Mesoporous vanadium dioxide nano strip material as well as preparation method and application thereof

A technology of vanadium dioxide nanometer and tape materials, which is applied in the direction of electrical components, battery electrodes, circuits, etc., can solve the problems of not having a mesoporous structure, and achieve the effects of good reproducibility, high yield, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

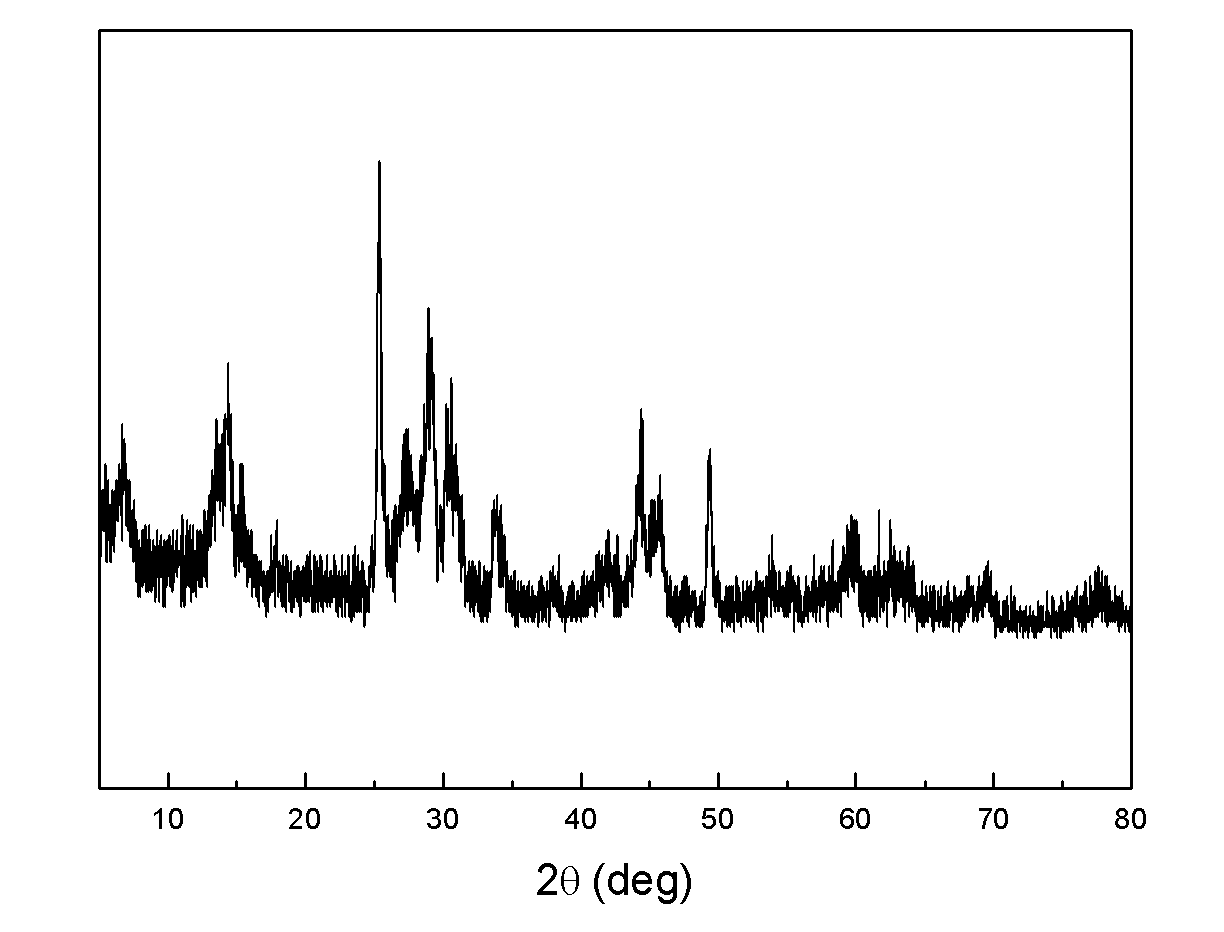

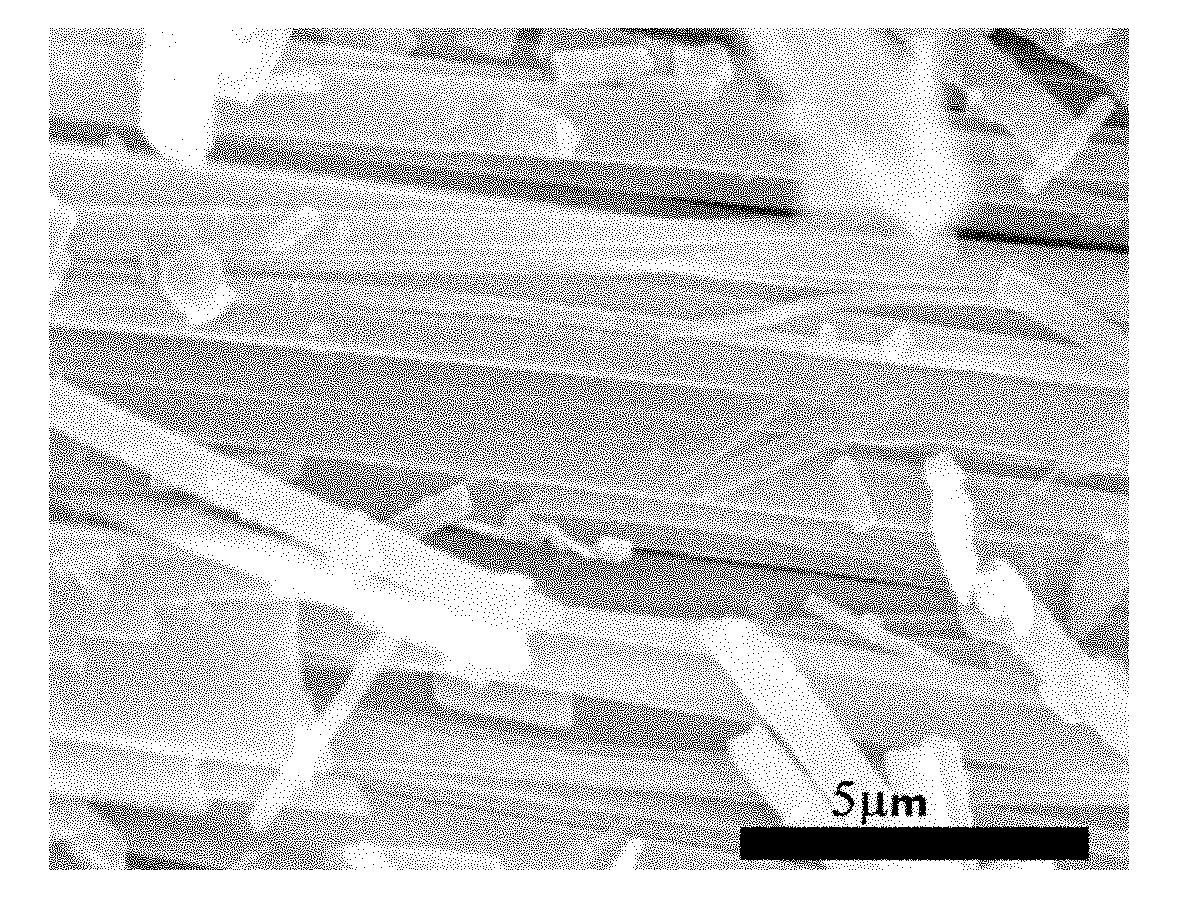

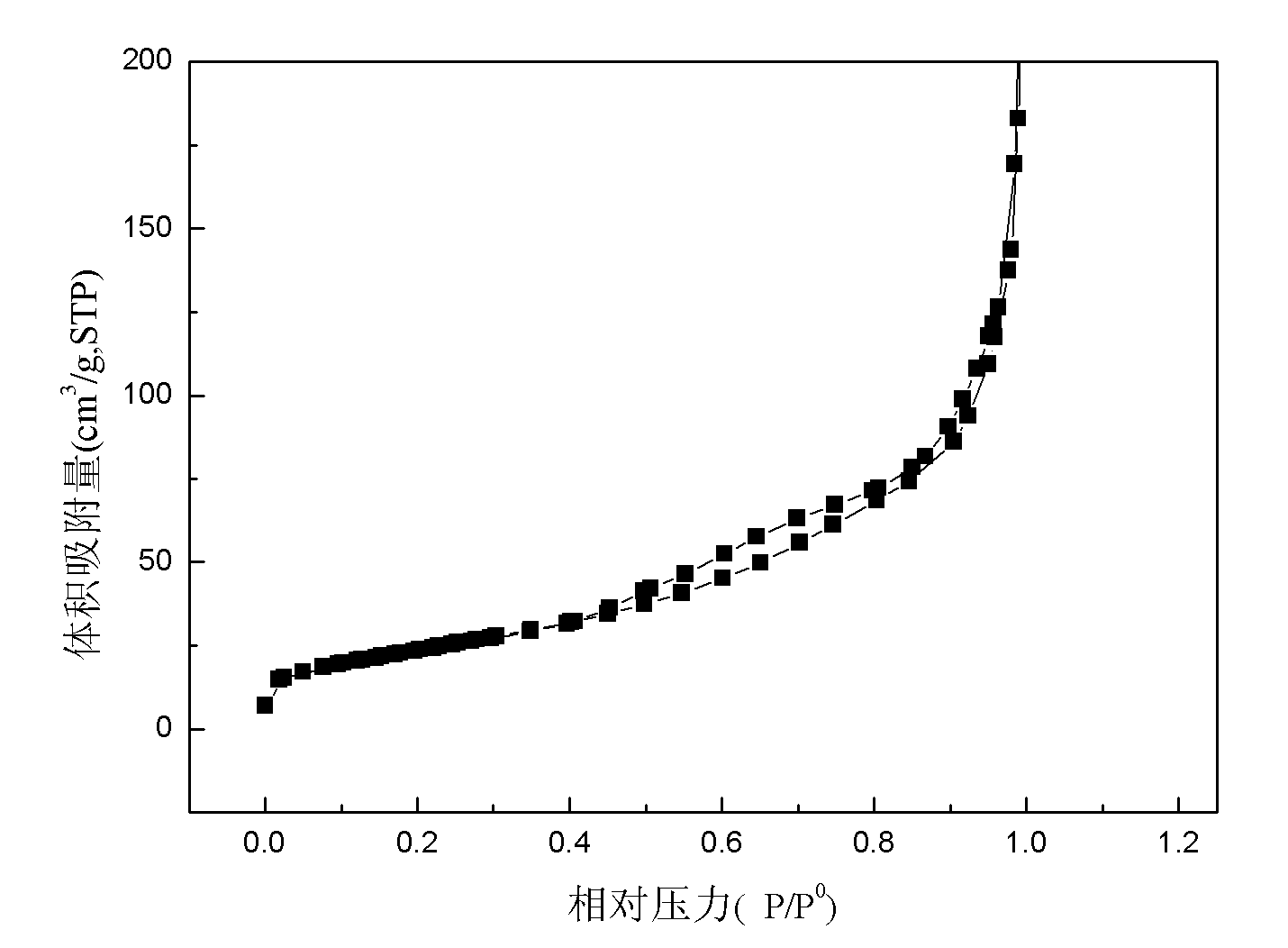

[0026] Accurately weigh 1 gram of vanadium pentoxide and 50 mL of 10% H by volume 2 o 2 Aqueous solution reaction prepares vanadium pentoxide sol; Then vanadium pentoxide sol, 0.1 gram of glucose and 0.1 gram of polyethylene glycol (PEG-2000) are mixed homogeneously and after ultrasonic dispersion 20 minutes, transfer the mixture to a polytetrafluoroethylene In an ethylene-lined reactor, react at a constant temperature of 180°C for 12 hours, cool, separate, wash with deionized water and cyclohexane three times each, and then vacuum dry at 90°C for 10 hours to obtain black mesoporous Vanadium dioxide nanoribbons. The XRD pattern of the product is shown in figure 1 ; SEM image see figure 2 , indicating that the morphology of the prepared product is nanobelt; nitrogen adsorption-desorption isotherm see image 3 , indicating that the product has a typical mesoporous substance absorption-solubility characteristic curve; the pore size distribution diagram is shown in Figure 4...

Embodiment 2

[0028] Electrode preparation and constant current charge and discharge test:

[0029] The mesoporous vanadium dioxide nanoribbon material prepared in Example 1 was used as the active material of the positive electrode material, and the positive electrode sheet of the battery was pressed according to the mass ratio of the active material, acetylene black and binder (PTFE): 80:15:5. The prepared electrode sheet is a disc with a diameter of 8mm, and is dried in a vacuum oven at 80°C for 12 hours; the negative electrode is a polished magnesium sheet; the electrolyte is 0.25mol / L Mg(AlBu 2 Cl 2 ) 2 / THF; the diaphragm is: celgard 2300. In a glove box filled with high-purity argon, the water content is less than 5ppm, and a simulated battery is assembled. The charge-discharge cycle performance graph when the charge-discharge current density is 50mA / g is shown in Figure 5 , the prepared product has better cycle stability and higher capacity when applied to magnesium secondary ba...

Embodiment 3

[0031] A mesoporous vanadium dioxide nanoribbon material is made by the following method:

[0032] (1) be the ratio of 1: 50 by mass ratio, be the hydrogen peroxide solution mixed reaction of 10% by volume percent concentration with vanadium pentoxide, make vanadium pentoxide sol;

[0033] (2) According to the mass ratio of 20:30:50, vanadium pentoxide sol, glucose and PEG-1000 were evenly mixed and ultrasonically dispersed for 20 minutes, and transferred to a reaction kettle with a polytetrafluoroethylene liner, React at a constant temperature of 100°C for 48 hours, cool, and centrifuge to separate the solid. The solid is washed with deionized water and cyclohexane in turn, and then vacuum-dried at 90°C for 5 hours to obtain a black pore size distribution mainly in 3-5 nm. mesoporous vanadium dioxide nanoribbons.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com