Method for preparing graphene-loaded antimony nanotube negative electrode material for sodium ion battery and application of graphene-loaded antimony nanotube negative electrode material

A technology for sodium ion batteries and negative electrode materials, which is applied in battery electrodes, secondary batteries, circuits, etc., and can solve problems such as poor electrode stability, particle pulverization, and capacity reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1). Add 3mmol Na 2 S·9H 2 O is dissolved in 20ml ethylene glycol to obtain solution A;

[0035] (2). Add 1mmol SbCl 3 Dissolve in 20ml ethylene glycol to obtain solution B;

[0036] (3). Add solution B dropwise to solution A and stir to obtain solution C;

[0037] (4). 2ml concentration of 1mg / ml graphene dispersion was added to solution C and transferred to a polytetrafluoroethylene-lined autoclave, and synthesized product D was obtained after maintaining at 120°C for 3h;

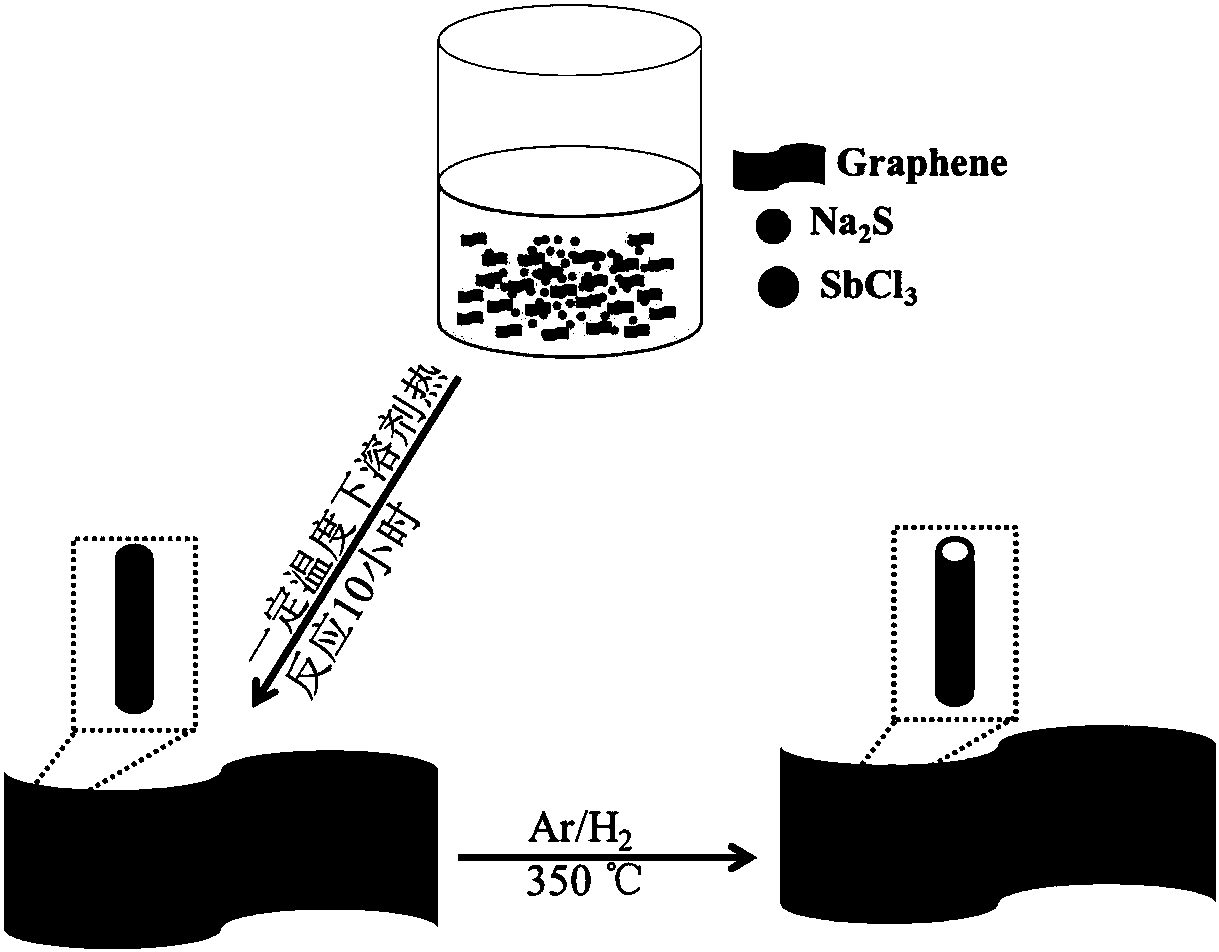

[0038] (5). The product D was synthesized by solvothermal reaction at 120°C for 10 hours, centrifuged at 10,000 rpm, washed with deionized water and ethanol, and dried at 85°C for 12 hours to obtain product E;

[0039] (6). Product E in H 2 Annealed at 350 °C for 12 h in a mixed atmosphere with Ar to obtain graphene-supported antimony nanotube composites. (Such as figure 1 shown)

[0040] Gained graphene-supported antimony nanotube composite material is used as a sodium-ion battery negative...

Embodiment 2

[0043] (1) Add 3mmol Na 2 S·9H 2 O is dissolved in 20ml ethylene glycol to obtain solution A;

[0044] (2) 2mmolSbCl 3 Dissolve in 20ml ethylene glycol to obtain solution B;

[0045] (3) Add solution B dropwise to solution A and stir to obtain solution C;

[0046] (4) 2ml concentration of 1mg / ml graphene dispersion was added to solution C and transferred to a polytetrafluoroethylene-lined autoclave, kept at 120°C for 3h to obtain synthetic product D;

[0047] (5) The synthesized product D was synthesized by solvothermal reaction at 120°C for 10 hours, centrifuged at 10,000 rpm, washed with deionized water and ethanol, and dried at 85°C for 12 hours to obtain product E;

[0048] (6) The product E is in H 2 Or annealing at 350° C. for 12 h in an Ar atmosphere to obtain a graphene-supported antimony nanotube anode material.

[0049] Gained graphene loaded antimony nanotube negative electrode material electrochemical test method is as follows:

[0050] A button cell is used...

Embodiment 3

[0052] (1) Add 3mmol Na 2 S·9H 2 O is dissolved in 20ml ethylene glycol to obtain solution A;

[0053] (2) 3mmolSbCl 3 Dissolve in 20ml ethylene glycol to obtain solution B;

[0054] (3) Add solution B dropwise to solution A and stir to obtain solution C;

[0055] (4) 2ml concentration of 1mg / ml graphene dispersion was added to solution C and transferred to a polytetrafluoroethylene-lined autoclave, kept at 120°C for 3h to obtain synthetic product D;

[0056](5) The synthesized product D was synthesized by solvothermal reaction at 200°C for 10 hours, centrifuged at 10,000 rpm, washed with deionized water and ethanol, and dried at 85°C for 12 hours to obtain product E;

[0057] (6) The product E is in H 2 Or annealing at 350° C. for 12 h in an Ar atmosphere to obtain a graphene-supported antimony nanotube anode material.

[0058] Gained graphene loaded antimony nanotube negative electrode material electrochemical test method is as follows:

[0059] A button cell is used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com