Patents

Literature

103results about How to "High cycle capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

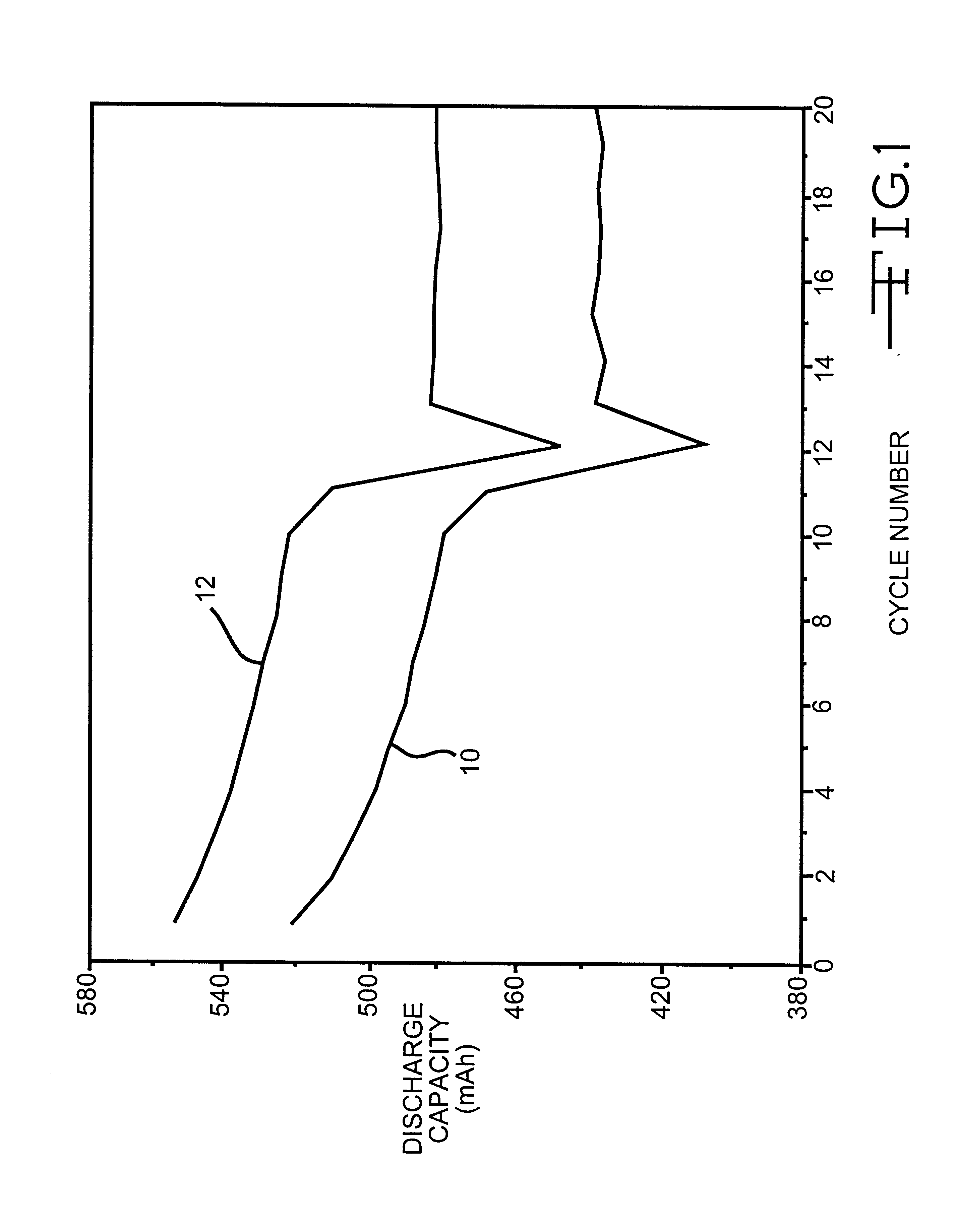

Phosphonate additives for nonaqueous electrolyte in rechargeable cells

InactiveUS6200701B1Improve oxidation stabilityImprove dynamic stabilityOrganic electrolyte cellsSecondary cellsRechargeable cellPhysical chemistry

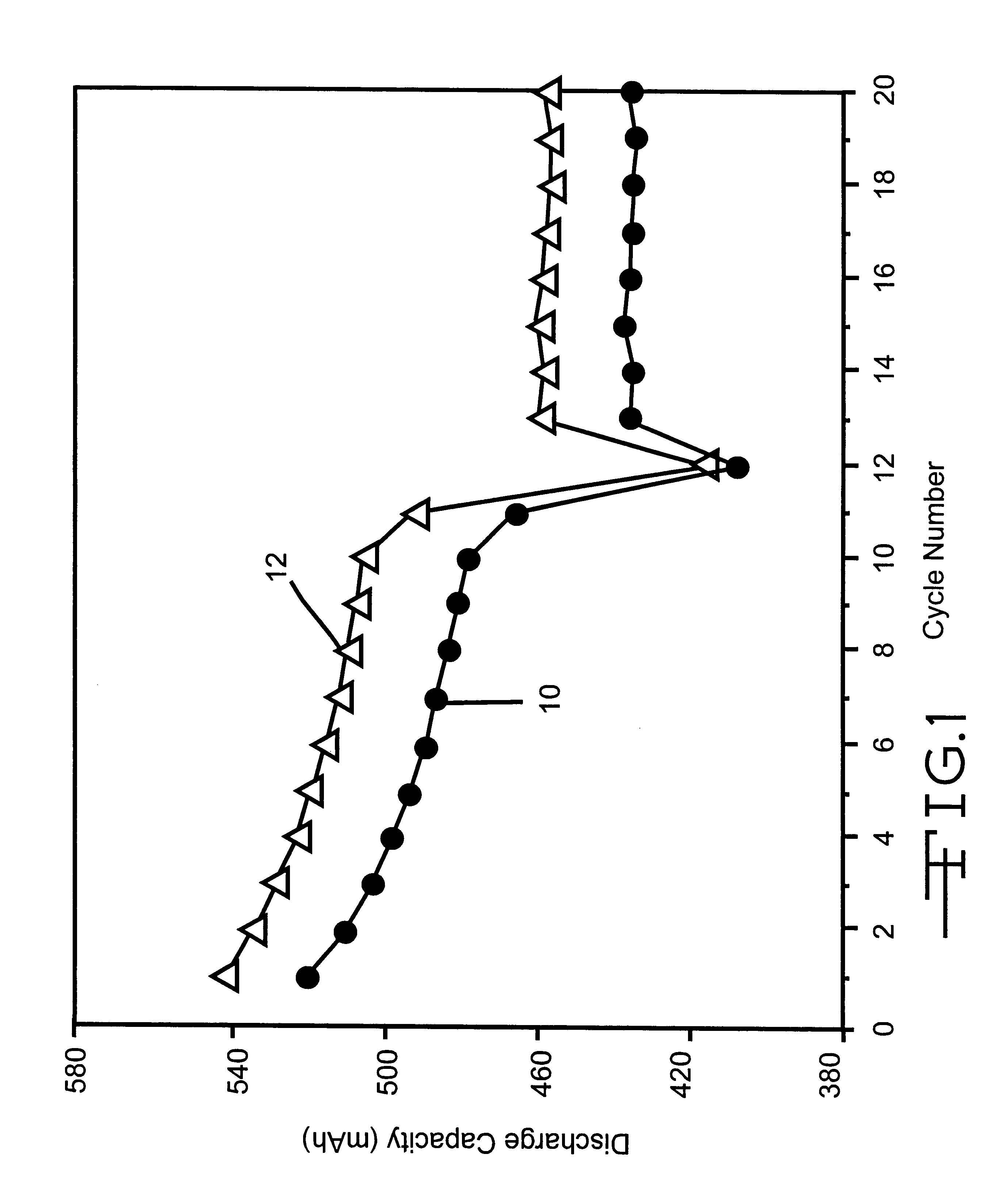

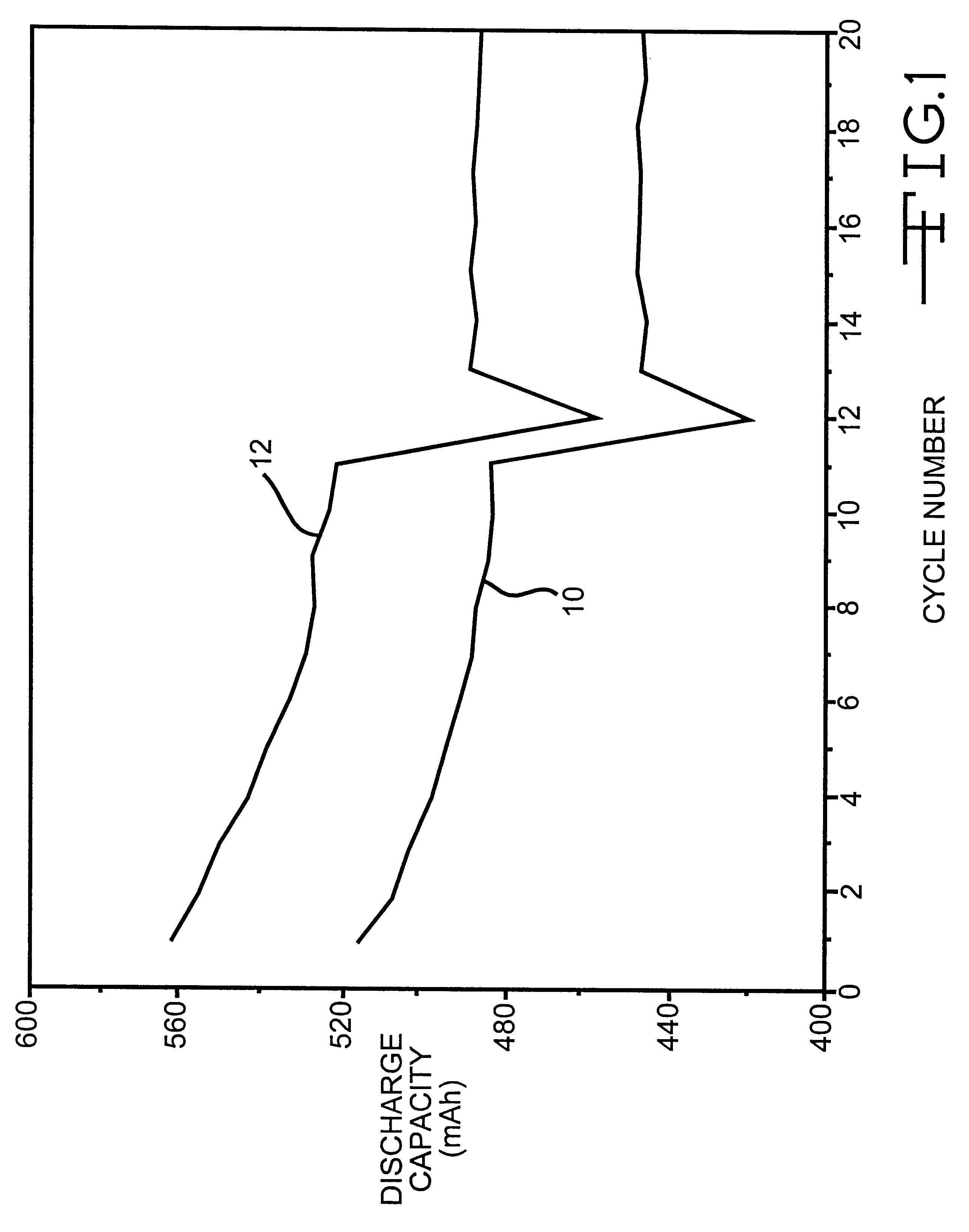

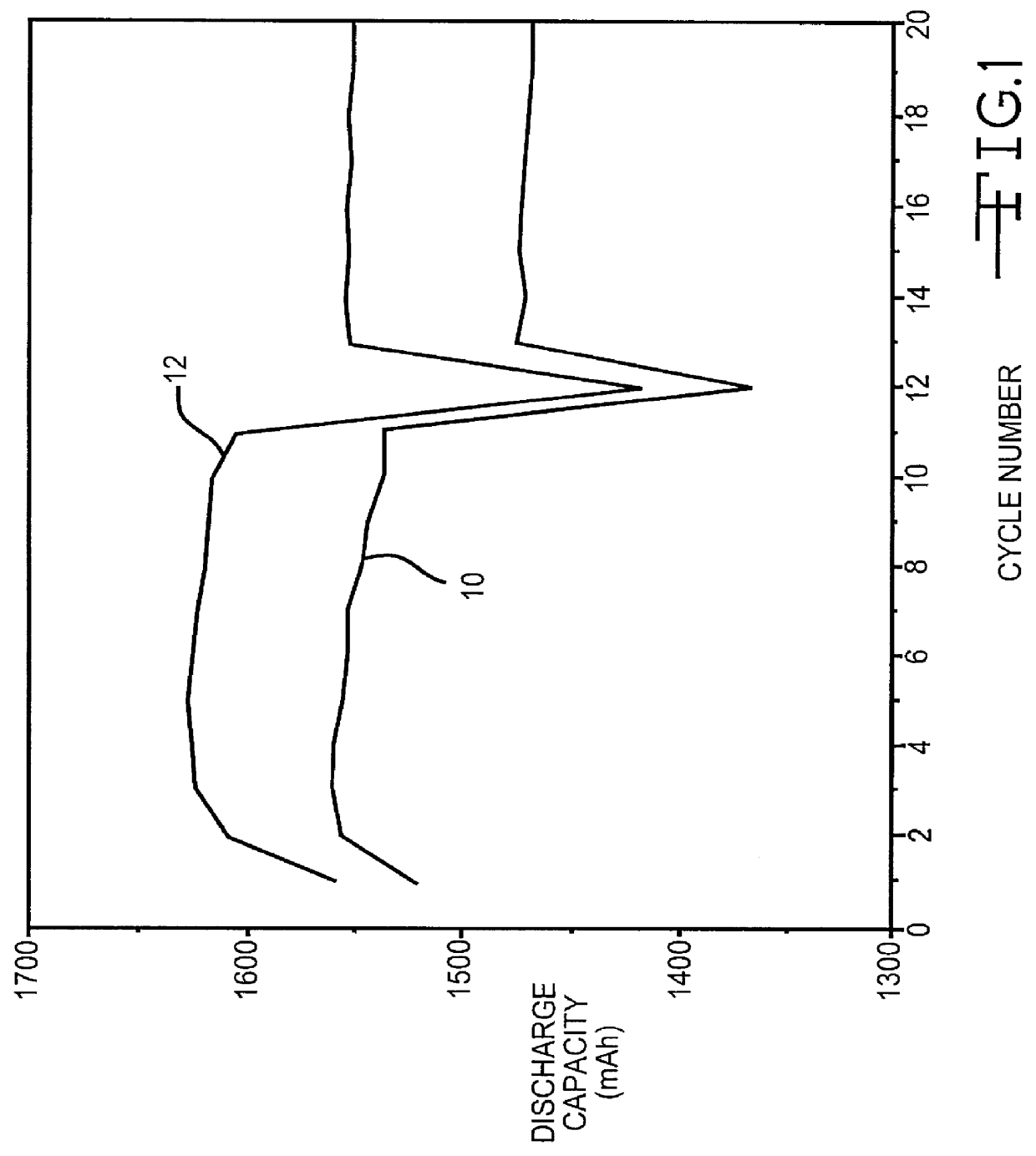

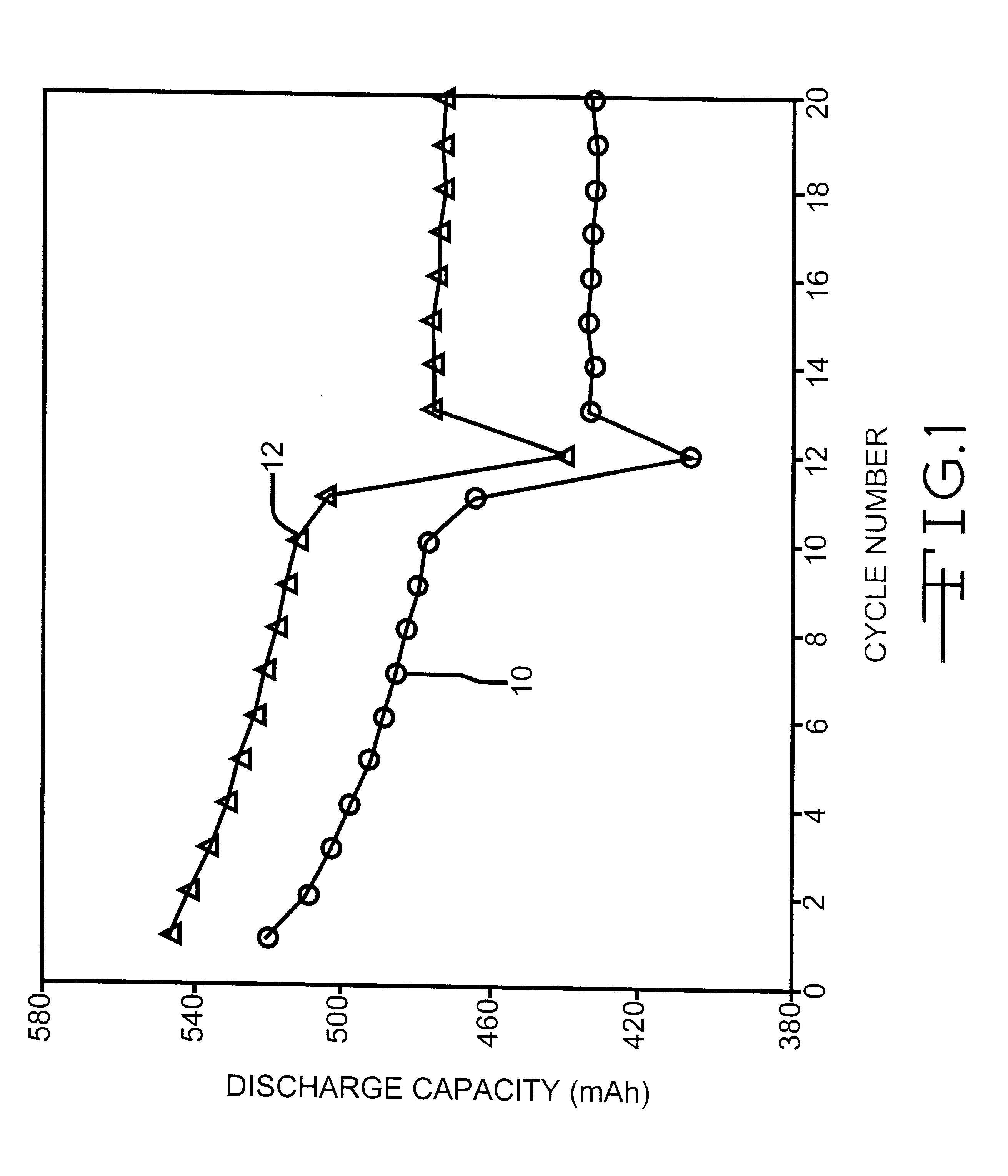

A lithium ion electrochemical cell having high charge / discharge capacity, long cycle life and exhibiting a reduced first cycle irreversible capacity, is described. The stated benefits are realized by the addition of at least one phosphonate additive to an electrolyte comprising an alkali metal salt dissolved in a solvent mixture that includes ethylene carbonate, dimethyl carbonate, ethylmethyl carbonate and diethyl carbonate. The preferred additive is an alkyl phosphonate compound.

Owner:WILSON GREATBATCH LTD

Phosphate additives for nonaqueous electrolyte rechargeable electrochemical cells

InactiveUS6203942B1Improve oxidation stabilityImprove dynamic stabilityPrimary cell maintainance/servicingOrganic electrolyte cellsAlkylphosphateSolvent

A lithium ion electrochemical cell having high charge / discharge capacity, long cycle life and exhibiting a reduced first cycle irreversible capacity, is described. The stated benefits are realized by the addition of at least one phosphate additive to an electrolyte comprising an alkali metal salt dissolved in a solvent mixture that includes ethylene carbonate, dimethyl carbonate, ethylmethyl carbonate and diethyl carbonate. The preferred additive is an alkyl phosphate compound.

Owner:WILSON GREATBATCH LTD

Nitrate additives for nonaqueous electrolyte rechargeable cells

InactiveUS6136477AImprove oxidation stabilityImprove dynamic stabilityOrganic electrolyte cellsSecondary cellsNitrateRechargeable cell

A lithium ion electrochemical cell having high charge / discharge capacity, long cycle life and exhibiting a reduced first cycle irreversible capacity, is described. The stated benefits are realized by the addition of at least one nitrate additive to an electrolyte comprising an alkali metal salt dissolved in a solvent mixture that includes ethylene carbonate, dimethyl carbonate, ethylmethyl carbonate and diethyl carbonate. The preferred additive is an organic alkyl nitrate compound.

Owner:WILSON GREATBATCH LTD

Nitrite additives for nonaqueous electrolyte rechargeable electrochemical cells

InactiveUS6210839B1Improve oxidation stabilityImprove dynamic stabilityOrganic electrolyte cellsSolid electrolyte cellsNitritePhysical chemistry

A lithium ion electrochemical cell having high charge / discharge capacity, long cycle life and exhibiting a reduced first cycle irreversible capacity, is described. The stated benefits are realized by the addition of at least one nitrite additive to an electrolyte comprising an alkali metal salt dissolved in a solvent mixture that includes ethylene carbonate, dimethyl carbonate, ethylmethyl carbonate and diethyl carbonate. The preferred additive is an alkyl nitrite compound.

Owner:WILSON GREATBATCH LTD

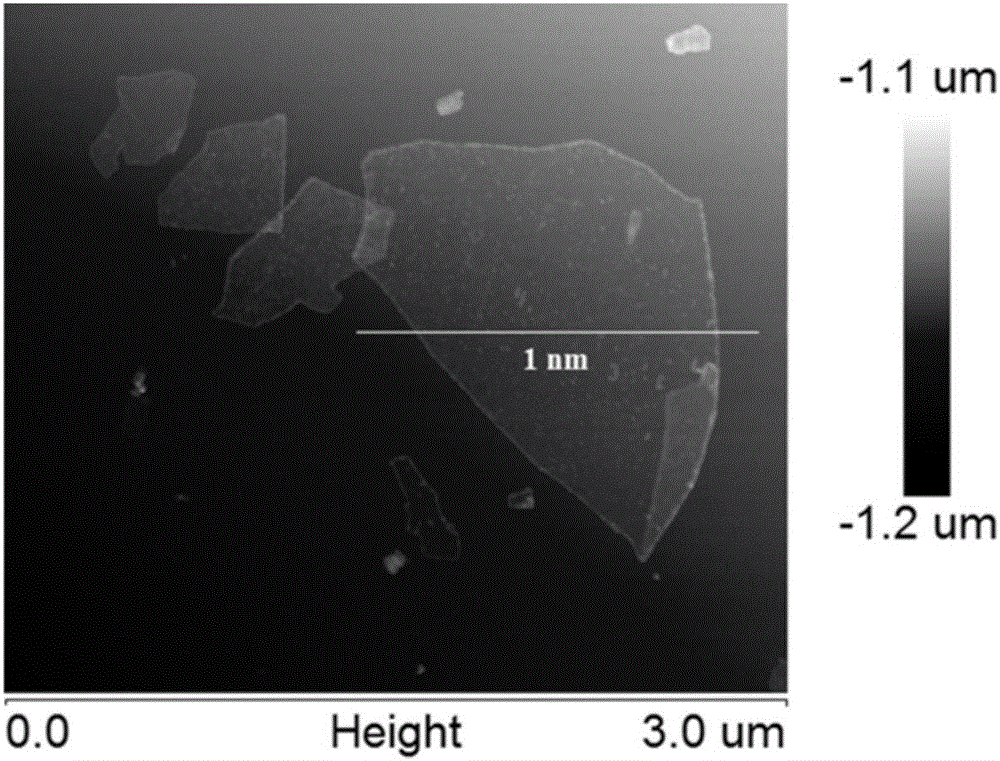

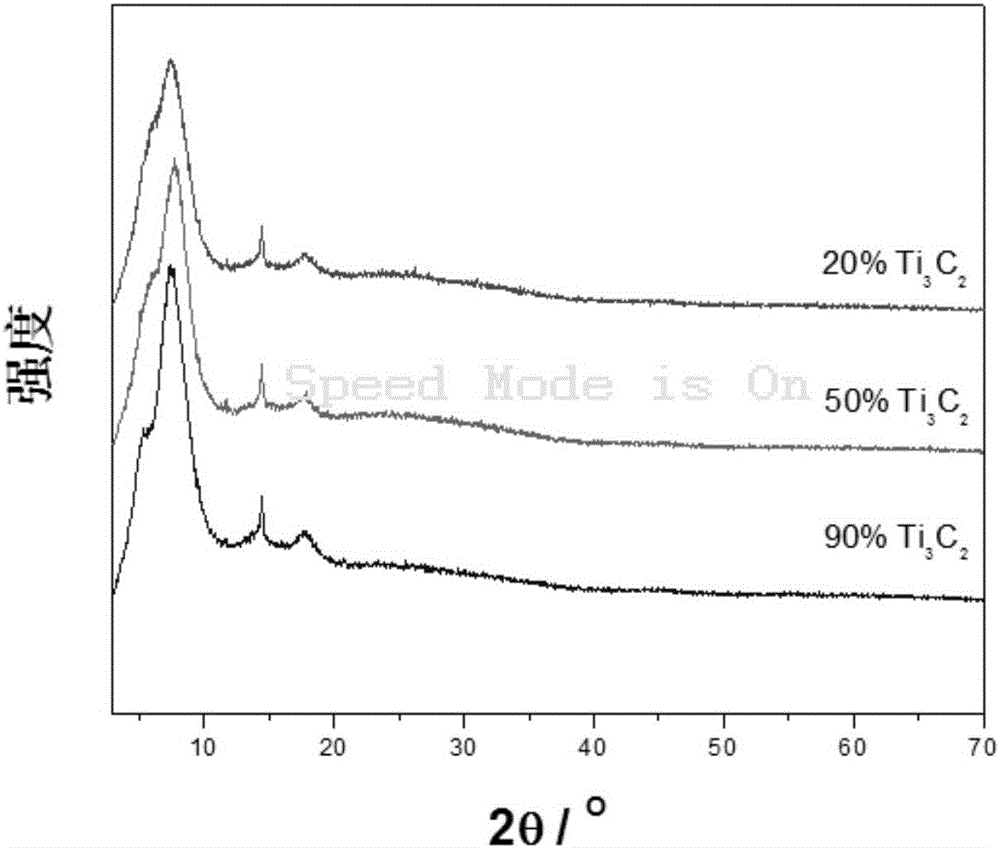

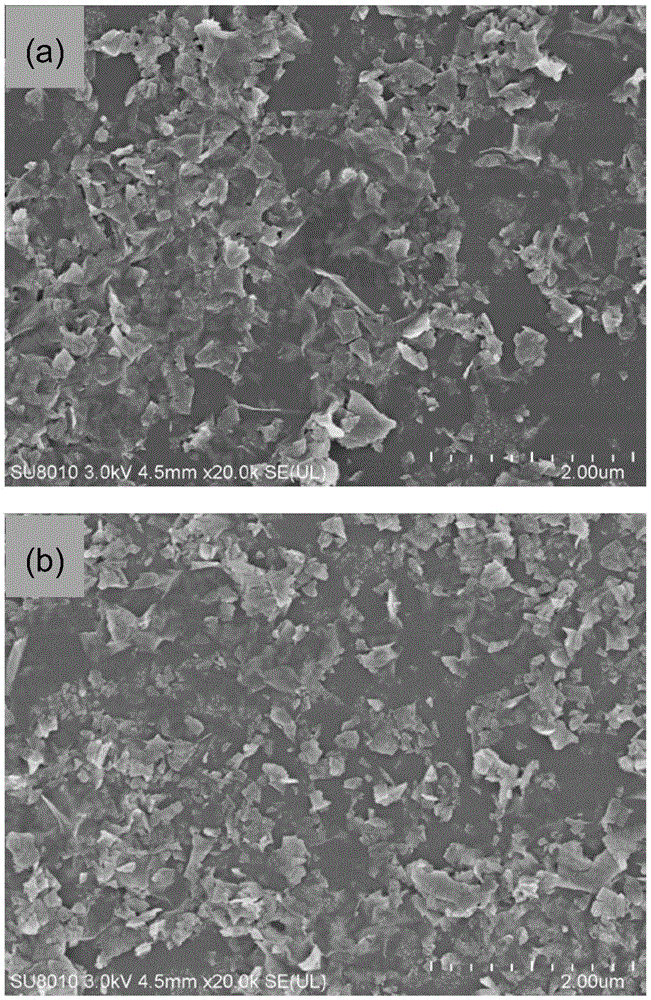

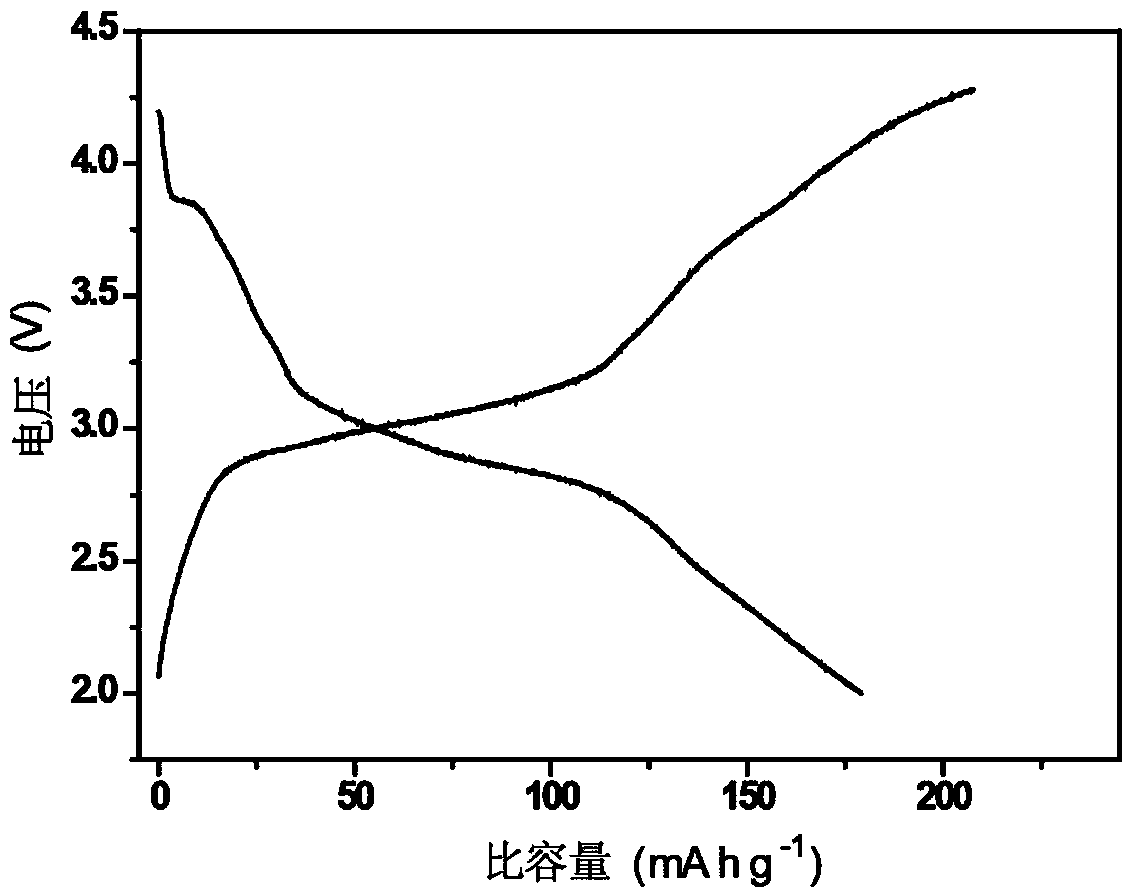

Two-dimensional transition metal carbon (nitrogen) compound and two-dimensional transition metal sulfide nano-composite powder, and preparation and application thereof

InactiveCN106571244AConductivity regulationSimple preparation processMaterial nanotechnologyHybrid capacitor electrodesNitrogenSupercapacitor

The invention relates to a two-dimensional transition metal carbon (nitrogen) compound and two-dimensional transition metal sulfide nano-composite powder, and a preparation and application thereof. The nano-composite powder is formed by the uniform scattered recombination of a two-dimensional transition metal carbon (nitrogen) compound nanosheet and a two-dimensional transition metal sulfide nanosheet, wherein the percentage of the mass of the two-dimensional transition metal sulfide to the total mass of the nano-composite powder is 10%-99%. The method comprises the steps: enabling the steady suspension liquid of the two-dimensional transition metal carbon (nitrogen) compound nanosheet and the suspension liquid of the two-dimensional transition metal sulfide nanosheet are mixed according to a proportion; carrying out cooling and drying after supersonic mixing, and then obtaining the nano-composite powder. The nano-composite powder is simple in preparation, is safe and high in efficiency, is low in cost, remarkably irons out the defects of conductivity of the two-dimensional transition metal sulfide, and can regulate the conductivity through proportion change. The nano-composite powder serves as a negative electrode of a lithium ion battery and the electrode material of a supercapacitor, is good in application prospect in the field of energy storage devices, and is better in electrochemical performance than the two-dimensional transition metal sulfide.

Owner:NANJING TECH UNIV

Preparation method and application of prussian blue complex/carbon composite material

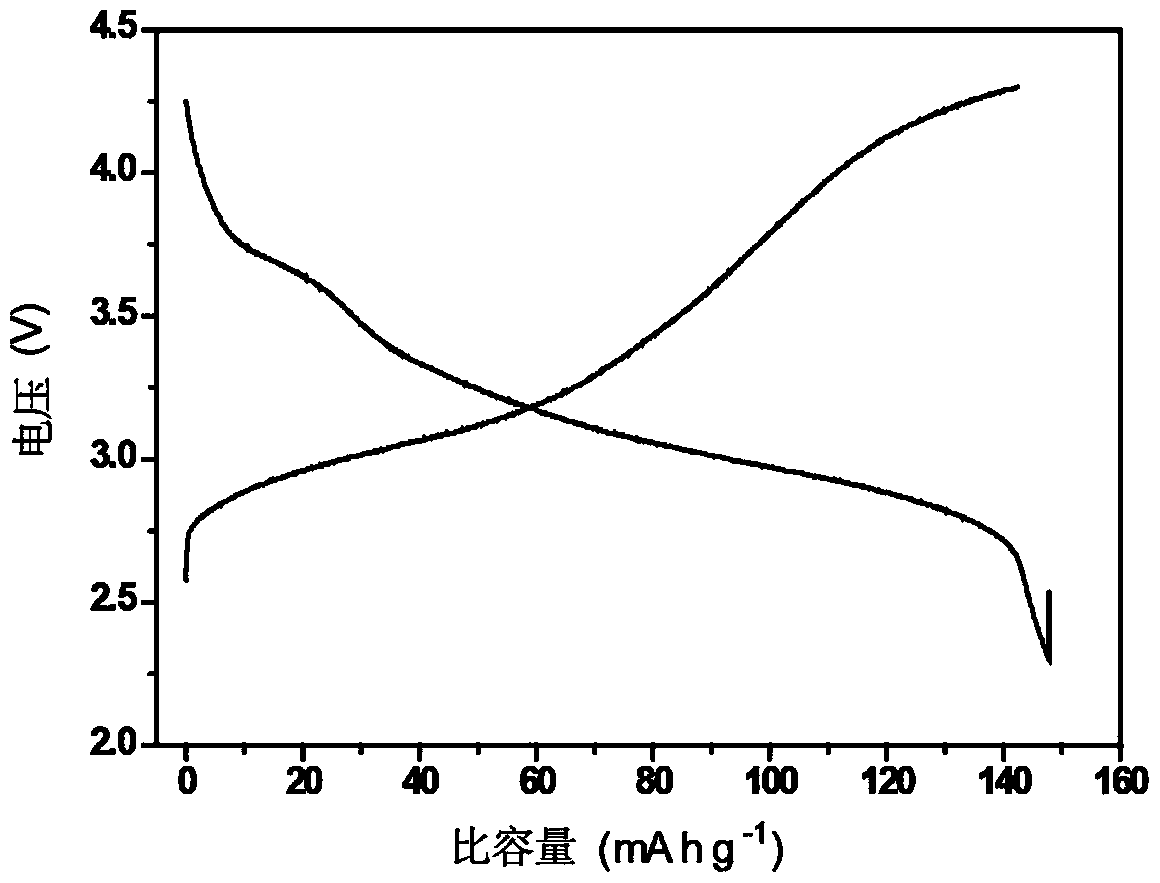

ActiveCN103441241AHigh degree of practicalityPromote growthCell electrodesCarbon compositesSodium-ion battery

The invention discloses a preparation method of a prussian blue complex / carbon composite material and an application of the composite material as a positive electrode material for lithium ion and sodium ion batteries. The preparation method of the prussian blue complex / carbon composite material comprises at least the steps of uniformly dispersing a transition metal cyano complex, an inorganic acid and a carbon material in water to obtain a reaction solution; and heating the solution for a certain time to obtain the prussian blue complex / carbon composite material. The method is simple in preparation, can be controlled easily and has high practical degree. Crystal water content and coordinated water content in the obtained prussian blue complex / carbon composite material are little, so that the prussian blue complex / carbon composite material presents high capacity and excellent cycle performance when being used as the positive electrode material for the lithium ion and sodium ion batteries.

Owner:INST OF CHEM CHINESE ACAD OF SCI

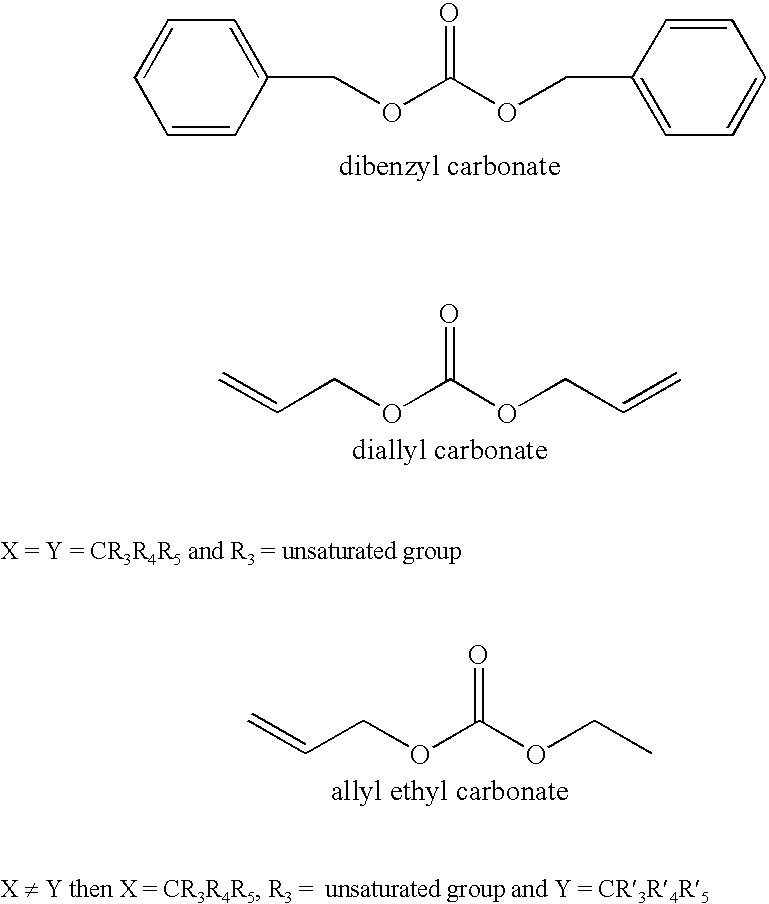

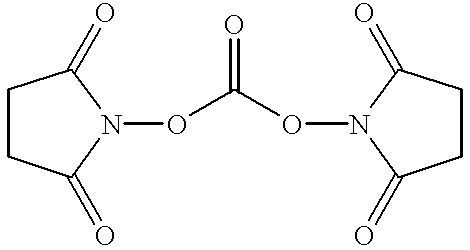

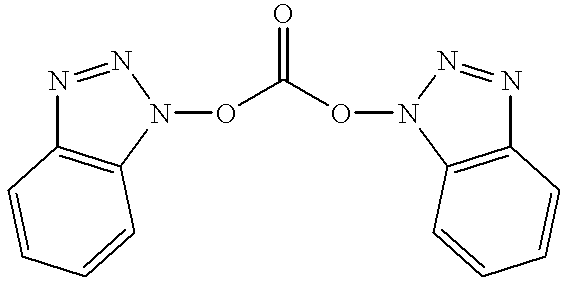

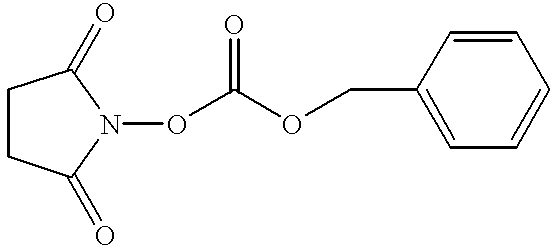

Dicarbonate additives for nonaqueous electrolyte rechargeable cells

InactiveUS6174629B1Improve oxidation stabilityImprove dynamic stabilityAlkaline accumulatorsOrganic electrolyte cellsRechargeable cellPhysical chemistry

A lithium ion electrochemical cell having high charge / discharge capacity, long cycle life and exhibiting a reduced first cycle irreversible capacity, is described. The stated benefits are realized by the addition of at least one dicarbonate additive to an electrolyte comprising an alkali metal salt dissolved in a solvent mixture that includes ethylene carbonate, dimethyl carbonate, ethylmethyl carbonate and diethyl carbonate. The preferred additive is an alkyl dicarbonate compound.

Owner:WILSON GREATBATCH LTD

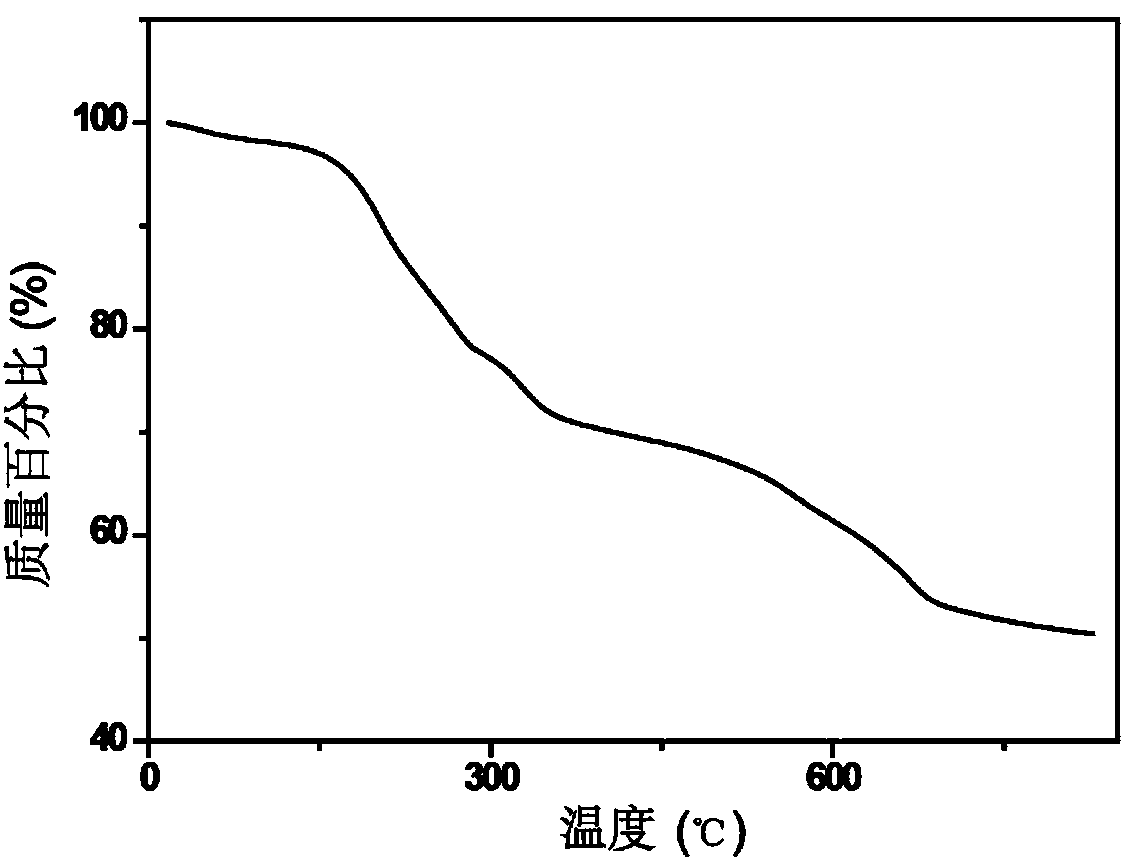

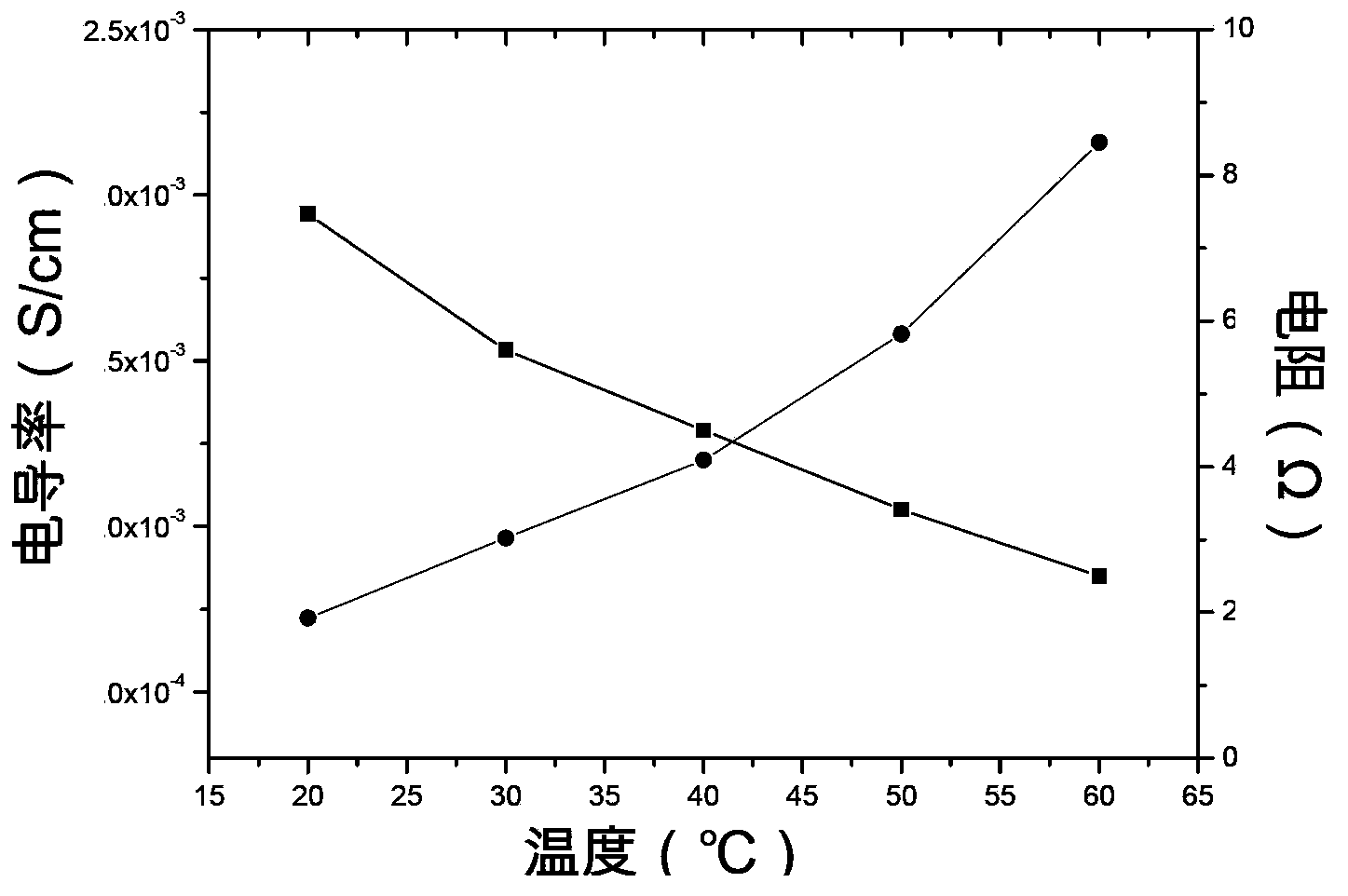

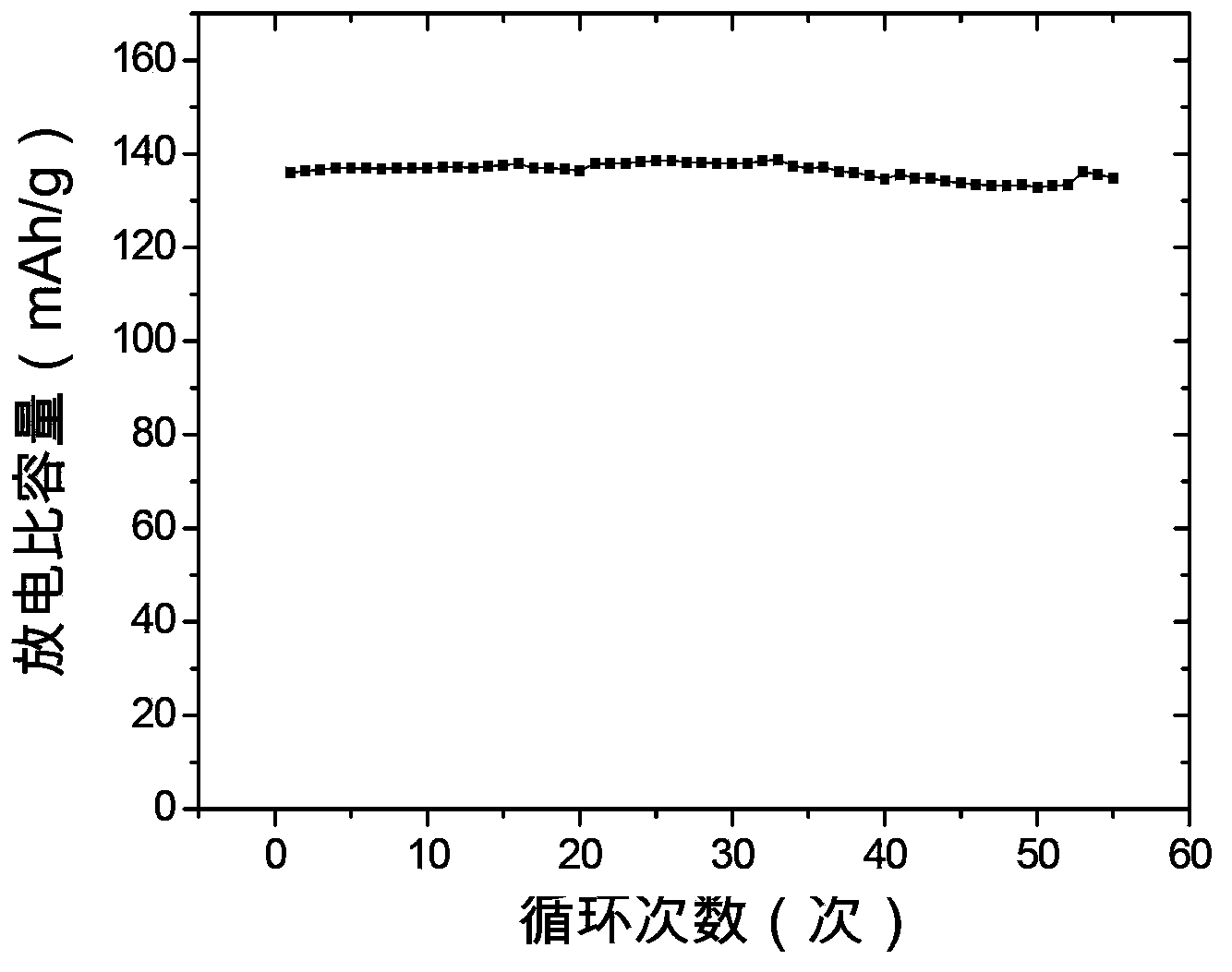

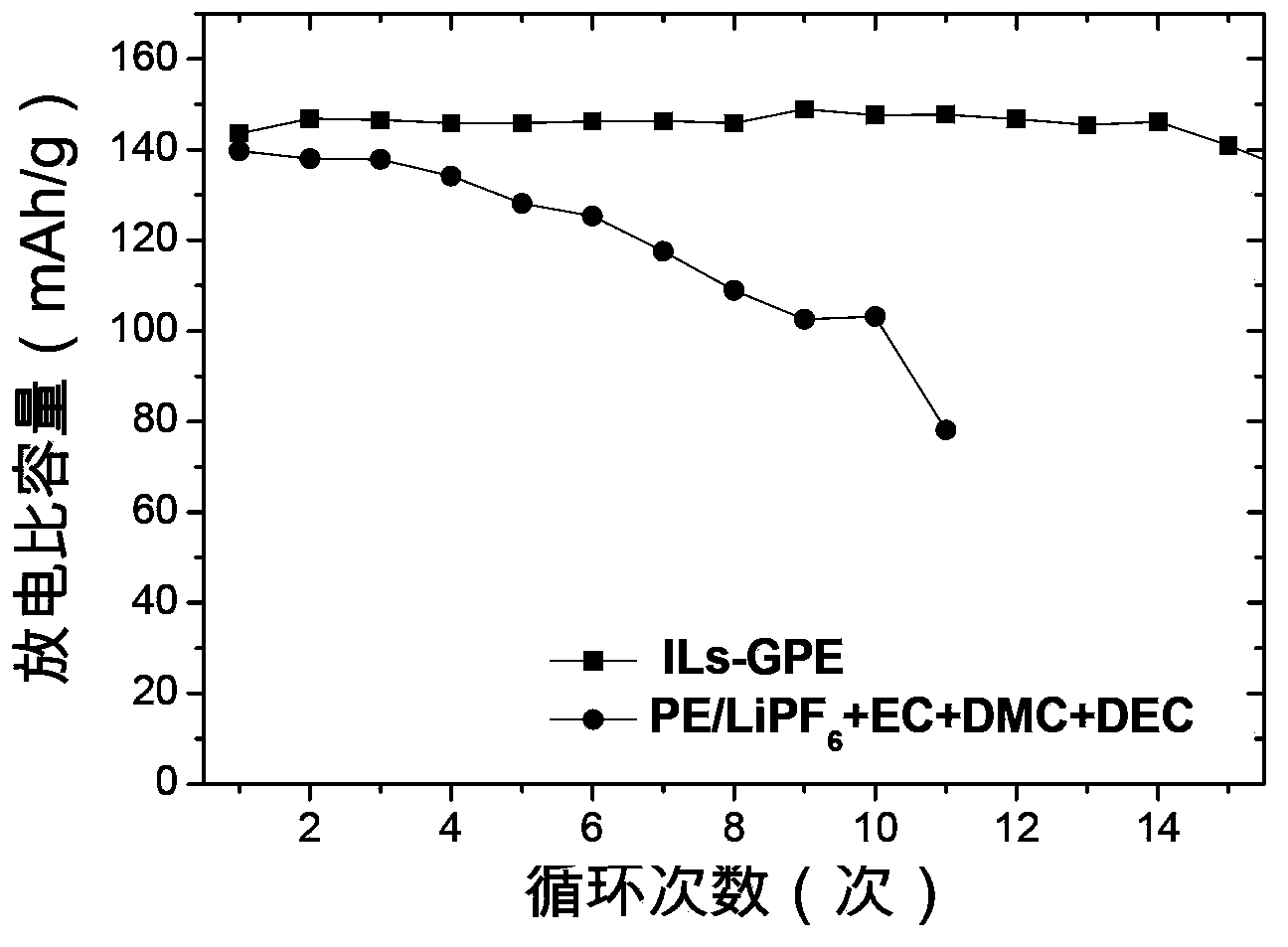

Lithium ion battery gel polymer electrolyte and preparation method thereof

InactiveCN103840198AAddress effectivenessSolving the problem of delithiation cycleSecondary cellsSupporting electrolyteCharge discharge

The invention provides a lithium ion battery gel polymer electrolyte and a preparation method thereof. The lithium ion battery electrolyte is composed of a macromolecular polymer, an ionic liquid, an organic solvent, a lithium salt and a film-forming additive. Through preparation of the gel polymer electrolyte, the disadvantages of leakage, easy corrosion of electrode materials and the like can be eliminated. The high temperature performance of the electrolyte can be improved by using an ionic liquid. By adding the organic solvent, the viscosity of the ionic liquid is reduced and the conductivity is enhanced. And by adding the film-forming additive, the problem of poor compatibility between the ionic liquid and graphite or a lithium electrode material can be solved. Experiments prove that the lithium ion battery gel polymer electrolyte provided by the invention is an elastic self-supporting electrolyte membrane, which has ionic conductivity up to the 10<-3>S / cm magnitude order, good high temperature stability and safety, and has good compatibility with a lithium cathode or a graphite cathode material. Lithium ions can undergo effective lithium insertion and removal circulation, and can achieve high capacity when applied to lithium ion battery charge-discharge cycle.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

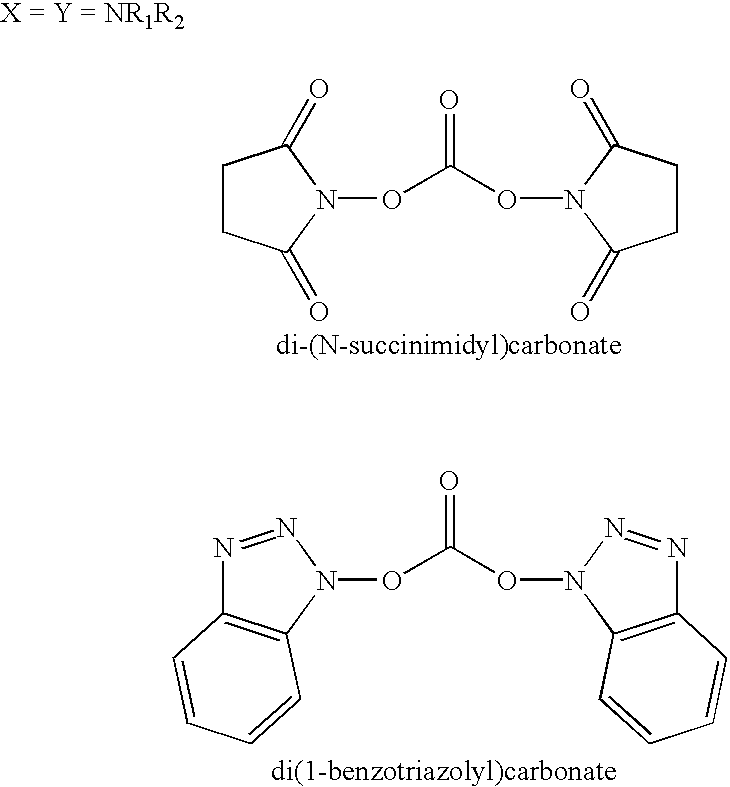

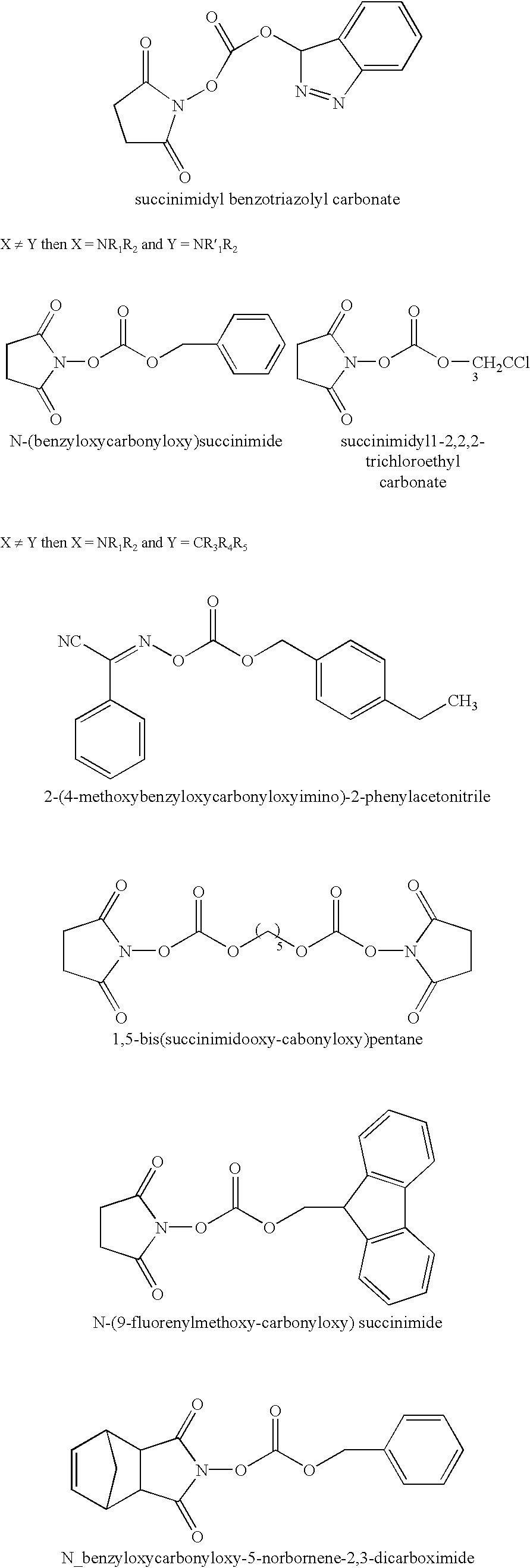

Organic carbonate additives for nonaqueous electrolyte rechargeable electrochemical cells

InactiveUS20030129500A1Improve oxidation stabilityImprove dynamic stabilityElectrode carriers/collectorsOrganic electrolyte cellsMethyl carbonateSolvent

A lithium ion electrochemical cell having high charge / discharge capacity, long cycle life and exhibiting a reduced first cycle irreversible capacity, is described. The stated benefits are realized by the addition of at least one carbonate additive to an electrolyte comprising an alkali metal salt dissolved in a solvent mixture including ethylene carbonate, dimethyl carbonate, ethyl methyl carbonate and diethyl carbonate. The preferred additive is either a linear or cyclic carbonate containing covalent O-X and O-Y bonds on opposite sides of a carbonyl group wherein at least one of the O-X and the O-Y bonds has a dissociation energy less than about 80 kcal / mole.

Owner:WILSON GREATBATCH LTD

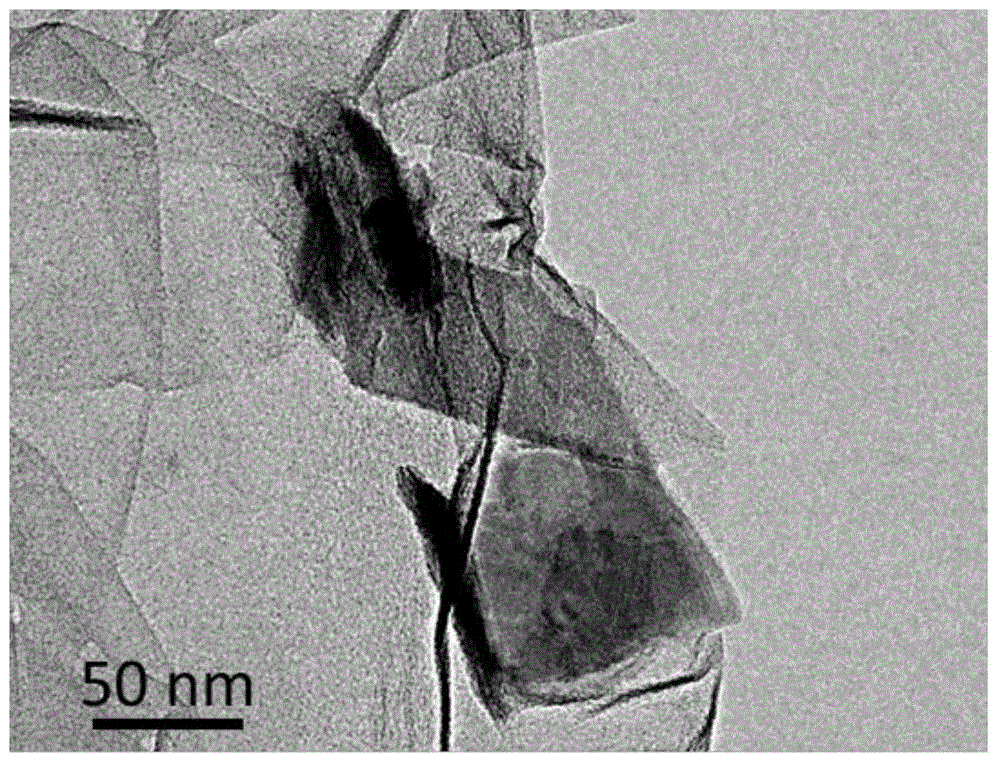

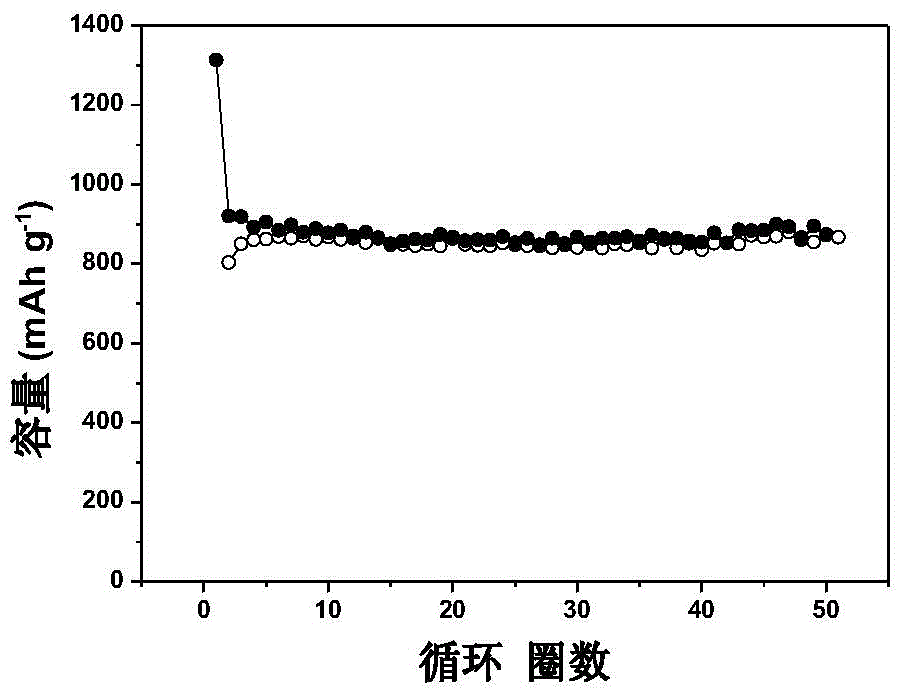

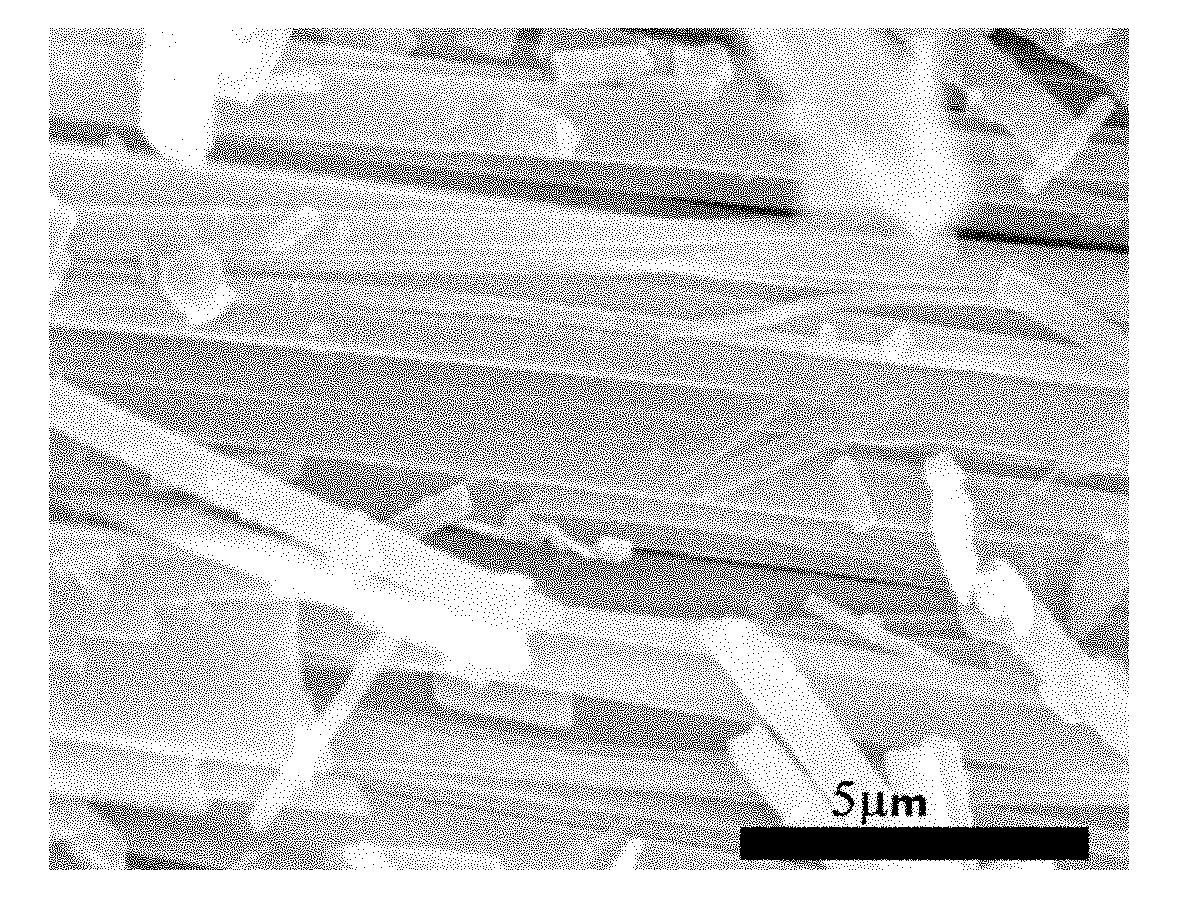

Preparation method for molybdenum disulfide/nitrogen-doped graphene three-dimensional composite material and application of molybdenum disulfide/nitrogen-doped graphene three-dimensional composite material

InactiveCN104409703AHigh cycle capacityIncrease capacitySecondary cellsNon-aqueous electrolyte accumulator electrodesCvd grapheneN-Methyl-2-pyrrolidone

The invention relates to a preparation method for a molybdenum disulfide / nitrogen-doped graphene three-dimensional composite material. The preparation method comprises the steps: preparing a few-layer molybdenum disulfide nanosheet dispersion solution from molybdenum disulfide powder serving as a raw material and N-methyl pyrrolidone serving as an intercalation solvent by an ultrasonic solvent thermal intercalation stripping method, mixing the few-layer molybdenum disulfide nanosheet dispersion solution with a graphene oxide aqueous solution to prepare a uniform molybdenum disulfide / graphene oxide dispersion system with different proportions, forming a compact molybdenum disulfide / graphene oxide composite structure from a solution under the action of sodium ions in a solution self-assembling process, performing in-situ reducing by using hydrazine hydrate to obtain a molybdenum disulfide / reduced graphene oxide three-dimensional composite system, and performing high-temperature nitrogen doping process under an ammonia atmosphere so as to obtain the molybdenum disulfide / nitrogen-doped graphene three-dimensional composite material. The method can be used for better balancing component control and structure control; the process is simple, and large-scale production is easy. The obtained molybdenum disulfide / nitrogen-doped graphene three-dimensional composite material can be applied to negative electrodes of high-performance lithium batteries.

Owner:TIANJIN UNIV

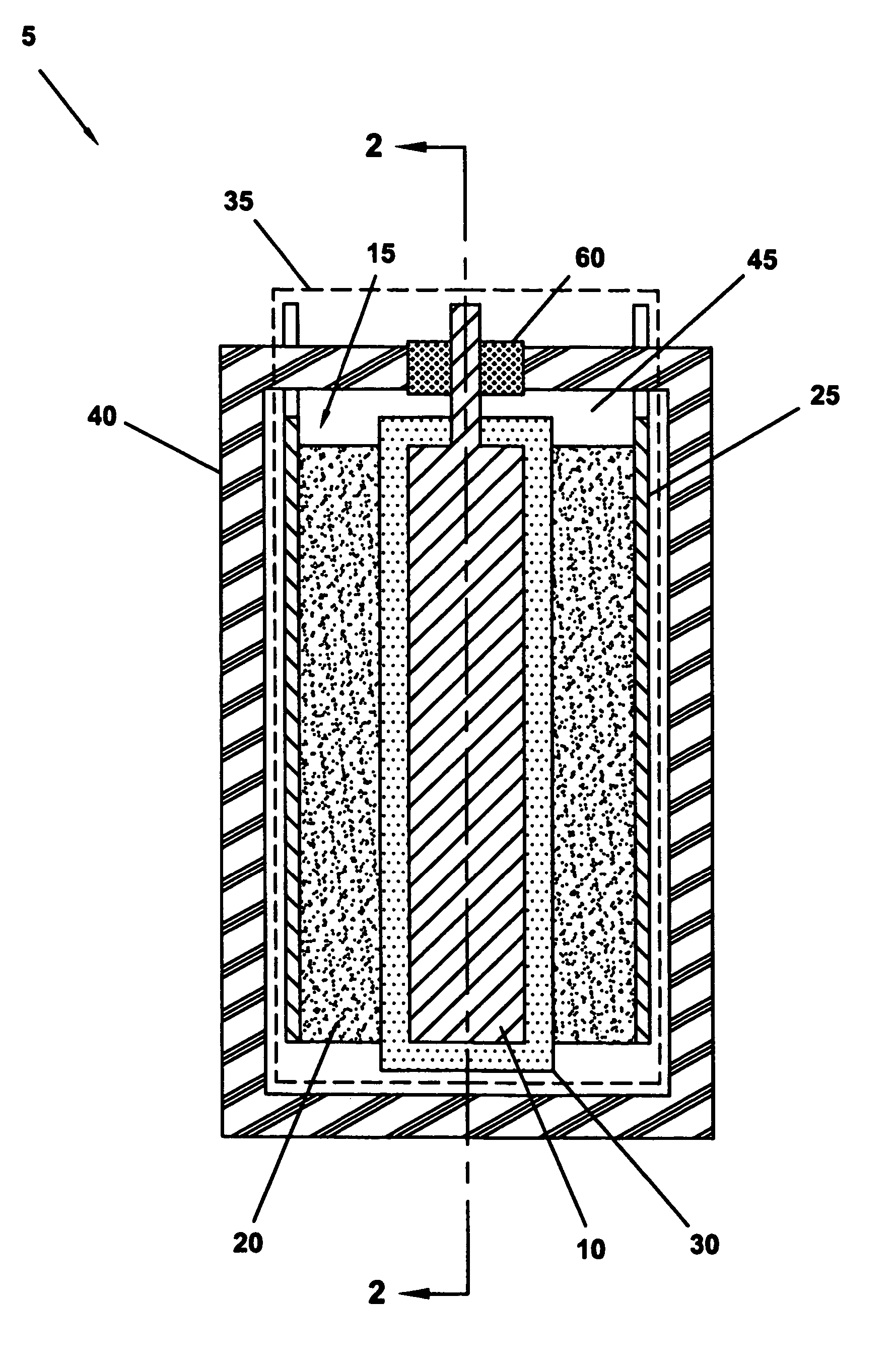

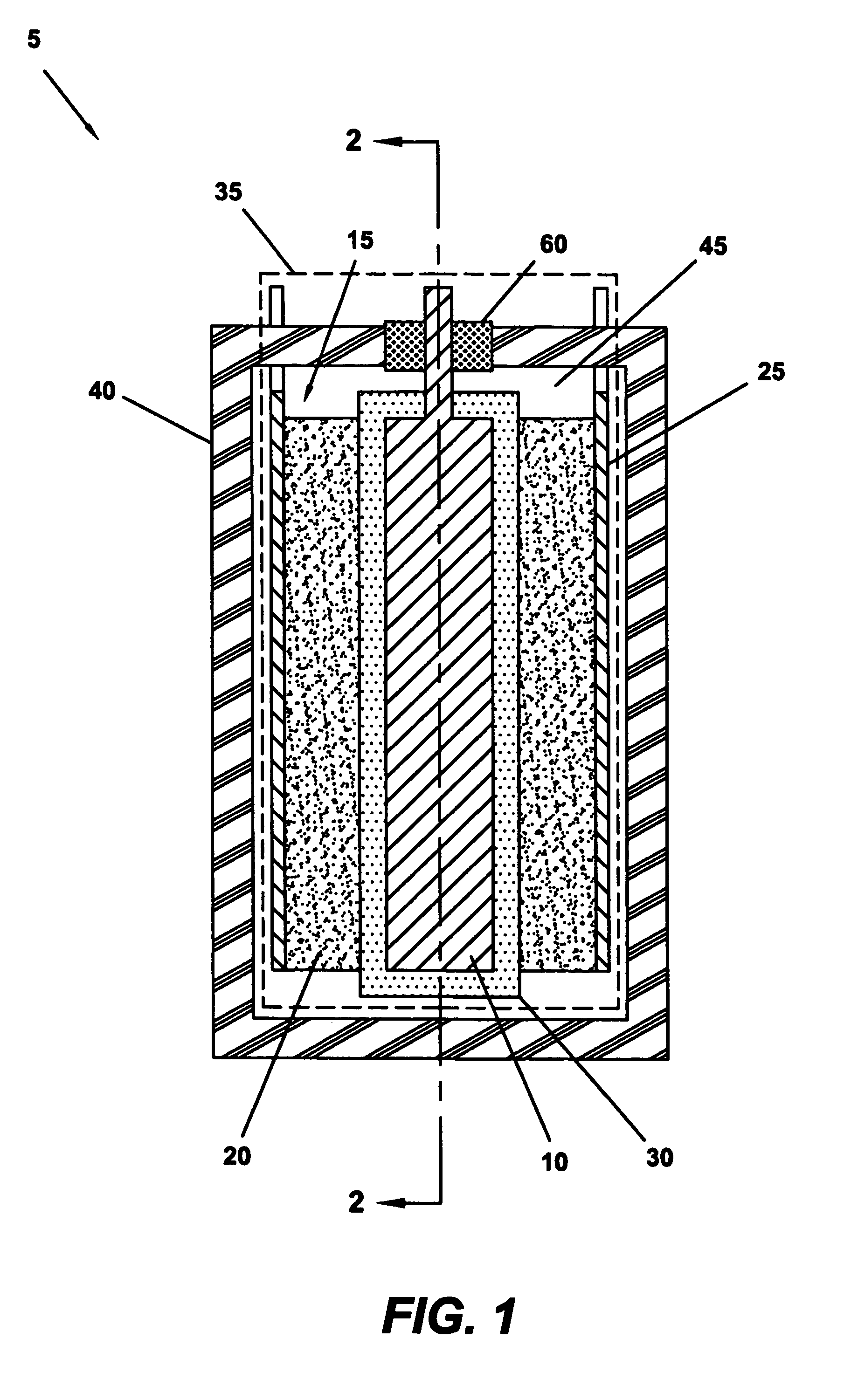

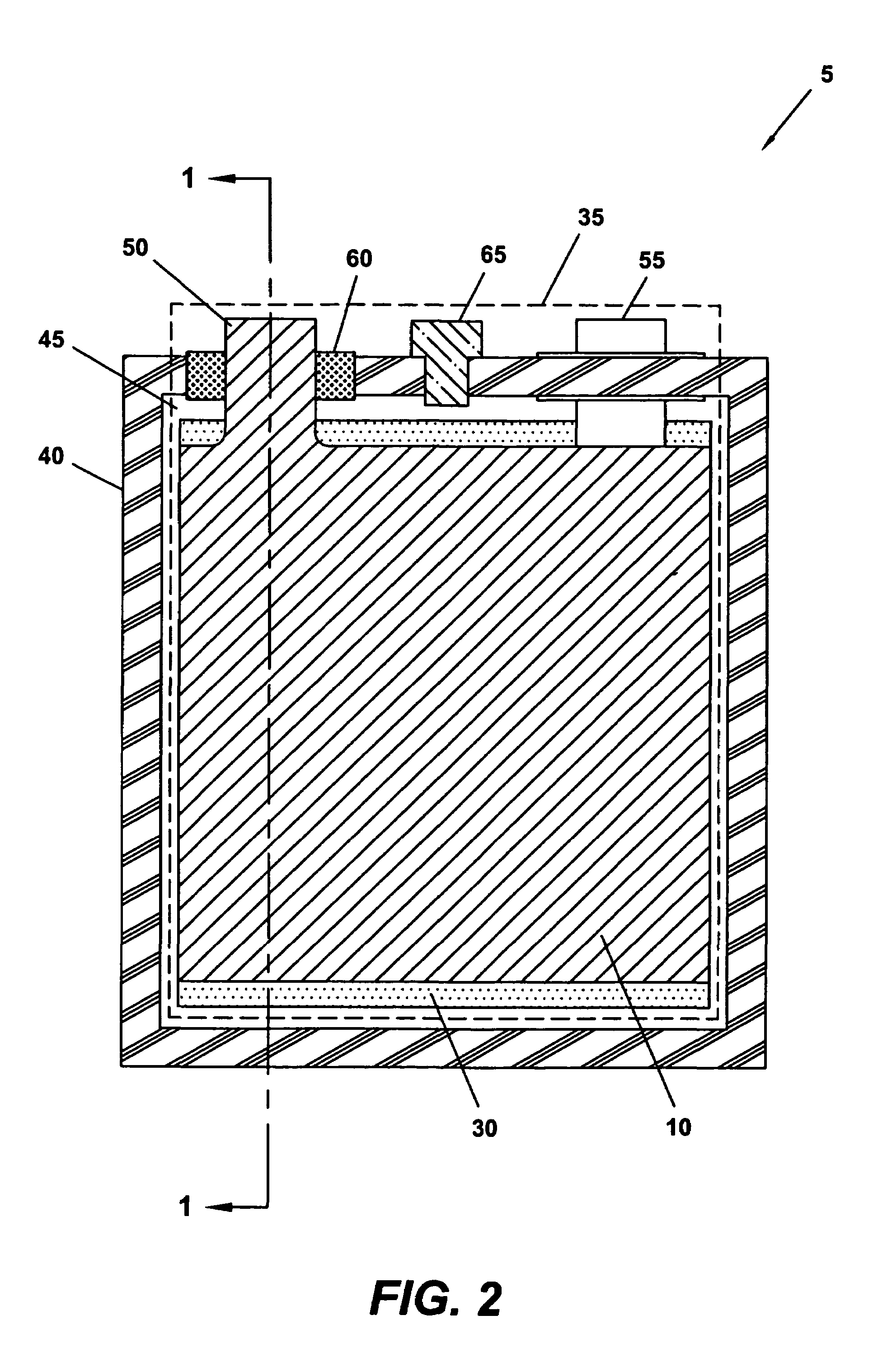

Heterogeneous electrochemical supercapacitor and method of manufacture

InactiveUS7312976B2Increase discharge powerHigh specific power characteristicHybrid capacitor electrolytesHybrid capacitor electrodesHydrogenEngineering

Owner:UNIVERSAL SUPERCAPACITORS LLC

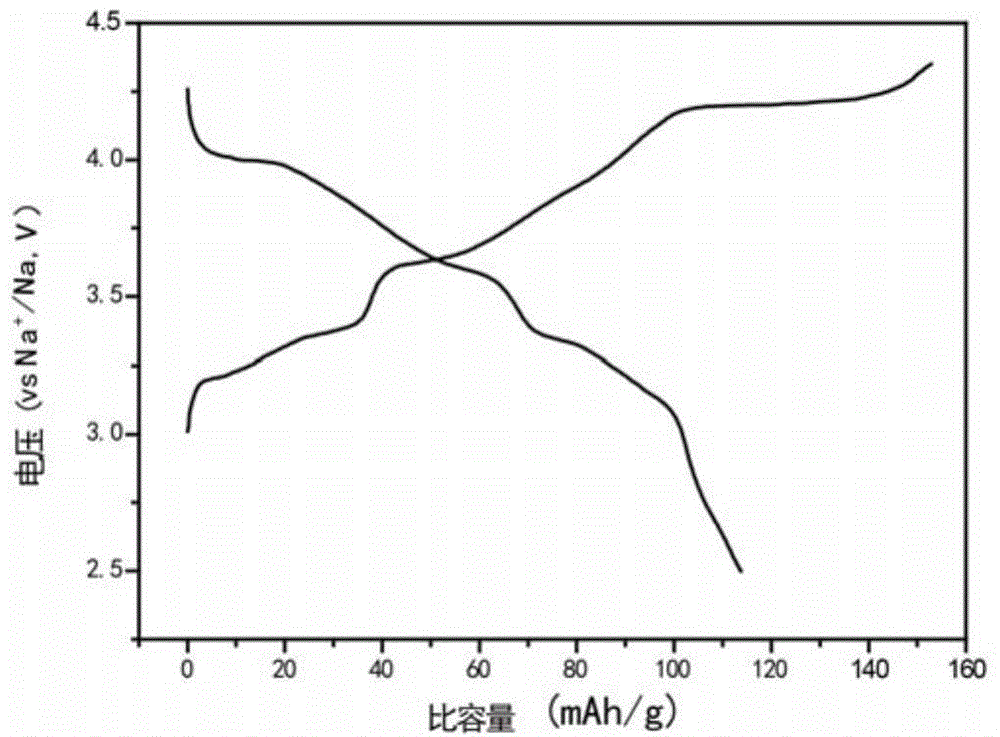

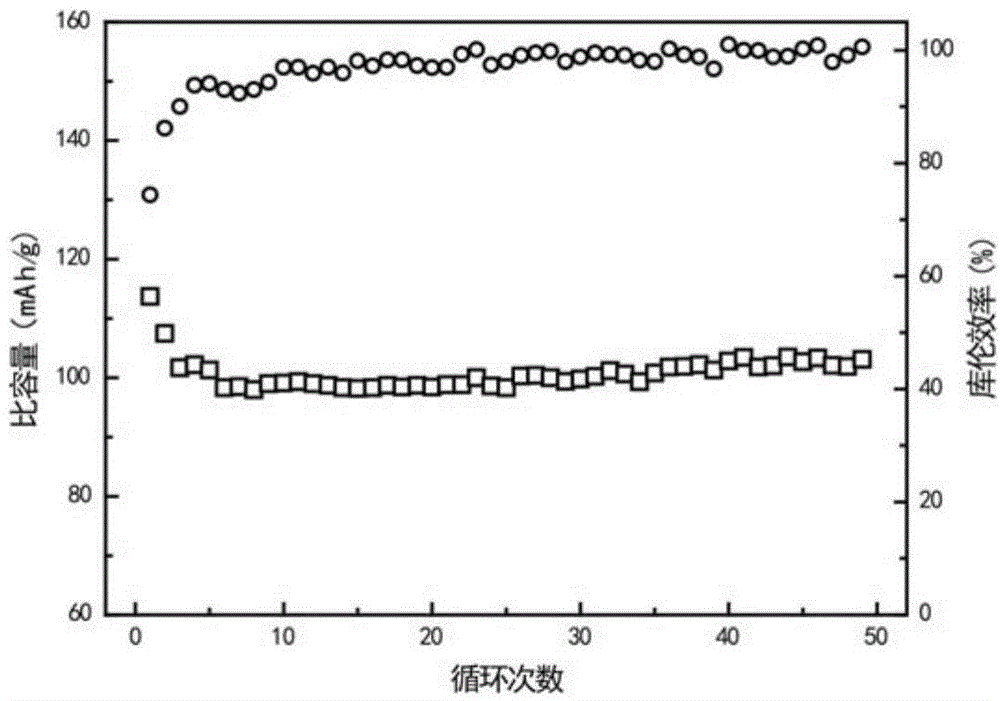

Method for manufacturing anode materials for sodium ion batteries and application of anode materials

InactiveCN104934597ARaw materials are easy to getHigh cycle specific capacityCell electrodesSecondary cellsIonEnergy density

The invention discloses a method for manufacturing anode materials for sodium ion batteries and application of the anode materials. Different types of metal are doped in each anode material. The anode materials can be expressed as Na<2 / 3>A<1-x>B<x>O<2>. The A represents selected transition metal with electrochemical activity, the B represents the doped metal, and the content x of the B is higher than 0 and is lower than or equal to 0.20. The method includes mixing materials at earlier stages; drying the materials and carrying out heat treatment on the materials; compressing the materials to obtain sheets; calcining the sheets at high temperatures to obtain the metal-doped anode materials for the sodium ion batteries. The method and the application have the advantages that the anode materials for the sodium ion batteries have high discharge voltages and are high in circulation capacity and excellent in stable circulation, accordingly, the specific capacity and the energy density of the batteries can be greatly improved when the anode materials are used as anodes of the sodium ion batteries, and the anode materials have excellent application prospects.

Owner:INST OF CHEM CHINESE ACAD OF SCI

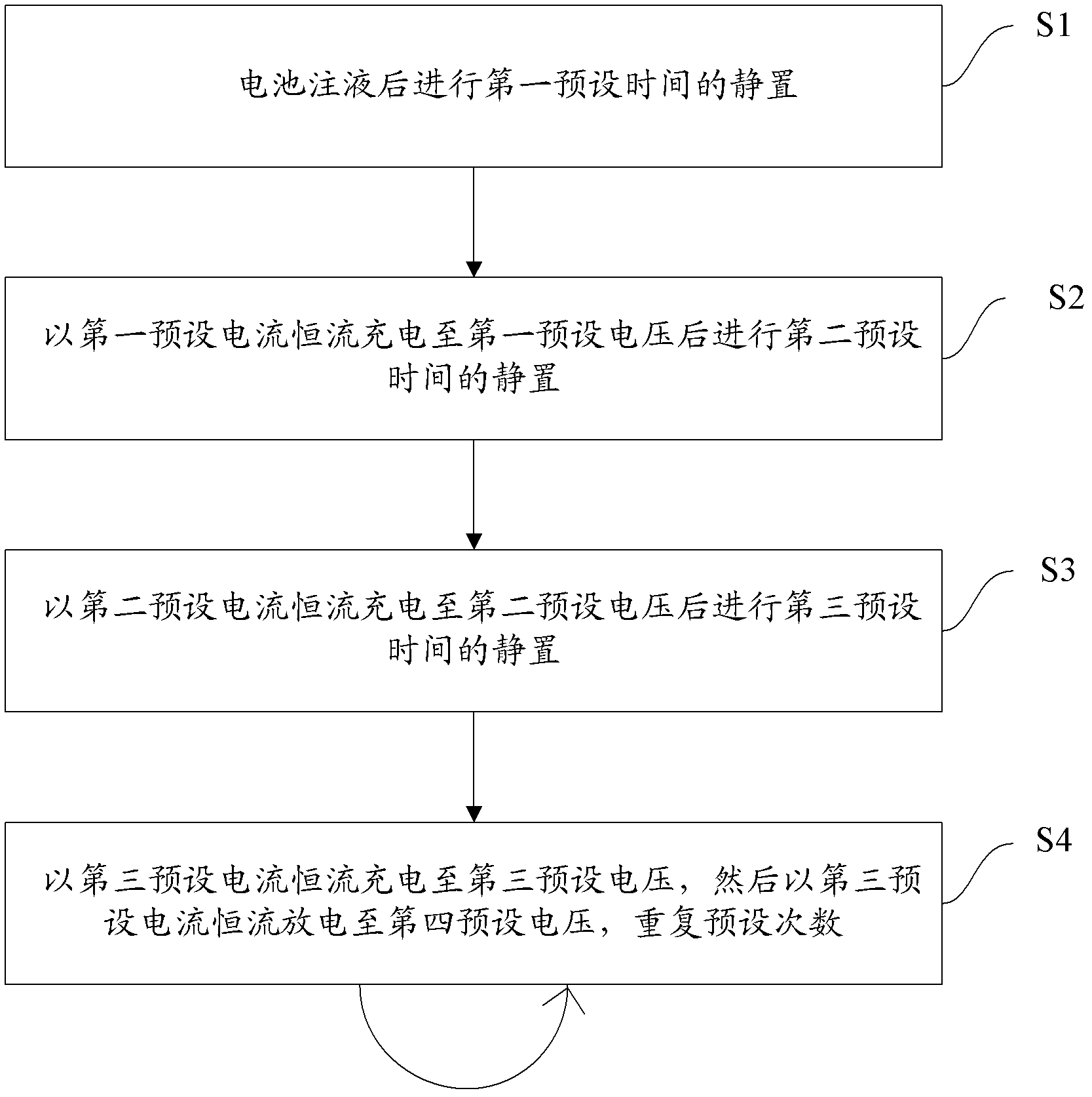

Method for forming lithium manganese power cells

ActiveCN103326069AImprove usable capacityImprove cycle performanceFinal product manufactureSecondary cells charging/dischargingLithiumElectric vehicle

The invention discloses a method for forming lithium manganese power cells. The method comprises the following steps: injecting liquid to a power cell and allowing for standing for a first preset time thereafter; allowing for standing for a second preset time after constant-current charge to a first preset voltage with a first preset current; allowing for standing for a third preset time after constant-current charge to a second preset voltage with a second preset current; and performing constant-current charge to a third preset voltage with a third preset current, then performing constant-current discharge to a fourth preset voltage with a third preset current, and repeating the step for a preset number of times. The method provided by an embodiment of the invention can form a compact and stable SEI film and completely eliminate gases generated in formation. The method effectively improves the available capacity of cells, the cycling performance, the consistency and the safety. Besides, the method is easy and reliable, is particularly suitable for lithium manganese power cells for electric vehicles, and can be promoted for wide applications.

Owner:BEIQI FOTON MOTOR CO LTD

Organic carbonate additives for nonaqueous electrolyte rechargeable electrochemical cells

InactiveUS20010004507A1Improve oxidation stabilityImprove dynamic stabilityOrganic electrolyte cellsSecondary cellsMethyl carbonateSolvent

A lithium ion electrochemical cell having high charge / discharge capacity, long cycle life and exhibiting a reduced first cycle irreversible capacity, is described. The stated benefits are realized by the addition of at least one carbonate additive to an electrolyte comprising an alkali metal salt dissolved in a solvent mixture that includes ethylene carbonate and an equilibrated mixture of dimethyl carbonate, ethylmethyl carbonate and diethyl carbonate. The preferred additive is either a linear or cyclic carbonate containing covalent O-X and O-Y bonds on opposite sides of a carbonyl group wherein at least one of the O-X and the O-Y bonds has a dissociation energy less than about 80 kcal / mole.

Owner:WILSON GREATBATCH LTD

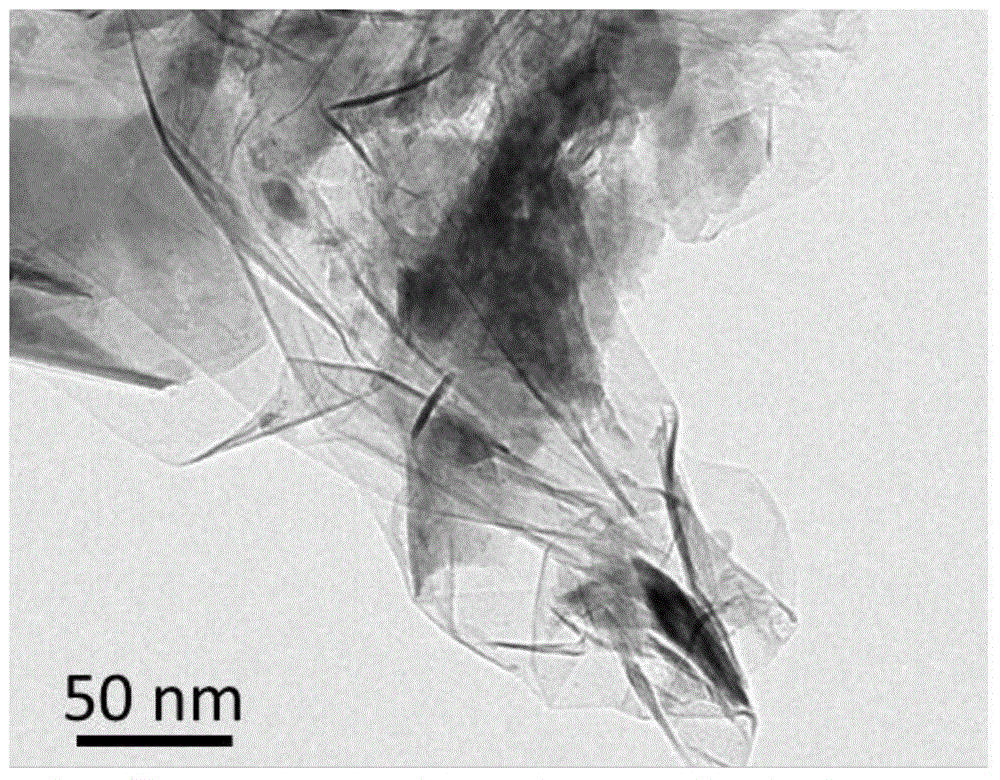

Molybdenum disulfide-coated carbon nanofiber used as negative electrode material for lithium-ion battery and preparation method of molybdenum disulfide-coated carbon nanofiber

ActiveCN107681142AHigh cycle capacityImprove cycle performanceMaterial nanotechnologyCell electrodesFiberPorous carbon

The invention discloses a molybdenum disulfide-coated carbon nanofiber used as a negative electrode material for a lithium-ion battery and a preparation method of the molybdenum disulfide-coated carbon nanofiber. The molybdenum disulfide-coated carbon nanofiber is characterized in that the outer surface of a mesoporous carbon nanofiber is coated with a layer of molybdenum disulfide nanosheet; andduring preparation, a nanofiber containing ZIF-8 is firstly prepared by using an electrostatic spinning assembly method, a porous carbon nanofiber is formed after high-temperature carbonization of thefiber, and the surface of the carbon nanofiber is coated with a layer of flaky molybdenum disulfide through a hydrothermal method, thereby obtaining a target product used as a negative electrode material for a lithium-ion battery. The molybdenum disulfide-coated carbon nanofiber is the negative electrode material for the lithium-ion battery capable of being charged and discharged, the problems ofpoor stability and poor conductivity of the flaky molybdenum disulfide material in charging and discharging processes of the battery are effectively solved, the cycle performance and the rate capability of the battery are improved and the electron transport rate in the cycle process of the battery is improved; and the preparation method is simple, massive production can be achieved and the preparation method has a good application prospect.

Owner:HEFEI UNIV OF TECH

Lithium-sulfur battery composite anode material and preparation method and application thereof

InactiveCN105826540AHigh cycle capacityImprove cycle stabilityCell electrodesLi-accumulatorsHigh current densityThree level

The invention discloses a lithium-sulfur battery composite anode material and a preparation method and application thereof. The lithium-sulfur battery composite anode material is characterized in that the anode material is formed by mixing and heating sulfur and a conductive network embedded graded porous carbon carrier, and sulfur is evenly dispersed in carbon pore channels of the conductive network embedded graded porous carbon carrier in the form of active nano particles and molecules. According to the conductive network embedded graded porous carbon carrier, porous carbon containing a three-level pore structure of micropores, mespores and macropores is adopted as a base body, and a high-conductivity nano carbon material is embedded into the base body to form a conductive network. The lithium-sulfur battery composite anode material can keep high circulating capacity, excellent stable circulation performance, good high-magnification (high-current-density charge and discharge) performance within a large temperature range including room temperature, the raw materials adopted in the material preparing process are cheap, available and environmentally friendly, the preparation process is simple, amplification is easy, and good application prospects are achieved.

Owner:HEFEI UNIV OF TECH

Double-oxide co-coated high-nickel lithium battery positive electrode material and preparation method thereof

InactiveCN108390039ASuppresses the problem of high alkali contentImprove cycle performanceCell electrodesSecondary cellsDecompositionLithium hydroxide

The invention provides a double-oxide co-coated high-nickel lithium battery positive electrode material and a preparation method thereof. A high-nickel ternary precursor material is prepared through aco-precipitation method; and then, vacuum pre-sintering is carried out after fully mixing and ball-milling with lithium hydroxide and calcium hydroxide; later, sulfate, metal oxide titanium oxide, cerium oxide and the like are added into gel synthesized in an organic solvent; and the high-nickel lithium battery positive electrode material coated by a double-oxide layer is obtained after sintering. According to the method in the invention, the problem that the alkali content of the traditional high-nickel ternary material is excessively high in the precursor preparation process is solved; theprepared double-oxide-layer coated high-nickel lithium battery positive electrode material forms a physical isolation layer, so that the corrosion of HF in the electrolyte and the generation of side reactions are inhibited, the high-nickel lithium battery positive electrode material is protected; therefore, the cycling performance of the battery is improved; meanwhile, the introduced sulfate ionsform a stable electrolyte layer, so that the decomposition of the electrolyte is inhibited, and the cycling performance of the battery is further improved.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

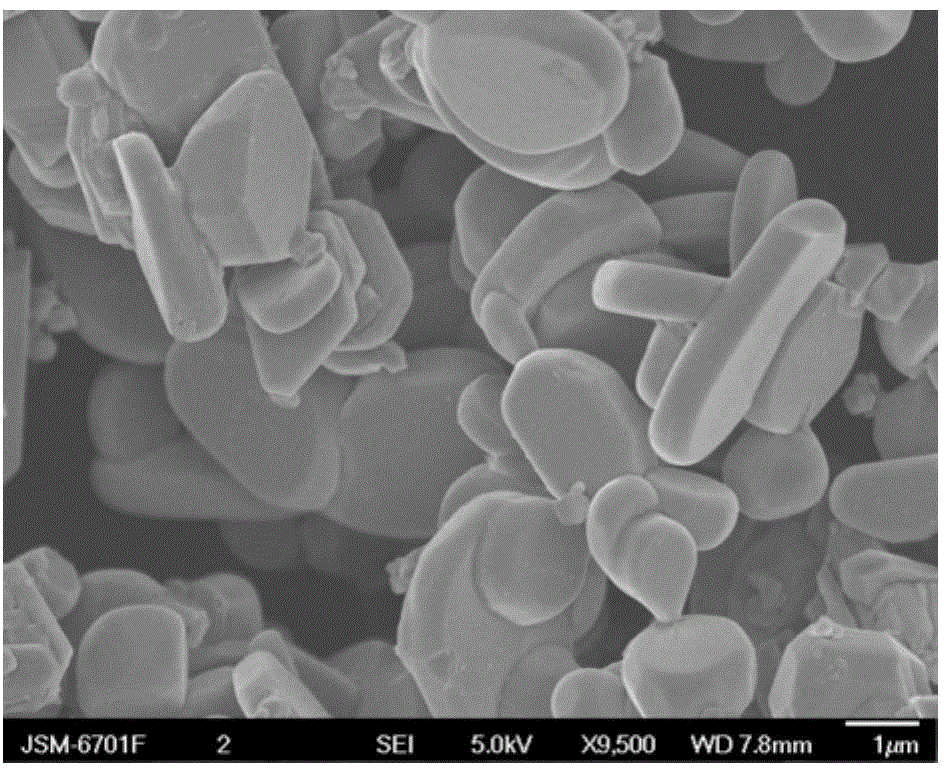

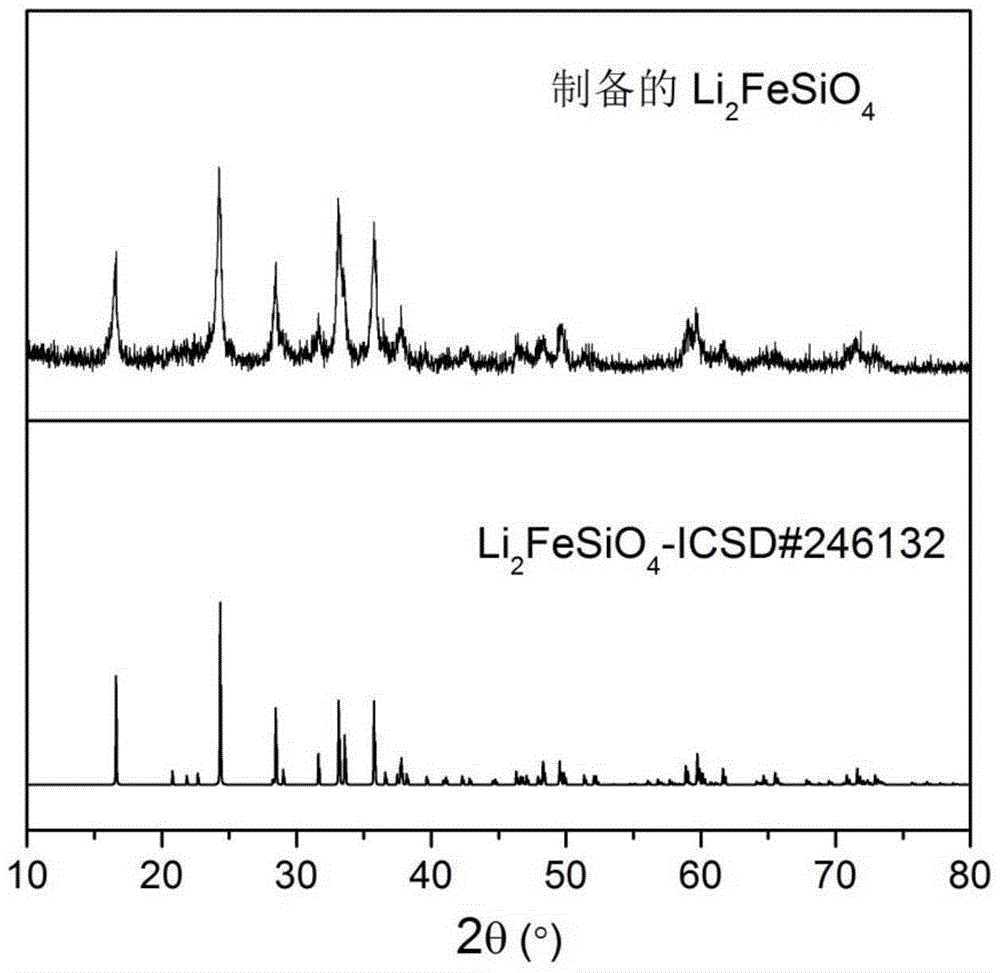

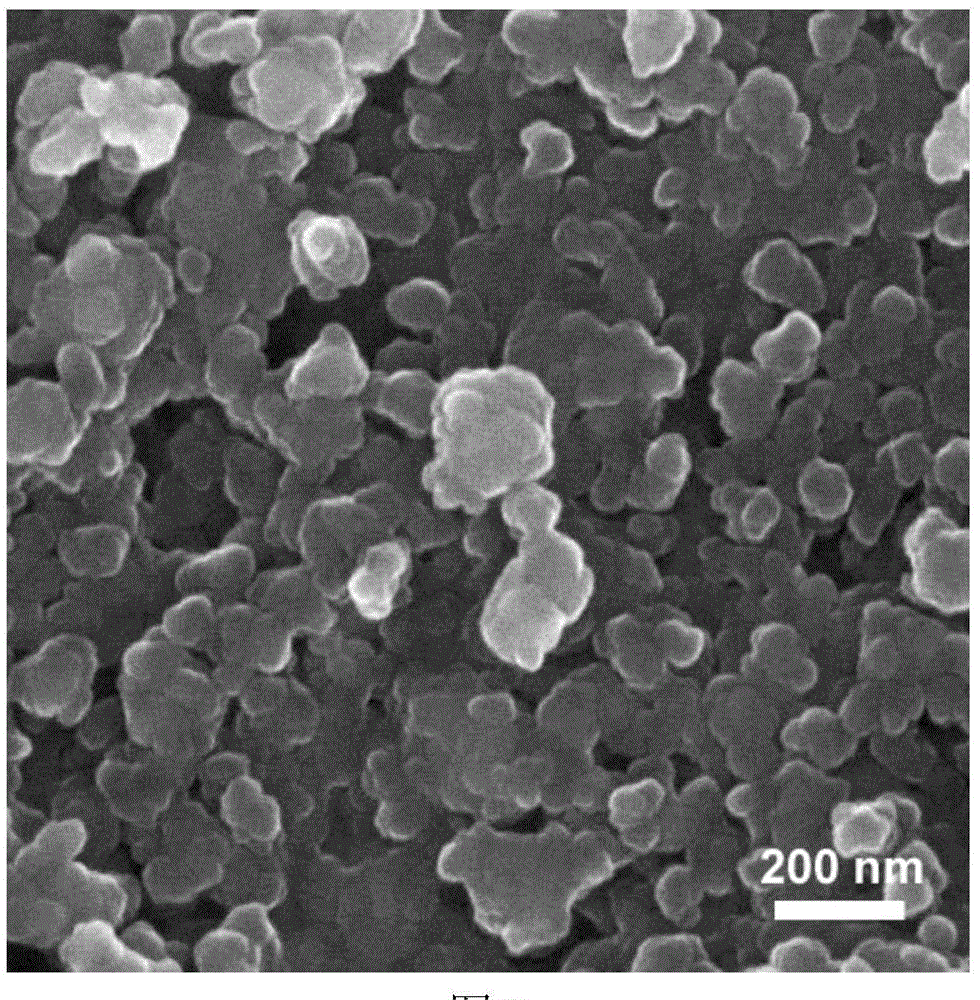

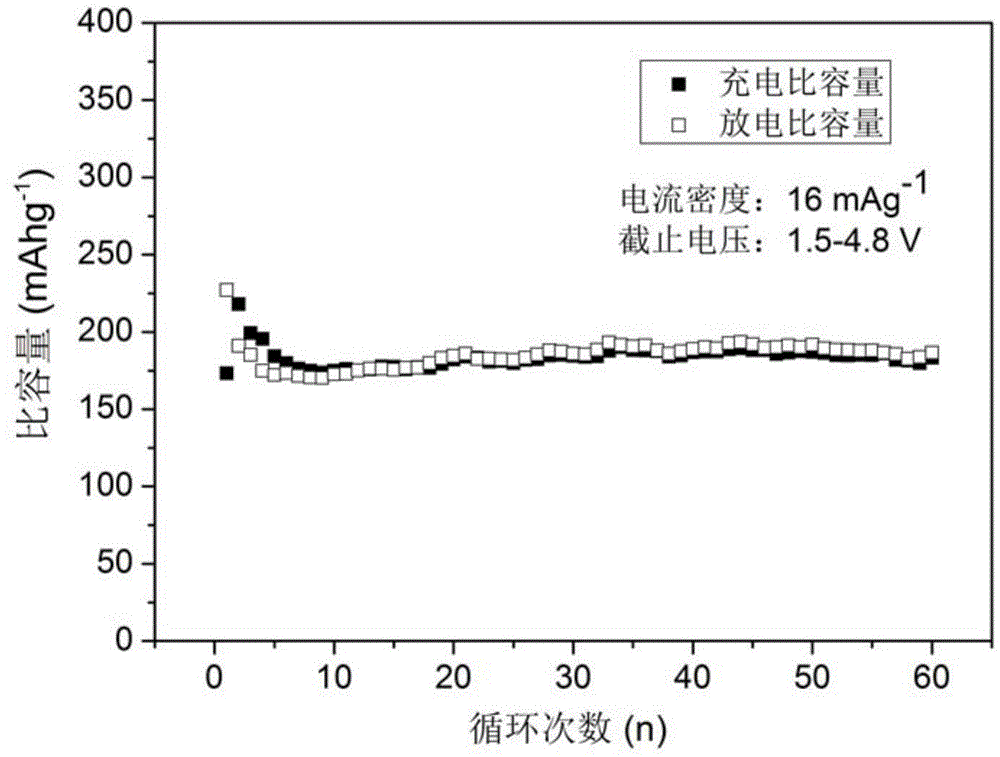

Method for preparation of Li2FeSiO4 and Li2FeSiO4/C anode material

InactiveCN104134784AReduce synthesis conditionsLow raw material costCell electrodesSecondary cellsIron saltsNew energy

Belonging to the technical field of new energy materials and electrochemistry, the invention discloses a method for preparation of a Li2FeSiO4 and Li2FeSiO4 / C anode material. The method provided by the invention adopts an inorganic trivalent iron salt as the iron source and takes an organic dispersant as the carbon source. In the process of introducing the organic dispersant into co-precipitation, the dispersant is adsorbed on the surface of the obtained precipitate, thus effectively preventing agglomeration of precipitate particles. In a calcination process, the organic dispersant undergoes in situ decomposition to generate amorphous carbon coating the particles, thereby preventing further growth of the particles. At the same time, the amorphous carbon forms a conductive network on the material surface, thus increasing electronic conduction of the material and improving the electrochemical performance of the material. The method provided by the invention has the advantages of cheap raw materials and simple preparation process, and is easy for industrial production. By adjusting the dispersant content, the synthesized Li2FeSiO4 and Li2FeSiO4 / C material has uniform particle size, good dispersibility, and excellent electrochemical performance, thus being a lithium ion battery anode material with broad application prospects.

Owner:UNIV OF SCI & TECH BEIJING

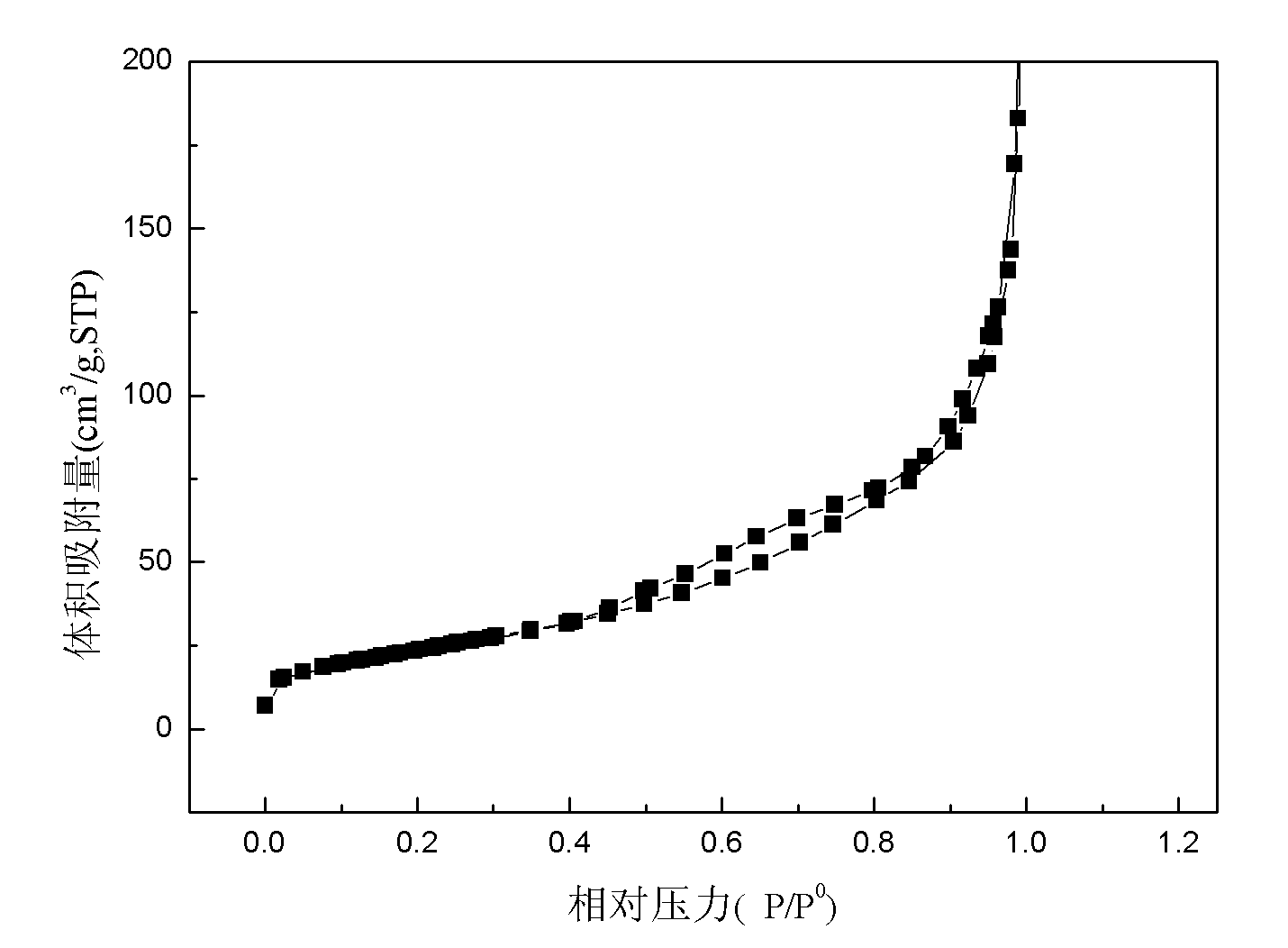

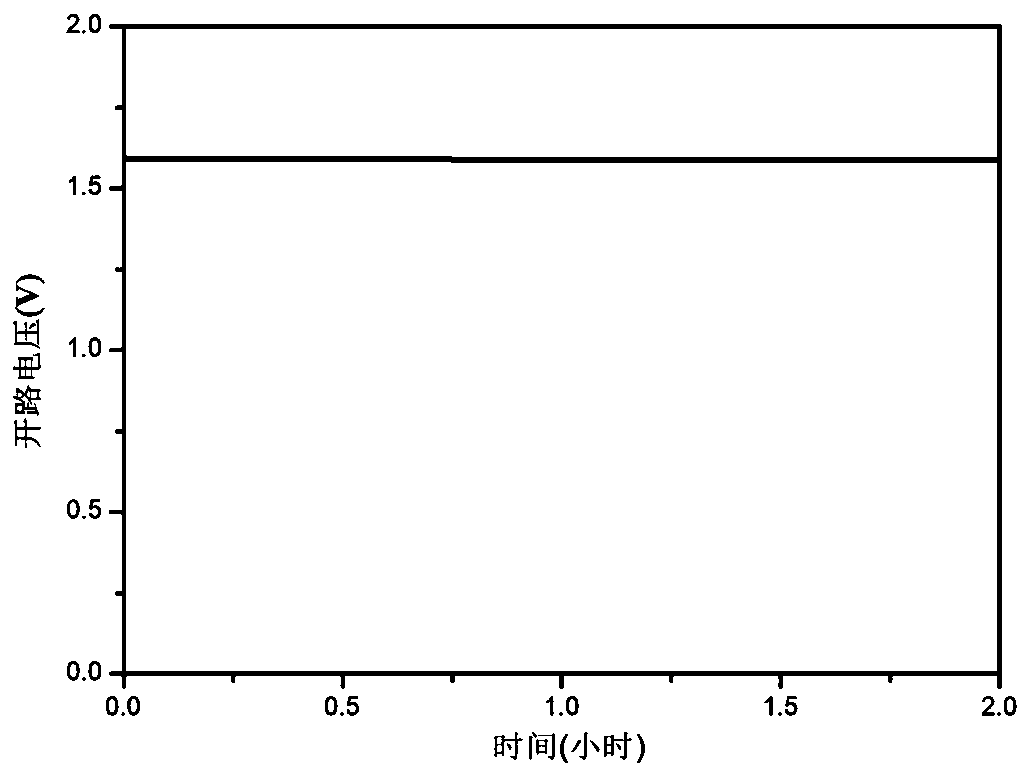

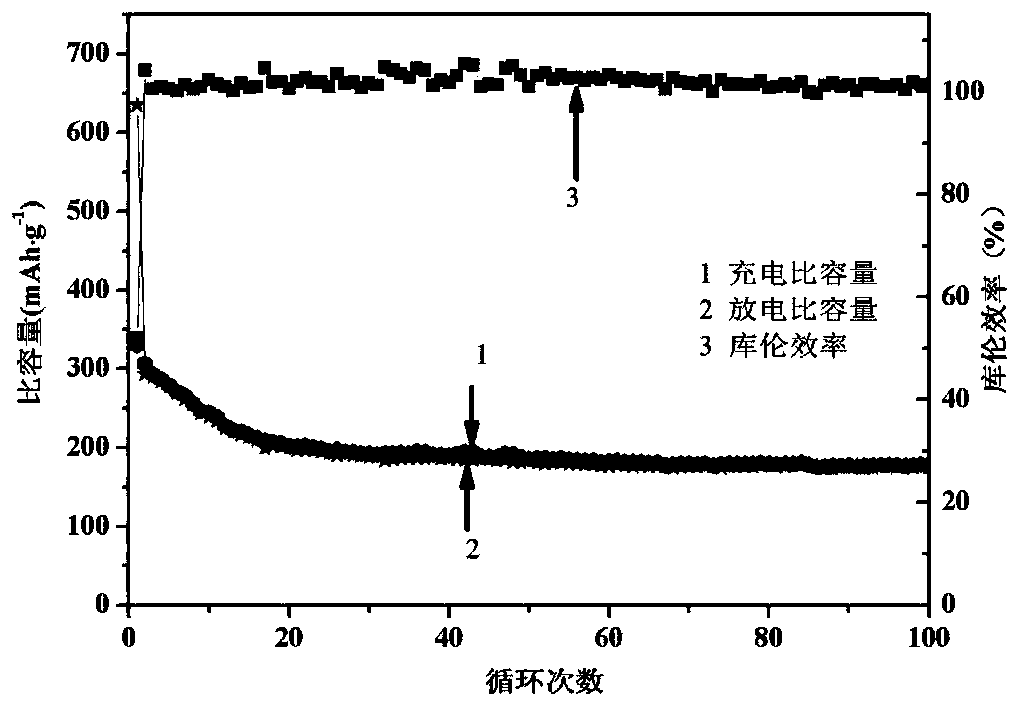

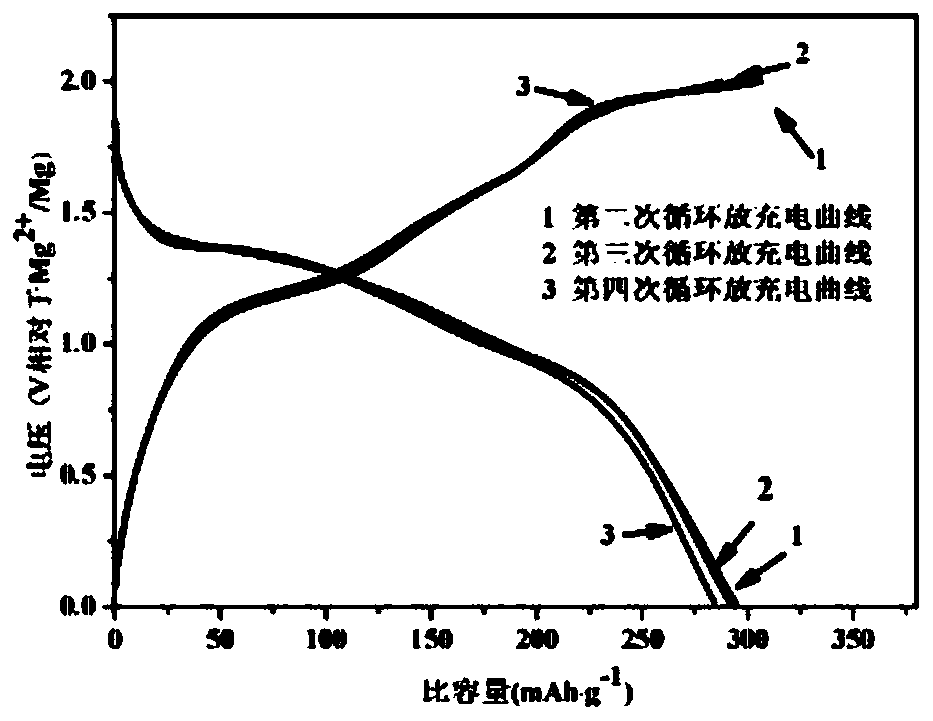

Mesoporous vanadium dioxide nano strip material as well as preparation method and application thereof

InactiveCN102064323AHigh cycle capacityImprove rate discharge performanceCell electrodesVanadium dioxidePolyethylene glycol

The invention discloses a mesoporous vanadium dioxide nano strip material as well as a preparation method and application thereof. The mesoporous vanadium dioxide nano strip material is prepared by using the following steps of: mixing vanadium pentoxide with hydrogen peroxide to obtain vanadium pentoxide sol; uniformly mixing and ultrasonically dispersing the vanadium pentoxide sol, glucose and polyethylene glycol and transferring to a reactor; reacting at the constant temperature of 100-240 DEG C, cooling and centrifugally separating a solid; and washing the solid sequentially with deionized water and cyclohexane; then drying in vacuum to obtain a black mesoporous vanadium dioxide nano strip with the hole diameter mainly distributed in 3-5 nano. The mesoporous vanadium dioxide nano strip disclosed in the invention is a good magnesium secondary battery anode material. The constant current charge and discharge performance research of a magnesium secondary battery formed by the anode material indicates that the circulating volume and magnification discharge performance of the material are obviously improved. The method disclosed in the invention has the advantages of mild reaction condition, simple reaction process, high yield of products, high purity and high reproducibility.

Owner:LOGISTICS UNIV OF CAPF

Electrodes comprising mixed active particles

InactiveCN101663710AHigh cycle capacityImprove featuresNon-metal conductorsLi-accumulatorsCharge carrierActive particles

A battery containing a first electrode and a second electrode, and an electrolyte for transferring ionic charge-carriers there between, wherein the first electrode contains a first electrode active material represented by the formula A<2>eM<4>kM<5>mM<6>nM<7>oOg, and at least one second electrode active material selected from the group consisting of active materials represented by the formula A<1>aM<1>b(XY4)cZd, active materials represented by the formula A<3>hMniO4, and mixtures thereof.

Owner:VALENCE TECH INC

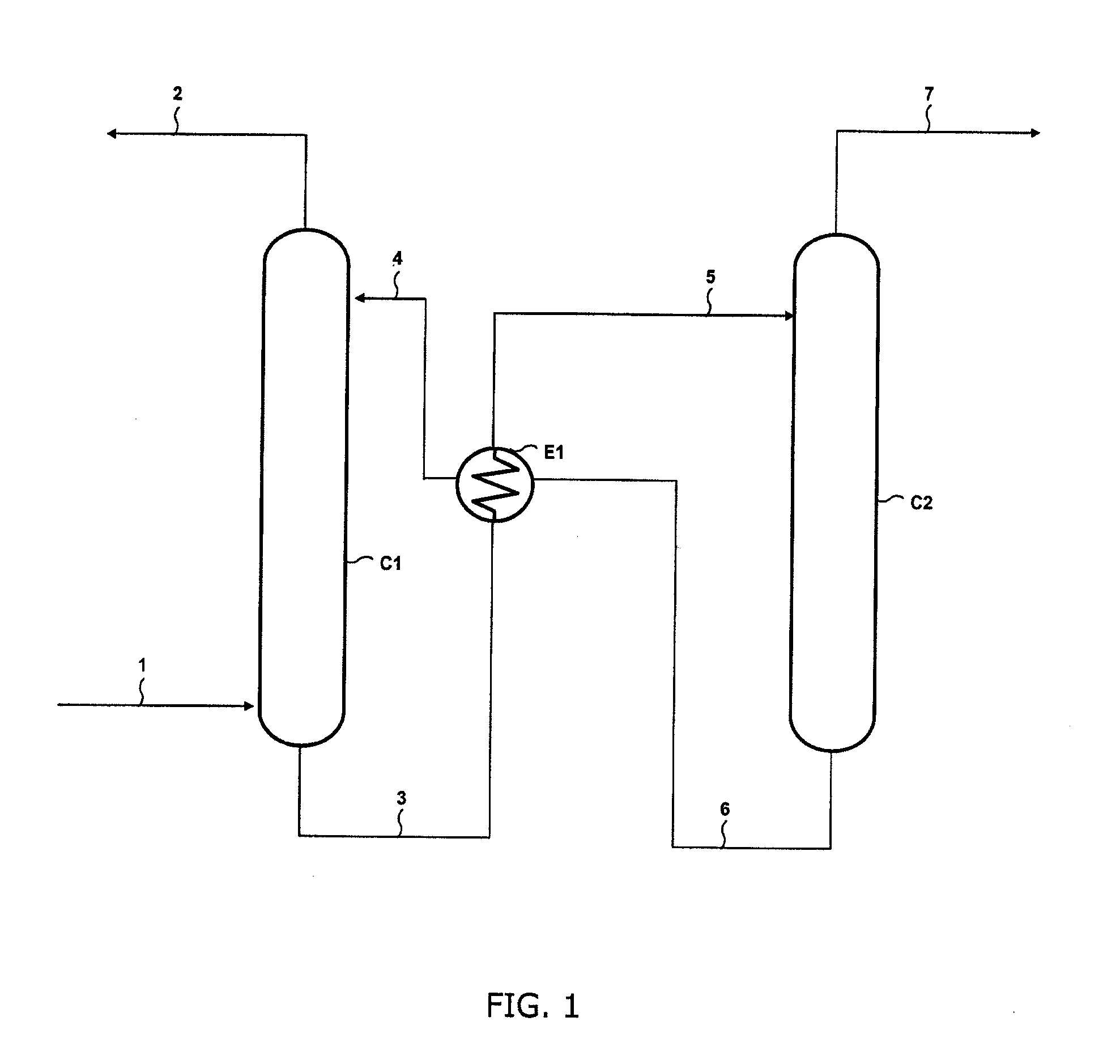

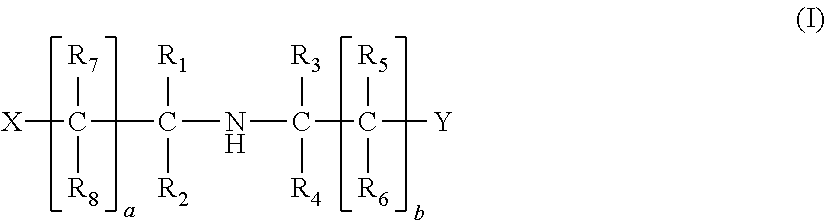

Method of removing acid compounds from a gaseous effluent with an absorbent solution based on i/ii/iii triamines

InactiveUS20130023712A1High cycle capacityHigh densityGas treatmentGaseous fuelsAqueous solutionEffluent

The invention relates to the removal of acid compounds from a gaseous effluent in an absorption method using an aqueous solution containing one or more triamines wherein the three amine functions are not connected to each other by rings and whose amine functions in the a and the co positions are always tertiary, and the amine function in central position is always secondary, more or less sterically hindered, and which have the general formula (I) as follows:

Owner:INST FR DU PETROLE

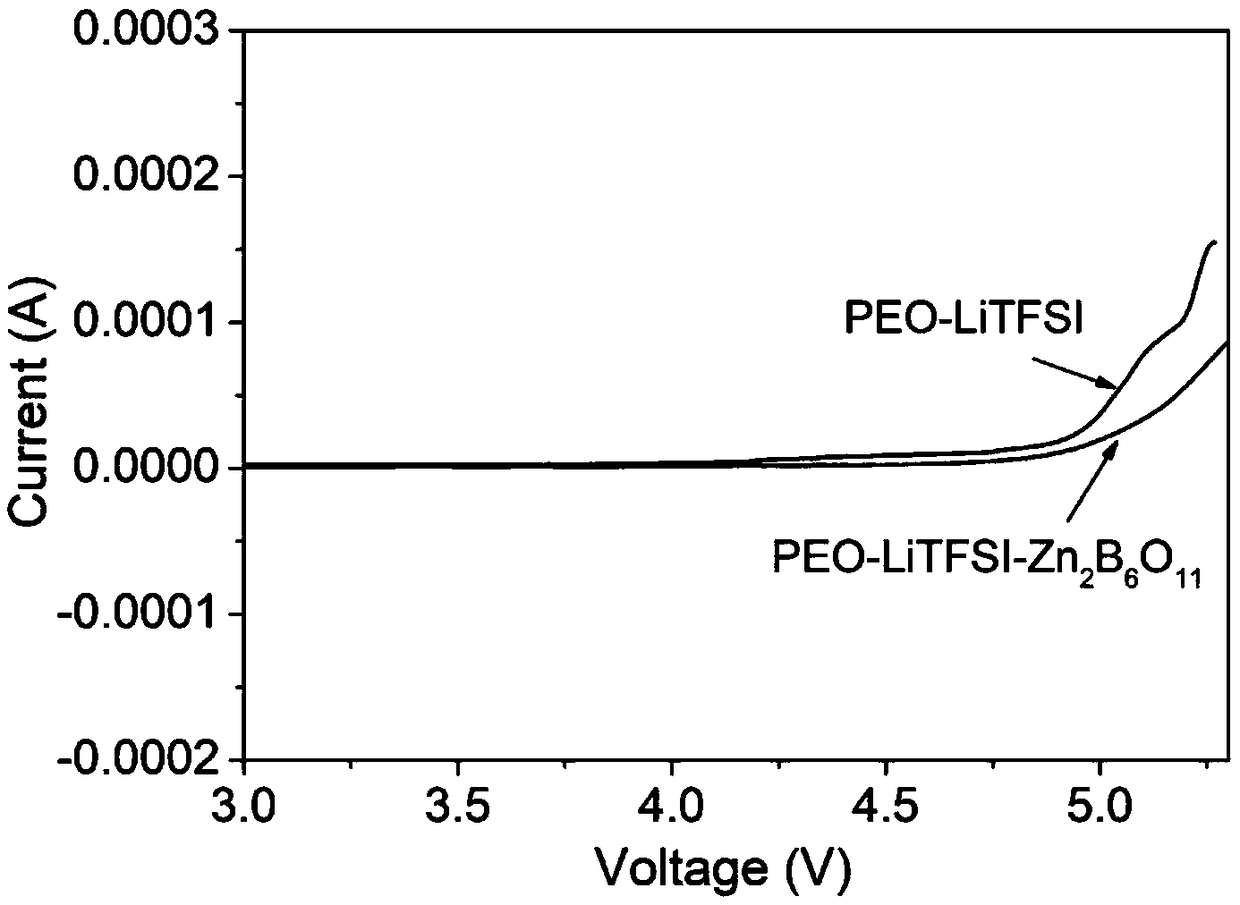

Preparation method of high-voltage-resistant solid polymer electrolyte

ActiveCN109301317AImprove high pressure performanceIncrease energy densitySolid electrolytesLi-accumulatorsPolymer scienceNanowire

A preparation method of a high-voltage-resistant solid polymer electrolyte includes the steps of: 1) according to certain ratio, dissolving a polymer substrate, lithium salt, and an inorganic additivein anhydrous acetonitrile and stirring the mixture at room temperature to obtain a uniform solution, wherein the polymer substrate is polyoxyethylene, the lithium salt is lithium bistrifluoromethylsulfonimide or lithium perchlorate; the inorganic additive is nano-wires or nano-particles of zinc borate, aluminum borate, sodium tetraborate, barium metaborate or calcium borate, the mass ratio of thepolyoxyethylene to the lithium salt EO : Li<+> is 10-20:1, and the mass of the inorganic additive is not more than 20% of the total mass of the polymer substrate and lithium salt; 2) pouring the solution into a polytetrafluoroethylene mold to volatilize the solution until completely dried, thus preparing the solid polymer electrolyte. The method improves the high-voltage resistance of the solid polymer electrolyte, so that the product fits a high-voltage ternary cathode material and energy density and safety of an all-solid-state battery are improved.

Owner:ZHEJIANG UNIV OF TECH

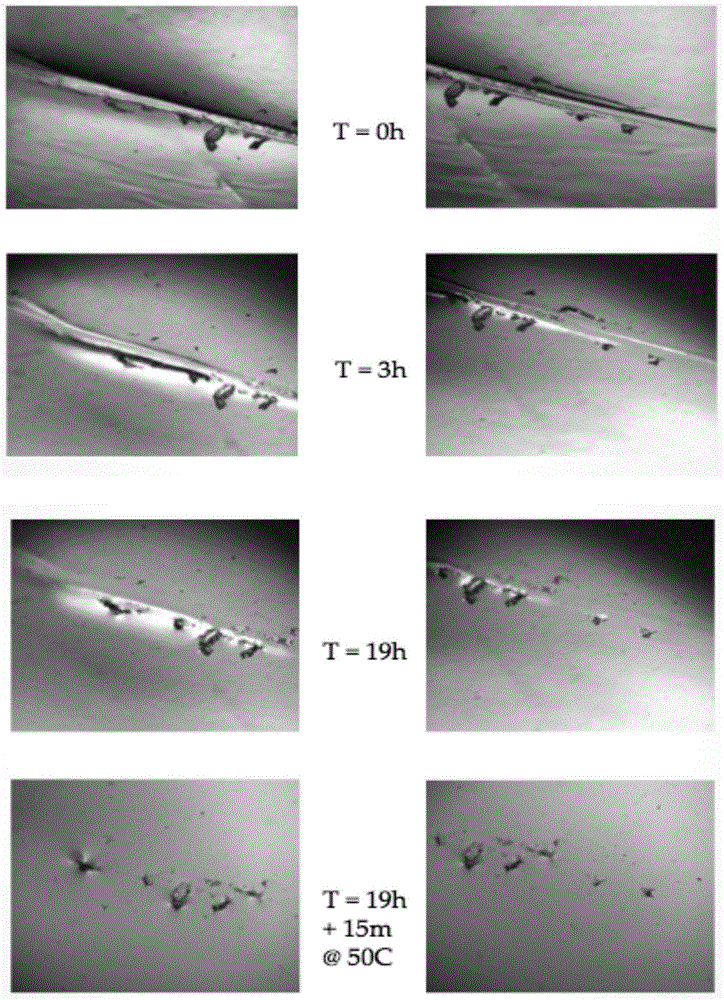

Binder, and preparation method and application thereof

ActiveCN106207183AHigh cycle capacityImprove electrochemical performanceCell electrodesOligomerOrganic solvent

The invention discloses a binder, and a preparation method and application thereof. In an embodiment, the preparation method comprises the steps of, in a protective atmosphere, fully reacting polyacid with an ethyleneamine monomer, dissolving a reaction product into an organic solvent, carrying out full washing through a mixture of water and methanol and then removing an organic solvent to obtain an oligomer; and in the protective atmosphere, reacting the oligomer with carbomite to obtain the binder. The preparation technology is simple and low in cost and large-scale implementation is facilitated; and the obtained binder is a bright yellow translucent polymer, has the characteristics of glass and rubber, and not only has excellent ductility, but also has self-repairing property. The binder is excellent adaptation with a current collector or an electrode material when used for an electrode, and the structure stability of an electrode slice can be effectively improved, so that the overall electrochemical properties of a battery are greatly improved.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Magnesium-lithium double-ion battery composite cathode material, preparation method and application thereof, and battery system

ActiveCN109755553ASimple structureComplete structureMaterial nanotechnologyCell electrodesElectrochemical responseHigh current density

The invention provides a magnesium-lithium double-ion battery composite cathode material, a preparation method and application thereof, and a battery system, and belongs to the field of magnesium ionbatteries. In the magnesium-lithium double-ion battery composite cathode material, a polyaniline layer has a protective effect on the composite cathode material, and PANI-coated VS4 / rGO is higher in conductivity and of a more complete structure, which is favorable for achieving charging and discharging under a large current density; a PANI conductive layer does not participate in electrochemical reaction, and coats the surface of VS4 to improve the conductivity of VS4, and can well adapt to the charging and discharging process under the high current density; meanwhile, the PANI layer reduces the loss of active substances in the core VS4 during charging and discharging, thus maintaining the structural integrity; and the PANI layer allows VS4 to better adapt to the volume change caused by the intercalation and deintercalation of Mg<2+> and Li<+>, and reduces the loss of the active substances on a current collector, thereby significantly increasing the stable cycle capacity of the cathodematerial.

Owner:BEIHANG UNIV

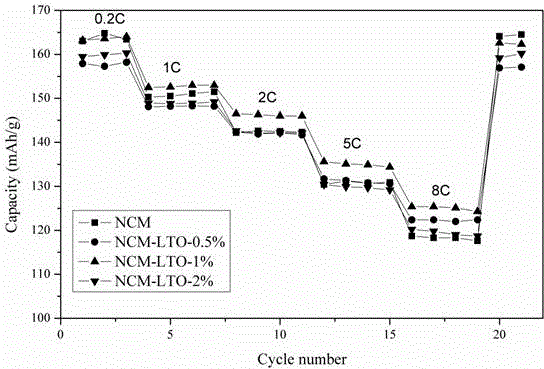

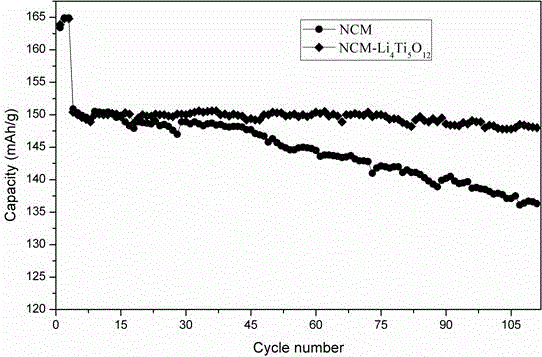

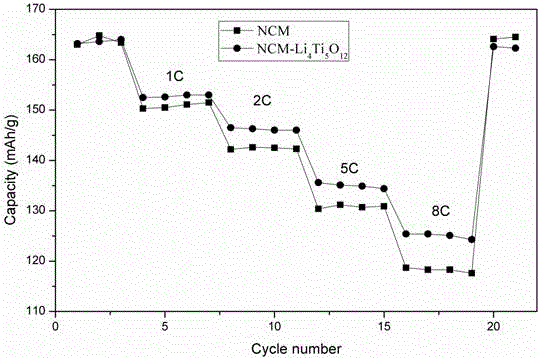

Preparation method of lithium titanate coated lithium ion battery nickel cobalt manganese cathode material

InactiveCN105789606AImprove cycle stabilityImproved magnification performanceCell electrodesBatteriesManganeseCobalt

The invention relates to the technical field of battery materials, in particular to a preparation method of the lithium titanate coated lithium ion battery nickel cobalt manganese cathode material. According to the method, the existing preparation process of the lithium ion battery cathode material is improved, a lithium titanate nanomaterial is synthesized via a sol-gel method and then dipped on a nickel cobalt manganese ternary material via a solution method, so that the composite material high in safety, good in cycling stability and high in initial coulomb efficiency is obtained. The method is simple, feasible, high in production efficiency and suitable for large-scale production, production procedures are reduced, sintering temperature is lowered, sintering time is shortened, and production cost is saved.

Owner:SHANDONG YUHUANG NEW ENERGY TECH

Carbon black modified water-based SBR lithium ion battery binder and preparation method thereof

InactiveCN108598482AHigh cycle capacityImprove cycle lifeCell electrodesSecondary cellsWater basedSodium stearate

The invention discloses a carbon black modified water-based SBR lithium ion battery binder and a preparation method thereof, and relates to the technical field of a lithium ion battery binder, whereinthe binder is prepared through the following steps: using styrene and butadiene as raw materials; bonding the conductive carbon black on an SBR molecular chain through an in-situ emulsion polymerization method, wherein the preparation method comprises adding an aqueous solution of sodium stearate to an aqueous surfactant solution to obtain an emulsified solution; then adding carbon black to disperse to obtain a carbon black emulsion system; dissolving an reducibility initiator and electrolyte in deionized water to obtain a reducing solution; adding the deionized water, the reducing solution,a molecular weight regulator SD-12 and styrene to the carbon black emulsion system, vacuumizing to the negative pressure, and then adding butadiene, cooling, and adding an oxidizing initiator to initiate a polymerization reaction. The binder of the present invention is used for battery preparation. In the case that no conductive carbon black is additionally added, the battery has a high cycle capacity, thereby increasing the additive proportion of the active material, and indirectly increasing the energy density of the battery system.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

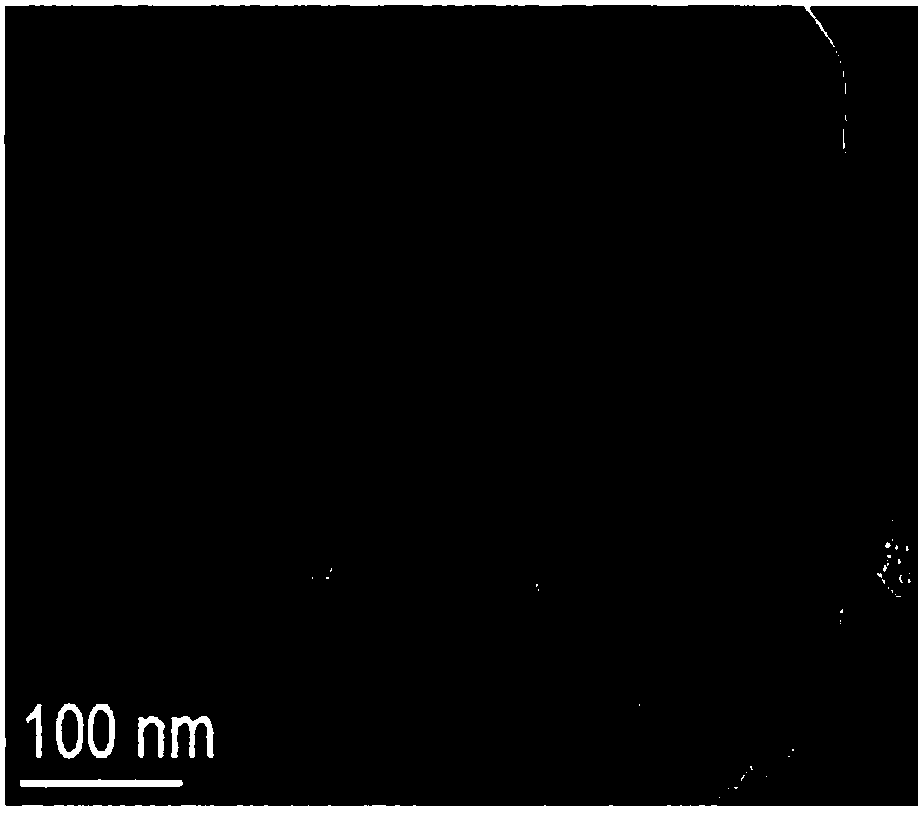

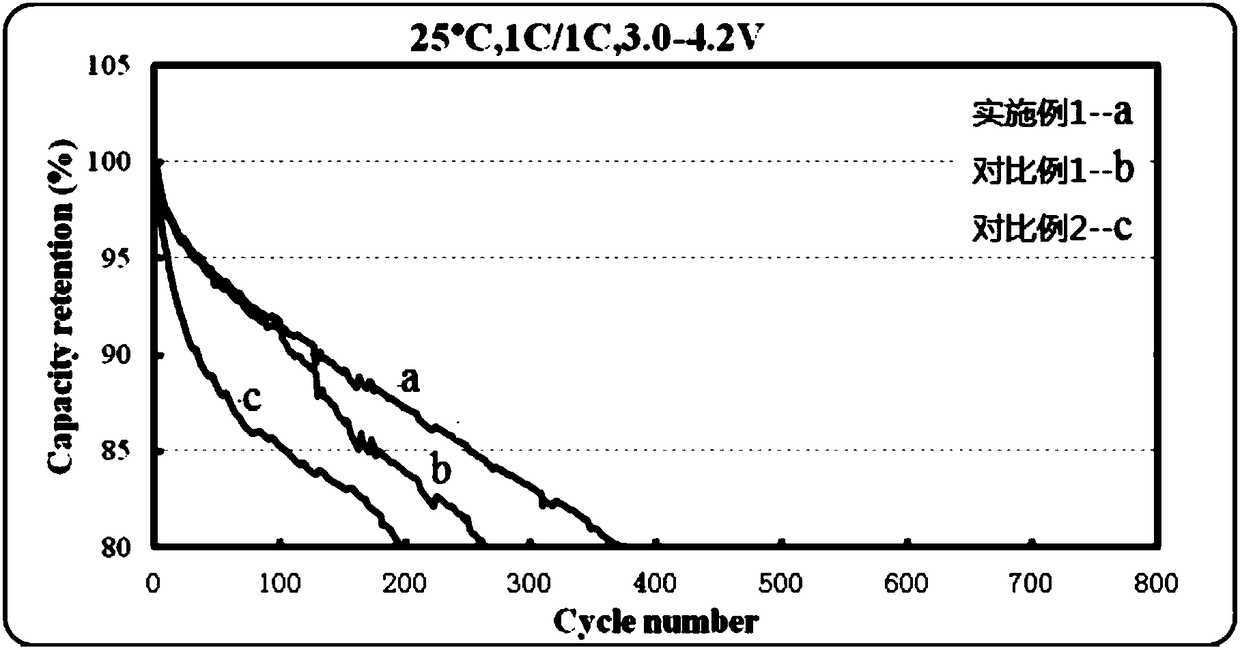

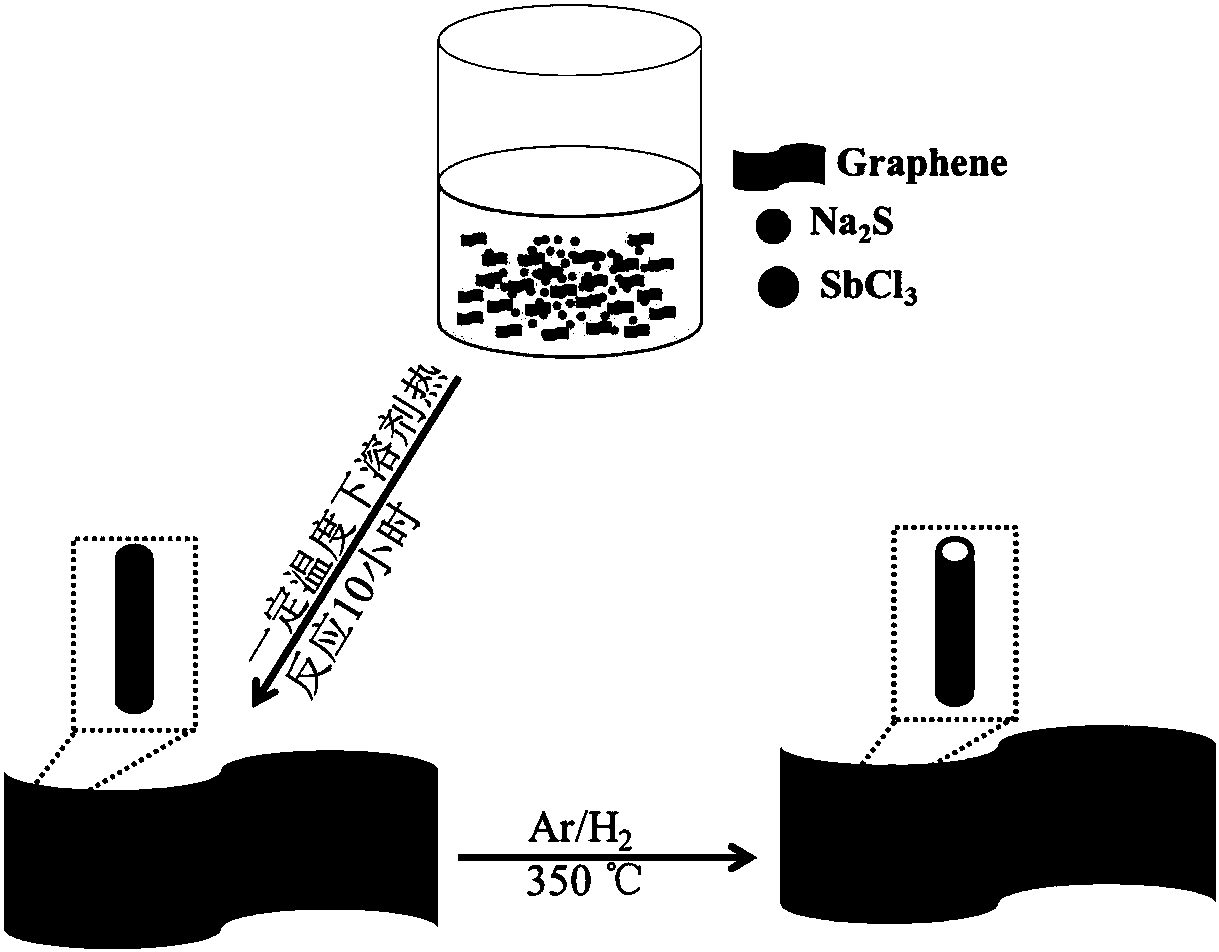

Method for preparing graphene-loaded antimony nanotube negative electrode material for sodium ion battery and application of graphene-loaded antimony nanotube negative electrode material

ActiveCN108400298AHigh cycle capacityImprove Coulombic efficiencyCell electrodesSecondary cellsSodium-ion batteryHigh pressure

The invention relates to a method for preparing a graphene-loaded antimony nanotube negative electrode material for a sodium ion battery and application of the graphene-loaded antimony nanotube negative electrode material. The preparation method comprises the steps of dissolving sodium sulfide with a certain mole ratio in ethylene glycol to obtain a solution A; dissolving antinomy chloride with acertain mole ratio in the ethylene glycol to obtain a solution B, dropwise adding the solution A into the solution B, and performing stirring to obtain a solution C; adding a graphene dispersion liquid with certain concentration into the solution C, transferring the mixed liquid to a high-pressure kettle with a polytetrafluoroethylene lining, and maintaining for a certain time under a certain temperature to obtain a synthesis product D; centrifugally separating the solvent thermal synthesis product D at 10,000rpm, washing the synthesis product D with deionized water and alcohol, and obtaininga product E after drying for 12 hours at 85 DEG C; and obtaining the graphene-loaded antimony nanotube composite material after the product E is annealed for a certain time in a mixed atmosphere of H2and Ar under a special temperature. The graphene-loaded antimony nanotube negative electrode material has the advantages of high cycle specific capacity, high coulombic efficiency and stable cycle property.

Owner:连云港鼎之材能源科技有限公司

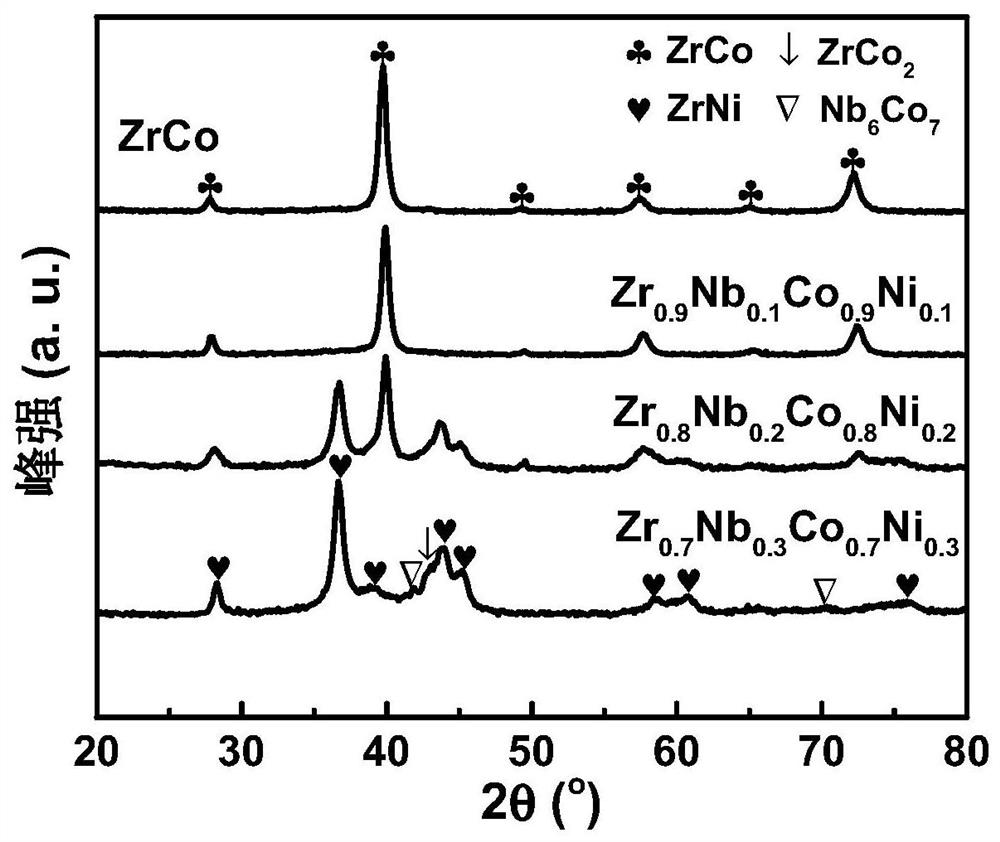

High-cycling-capacity ZrCo-based hydrogen isotope storage alloy as well as preparation and application thereof

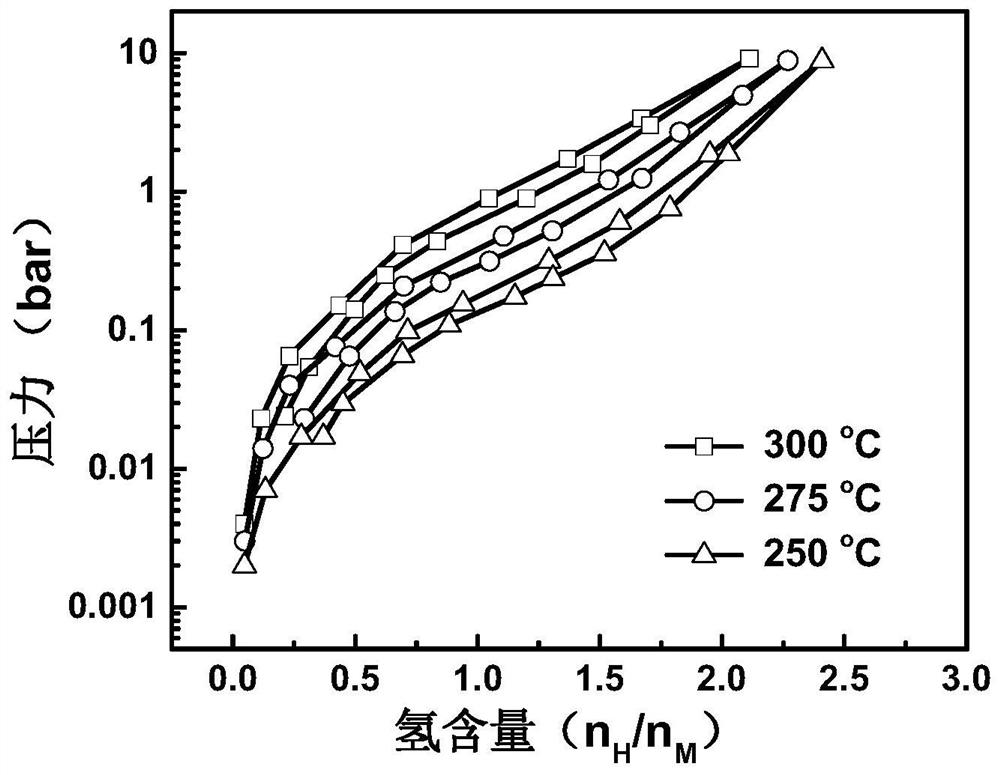

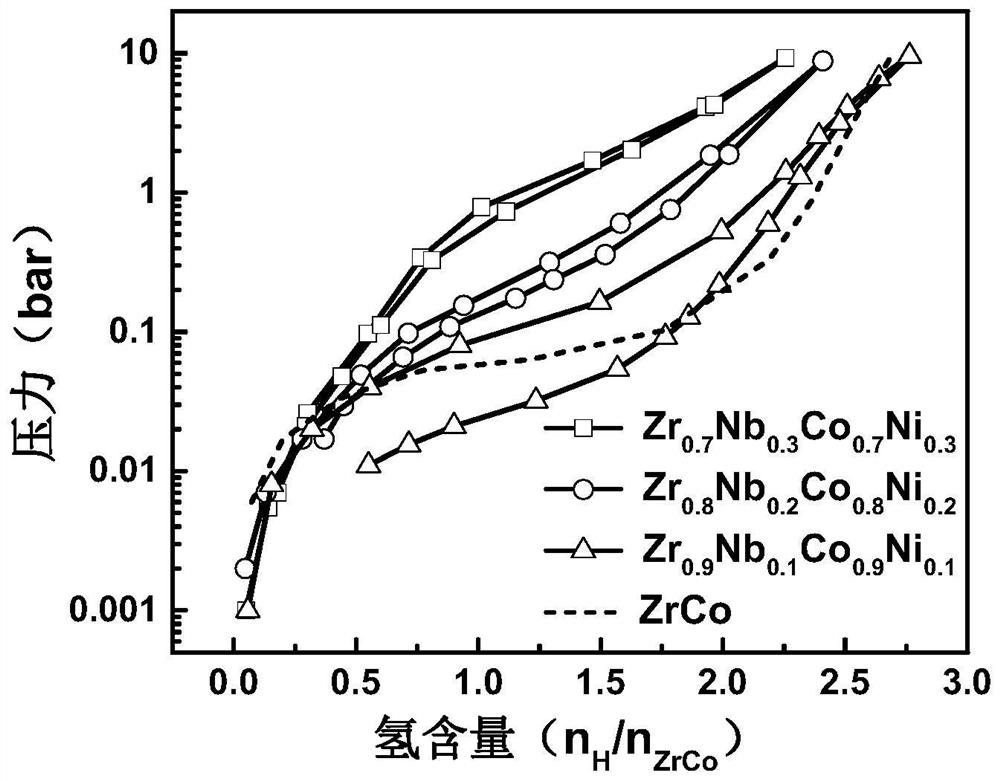

The invention discloses a high-cycling-capacity ZrCo-based hydrogen isotope storage alloy, preparation of the alloy and application of the alloy to storage, supply and recovery of hydrogen isotopes. The chemical general formula of the high-cycling-capacity ZrCo-based hydrogen isotope storage alloy is Zr(1-x)NbxCo(1-y)Niy, wherein x is larger than 0 but smaller than or equal to 0.5, and y is largerthan 0 but smaller than or equal to 0.5. A preparation method of the alloy includes the following steps that (1) Zr, Nb, Co and Ni elementary substance raw materials are mixed according to the proportion in the chemical general formula and then are placed into a magnetic suspension induction smelting furnace; and (2) smelting, cooling and solidifying are performed under the protection of an argonatmosphere to prepare the high-cycling-capacity ZrCo-based hydrogen isotope storage alloy. The method is simple in step and high in safety, the prepared hydrogen isotope storage alloy is not requiredto be subjected to vacuum operation in the circulation process, the method is still applicable in complex hydrogen isotope scenes, and the method has long-term significance in promoting application and popularization of the ZrCo-based alloy in the field of hydrogen isotope storage.

Owner:ZHEJIANG UNIV

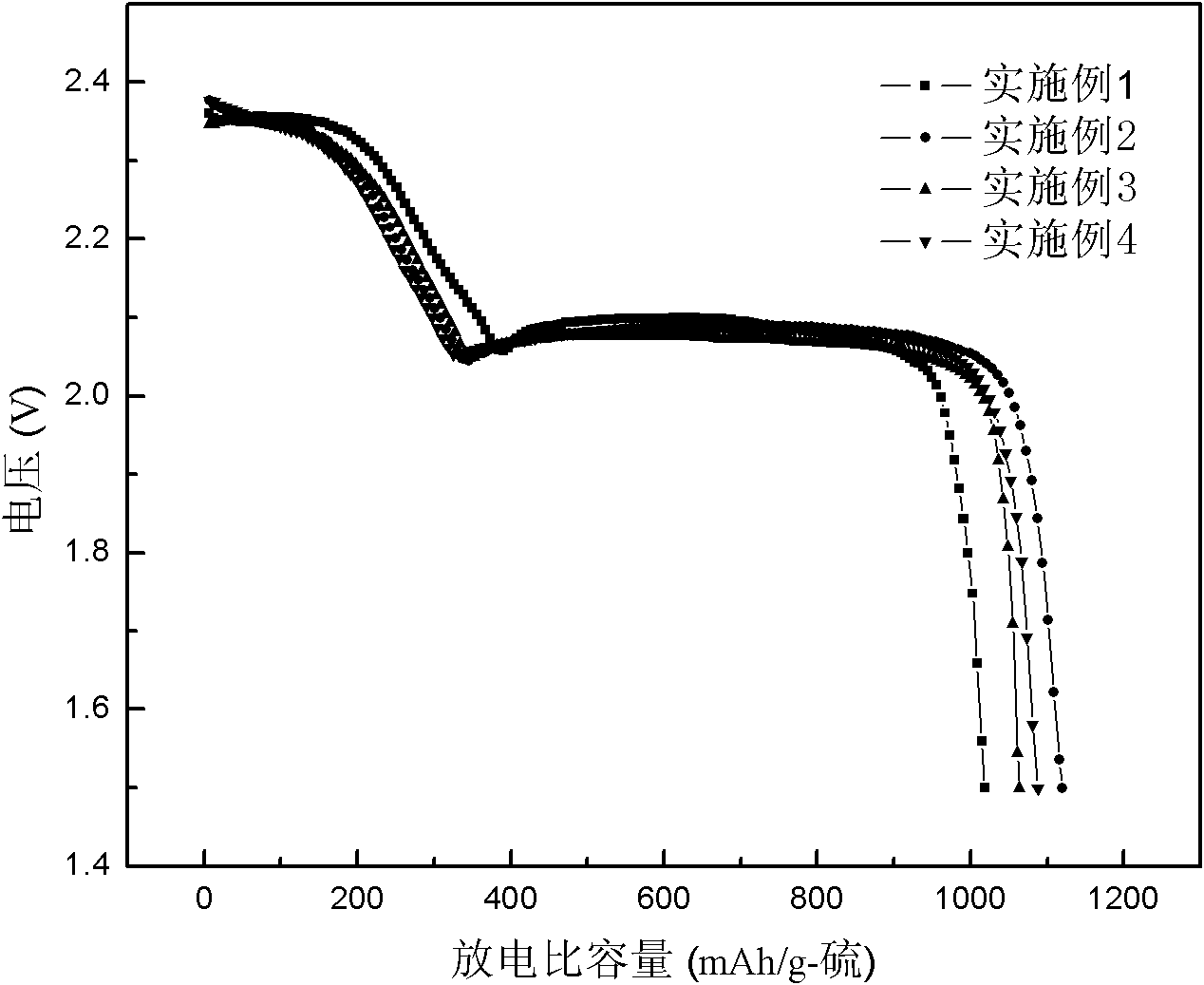

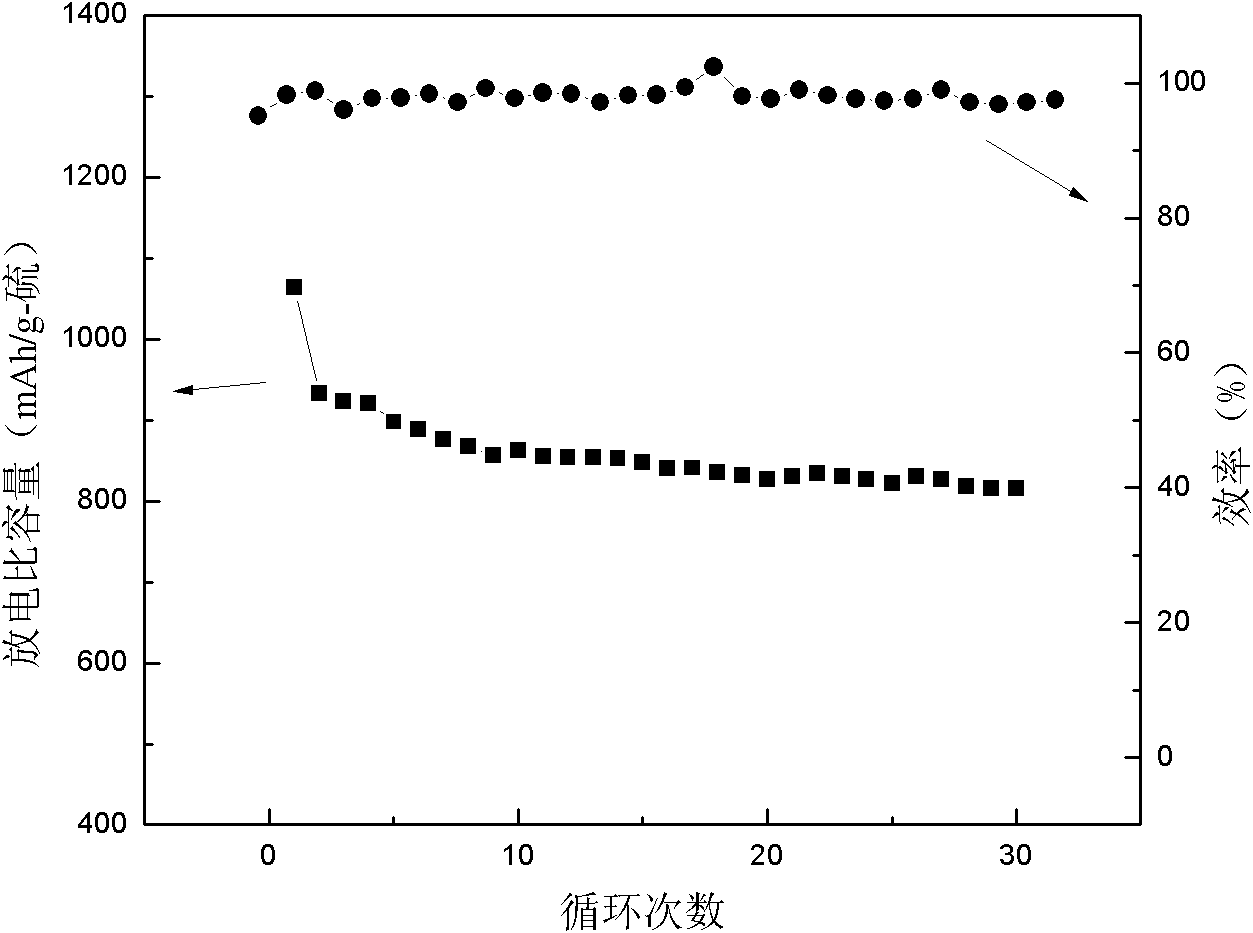

Positive pole piece of lithium-sulphur battery and preparation method thereof

ActiveCN102208599AHigh cycle capacityImprove cycle lifeElectrode carriers/collectorsNon-aqueous electrolyte accumulator electrodesAdhesiveEngineering

The invention relates to a positive pole piece of a lithium-sulfur battery based on an L-cysteine or L-cystine agent as an additive and a preparation method thereof. According to the method, based on gelatin as a binder, the L-cysteine or L-cystine additive is introduced, thus the redox property of a sulphur electrode is obviously improved, and the electrochemistry reversibility and circulation stability of the lithium-sulfur battery are significantly improved.

Owner:BEIJING UNIV OF CHEM TECH

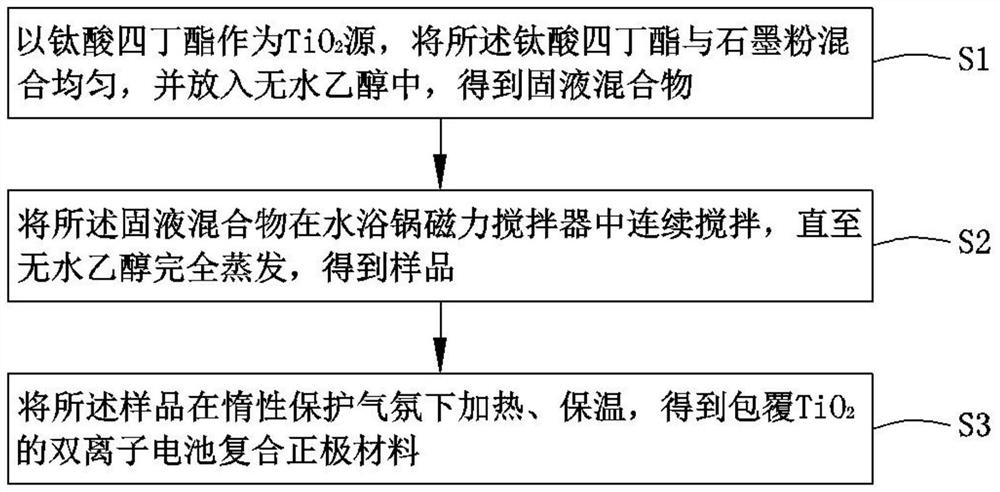

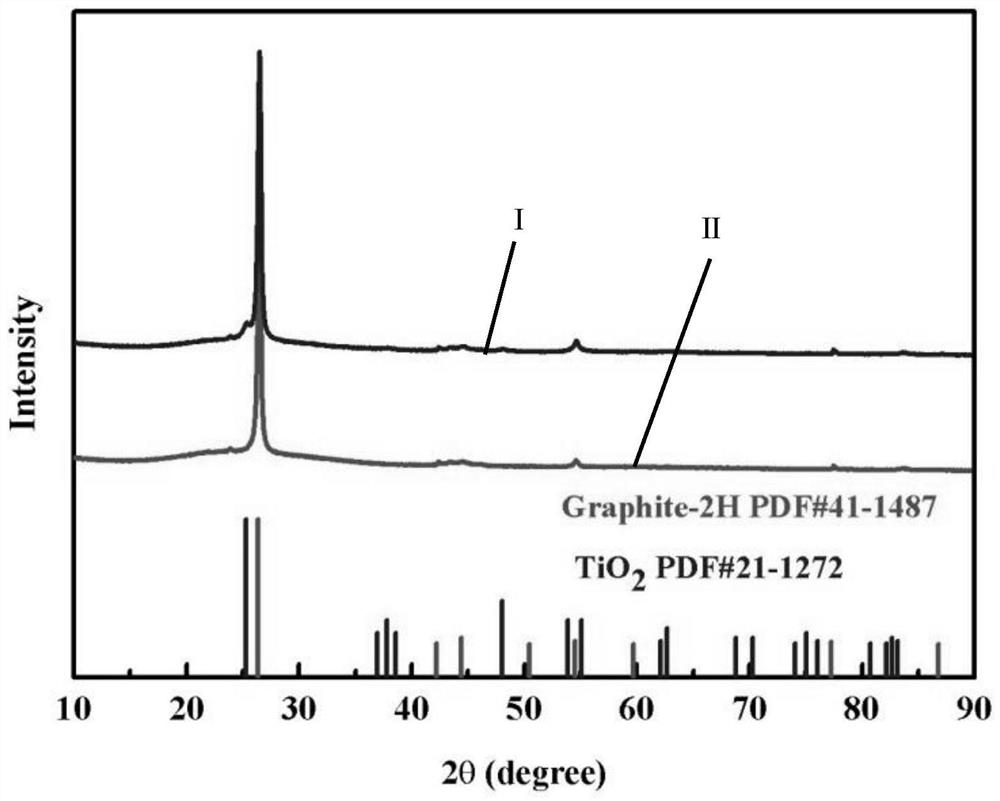

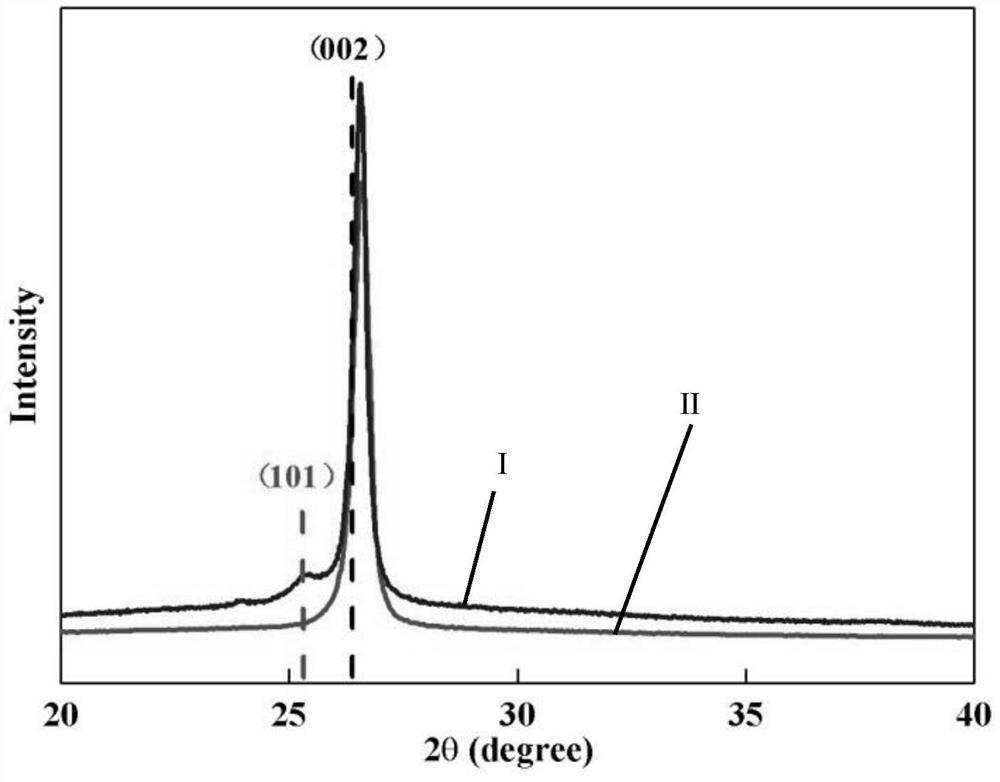

TiO2-coated graphite double-ion battery composite positive electrode material and preparation method thereof

ActiveCN111969185AImprove cycle stabilitySuppression of mechanical stressGraphiteCell electrodesGraphiteMagnetic stirrer

The invention provides a preparation method of a TiO2-coated graphite double-ion battery composite positive electrode material. The method comprises the following steps: S1, by taking tetrabutyl titanate as a TiO2 source, uniformly mixing the tetrabutyl titanate with graphite powder, and putting the mixture into absolute ethyl alcohol to obtain a solid-liquid mixture; S2, continuously stirring thesolid-liquid mixture in a magnetic stirrer of a water bath kettle until absolute ethyl alcohol is completely evaporated to obtain a sample; and S3, heating the sample in an inert protective atmosphere, and carrying out heat preservation to obtain the TiO2-coated graphite double-ion battery composite positive electrode material. The TiO2-coated graphite double-ion battery composite positive electrode material provided by the invention is relatively good in cycle performance.

Owner:HUNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com