Preparation method of lithium titanate coated lithium ion battery nickel cobalt manganese cathode material

A lithium titanate-coated, lithium-ion battery technology, applied to battery electrodes, batteries, circuits, etc., can solve the problems of long sintering time, increased material production costs, and complicated steps in high-temperature treatment processes, so as to reduce production processes and inhibit Irreversible capacity loss, effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

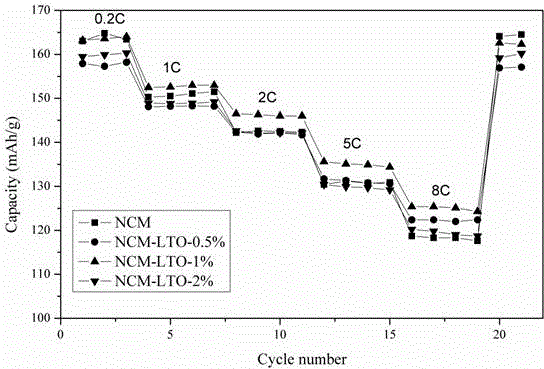

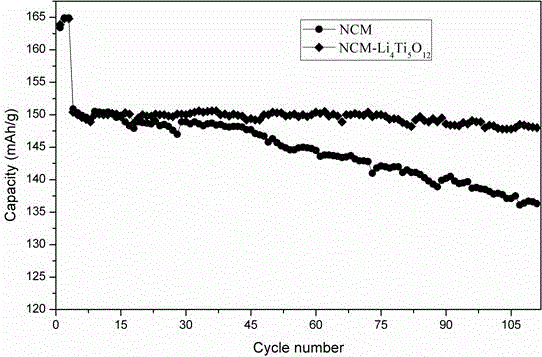

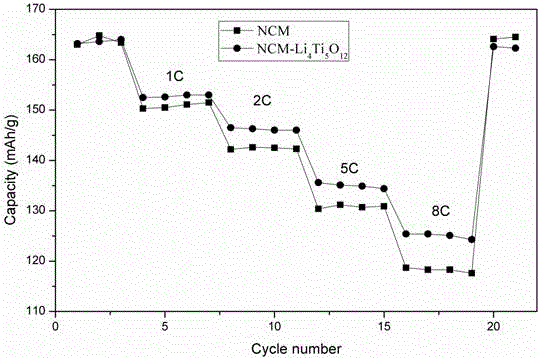

Image

Examples

Embodiment 1

[0026] (1) Preparation of lithium titanate material:

[0027] At room temperature, dissolve lithium acetate, tetrabutyl titanate, and oxalic acid in an aqueous solution of absolute ethanol, stir and ultrasonically dissolve them completely; first slowly add the oxalic acid solution to the tetrabutyl titanate solution, and simultaneously Stir for about 30-40 minutes to obtain a white sol; then slowly add lithium acetate solution dropwise to the above white sol, and age to obtain a light yellow transparent gel or white gel; secondly, place the gel in a heating mantle and heat at 80°C Stir to obtain a white gel; place it in a blast drying oven at 80°C for 12 hours, and remove the solvent to obtain a white / light yellow xerogel. The precursor was treated at 600°C for 6 hours, and then at 800°C for 8 hours to obtain a lithium titanate negative electrode material;

[0028] (2) Preparation of lithium titanate coated nickel cobalt lithium manganese oxide

[0029] According to the mass...

Embodiment 2

[0040] (1) Preparation of lithium titanate material:

[0041] At room temperature, dissolve lithium acetate, tetrabutyl titanate, and oxalic acid in an aqueous solution of absolute ethanol, stir and ultrasonically dissolve them completely; first slowly add the oxalic acid solution to the tetrabutyl titanate solution, and simultaneously Stir for about 30-40 minutes to obtain a white sol; then slowly add lithium acetate solution dropwise to the above white sol, and age to obtain a light yellow transparent gel or white gel; secondly, place the gel in a heating mantle and heat at 80°C Stir to obtain a white gel; place it in a blast drying oven at 80°C for 12 hours, and remove the solvent to obtain a white / light yellow xerogel. The precursor was treated at 600°C for 6 hours, and then at 800°C for 8 hours to obtain a lithium titanate negative electrode material;

[0042] (2) Preparation of lithium titanate coated nickel cobalt lithium manganese oxide

[0043] According to the mass...

Embodiment 3

[0045] (1) Preparation of lithium titanate material:

[0046] At room temperature, dissolve lithium acetate, tetrabutyl titanate, and oxalic acid in an aqueous solution of absolute ethanol, stir and ultrasonically dissolve them completely; first slowly add the oxalic acid solution to the tetrabutyl titanate solution, and simultaneously Stir for about 30-40 minutes to obtain a white sol; then slowly add lithium acetate solution dropwise to the above white sol, and age to obtain a light yellow transparent gel or white gel; secondly, place the gel in a heating mantle and heat at 80°C Stir to obtain a white gel; place it in a blast drying oven at 80°C for 12 hours, and remove the solvent to obtain a white / light yellow xerogel. The precursor was treated at 600°C for 6 hours, and then at 800°C for 8 hours to obtain a lithium titanate negative electrode material;

[0047] (2) Preparation of lithium titanate coated nickel cobalt lithium manganese oxide

[0048] According to the mass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com