Patents

Literature

196results about How to "Not easy to lose powder" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

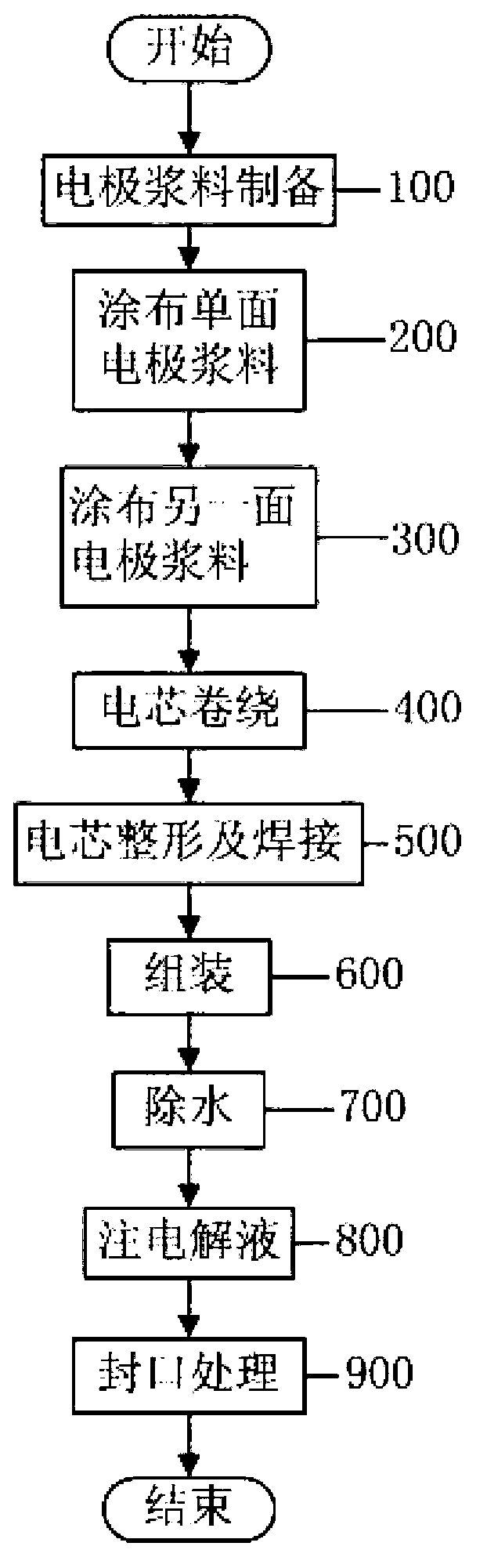

A making method for anode slice of lithium ion battery

InactiveCN101241988AImprove adhesionHigh bonding strengthElectrode manufacturing processesActive material electrodesAdhesivePhysical chemistry

The present invention discloses a method for manufacturing a positive pole piece of the lithium ion battery, and the method comprises coating the positive material adhesive on the collector after mixing, and at the same time substituting the single adhesive in the conventional method with two or more than two adhesives with different magnitude of molecular weight. The method of the invention effectively increases the binding adhesive force of the positive pole piece after coating, further the processing capabilities of coating surface density of the pole piece, compacted density and flexibility can be further increased, and effectively realize the advancing of the battery capability and the optimizing of the capability.

Owner:SHENZHEN BAK BATTERY CO LTD

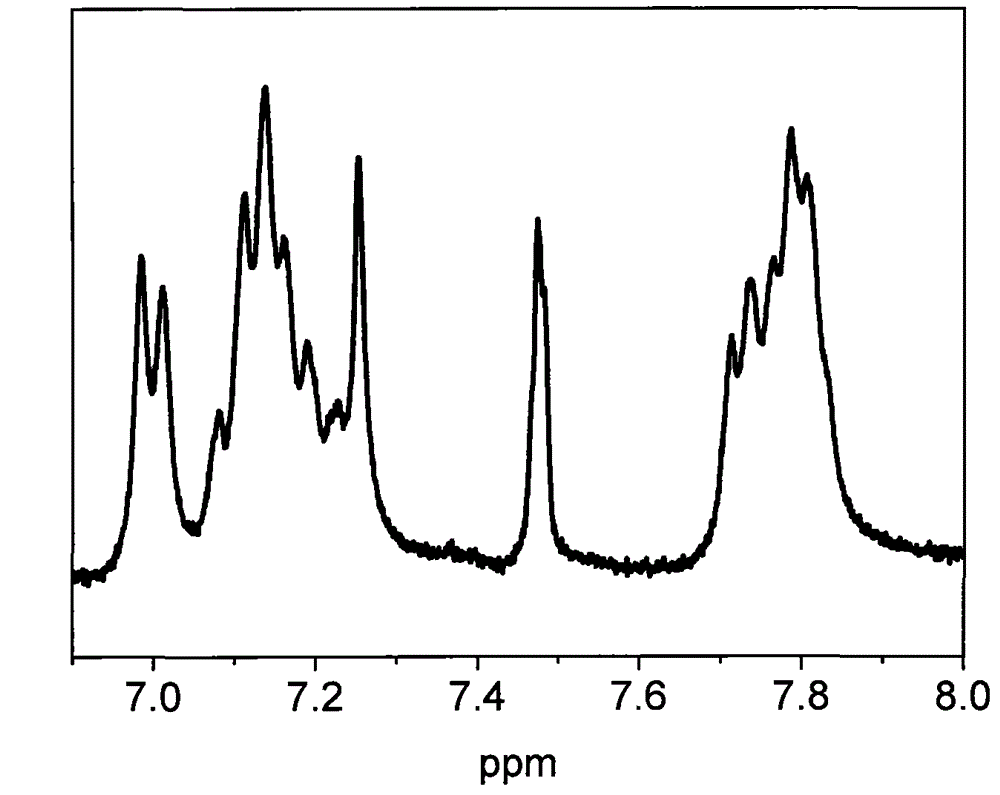

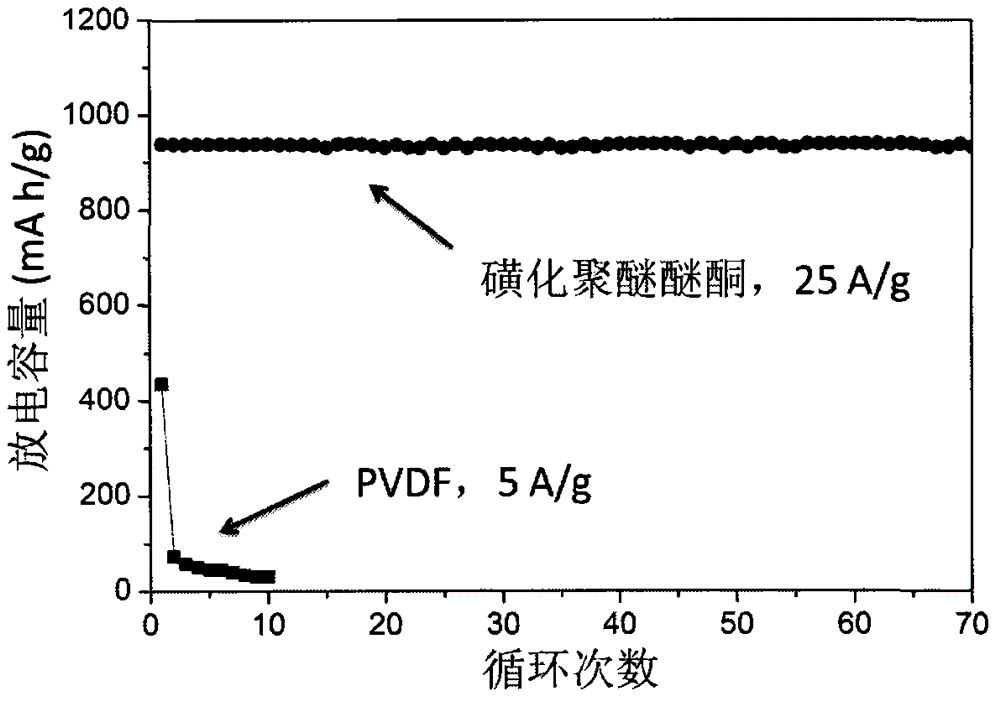

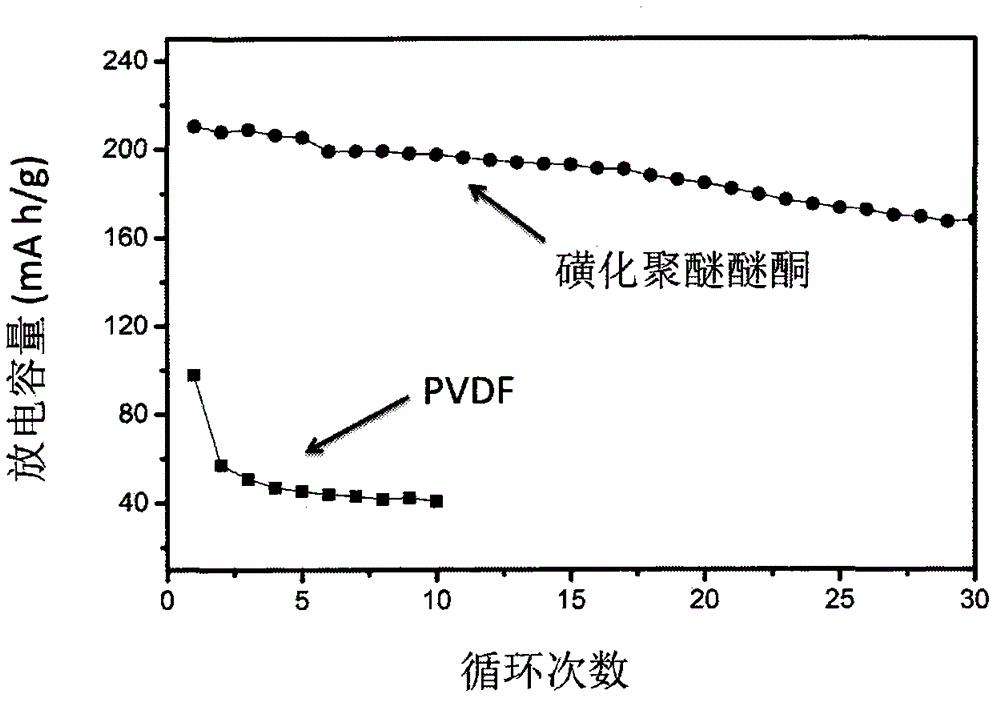

Sulfonated polymer applied to lithium battery electrode as binder

ActiveCN104466112AHigh performance featuresHigh rate characteristicsSecondary cellsNon-aqueous electrolyte accumulator electrodesHigh current densitySulfonated polymer

The invention relates to a sulfonated polymer applied to a lithium battery electrode as a binder as well as a method for preparing the lithium battery electrode. The sulfonated polymer is used as the binder in electrode slurry of the lithium battery electrode, the obtained lithium battery electrode is used for assembling a lithium battery, and the lithium battery is relatively long in charging-discharge cycle life and stable in work under a relatively high current density. The sulfonated polymer with a sulfonic acid group has excellent capacity of transferring lithium ions, so that the lithium ions can be rapidly transmitted back and forth between an electrode active material and an electrolyte, and the lithium battery which is stable to run under the rapid charging-discharging condition can be obtained. The sulfonated polymer which is used as the binder is sufficient in cohesion force and binding strength, and the electrode active material and a conductive medium are stuck onto a current collector by the sulfonated polymer and are unlikely to fracture and dust, so that the lithium battery has sufficient capacity and cycle performance as well as excellent rate capacity.

Owner:BEIJING NATURE STONE SCI TECH DEVP

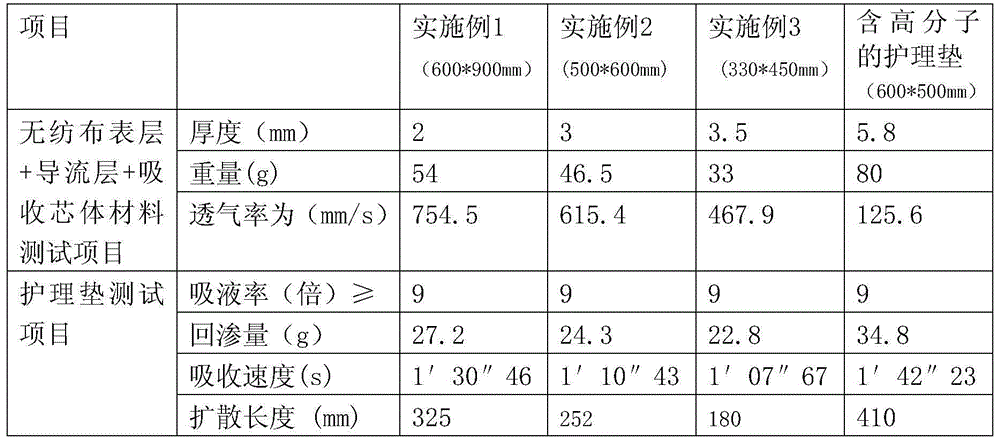

Portable nursing pad containing polylactic acid fiber and preparation method thereof

ActiveCN104002527ANot easy to lose powderEasy to operateSynthetic resin layered productsLaminationPolylactic acidMaterial resources

The invention discloses a portable nursing pad containing a polylactic acid fiber and a preparation method thereof. A conventional nursing pad has a relatively long processing flow, and the long production process wastes a lot of manpower, material resources and financial resources. The nursing pad is composed of an upper-layer assembly body and an impermeable bottom layer, wherein the upper-layer assembly body is composed of a surface layer composed of a polylactic acid fiber net, a flow-guiding moisture-absorption layer composed of a water-repellency bicomponent fiber and a superabsorbent fiber net, and an absorption layer composed of a hydrophilic bicomponent fiber and a superabsorbent fiber net, and the three layers are subjected to hot melt compounding to form a whole; the upper layer and the impermeable bottom layer are subjected to hot melt adhesive compounding to form a whole. The prepared nursing pad has the characteristics of short process flow, good molding, bacteriostasis, deodorness, gas permeation and dryness, does not produce lumps and allows powder not to fall off in a use process, and is an ideal material for preparing disposable medical treatment health supplies.

Owner:HANGZHOU COCO HEALTHCARE PRODS

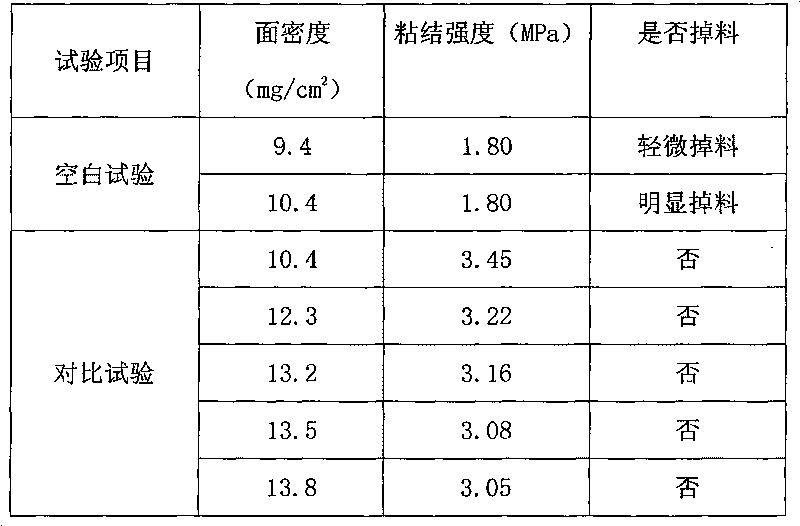

Self-assembly coating cloth or paper for treating VOCs (volatile organic compounds) like formaldehyde and preparation method thereof

ActiveCN107029552AIncrease coverageImprove bindingGas treatmentDispersed particle separationNano catalystFiber

The invention provides self-assembly coating cloth or paper for treating VOCs (volatile organic compounds) like formaldehyde and a preparation method thereof. The self-assembly coating cloth comprises a cloth substrate, an adsorption layer, a cured layer and a composite nano catalyst particle layer which are arranged layer upon layer, nanoparticles in the composite nano catalyst particle layer exist on the surface of all fiber of the cloth substrate, overall coverage rate reaches higher than 90%, and the nanoparticles in the composite nano catalyst particle layer is embedded in the cured layer partly. The composite nano catalyst particles are high in coverage rate, high in binding force with cloth fiber, sufficient in contact area with the VOCs like formaldehyde and capable of thoroughly catalyzing and decomposing the VOCs like formaldehyde.

Owner:TIANJIN RES INST FOR ADVANCED EQUIP TSINGHUA UNIV +1

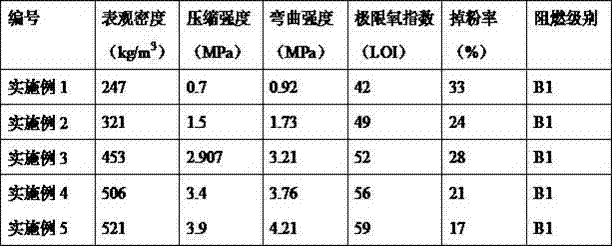

Nano modified phenolic aldehyde foam insulation board and preparation method thereof

The invention relates to a nano modified phenolic aldehyde foam insulation board and a preparation method thereof. The nano modified phenolic aldehyde foam insulation board comprises the following raw materials: 50-65 parts of phenolic resin, 20-25 parts of reactivity polyamide resin, 2-8 parts of fumed silica, 5-15 parts of liquid acrylonitrile-butadiene rubber, 4-8.5 parts of a modified surface-active agent, 9-18 parts of a toughness modifying agent, 4-10 parts of a foaming agent, 6-8 parts of a solidifying agent, and 1-5.5 parts of a catalyst promoter. The preparation method for the nano modified phenolic aldehyde foam insulation board comprises the following steps: firstly, raw materials are prepared; the raw materials are uniformly stirred; meanwhile, the solidifying agents and the catalyst promoters are added, so that the raw materials can be uniformly mixed; foaming mixture is placed on a sheet continuous production line and the temperature is kept to be 40-50 DEC G; after the foaming mixture is mixed, the foaming mixture is cross linked, expands foams and is solidified; the thermosetting phenolic resin rigid foam board is formed. According to the invention, properties of the phenolic aldehyde foam insulation boards prepared according to the technical scheme provided by the invention are improved, particularly the fire-resistant property is improved.

Owner:锦州市好为尔保温材料有限公司

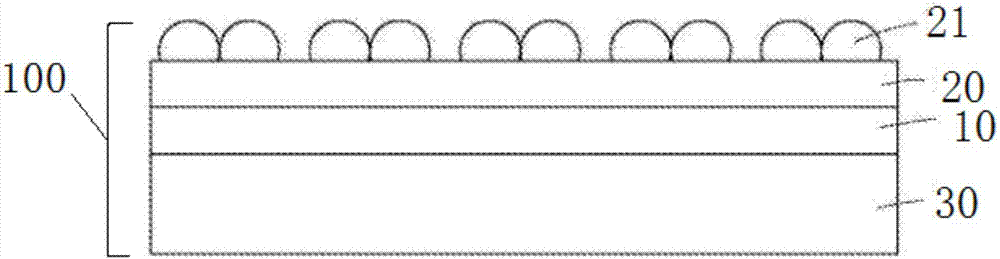

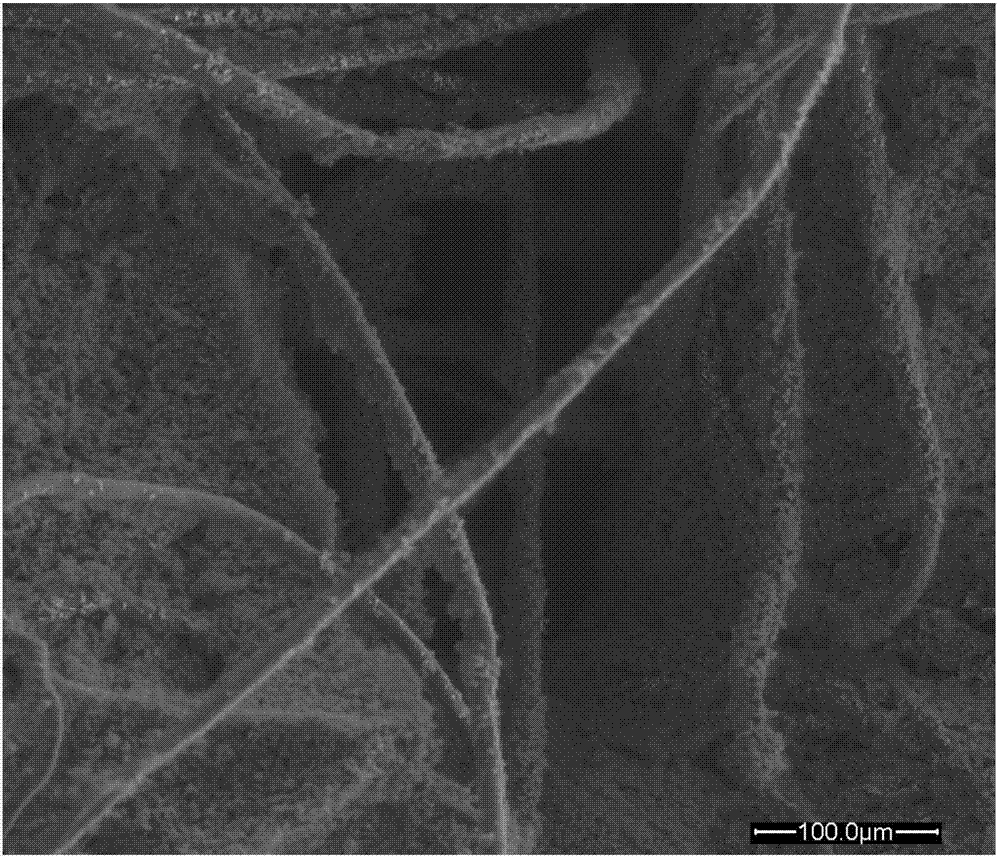

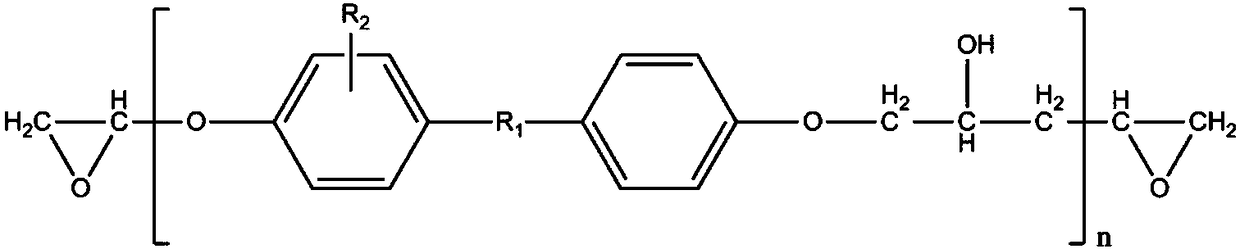

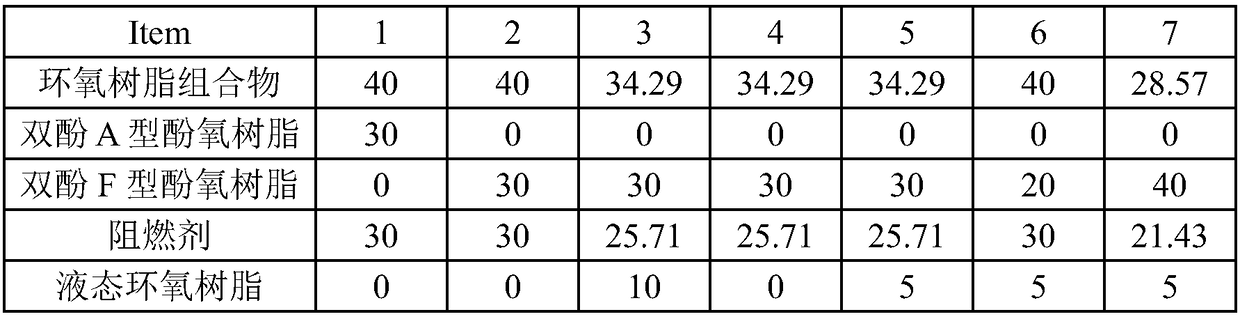

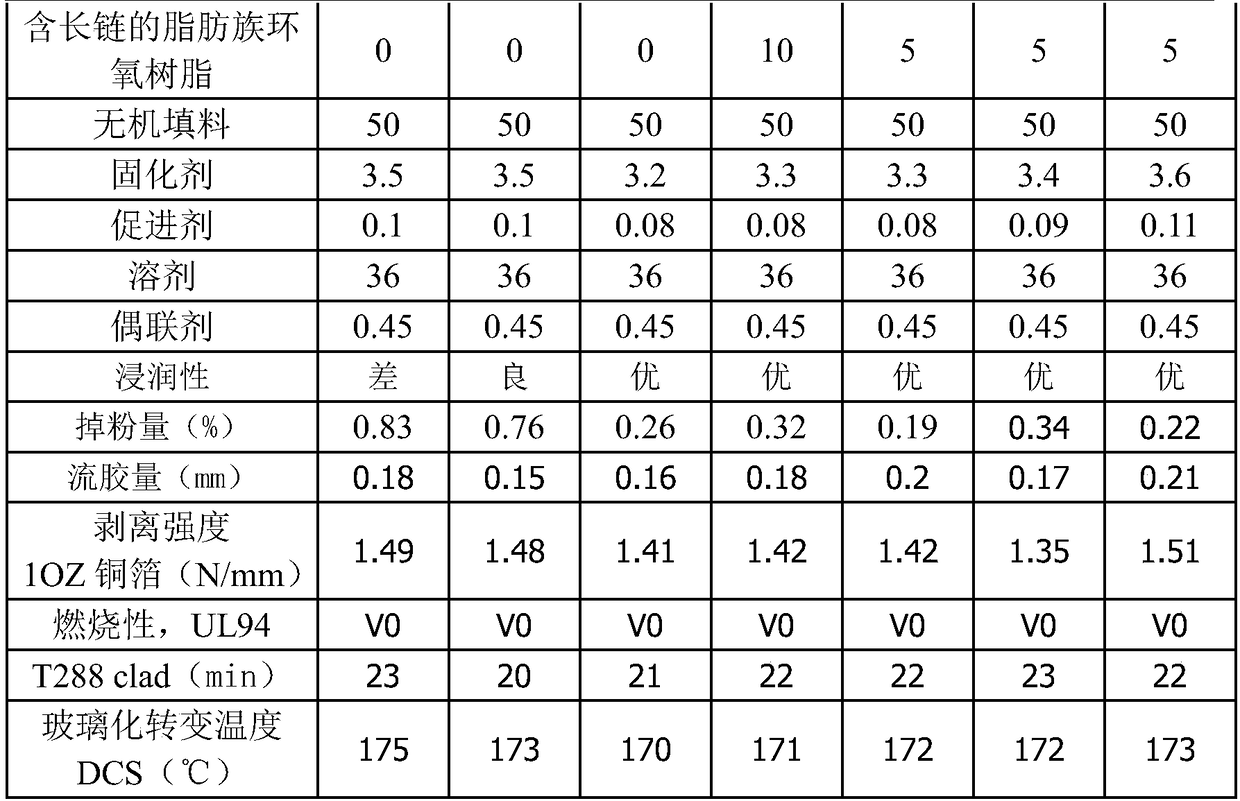

Halogen-free resin composition and low-fluidity prepreg thereof

The invention discloses a halogen-free resin composition and a low-fluidity prepreg thereof. The halogen-free resin composition comprises, by weight, 20-80 parts of an epoxy resin composition, 10-50 parts of phenoxy resin, 10-50 parts of a flame retardant, 3-30 parts of a toughening agent, 10-80 parts of an inorganic filler, 1-10 parts of a curing agent, 0-5 parts of an accelerator and 0-80 partsof an additive. The halogen-free resin composition obtained by modifying common epoxy resin with bisphenol F phenoxy resin, liquid epoxy resin and long chain-containing aliphatic epoxy resin has low viscosity and good wettability, and the low-fluidity prepreg produced from the halogen-free resin composition has the advantages of high flexibility, high Tg and bonding strength, excellent heat resistance, greenness, environmental protection, no resin dust, and realization of long-term preservation.

Owner:ZHEJIANG WAZAM NEW MATERIAL CO LTD +1

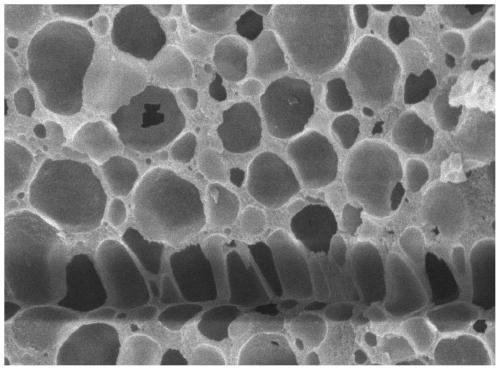

Fiber reinforced phenolic foam composite material and preparation method thereof

ActiveCN104497473AImprove fire performanceControllable cell sizePhenolformaldehyde foamFoaming agent

The invention discloses a fiber reinforced phenolic foam composite material. The fiber reinforced phenolic foam composite material is prepared from the following components in parts by weight: 10-100 parts of fiber felts, 100 parts of phenolic resin, 5-20 parts of a foaming agent, 1-6 parts of a modifier, 5-18 parts of a curing agent and 0-200 parts of a solvent. Interaction of a microsphere foaming agent, fiber felts and the modifier is adopted, so that the phenolic resin foam composite material obtained by the preparation method disclosed by the invention is not only relatively excellent in fireproof performance, but also controllable in hole diameter of foam holes; the obtained composite material is high in strength, not prone to drop powder and capable of being bent into various shapes. Domestic requirements such as fire resistance, water resistance and heat resistance can be completely satisfied, the material strength is greatly improved, and the application field of the fiber reinforced phenolic foam composite material is expanded.

Owner:镇江三阳装饰材料有限公司

Binding agent for electrode of super capacitor

InactiveCN101709204AImprove adhesionHigh bonding strengthCapacitor electrodesPolyether adhesivesSupercapacitorVolumetric Mass Density

The invention discloses a binding agent for an electrode of a super capacitor, which is made of low molecular weight binding agent and high molecular weight binding agent that have different molecular weight, wherein the low molecular weight binding agent has the molecular weight of 10,000-400,000, and the high molecular weight binding agent has the molecular weight of more than 400,000. When in electrode homogenate, by replacing the single binding agent in the traditional method by matching two or more binding agents with different molecular weight for use, the binding agent effectively improves the adhesive force and the adhesive strength of a pole piece of the electrode which is coated, enhances the flexibility of the pole piece, ensures the pole piece not to be easily cracked and fall off powder, and effectively increases the compaction density, thus effectively improving the capacity and the circulation property of the super capacitor.

Owner:NANJING SHUANGDENG SCI TECH DEV RES INST

Production method of paper pulp molded product

InactiveCN105908578ANot easy to absorb moistureNot easy to lose powderNon-fibrous pulp additionPaper/cardboardShell moldingMoisture absorption

The invention provides a production method of a paper pulp molded product with the smooth surface. The production method includes the following steps that 1, after paper pulp fibers, water and a polyacrylamide resin solution are mixed and stirred, pulp is obtained; 2, under the negative pressure condition, the pulp is sucked and dewatered, and a paper pulp molded wet blank with the water content being 60%-70% is obtained; 3, the paper pulp molded wet blank with the water content being 60%-70% is subjected to heat setting, and a paper pulp molded dry blank with the water content of 6%-10% is obtained. The production method has the advantages that the pulp is sucked and dewatered under the negative pressure condition, polyacrylamide reticular molecular structures in the pulp are centralized on the surface of the wet blank, a smooth film is formed on the surface of the pulp molded product after heat setting, and moisture absorption and powder falling are not likely to happen.

Owner:DONGGUAN DANGNA PRINTING CO LTD

Method for manufacturing organic supercapacitor electrode plate

The invention provides a method for manufacturing an organic supercapacitor electrode plate. The method comprises the following steps of: manufacturing an aluminum foil pretreatment coating, adding an adhesive into deionized water, and uniformly stirring at normal temperature; adding a conductive agent, absolute ethanol, a carbon nano tube and sodium carboxymethyl cellulose, stirring at a high speed and dispersing to obtain the coating; uniformly coating the manufactured pretreatment coating on an aluminum foil by employing a coating process, coating active substance slurry on the pretreated aluminum foil, and drying to manufacture the electrode plate. A corrosive aluminum foil is replaced by a common aluminum foil, the cost of raw materials is effectively reduced, and the production operability and stability are improved; meanwhile, after the aluminum foil is pretreated, internal resistance of the supercapacitor is greatly reduced, and high-power output performance of the product is improved.

Owner:JIANGSU FRONT NEW ENERGY

Foam insulation board with flame retardation function

InactiveCN105694253AHigh strengthReduce dosageNon-macromolecular adhesive additivesMacromolecular adhesive additivesCompression moldingAdhesive

The invention discloses a foam insulation board with a flame retardation function. A preparation method for the foam insulation board comprises the following steps: (1) coating of EPS particles: weighing 100 parts of prefoamed and cured EPS particles and 150 to 200 parts of a flame-retardant adhesive, carrying out uniform mixing under stirring, adding 10 to 15 parts of a curing agent and continuing stirring so as to obtain uniformly coated EPS particles; (2) gelation: subjecting the uniformly coated EPS particles to microwave heating for drying for 0.5 min and then delivering hot air for drying for 1 to 2 min so as to obtain gelated foam EPS particles; and (3) compression molding: putting the uniformly coated EPS foam particles into a die, closing the die, introducing water vapor with pressure intensity of 0.06 to 0.08 Mpa, maintaining the pressure for 1 to 2 min and then successively carrying out pressure relief, cooling and die-opening. The foam insulation board provided by the invention has good production efficiency, good flame retardation effect and high comprehensive properties.

Owner:SHANGHAI YIZUN WOOD

Production process of lithium-ferrous disulfide battery anode

The invention provides a production process of a lithium-ferrous disulfide battery anode, comprising the following steps of: (a) integrally punching a metal strap to form a metal mesh; (b) cleaning and drying the metal mesh; (c) preparing half-dry sizing and coating the sizing on the meta mesh, wherein the half-dry sizing is prepared from ferrous disulfide, a conductive agent and a caking agent; (d) drying the coated metal mesh; and (e) cutting, rolling and welding the dried metal mesh by using electrode lugs. By using the metal mesh as anode matrix and coating the prepared half-dry sizing on the metal mesh to obtain an anode plate, the production process of the lithium-ferrous disulfide battery anode solves the problem that strap breaking easily generates in the coating process; the coating on the anode plate has favorable adhering performance; powder of the anode plate is not easy to fall in the preparation and winding process; the consumption of solvent for stirring the sizing is less; the filling quantity of active substances is high; and the capacity of batteries is larger.

Owner:ZHONGYIN NINGBO BATTERY CO LTD

Preparation method of melamine-formaldehyde resin foam

The invention discloses a preparation method of melamine-formaldehyde resin foam, and belongs to the technical field of microwave foaming. The method comprises the following steps: taking 120-180 parts by weight of a melamine-formaldehyde resin; adding 5-12 parts by weight of a foaming agent, 3-6 parts by weight of an emulsifier, 3-6 parts by weight of a stabilizing agent, and 2-5 parts by weight of a curing agent in sequence, performing mixing and uniform stirring, and putting the obtained product in a microwave oven for foaming; and putting the obtained foam in an oven for curing for 2 h, wherein the temperature of the oven is 180-250 DEG C, and performing cutting molding. The melamine-formaldehyde resin foam is small in brittleness, not prone to shred particles, and high in tensile and tearing strength. The problem existing in the prior art is effectively solved, and the melamine-formaldehyde resin foam in excellent in mechanical property, flame retardance and sound attenuation.

Owner:郑州峰泰纳米材料有限公司

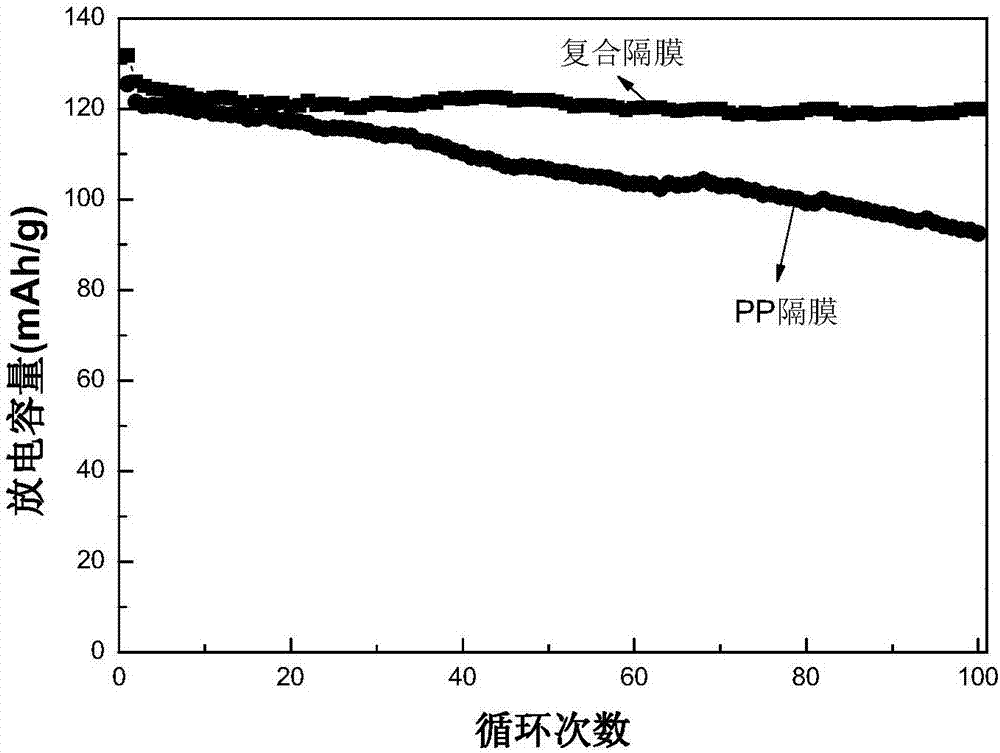

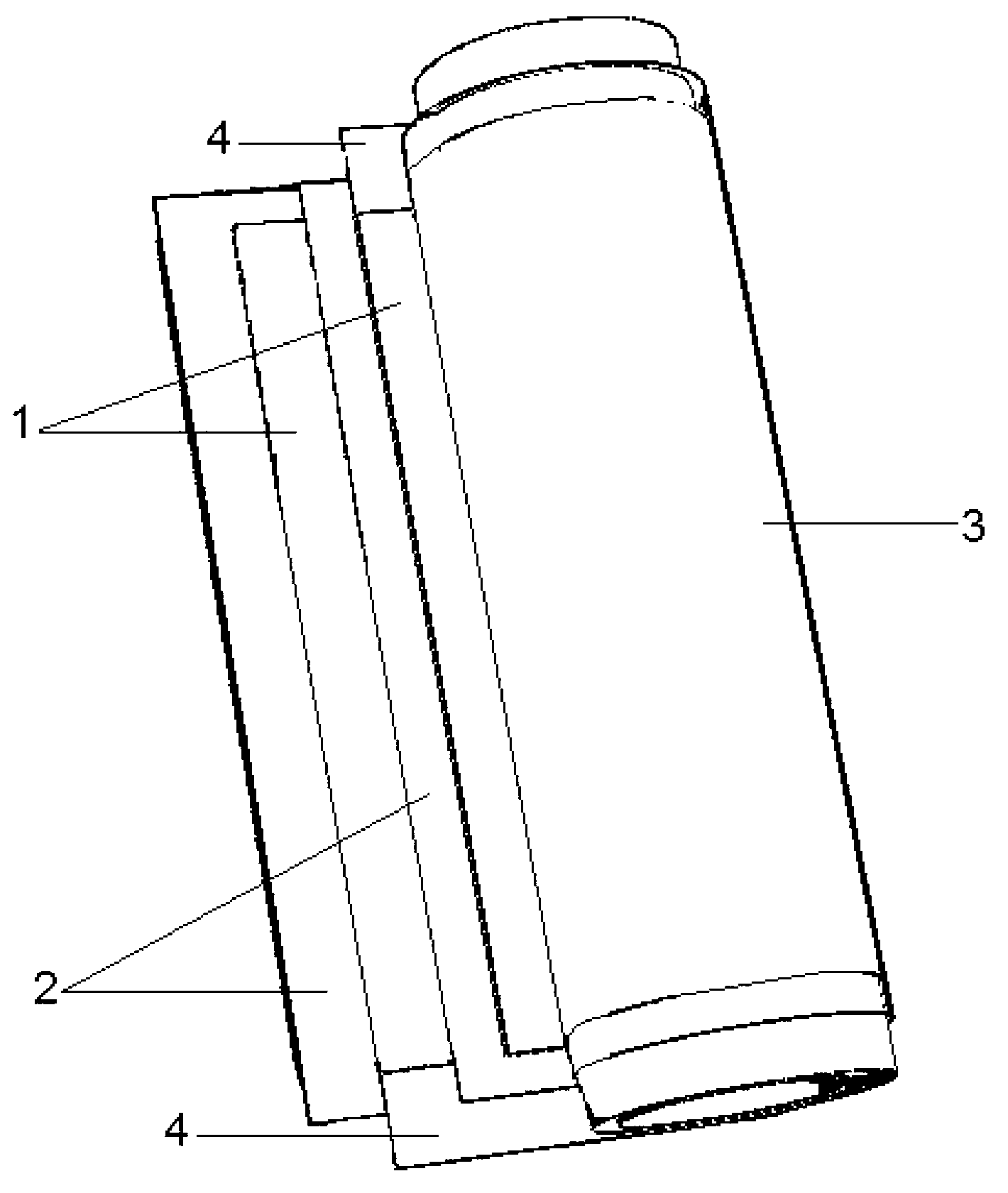

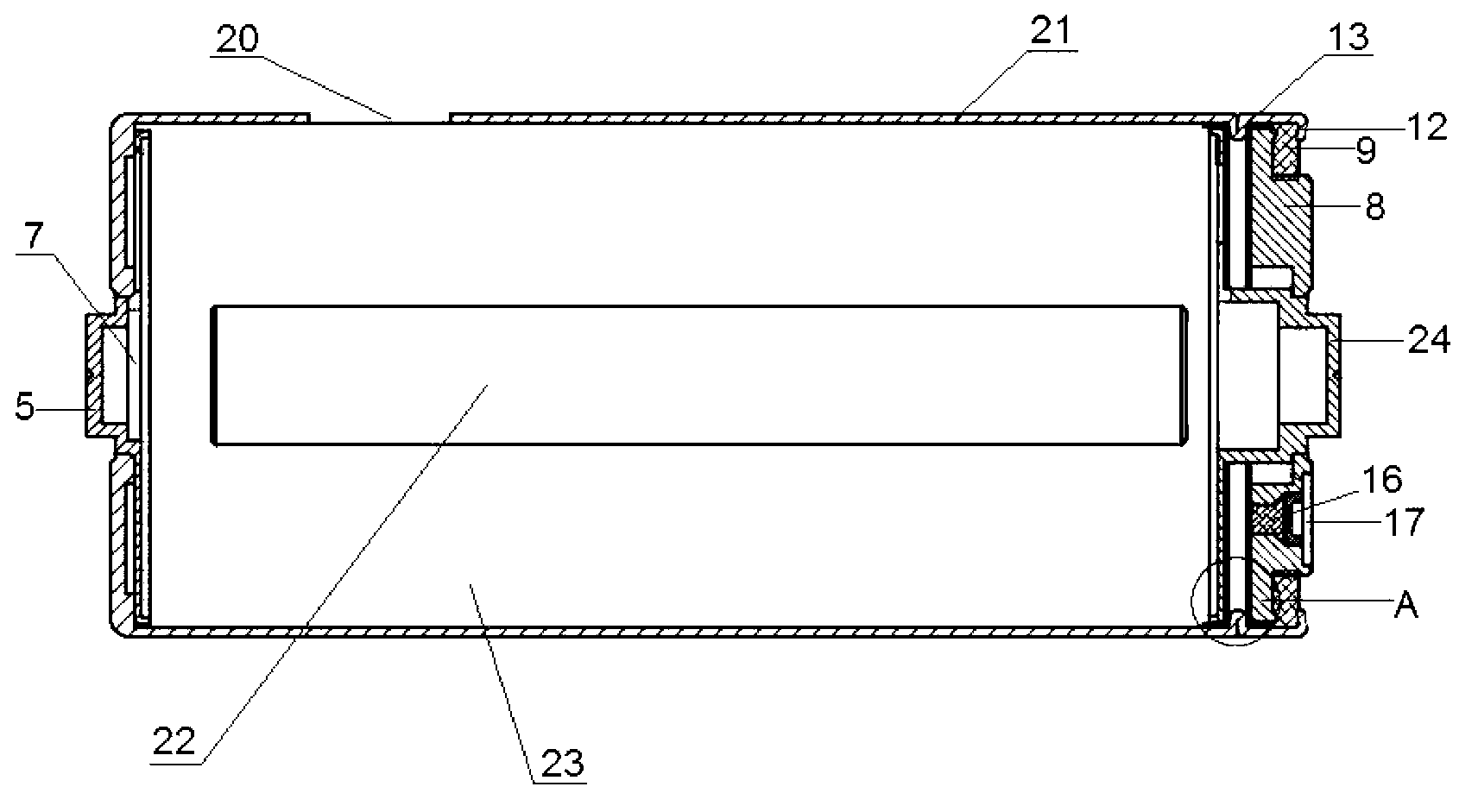

High-heat-resistance lithium battery composite diaphragm and preparation method thereof

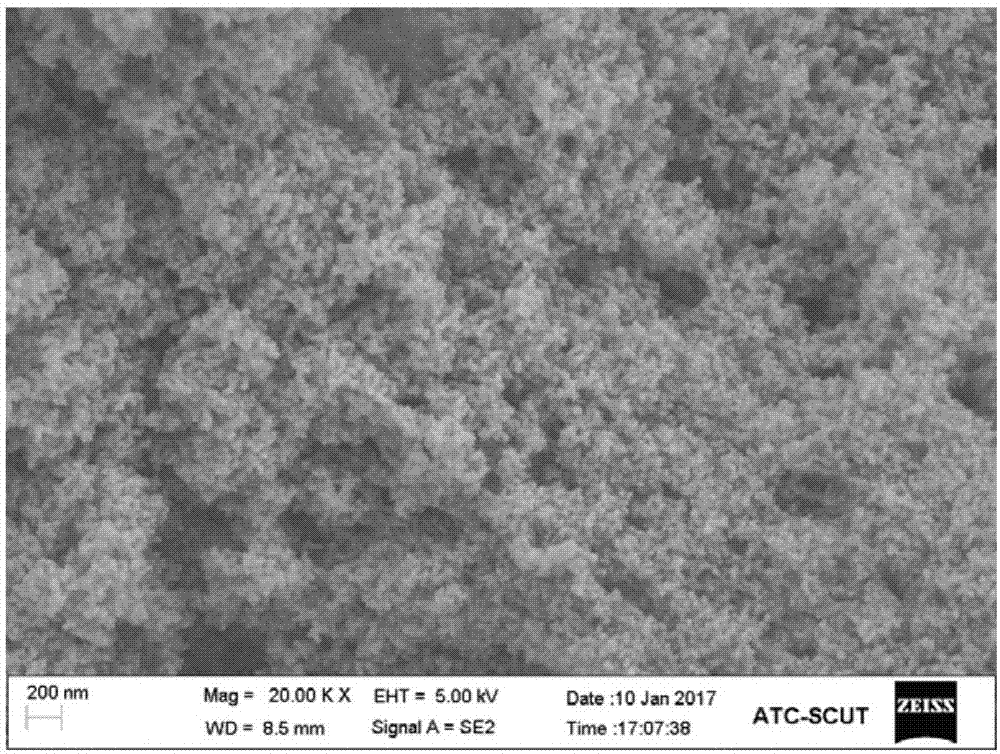

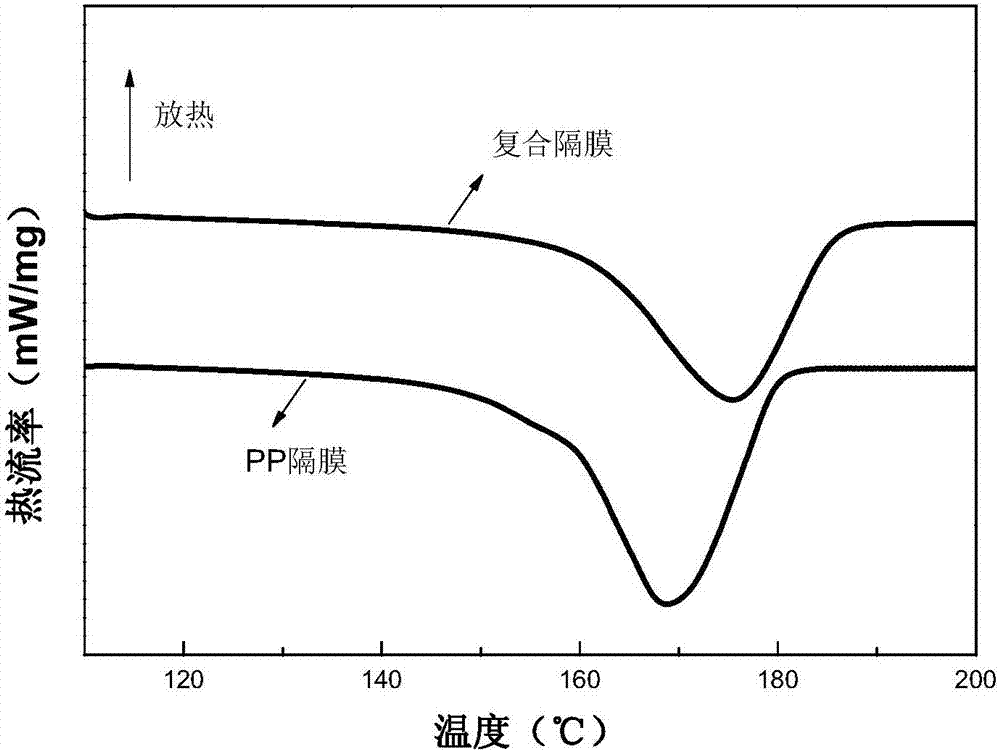

ActiveCN107216472AImprove securityImprove electrochemical performanceCell component detailsCoatingsPolyolefinPolyvinyl alcohol

The invention discloses a high-heat-resistance lithium battery composite diaphragm and a preparation method thereof. The preparation method comprises the following steps: adding polyvinyl alcohol powder into deionized water, swelling at the room temperature for 10-12 hours, and stirring at 85-95 DEG C for 4-5 hours, so as to prepare a polyvinyl alcohol solution; mixing and stirring ethyl orthosilicate, absolute ethyl alcohol and deionized water, dropwise adding ammonia water, and stirring at 40-45 DEG C for 0.5-1 hour, so as to obtain a mixture; adding the obtained mixture and aluminum oxide powder into the obtained polyvinyl alcohol solution, and stirring at 40-45 DEG C for 10-12 hours, so as to obtain a coating sizing agent; and coating the surface of a pretreated polyolefin microporous membrane with the sizing agent by virtue of a coating method, drying at the room temperature, and carrying out vacuum drying, so as to obtain the high-heat-resistance lithium battery composite diaphragm. The preparation method is simple in process and environment-friendly, and the prepared composite diaphragm is high in heat resistance, liquid absorbing rate and liquid retention rate and excellent in electrochemical performance and has good application prospects.

Owner:SOUTH CHINA UNIV OF TECH

Travertine-like arabesquitic vat and production technology thereof

The invention discloses a travertine-like arabesquitic vat. The forming material of the travertine-like arabesquitic vat mainly comprises a solid material, a blended solution and staple, wherein the solid material comprises the following components in percentage by weight: 30-45% of rapid-hardening sulphoaluminate cement, 45-65% of fine river sand, 1-3% of titanium dioxide, 1-3% of yellow powder and 0.01-0.15% of red powder; the blended solution comprises the following components in percentage by weight: 99-99.9% of water and 0.01-0.1% of polyacrylamide; and the staple is glass fiber of which the length is 5-10cm. The invention also discloses a production technology for the travertine-like arabesquitic vat, which comprises the following steps of: burdening, mixing, cleaning a mold, installing a material mold, installing the staple, demolding, nursing, trimming, repairing, brushing to be smooth, applying a surface coating and the like. The travertine-like arabesquitic vat disclosed by the invention has the advantages of clear and natural texture, good product intensity, light weight, hard surface layer, abrasion resistance, small possibility of delaminating and falling powder, low cost and good decoration effect, is convenient to produce on a large scale and is easy for stable control of product chromatic aberration, natural travertine in the natural world can be prevented from being mined on a large scale, and mine waste can be utilized to protect the ecological environment.

Owner:泉州市嘉利来石材工艺有限公司

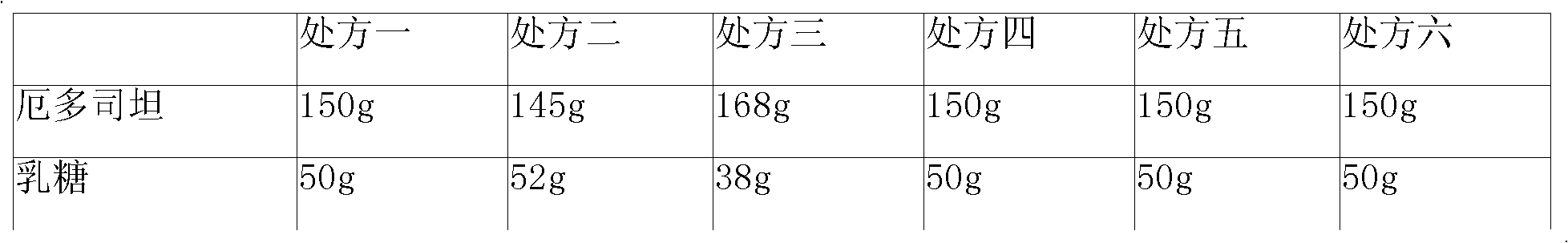

Erdosteine composition and preparation method thereof

ActiveCN101606931AGood lookingNot easy to lose powderOrganic active ingredientsPharmaceutical product form changeErdosteineSodium carboxymethyl starch

The invention provides an Erdosteine composition which consists of the following components by weight portions: 130 to 170 portions of Erdosteine, 35 to 65 portions of lactose, 30 to 70 portions of microcrystalline cellulose, 20 to 40 portions of low substituted hydroxypropyl cellulose, 1 to 5 portions of acesulfame, 10 to 30 portions of sodium carboxymethyl starch and 0.1 to 0.5 portions of magnesium stearate; the invention also provides a preparation method of the Erdosteine composition, comprising the following steps of: preparing materials and pelleting; mixing the Erdosteine and the low substituted hydroxypropyl cellulose evenly, then grinding, adding the sodium carboxymethyl starch, adding absolute ethyl alcohol, wet-mixing, cutting, drying, granulation and tabletting; mixing granules and microcrystalline cellulose evenly, adding the lactose, the acesulfame and the magnesium stearate for pelleting, subpackaging and obtaining the Erdosteine composition. The Erdosteine composition has good dispersible uniformity and high drug dissolution efficiency.

Owner:SHANDONG LUOXIN PARMACEUTICAL GROUP STOCK CO LTD

Thermal-insulating coating containing hollow silica microspheres and application of coating

ActiveCN110157315AImprove insulation performanceImprove water resistanceFireproof paintsNon-fibrous pulp additionGlass fiberMicrosphere

The invention relates to a thermal-insulating coating containing hollow silica microspheres and application of the coating. The thermal-insulating coating is a mixture of the hollow silica microspheres, a solvent and a binder, wherein the hollow silica microspheres include hollow inner cavities, honeycomb-shaped inner shell layers and outer shell layers, the hollow inner cavities are surrounded bythe honeycomb-shaped inner shell layers which contain dense micropores, mesopores and macropores, and the outer shell layers are adjacent to the honeycomb-shaped inner shell layers, and contain onlymesopores. The invention also provides the application of the thermal-insulating coating to thermal-insulating coated fabric or glass fiber paper, and an application method comprises the steps: applying the thermal-insulating coating on the surface of base cloth of the fabric or the surface of the glass fiber paper, and then performing drying. According to the thermal-insulating coating, the hollow silica microspheres of a novel structure are added, and after the coating is applied to the surface of the base cloth of the fabric or the surface of the glass fiber paper, the thermal insulation effect of the surface of the fabric or glass fiber paper can be improved greatly, so that blanks in application of the hollow silica microspheres in the field of thermal insulation of the fabric or glass fiber paper are filled.

Owner:杭州纳硅微球科技有限公司

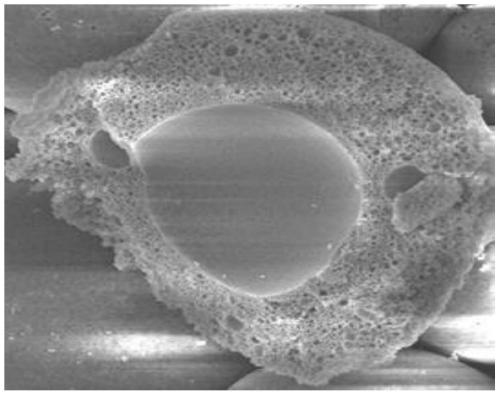

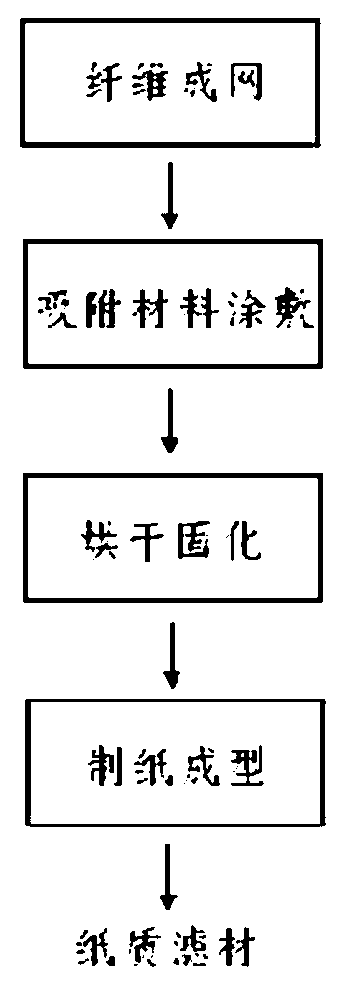

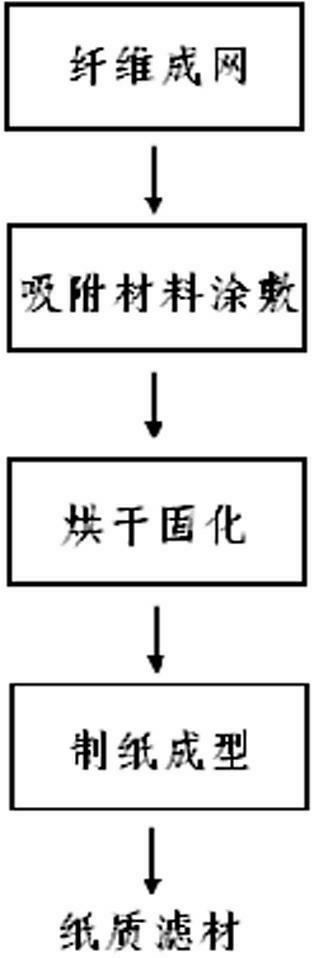

Selective absorbing dry method paper filter material for cigarette filter tip rod and preparation method thereof

The invention discloses a selective absorbing dry method paper filter material for a cigarette filter tip rod and a preparation method thereof. The selective absorbing dry method paper filter material is formed by processing 80-100 parts of base material fibers, 0-20 parts of adhesive and adsorbing materials of which the weight is 0.5 percent to 10 percent of that of the base material fibers through a dry method papermaking technology. The preparation method comprises working procedures of fiber net formation, adsorbing material coating and paper making and formation, that is to say, after fiber nets are formed by fibrous raw materials containing hot melting fibers in an air-laid manner and are pre-pressed, the adsorbing materials are evenly sprayed into accumulated fiber net layers, or are sprayed and coated on the front surfaces of the fiber nets after being mixed with the adhesive, and the fiber nets are formed in a rolled manner; after the adsorbing materials are sprayed and coated on the back surfaces of the fiber nets, glue is applied to the fiber nets, the fiber nets are additionally formed in a rolled manner, and then the paper filter material is obtained. By adopting the selective absorbing dry method paper filter material, harmful ingredients such as solid particle matters, nicotine and nicotinamide in cigarette smoke can be effectively reduced, the tar content can be markedly reduced, the cigarette smoking quality can be improved and the cigarette safety can be enhanced. The preparation method of the selective absorbing dry method paper filter material has the advantages of simple and convenient technology, easiness in operation and high practicality.

Owner:YUNNAN REASCEND TOBACCO TECH GRP

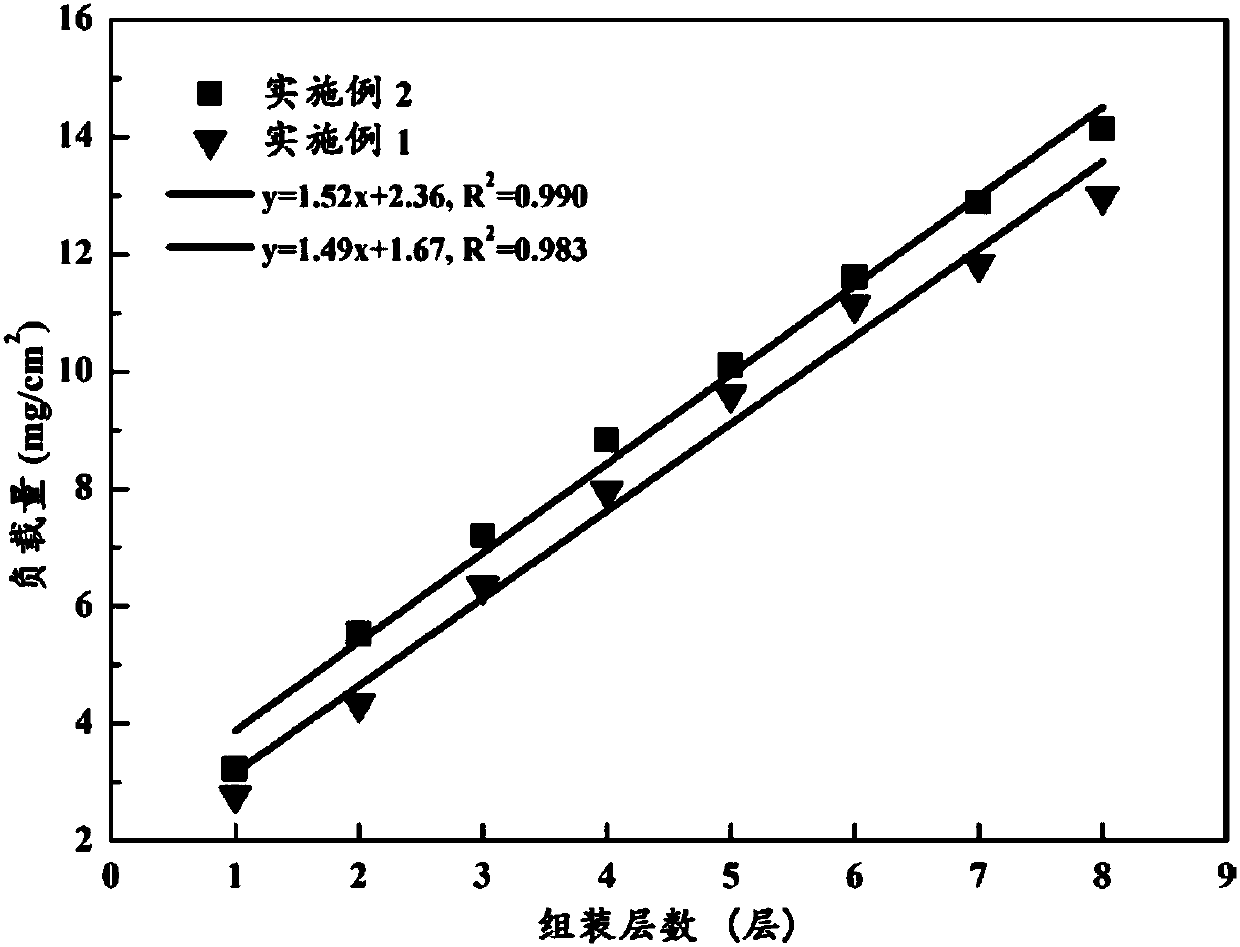

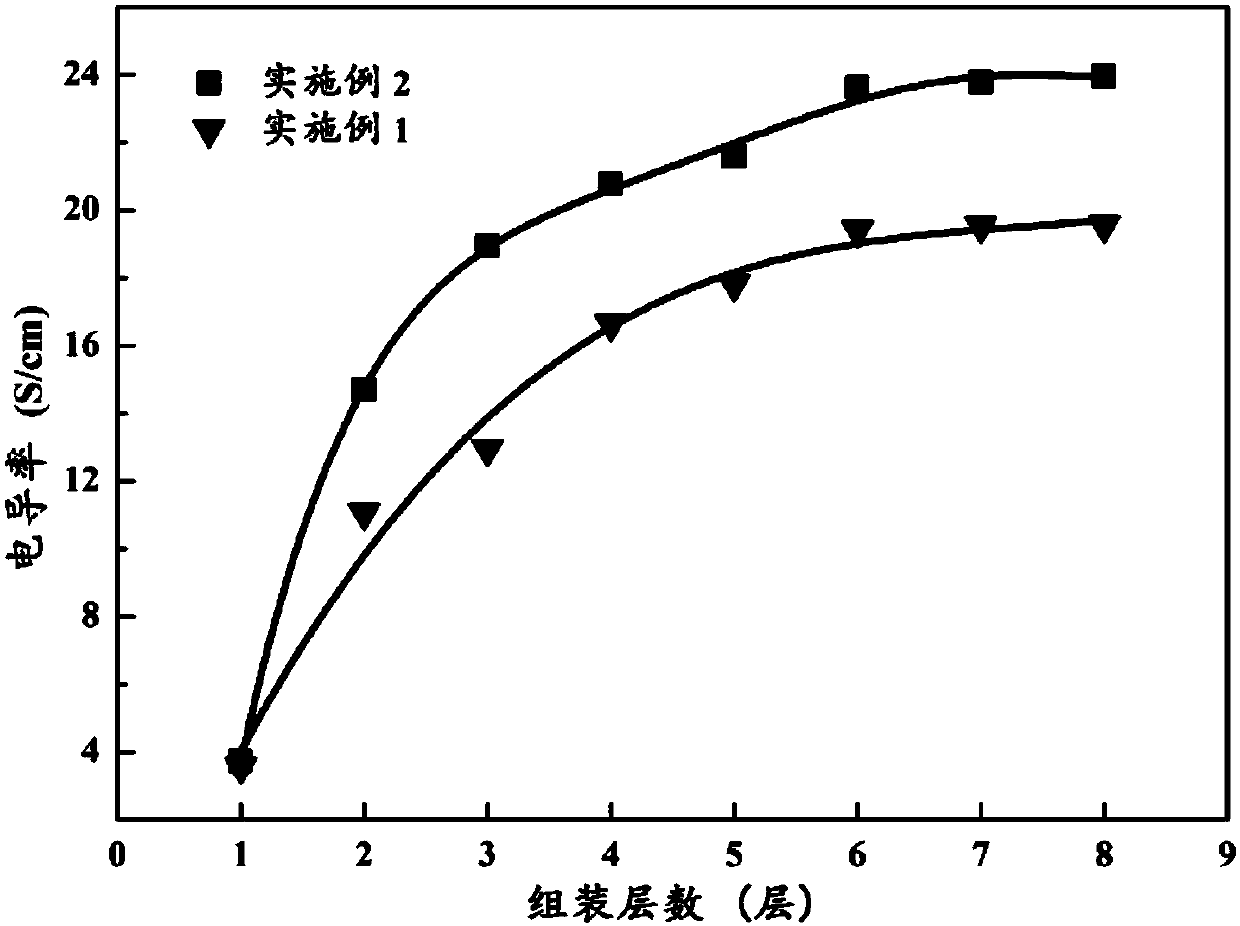

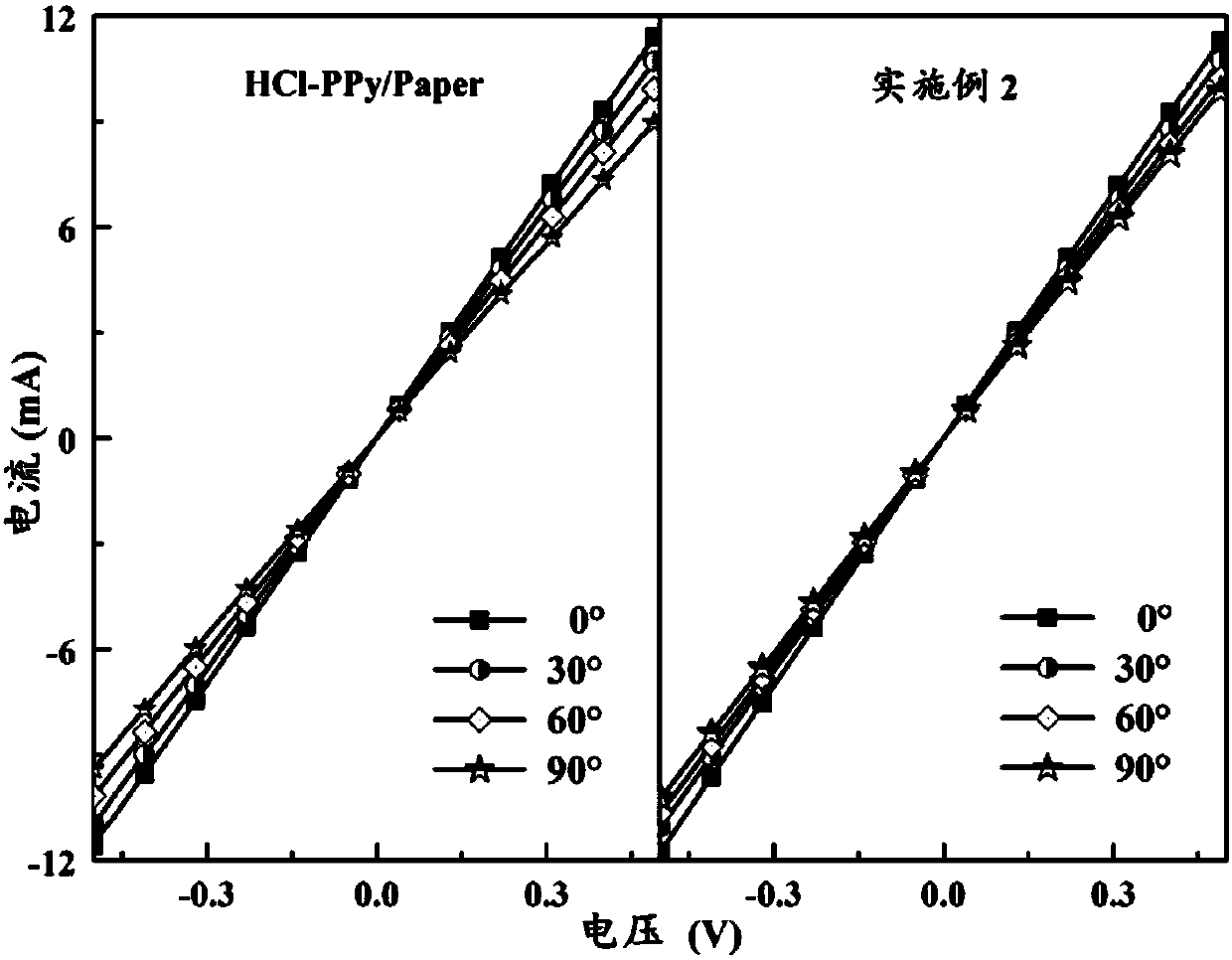

Lignosulfonic acid-reinforced polypyrrole conductive paper and preparation method thereof

ActiveCN107630390AImprove adsorption capacityImprove adsorption strengthSpecial paperNon-macromolecular organic additionUltrafiltrationPolypyrrole

The invention belongs to the technical field of functional materials and discloses a lignosulfonic acid-reinforced polypyrrole conductive paper and a preparation method thereof. The method comprises (1) separating a lignosulfonate through an ultrafiltration membrane and then purifying the lignosulfonate through a cation exchange resin to obtain lignosulfonic acid, (2) soaking a paper in the lignosulfonic acid for 10-30min, then soaking the paper in an aldehyde aqueous solution for 10-30min and heating the paper to 80-110 DEG C for a condensation reaction for 1-2h, (3) soaking the paper in a pyrrole solution for 10-30min, and (4) soaking the paper in a mixed solution of an oxidant and an inorganic acid for a reaction for 10-120min to obtain a self-assembled single-layer conductive paper andrepeating the above steps (2) to (4) to obtain a self-assembled multi-layer conductive paper. The lignosulfonic acid-reinforced polypyrrole conductive paper has high conductivity, good stability, adjustable loading capability and no dusting and can be used in the fields of surface heating materials, electromagnetic shielding materials and flexible electrode materials.

Owner:SOUTH CHINA UNIV OF TECH

Modified sludge composite adsorbent

InactiveCN104888736AHigh carbon contentImprove adsorption capacityOther chemical processesSorbentPolyvinyl alcohol

The invention discloses a modified sludge composite adsorbent which is characterized by being prepared from the following raw materials, by weight, 100-150 parts of sludge, 13-17 parts of corn straw, 15-24 parts of peanut shell, 10-15 parts of manganese ore powder, 30-50 parts of zinc chloride, 13-16 parts of magnesium silicate, 5-8 parts of silicon dioxide, 3-5 parts of polyvinyl alcohol, 3-5 parts of polyacrylamide, 2-4 parts of phytoncide essential oil, 6-7 parts of tourmaline powder, 4-6 parts of borax, 6-8 parts of activated alumina and a proper amount of distilled water. By interaction of the added phytoncide essential oil, tourmaline powder, borax, activated alumina, sludge and activated carbon, adsorptivity and bactericidal property of the activated carbon are enhanced. The composite adsorbent is nontoxic and pollution-free, is healthy and harmless to human body, has a good effect when used in water purification, and is beneficial to body health. The adsorbent provided by the invention is nontoxic and environmentally friendly, has advantages of simple preparation technology, wide material source, good chemical stability and high mechanical property, and is worthy of popularization.

Owner:BENGBU PIONEER FILTER

Bacteriostatic deodorizing modified active carbon adsorbent

InactiveCN104888702AHigh carbon contentImprove adsorption capacityOther chemical processesMenthonePolyvinyl alcohol

The invention discloses a bacteriostatic deodorizing modified active carbon adsorbent which is characterized by being prepared from the following raw materials, by weight, 100-150 parts of sludge, 13-17 parts of corn straw, 15-24 parts of peanut shell, 10-15 parts of manganese ore powder, 30-50 parts of zinc chloride, 13-16 parts of magnesium silicate, 5-8 parts of silicon dioxide, 3-5 parts of polyvinyl alcohol, 3-5 parts of polyacrylamide, 3-5 parts of silver nitrate, 7-8 parts of diatomite, 2-3 parts of menthone, 4-7 parts of hydroxy nickel powder and a proper amount of distilled water. With addition of silver nitrate, diatomite, menthone and hydroxy nickel powder, bactericidal activity and adsorptivity of the adsorbent are enhanced, and smell deodorizing effect can be greatly improved. The preparation process of the adsorbent is simple; preparation cost is low; experimental operating conditions are mild; and there is no secondary pollution. The adsorbent provided by the invention is an environmentally-friendly adsorbent.

Owner:BENGBU PIONEER FILTER

Active carbon air-conditioner filter core material and preparation method thereof

InactiveCN104888530AHigh carbon contentImprove adsorption capacityDispersed particle filtrationFiltration separationPolyvinyl alcoholSorbent

The invention discloses an active carbon air-conditioner filter core material and a preparation method thereof. The air-conditioner filter core material comprises the following raw materials, by weight part: 100-150 of sludge, 13-17 of cornstalk, 15-24 of peanut hull, 30-50 of zinc chloride, 13-16 of magnesium silicate, 6-9 of zirconia, 2-4 of cetyltrimethylammonium bromide, 2-3 of polyvinyl alcohol, 6-8 of zirconium fluoride, 8-12 of hydrotalcite, 5-6 of meerschaum powder, and a proper amount of distilled water. Zirconium fluoride, hydrotalcite, and meerschaum powder added in the air-conditioner filter core material greatly improve bactericidal activity, thermostability, and ion exchange performance of sludge active carbon, increase the adsorption capacity and adsorption range, and enlarge the application range of the adsorbent. According to the invention, the active carbon adsorbent is simple in preparation technology, wide in raw material source, low in cost, and excellent in performance, is good in use effect when taken as the air-conditioner filter core material, is less in change frequency, and has a long service life.

Owner:BENGBU DEMO FILTRATION TECH

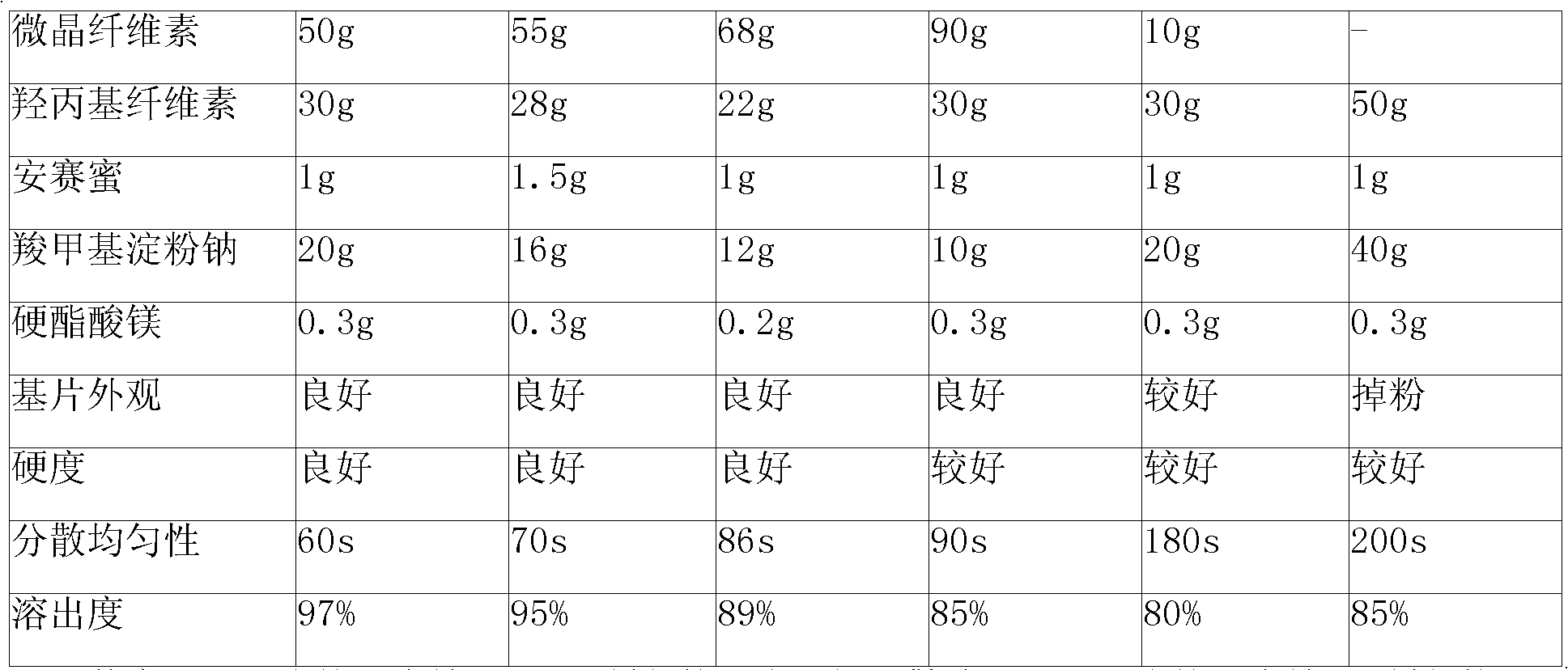

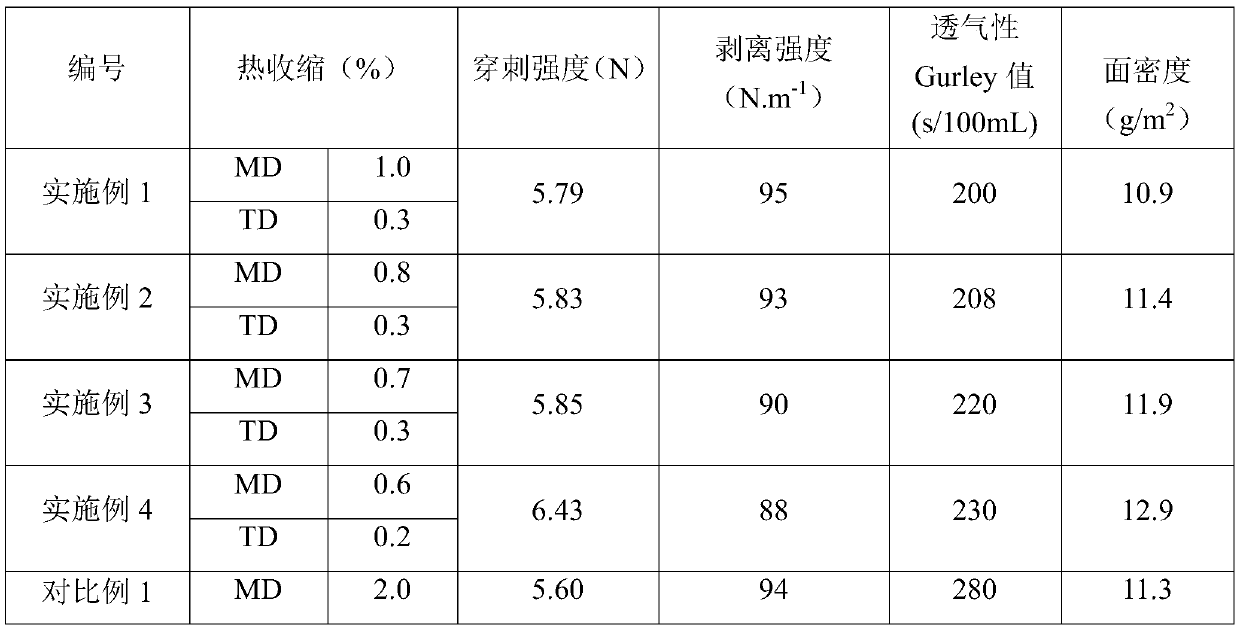

Polyimide microsphere slurry, composite separator and lithium ion battery

ActiveCN109817870AImprove mechanical propertiesEnsure safetyCell component detailsWater basedAdhesive

The invention relates to the technical field of lithium ion battery separator preparation, and discloses polyimide microsphere slurry, a composite separator and a lithium ion battery. The slurry comprises polyimide microspheres, a surfactant, a water-based adhesive, a wetting agent and deionized water. The composite separator prepared from the slurry is good in thermal stability, excellent in puncture resistance and good in air permeability, and compared with a ceramic coated separator, the surface density of a coating is lower, and relatively, the specific capacity of a lithium battery comprising the composite separator is higher.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

Activated carbon adsorbent for adsorbing gasoline vapor

InactiveCN104923180AHigh carbon contentImprove adsorption capacityOther chemical processesSorbentSludge

The invention discloses an activated carbon adsorbent for adsorbing gasoline vapor. The activated carbon adsorbent is characterized by being prepared from the following raw materials in parts by weight: 100-150 parts of sludge, 13-17 parts of maize straw, 15-24 parts of peanut shell, 10-15 parts of manganese ore flour, 30-50 parts of zinc chloride, 13-16 parts of magnesium silicate, 5-8 parts of silicon dioxide, 3-5 parts of polyvinyl alcohol, 3-5 parts of polyacrylamide, 6-8 parts of basalt fiber, 2-4 parts of polyisobutylene succinimide, 8-11 parts of magnesium oxide and proper amount of distilled water. By adding the basalt fiber, the polyisobutylene succinimide and the magnesium oxide, the strength and the adsorption capacity of the sludge activated carbon can be enhanced, and the adsorbent has good purification and cleaning effects on gasoline; and the adsorbent prepared by the invention is high in gasoline adsorption capacity, good in desorption, high in strength, capable of effectively relieving the harm to environment and human bodies and is worthy of popularizing.

Owner:BENGBU PIONEER FILTER

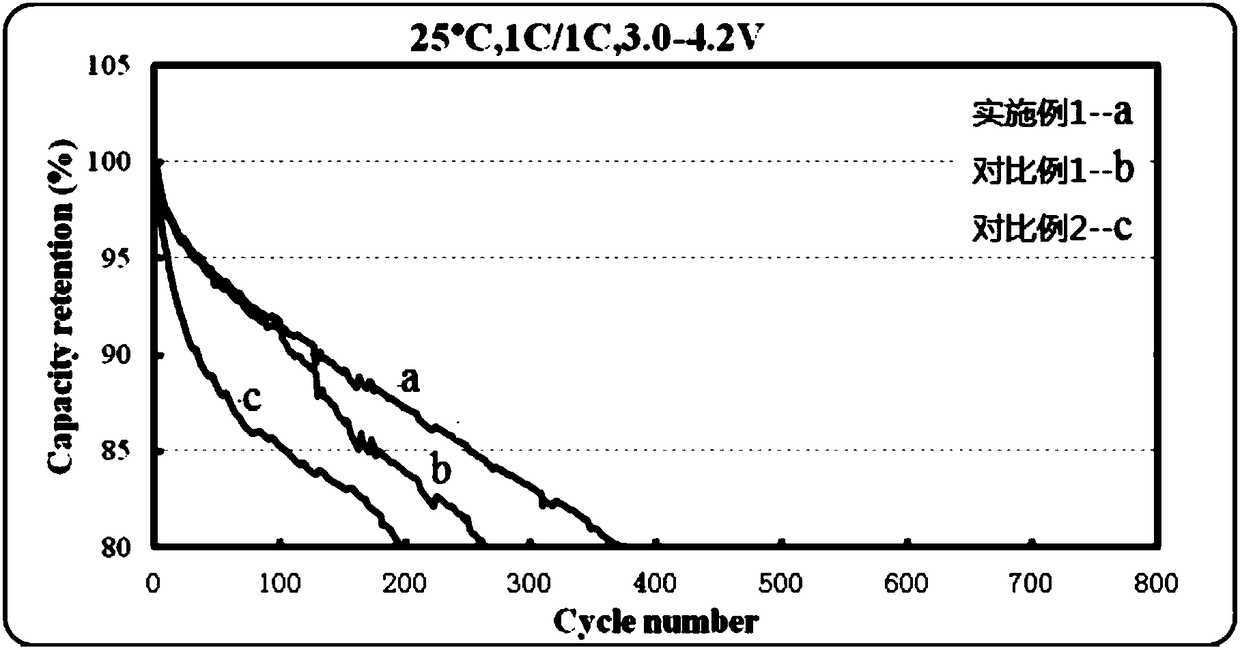

Carbon black modified water-based SBR lithium ion battery binder and preparation method thereof

InactiveCN108598482AHigh cycle capacityImprove cycle lifeCell electrodesSecondary cellsWater basedSodium stearate

The invention discloses a carbon black modified water-based SBR lithium ion battery binder and a preparation method thereof, and relates to the technical field of a lithium ion battery binder, whereinthe binder is prepared through the following steps: using styrene and butadiene as raw materials; bonding the conductive carbon black on an SBR molecular chain through an in-situ emulsion polymerization method, wherein the preparation method comprises adding an aqueous solution of sodium stearate to an aqueous surfactant solution to obtain an emulsified solution; then adding carbon black to disperse to obtain a carbon black emulsion system; dissolving an reducibility initiator and electrolyte in deionized water to obtain a reducing solution; adding the deionized water, the reducing solution,a molecular weight regulator SD-12 and styrene to the carbon black emulsion system, vacuumizing to the negative pressure, and then adding butadiene, cooling, and adding an oxidizing initiator to initiate a polymerization reaction. The binder of the present invention is used for battery preparation. In the case that no conductive carbon black is additionally added, the battery has a high cycle capacity, thereby increasing the additive proportion of the active material, and indirectly increasing the energy density of the battery system.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Production process of melamine-formaldehyde resin foam sponge

The invention discloses a production process of melamine-formaldehyde resin foam sponge. The production process comprises the following steps: melamine and paraformaldehyde are taken and mixed evenly; the mixed material is conveyed into a first screw machine by a material pump, and lye is added at a feed inlet of the first screw machine; an auxiliary material solution is added to the feed end, the middle position or the tail end of the first screw machine; transparent resin extruded from an outlet of the first screw machine enters a second screw machine to be subjected to a polymerization reaction continuously in the second screw machine; the transparent resin discharged out of the tail of the second screw machine enters a third screw machine after passing through a cooling device; a foaming agent, an emulsifier, a stabilizer and a curing agent are fed from the middle of the third screw machine and mixed with the resin uniformly; the resin mixed uniformly is introduced into a microwave foaming furnace for foaming, and the melamine-formaldehyde resin foam sponge with high aperture ratio is formed. The production process of the melamine-formaldehyde resin foam sponge has high utilization rate and high yield, the melamine-formaldehyde resin foam sponge with stable production quality can be produced continuously, and the aperture ratio is high.

Owner:郑州峰泰纳米材料有限公司

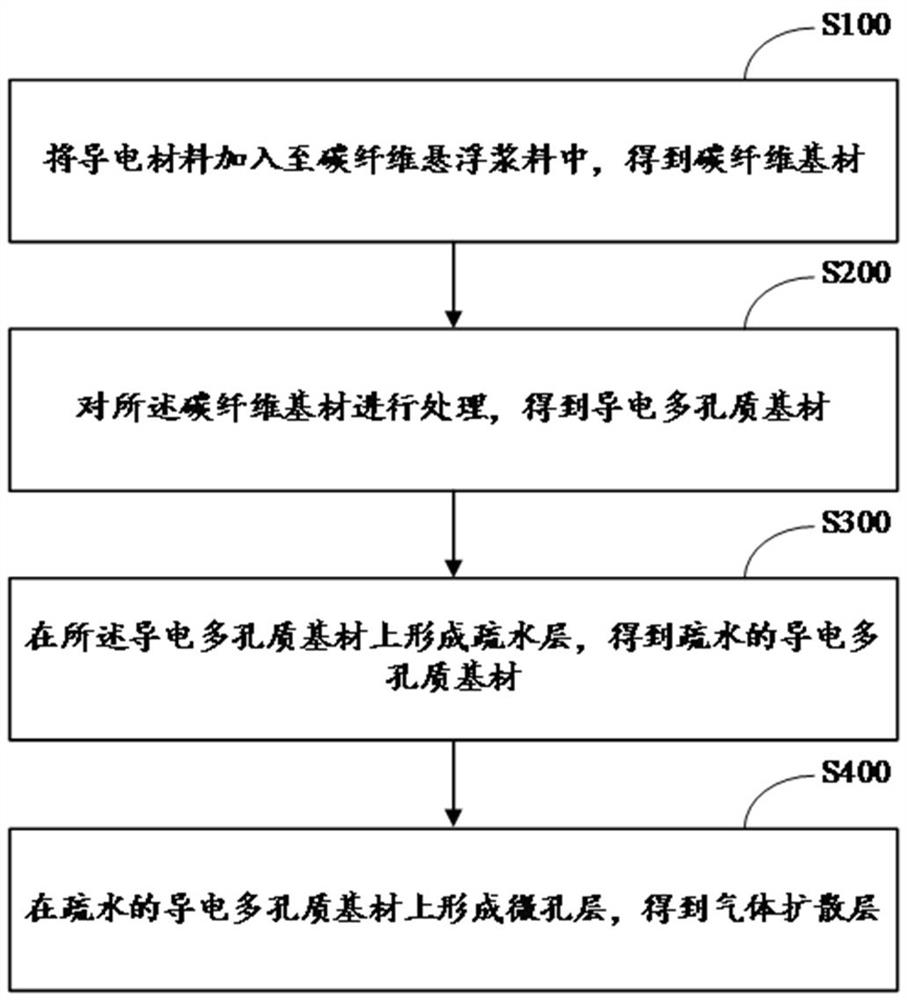

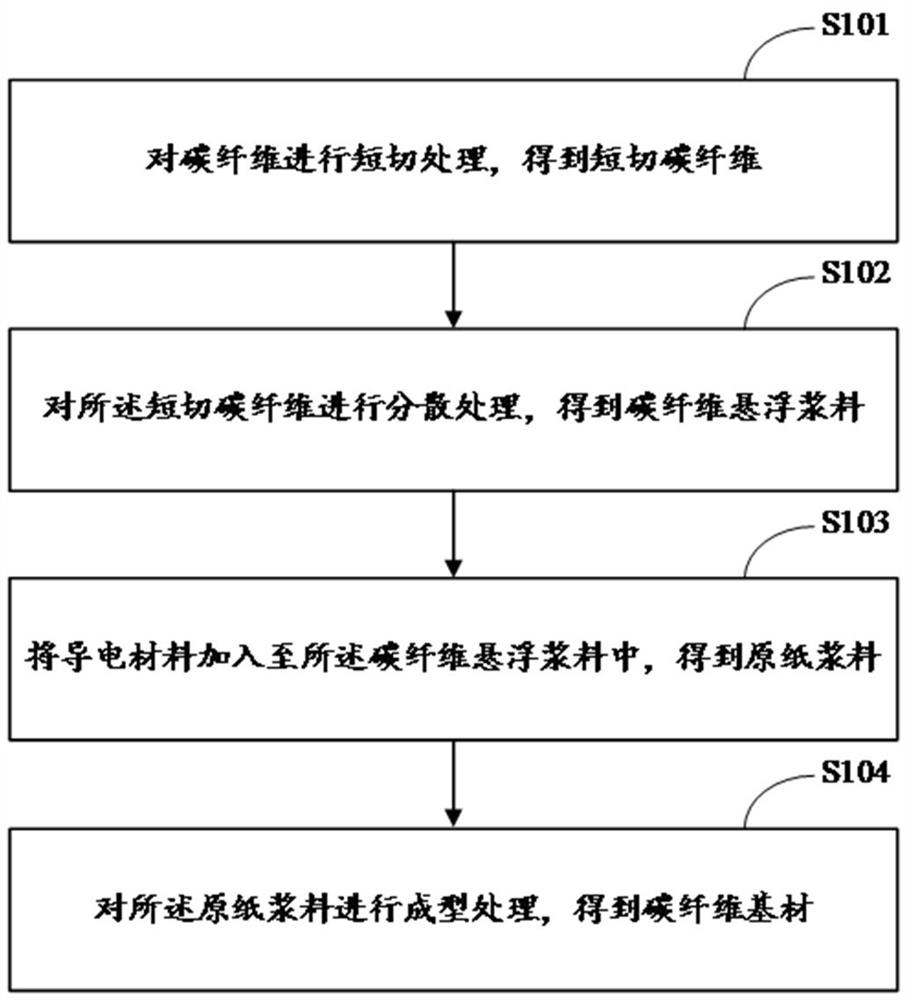

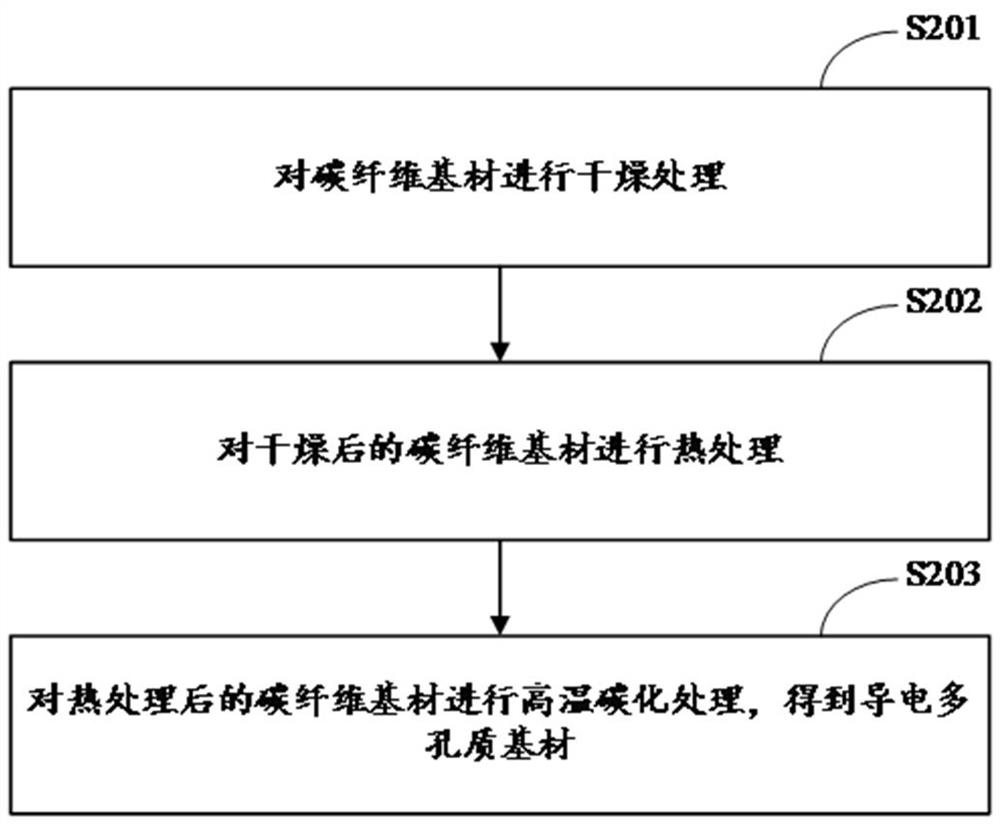

Gas diffusion layer and preparation method

The invention discloses a gas diffusion layer and a preparation method thereof. The preparation method of the gas diffusion layer comprises steps that a conductive material is added into carbon fibersuspension slurry, and a carbon fiber base material is obtained; the carbon fiber base material is treated to obtain a conductive porous base material; a hydrophobic layer is formed on the conductiveporous base material to obtain a hydrophobic conductive porous base material; and a microporous layer is formed on the hydrophobic conductive porous substrate to obtain the gas diffusion layer. In theprocess of preparing the carbon fiber base material, the conductive material is directly added into the carbon fiber suspension slurry, so the conductive material can be uniformly distributed in thecarbon fiber base material, the conductive material and the carbon fiber can be better combined, the whole carbon fiber base material has conductivity, and performance of the gas diffusion layer is further improved. Time consumption caused by coating of the guide material can be avoided, so the production time can be saved, and production efficiency is improved.

Owner:SHENZHEN GENERAL HYDROGEN ENERGY TECH CORP LTD

Tree trunk whitening agent and preparation method thereof

ActiveCN105802292AImprove breathabilityNot easy to lose powderBiocideAntifouling/underwater paintsTree trunkWhitening Agents

The invention relates to a tree trunk whitening agent.The tree trunk whitening agent is characterized by being prepared by stirring, by weight, 15-20 parts of quick lime, 6-10 parts of micropore foaming glass pumice particles, 3-5 parts of white cement, 3-5 parts of sulphur powder and 30-40 parts of water.The diameter of the micropore foaming glass pumice particles is 0.5-2 mm.The diameter of micropores of the micropore foaming glass pumice particles is 0.1-1 mm.The invention further relates to a preparation method of the tree trunk whitening agent.The tree trunk whitening agent has the advantages that tree trunk breathability can be improved, and a dried and fixed coating is not likely to fall or crack.

Owner:江苏晶瑞特环保新材料有限公司

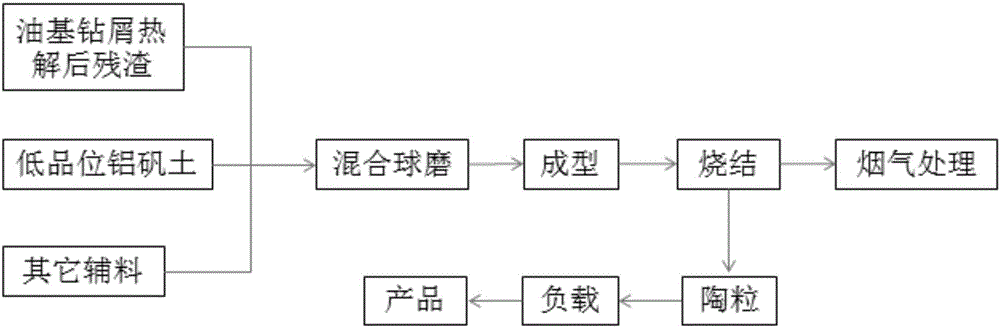

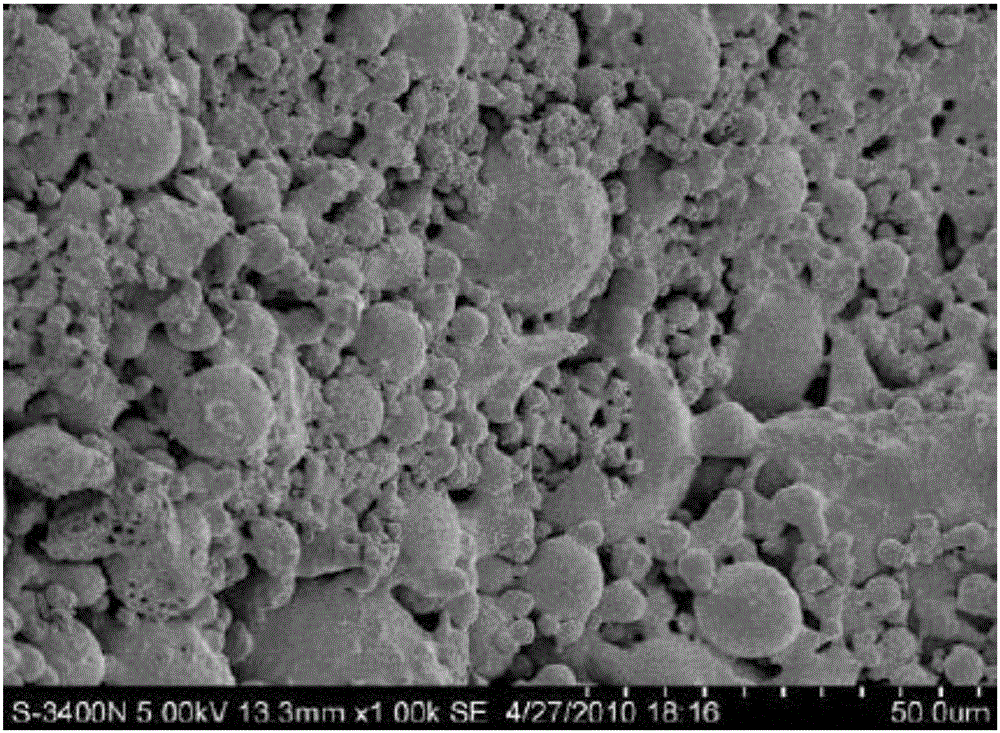

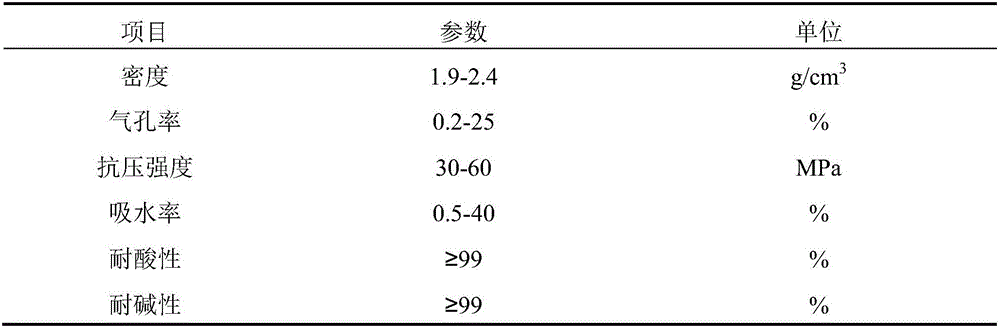

Oleophylic ceramsite adopting oil-based drilling cutting residues obtained after thermal decomposition and preparation method of oleophylic ceramsite

InactiveCN106518147AHigh compressive strengthImprove acid and alkali corrosion resistanceCeramic materials productionCeramicwarePotassiumDyeing wastewater

The invention discloses ceramsite with an oleophylic property. The different proportions of oil-based drilling cutting residues obtained after thermal decomposition, potassium feldspar, bauxite and bentonite are utilized, the performance of the ceramsite can be improved by adding a small amount of waste glass powder, and the prepared ceramsite has the oleophylic property through loading of an aluminic acid ester coupling agent. The ceramsite with the oleophylic property is large in compressive strength and good in acid and alkali corrosion resistance, and has the oleophylic property, powder is not likely to fall off, backflushing regeneration of the ceramsite is easy, hardening is avoided, and a good effect can be achieved when the ceramsite serves as a filtering medium. The ceramsite can be used for treating oily sewage and production sewage or printing and dyeing wastewater; when the ceramsite is used for treating the oily sewage, the oil removal rate is 85% or above, and the suspended solid removal rate is 80% or above.

Owner:SINOPEC ENERGY & ENVIRONMENTAL ENG CO LTD +1

Method for manufacturing super capacitor

The invention discloses a method for manufacturing a super capacitor. The method for manufacturing the super capacitor comprises the step of electrode slurry preparation, wherein the electrode slurry preparation comprises the following steps that deionized water and polyurethane are placed into a planetary mixer to be mixed, and a binding agent blended well like water and milk is obtained; the binding agent is placed into a kneading machine, acetylene black is placed into the kneading machine, and the binding agent and the acetylene black are mixed in the kneading machine; activated carbon powder is put into the kneading machine to be stirred for 20-40 minutes to obtain paste-shaped pre-finished electrode slurry; the pre-finished electrode slurry is put into a stirring tank of the planetary mixer and deionized water is added into the stirring tank; the stirring tank is vacuumized to 300-200 pa and the mixture of all the materials is stirred in the stirring tank for 20-40 minutes to obtain electrode slurry. The super capacitor manufactured with the method is high in reliability, high in power density and high in energy density. The production efficiency is high and the energy consumption is low in a production process.

Owner:NINGBO CRRC NEW ENERGY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com