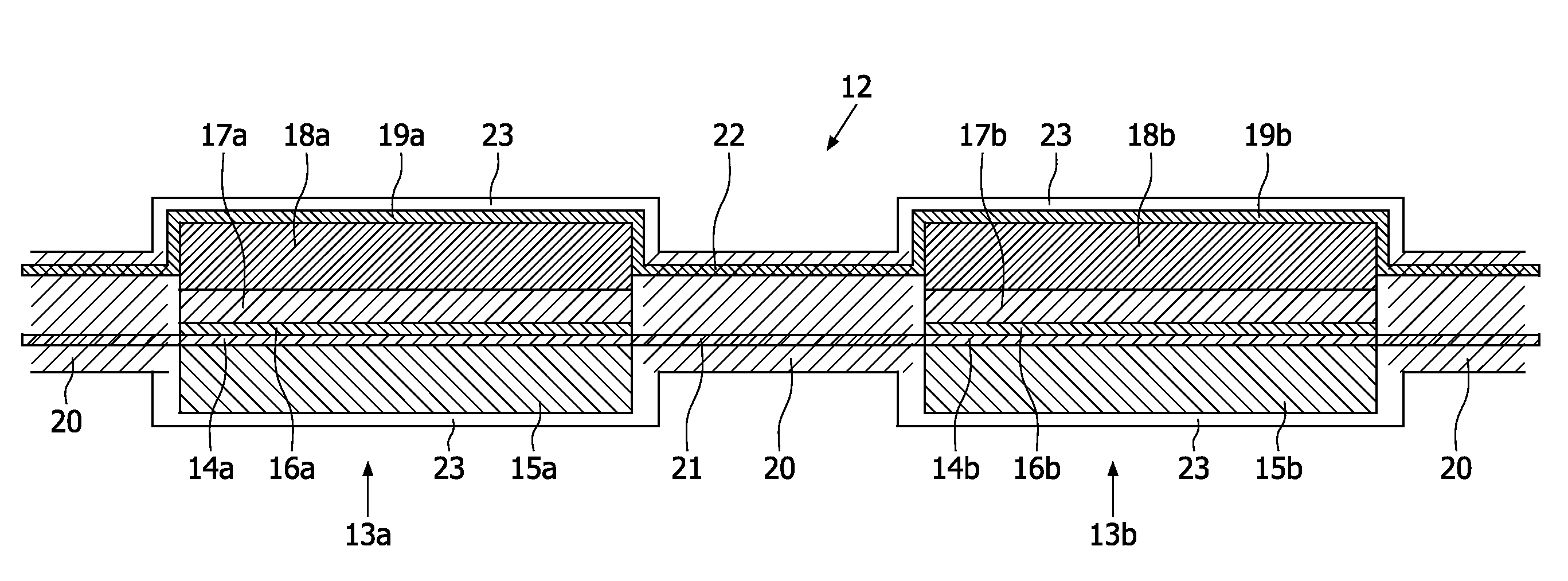

Inductively coupled wireless power and data for a garment via a dongle

ActiveUS20160094051A1Reduce stray magnetic fieldHigh efficiency designNear-field transmissionElectric devicesMagnetic coreInductive coupling

A system for transmission of at least power using inductive wireless coupling includes an environmentally sealed dongle and a mounting component which releasably mates with the dongle. The dongle is sized for use with one hand, and may be coupled by an umbilical to either a garment of the user or to a vehicle structure for example a seat, in which case the mounting component is coupled to the vehicle structure or to the garment respectively. The dongle and the mounting component include first and second inductive coils respectively and corresponding ferrite cores. The coils are positioned within the dongle and mounting component so that they are aligned for their inductive coupling when the dongle and mounting component are mated. The positioning and alignment of the coils provides a substantially closed magnetic path between the coils. The mounting component may be a receptacle.

Owner:CYNETIC DESIGNS

Adaptive time diversity and spatial diversity for OFDM

InactiveUS20060104196A1Gain is assured with time diversityReduce signalingSpatial transmit diversityMultiple modulation transmitter/receiver arrangementsData rateEngineering

An adaptable orthogonal frequency-division multiplexing system (OFDM) that uses a multiple input multiple output (MIMO) to having OFDM signals transmitted either in accordance with time diversity to reducing signal fading or in accordance with spatial diversity to increase the data rate. Sub-carriers are classified for spatial diversity transmission or for time diversity transmission based on the result of a comparison between threshold values and at least one of three criteria. The criteria includes a calculation of a smallest eigen value of a frequency channel response matrix and a smallest element of a diagonal of the matrix and a ratio of the largest and smallest eigen values of the matrix.

Owner:APPLE INC

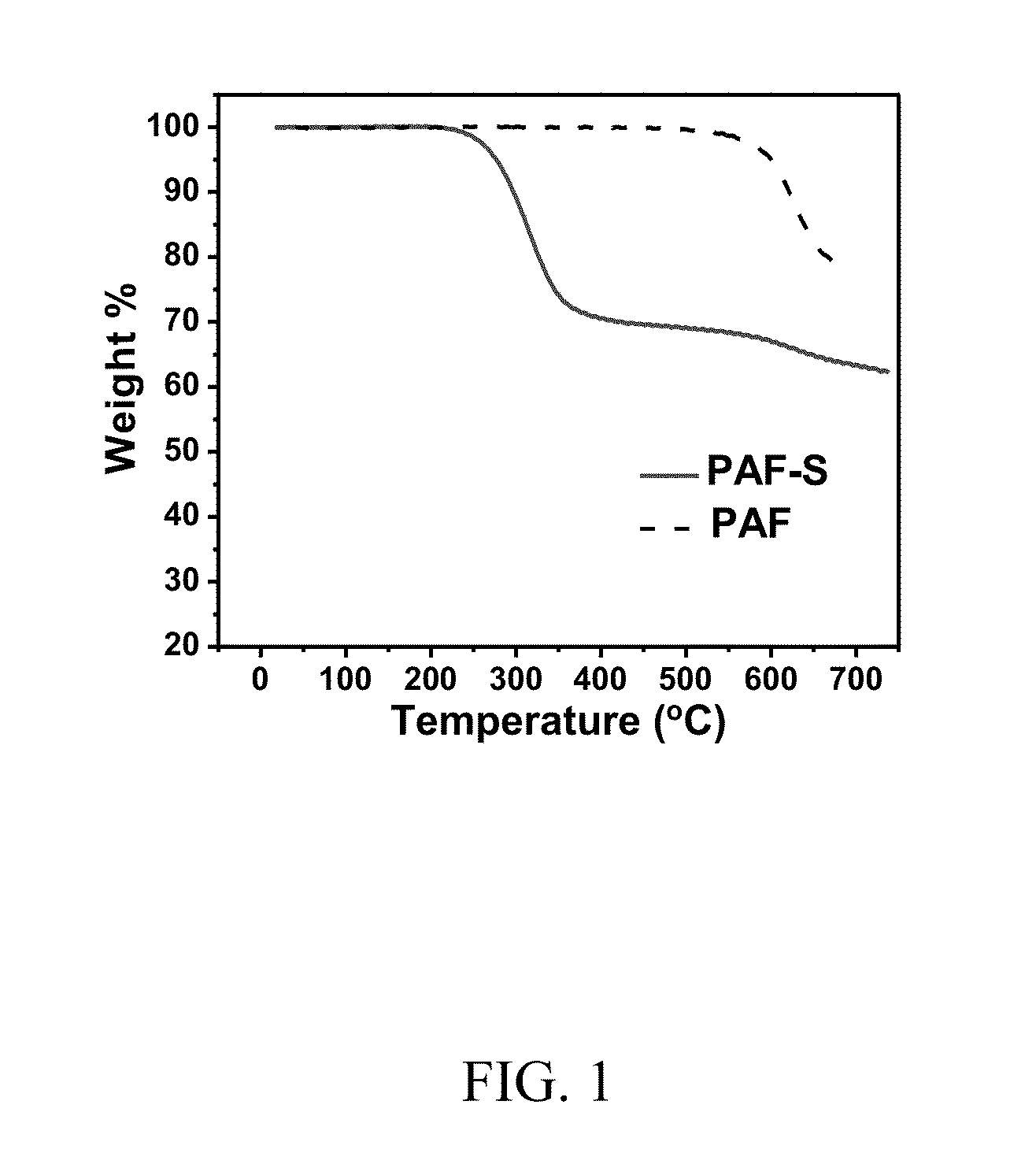

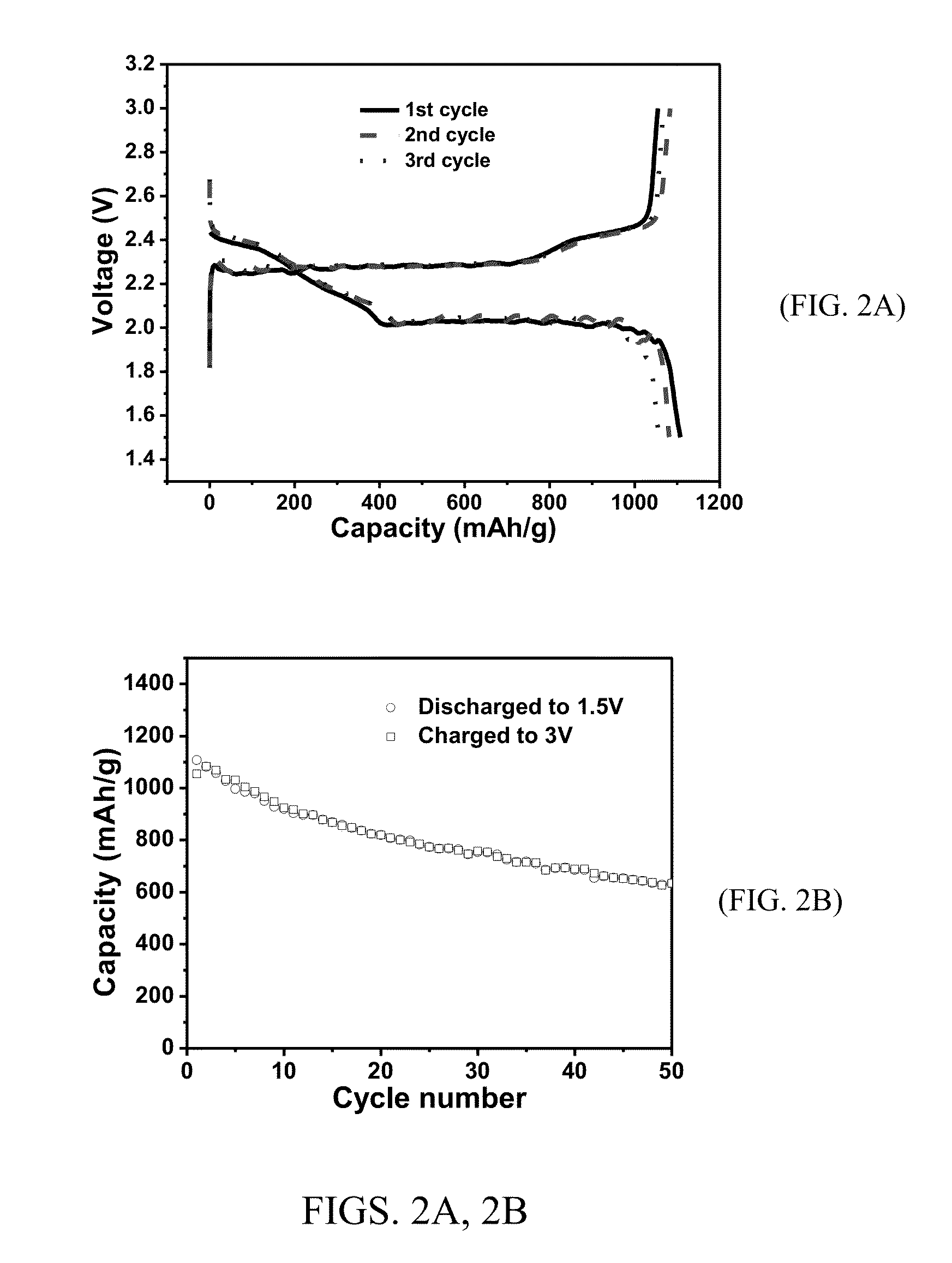

Nitrogen-sulfur-carbon nanocomposites and their application as cathode materials in lithium-sulfur batteries

ActiveUS20140141328A1Minimize formationImprove initial discharge capacityMaterial nanotechnologySecondary cellsLithium–sulfur batterySulfur

The invention is directed in a first aspect to electron-conducting porous compositions comprising an organic polymer matrix doped with nitrogen atoms and having elemental sulfur dispersed therein, particularly such compositions having an ordered framework structure. The invention is also directed to composites of such S / N-doped electron-conducting porous aromatic framework (PAF) compositions, or composites of an S / N-doped mesoporous carbon composition, which includes the S / N-doped composition in admixture with a binder, and optionally, conductive carbon. The invention is further directed to cathodes for a lithium-sulfur battery in which such composites are incorporated.

Owner:UT BATTELLE LLC

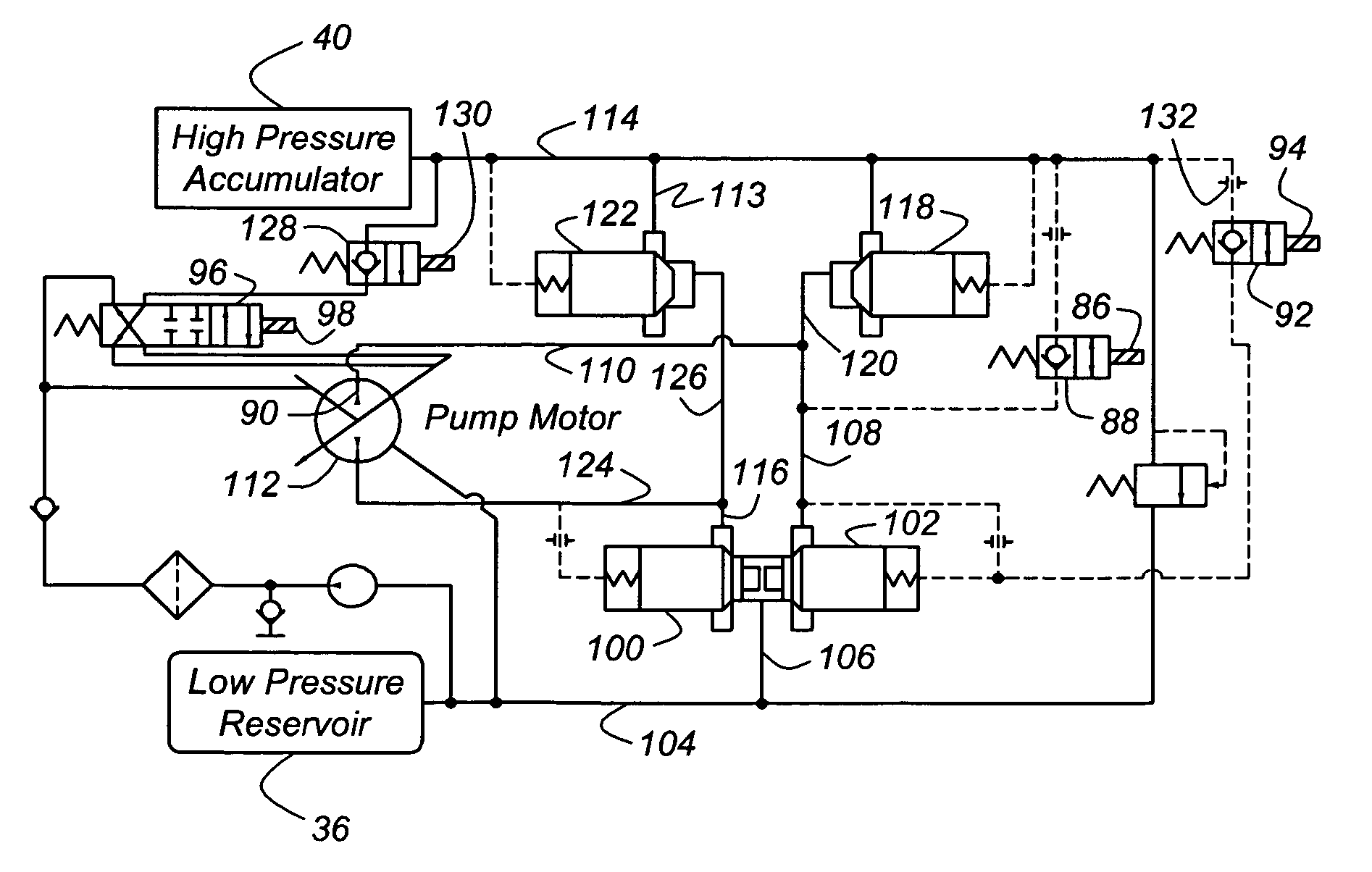

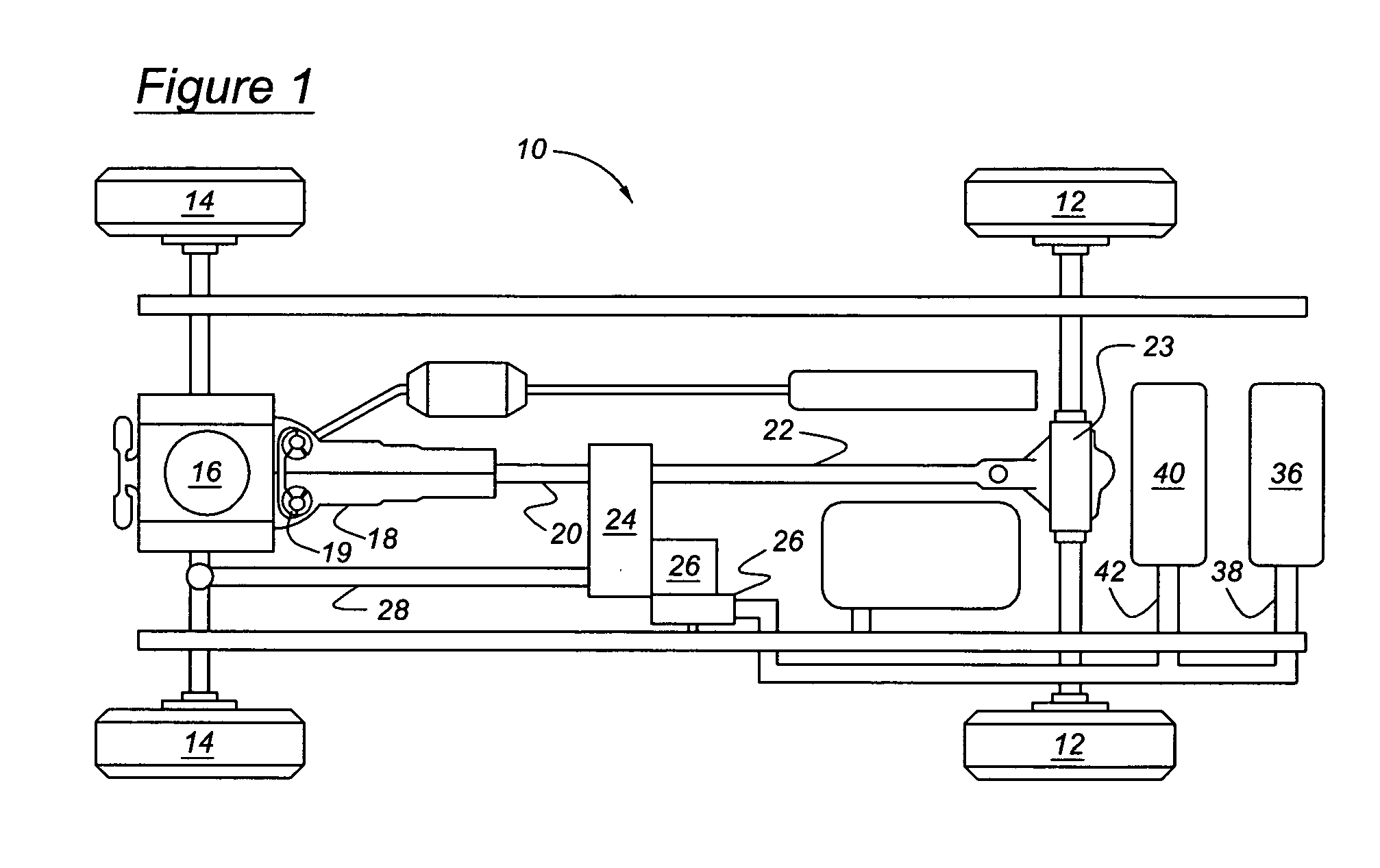

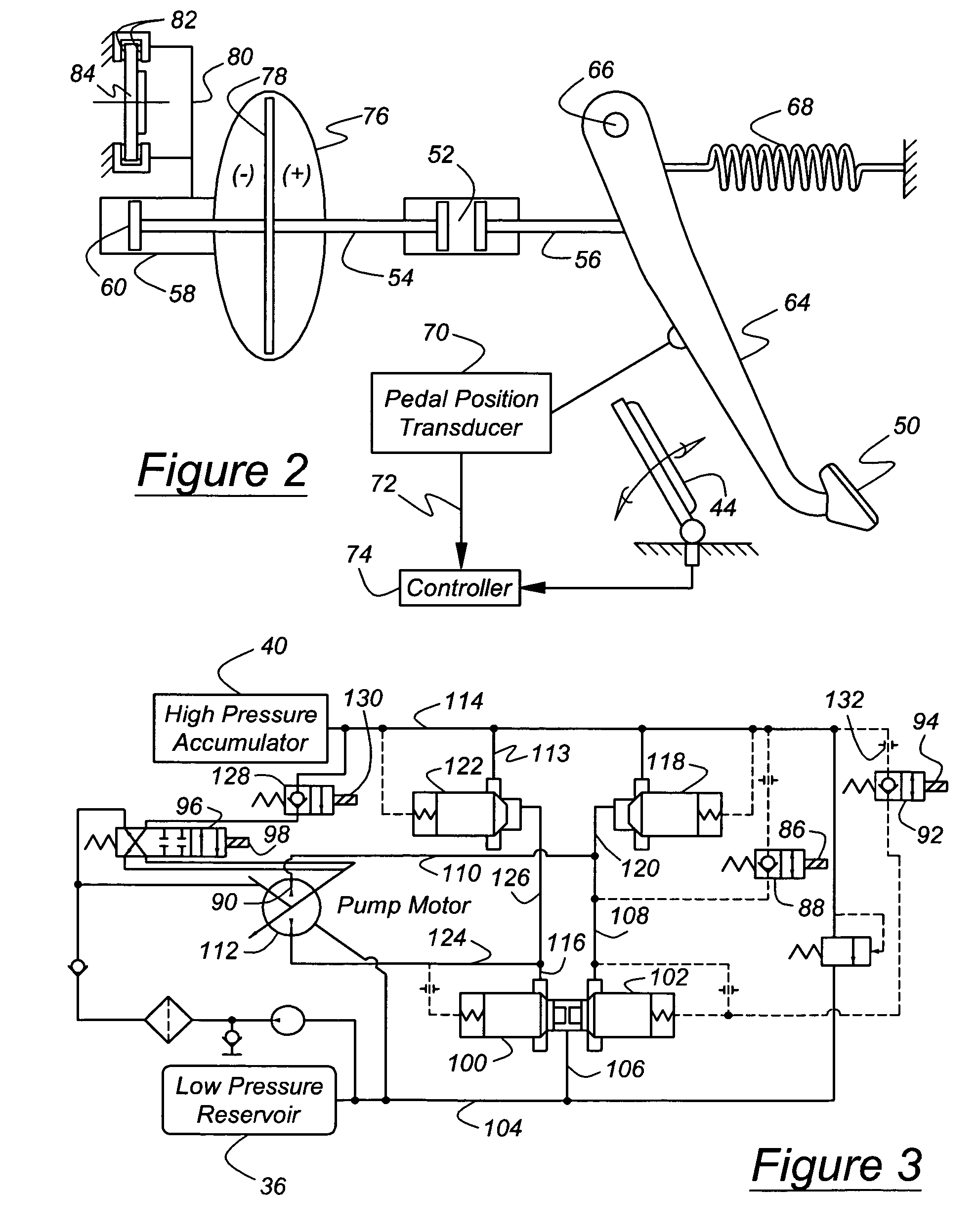

Pump/motor operating mode switching control for hydraulic hybrid vehicle

ActiveUS20060000208A1Slow pressureAvoid cavitationAuxillary drivesBraking element arrangementsTransmitted powerEngineering

A system according to this invention for transmitting power hydraulically to and from the wheels of a motor vehicle includes an accumulator containing fluid at relatively high pressure, a reservoir containing fluid at lower pressure, and a pump / motor driveably connected to the wheels and having an inlet, an outlet, and a variable volumetric displacement for pumping fluid between the accumulator and the reservoir. A first circuit connects the inlet to the reservoir and the outlet to the accumulator. A second circuit, which connects the inlet to the accumulator and the outlet to the reservoir, includes a first path having a low flow rate capacity, a second path having a higher flow rate capacity. A controller switches between pumping operation and motoring operation, opens and closes the first path during motoring operation, and reduces the displacement before switching between pumping operation and motoring operation. The first path includes a first valve responsive to the controller for opening and closing a connection between the accumulator and the inlet, and a first orifice arranged in series with the first valve having a relatively low flow rate capacity. The second path, arranged in parallel with the first path between the accumulator and the inlet, includes a second valve responsive to the controller for opening and closing a connection between the accumulator and the inlet, and a second orifice arranged in series with the second valve having a higher flow rate capacity than that of the first orifice.

Owner:FORD GLOBAL TECH LLC

Graphene nanocomposites for electrochemical cell electrodes

ActiveUS9190667B2Reduce the amount of solutionIncreased rate capacityMicroscopic fiber electrodesHybrid capacitor electrodesGraphene nanocompositesSolid particle

Owner:NANOTEK INSTR GRP LLC

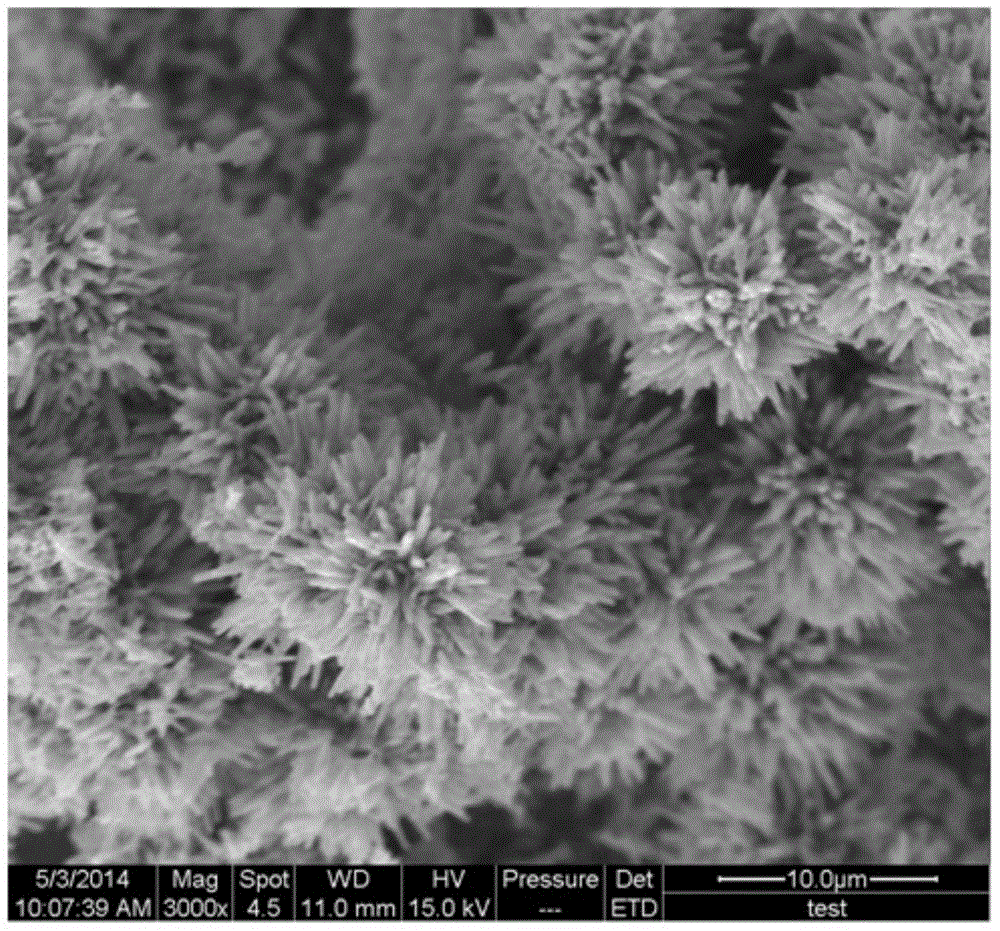

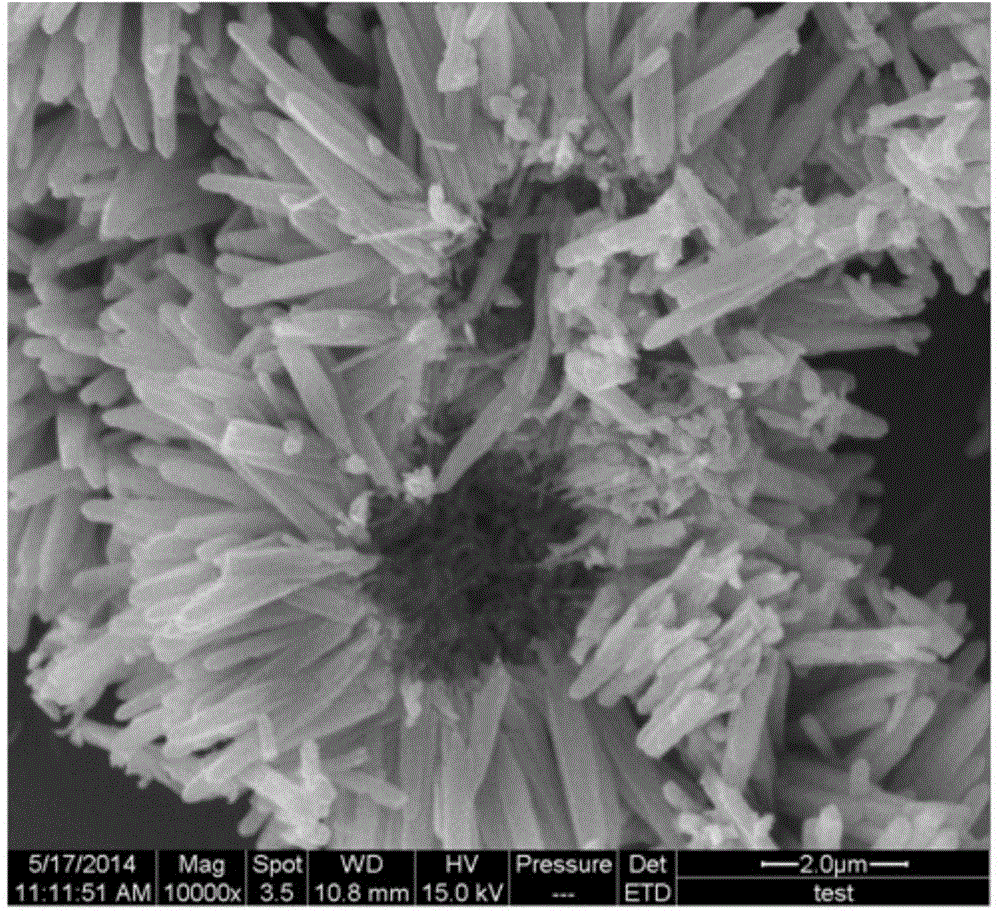

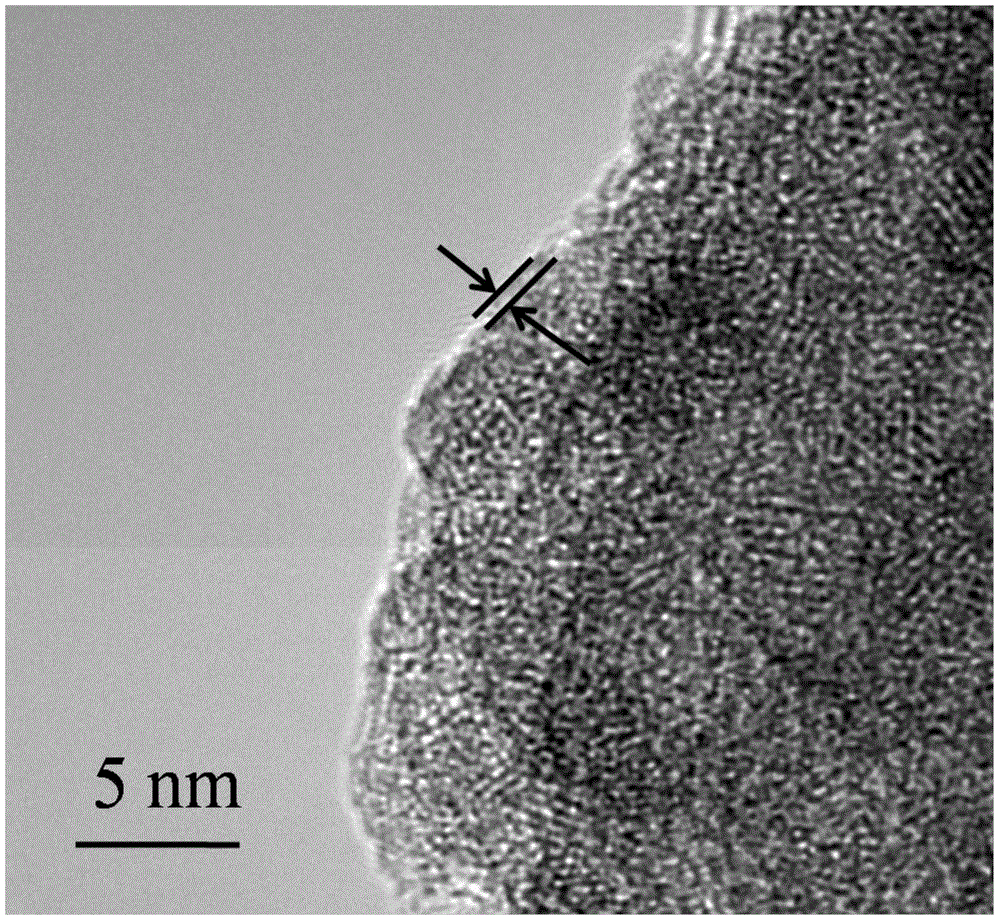

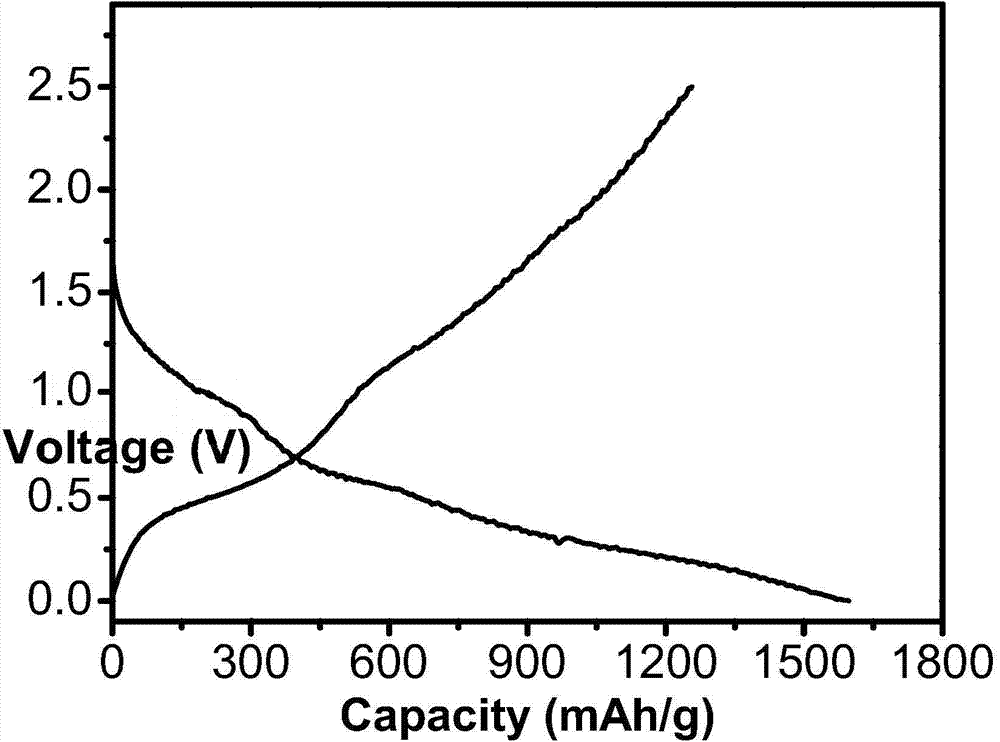

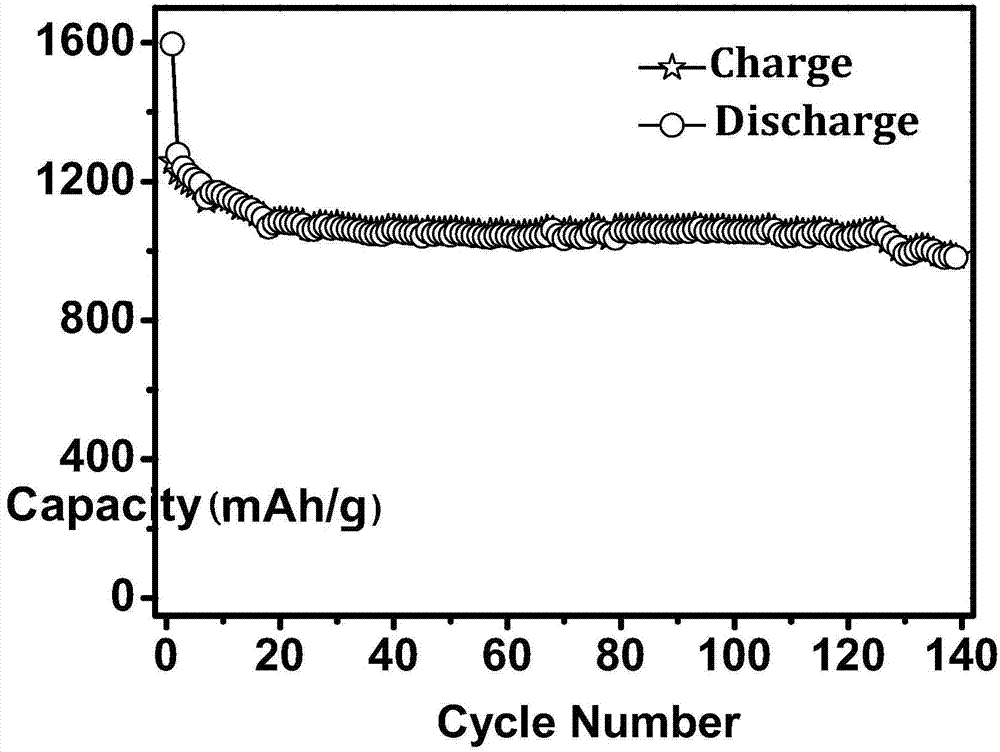

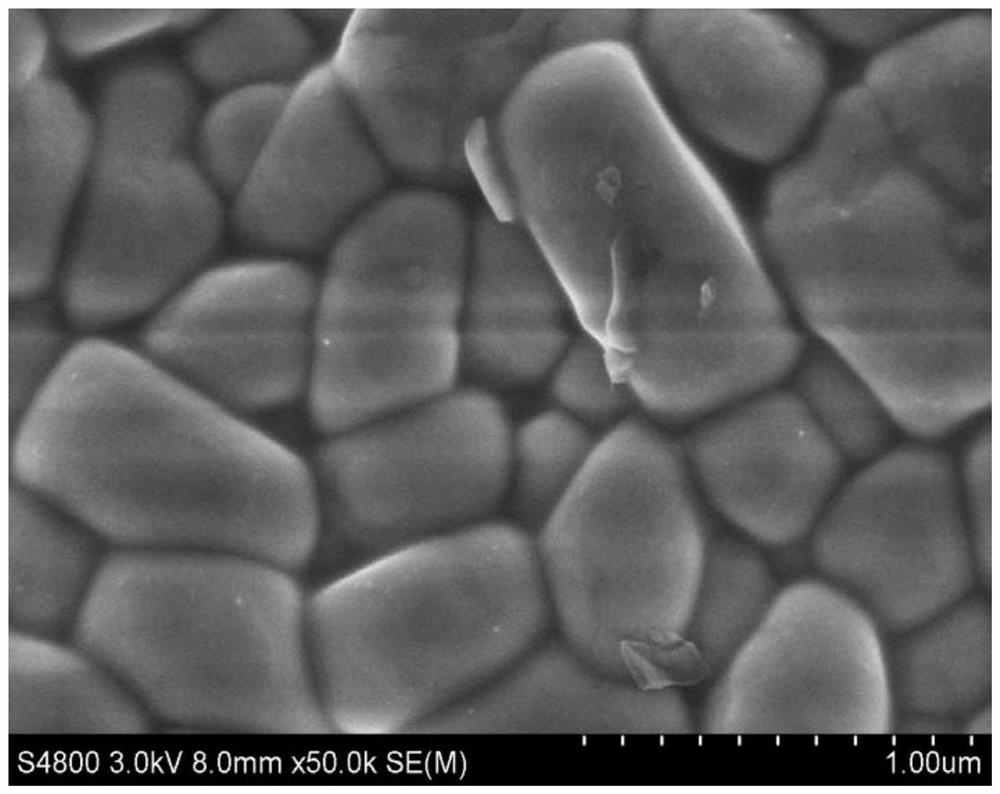

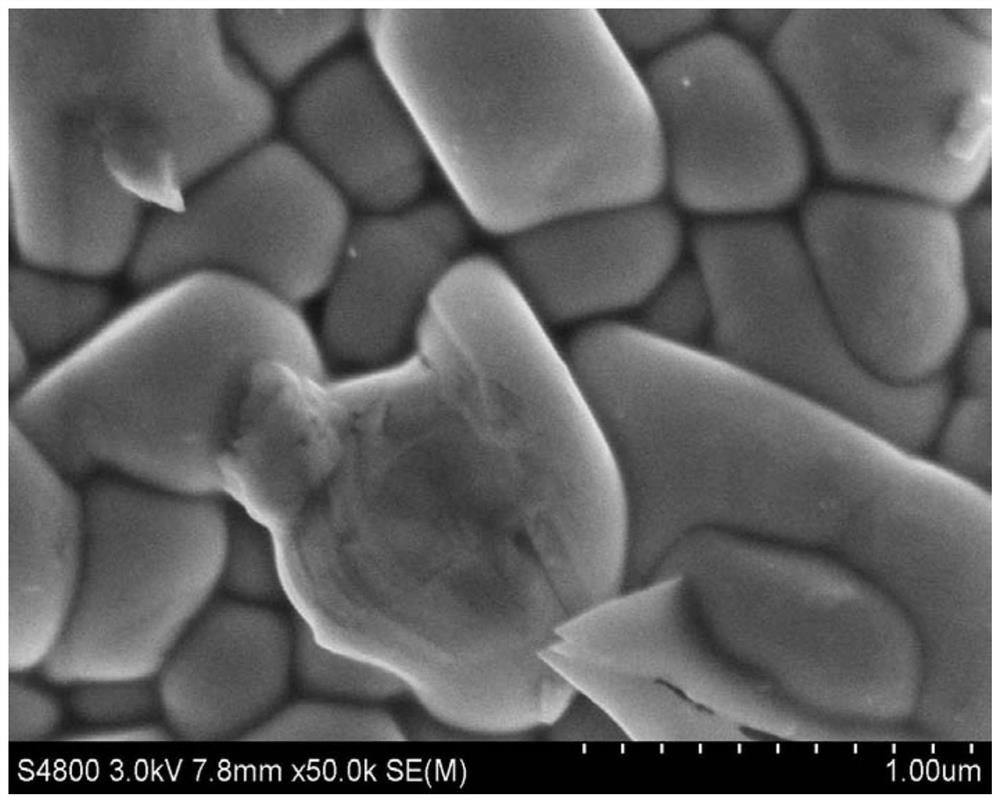

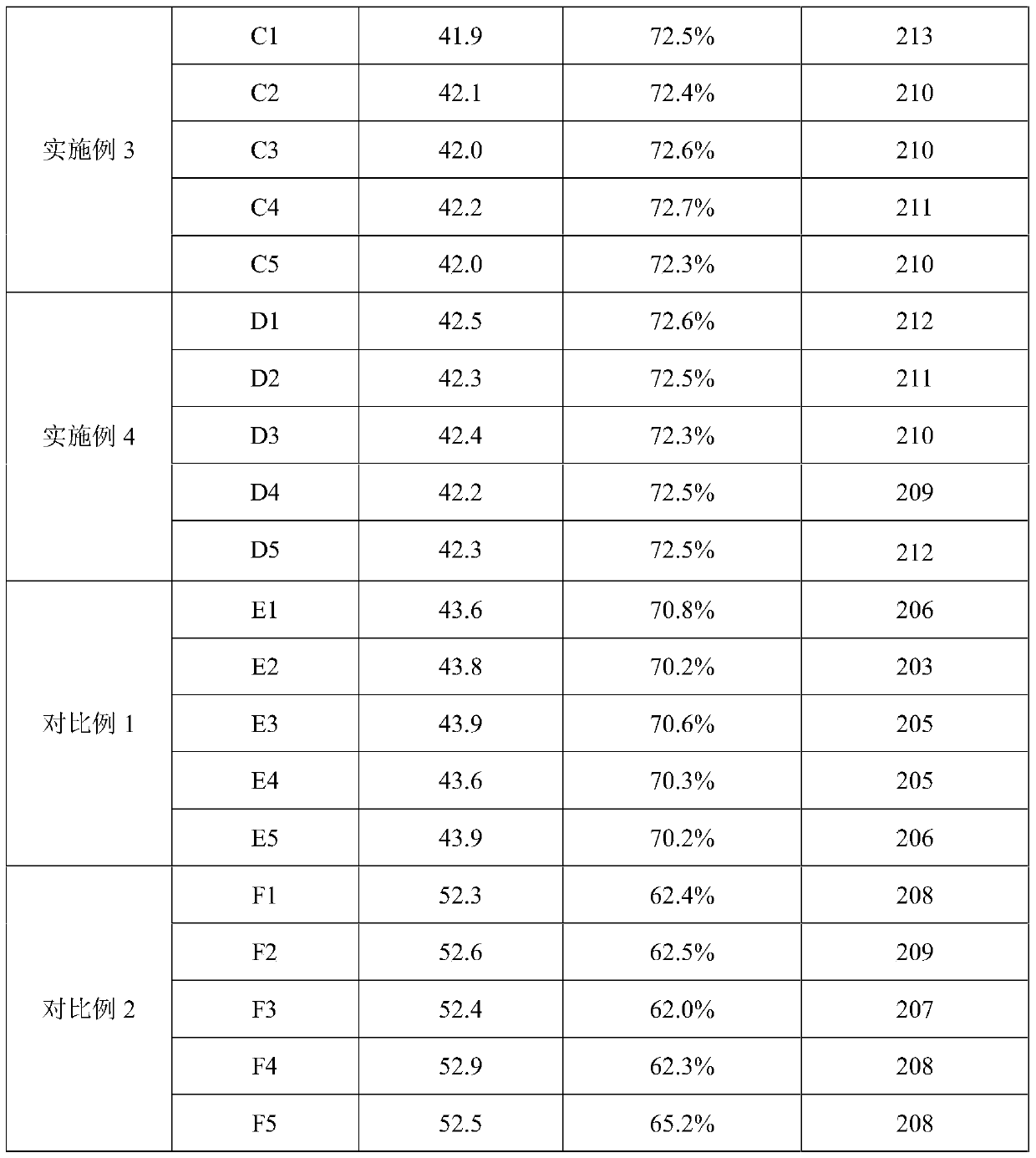

High magnifying power lithium-rich manganese-based cathode material with nano/microstructure

ActiveCN104157844ASimple processSignificant performance improvementMaterial nanotechnologyCell electrodesSodium chlorateChemical stability

The invention relates to a high magnifying power lithium-rich manganese-based cathode material with a nano / microstructure, which belongs to the technical field of material synthesis. A chemical reaction of the cathode material is aLi2MnO3.(1-a)LiMO2, wherein a is greater than or equal to 0.3 and less than 1, M is NixCoyMn1-x-y, wherein x is greater than or equal to 0 and less than 0.5, and y is greater than or equal to 0 and less than 0.5. A preparation method comprises the following steps: 1)weighing manganese salt, a surfactant and sodium chlorate, uniformly mixing, performing a hydrothermal reaction to obtain radicalized hollow nano / microstructure formed by self assembly of a manganese dioxide nanorod; 2)uniformly mixing manganese dioxide with the nano / microstructure obtained in the step 1) with lithium salt, cobalt salt and nickel salt to obtain a precursor; and 3)calcining the precursor at high temperature to obtain the lithium-rich manganese-based cathode material with nano / microstructure. The method uses the advantage of short diffusion path of a carrier of a nanostructure in the nano / microstructure to effectively increase the multiplying power capacity of the material, and the method also uses characteristics of low surface energy, difficult agglomeration and high chemical stability of a micrometer structure for keeping the cycle performance of the material.

Owner:哈尔滨博尔特能源科技有限公司

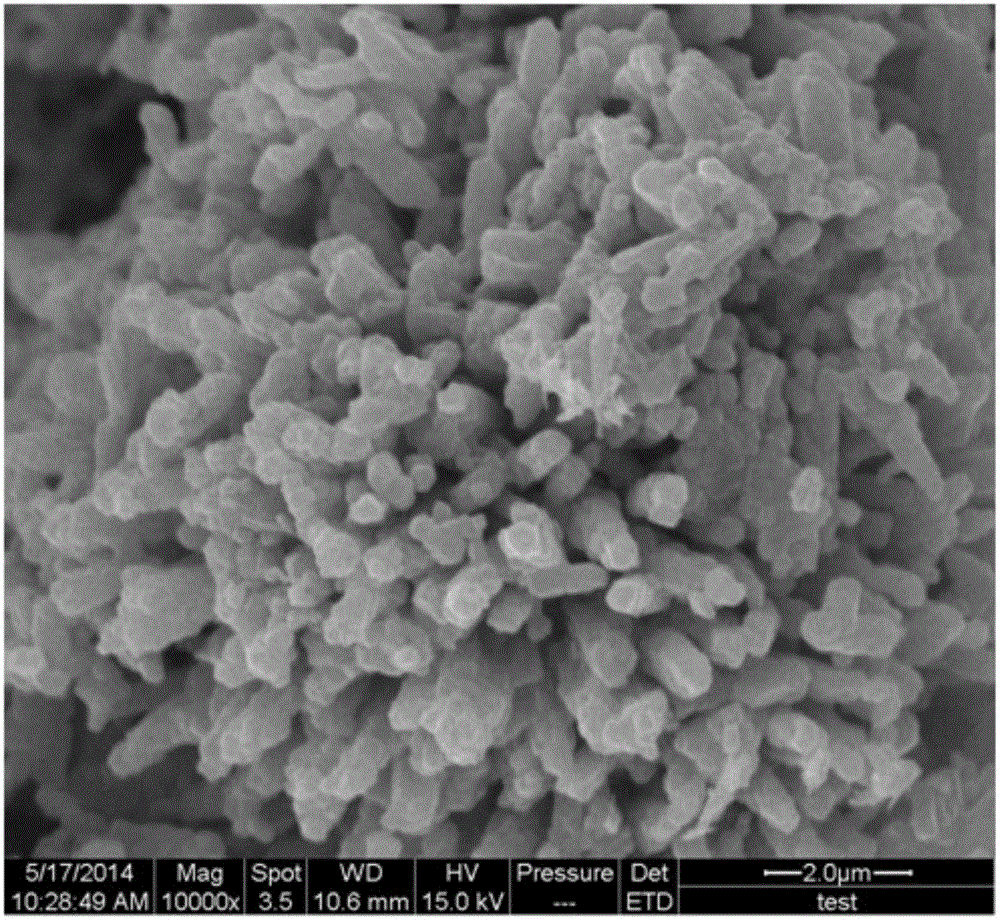

Spherical molybdenum disulfide composite material and preparation method and application thereof

InactiveCN104681815AEasy to prepareEasy to operateCell electrodesSecondary cellsHigh rateNitrogen gas

The invention discloses a spherical molybdenum disulfide composite material and a preparation method and an application thereof. The preparation method disclosed by the invention comprises the following steps: (1) respectively adding sodium molybdate and L-cysteine in deionized water, mixing uniformly, heating for 8-16 hours, naturally cooling, and alternatively washing with water and ethanol to obtain spherical molybdenum disulfide nano spheres; (2) soaking molybdenum disulfide in oleic acid for 24-72 hours, and centrifuging to remove excessive oleic acid; and (3) heating the soaked molybdenum disulfide in nitrogen or argon for 2-6 hours at 400-1100 DEG C to obtain a spherical molybdenum disulfide composite material coated with amorphous carbon. In the preparation method disclosed by the invention, the oleic acid is used for adsorbing crystal face and annealing to form the amorphous carbon, so that molybdenum disulfide is coated by an amorphous carbon layer, and the preparation method is simple and easy to operate; the prepared molybdenum disulfide composite material has uniform particle size distribution and good conductivity, and has the advantages of high capacity, good cycle stability and high rate capacity and the like, when being used as battery anode.

Owner:SHENZHEN CAPCHEM TECH

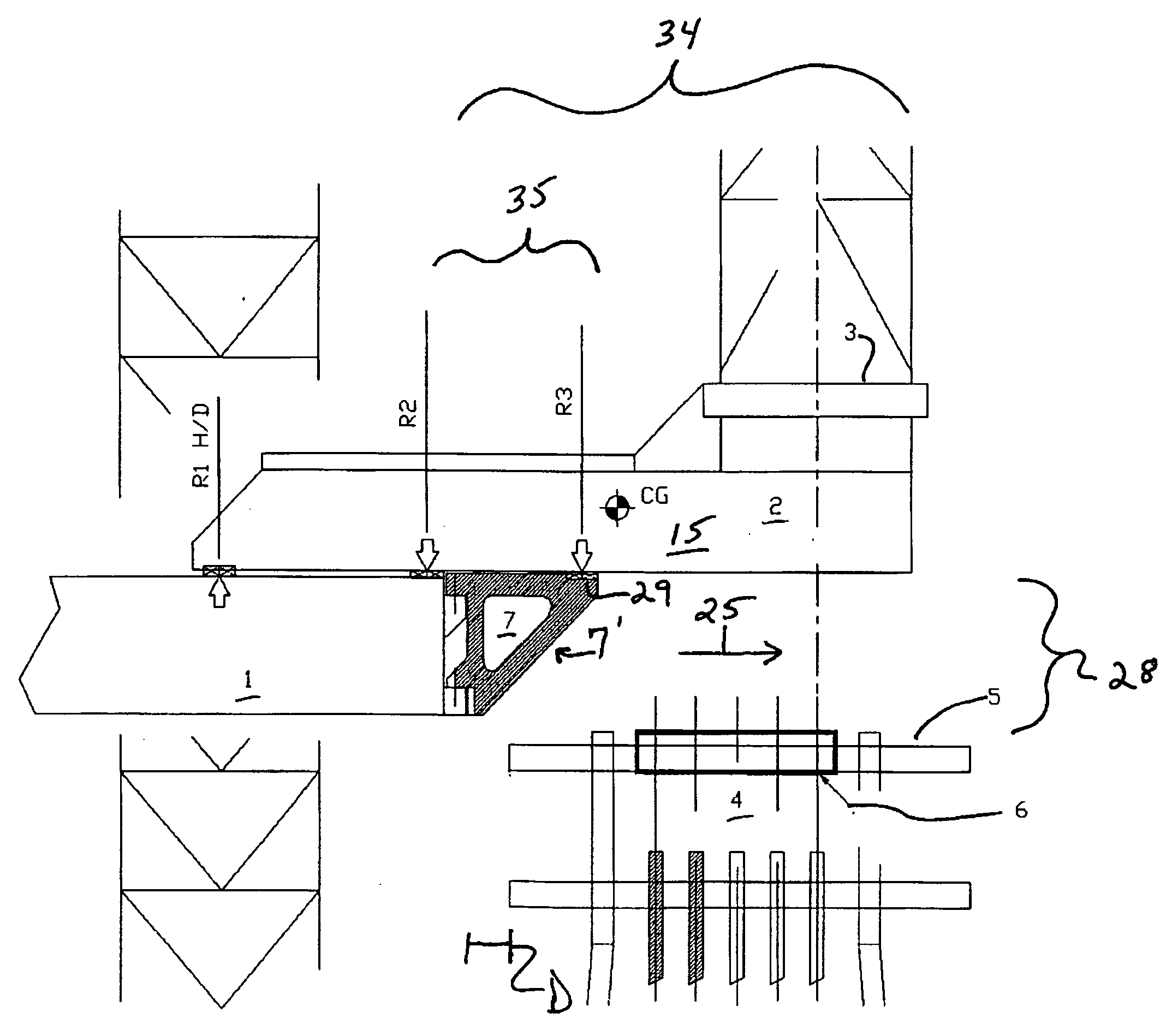

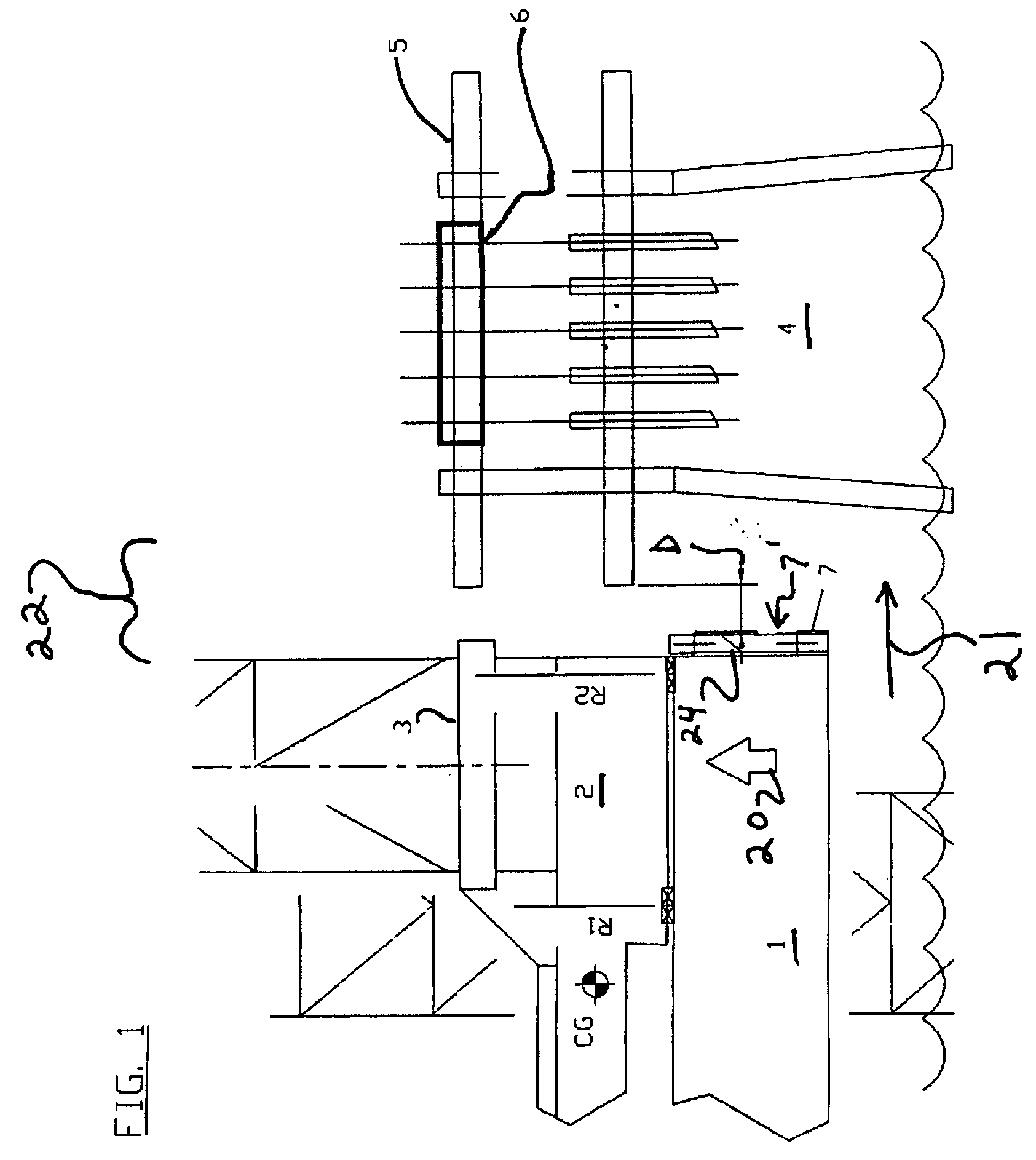

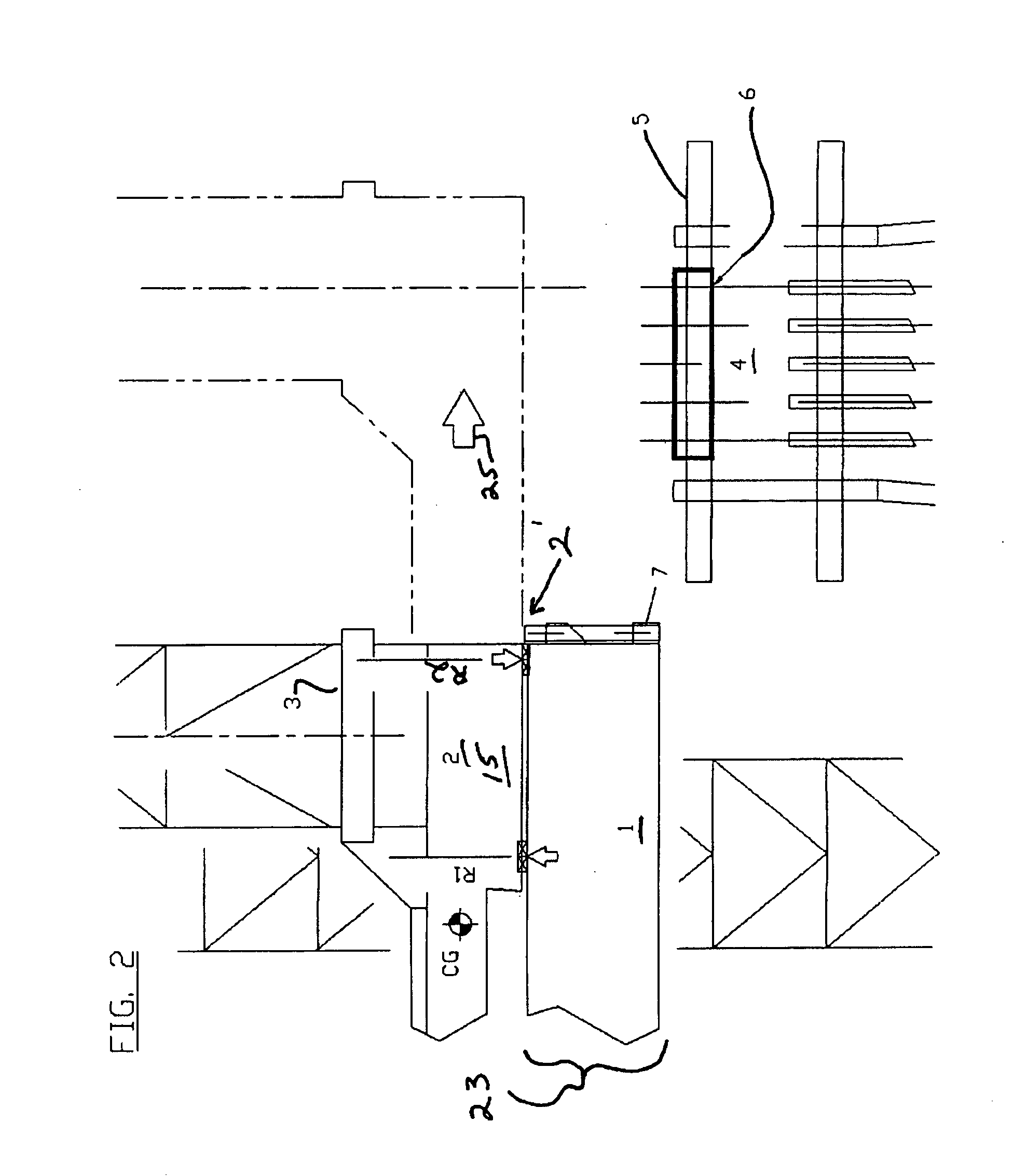

Auxiliary reaction frame system for cantilevered jack-up rigs, and method therefore

ActiveUS20080044234A1Positive reactionEasy loadingArtificial islandsDrilling rodsBraced frameEngineering

A retractable stern reaction frame for reinforcing self elevating platform cantilever beams. The preferred embodiment contemplates a support framework mounted on a self elevating platform transom and positioned to engage the cantilever to project the reaction point farther towards the cantilever reach. The frameworks are to be retractable (or portable) to allow the self elevating unit to position itself closer to the jackets than would otherwise be possible. The framework is designed to transmit the reaction forces back to the main deck, cantilever support bulkheads, inner bottom and bottom structure.

Owner:LEFEBVRE MAXIME H

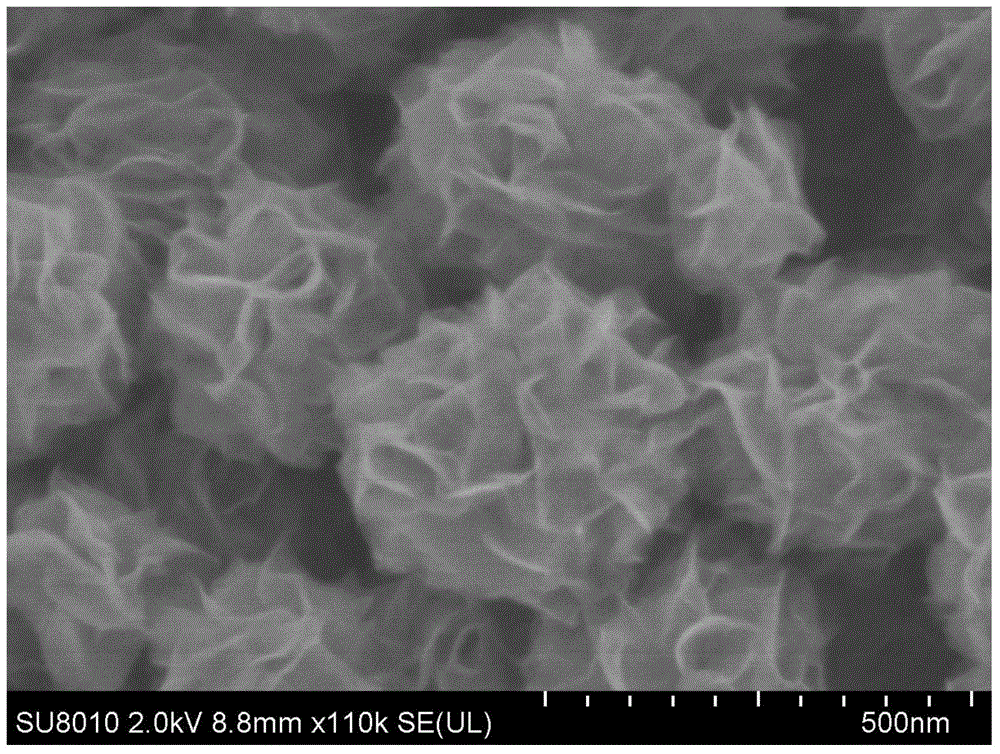

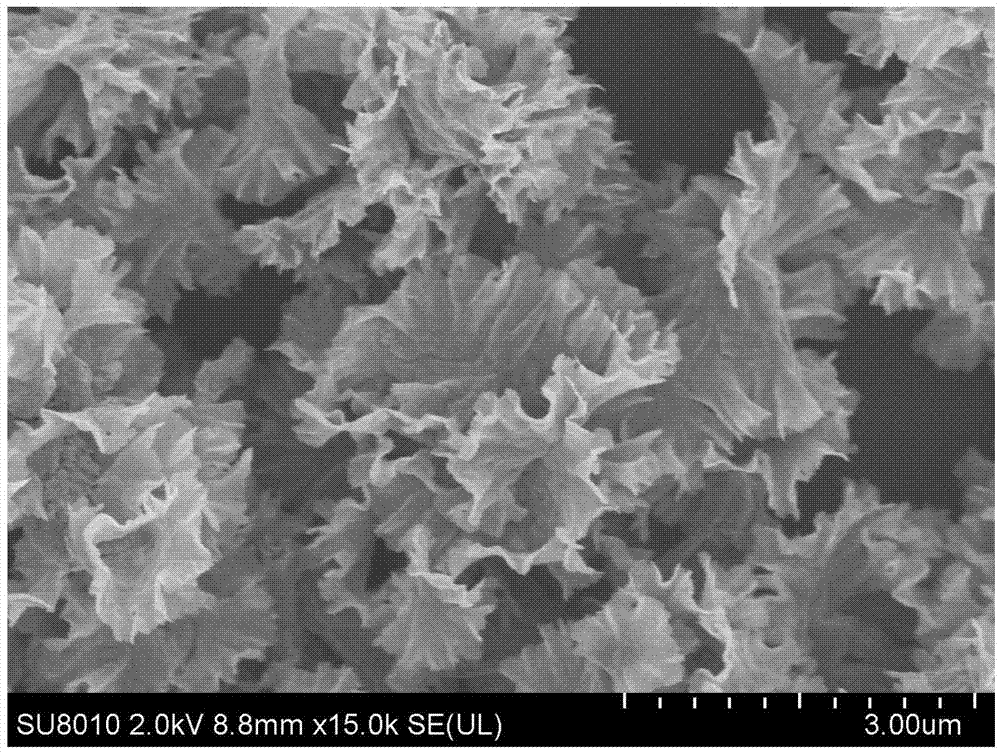

Tin bisulfide nanosheet composite material, as well as preparation method and application thereof

ActiveCN104716311AIncrease surface areaImprove cycle stabilityMaterial nanotechnologyCell electrodesBisulfideCysteine thiolate

The invention discloses a tin bisulfide nanosheet composite material, as well as a preparation method and application thereof. The preparation method comprises the following steps: (1) uniformly mixing a tin source and an L-cysteine solution, performing heating reaction for 5 to 30 hours, naturally cooling the reaction product, and alternately washing the reaction product with water and ethanol to obtain a flower-like tin bisulfide nanosheet; (2) mixing tin bisulfide and oleic acid according to the weight ratio of (1 to 20) to (1 to 60), performing soaking for 24 to 48 hours, centrifugally removing redundant oleic acid, and performing heating for 1 to 8 hours in the inert gas atmosphere of 400 to 1,000 DEG C to obtain an amorphous carbon-coated tin bisulfide nanosheet composite material. According to the method, amorphous carbon is formed by oleic acid adsorption material surface annealing, and the surface of the flower-like tin bisulfide nanosheet prepared by a hydrothermal method is coated with an amorphous carbon layer, so that the method is simple and easy to operate; the prepared amorphous carbon-coated tin bisulfide nanosheet composite material is large in surface area and thin, and has the characteristics of high cycling stability, high rate capacity and the like when being used as a battery cathode.

Owner:太湖县市场监督检验所(太湖县功能膜检测研究院)

Inductively coupled wireless power and data for a garment via a dongle

ActiveUS9912174B2Reduce stray magnetic fieldLower levelNear-field transmissionCircuit arrangementsDongleInductive coupling

A system for transmission of at least power using inductive wireless coupling includes an environmentally sealed dongle and a mounting component which releasably mates with the dongle. The dongle is sized for use with one hand, and may be coupled by an umbilical to either a garment of the user or to a vehicle structure for example a seat, in which case the mounting component is coupled to the vehicle structure or to the garment respectively. The dongle and the mounting component include first and second inductive coils respectively and corresponding ferrite cores. The coils are positioned within the dongle and mounting component so that they are aligned for their inductive coupling when the dongle and mounting component are mated. The positioning and alignment of the coils provides a substantially closed magnetic path between the coils. The mounting component may be a receptacle.

Owner:CYNETIC DESIGNS

Germanium/carbon composite negative electrode material and preparation method thereof

InactiveCN104659346AImprove conductivityIncreased rate capacityNegative electrodesCarbon compositesHydrogen atmosphere

The invention discloses a germanium / carbon composite negative electrode material and a preparation method thereof. The preparation method comprises the steps of carrying out ball milling and mixing on germanium dioxide and polyvinylpyrrolidone, annealing at a hydrogen atmosphere in the presence of argon, so as to prepare the germanium / carbon composite negative electrode material. When being used as a negative electrode material of a lithium ion battery, the germanium / carbon composite negative electrode material has the characteristics of good cycling stability and high multiplying power capacity.

Owner:SHENZHEN CAPCHEM TECH

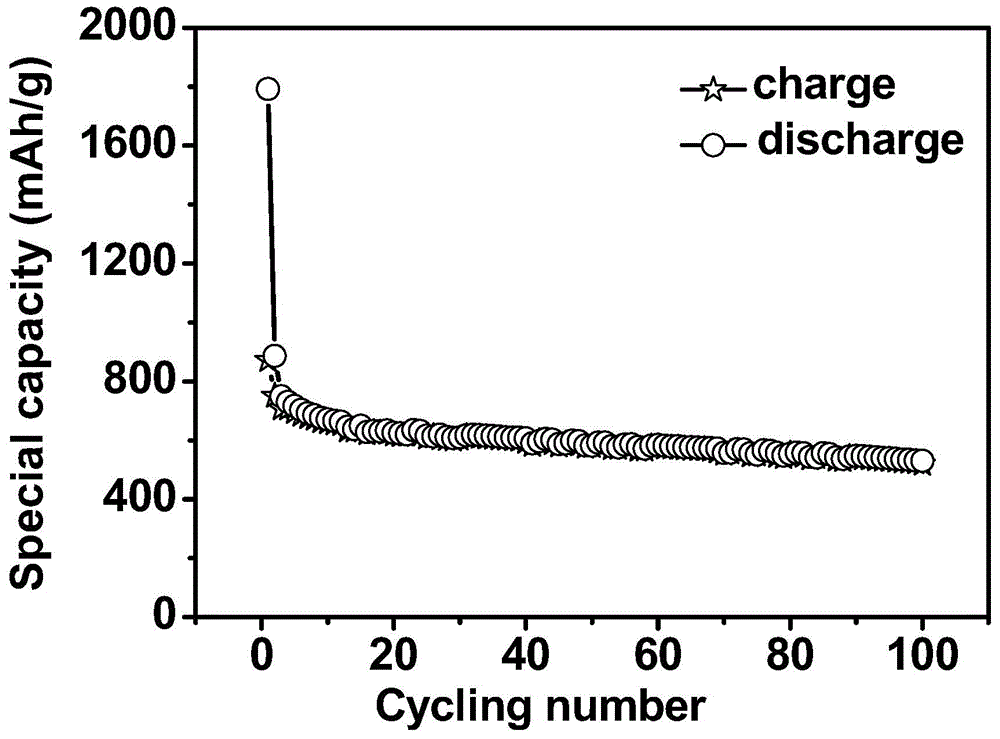

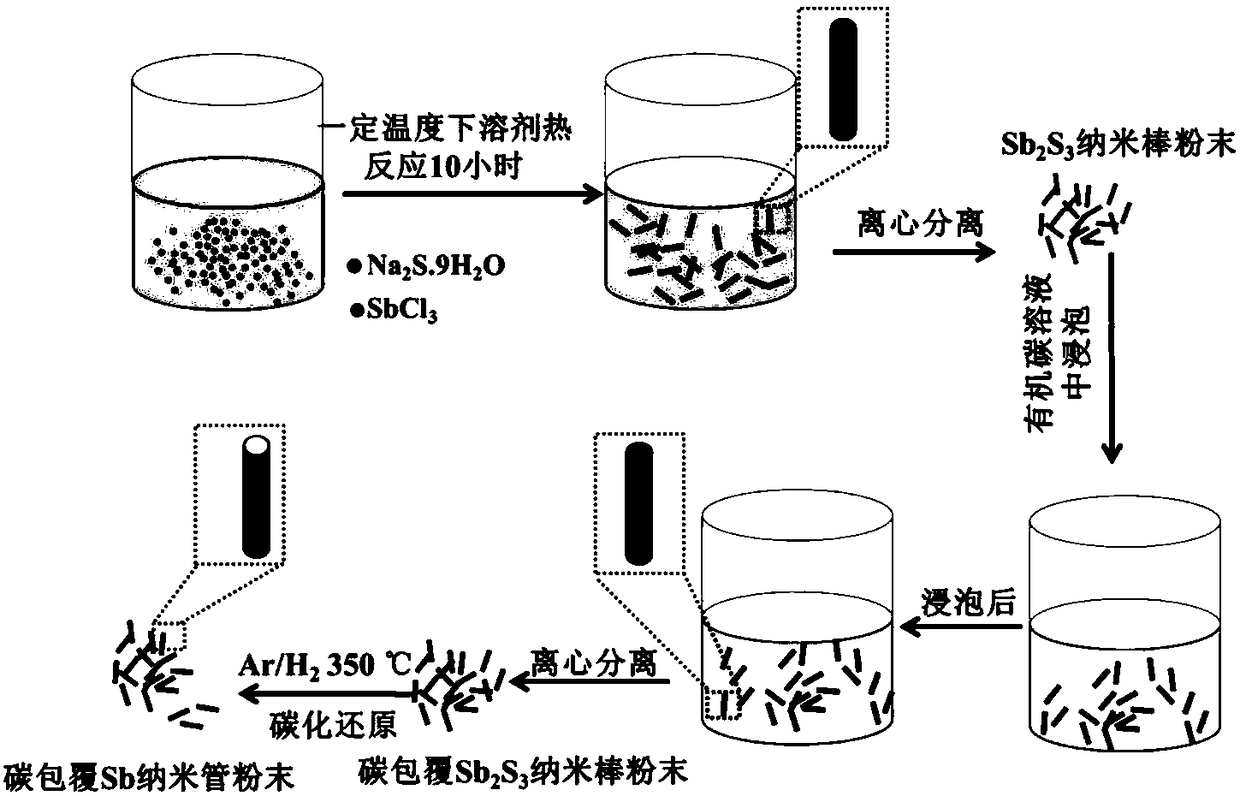

Preparation method and application of carbon-coated tantalum nanotube material of negative electrode material of sodium ion battery

ActiveCN108390033AIncrease storage capacityImprove cycle stabilityMaterial nanotechnologyCell electrodesSodium-ion batteryLithium-ion battery

The invention provides a preparation method and application of a carbon-coated tantalum nanotube material of a negative electrode material of a sodium ion battery. The preparation method comprises thefollowing steps: dissolving Na2S.9H2O in 20ml ethylene glycol to obtain a solution A; dissolving SbCl3 in 20ml ethylene glycol to obtain a solution B; adding the solution A to the solution B dropwise, and stirring to obtain a solution C; transferring the C solution to a polytetrafluoroethylene-lined autoclave to obtain a synthetic product D; performing centrifugal separation at 10,000 rpm on theolvothermally synthesized product D, washing the olvothermally synthesized product D with deionized water and ethanol, drying the olvothermally synthesized product D at 85 DEG C for 12 h to obtain Sb2S3 nanorod powder, soaking a Sb2S3 nanorod precursor in an organic carbon source solution with certain concentration, performing centrifugal separation and drying to obtain a product E; and placing the product E in an H2 or Ar atmosphere to obtain the carbon-coated tantalum nanotube negative electrode material. The material has the characteristics of high capacity, good cycle performance and highrate capacity, simple preparation process and low cost, and is suitable for large-scale energy storage.

Owner:北京博雅合众环保科技有限公司

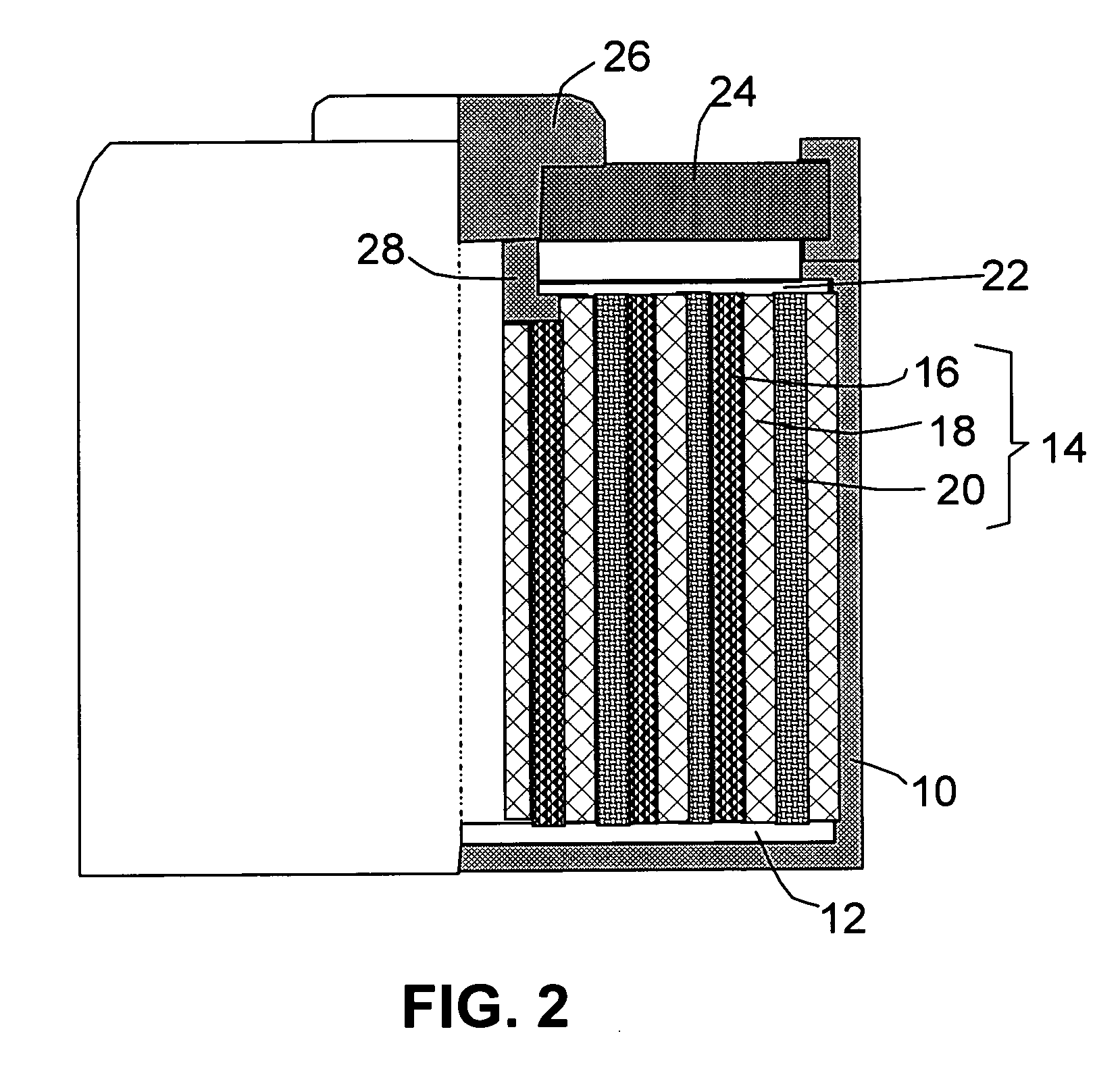

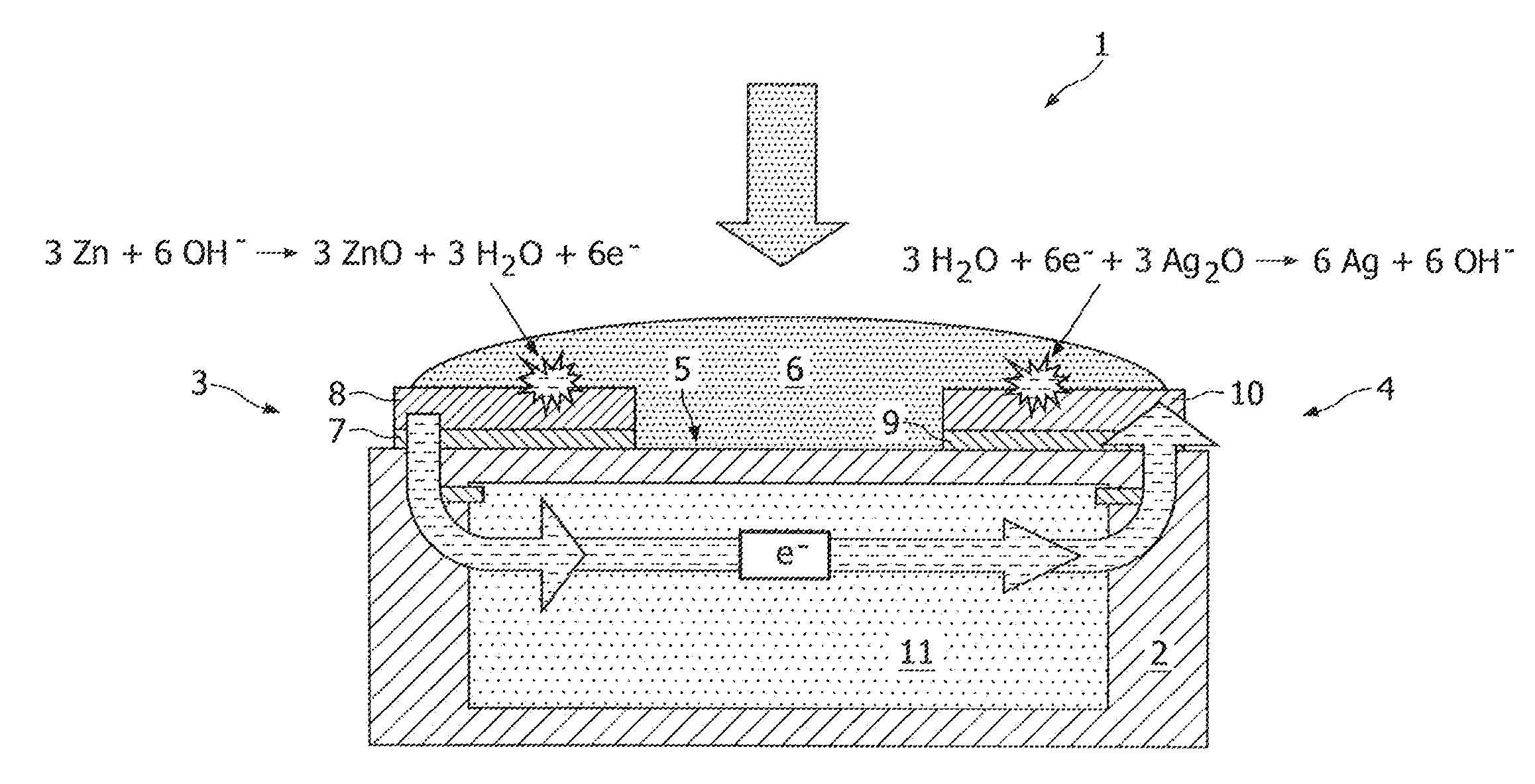

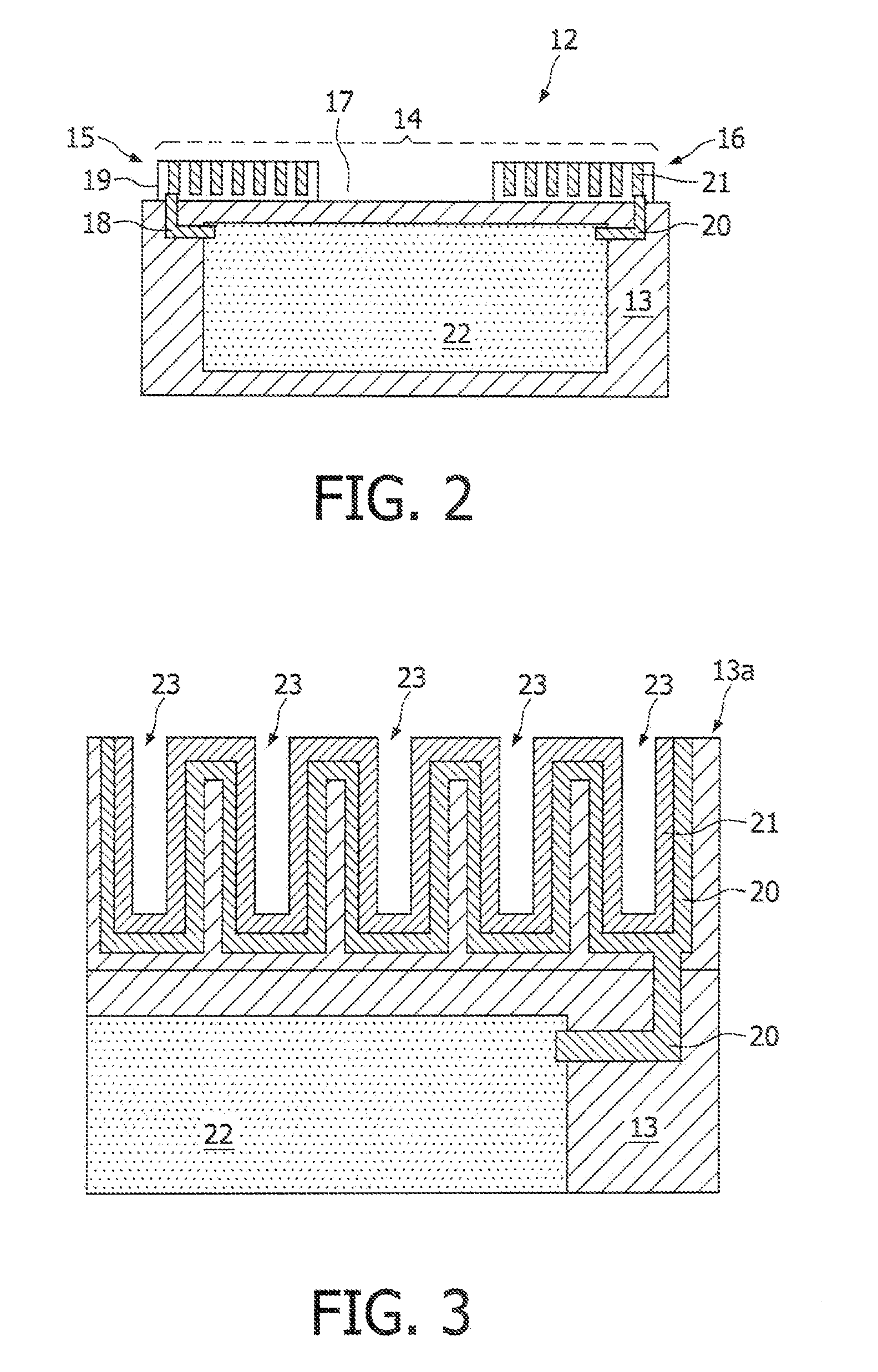

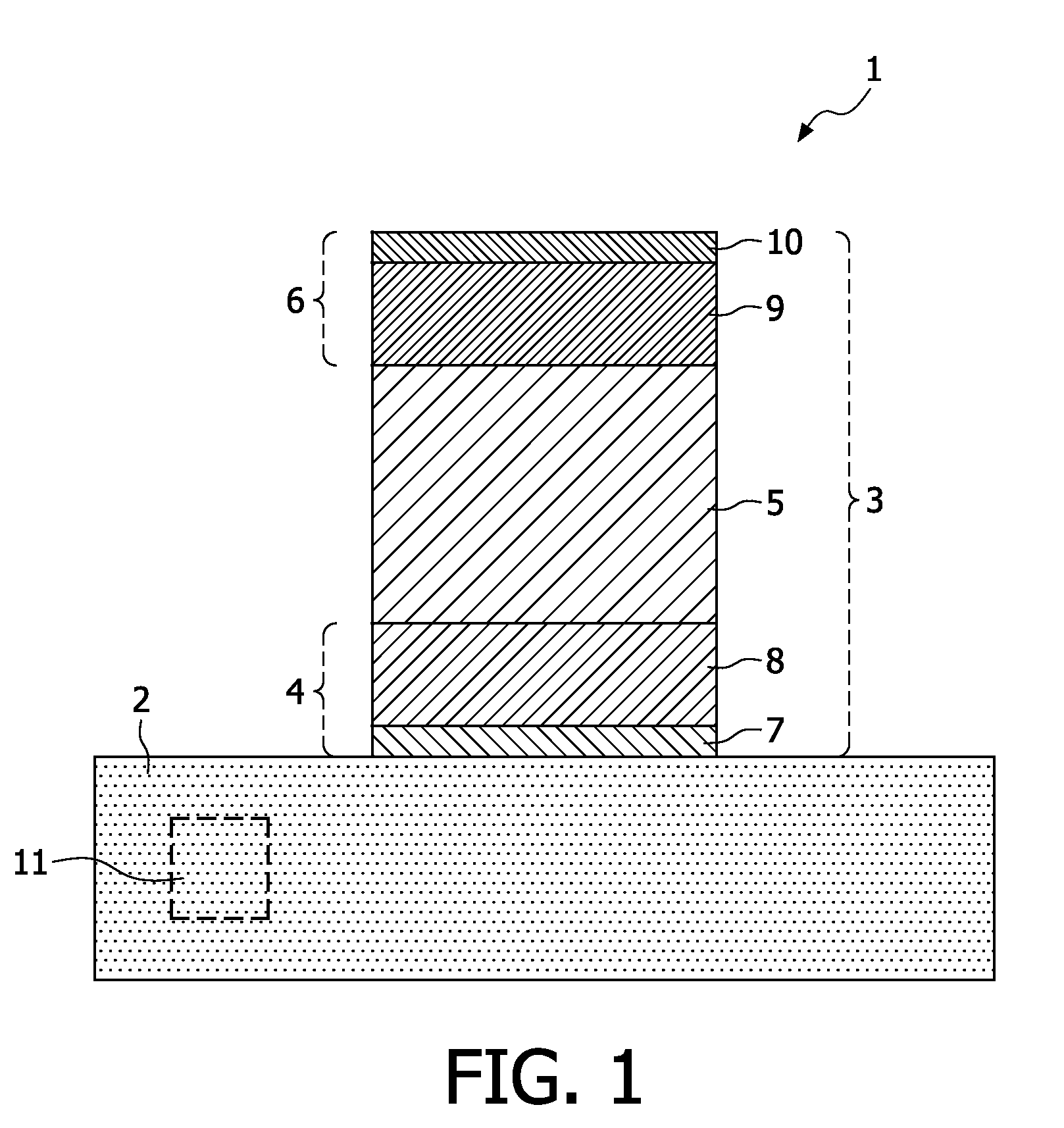

Electrochemical energy source and electronic device

InactiveUS20100099010A1Increased rate capacityImprove performanceActive material electrodesAlkaline accumulator electrodesElectricityEngineering

The invention relates to an electrochemical energy source, comprising a substrate, and at least one cell deposited onto said substrate. The invention also relates to an electronic device, said device comprising at least one electrochemical energy source according to invention, and at least one electronic component electrically connected to said electrochemical energy source.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

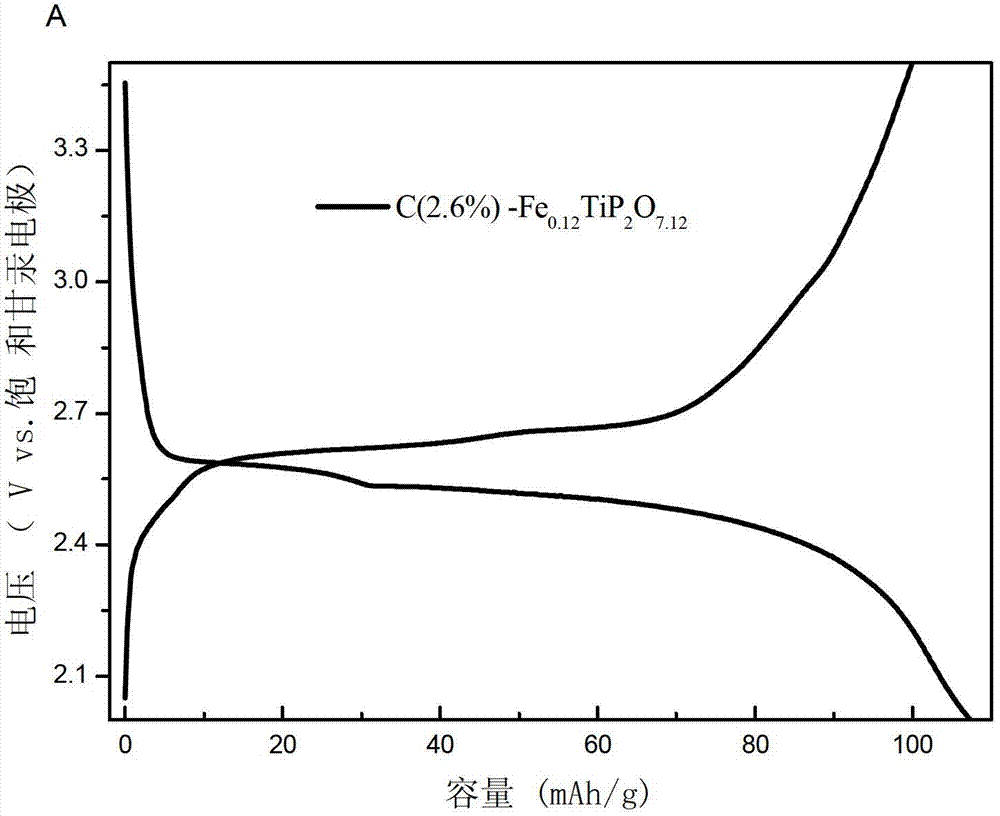

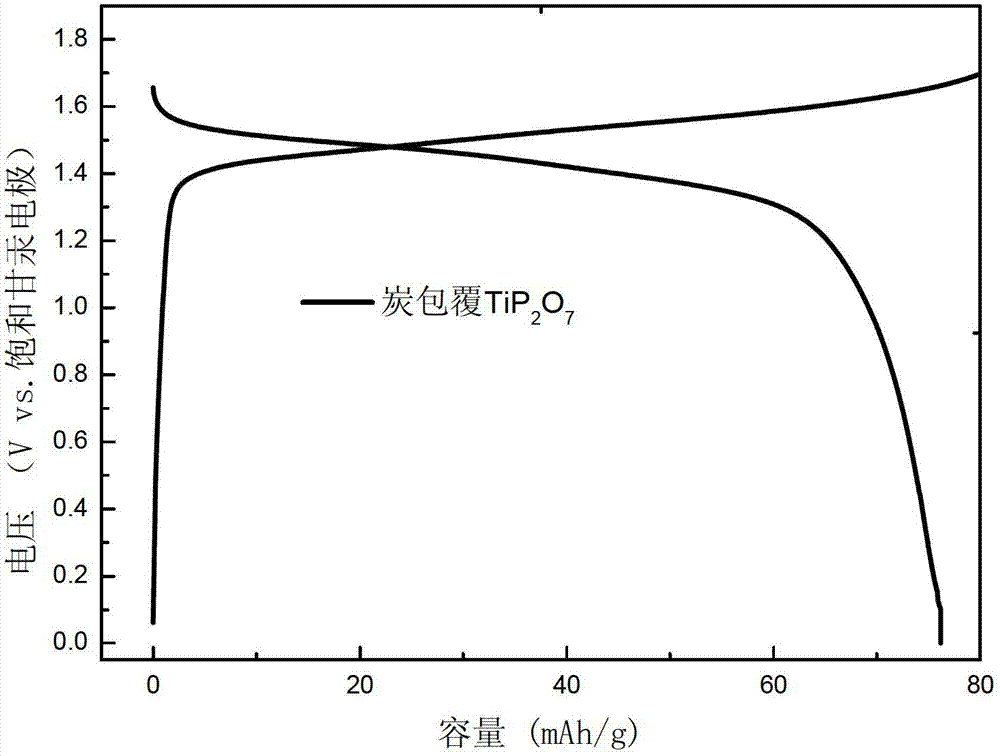

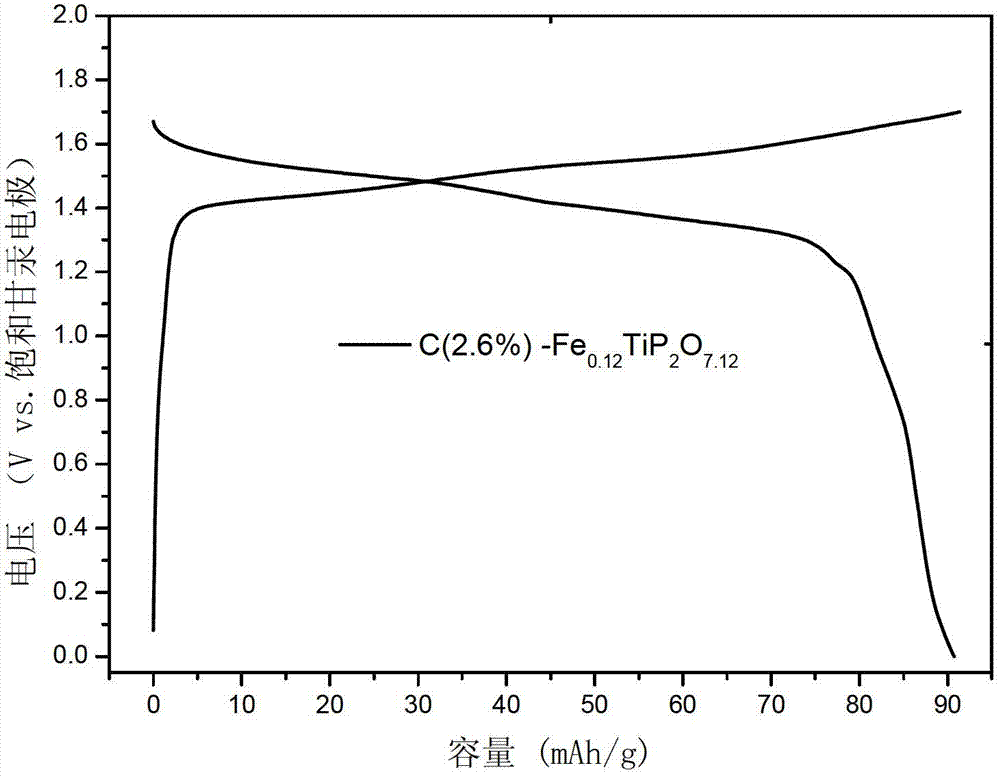

High-performance lithium ion battery electrode material and preparation method

ActiveCN103199245AIncreased rate capacityImproved magnification performanceCell electrodesElectrical conductorPhosphoric acid

The object of the present invention is to provide a novel titanium phosphate electrode material having good lithium ion battery characteristics, and is to solve the problem that the cycle life of a titanium pyrophosphate electrode material is poor in the prior art. The electrode material is intercalation compound carbon-coated C-Fe[x]TiP[2]O[7+x], and is a fast ion conductor electrode material of a three-dimensional structure. A preparation method comprises: (1) mixing and grinding TiO2 and NH4H2PO4, adding distilled water, stirring until the mixture is dried, finally placing the mixture in air for calcination to obtain TiP2O7; and (2) taking TiP2O7 obtained in Step (1) as a raw material, weighing TiP2O7 and an iron source material, mixing evenly, then adding a carbon source aqueous solution, stirring continuously at 40 DEG C until the mixture is dried, and finally calcining the mixture in a nitrogen atmosphere to obtain carbon-coated C-Fe[x]TiP[2]O[7+x].

Owner:常州孚达新能源科技有限公司

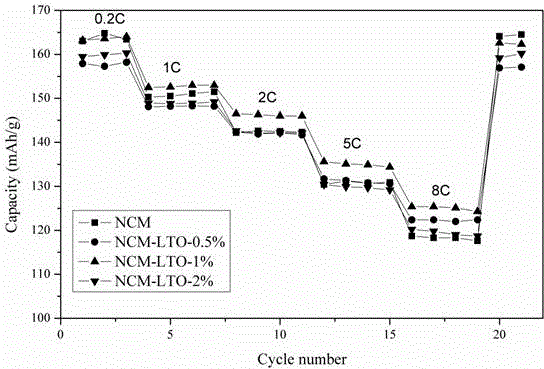

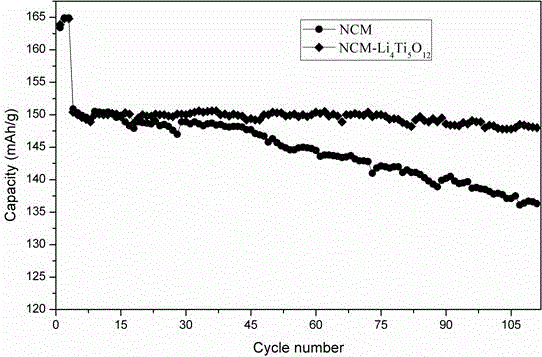

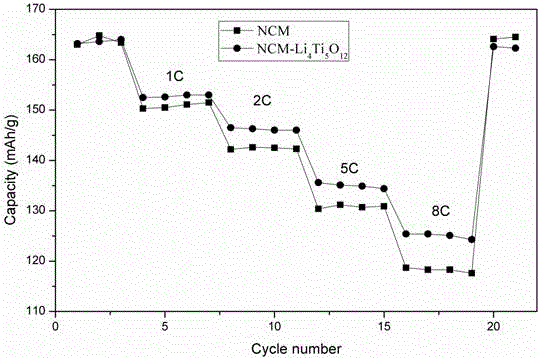

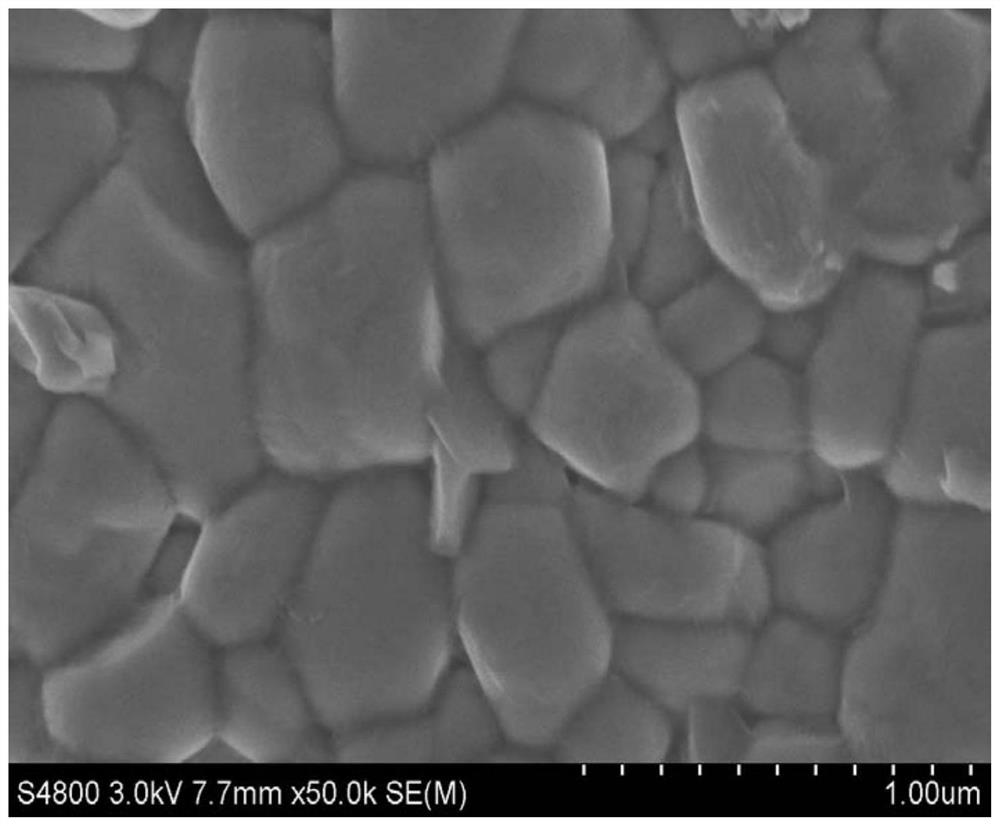

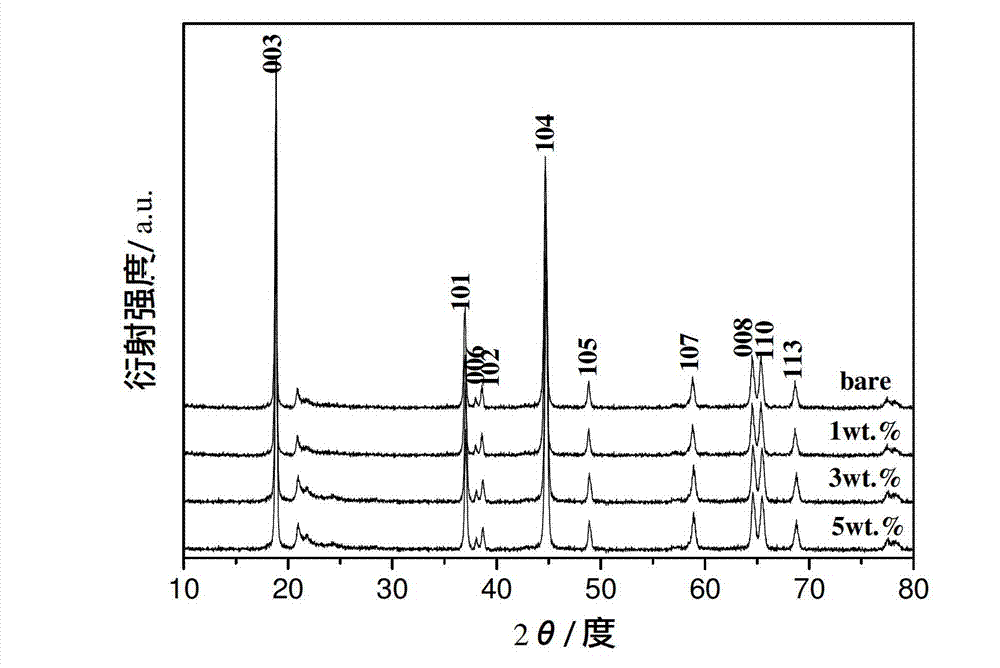

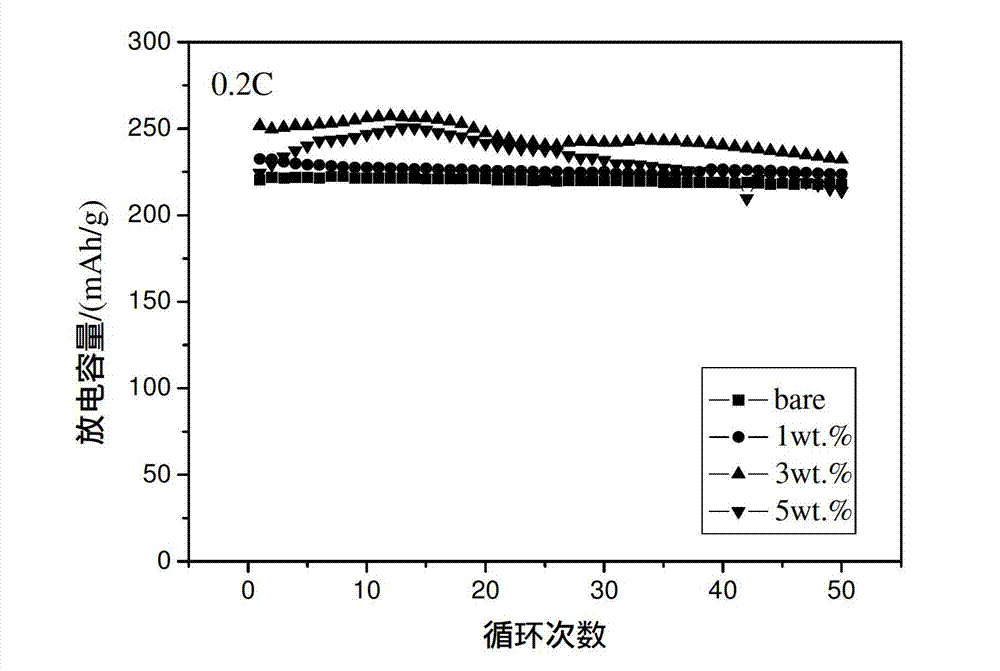

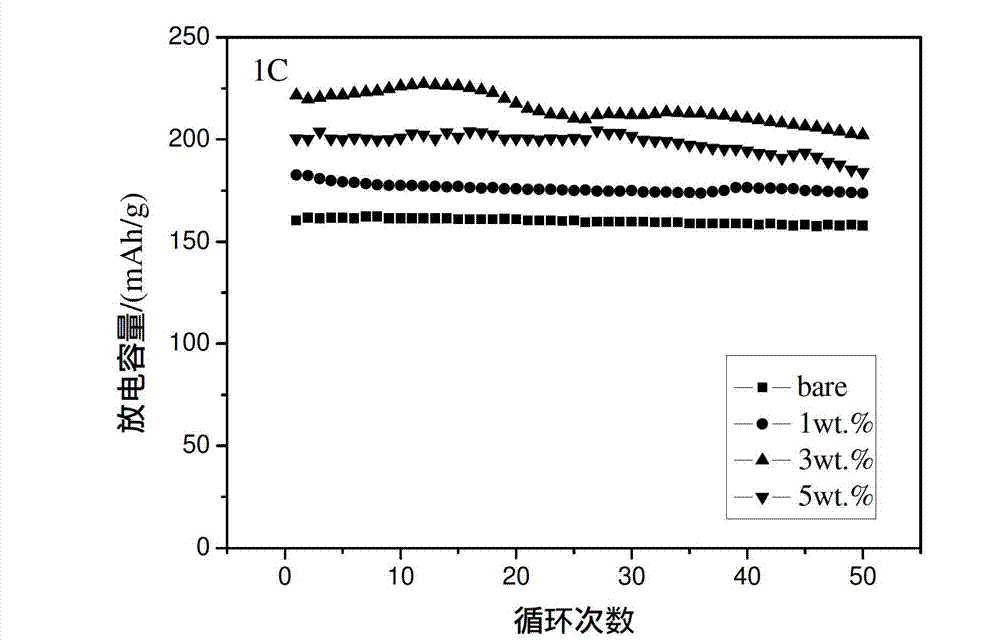

Preparation method of lithium titanate coated lithium ion battery nickel cobalt manganese cathode material

InactiveCN105789606AImprove cycle stabilityImproved magnification performanceCell electrodesBatteriesManganeseCobalt

The invention relates to the technical field of battery materials, in particular to a preparation method of the lithium titanate coated lithium ion battery nickel cobalt manganese cathode material. According to the method, the existing preparation process of the lithium ion battery cathode material is improved, a lithium titanate nanomaterial is synthesized via a sol-gel method and then dipped on a nickel cobalt manganese ternary material via a solution method, so that the composite material high in safety, good in cycling stability and high in initial coulomb efficiency is obtained. The method is simple, feasible, high in production efficiency and suitable for large-scale production, production procedures are reduced, sintering temperature is lowered, sintering time is shortened, and production cost is saved.

Owner:SHANDONG YUHUANG NEW ENERGY TECH

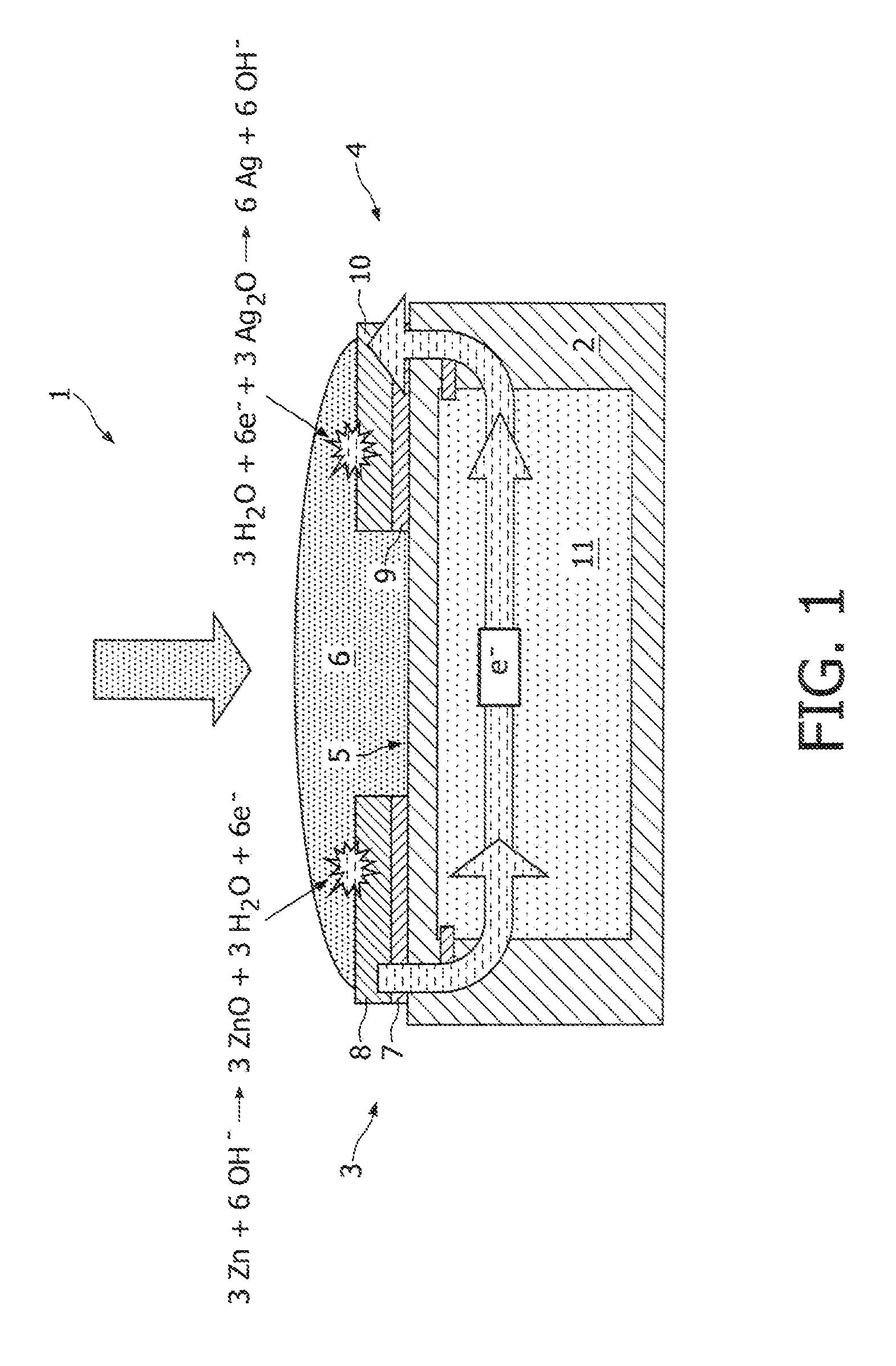

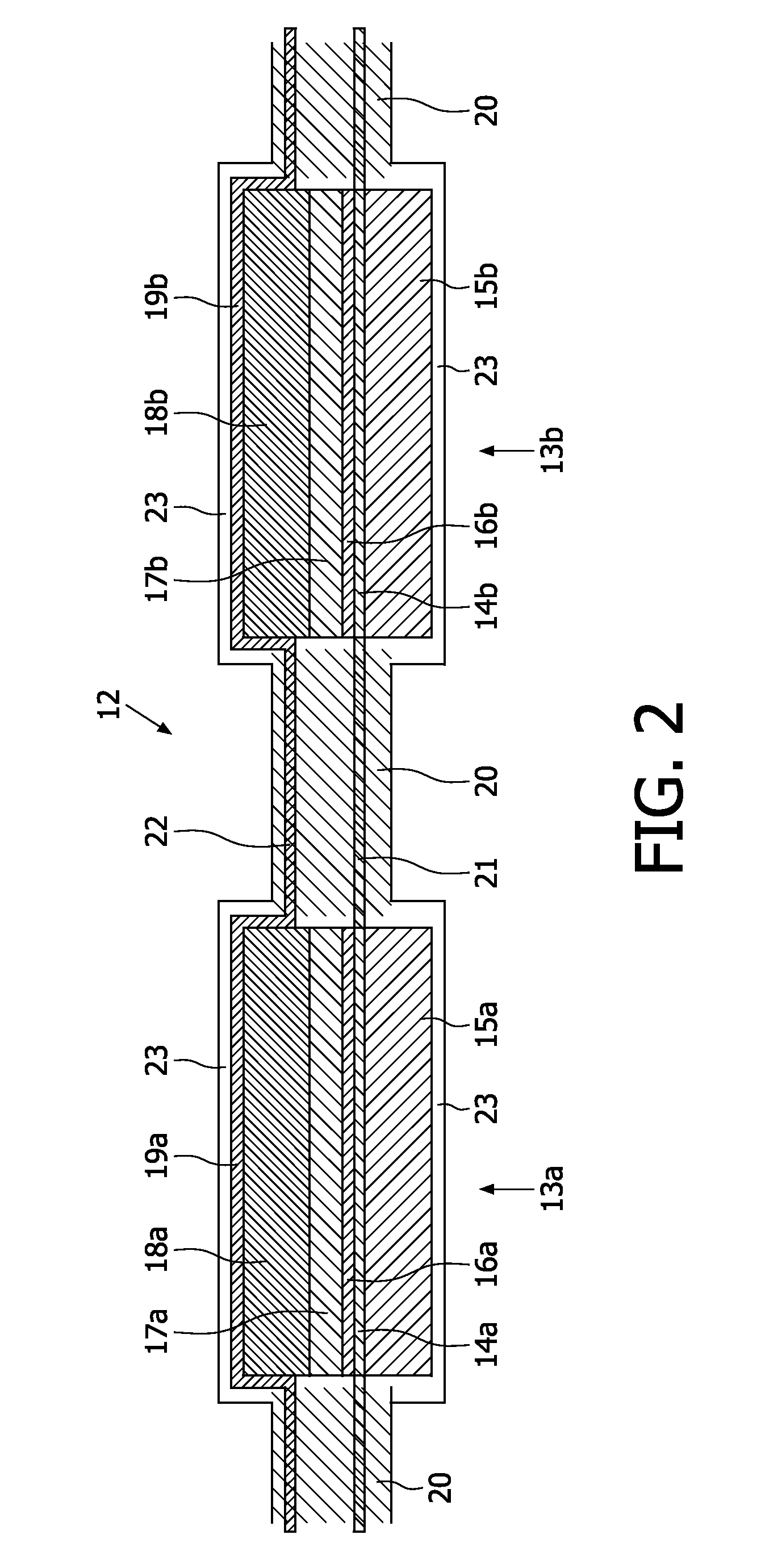

Electrochemical energy source and electronic device provided with such an electrochemical energy source

InactiveUS20100099020A1Suitable for useSufficient flexibilityCurrent conducting connectionsFinal product manufactureConductive polymerEngineering

Solid-state batteries, efficiently convert chemical energy into electrical energy and can be used as the power sources for portable-electronics. The invention relates to an improved electrochemical energy source. The invention also relates to an electronic device provided with such an electrochemical energy source. The energy source comprises at least two cells interconnected by means of at least one flexible element. This flexible element may comprise a conductive polymer or a conductive rubber. The electrodes may be provided with cavities (pillars, trenches, slits or holes). A barrier layer may be deposited between the electrodes and their substrate. The energy sources may be used in a “System in Package”.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Ternary positive electrode material, preparation method thereof and lithium ion battery

PendingCN112864385AReduce the amount of residual alkaliImprove cycle performanceSecondary cellsPositive electrodesPhysical chemistryLithium-ion battery

The invention provides a ternary positive electrode material, a preparation method thereof and a lithium ion battery. The ternary positive electrode material comprises a core and a composite coating layer coating the core, the core is a high-nickel ternary material, and the composite coating layer comprises a boron-containing compound and a phosphorus-containing compound. The method comprises the following steps: mixing a boron source, a phosphorus source and a high-nickel ternary material, and sintering in an oxidizing atmosphere to obtain the ternary positive electrode material. According to the ternary positive electrode material provided by the invention, through the high-nickel ternary material core and the composite coating layer including the boron-containing compound and the phosphorus-containing compound, the residual alkali amount is low, and the rate discharge capacity and the cycle performance are good.

Owner:SHENZHEN CITY BATTERY NANOMETER TECH

Modification method of lithium-rich cathode material

InactiveCN102969495AReduce the first irreversible capacity lossIncreased rate capacityCell electrodesSlurryLithium-ion battery

The invention relates to a surface modification method of lithium ion battery cathode material, and especially a modification method of a lithium-rich cathode material. The method is characterized by comprising the following steps: preparing a lithium ion battery cathode material Li [NixLi1 / 3-2x / 3Mn2 / 3-x / 3] O2, wherein x satisfies the relation of 1 / 5<= x<=1 / 3; dispersing the lithium-rich cathode material in a FeC2O4 solution with concentration no higher than 0.95g / L in and treating the solution with ultrasound for 0.5-5 h, then stirring for 0.5-5 h, dropwise adding NH4H2PO4 solution with concentration no higher than 0.76g / L, and completely drying the obtained slurry at 80-150 DEG C; and sintering at 200-700 DEG C for 4-15 h to obtain FePO4 surface modified lithium ion battery cathode material. The invention has advantages of simple process, low temperature heat treatment, simple operation and low cost, and is suitable for large-scale industrial production.

Owner:IRICO

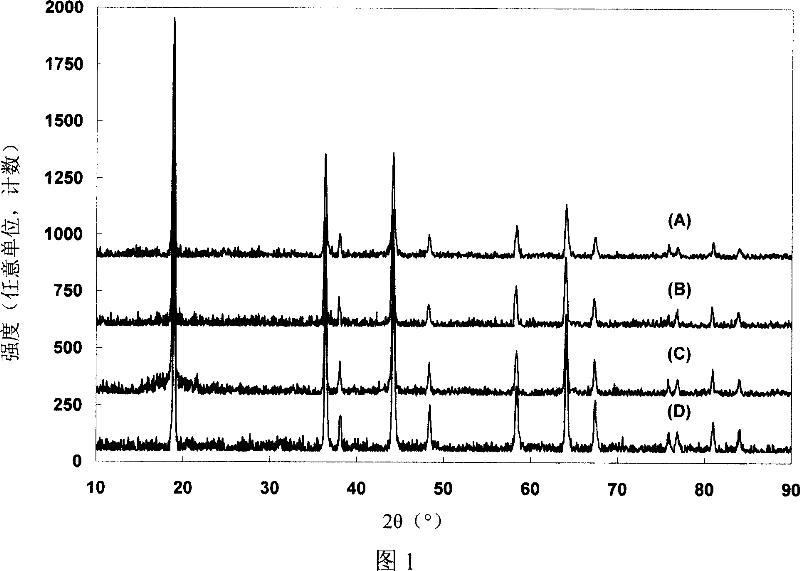

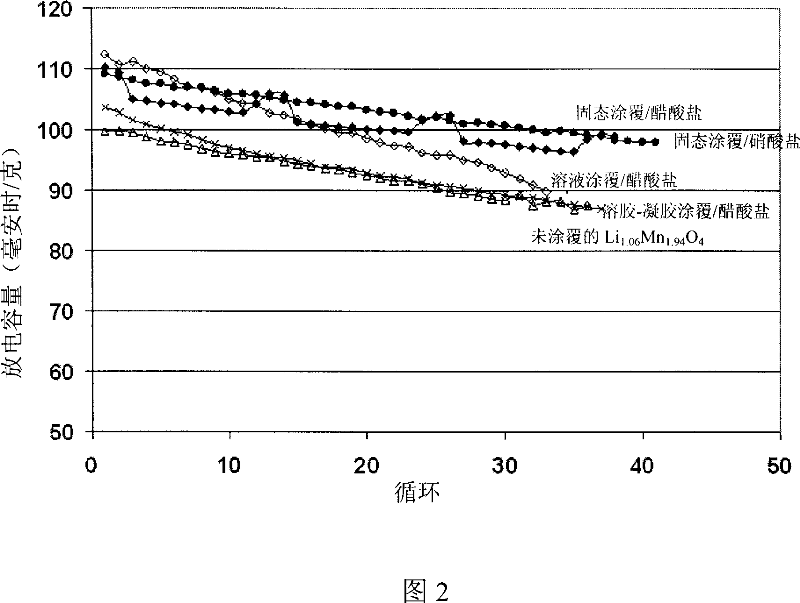

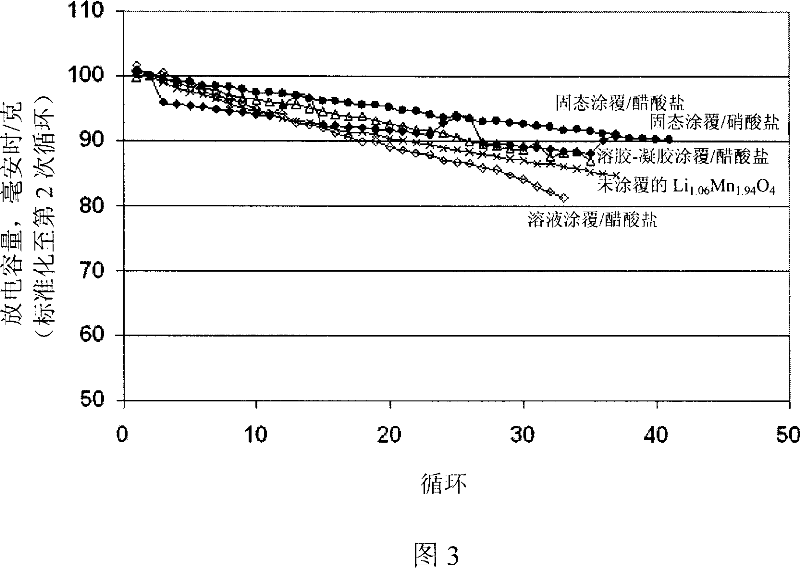

Metal oxide cathode materials with improved performance

PendingCN101043076AIncreased rate capacityImprove cycle lifeElectrode manufacturing processesPositive electrodesOxide cathodeLithium-ion battery

Owner:FARASIS ENERGY

Preparation method of solid spherical multiple-ring-shaped lithium-rich manganese-based solid solution cathode material oxide precursor

The invention relates to a preparation method of a solid spherical multiple-ring-shaped lithium-rich manganese-based solid solution cathode material oxide precursor, belonging to the field of electrode material preparation. The lithium-rich manganese-based solid solution cathode material oxide precursor prepared by the invention has a solid spherical multiple-ring-shaped structure, a liquid-liquidcoprecipitation method is adopted to obtain a carbonate precursor, and the solid spherical multiple-ring-shaped lithium-rich manganese-based solid solution cathode material oxide precursor is obtained by performing special calcination treatment on the carbonate precursor. The lithium-rich manganese-based solid solution cathode material prepared from the solid spherical multiple-ring-shaped structure oxide precursor has the excellent electrochemical performance and high compaction density. The solid spherical multiple-ring-shaped structure oxide precursor, prepared by the method, is uniform inelement distribution, high in yield, simple in process, environment-friendly, efficient, energy-saving, uniform in product quality, good in repeatability and capable of achieving large-scale production.

Owner:HUNAN ZHENGYUAN ENERGY STORAGE MATERIALS & DEVICE INST

Adaptive Time Diversity and Spatial Diversity for OFDM

InactiveUS20130142031A1Gain is assured with time diversityReduce signalingSpatial transmit diversityModulated-carrier systemsCarrier signalData rate

Owner:APPLE INC

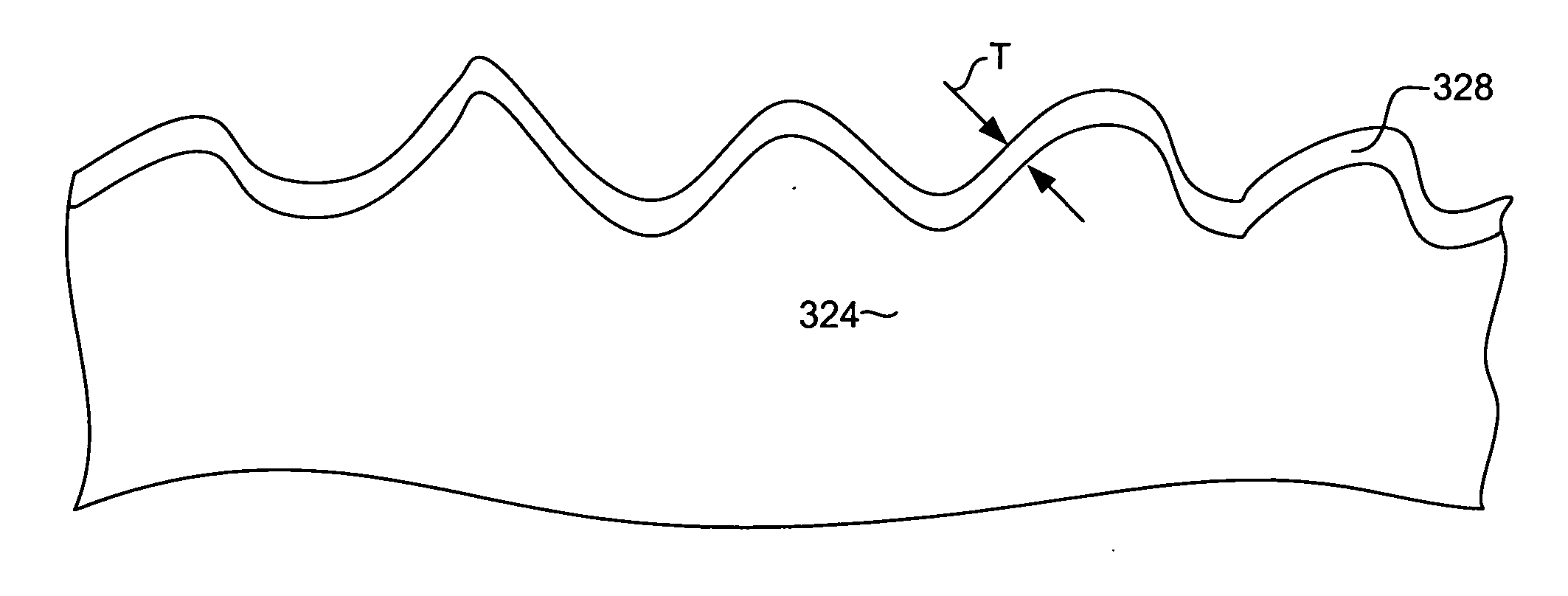

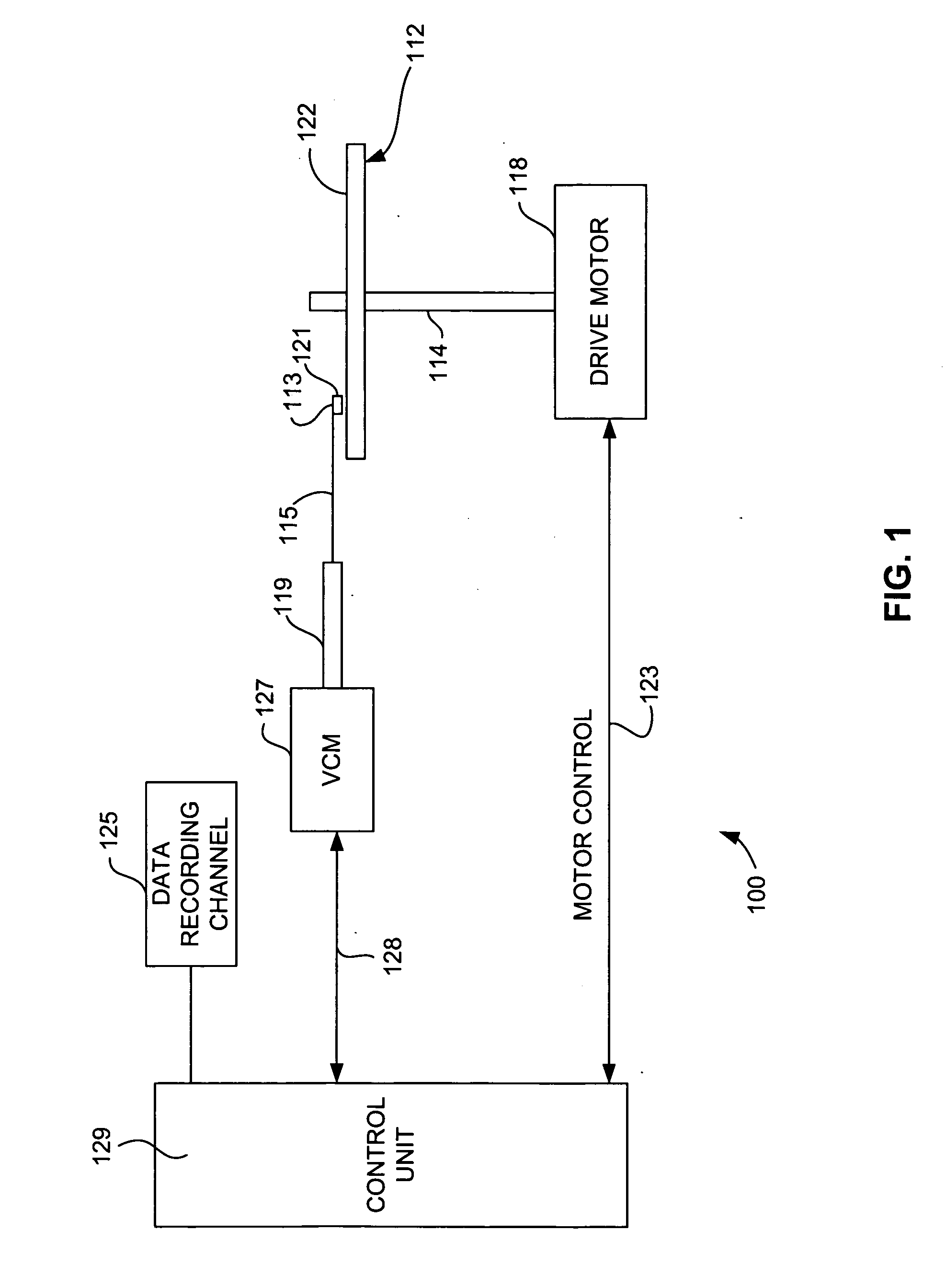

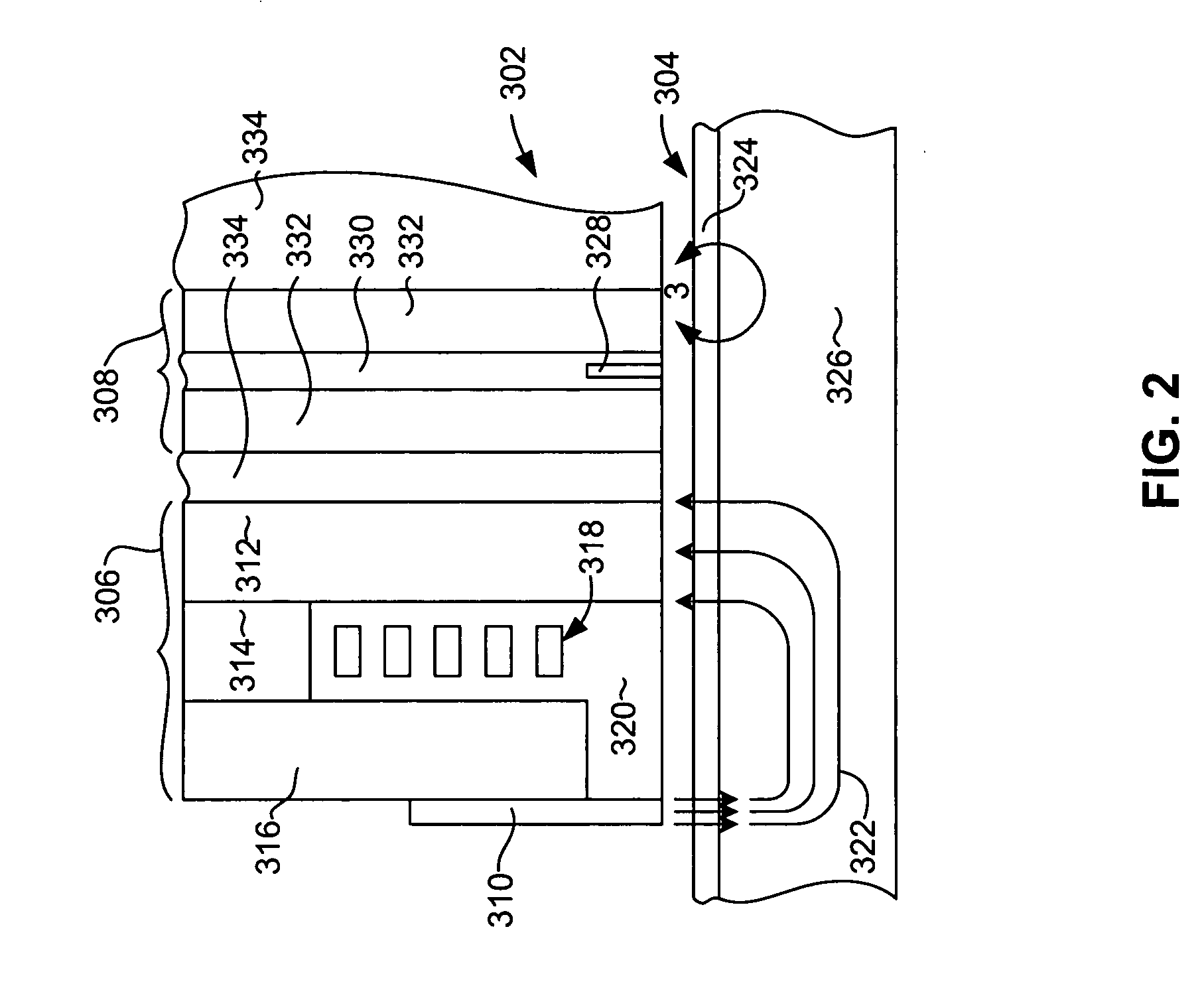

SiN overcoat for perpendicular magnetic recording media

InactiveUS20070054153A1High densityThinner overcoatProtective coatings for layersRecord information storageHigh densityMagnetic media

A SiON overcoat for use on magnetic media for magnetic recording. The SiON overcoat is deposited by pulsed DC sputtering while applying a negative DC bias. The SiON overcoat is especially useful on perpendicular magnetic recording media because of its ability to deposit thinly and evenly on a rough, granular high coercivity recording media while maintaining excellent corrosion protection properties. A SiON overcoat can be applied less than 3 nm thick while still maintaining excellent mechanical and corrosion protection. The overcoat also has a very high density and water contact angle.

Owner:WESTERN DIGITAL TECH INC

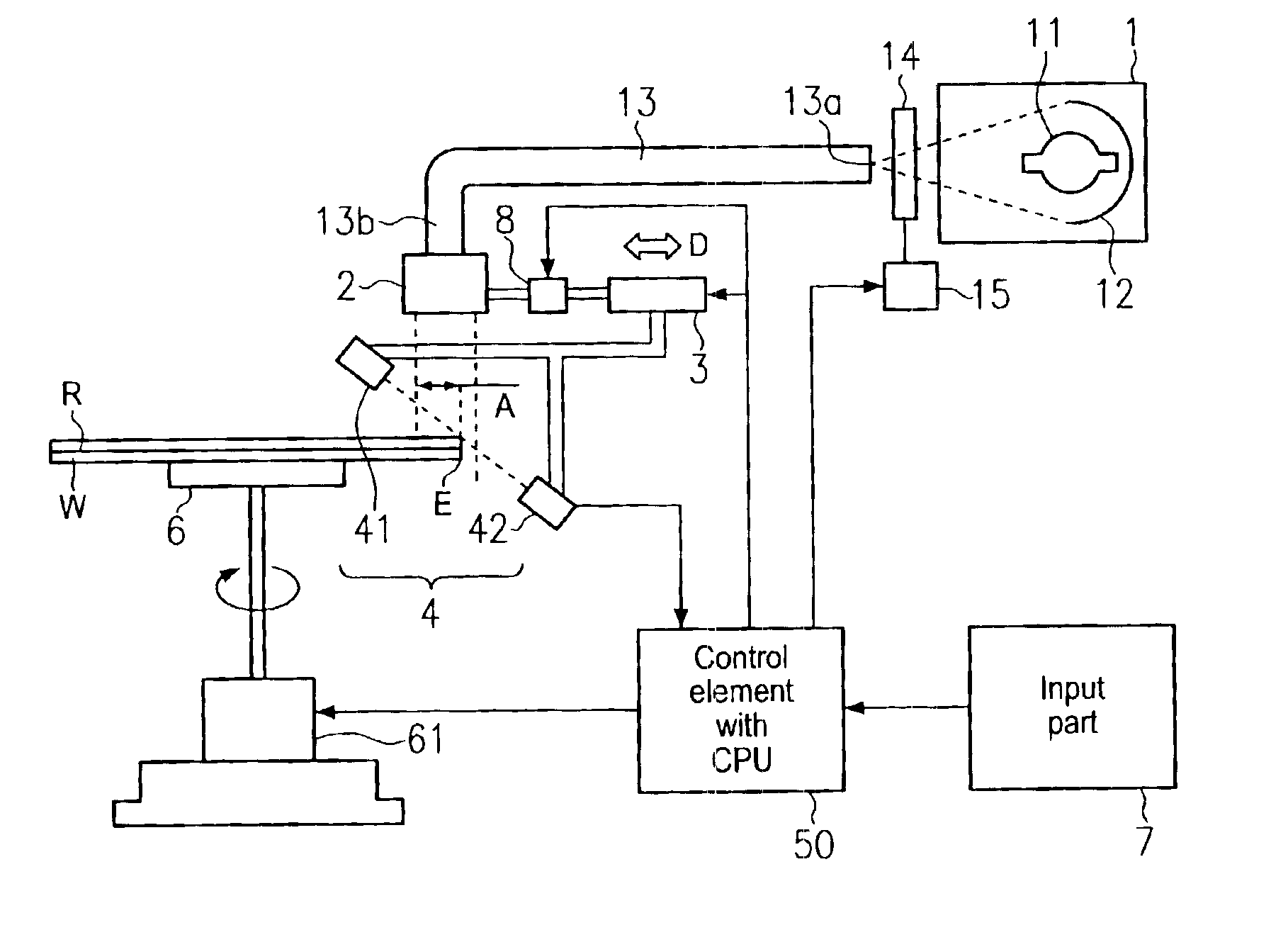

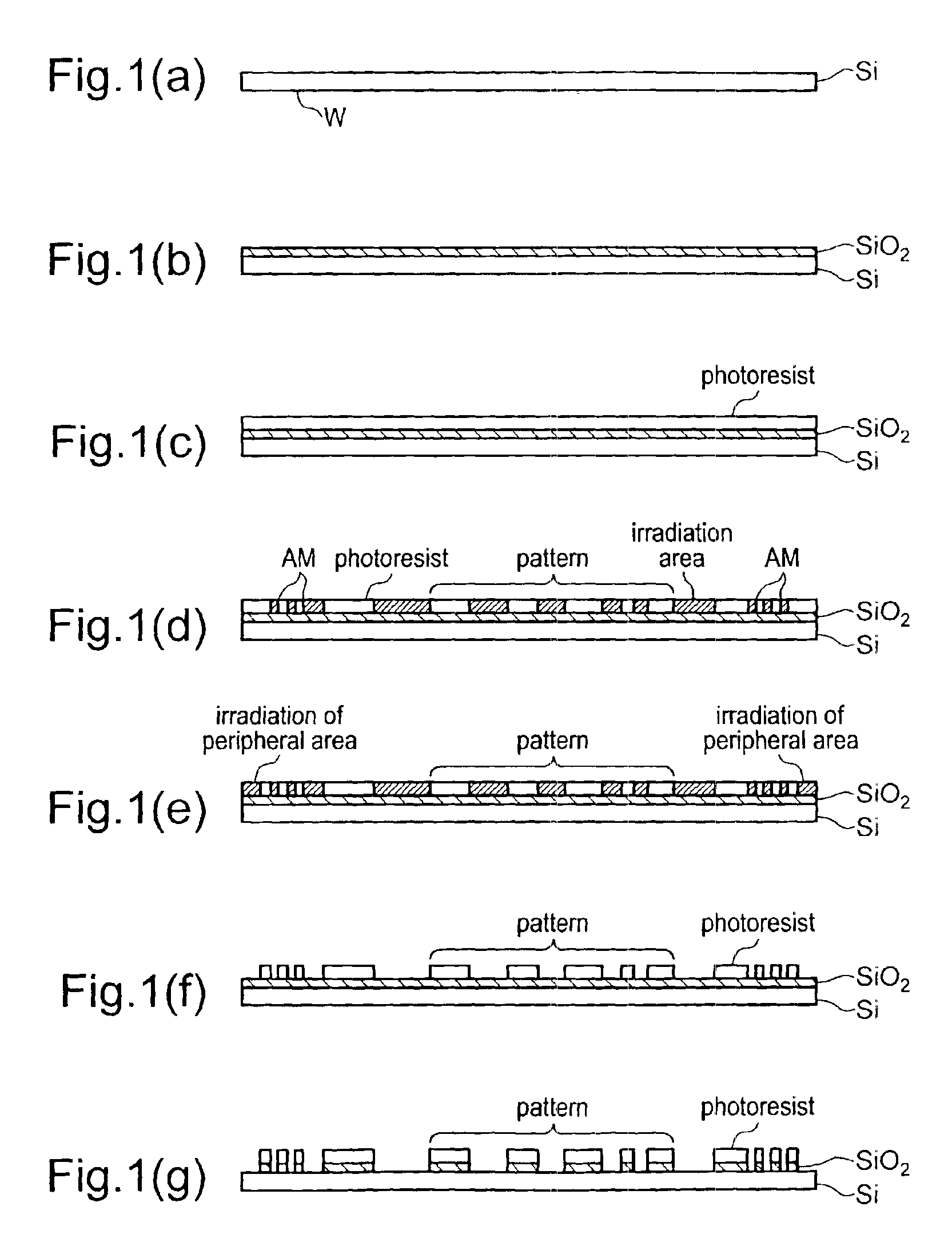

Exposure process and exposure device

InactiveUS6864954B2Difficult to align markEliminate disadvantagesSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusRotary stageResist

To eliminate the disadvantage that determination of the alignment marks becomes difficult also in the case in which the peripheral area of the wafer is provided with alignment marks, a wafer, with a surface provided with alignment marks, and with a peripheral area provided with a singularly shaped point and to which a photoresist has been applied, is placed on a rotary stage and the edge position of the wafer and the singularly shaped point, such as a notch or the like, is determined by a device for determination of the singularly shaped point and the edge position. Based on the position information of the alignment marks formed in the wafer and based on the singularly shaped point and the edge position, a control element computes the positions of the alignment marks of the wafer which was seated on the rotary stage. Based on the above described computation result, the area which is irradiated with the exposure light and the positions of the alignment marks on the wafer are brought into agreement with one another. In this way, the photoresist which has been applied to the alignment marks is exposed. This exposure is carried out for each formation of a pattern on the substrate and thus the film formed on the alignment marks is eliminated.

Owner:USHIO DENKI KK

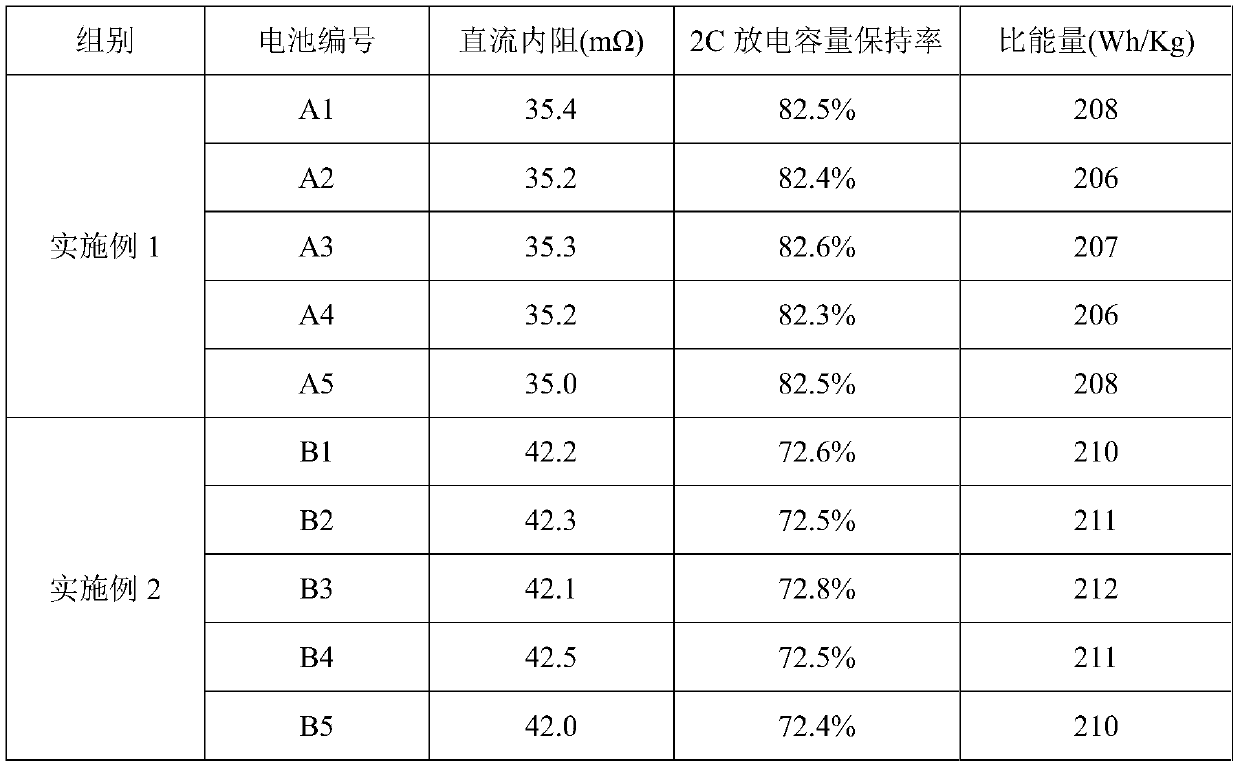

Preparation method of positive and negative conductive liquid storage layer slurry and thick electrode

InactiveCN110993952AIncreased rate capacityImprove dynamic performanceElectrode carriers/collectorsSecondary cellsElectrical batteryInternal resistance

The invention discloses a preparation method of positive and negative conductive liquid storage layer slurry and a thick electrode. Positive / negative electrode conductive liquid storage layer slurry is prepared, a current collector (3) is coated with the positive / negative electrode slurry, the positive / negative electrode conductive liquid storage layer slurry is sprayed after drying, a layer of positive / negative electrode slurry is coated after drying, and the positive / negative electrode pole piece of the sandwich structure of the active layer (1), a conductive liquid storage layer (2) and theactive layer (1) is obtained through cold pressing and slitting after drying. Through the introduction of the conductive liquid storage layer, the problem of poor dynamics caused by the thickening ofthe existing electrode is solved, the direct-current internal resistance and the high-rate capacity are greatly improved when the same coating surface density is achieved, and the dynamics performance is better; when the surface density is increased by 15%, the similar dynamic performance is still kept; and moreover, the energy density of the prepared battery is improved by 1-1.5% compared with that of a conventional battery under the same positive electrode surface density (520-600g / m<2>).

Owner:江苏智泰新能源科技有限公司

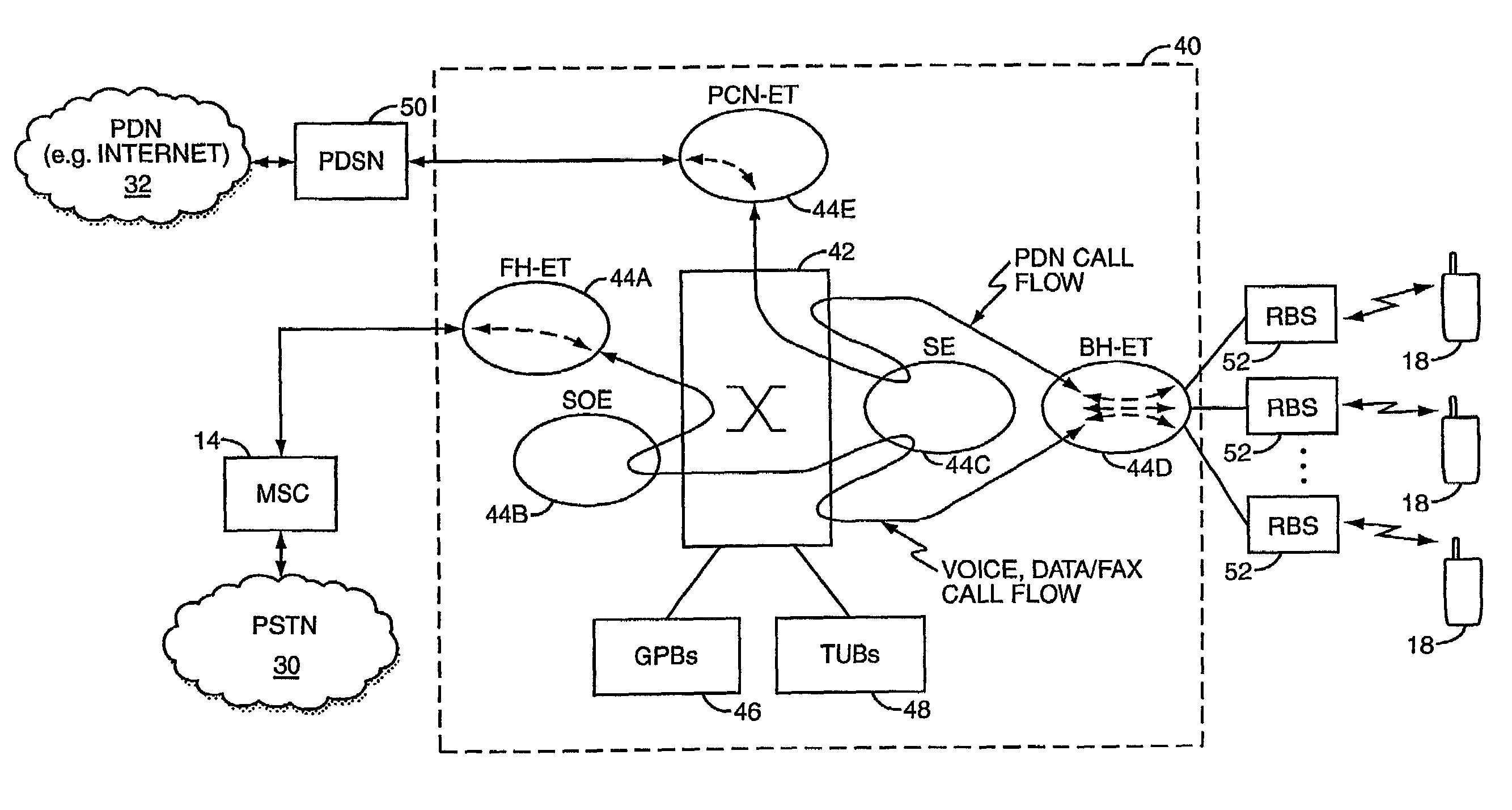

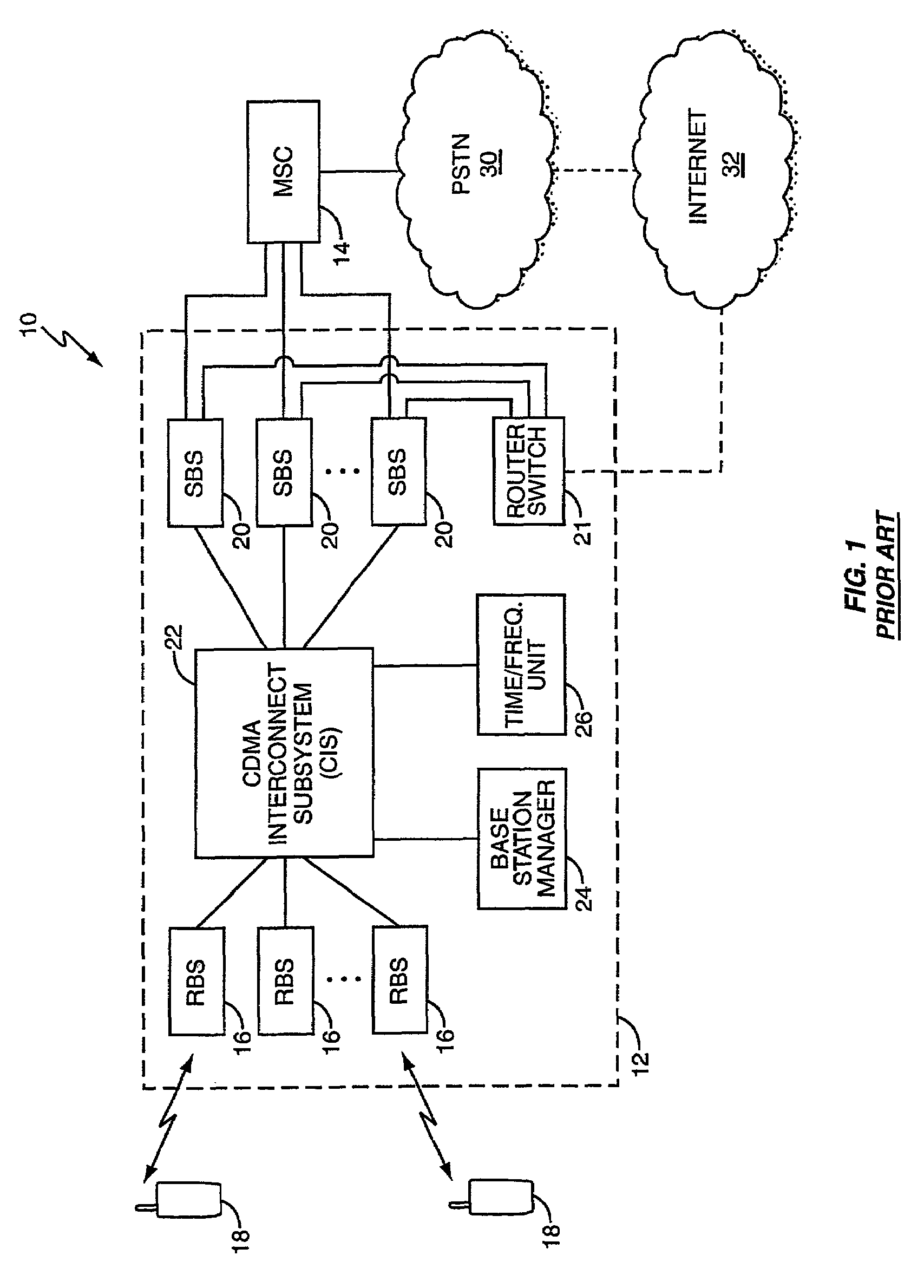

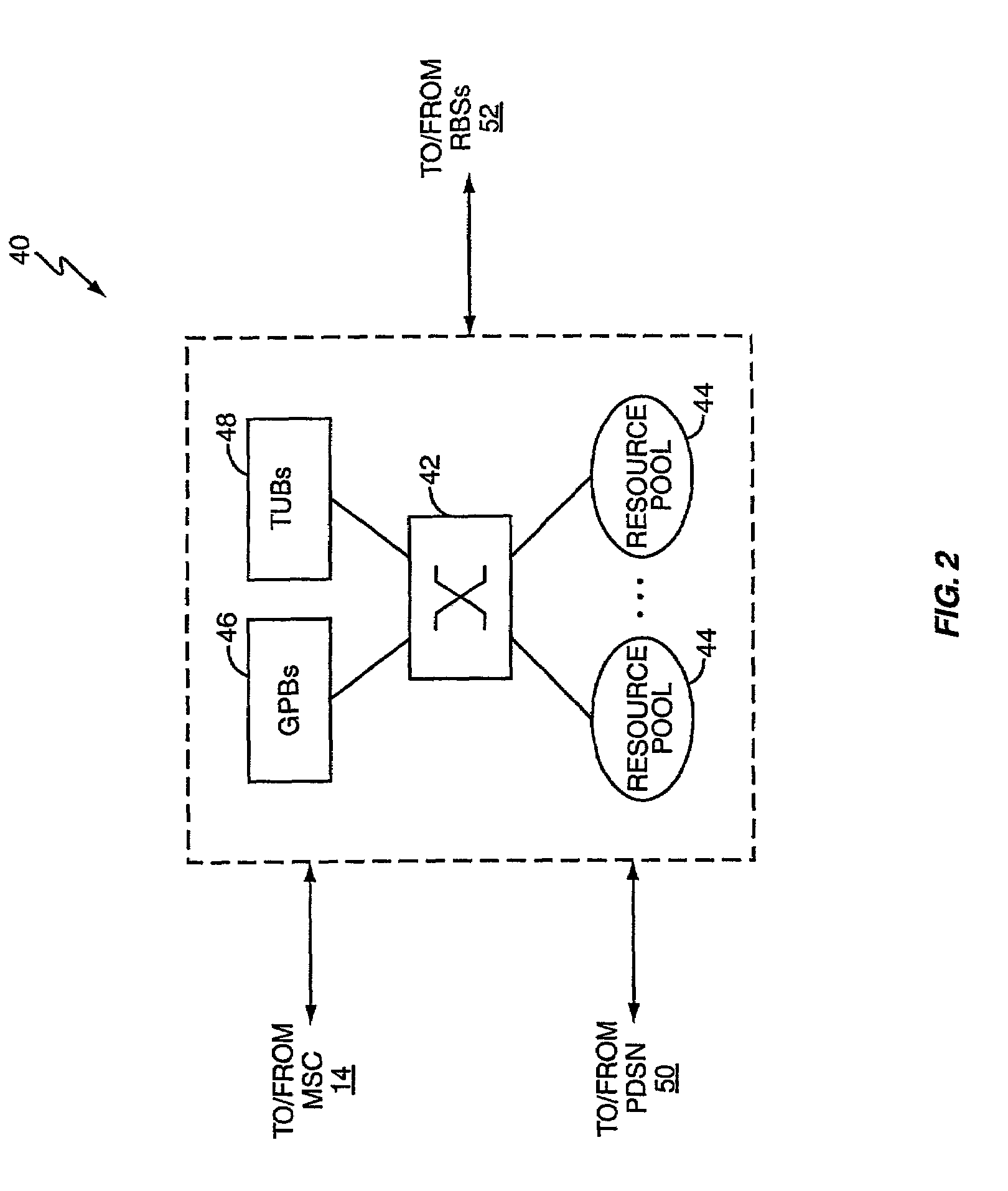

Robust radio base station controller architecture

InactiveUS7269181B2High call density and scalabilityIncreased rate capacityError preventionNetwork traffic/resource managementResource poolController architecture

A base station controller system comprises a high data rate distributed switching fabric providing flexible access to call processing resource pools. The arrangement permits a system controller to selectively assign specific resources depending on call type based on configuring the distributed switching fabric. The transport links comprising the distributed switching fabric provide redundant access to each of the resource pools, greatly reducing the portion of overall call processing capability lost with a single failure. Preferably, the distributed switching fabric comprises a central ATM switch and a number of distributed ATM switches interconnecting the resource pools to the central switching resource. The system may adopt a rack arrangement wherein a processing subrack includes the mix of different processing resources necessary to support substantially all call flow processing for one or more types of calls. The system's call capacity is thus easily scalable based on adding additional processing subracks.

Owner:UNWIRED PLANET

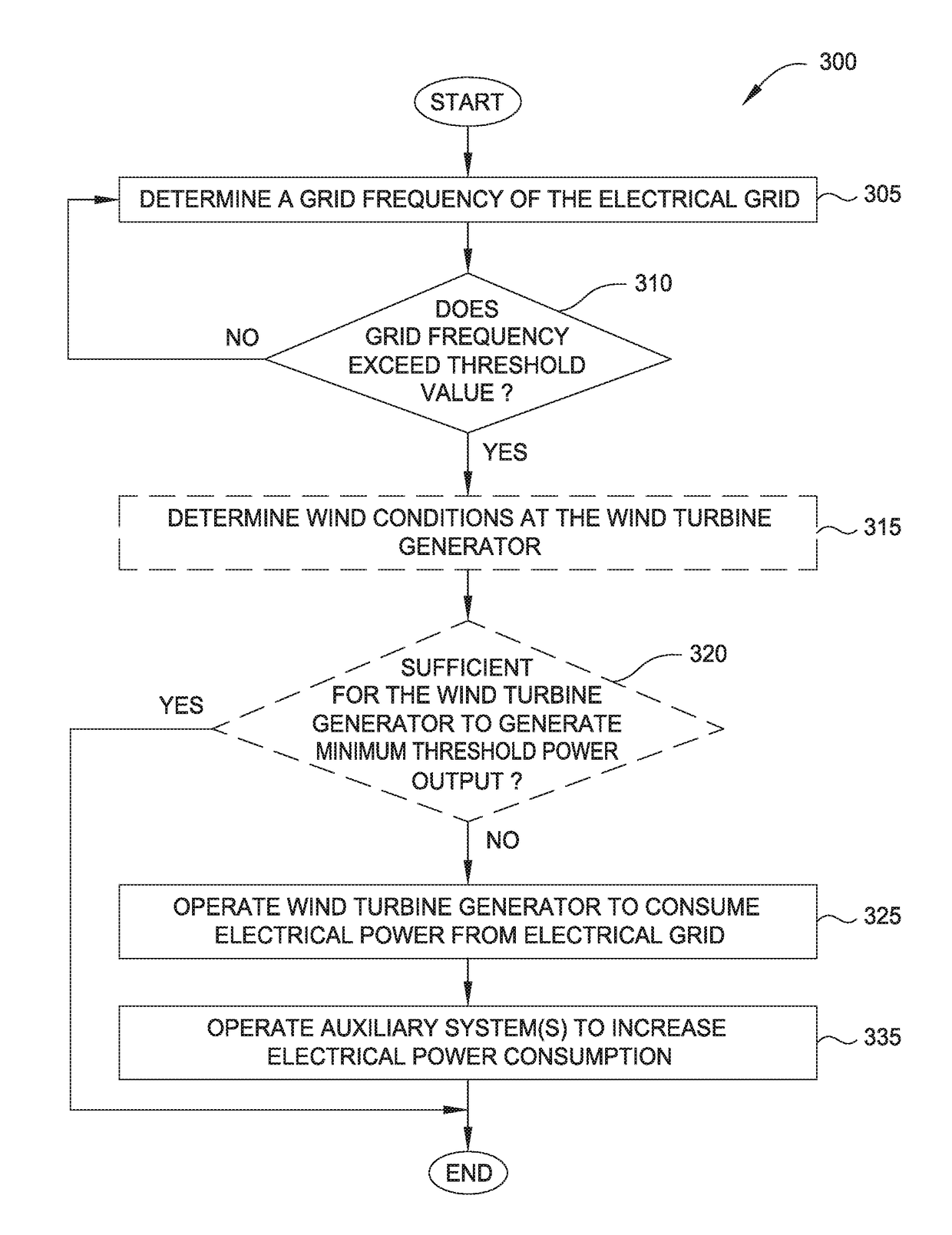

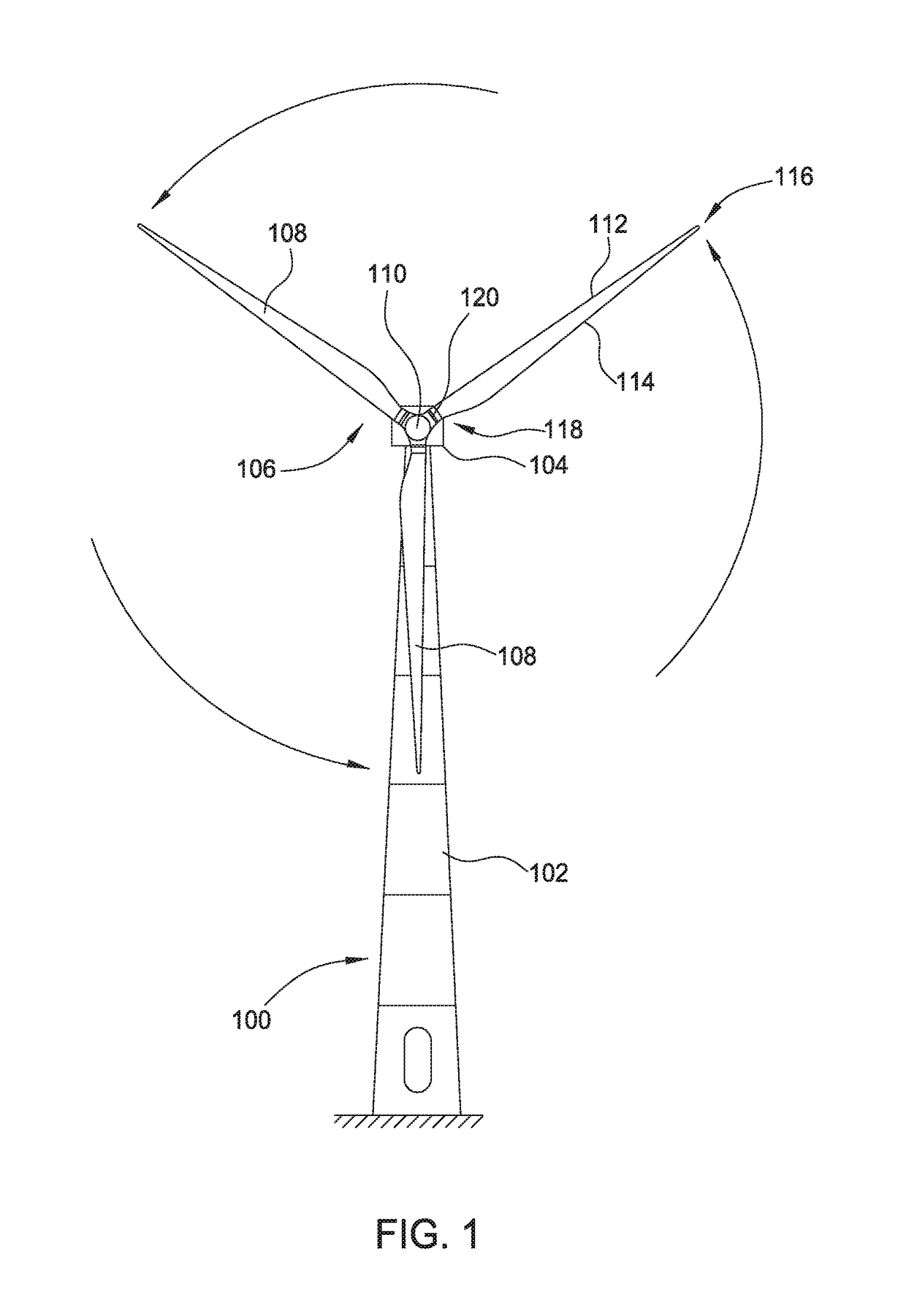

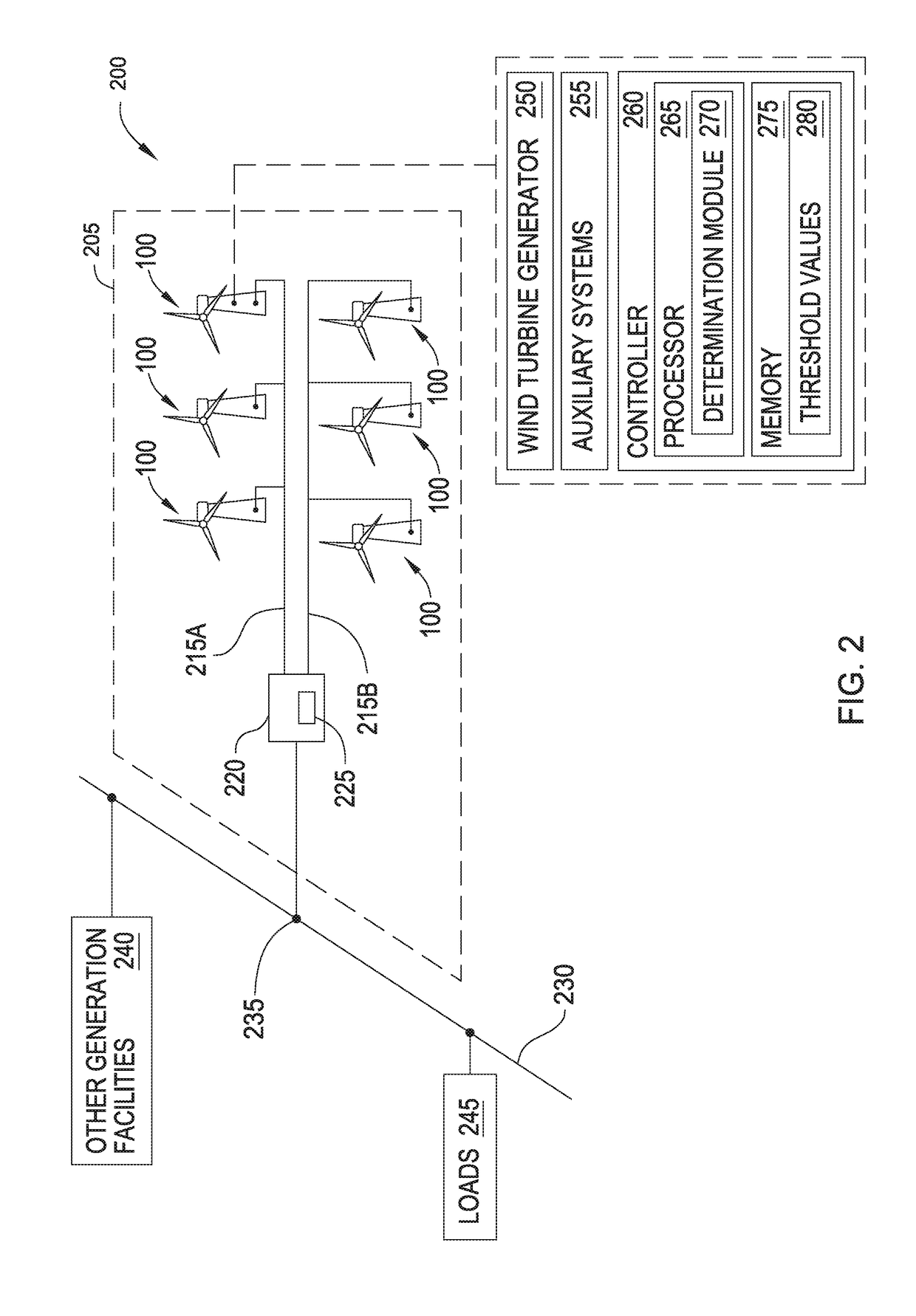

Frequency regulation using wind turbine generators

InactiveUS20180195493A1Increased rate capacityWind motor controlMachines/enginesPower stationPower grid

Disclosed are a method and a control arrangement for frequency regulation of an electrical grid operatively coupled with at least one wind turbine generator. The method includes operating the wind turbine generator to consume electrical power from the electrical grid. Further disclosed is a method for increasing a ramp rate capacity of a wind power plant comprising a plurality of wind turbine generators. The method includes operating at least one of the plurality of wind turbine generators to consume electrical power.

Owner:VESTAS WIND SYST AS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com