TiO2-coated graphite double-ion battery composite positive electrode material and preparation method thereof

A composite cathode material, dual-ion technology, applied in battery electrodes, graphite, secondary batteries, etc., can solve the problems of electrolyte viscosity increase, affecting the fast charge and discharge performance of dual-ion batteries, etc., to improve cycle stability, excellent High current charge and discharge performance, reducing the effect of crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

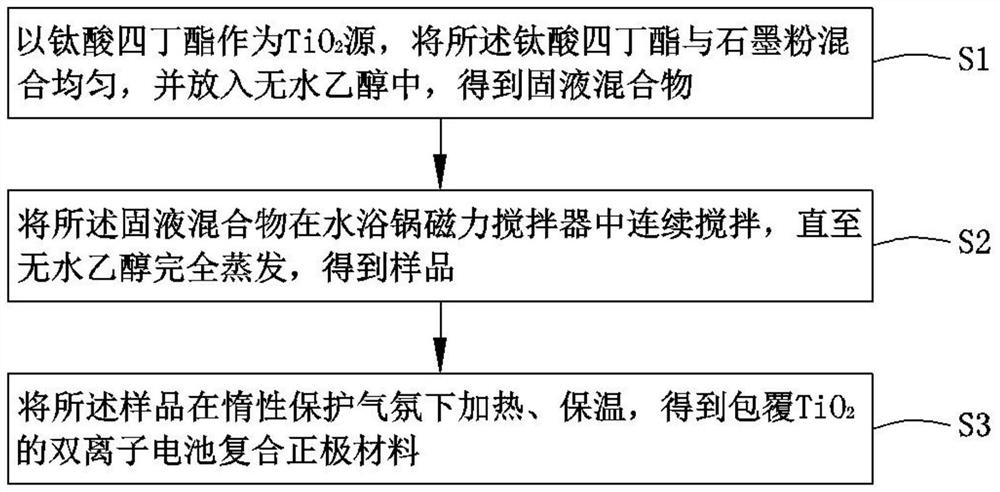

[0031] see figure 1 , the present invention provides the present invention provides a coated TiO 2 The preparation method of graphite double-ion battery composite cathode material comprises the steps:

[0032] S1: Using tetrabutyl titanate as TiO 2 source, mix the tetrabutyl titanate and graphite powder evenly, and put them into absolute ethanol to obtain a solid-liquid mixture;

[0033] S2: Stir the solid-liquid mixture continuously in a water bath with a magnetic stirrer until the absolute ethanol is completely evaporated to obtain a sample;

[0034] S3: The sample is heated and kept warm under an inert protective atmosphere to obtain a coated TiO 2 Graphite composite cathode material for dual-ion batteries.

[0035] Preferably, the mass ratio of tetrabutyl titanate to graphite powder is (0.05-0.15):1.

[0036] Preferably, the temperature of the water bath in the step S2 is 40-70°C.

[0037] Preferably, the heating temperature in the step S4 is 400°C-600°C, and the hol...

Embodiment 1

[0040] Mix tetrabutyl titanate and graphite powder according to the mass ratio of 0.15:1 and put them into an appropriate volume of absolute ethanol, place it in a 60°C water bath and continue magnetic stirring until the absolute ethanol is completely evaporated; the collected The sample was carbonized at 600°C for 3 hours in an argon atmosphere to obtain coated TiO 2 Graphite composite cathode material for dual-ion batteries.

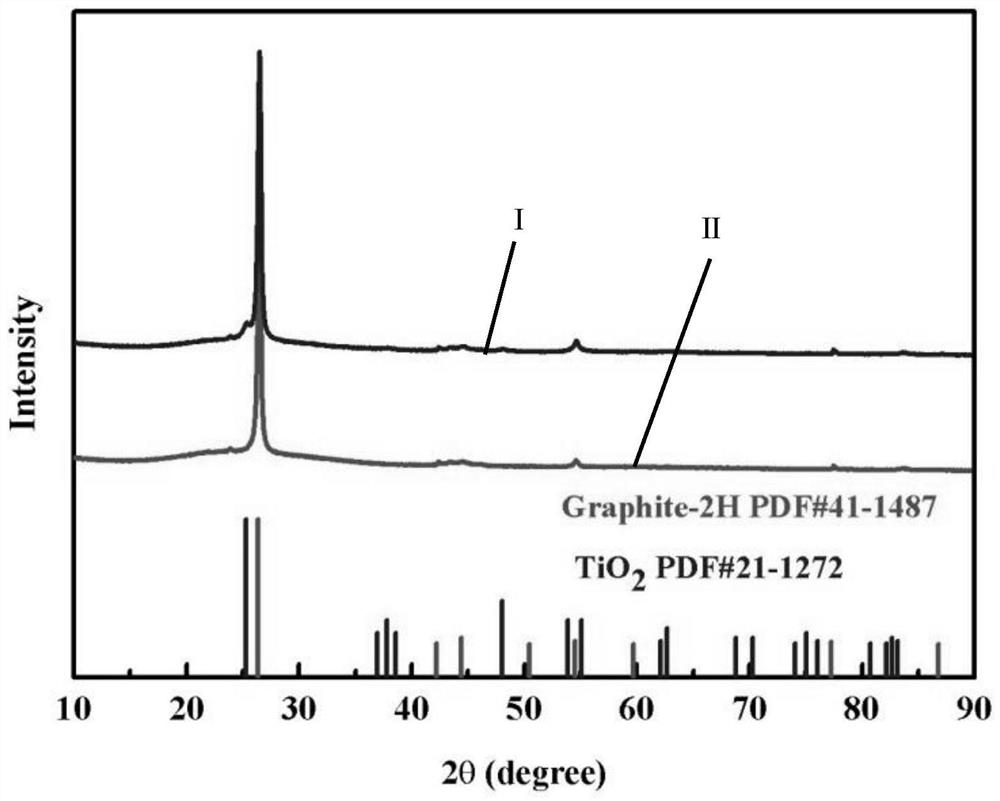

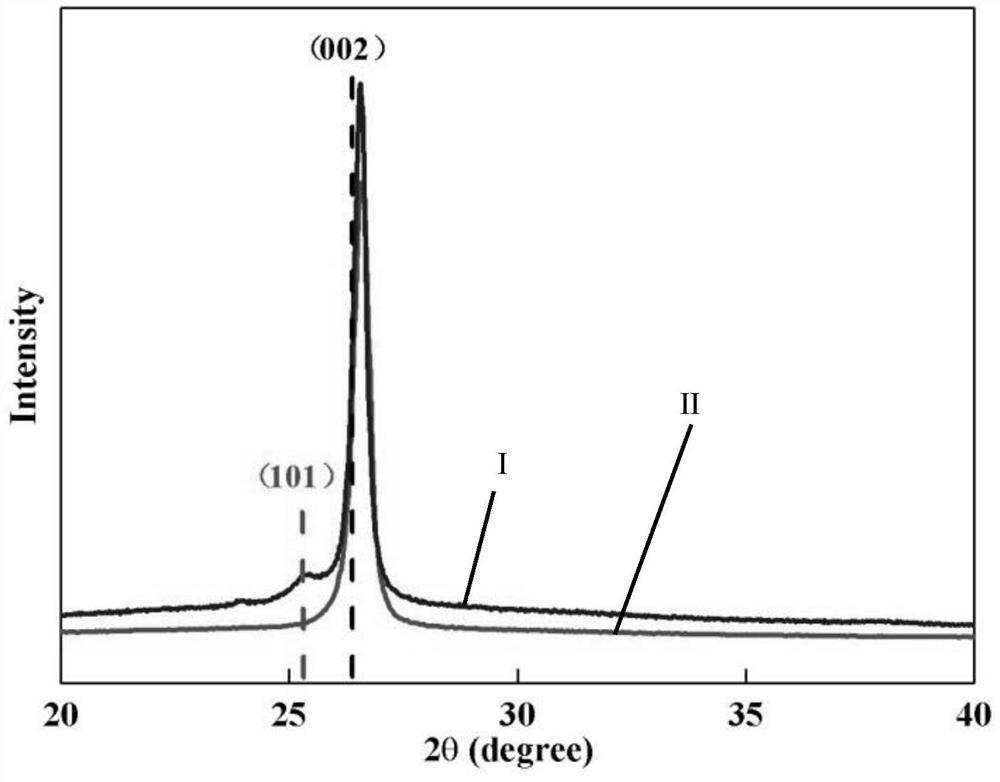

[0041] Figure 2(a) shows the coated TiO 2 Composite cathode materials for graphite dual-ion batteries and uncoated TiO 2 The X-ray diffraction spectrum (XRD) contrast figure of the graphite double-ion battery cathode material of the present invention, wherein graph I is coated TiO 2 The X-ray diffraction spectrum (XRD) figure of the graphite dual-ion battery composite positive electrode material; Curve II is uncoated TiO 2 The X-ray diffraction spectrum (XRD) pattern of graphite dual-ion battery cathode material. Uncoated TiO 2 The graphite dual-i...

Embodiment 2

[0047] Mix tetrabutyl titanate and graphite powder according to the mass ratio of 0.05:1 and put them into an appropriate volume of absolute ethanol, place it in a 40°C water bath and continue magnetic stirring until the absolute ethanol evaporates; collect the obtained The sample was carbonized at 400°C for 6 hours in an argon atmosphere to obtain coated TiO 2 Graphite composite cathode material for dual-ion batteries.

[0048] Figure 3(a) is the coated TiO 2 SEM topography of graphite dual-ion battery composite cathode material, TiO 2 The nanoparticles are uniformly coated on the graphite surface. Figure 3(b) shows the coated TiO 2 The cycle performance diagram of graphite dual-ion battery composite positive electrode material at 2C current density, where curve I is coated TiO 2 The Coulombic efficiency curve of graphite dual-ion battery composite positive electrode material; Curve II is coated TiO 2 The charging capacity curve of graphite dual-ion battery composite cat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com