Blend superfine fiber diaphragm for lithium ion battery

A lithium-ion battery and ultra-fine fiber technology, which is used in the field of lithium-ion battery separators and blended ultra-fine fiber separators for high-specific-capacity lithium-ion batteries, can solve the problems of small output and low production efficiency, and achieve a short processing flow. , high strength, the effect of improving the utilization rate of lithium intercalation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

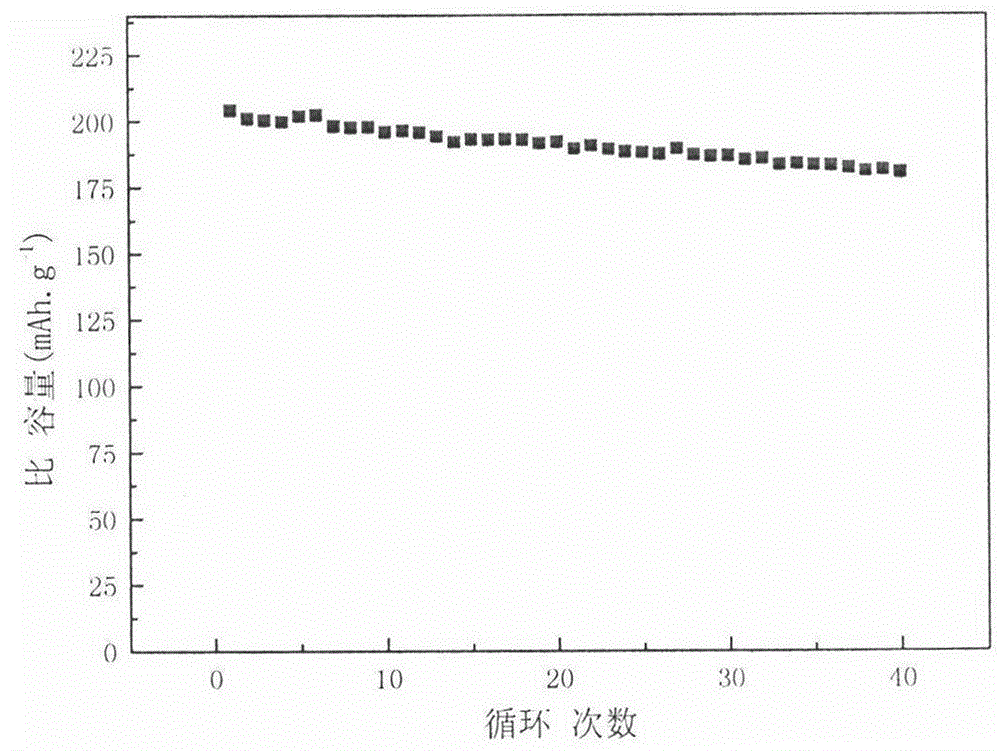

Embodiment 1

[0021] (1) 80 parts by weight of polyvinylidene fluoride with a molecular weight of 350,000, 18 parts by weight of cellulose acetate with a molecular weight of 60,000, and 2 parts of aryl cage silsesquioxane are dissolved in N, N with a weight mixing ratio of 3:7. - in dimethylformamide / acetone composite organic solvent, stir it with a high-speed stirrer to make it completely dissolved to make a uniform and stable spinning solution with a total mass fraction of 13% polyvinylidene fluoride / cellulose acetate;

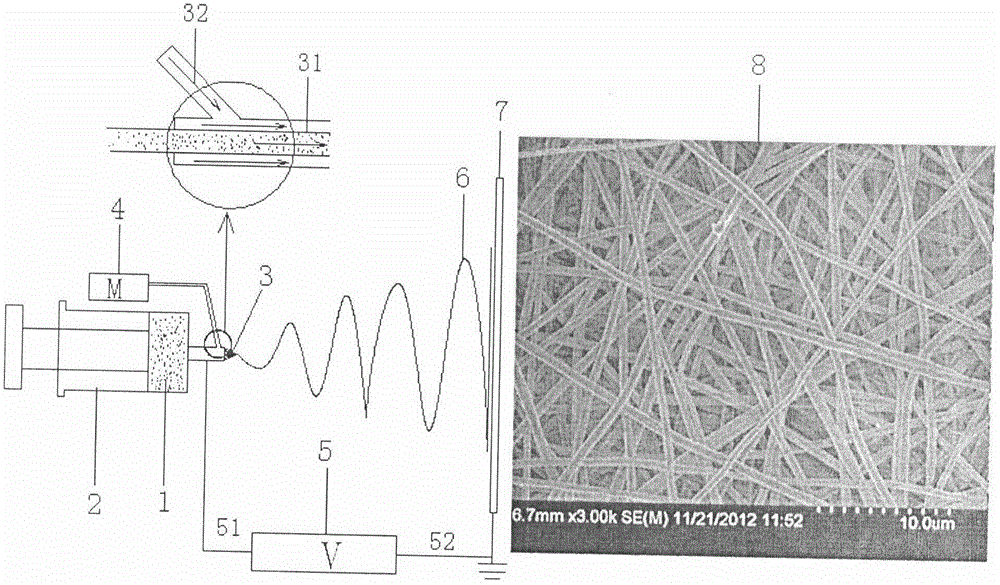

[0022] (2) The above configuration spinning solution 1 is injected into the microinjector 2, and extruded from the inner channel 31 of the metal nozzle 3 at an extrusion rate of 15ml / h. The spinning solution 1 is connected to the outer channel at the outlet of the nozzle inner channel 31. In 32, the high-speed airflow of 0.15MPa generated by the air compressor 4 meets, and the metal nozzle 3 is connected to the positive electrode 51 of the high-voltage electrostatic genera...

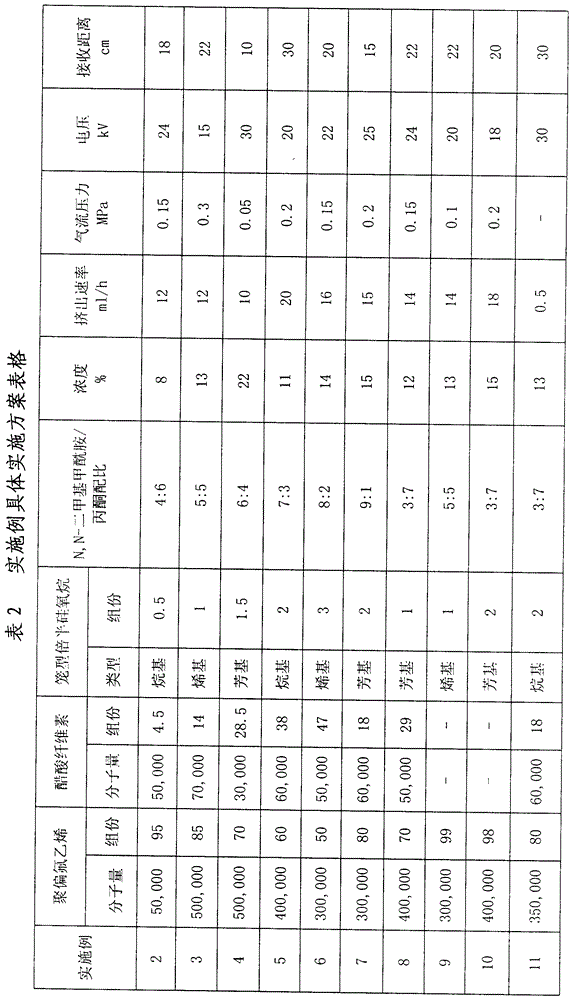

Embodiment 2~11

[0025] Implementation process embodiment 1 is basically the same, but differs to some extent in the processing conditions, as shown in table 1 and table 2:

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com