Carbon black modified water-based SBR lithium ion battery binder and preparation method thereof

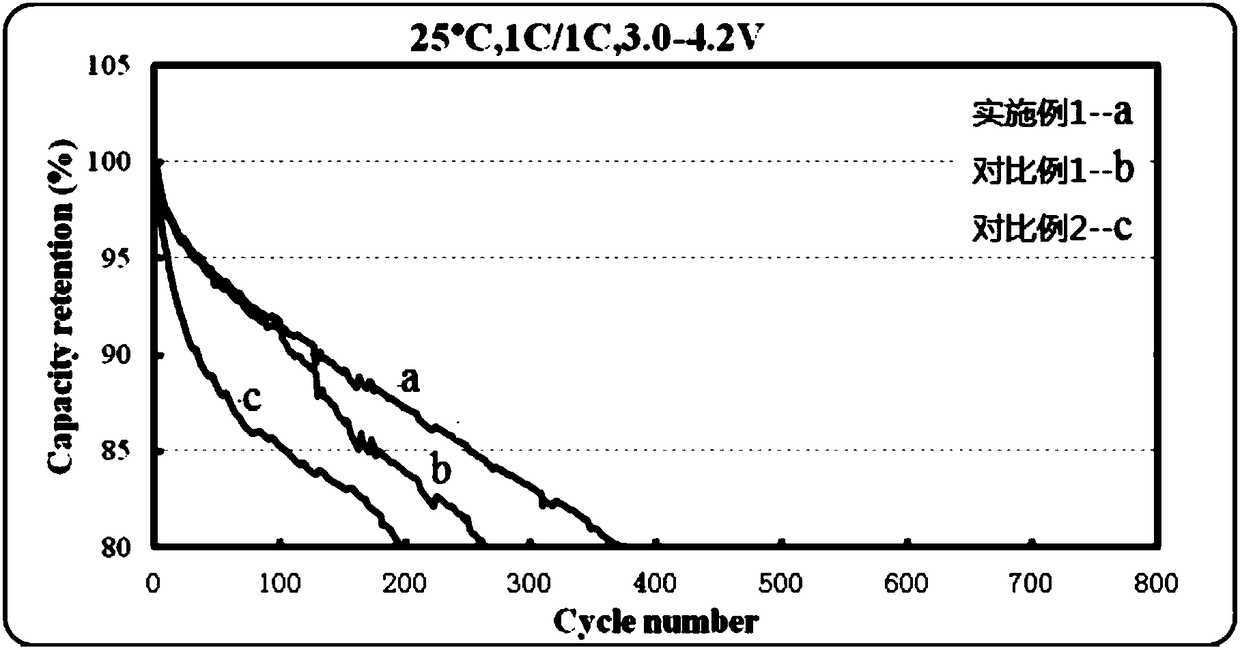

A lithium-ion battery and binder technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as unfavorable large-scale application, a large amount of manpower and material resources, and long time period, so as to prevent powder loss and increase energy density , long cycle life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The present invention proposes a kind of preparation method of carbon black modified water system SBR lithium ion battery binder, comprises the following steps:

[0026] S1. Add 9.45g of sodium stearate to 186g of deionized water, and stir at 60°C until completely dissolved, add 92.1g of disproportionated potassium abietate into 400g of deionized water and stir until fully dissolved, and then dissolve the dissolved hard The sodium fatty acid solution is poured into the disproportionated potassium rosinate solution, and stirred in a water bath at 50°C, and this part of the solution is used as an emulsified solution;

[0027] S2. Slowly add 100g super P into the emulsified solution, and use a shearing machine to shear and disperse for about 30 minutes to fully emulsify super P;

[0028] S3. Add 0.06g of ferrous sulfate, 0.2111g of white block, 0.2015g of disodium EDTA, 3.0102g of potassium chloride, and 0.0914g of sodium hydrosulfite into 50g of deionized water in turn, s...

Embodiment 2

[0031] The present invention proposes a kind of preparation method of carbon black modified water system SBR lithium ion battery binder, comprises the following steps:

[0032] S1. Add 3g of sodium stearate into 150g of deionized water, and stir at 60°C until completely dissolved, add 20g of sodium dodecylbenzenesulfonate into 150g of deionized water and stir until fully dissolved, and then dissolve well The sodium stearate solution is poured into the sodium dodecylbenzenesulfonate solution, and stirred in a water bath at 30°C, and this part of the solution is used as an emulsified solution;

[0033] S2. Slowly add 20 g of acetylene black into the emulsified solution, and use a shearing machine to shear and disperse for about 20 minutes to fully emulsify the acetylene black;

[0034] S3. Add 0.01g of ferrous sulfate, 0.0750g of disodium EDTA, and 1.0100g of potassium chloride to 20g of deionized water in turn, stir until completely dissolved, and record this solution as the re...

Embodiment 3

[0037] The present invention proposes a kind of preparation method of carbon black modified water system SBR lithium ion battery binder, comprises the following steps:

[0038] S1. Add 15g of sodium stearate into 300g of deionized water, and stir at 60°C until completely dissolved, add 160g of CTAB into 700g of deionized water and stir until fully dissolved, then pour the dissolved sodium stearate solution into into the CTAB solution, and stirred in a water bath at 80°C, this part of the solution is used as an emulsified solution;

[0039] S2. Slowly add 200g KS-6 into the emulsified solution, and use a shearing machine to shear and disperse for about 40 minutes to fully emulsify KS-6;

[0040]S3, sequentially add 0.2g sodium bisulfite, 4g saffron, 5g disodium EDTA, 20g potassium chloride, 1g sodium sulfate into 400g deionized water, stir until completely dissolved, and record this solution as reducing base solution;

[0041] S4, sequentially add 200g deionized water, reducin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com