Patents

Literature

83results about How to "Improve lyophilicity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

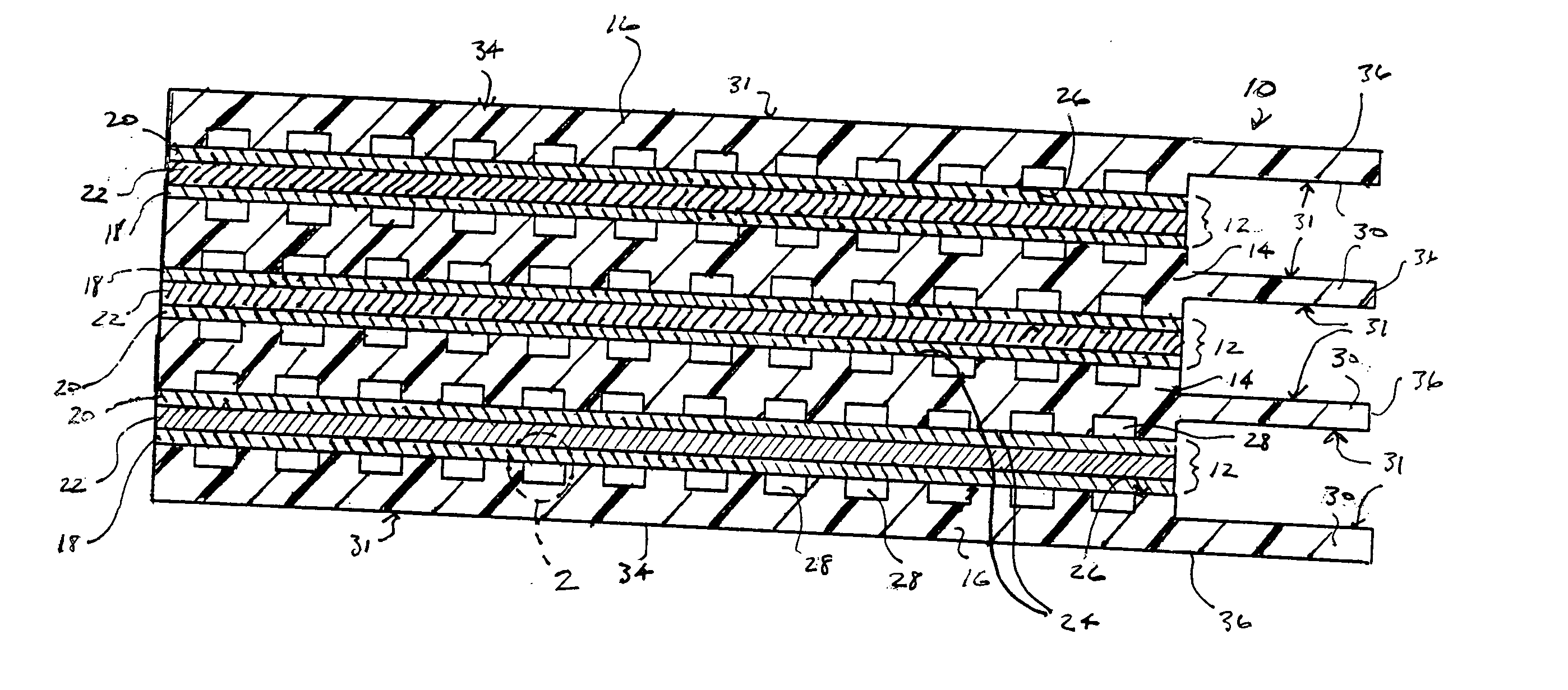

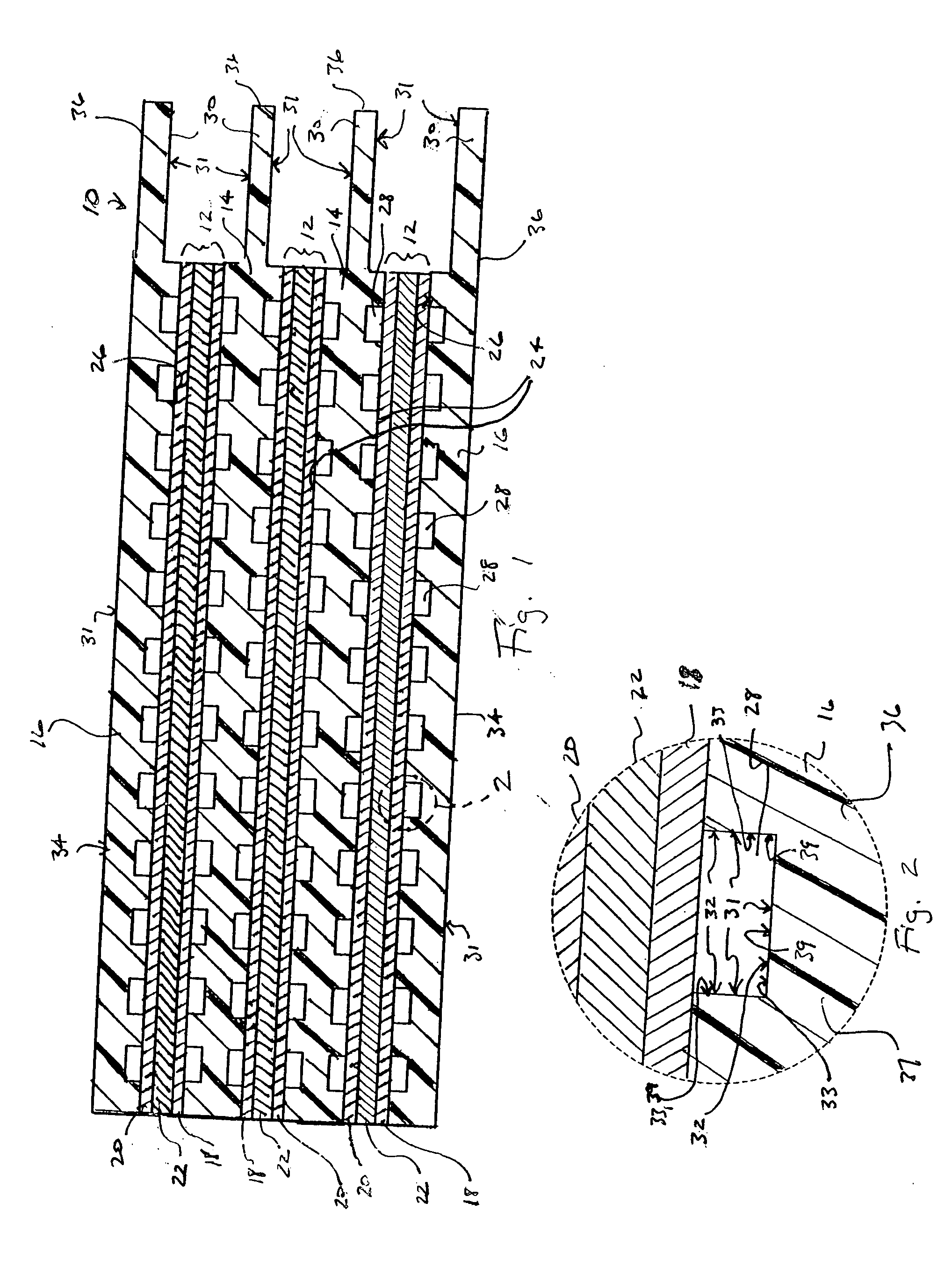

Lyophilic fuel cell component

InactiveUS20050008919A1Improve wettabilityImprove lyophilicityMaterial nanotechnologyElectrode carriers/collectorsFuel cellsThin layer

A fuel cell component with surfaces having improved lyophilicity so that liquid on the component adheres closely to the surface in relatively flat droplets or sheets. The lyophilic surfaces may be formed with a thin layer of inherently lyophilic polymer on the surface of the component. The lyophilic surfaces may be selectively provided on critical areas of the component, such as for example on flow channel wall surfaces of bipolar plates and membrane electrode assemblies, thereby inhibiting liquid blocking of the flow channels during operation of the fuel cell.

Owner:ENTEGRIS INC

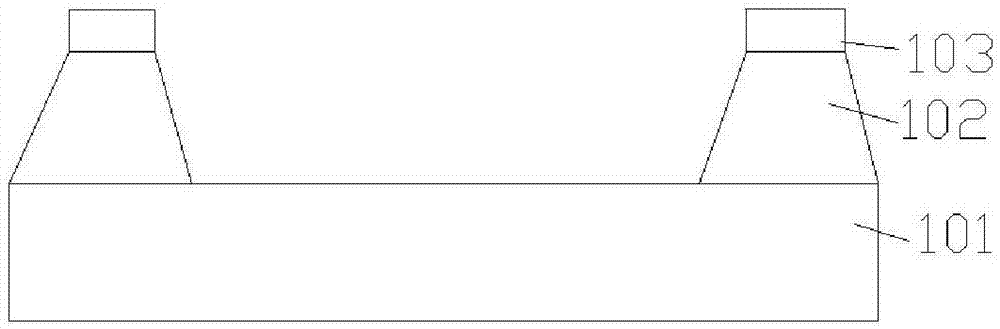

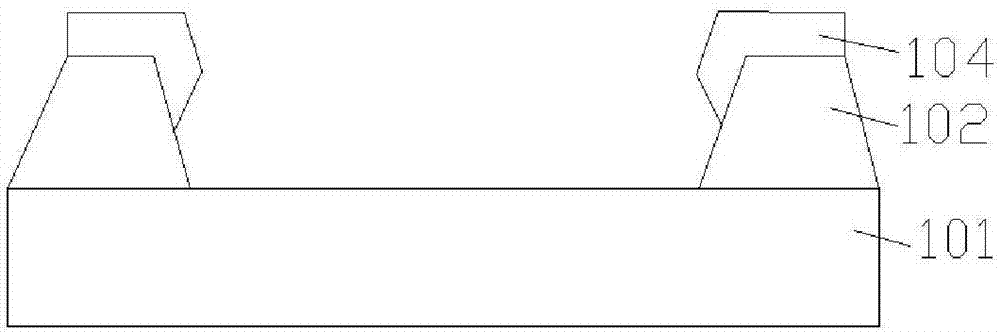

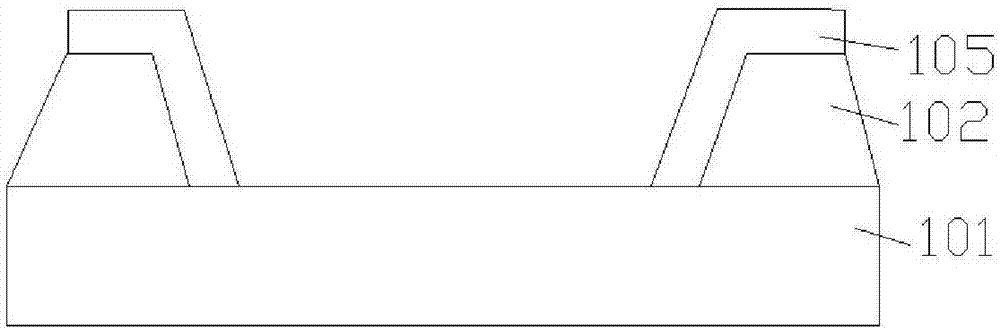

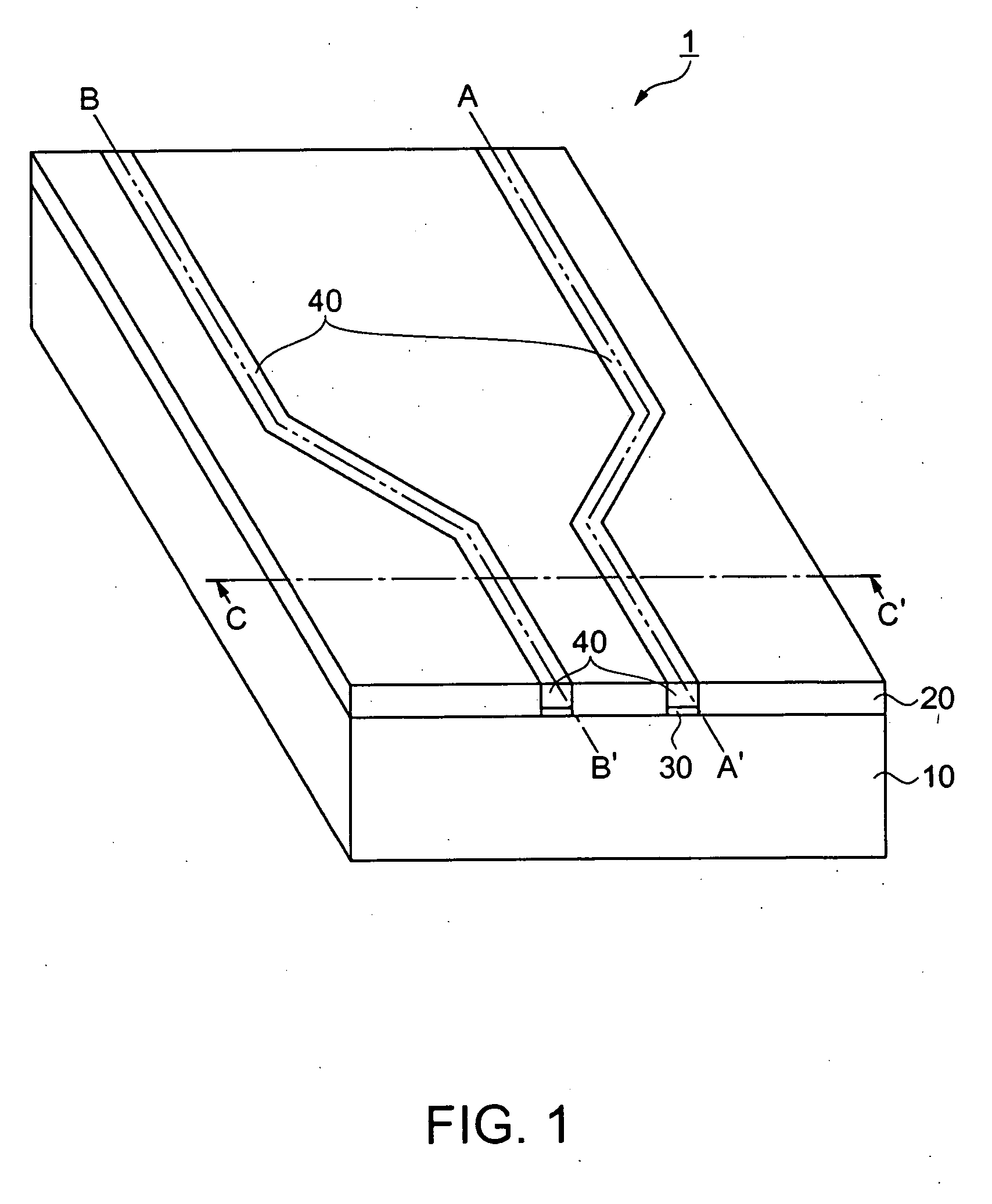

Pixel defining layer and manufacturing method thereof

ActiveCN107248523AEasy to prepareReduce manufacturing costSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

According to the invention, a first defining layer of a pixel defining layer comprises dam bodies locally covering a substrate; second defining layers are arranged at the tops of the dam bodies; and the second defining layers are made of a lyophobic material. A manufacturing method of the pixel defining layer disclosed by the invention comprises the steps of: preparing the first defining layer on the substrate; preparing one layer of lyophobic material on the substrate and the first defining layer; and by the etching process, removing the lyophobic material between the dam bodies to obtain the second defining layers covering the dam bodies of the first defining layer. According to the pixel defining layer disclosed by the invention, hydrophobic layers are arranged at the tops of the dam bodies, and a material of the substrate has the lyophilic property, so that the requirements for top lyophobicity and bottom lyophilic property of the pixel defining layer are met; and the manufacturing method of the pixel defining layer disclosed by the invention is simple, low in manufacturing cost and very simple and convenient in process flow.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

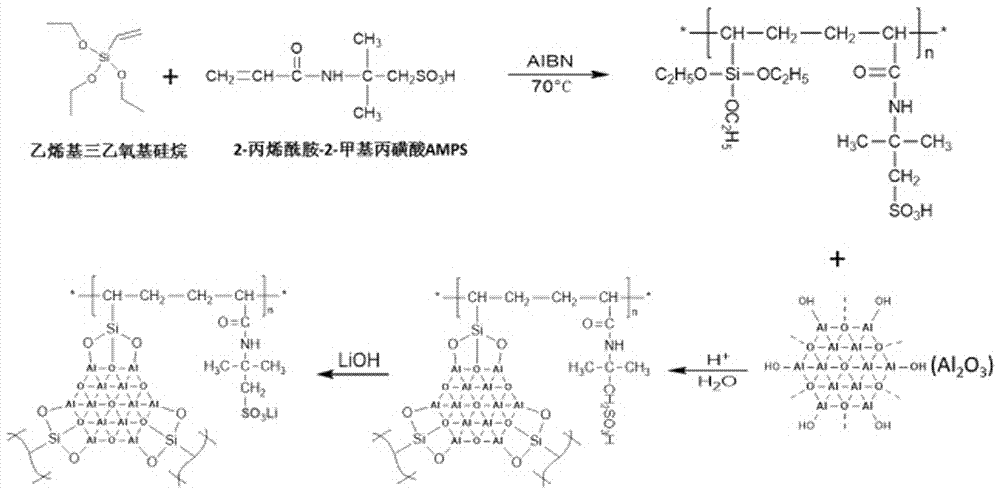

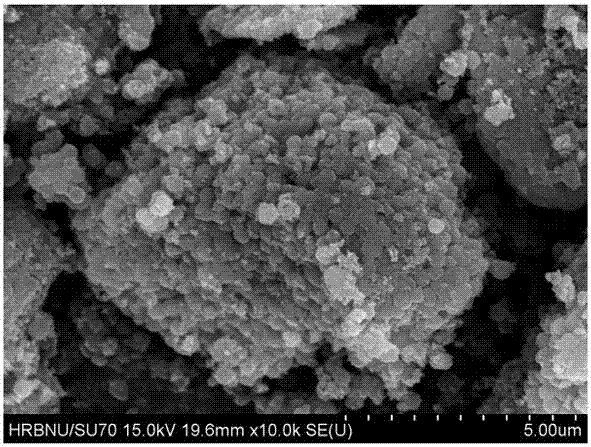

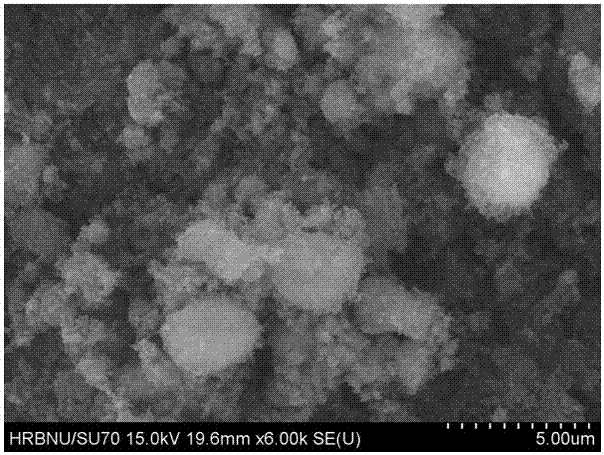

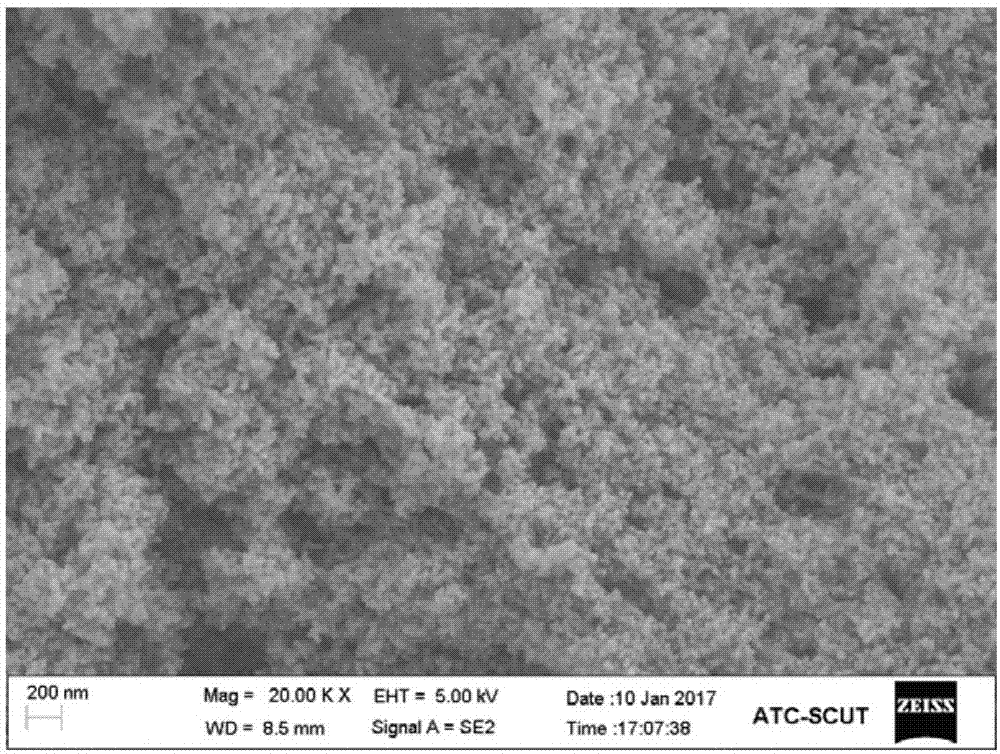

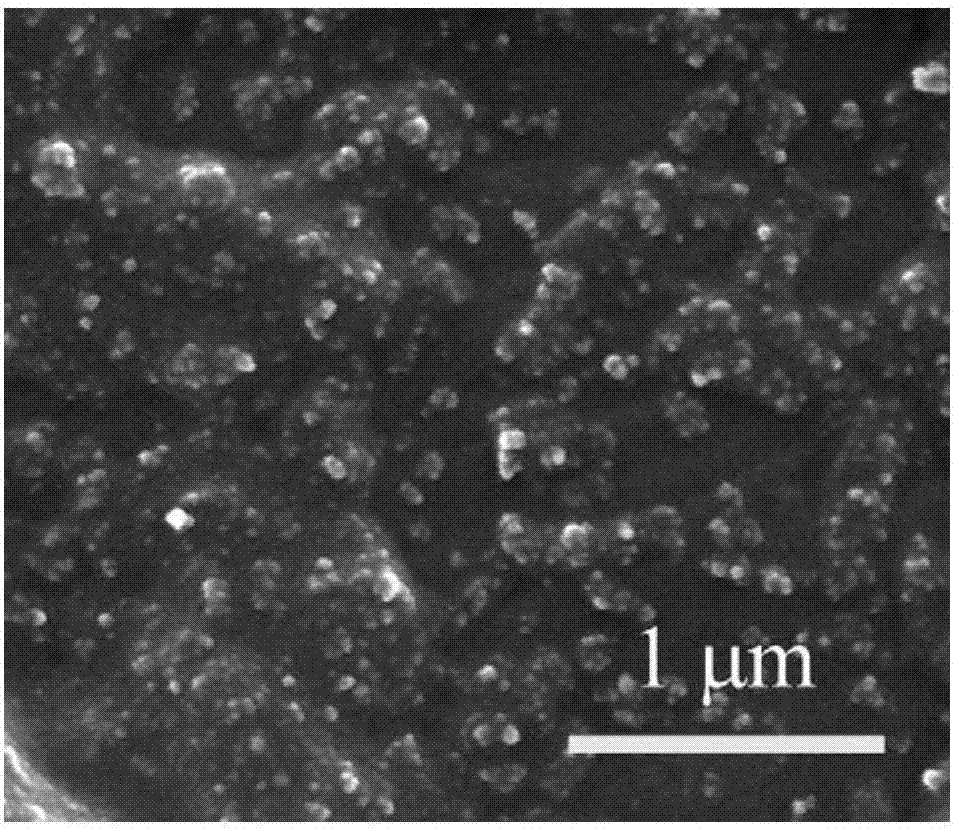

Surface-modified inorganic nanoparticles as well as preparation method and application thereof

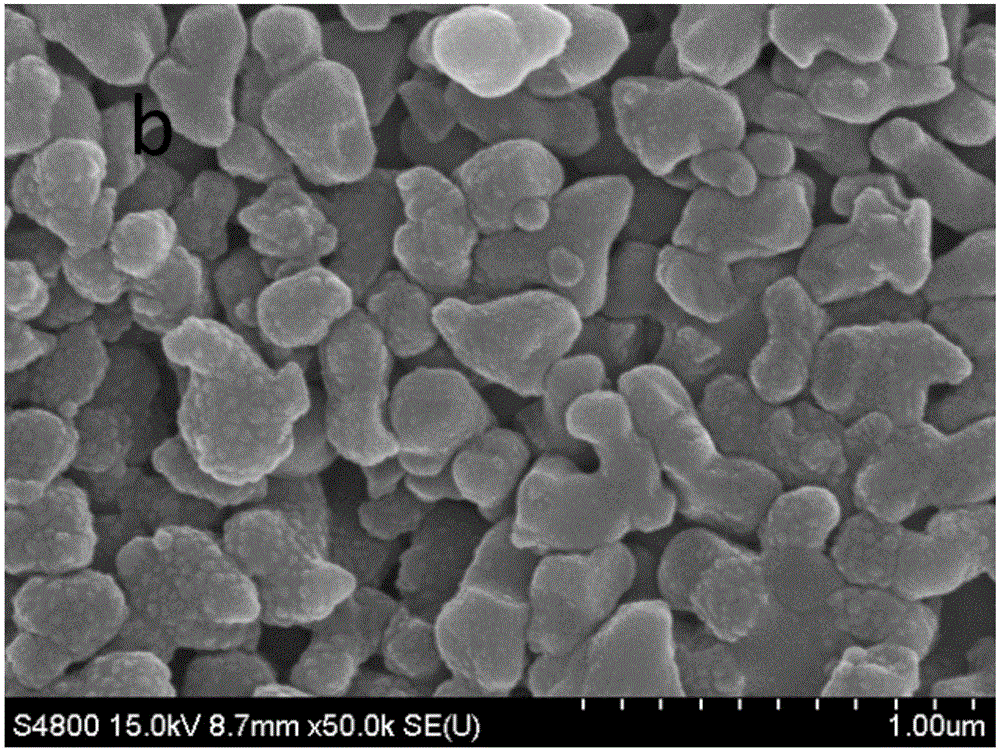

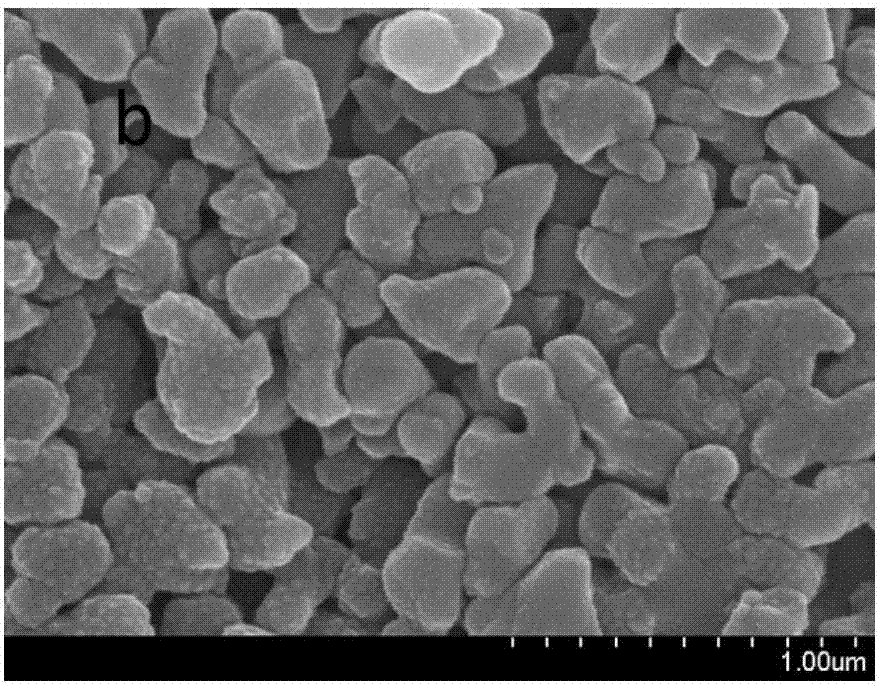

ActiveCN107134590AGood dispersionEvenly dispersedMaterial nanotechnologySolid electrolytesDispersityMetal oxide nanoparticles

The invention discloses surface-modified inorganic nanoparticles as well as a preparation method and application thereof. The surface-modified inorganic nanoparticles are composed of a core of inorganic metal oxide nanoparticles and amphipathic organic segments grafted on the surface of the particles, wherein the amphipathic organic segments grafted on the surface of the particles account for 0.1-50% of total mass of the surface-modified inorganic nanoparticles; the inorganic metal oxide nanoparticles refer to one or several in aluminum oxide, silicon dioxide, titanium dioxide, zirconium dioxide and zinc oxide inorganic nanoparticles; and the amphipathic organic segments are produced from a vinyl silicane coupling agent and 2-acrylamido--methylpropane sulfonic acid through solution polymerization. The surface-modified inorganic nanoparticles can be used for preparing polymer electrolyte. Therefore, the inorganic nanoparticles are high in dispersity in a polymer matrix, and the prepared polymer electrolyte is high in lyotropic property, high in ionic conductivity and stable in electrochemical performance.

Owner:浙江久功新能源科技有限公司

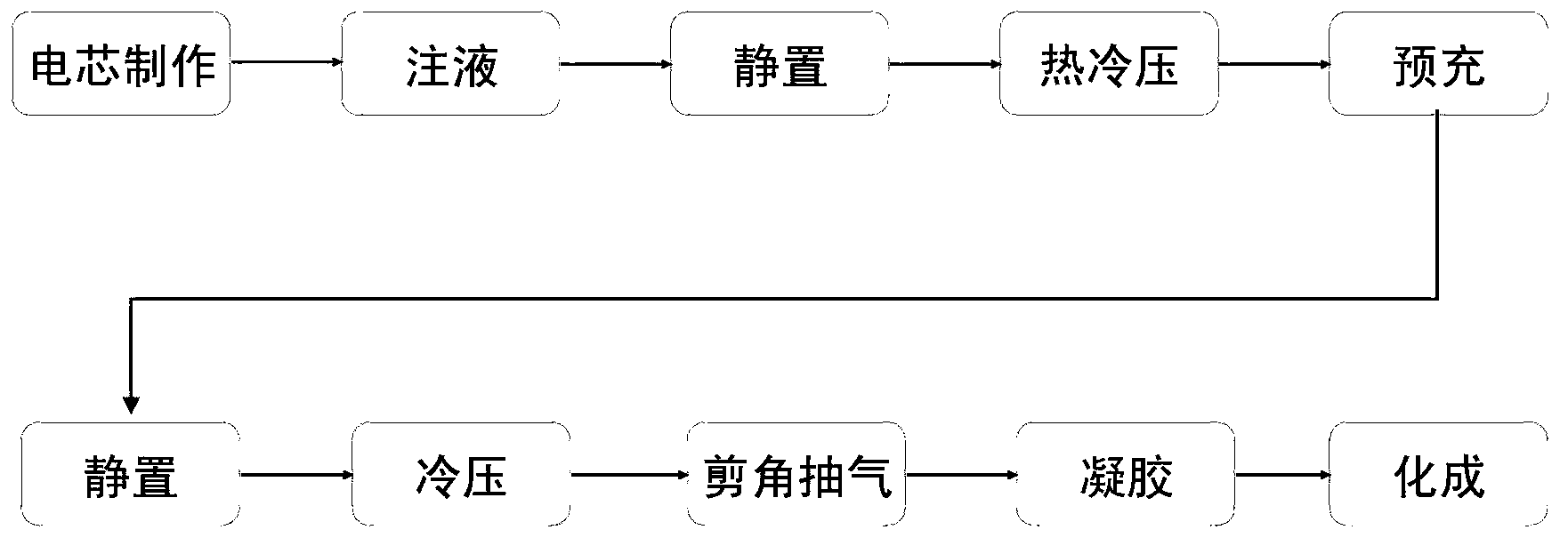

Method for preparing gel diaphragm cell by in-situ polymerization and prepared battery

ActiveCN103258977ASmall difference in performanceConducive to consistencySecondary cellsCell component detailsChemistryIn situ polymerization

The invention discloses a method for preparing a gel diaphragm cell by in-situ polymerization and a prepared battery. The method comprises the following steps of: adding a special initiator and a monomer, which are needed for a polymerization reaction, into an organic solvent electrolyte for dissolving lithium salts to prepare a polymer electrolyte; and then manufacturing a gel cell. According to the conditions of the polymerization reaction of the polymer electrolyte, due to a designed polymerization process technology, the polymer electrolyte and a polymer diaphragm gradually form a gel diaphragm in the gel battery so as to manufacture the cell with good diaphragm gel effect, good interface effect of an electrolyte electrode and consistent electric performance.

Owner:CENT SOUTH UNIV +1

Method for preparing modified ceramic diaphragm through dopamine compound adhesive and application thereof

InactiveCN106654125AStrong adhesionImprove thermal stabilitySecondary cellsCell component detailsWater basedAdhesive

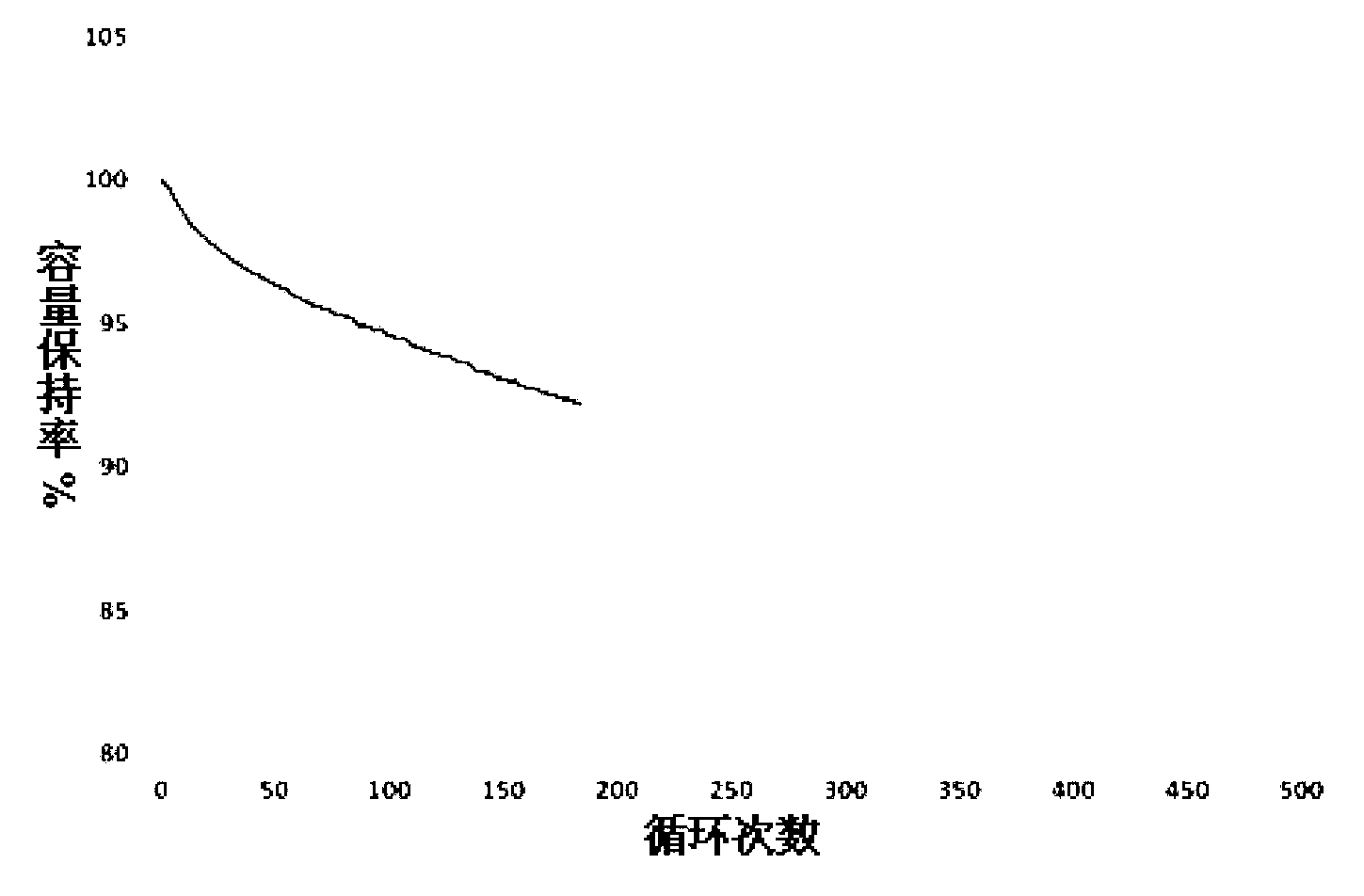

The invention discloses a method for preparing a modified ceramic diaphragm through a dopamine compound adhesive. The method comprises the following steps: compounding dopamine or polydopamine nanoparticles with an aqueous adhesive to form a compound adhesive, mixing the compound adhesive, nano ceramic particles and a water-based solvent, then coating the mixture on an organic microporous diaphragm substrate to form a modified ceramic layer, thereby obtaining the modified ceramic diaphragm, namely the nano ceramic particles are tightly adhered to the surface of the diaphragm substrate due to good infiltration and adhesion of the aqueous adhesive; meanwhile, through polydopamine, the thermal stability and the mechanical performance are improved; positive and negative electrodes are effectively blocked, so that the short circuit is avoided; the cycle performance of the battery using the modified ceramic diaphragm prepared by the method is improved.

Owner:XIAMEN UNIV

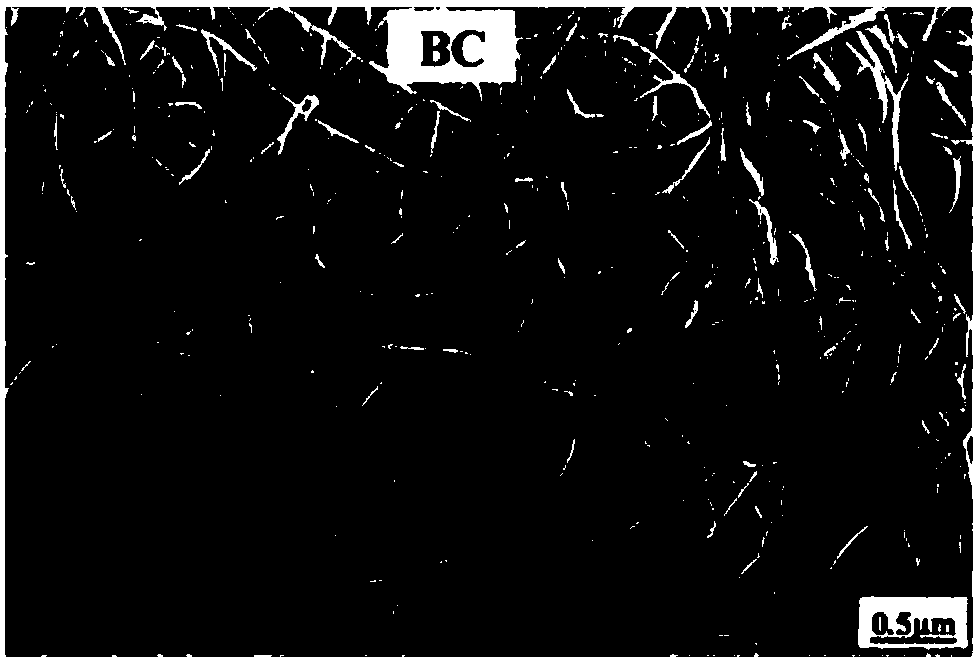

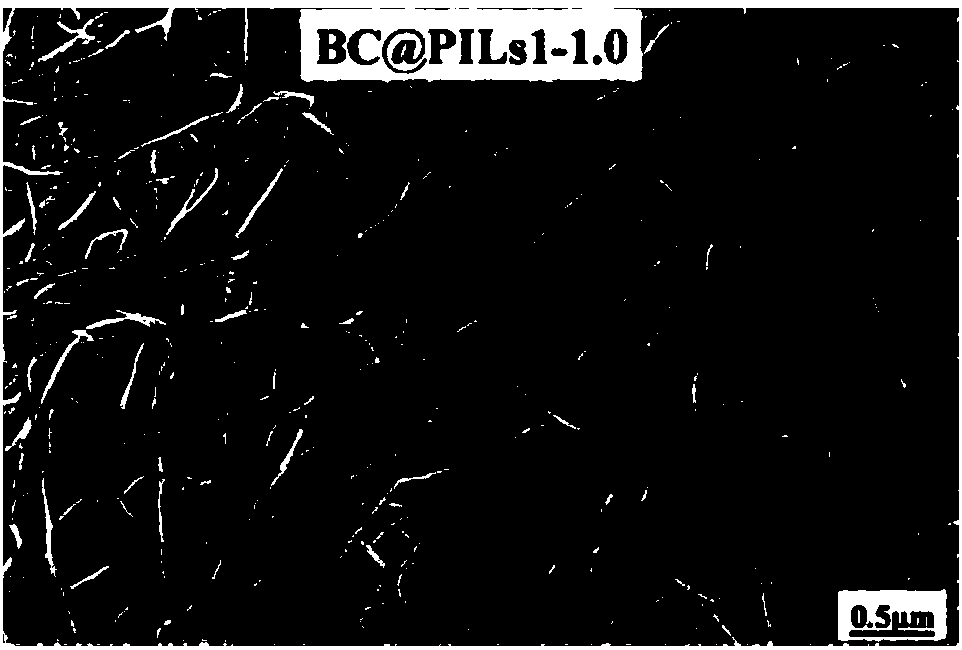

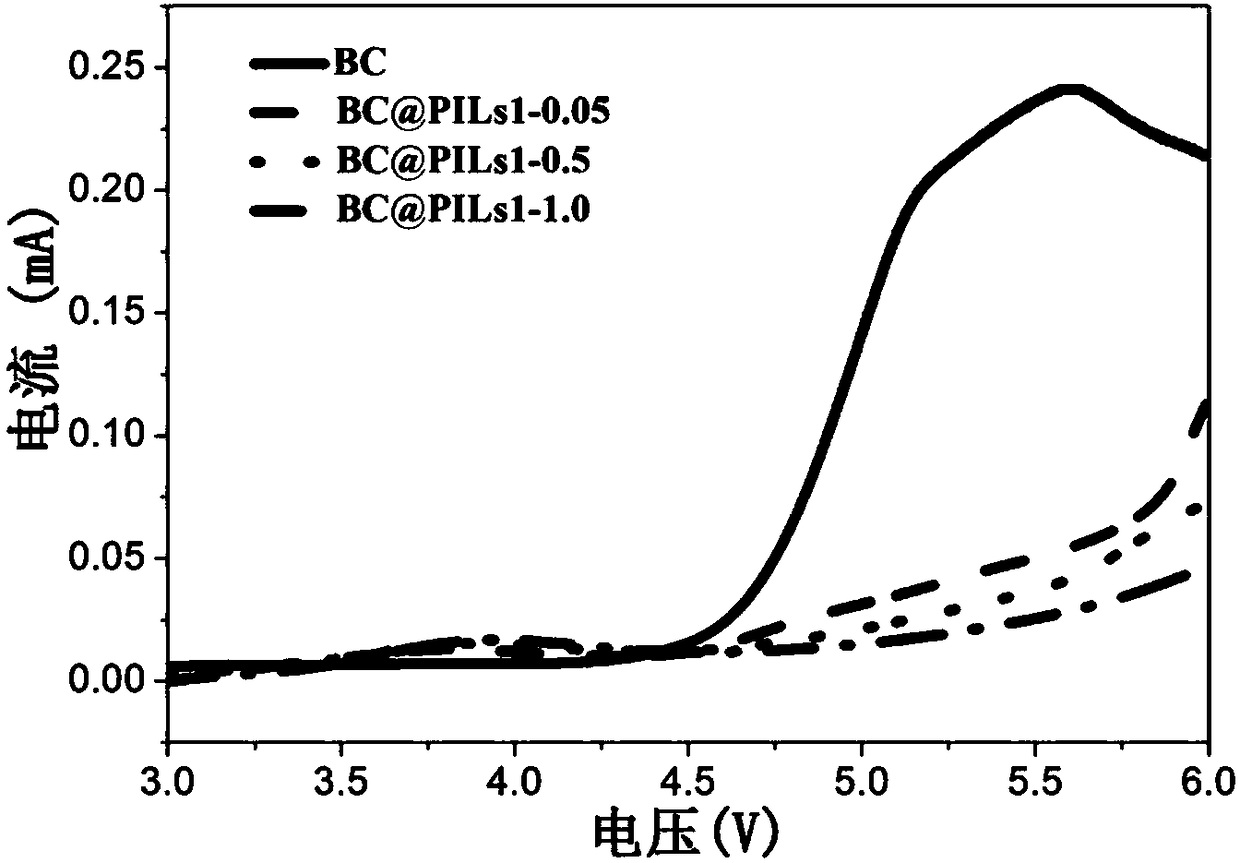

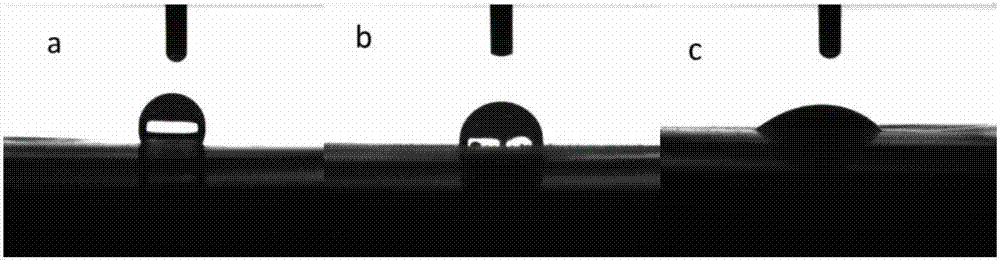

Polyionic liquid-coated bacterial cellulose diaphragm and preparation method thereof

ActiveCN108232085AImprove cycle stabilityImprove securitySecondary cellsCell component detailsPorosityLithium-ion battery

The invention discloses a bacterial cellulose diaphragm and a preparation method thereof. The surfaces of nanofibers of the bacterial cellulose diaphragm are coated with a layer of polyionic liquid, and the polyionic liquid is one or the combination of more of imidazolium salt polyionic liquid, pyrrolidine salt polyionic liquid, piperidine salt polyionic liquid and quaternary ammonium salt polyionic liquid. The preparation method comprises the following steps: the bacterial cellulose diaphragm is sequentially immersed in aqueous polyionic liquid solution for 2 to 48 hours, immersed in precipitator for 30 minutes to 24 hours and immersed in lithium salt solution for 2 to 48 hours, finally, a hot press is utilized to press the bacterial cellulose diaphragm to be thin, and after drying, the polyionic liquid-coated bacterial cellulose diaphragm is obtained. The advantages of the invention are as follows: (1) the polyionic liquid-coated bacterial cellulose diaphragm has the advantages of high mechanical strength, good thermal stability, good lyophilic property, high porosity and high ionic conductivity, and can increase the cyclic stability and safety of lithium ion batteries; (2) the preparation method is simple, has low requirement on equipment, and is suitable for mass production.

Owner:SHANGHAI ENERGY NEW MATERIALS TECH CO LTD

Preparation of high-safety ceramic-coated separator and application of ceramic-coated separator in lithium ion battery

ActiveCN107331825ARich sourcesWide range of usesSecondary cellsCell component detailsWater basedNanoceramic

The invention discloses preparation of a high-safety ceramic-coated separator and an application of the ceramic-coated separator in a lithium ion battery, and relates to a lithium ion battery. The preparation comprises the steps of uniformly mixing a nano ceramic particle, lignin, a lignin derivative, a water-base binding agent and a water-base solvent to obtain ceramic slurry, coating the ceramic slurry on the surface of a microporous separator, performing vacuum drying, and removing the solvent to obtain a modified ceramic-coated separator, namely the high-safety ceramic-coated separator. The high-safety ceramic-coated separator can be applied in the lithium ion battery. The application can replace the existing ceramic-coated separator. The lithium ion battery comprises an anode material, a cathode material and the ceramic-coated separator. The ceramic slurry is mixed into the ceramic-coated separator, so that the heat resistance and the interface performance of the ceramic-coated separator are improved.

Owner:XIAMEN UNIV

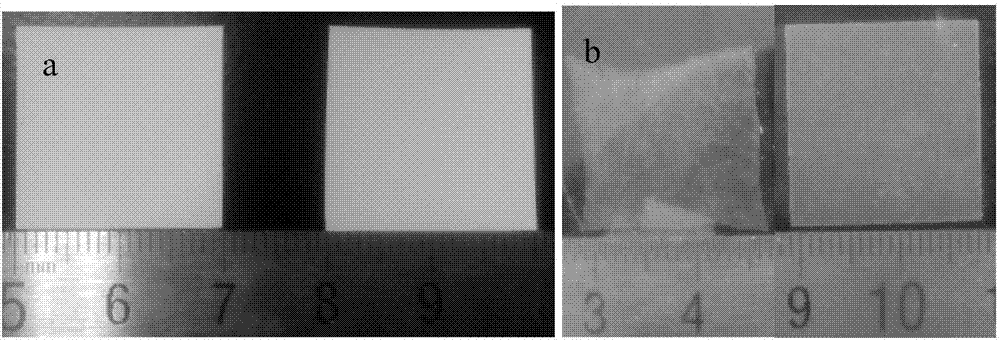

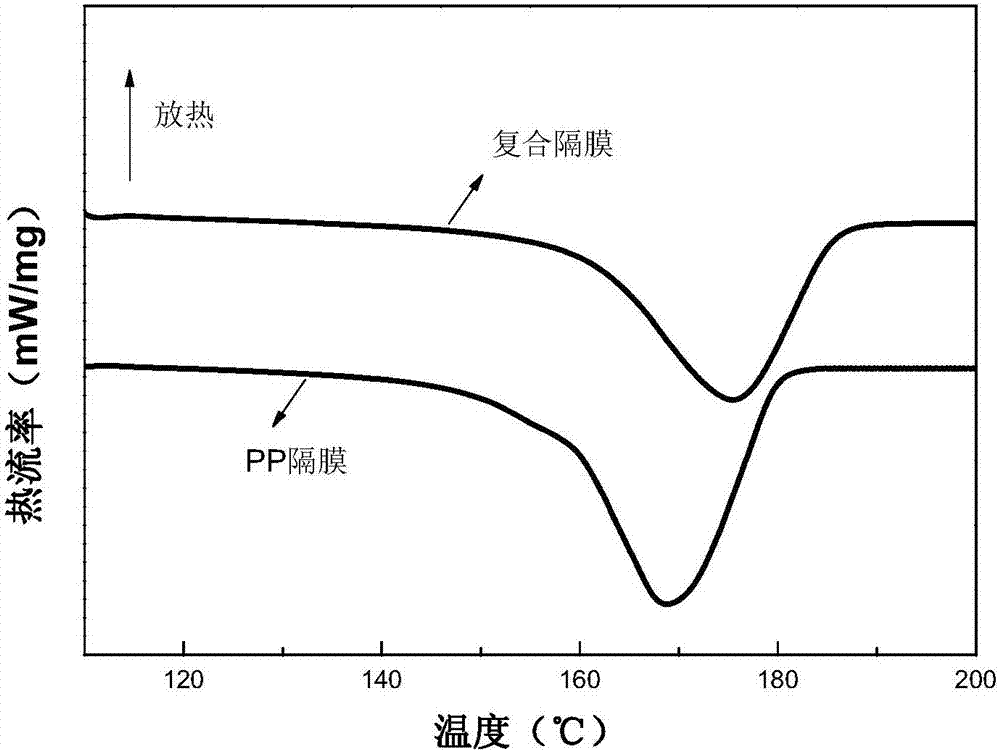

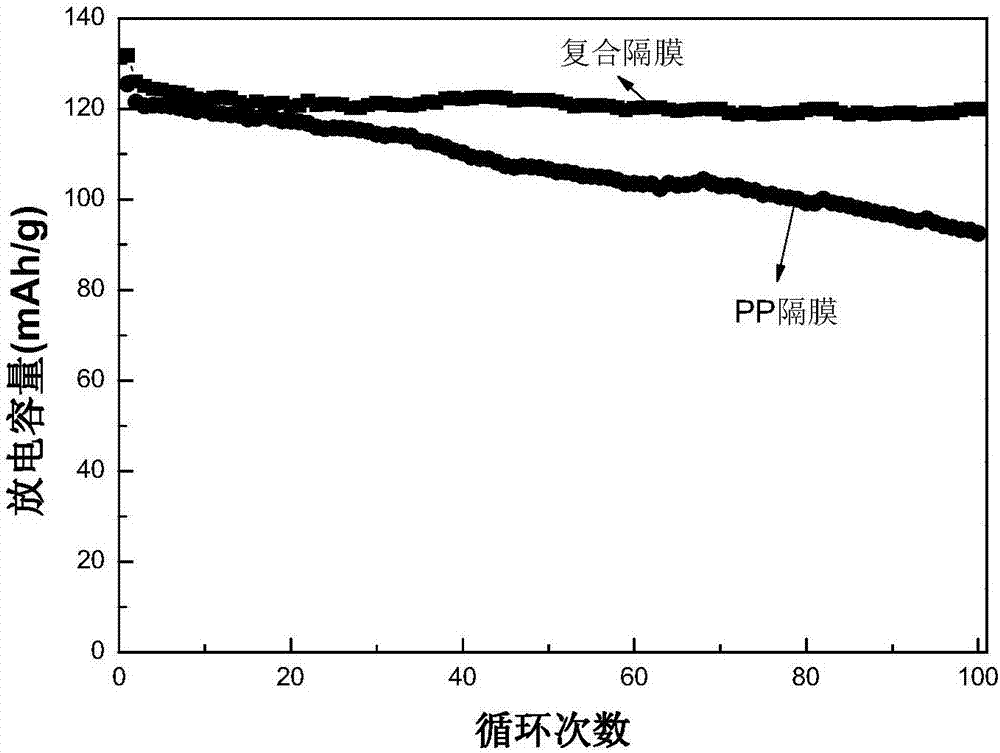

High-heat-resistance lithium battery composite diaphragm and preparation method thereof

ActiveCN107216472AImprove securityImprove electrochemical performanceCell component detailsCoatingsPolyolefinPolyvinyl alcohol

The invention discloses a high-heat-resistance lithium battery composite diaphragm and a preparation method thereof. The preparation method comprises the following steps: adding polyvinyl alcohol powder into deionized water, swelling at the room temperature for 10-12 hours, and stirring at 85-95 DEG C for 4-5 hours, so as to prepare a polyvinyl alcohol solution; mixing and stirring ethyl orthosilicate, absolute ethyl alcohol and deionized water, dropwise adding ammonia water, and stirring at 40-45 DEG C for 0.5-1 hour, so as to obtain a mixture; adding the obtained mixture and aluminum oxide powder into the obtained polyvinyl alcohol solution, and stirring at 40-45 DEG C for 10-12 hours, so as to obtain a coating sizing agent; and coating the surface of a pretreated polyolefin microporous membrane with the sizing agent by virtue of a coating method, drying at the room temperature, and carrying out vacuum drying, so as to obtain the high-heat-resistance lithium battery composite diaphragm. The preparation method is simple in process and environment-friendly, and the prepared composite diaphragm is high in heat resistance, liquid absorbing rate and liquid retention rate and excellent in electrochemical performance and has good application prospects.

Owner:SOUTH CHINA UNIV OF TECH

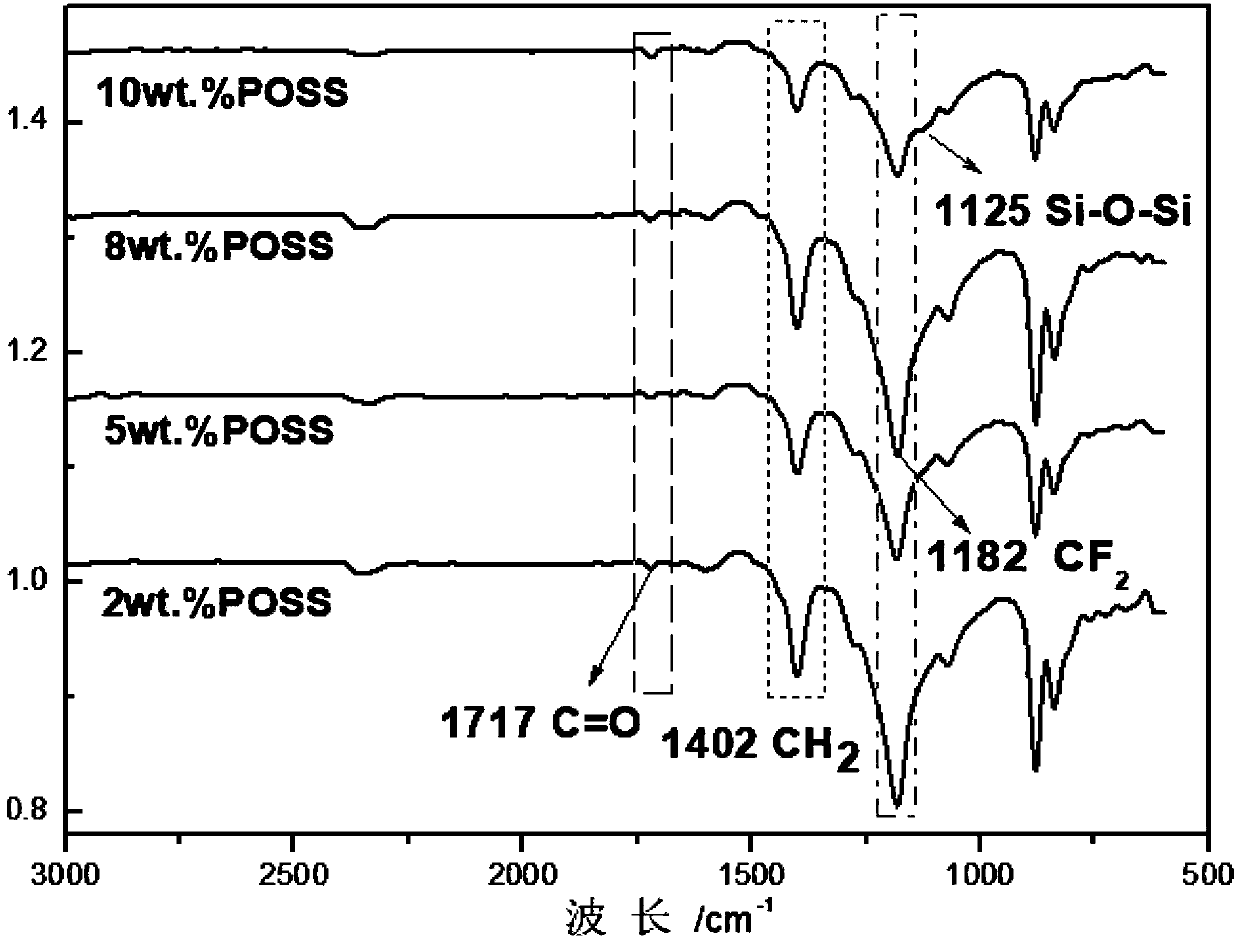

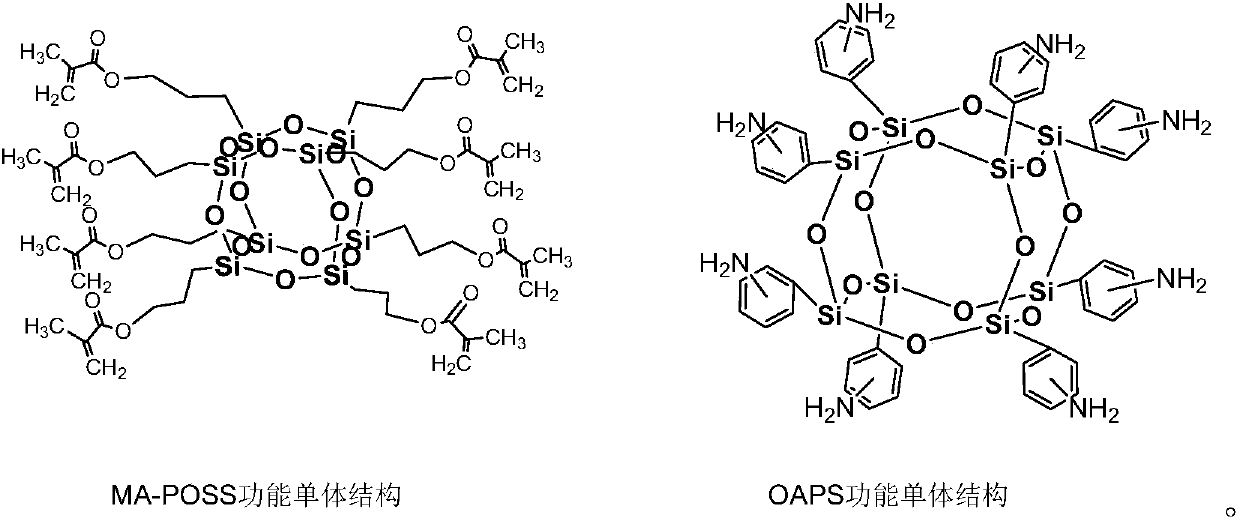

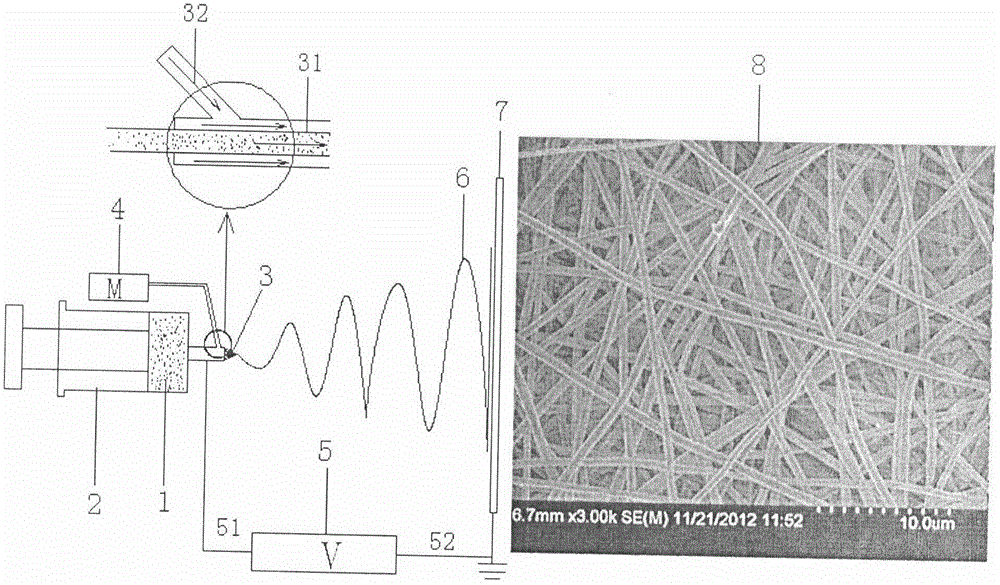

POSS modified nanofiber membrane and preparation method and application thereof

ActiveCN107938169AImprove thermal stabilityHigh mechanical strengthElectro-spinningConjugated synthetic polymer artificial filamentsFiberOrganic solvent

The invention belongs to the field of nanofiber membranes, and discloses a POSS modified nanofiber membrane and a preparation method and application thereof. The preparation method comprises the following steps: dissolving PVDF and PMMA into an organic solvent to obtain an electrostatic spinning solution; dissolving functional monomers of MA-POSS and OAPS into the organic solvent to obtain an electrostatic spraying solution; adding a photoinitiator in the electrostatic spinning solution, then placing the electrostatic spinning solution and the electrostatic spraying solution in an electrostatic spinning machine together, carrying out electrostatic spinning and electrostatic spraying simultaneously under the condition of ultraviolet irradiation; and after spinning is finished, drying the obtained fiber membrane to obtain the POSS modified nanofiber membrane. The nanofiber membrane is modified by the functional monomers of MA-POSS and OAPS, and the thermals stability and mechanical strength of the nanofiber membrane can be improved remarkably; and reaction activity, separation and adsorption functions and the like can be given for the spinning fiber membrane, and thus, the application field of the spinning fiber membrane is expanded.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI +1

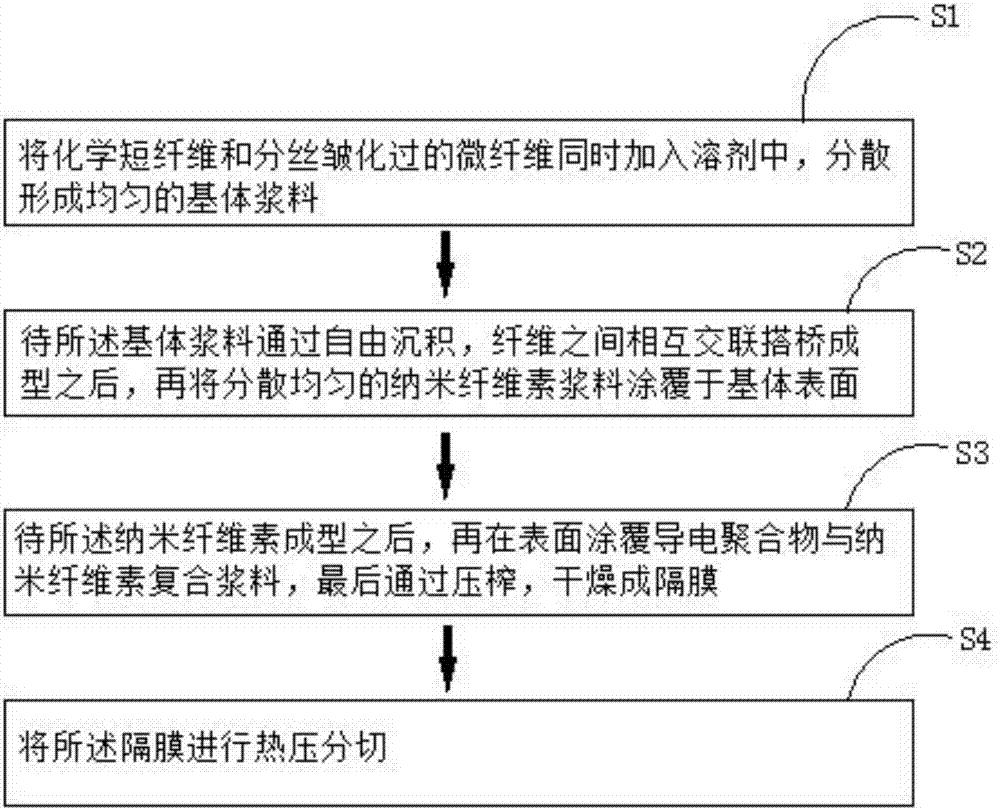

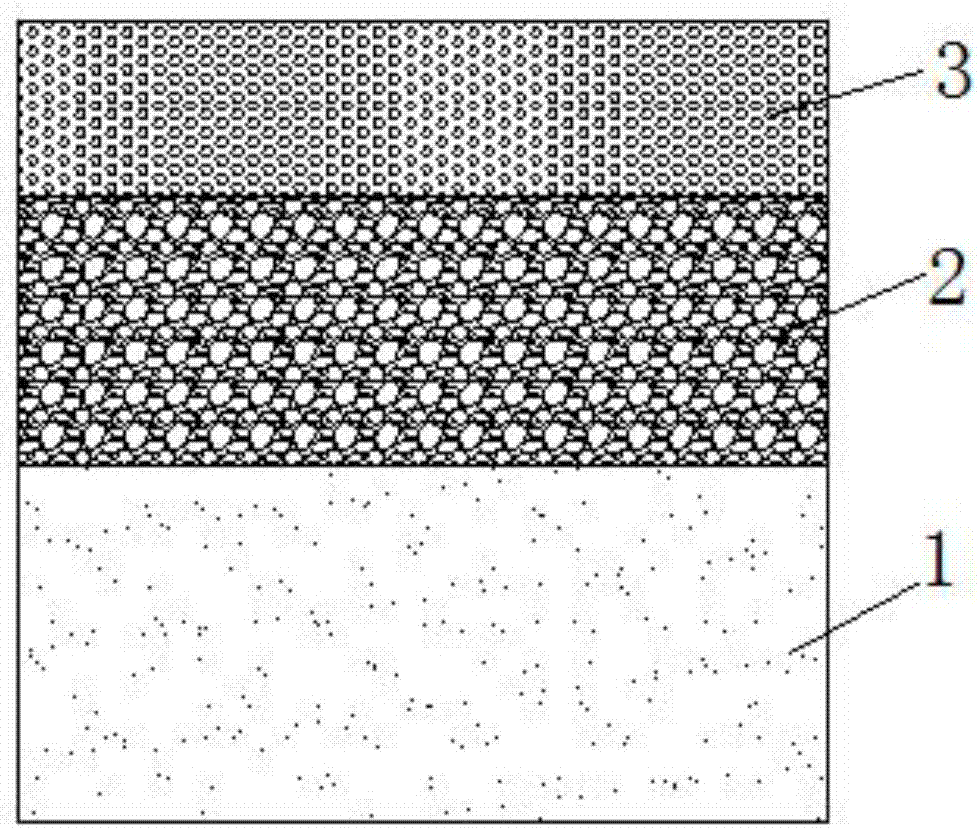

Lithium-sulphur battery diaphragm preparation method, lithium-sulphur battery diaphragm and lithium-sulphur battery

ActiveCN107230764AImprove Coulombic efficiencyImprove conductivityMaterial nanotechnologyLi-accumulatorsFiberSurface layer

The invention relates to the field of lithium-sulphur batteries, and provides a lithium-sulphur battery diaphragm preparation method. The lithium-sulphur battery diaphragm preparation method comprises the four steps of: simultaneously adding chemical staple fibre and separated and wrinkled micro-fibre into a solvent; after free deposition of matrix slurry, coating uniformly dispersed nano-cellulose slurry on the surface of a matrix; after nano-cellulose is formed, coating conductive polymer and nano-cellulose composite slurry on the surface, finally, squeezing, and drying to form the diaphragm; and, hot pressing and cutting the diaphragm. According to the lithium-sulphur battery diaphragm preparation method provided by the invention, the lithium-sulphur battery diaphragm can be obtained through the steps S1-S4; and thus, the coulombic efficiency of the lithium-sulphur battery can be improved. The invention provides a lithium-sulphur battery diaphragm comprising an intermediate layer, a basal layer and a surface layer. The lithium-sulphur battery diaphragm provided by the invention can store a lot of electrolyte; and thus, the battery cycle capacity is improved. The invention provides a lithium-sulphur battery comprising the diaphragm. The performance of the lithium-sulphur battery provided by the invention is greatly improved.

Owner:宁波柔创纳米科技有限公司

Ceramic diaphragm with dopamine-containing composite binder and application of ceramic diaphragm with dopamine-containing composite binder in lithium ion battery

InactiveCN107507950AImprove thermal stabilityImprove mechanical propertiesCell component detailsWater basedAdhesive

The invention discloses a ceramic diaphragm with a dopamine-containing composite binder and application of the ceramic diaphragm with the dopamine-containing composite binder in a lithium ion battery, and relates to the lithium ion battery. The ceramic diaphragm with the dopamine-containing composite binder comprises a diaphragm base material, wherein the surface of the diaphragm base material is coated with a protective layer; the protective layer is prepared from ceramic powder and the dopamine-containing composite binder. A method of preparing the ceramic diaphragm comprises the following steps: mixing inorganic particle powder, a water-based solvent and an adhesive, adjusting the pH to 6 to 12, adding dopamine, and uniformly mixing the materials, thus obtaining ceramic slurry; coating a single layer or two layers of surfaces of the diaphragm base material with the obtained ceramic slurry, leaving the diaphragm base material to stand for aging till the dopamine monomer is completely polymerized, washing the diaphragm base material with the water-based solvent to remove impurities, and drying the diaphragm base material to remove the solvent, thus obtaining the ceramic diaphragm with the dopamine-containing composite binder. The ceramic diaphragm with the dopamine-containing composite binder can be applied to the lithium ion battery.

Owner:XIAMEN UNIV

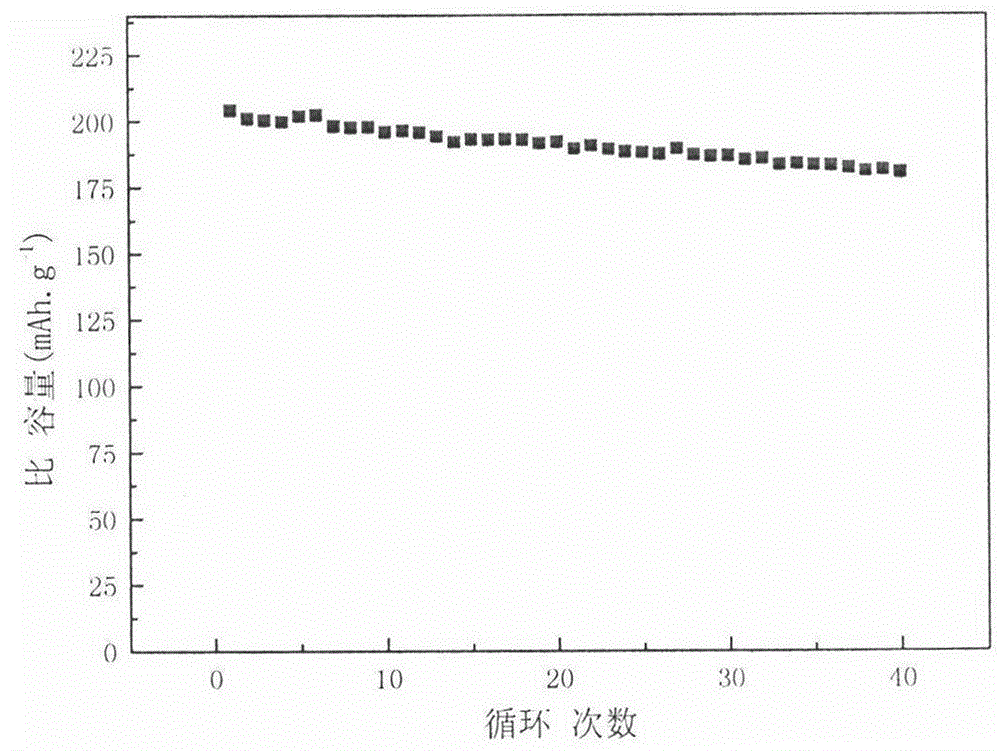

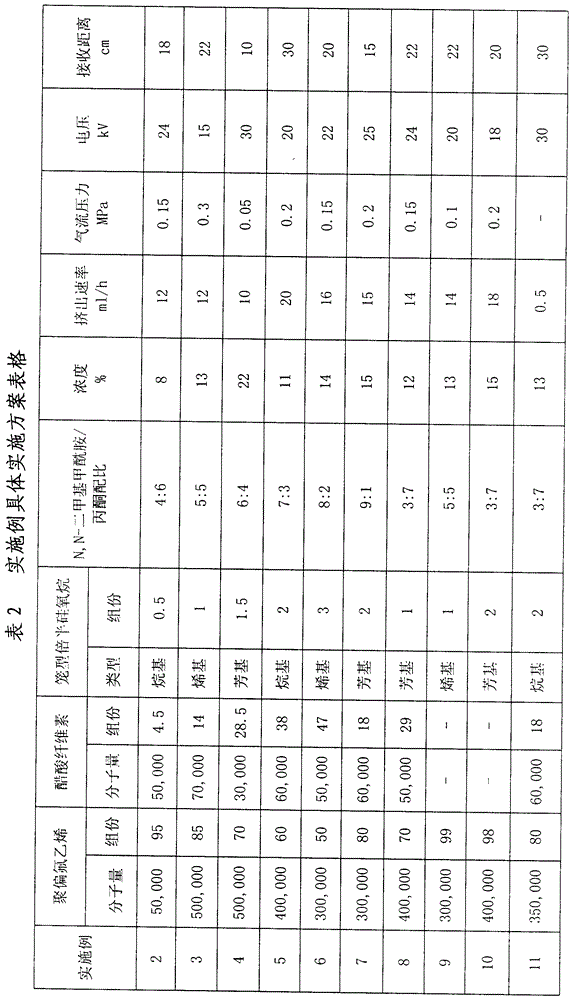

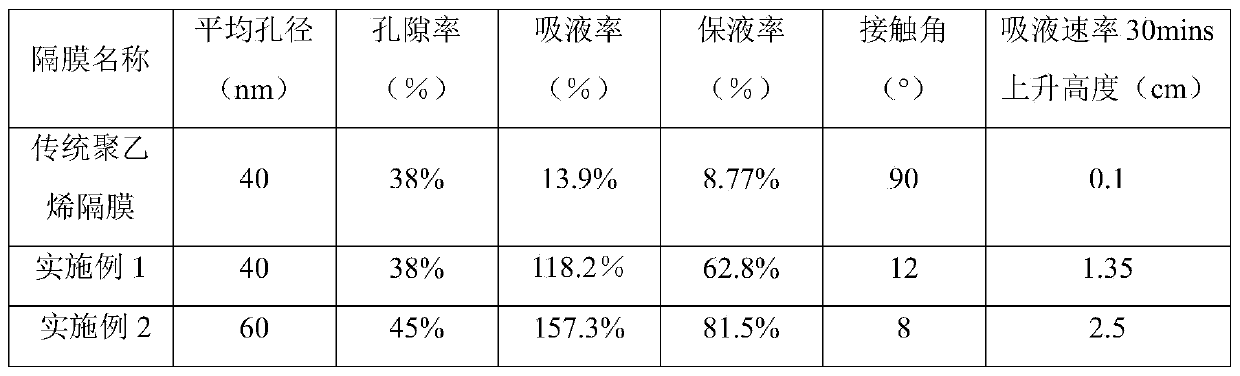

Blend superfine fiber diaphragm for lithium ion battery

InactiveCN104362280AShort processing flowSimple processSecondary cellsCell component detailsFiberCellulose acetate

The invention relates to a blend superfine fiber diaphragm for a lithium ion battery. The blend superfine fiber diaphragm is characterized by comprising polyvinylidene fluoride, cellulose acetate and polyhedral oligomeric silsesquioxane. The polyhedral oligomeric silsesquioxane is one of alkyl silsesquioxane, alkenyl silsesquioxane or aryl silsesquioxane. The blend superfine fiber diaphragm provided by the invention has good hydrophilcity, high strength and excellent thermal size stability; the solution absorbing rate of the blend superfine fiber diaphragm is 300-900 percent, the thermal shrinkage rate of the blend superfine fiber diaphragm is smaller than 5 percent, the specific capacity of a gel polymer lithium ion battery assembled by adopting the blend superfine fiber diaphragm reaches 200-220 mAh.g<-1>, and the lithium intercalation utilization rate of an anode material LiCoO2 can reach above 70 percent.

Owner:TIANJIN POLYTECHNIC UNIV

Water-based metal ion secondary battery diaphragm, and preparation method and application thereof

InactiveCN110364664AImprove wettabilityImprove liquid retention capacitySecondary cellsCell component detailsWater basedPolymer

The invention discloses a water-based metal ion secondary battery diaphragm, and a preparation method and application thereof, and belongs to the technical field of lithium battery diaphragms. The water-based metal ion secondary battery diaphragm comprises a porous base membrane; the surface of the porous base membrane is coated with a hydrophobic coating; the surface of the hydrophobic coating isgrafted with a hydrophilic coating; the hydrophilic coating is grafted on the surface of the hydrophobic coating through a laser radiation surface grafting method; the wavelength of a light beam forradiation is 9.1-10.6 [mu]m; and the radiation duration is 100-500 ns, preferably 100-200 ns. By adopting the technical scheme provided by the invention, the wettability and the liquid retention of the diaphragm can be effectively improved on the basis of keeping the original excellent physical properties, conductivity and cycle performance of the polymer diaphragm, so that the use requirements ofthe water-based metal ion secondary battery diaphragm are met.

Owner:安徽金力新能源有限公司

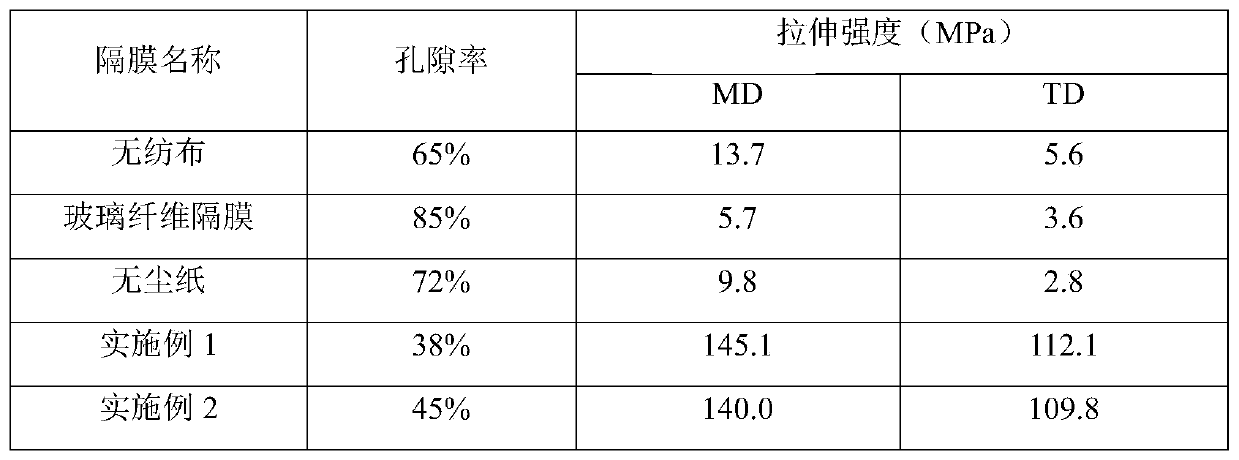

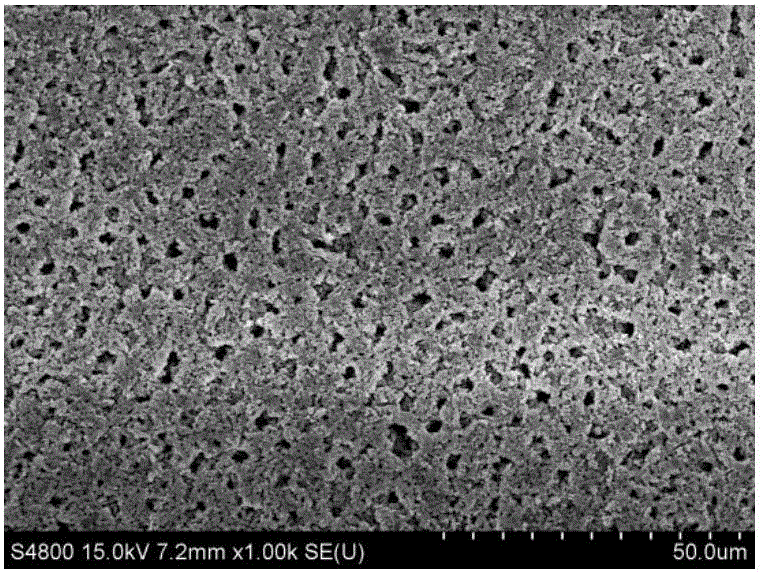

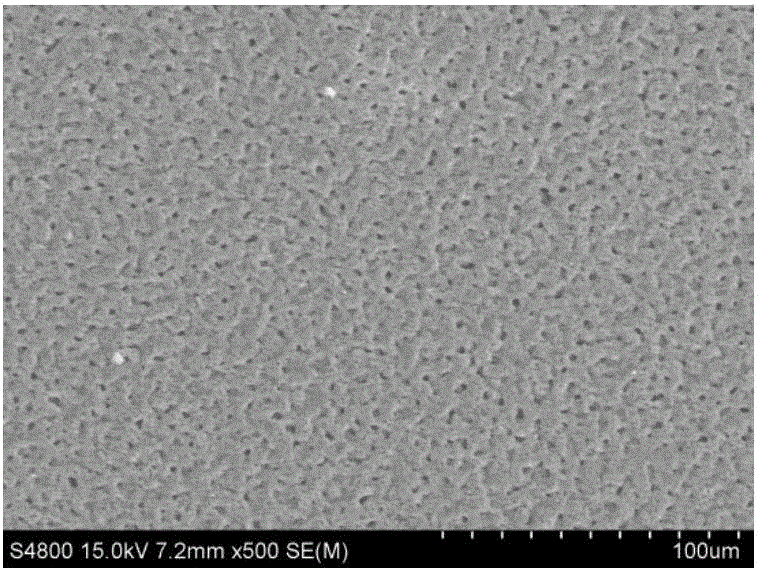

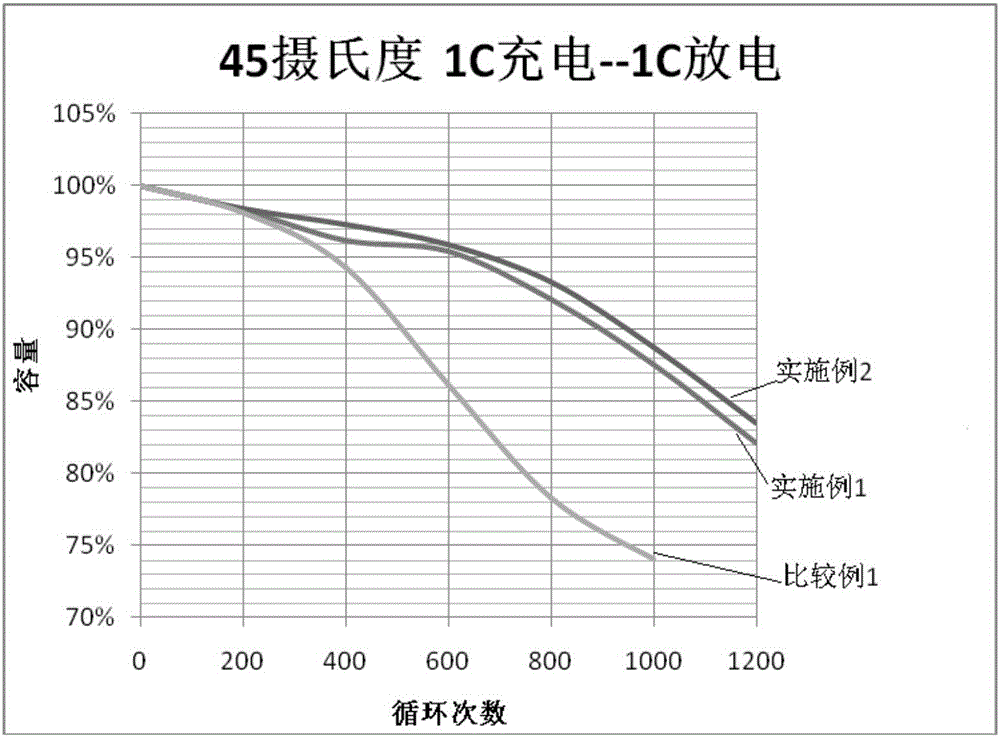

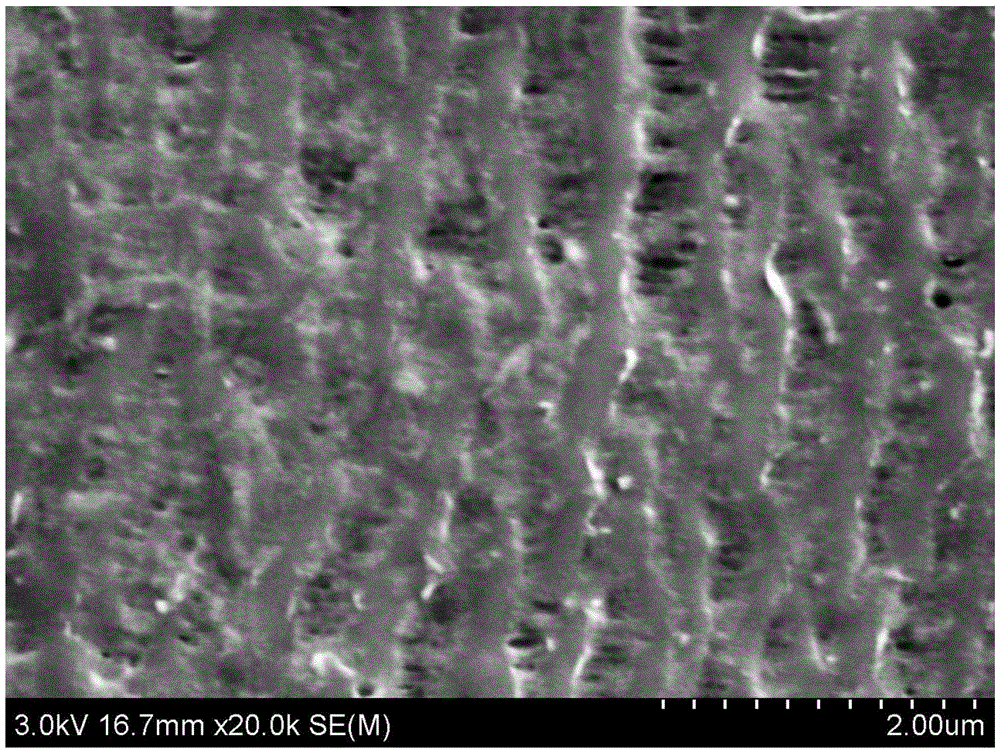

Reticular porous composite isolation film and preparation method thereof

InactiveCN106374075AHigh ion exchange capacityImprove lyophilicityCell seperators/membranes/diaphragms/spacersSecondary cellsIon exchangeDielectric layer

The invention discloses a reticular porous composite isolation film and a preparation method thereof. The reticular porous composite isolation film comprises a porous film layer and a reticular porous dielectric layer compounded on the porous film layer, wherein the aperture on the reticular porous dielectric layer is 0.1-1 micron; and the porosity of the reticular porous dielectric layer is 38%-43%. The reticular porous composite isolation film disclosed by the invention has relatively high ion-exchange capacity and lyophilic property; and the infiltrating ability of an electrolyte is high, the thermal shrinkage rate is low, the film rupture temperature is high and the safety is improved. Furthermore, according to the preparation method of the reticular porous composite isolation film, the technology is simple, the demand on equipment is low, the conditions are easy to control, the cost is low and the preparation method is suitable for industrial production. The prepared lithium battery is significantly improved in the aspects of the safety, the cyclicity, the rate capability and the like.

Owner:SINOMA SCI & TECH

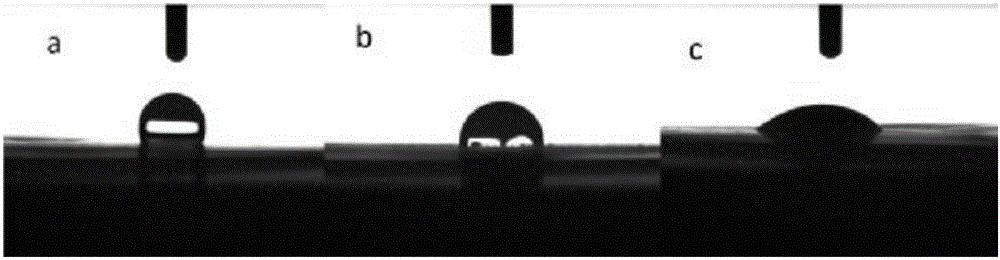

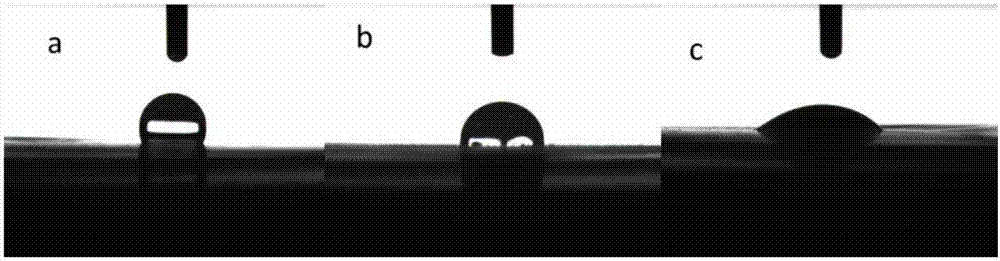

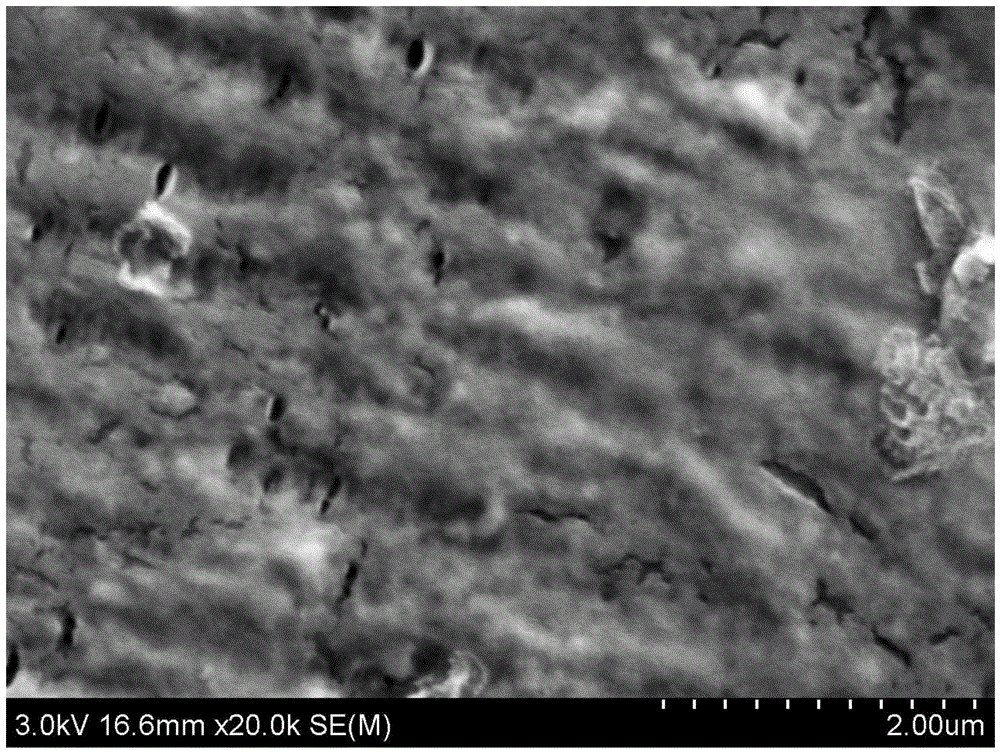

Super-lyophilic coating resistant to mechanical damages and preparation method thereof

ActiveCN107987296AImprove bindingImprove toughnessCoatings with pigmentsReinforcing agents additionToughnessPolymer chemistry

The invention discloses super-lyophilic coating resistant to mechanical damages. The super-lyophilic coating comprises at least three layers of coating structures, which are sequentially stacked; thefirst layer is a coating close to a substrate, and the next coating is sequentially stacked on the last coating; the first layer is made of low-molecular-weight polymer which is mixed with inorganic nano particles with amount 0-2 times that of the low-molecular-weight polymer; the second layer and each next layer are made of high-molecular-weight polymer which is mixed with inorganic nano particles with amount 0-2 times that of the high-molecular-weight polymer; and the polymer of each layer is a hydrophilic polymer material. The coating adopts a multi-layer bionic laminated layer, the bottom,close to the substrate layer, of the coating is made of low-molecular-weight polymer, and the coating is good in bonding force with the substrate layer; a plurality of high-molecular-weight polymer film layers are sequentially assembled in sequence, so that the super-lyophilic coating has very good bonding force; and the structures buffer with each other, has good toughness, so that the super-lyophilic coating is not liable to damage under action of mechanical friction damages.

Owner:CHENGDU SCI & TECH DEV CENT CHINA ACAD OF ENG PHYSICS

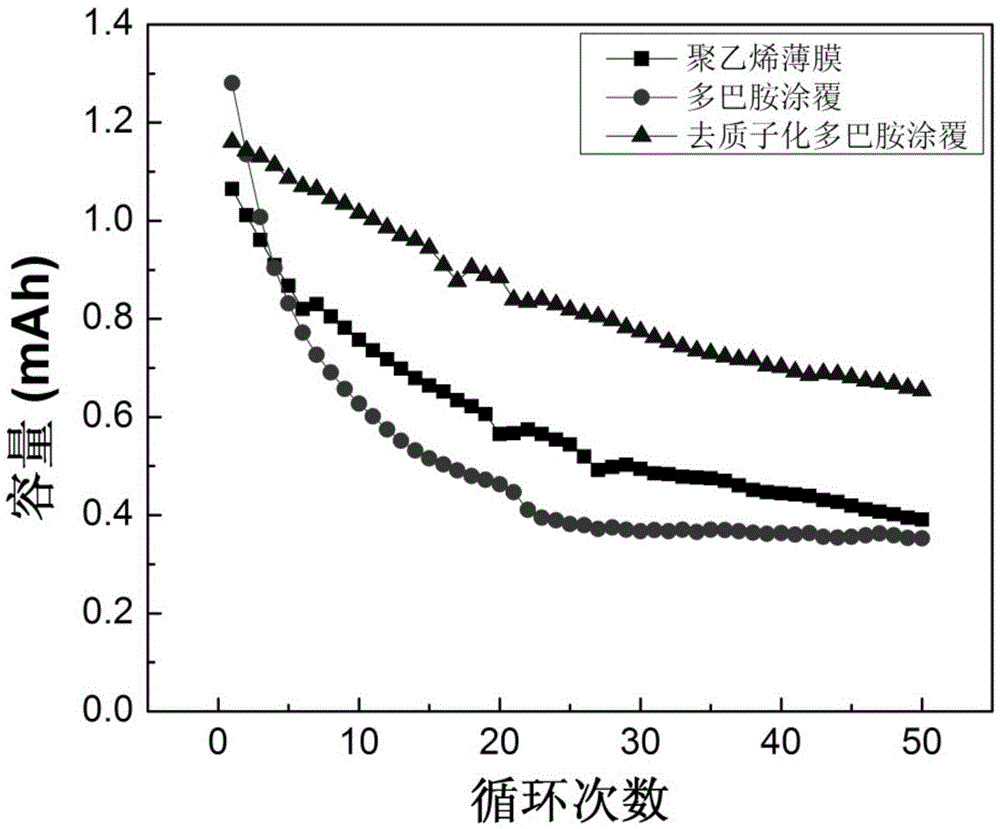

Deprotonated dopamine-coated film and preparation method and application thereof

ActiveCN105655523AImproved magnification performanceImproved selectivityCell seperators/membranes/diaphragms/spacersSecondary cellsChemistryDeprotonation

The invention discloses a deprotonated dopamine-coated film and a preparation method and application thereof. The preparation method of the deprotonated dopamine-coated film includes coating the polymer film matrix surface with dopamine monomers in a buffer solution by oxidization and self polymerization so as to form a uniform coating layer, soaking the uniform coating layer in an alkaline solution and removing protons of functional groups such as a phenolic hydroxyl group and carboxyl on the surface of the coating layer, namely deprotonating. The film modified by the preparation method is of low impedance and high ionic conductivity. Owing to deprotonation, initial charge-discharge efficiency and coulombic efficiency of batteries are improved remarkably, and battery cycle performance is enhanced.

Owner:SHANDONG UNIV

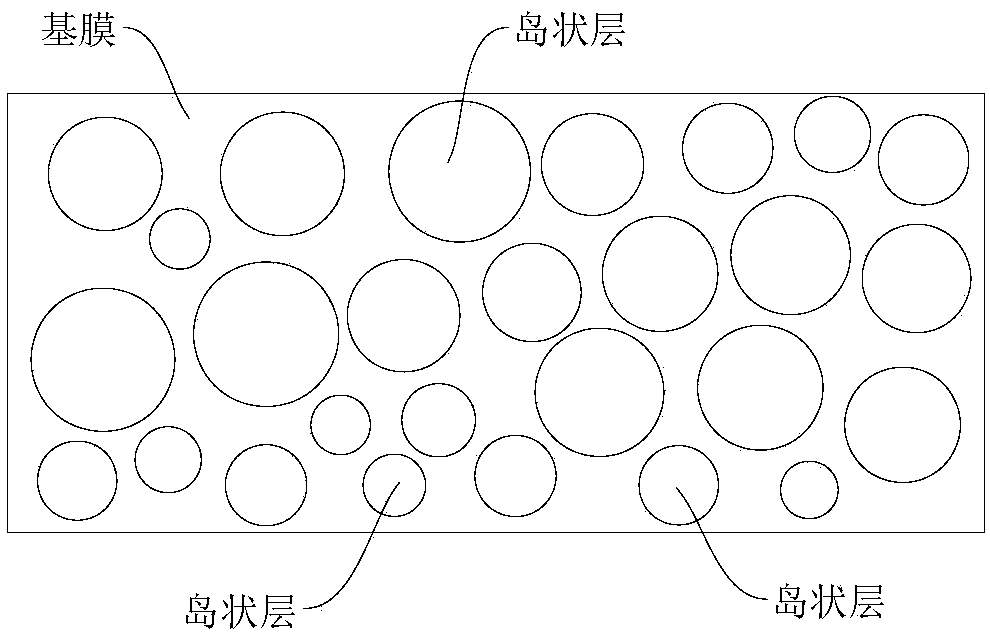

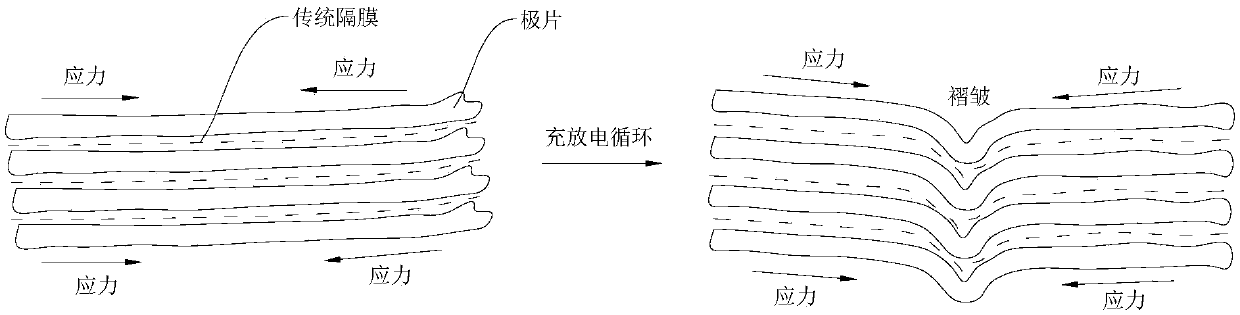

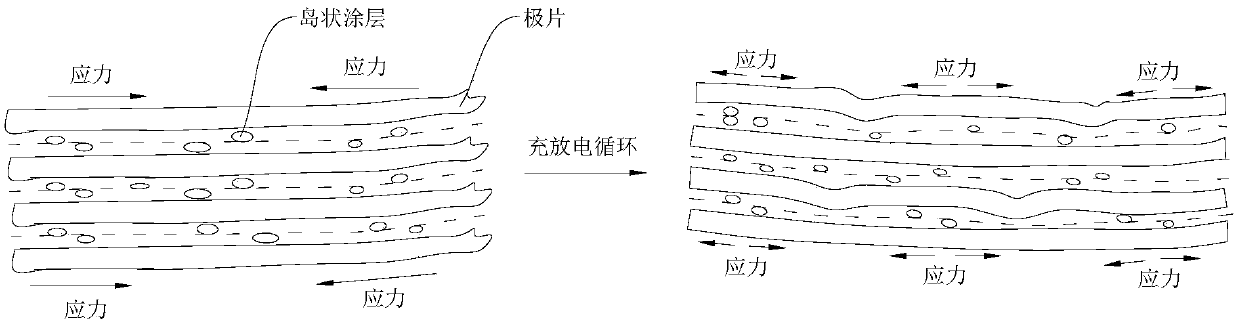

Functional diaphragm and preparation method thereof

ActiveCN109524603AStable structureElectrolyte resistantFinal product manufactureCell component detailsPolyolefinUV curing

The invention provides a functional diaphragm and a preparation method thereof, and relates to the technical field of lithium ion battery production. The functional diaphragm comprises a base film anda coating, wherein the base film comprises one or more of a polyolefin film, a polyolefin ceramic coating film, a non-woven fabric and a polyimide film; the coating is formed on the base film and isdistributed on the base film in the shape of an island; the coating is prepared from the following raw materials according to the parts by weight: 10-20 parts of photocurable resin, 5-10 parts of gelresin with an active functional group, 60-80 parts of main solvent, 4-10 parts of cosolvent and 0.01-0.1 part of photoinitiator. The preparation method of the functional diaphragm comprises the following steps of: applying a mixture of the photocurable resin, the gel resin with the active functional group, the main solvent, the cosolvent and the photoinitiator to the base film, and ensuring that the formed coating is distributed on the base film in the shape of island during applying. After applying, the functional diaphragm is subjected to UV pre-curing, pore-forming and UV curing in sequence. The functional diaphragm can solve the problem of battery bulging.

Owner:SHENZHEN SENIOR TECH MATERIAL

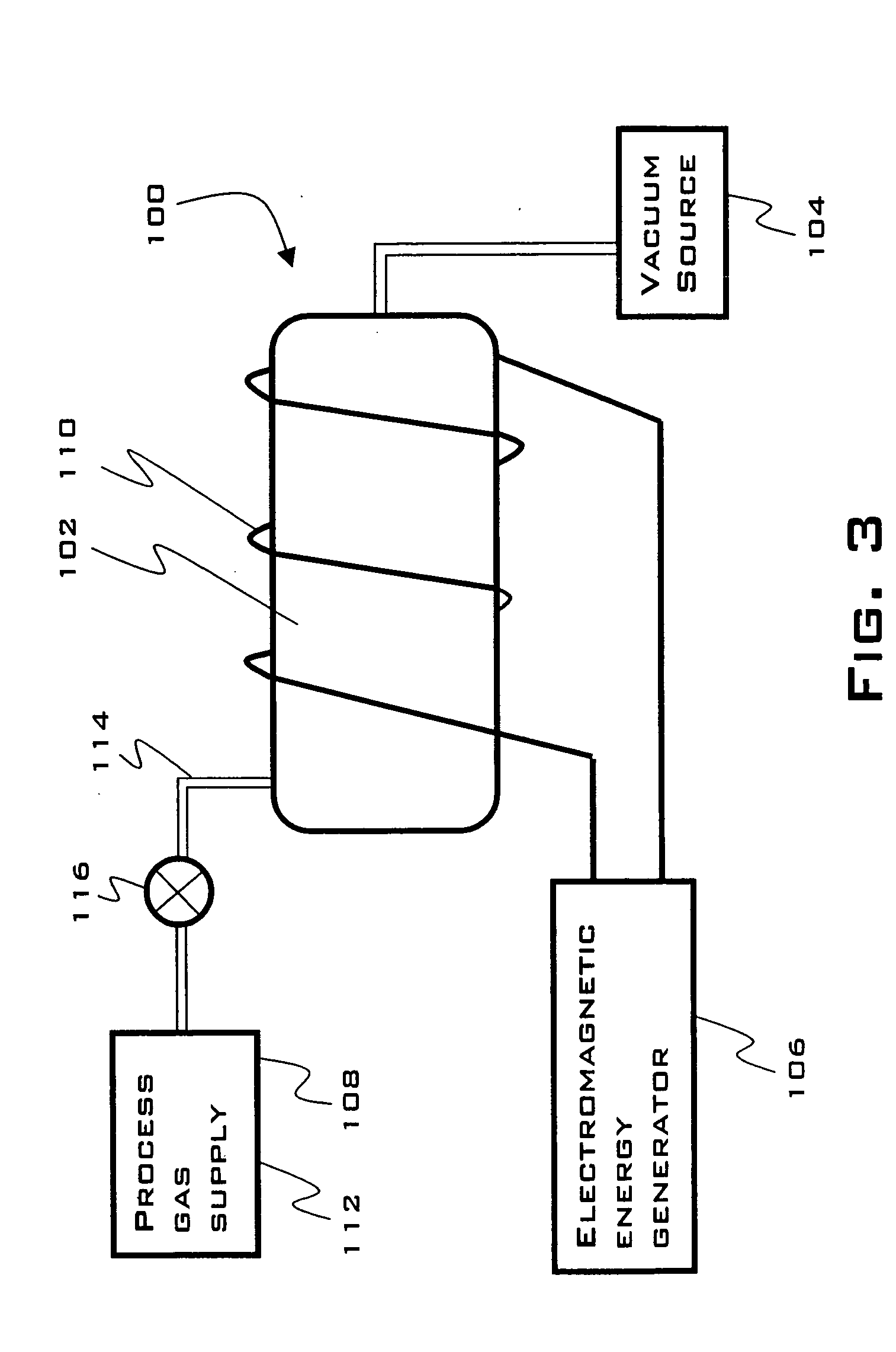

Method for assisting wood delignification through microwave-hot alkali pretreatment

InactiveCN111676723AHigh porosityImprove lyophilicityRadiation/waves wood treatmentWood treatment detailsPulp and paper industryWoodchips

The invention discloses a method for assisting wood delignification through microwave-hot alkali pretreatment. The method comprises the following steps: (1) wood chip pretreatment: adjusting the watercontent of prepared wood chips to 60%-100% through alkali liquor; and then carrying out microwave treatment; and 2) washing the pretreated wood chips with deionized water until the wood chips are neutral, putting the wood chips into a NaClO2 solution, adjusting the pH value of the solution with glacial acetic acid, and heating for delignification treatment. According to the method, the wood is pretreated with microwave-alkali liquor, so that the delignification treatment time of the wood can be shortened, and the treatment efficiency can be improved.

Owner:SHAANXI UNIV OF SCI & TECH

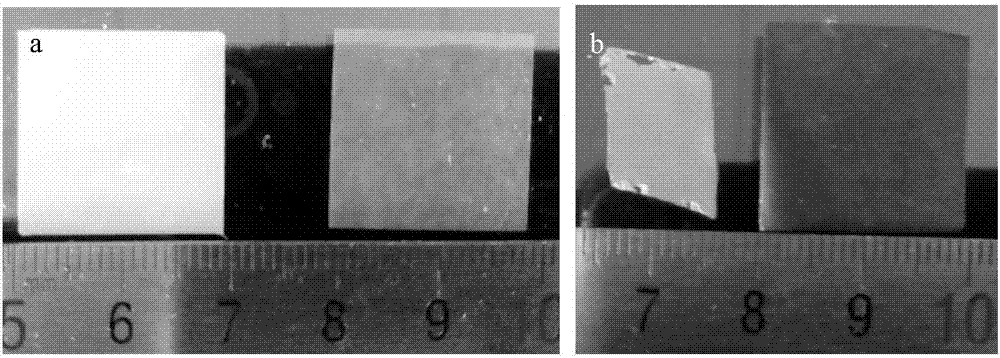

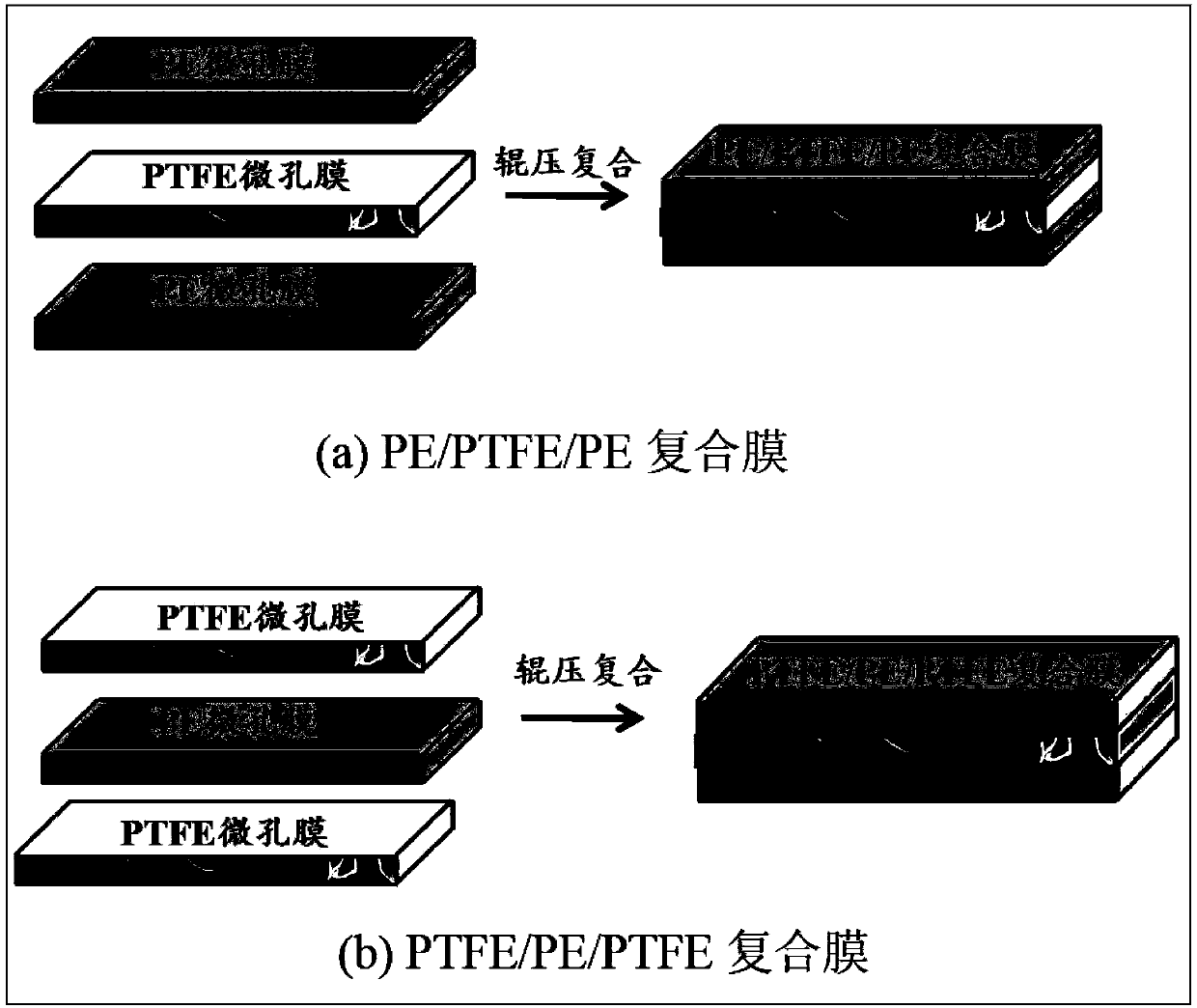

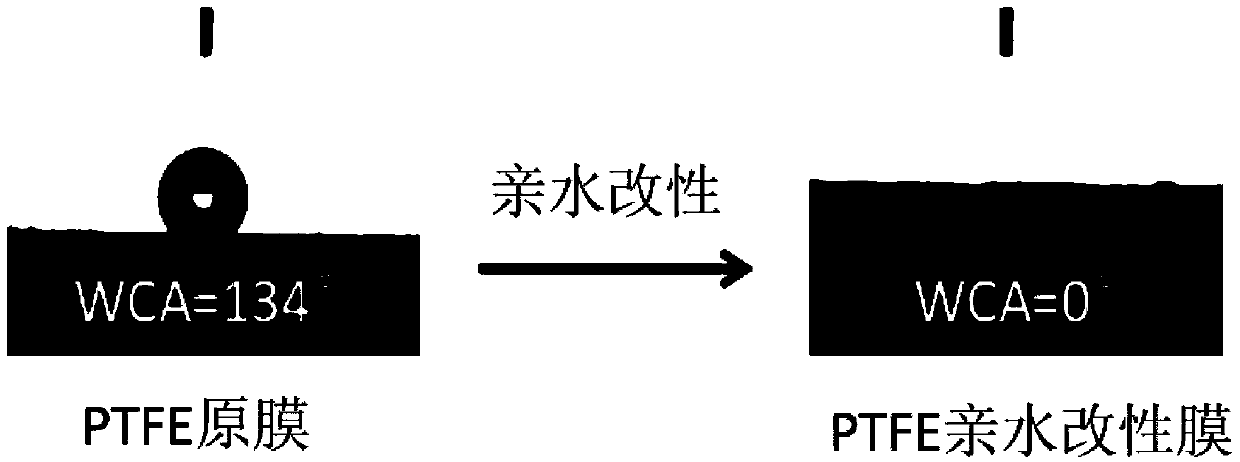

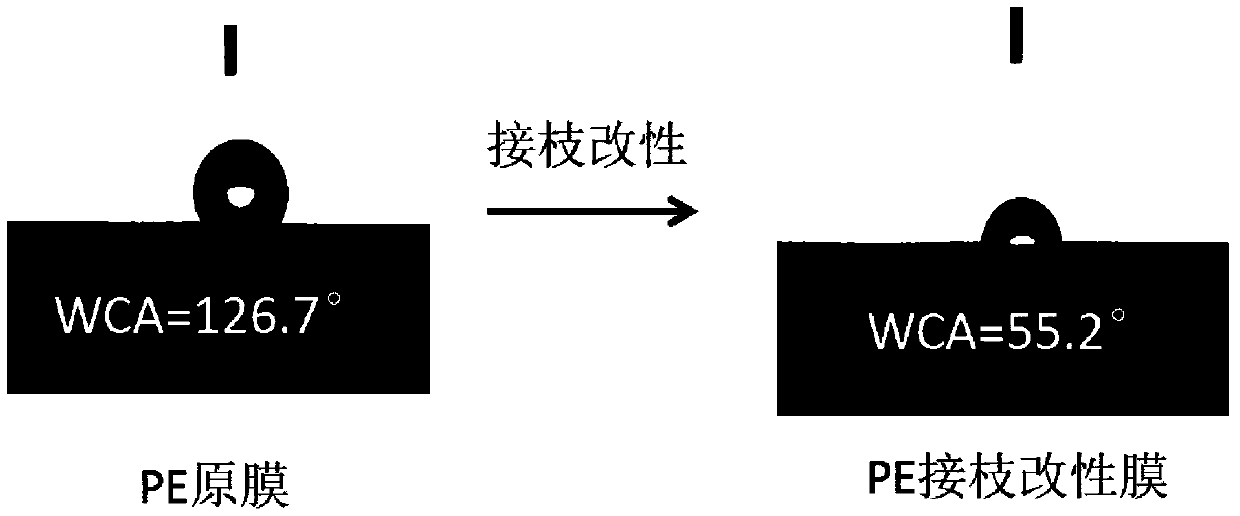

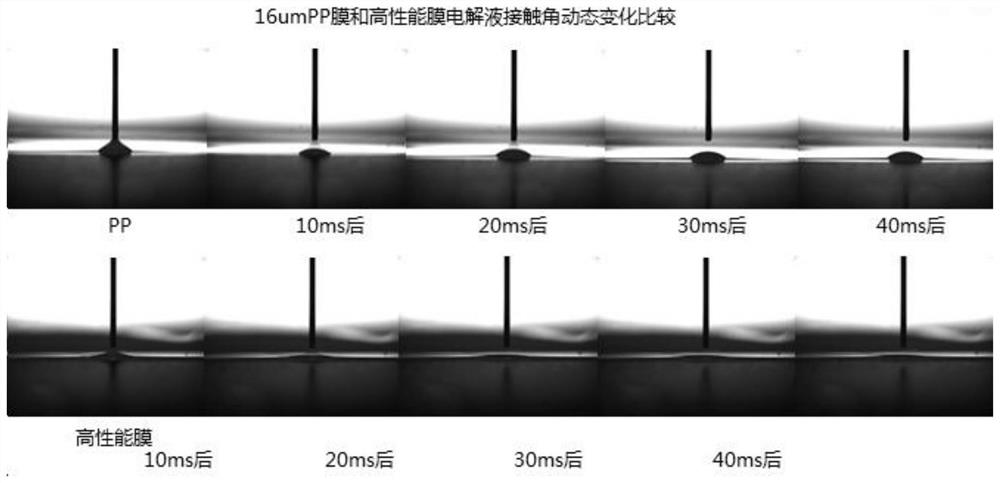

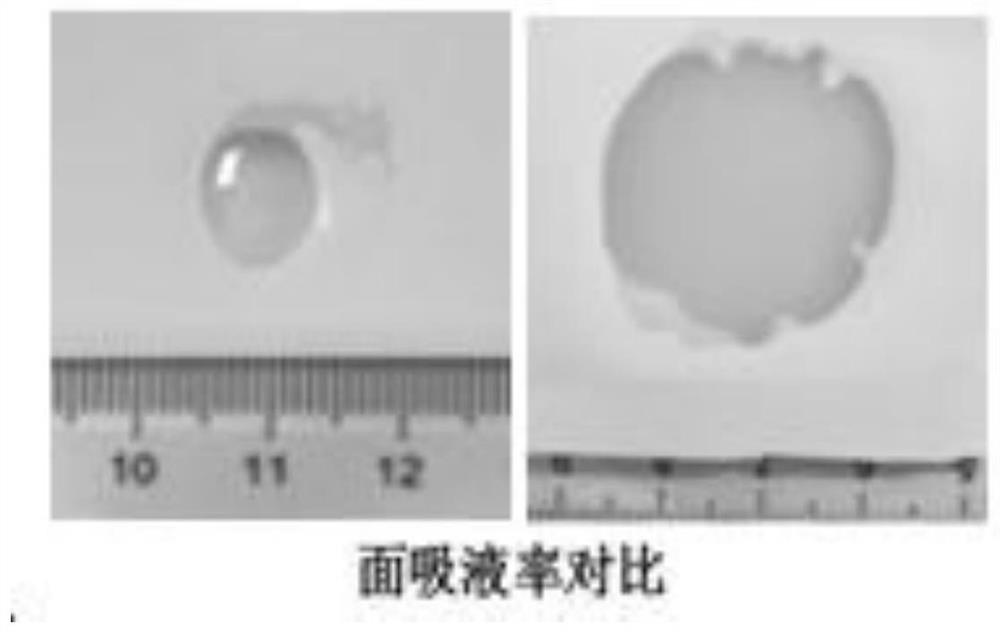

High-performance lithium ion battery composite membrane and preparation method thereof

ActiveCN108682776AImprove lyophilicityEasy to useSecondary cellsCell component detailsElectrical batteryLithium-ion battery

The invention relates to a high-performance lithium ion battery composite membrane and a preparation method of the high-performance lithium ion battery composite membrane, and belongs to the technicalfield of the lithium ion battery composite membranes. The surfaces of a PTFE (Polytetrafluoroethylene) microporous membrane and a PE (Polyethylene) microporous membrane are respectively modified, a hydrophilic group on the surface of the PTFE microporous membrane and a polar group on the surface of the PE microporous membrane are bonded through a hydrogen bond and a chemical bond in the compounding process, the bonding performance of the two microporous membranes is excellent due to the cohesive action of the polymer, the problem of excessively high internal resistance of the membrane causedby the gap interval in the hydrophobic compound is solved; in addition, the polar group is on the surface of the composite membrane, the lyophilic performance is improved, and the use performance of the composite membrane is greatly improved; according to the prepared composite membrane in the sandwich structure, the PTFE layer improves the temperature resistance performance of the battery membrane, the pore closing property of the PE layer is excellent, and the sandwich composite membrane greatly improves the safety of the lithium battery.

Owner:江苏北星新材料科技有限公司

Graphite fiber and preparation method thereof

ActiveCN102978747AImprove lyophilicityAvoid surface contaminationFibre chemical featuresResin matrixCeramic materials

The invention discloses a graphite fiber and a preparation method thereof. The preparation method is characterized by comprising the following steps: carrying out preoxidation on a polyacrylonitrile precursor so as to obtain a preoxidated fiber; carrying out low-temperature carbonization on the preoxidated fiber so as to obtain a low-temperature carbonized fiber; carrying out surface coating on the low-temperature carbonized fiber so as to obtain a coated fiber; carrying out high-temperature carbonization on the coated fiber so as to obtain a high-temperature carbonized fiber; carrying out secondary coating on the high-temperature carbonized fiber so as to obtain a secondary coated fiber; and carrying out graphitization on the secondary coated fiber so as to obtain a high-performance graphite fiber. The graphite fiber and the preparation method thereof disclosed by the invention has the advantages that a surface treatment by using an electrolytic bath is not performed, thereby improving the lyophilic property of the graphite fiber, reducing the equipment investments in the electrolytic bath and a rinsing bath, avoiding the surface pollution of the graphite fiber, improving the affinity of the graphite fiber to a resin matrix, and facilitating the preparation of high-performance, high-modulus and high-strength graphite fibers.

Owner:JILIN SHENZHOU CARBON FIBER CO LTD

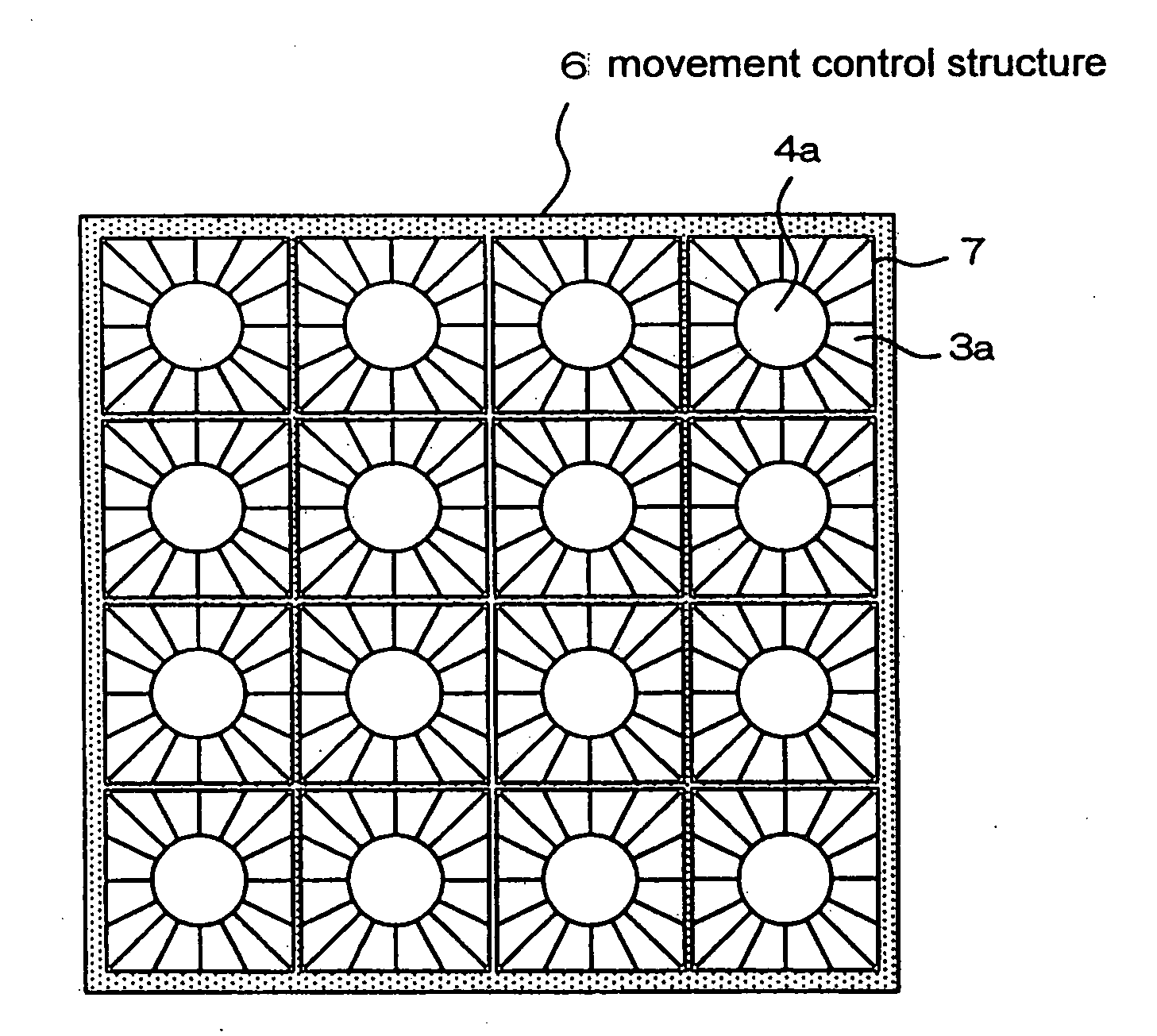

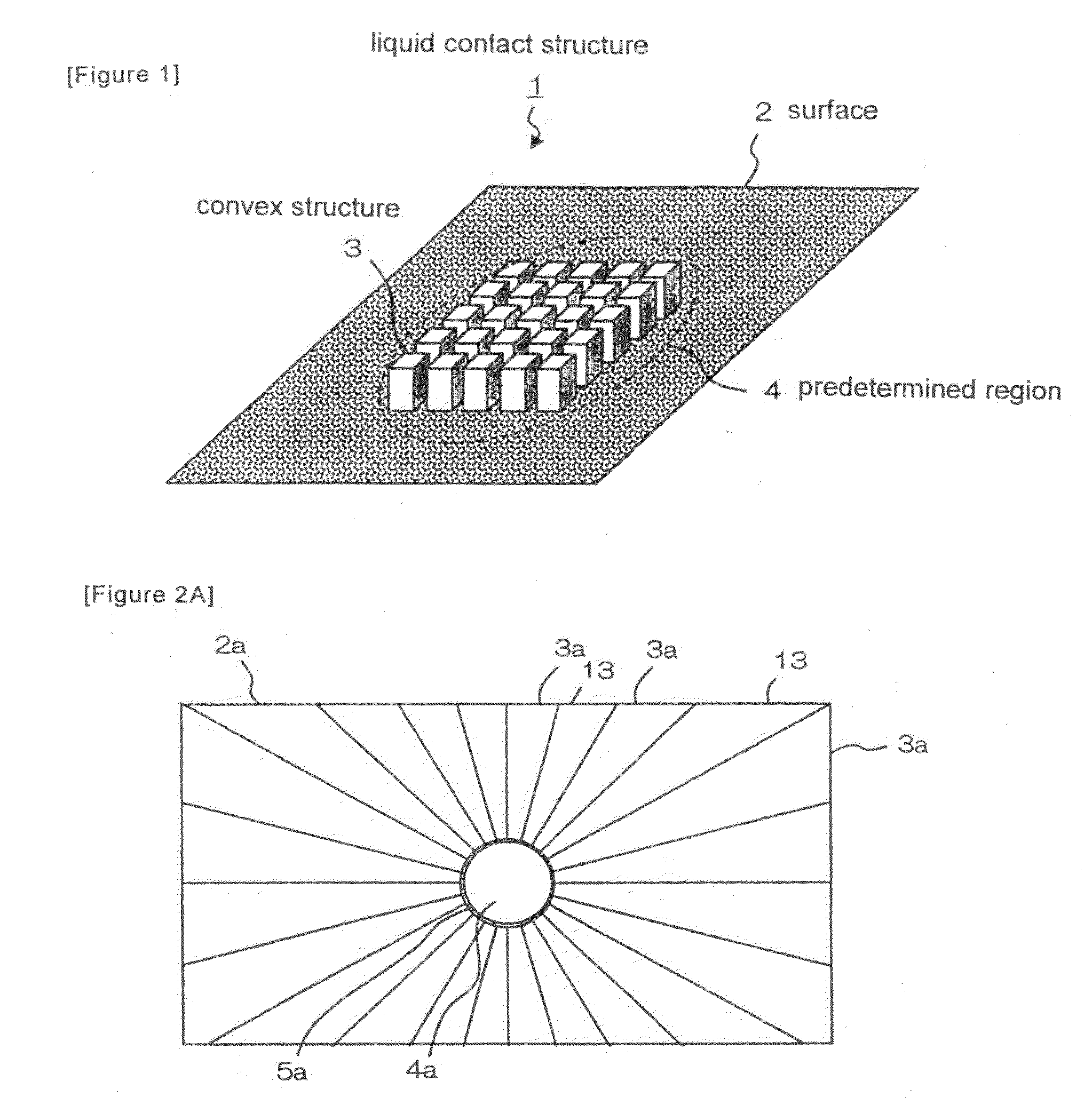

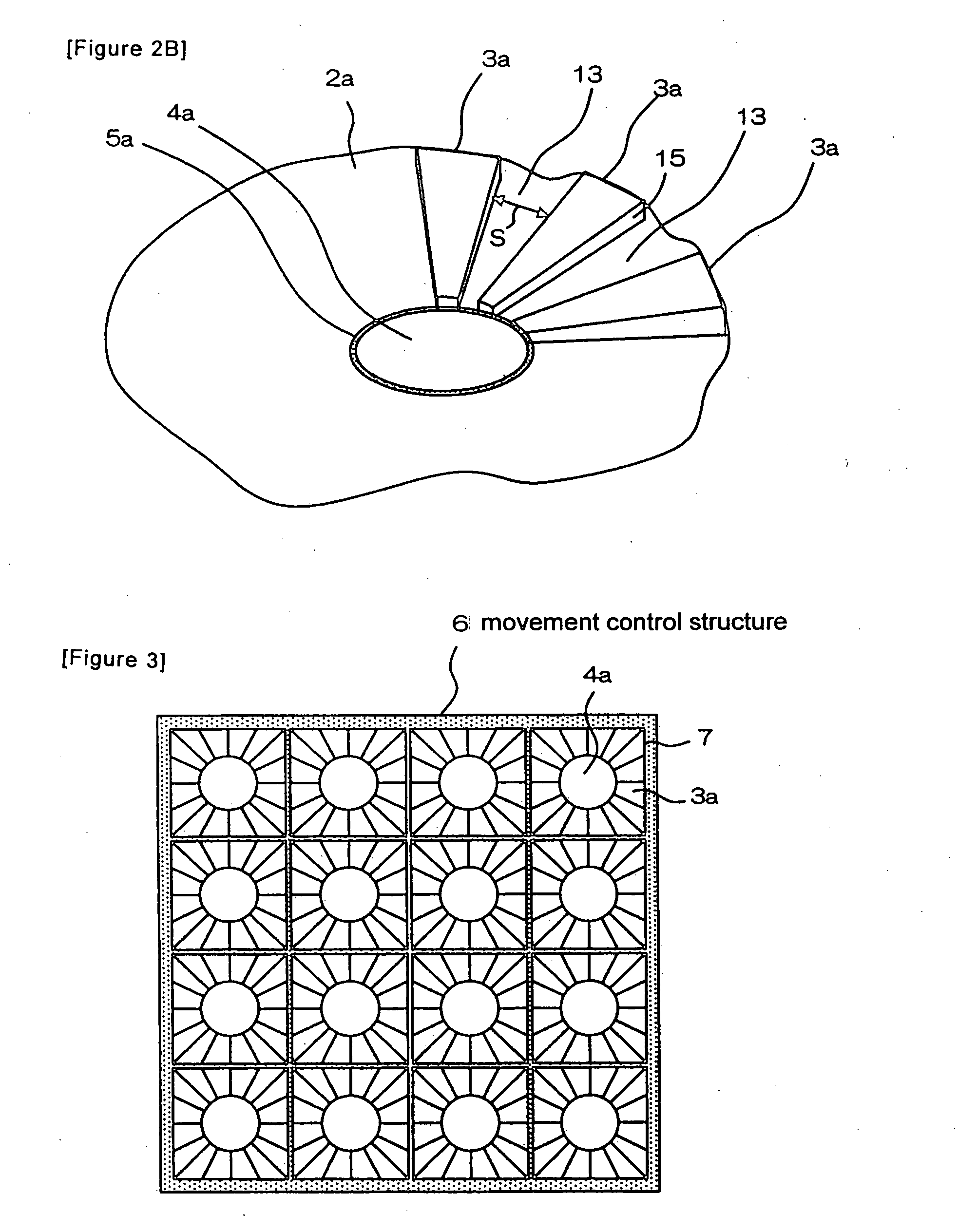

Liquid Contact Structure, Structure for Controlling Movement of Liquid and Method of Controlling Movement of Liquid

InactiveUS20090301227A1Simple configurationImprove lyophilicityParticle separator tubesPreparing sample for investigationConvex structureBiomedical engineering

Owner:NEC CORP

Thin film, preparation method thereof and battery

PendingCN114188658AImprove lyophilicityExcellent liquid retentionSecondary cellsCell component detailsPolymer scienceThin membrane

The invention relates to a thin film, a preparation method thereof and a battery. The thin film comprises the following components: thermoplastic resin and a lyophilic modifier. The thermoplastic resin is modified by adding the lyophilic modifier, so that the lyophilic property of the film is remarkably improved, the crystallinity is reduced, the lyophilic and liquid-retaining properties of the modified film are excellent, and the improvement of the battery performance is facilitated.

Owner:SHENZHEN ZHONGXING NEW MATERIAL TECH CO LTD

High-strength composite lithium ion battery diaphragm

InactiveCN110444719AGuaranteed safe operationSolve the mechanical propertiesElectro-spinningMonocomponent synthetic polymer artificial filamentFiberLithium-ion battery

The invention discloses a high-strength composite lithium ion battery diaphragm. TiO2 particles are subjected to surface modification and then dissolved in a polyacrylonitrile solution, TiO2 is successfully grafted to a PAN fiber, then composite blending is performed, and the high-performance lithium ion battery diaphragm is prepared. TiO2 is very stable in the composite diaphragm and an electrolyte system, the chemical resistance and the electrochemical performance of the composite diaphragm can be improved, the specific surface area and the lyophilicity are high, a good channel and a good transport carrier are provided for free shuttling of lithium ions between electrodes, so that the lithium ion battery diaphragm has excellent mechanical properties and thermal stability at high temperature, aging of the diaphragm in the reaction process of the battery is reduced, and meanwhile, the thermal shrinkage performance of the diaphragm is not influenced, so that the safe operation of the battery is ensured. The preparation method is simple and convenient, raw materials are simple and easy to obtain, cost is low, and industrial production is easy.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

Articles comprising wettable structured surfaces

InactiveCN101689652AEnhance hydrophilicity and lyophilicityReduce pipe blockageThin material handlingCollectors/separatorsRegular arrayEngineering

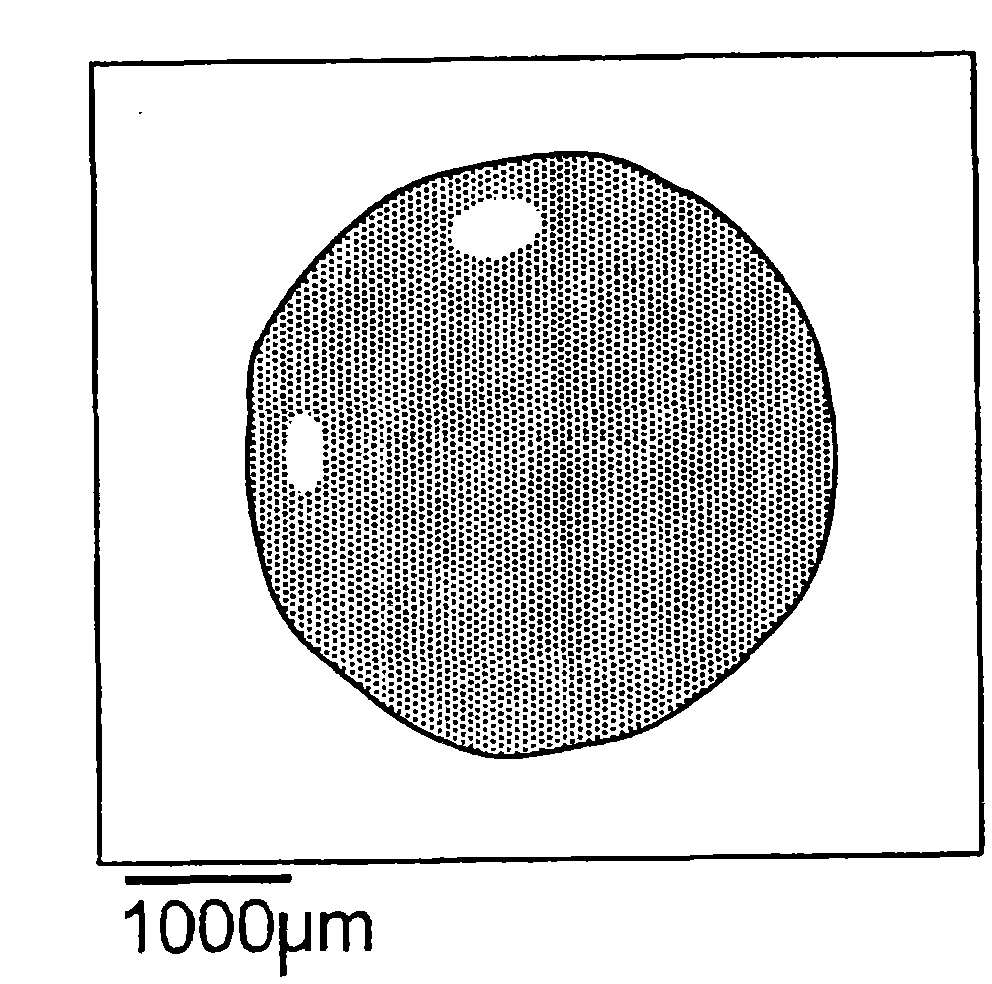

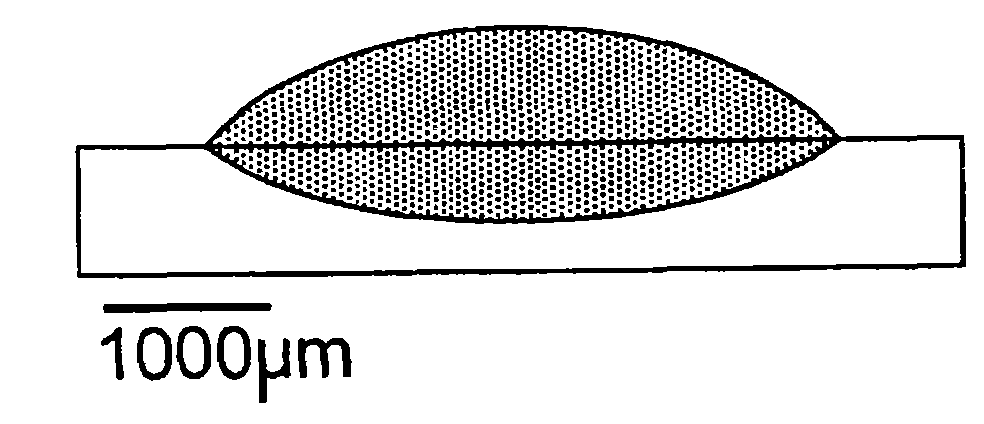

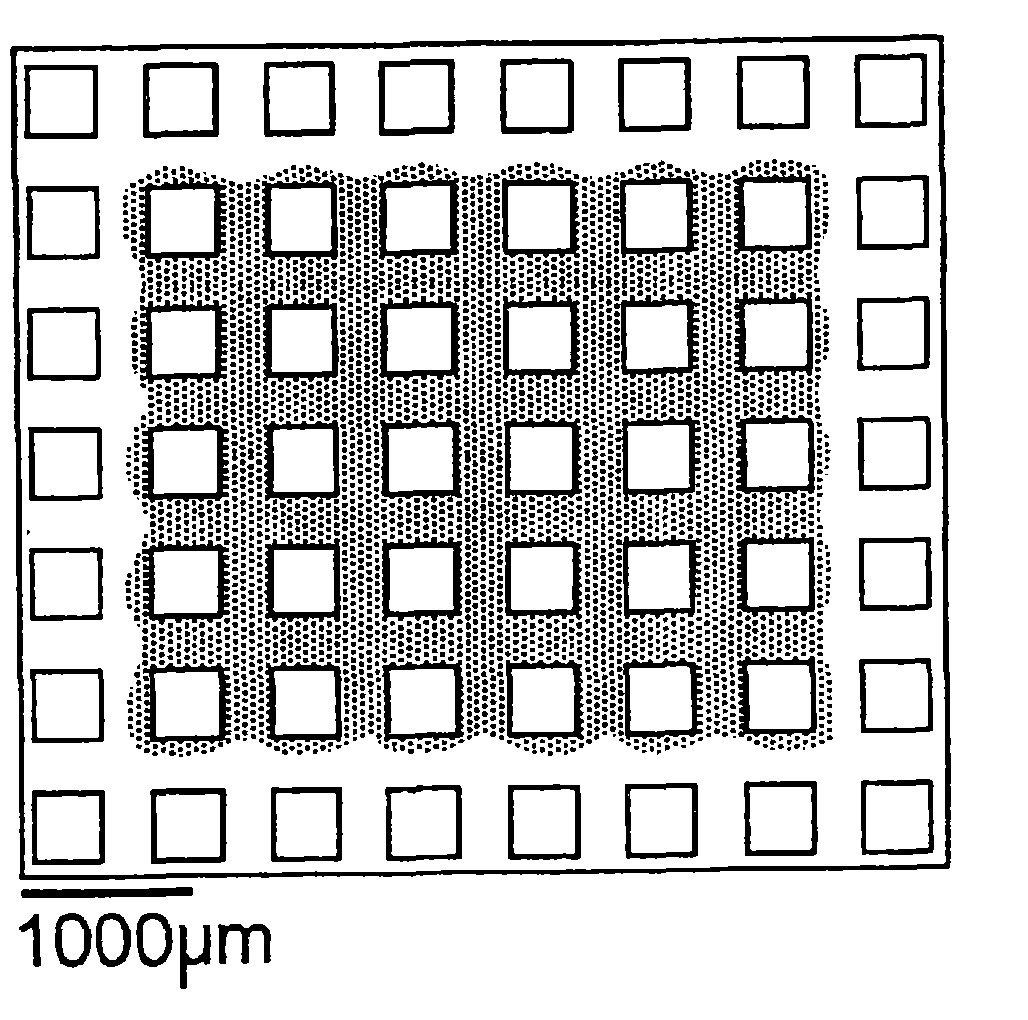

Embodiments of the invention include or comprise super wetting structured surfaces having one or more asperities, sometimes referred to as hemi-wicking. Structured substrates with regular arrays of asperities such as square pillars or frustra were machined from graphite blocks and then treated to render them lyophilic. Liquids spread over these surfaces to produce non- circular wetting areas. As the channels formed between the asperities were made shallower or narrower, liquids wicked more and spread over a larger area. The inherent wettability of the substrate was independent or nearly independent of the substrate. A combination of the appropriate surface structure and moderate inherent wettability can effectively flatten liquids, spreading them over very large areas.

Owner:ENTEGRIS INC

Adhesive for battery diaphragm coatings and preparation method for adhesive

ActiveCN108586757AImprove ionic conductivityGood chemical resistanceCell seperators/membranes/diaphragms/spacersCoatingsPolyolefinPolymer science

The invention relates to an adhesive for battery diaphragm coatings and a preparation method for the adhesive. The adhesive comprises a fluorinated polyolefin / hydrophilic macromolecular dendritic graft polymer. The preparation method comprises the step of grafting a hydrophilic macromolecular polymer to fluorinated polyolefin by using a photosensitizer under the action of ultraviolet rays, so as to form the dendritic polymer with a large number of hydrophilic groups. The adhesive is applied to ceramic diaphragms of lithium batteries and can be used for effectively inhibiting the spalling of ceramic powder and effectively improving the liquid absorbing and retaining capability of diaphragms; and after the diaphragms are assembled into the batteries, the batteries have the advantages of superior cycle performance, high ionic conductivity, excellent multiplying power performance and the like.

Owner:东莞市魔方新能源科技有限公司

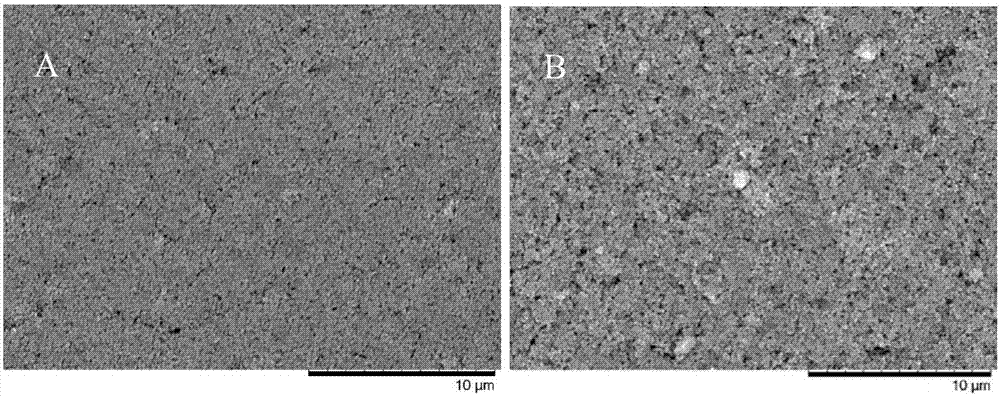

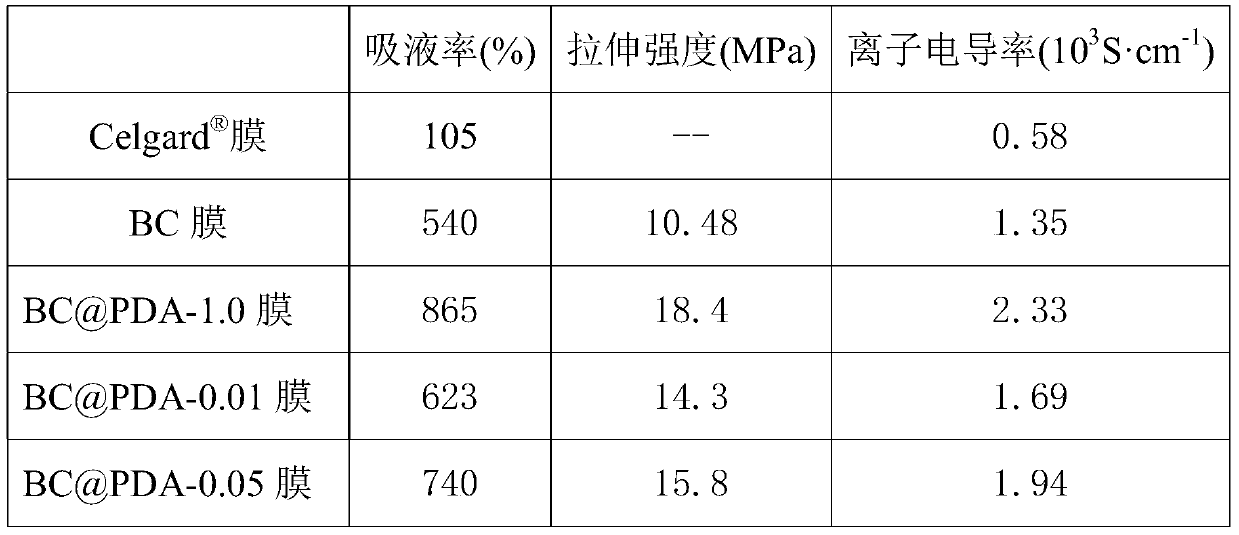

Polydopamine-coated bacterial cellulose membrane and preparation method thereof

InactiveCN109950453AReduce manufacturing costEasy to prepareSecondary cellsCell component detailsFiberSolvent

The invention discloses a polydopamine-coated bacterial cellulose membrane and a preparation method thereof. The preparation method comprises the following steps: firstly placing a bacterial cellulosegel film in dopamine water solution to enable dopamine to be adsorbed on the surfaces of nanofibers; secondly placing the nanofibers in weak alkali solution for dipping; thirdly placing the nanofibers in an organic solvent for solvent exchange; fourthly utilizing a hot press to thin the nanofibers; and finally drying the nanofibers. The invention has the beneficial effects that (1) the preparation method is simple, low in equipment requirement and suitable for large-scale production; (2) the surface of the nanofiber is coated with a layer of polydopamine, so that the combination of cellulosehydroxyl and lithium ions can be overcome, the conductivity and the rapid migration capability of the lithium ions in the electrolyte are improved, and the diaphragm is suitable for being used as a novel high-power power lithium ion battery diaphragm; and (3) the polydopamine is loaded by utilizing the bacterial cellulose which is low in cost and rich in yield, so that the preparation cost is reduced, and the market prospect of industrial popularization is achieved.

Owner:SHANGHAI ENERGY NEW MATERIALS TECH CO LTD

Application of porous composite membrane in lithium-ion battery

InactiveCN106531928AImprove lyophilicityFully infiltratedCell seperators/membranes/diaphragms/spacersSecondary cellsPolyetherimideMass ratio

The invention relates to an application of a porous composite membrane in a lithium-ion battery. The porous composite membrane is a blend porous membrane prepared from polyetherimide and one or more than two of silicon dioxide, titanium dioxide and zirconium dioxide; and the mass ratio of the polyetherimide to one or more than two of the silicon dioxide, the titanium dioxide and the zirconium dioxide is (10-40) to (1-30). The target of strengthening modification can be achieved through addition of the silicon dioxide. The membrane is uniform in pore size distribution, a lot of small holes are distributed in the porous membrane, the holes are in zigzag communication and the service life of the lithium-ion battery can be prolonged. The membrane also has relatively high heat stability and the security performance of the battery is improved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Preparation method of cellulose and polyarylester fibre-based battery diaphragm

ActiveCN107910477AGood physical and mechanical propertiesGood dispersionCell component detailsFiberCellulose pulp

The invention discloses a preparation method of a cellulose and polyarylester fibre-based battery diaphragm. The preparation method comprises the steps of preparing polyarylester fiber pulp, polyarylester short fibers, polyarylester long fibers and cellulose pulp, performing pulping on the four kinds of raw materials, and next, performing papermaking with pulp and forming. By preparing the cellulose-based battery diaphragm from cellulose and polyarylester, the advantage complementation of cellulose and polyarylester is played in a manner of overcoming own weak points by learning from each other's strong points; the prepared battery diaphragm material is excellent in wetting performance, high in mechanical strength, and reasonable in cost; by virtue of formula adjustment and process improvement, the problems of fiber scattering, dispersing and like caused in papermaking process for preparing the polyarylester fibre-based battery diaphragm can be solved; and the cellulose and polyarylester fibre-based battery diaphragm is prepared successfully.

Owner:宁波日新恒力科技有限公司

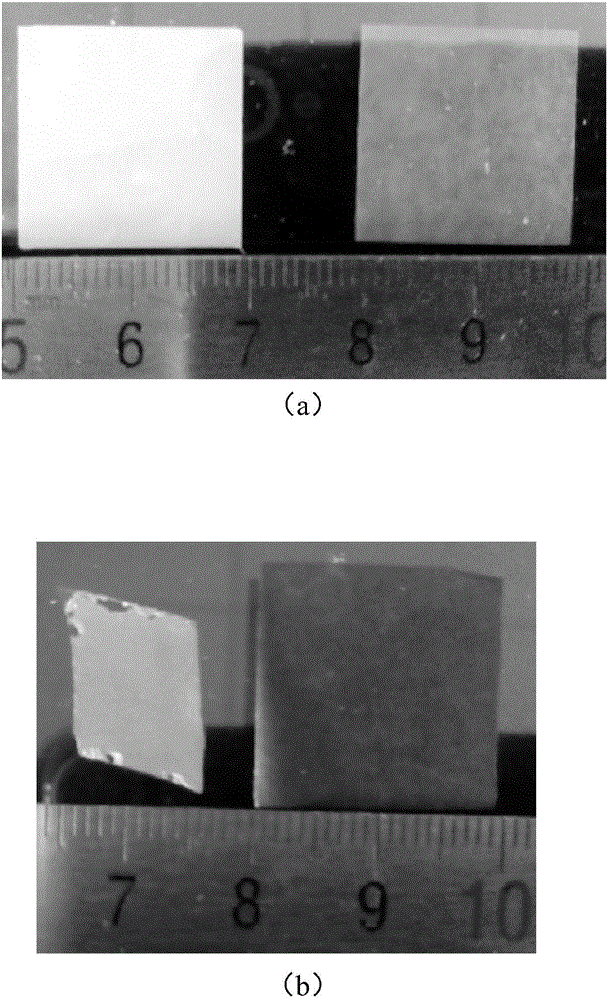

Non-woven fabric based PVDF (polyvinylidene fluoride) film preparation method

InactiveCN106192369AImprove lyophilicityImprove liquid absorption performanceFibre typesCell component detailsComposite filmPotassium hydroxide

A non-woven fabric based PVDF (polyvinylidene fluoride) film preparation method includes the steps: preparing a composite film; adding 2g of PVDF powder into 100mL of butanone in batches; strongly stirring the powder and the butanone; filtering solution for three times by a 500-mesh screen to obtain uniformly clarified coating liquid; soaking a PP (polypropylene) non-woven fabric in the coating liquid for 20 seconds; rapidly taking out the PP non-woven fabric; drying the PP non-woven fabric in butanone atmosphere for 3 hours to obtain a non-woven fabric based PVDF composite film. The composite film is modified, potassium hydroxide (with the mass fraction of 15%) diaphragm treatment liquid is prepared, the ratio of ethyl alcohol to water in the potassium hydroxide is 1:1, a diaphragm is subjected to alkali treatment for 100 minutes at the temperature of 35 DEG C, the treated diaphragm is repeatedly soaked by deionized water until being neutral, and the diaphragm is finally subjected to vacuum drying for 6 hours at the temperature of 80 DEG C to obtain the modified composite diaphragm. The preparation method has the advantages that reaction conditions are mild, production cost is low, repeatability is good, lyophilic and liquid-absorbent properties of the diaphragm can be improved, the structure and the morphology of the diaphragm are less affected, and the method is simple and effective.

Owner:王利萍

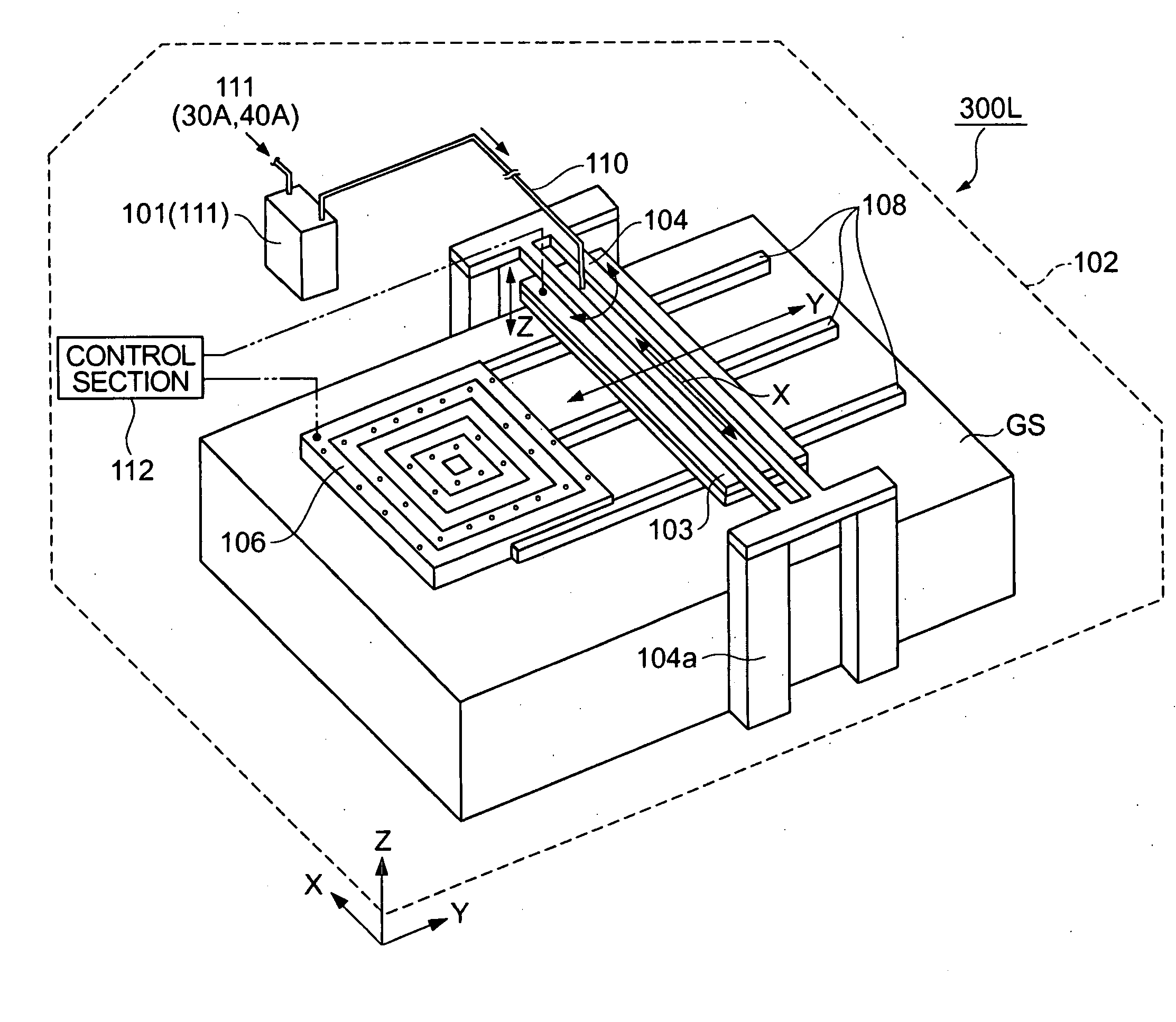

Electric wire formation method, wiring substrate manufacturing method, electrooptical element manufacturing method, electronic apparatus manufacturing method, wiring substrate, electrooptical element, and electronic apparatus

InactiveUS20060127564A1Reliable lyophilic propertyImprove lyophilicityPaste/ink/powder application resistSpecial surfacesEngineeringElectron

A method for forming electric wire by disposing a functional liquid by using a droplet ejection apparatus, including: forming on a substrate a partition wall defining a groove in a manner that a surface of the substrate becomes a bottom part of the groove; forming on the bottom part a lyophilic layer having a higher lyophilic property against a first functional liquid than a lyophilic property of the partition wall against the first functional liquid; and disposing on the lyophilic layer the first functional liquid containing metal by using a droplet ejection apparatus.

Owner:SEIKO EPSON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com