High-heat-resistance lithium battery composite diaphragm and preparation method thereof

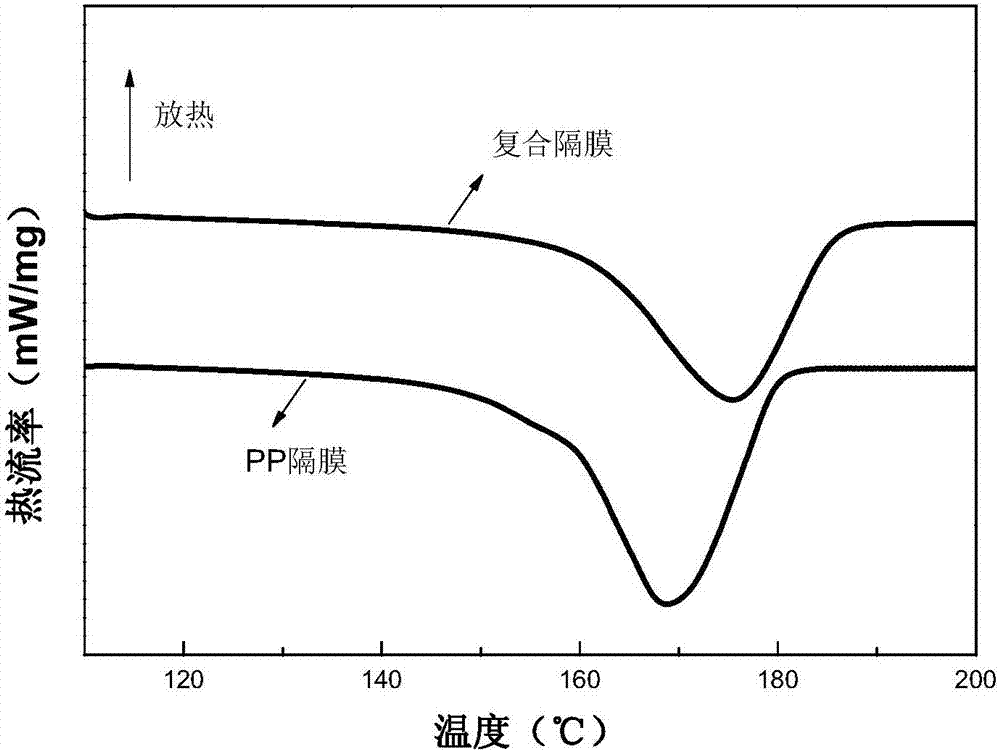

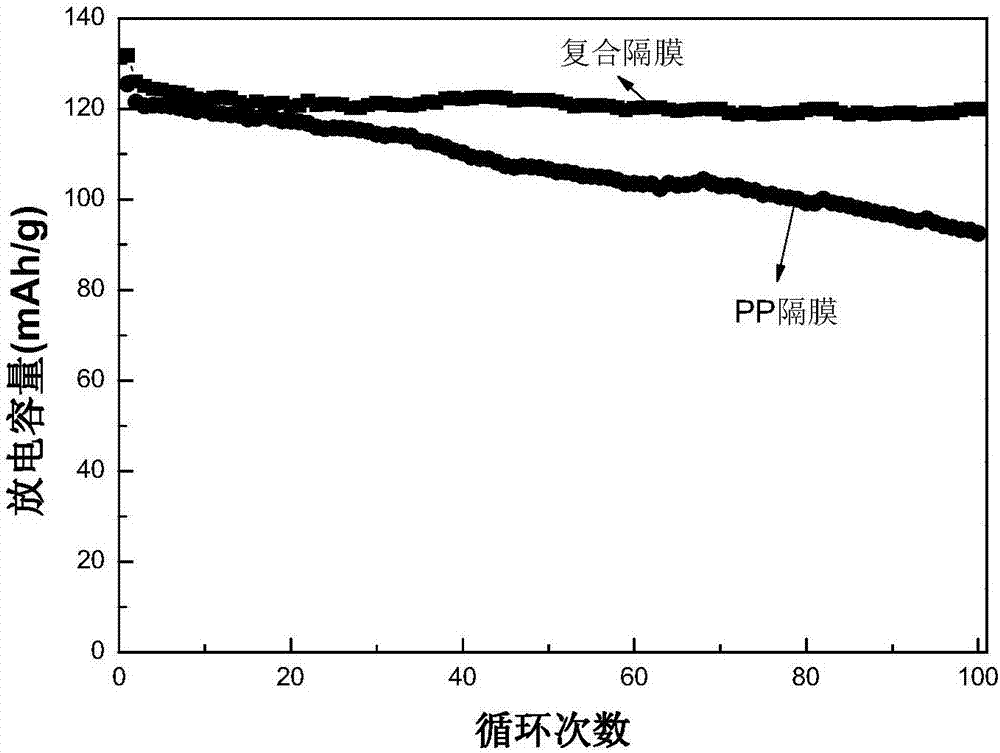

A composite diaphragm and lithium battery technology, which is applied to battery pack components, circuits, electrical components, etc., to achieve the effects of improving heat resistance, safety performance, safety performance and cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A preparation method of a high heat-resistant lithium battery composite diaphragm, comprising the following steps:

[0034] (1) Add 8 parts of polyvinyl alcohol powder into 100 parts of deionized water, swell at room temperature for 10 hours, and then mechanically stir for 4.5 hours at 90°C and a stirring rate of 800r / min to obtain a polyvinyl alcohol solution;

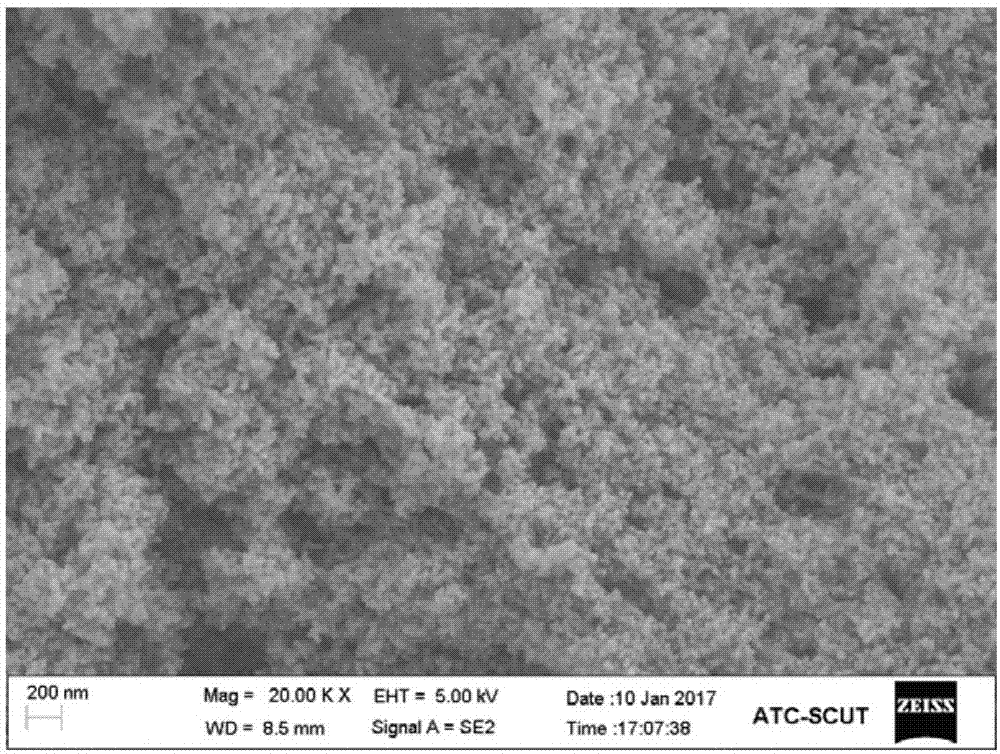

[0035] (2) Magnetically stir 4 parts of ethyl orthosilicate, 9 parts of absolute ethanol, and 9 parts of deionized water at a stirring rate of 400r / min for 20min, add 0.8 parts of ammonia water dropwise, and stir at 40°C and 800r / min After magnetically stirring for 1 hour at a high speed, add it and 0.8 parts of alumina powder with a particle size of 50 nm to the polyvinyl alcohol solution obtained in step (1), and stir for 12 hours at 45° C. to obtain the coating slurry;

[0036] (3) Apply the slurry to the surface of the PP separator by the coating method, dry it at room temperature for 2.5 hours, and dry it ...

Embodiment 2

[0041] A preparation method of a high heat-resistant lithium battery composite diaphragm, comprising the following steps:

[0042] (1) Add 9 parts of polyvinyl alcohol powder into 100 parts of deionized water, swell at room temperature for 10 hours, and then mechanically stir for 4.5 hours at 90°C and 800r / min stirring speed to obtain a polyvinyl alcohol solution;

[0043] (2) Magnetically stir 3 parts of ethyl orthosilicate, 9 parts of absolute ethanol, and 9 parts of deionized water at a stirring rate of 400r / min for 20min, add 0.6 parts of ammonia water dropwise, and stir at 40°C and 800r / min After magnetically stirring for 1 hour at a high speed, add it and 0.8 parts of alumina powder with a particle size of 40 nm to the polyvinyl alcohol solution obtained in step (1), and stir for 12 hours at 45° C. to obtain the coating slurry;

[0044](3) Apply the slurry to the surface of the PP separator by the coating method, dry it at room temperature for 2.5 hours, and dry it in va...

Embodiment 3

[0046] A preparation method of a high heat-resistant lithium battery composite diaphragm, comprising the following steps:

[0047] (1) Add 10 parts of polyvinyl alcohol powder into 100 parts of deionized water, swell at room temperature for 10 hours, and then mechanically stir for 4.5 hours at 90°C and 800r / min stirring speed to obtain a polyvinyl alcohol solution;

[0048] (2) Magnetically stir 4 parts of ethyl orthosilicate, 9 parts of absolute ethanol, and 9 parts of deionized water at a stirring rate of 400r / min for 20min, add 0.8 parts of ammonia water dropwise, and stir at 40°C and 800r / min After magnetically stirring for 1 hour at a high speed, add it and 0.8 parts of alumina powder with a particle size of 50 nm to the polyvinyl alcohol solution obtained in step (1), and stir for 12 hours at 45° C. to obtain the coating slurry;

[0049] (3) Apply the slurry to the surface of the PP separator by the coating method, dry it at room temperature for 2.5 hours, and dry it in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com