Patents

Literature

129results about How to "Short processing flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

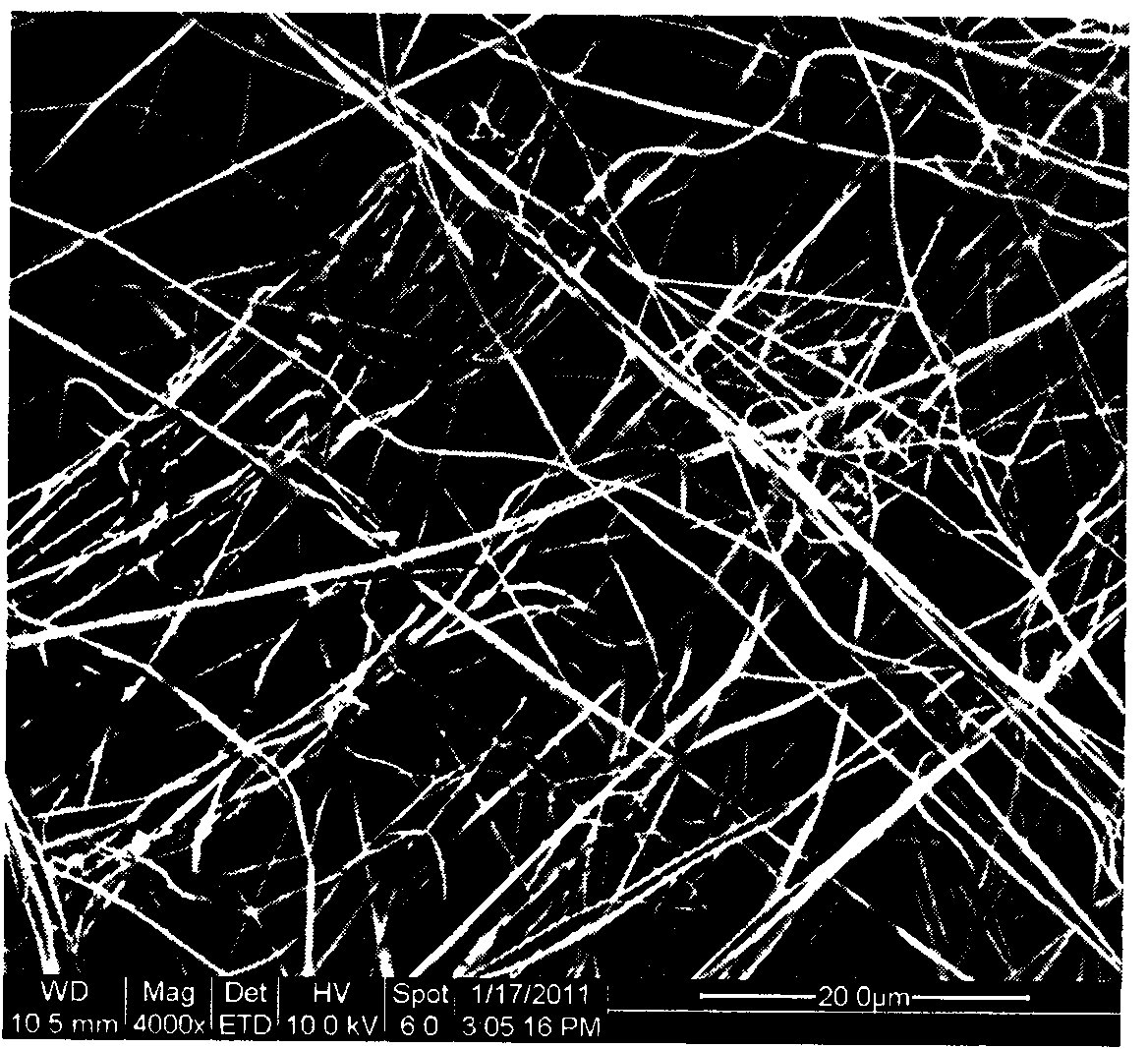

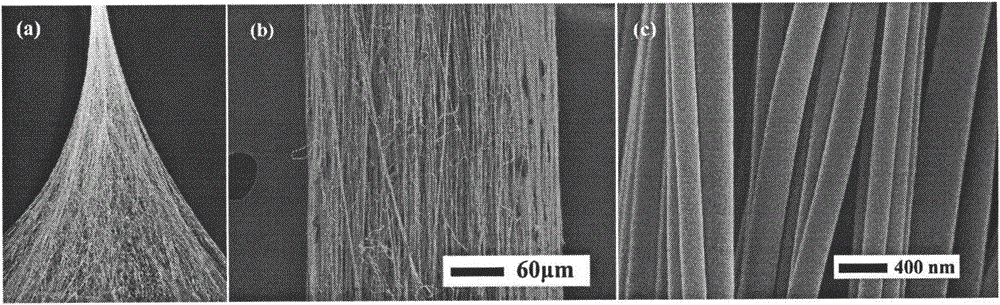

Method for preparing polymeric nano-micro fiber non-woven fabric

ActiveCN102071542AOvercoming demandsUniversally applicableNon-woven fabricsDry spinning methodsFiberPolymer dissolution

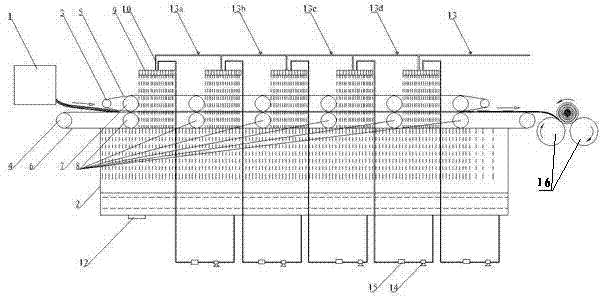

The invention discloses a method for preparing a polymeric nano-micro fiber non-woven fabric. The method comprises the following steps of: firstly, dissolving at least one polymer in at least one solvent to prepare spinning solution; then supplying the spinning solution to a spinneret plate with a series of spinneret orifices so as to make the spinning solution extruded from the spinneret orifices of the spinneret plate to form a trickle of the spinning solution; secondly, stretching and refining the trickle of the spinning solution by utilizing at least one high-speed jet airflow, and accelerating the volatilization of the solvent to form nano-micro fiber; and finally, collecting the nano-micro fiber on a web curtain by utilizing high-speed airflow and suction airflow. The polymer is a fiber-forming polymer; the solvent can dissolve the fiber-forming polymer and has the volatility; a jet angle of the high-speed airflow is between 15 and 60 degrees, and the jet velocity is at least 50 times higher than extrusion speed of the trickle of the spinning solution; the mass concentration of the polymer in the spinning solution is between 2 and 50 percent; and the viscosity of the spinning solution at a spinning temperature is between 10 and 100, 000mP.s.

Owner:上海榕融新材料技术有限公司

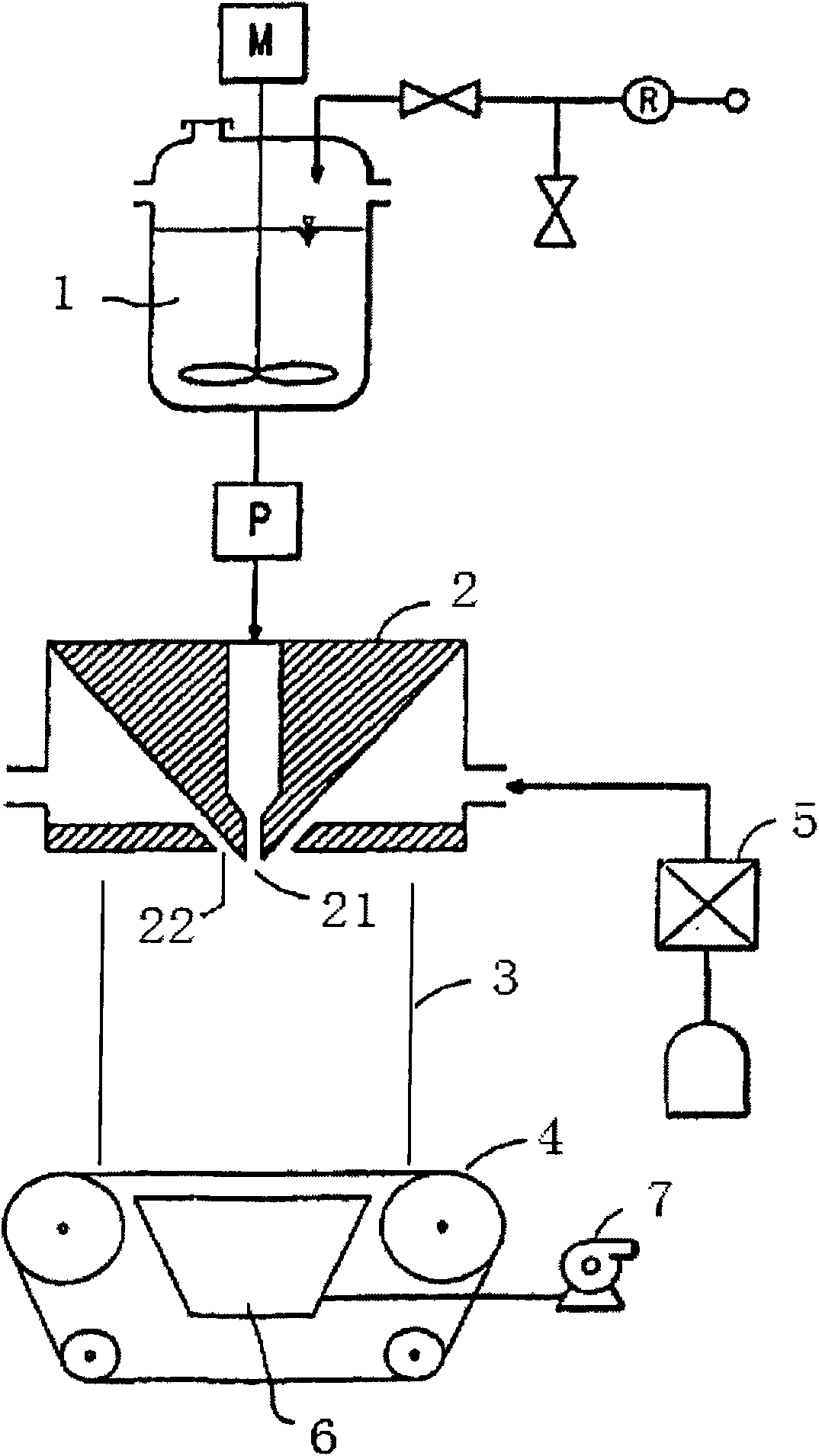

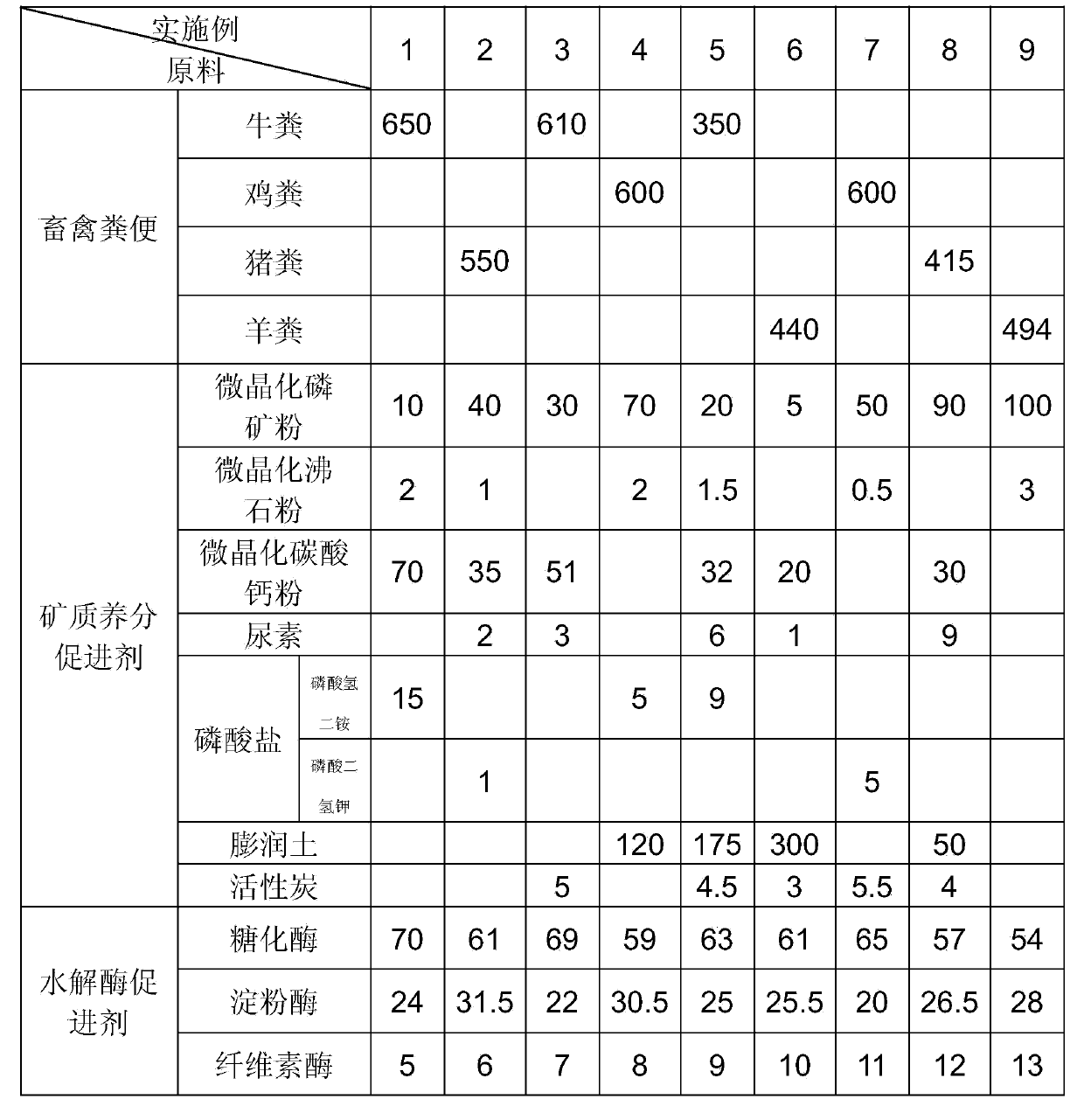

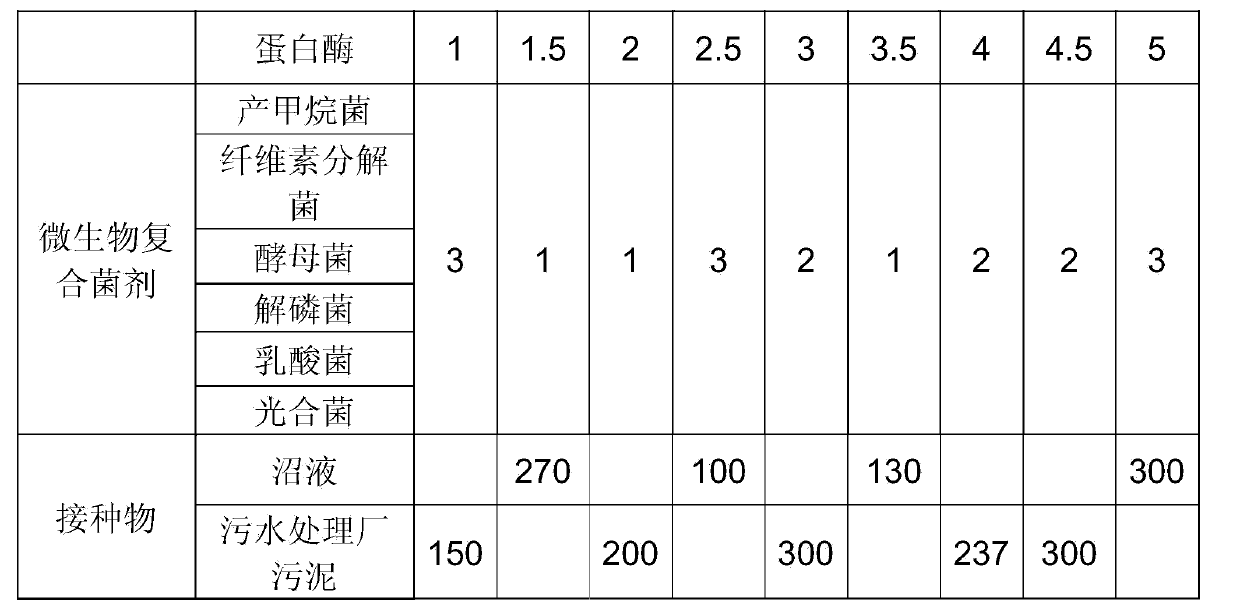

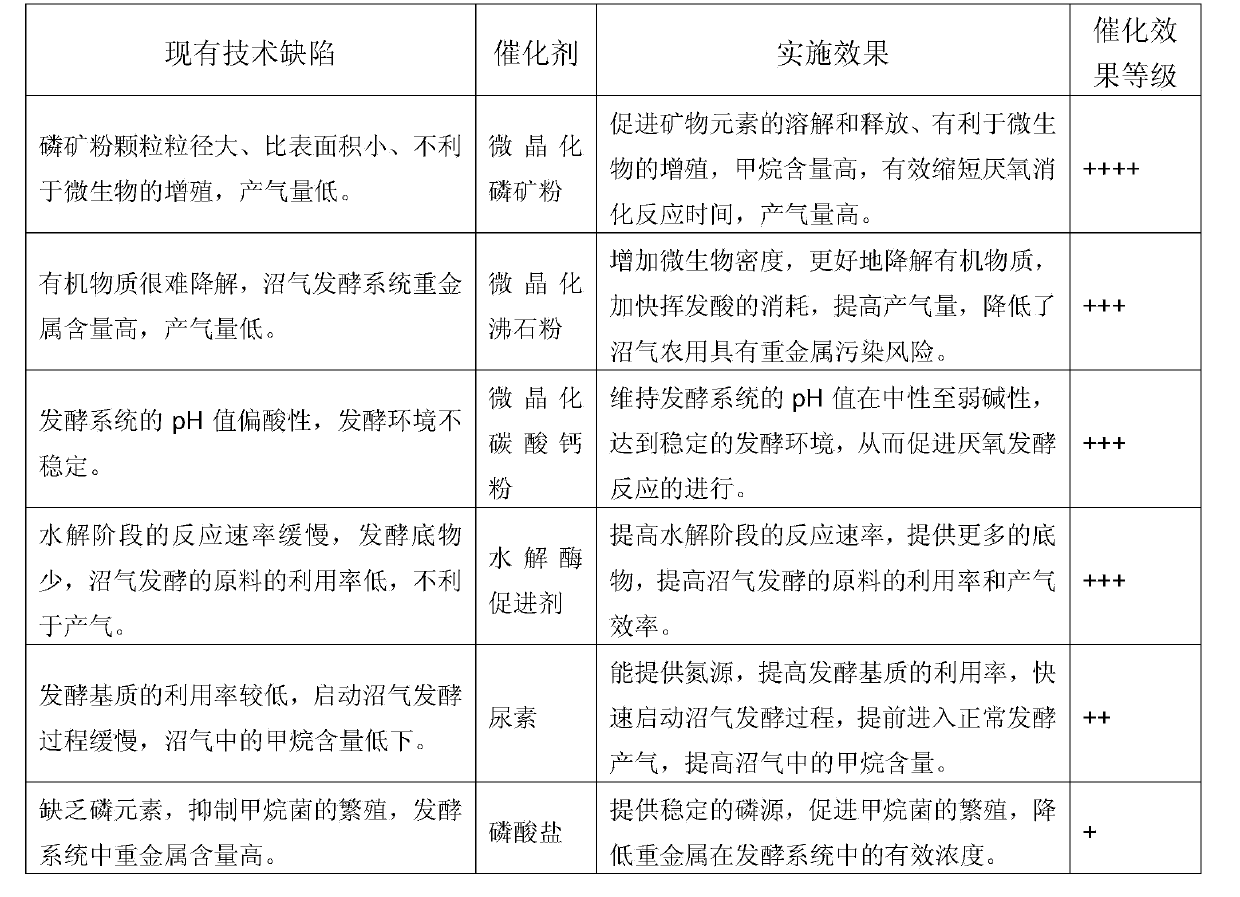

Functional biocatalyst for biogas fermentation and method for fermenting using catalyst

ActiveCN103740764ANo dischargeMethanogenic effect is stableWaste based fuelFermentationFiltrationSorbent

The invention discloses a functional biocatalyst for biogas fermentation and a method for fermenting using the catalyst. The catalyst comprises 1-3 parts of a microbial composite bacterial agent, 100 parts of hydrolase accelerant and 61-329 parts of mineral nutrient accelerant, wherein the mineral nutrient accelerant is one or more of microcrystalline ground phosphate rock, microcrystalline zeolite powder, microcrystalline calcium carbonate powder, urea, phosphate, bentonite and active carbon. The biogas fermentation method comprises the following steps: performing biogas fermentation by using 350-650 parts of poultry excrement, 100-300 parts of inoculum and 163-430 parts of functional biocatalyst while controlling the moisture content of the poultry excrement at 75-85%; and stirring and mixing for fermentation, wherein the concentration of the whole original feed liquid is 7-12%. In the invention, apart from the supplement of the nutritive elements for biogas fermentation, the effects of deodorization and inhibition of pathogenic microorganisms are realized through the functional complementation effect among the adsorption of an adsorbent, ion exchange, biodegradation and membrane filtration so that the biocatalyst is harmless; and moreover, the preparation technology has the advantages of simple process, easiness in operation, good effect, low investment, no pollution and wide application value.

Owner:INNER MONGOLIA HUAMENG KECHUANG ENVIRONMENTAL PROTECTION TECH ENG CO LTD

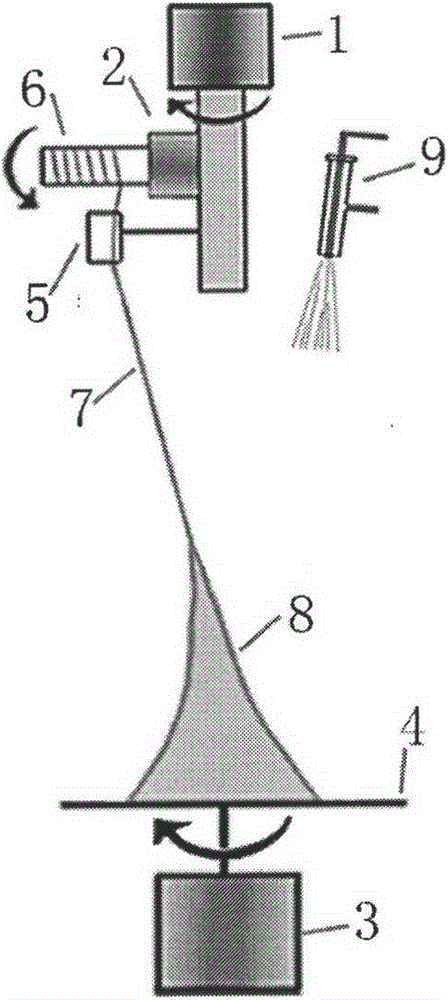

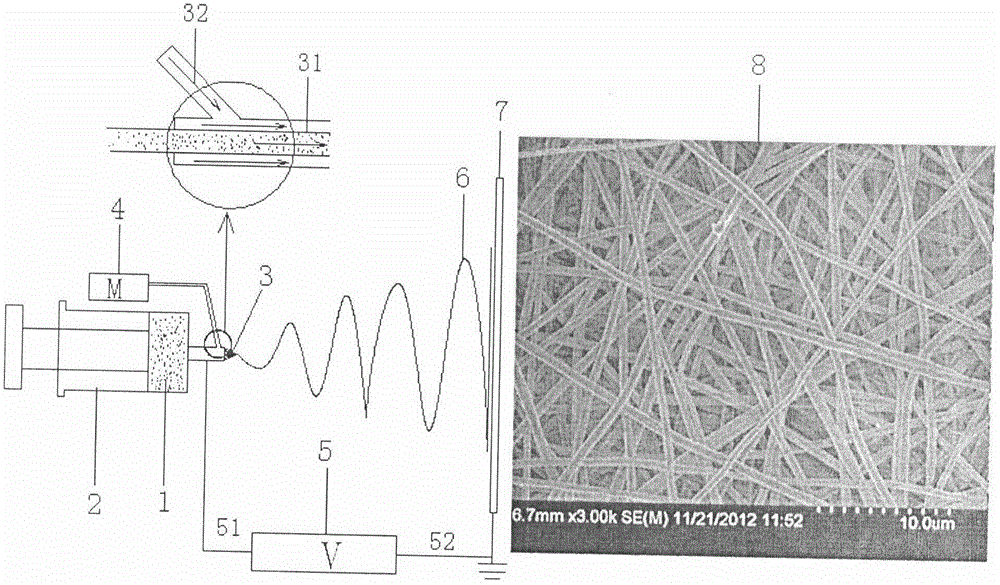

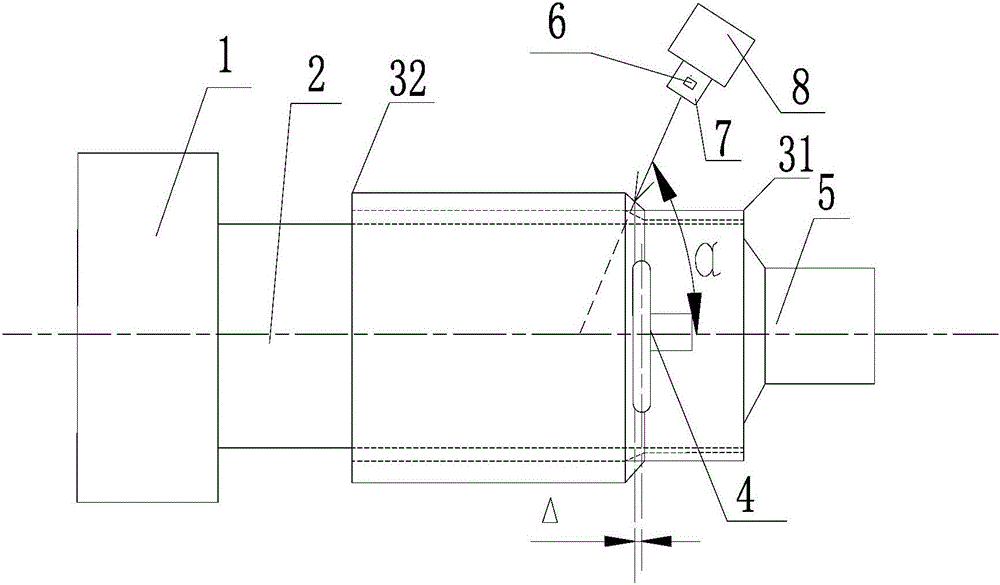

Continuous production device and method of orientation nanometer fiber yarns

The invention relates to a continuous production device and method of orientation nanometer fiber yarns. The continuous production device comprises a yarn bobbin (6), a yarn guiding pipe (5) and a receiver (4); the yarn bobbin (6) is driven by a motor (2) to rotate and is located above the yarn guiding pipe (5); the yarn bobbin (6) and the yarn guiding pipe (5) are perpendicular to each other; the yarn guiding pipe (5) and the motor (2) are fixed on a rotating shaft of a motor (1); the receiver (4) is driven by a motor (3) to rotate; the axes of the motor (1) and the motor (3) are located on the same straight line. According to the continuous production device and method of the orientation nanometer fiber yarns, the continuous production of the nanometer fiber yarns is achieved and the application in the biological, textile, material and electronic fields of nanometer fibers is expanded.

Owner:上海榕融新材料技术有限公司

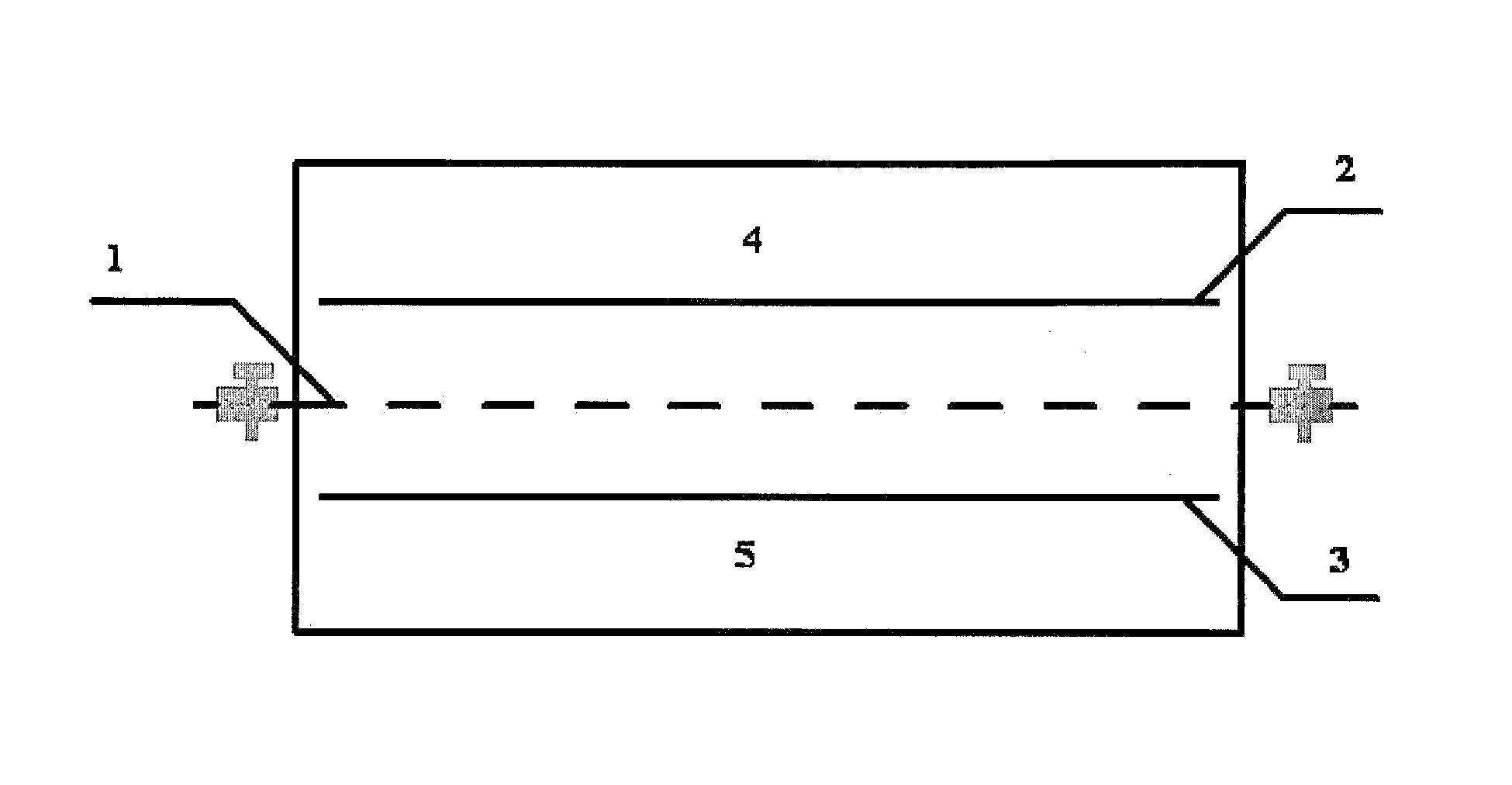

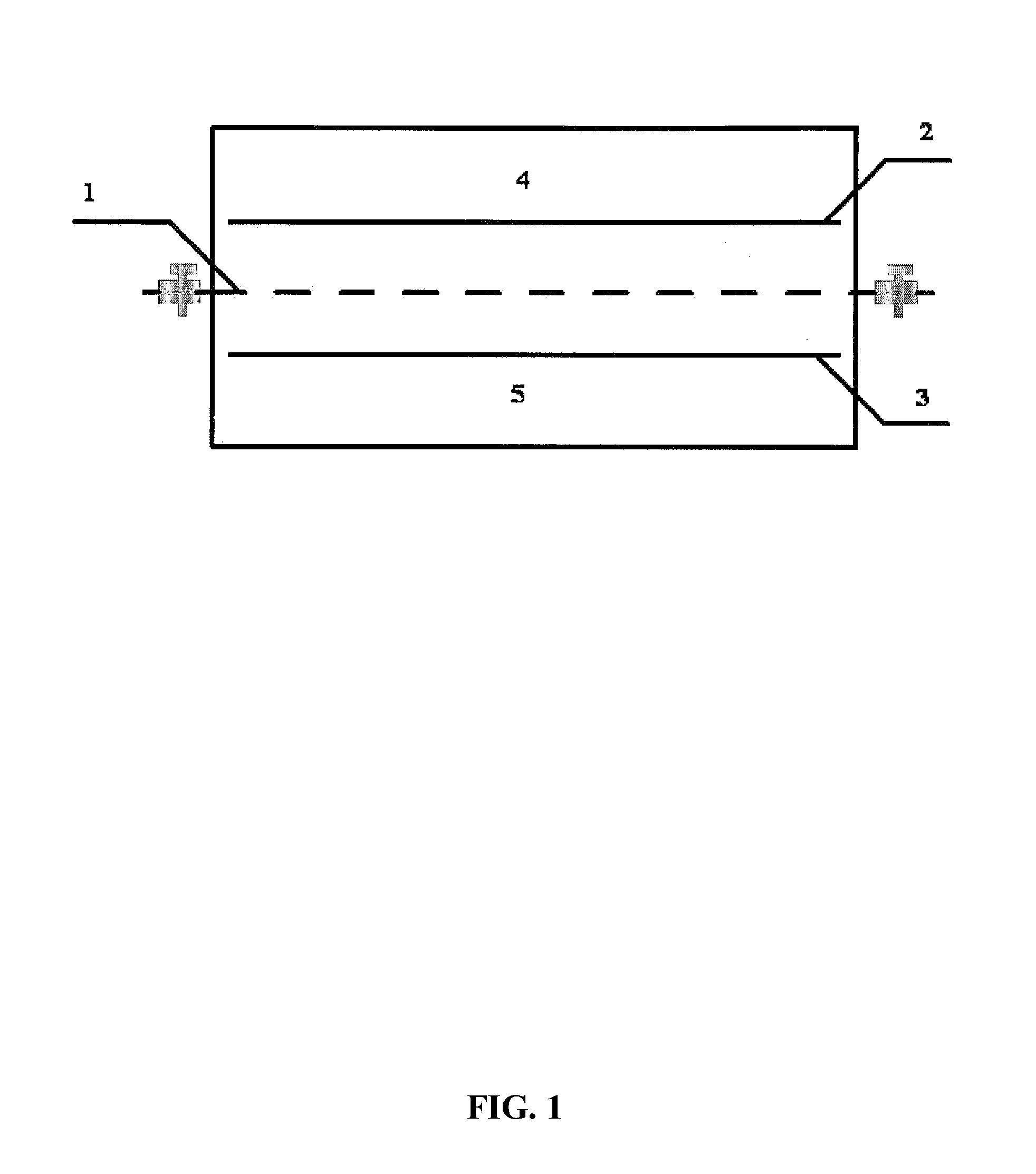

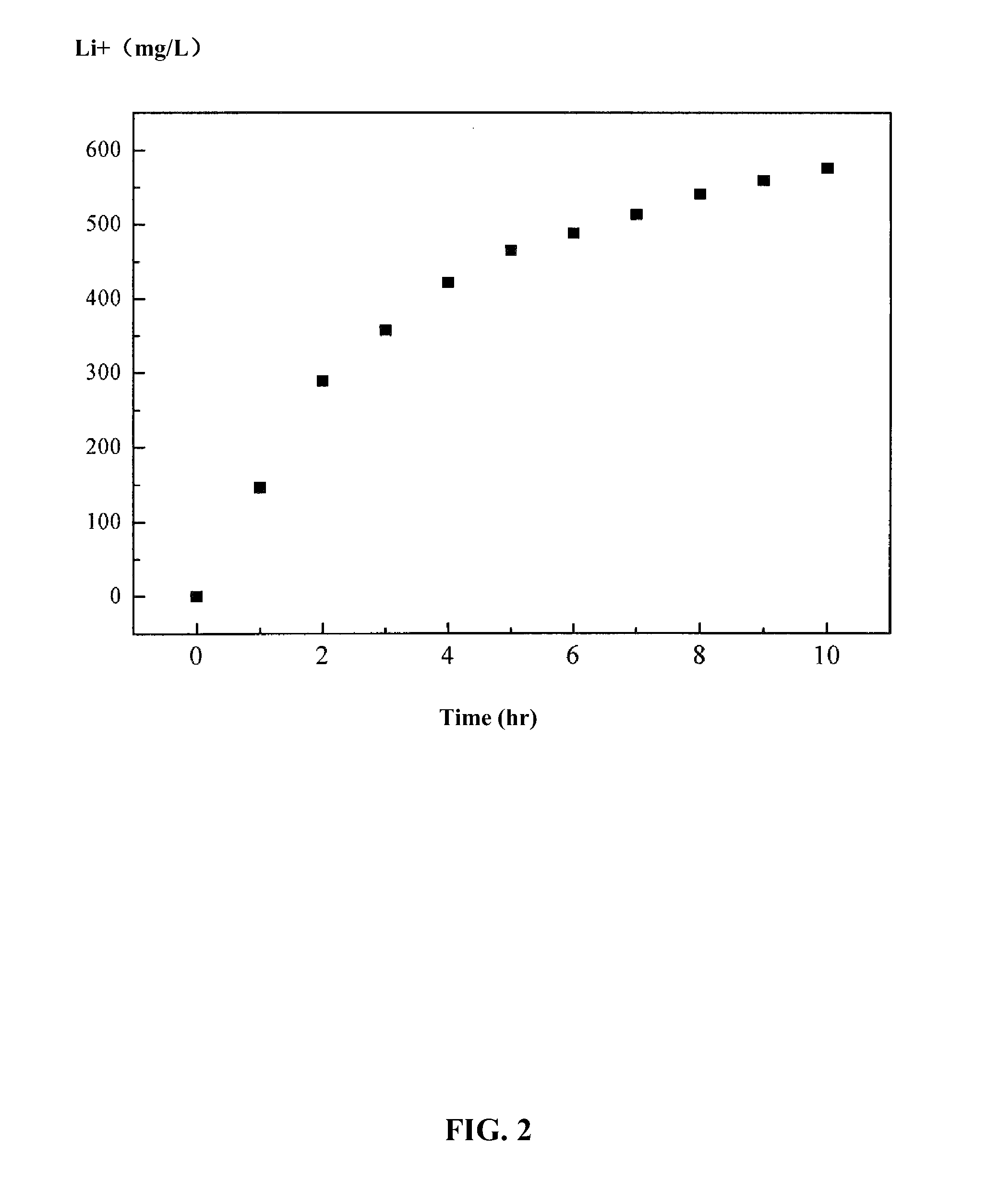

Method and device for extracting and enriching lithium

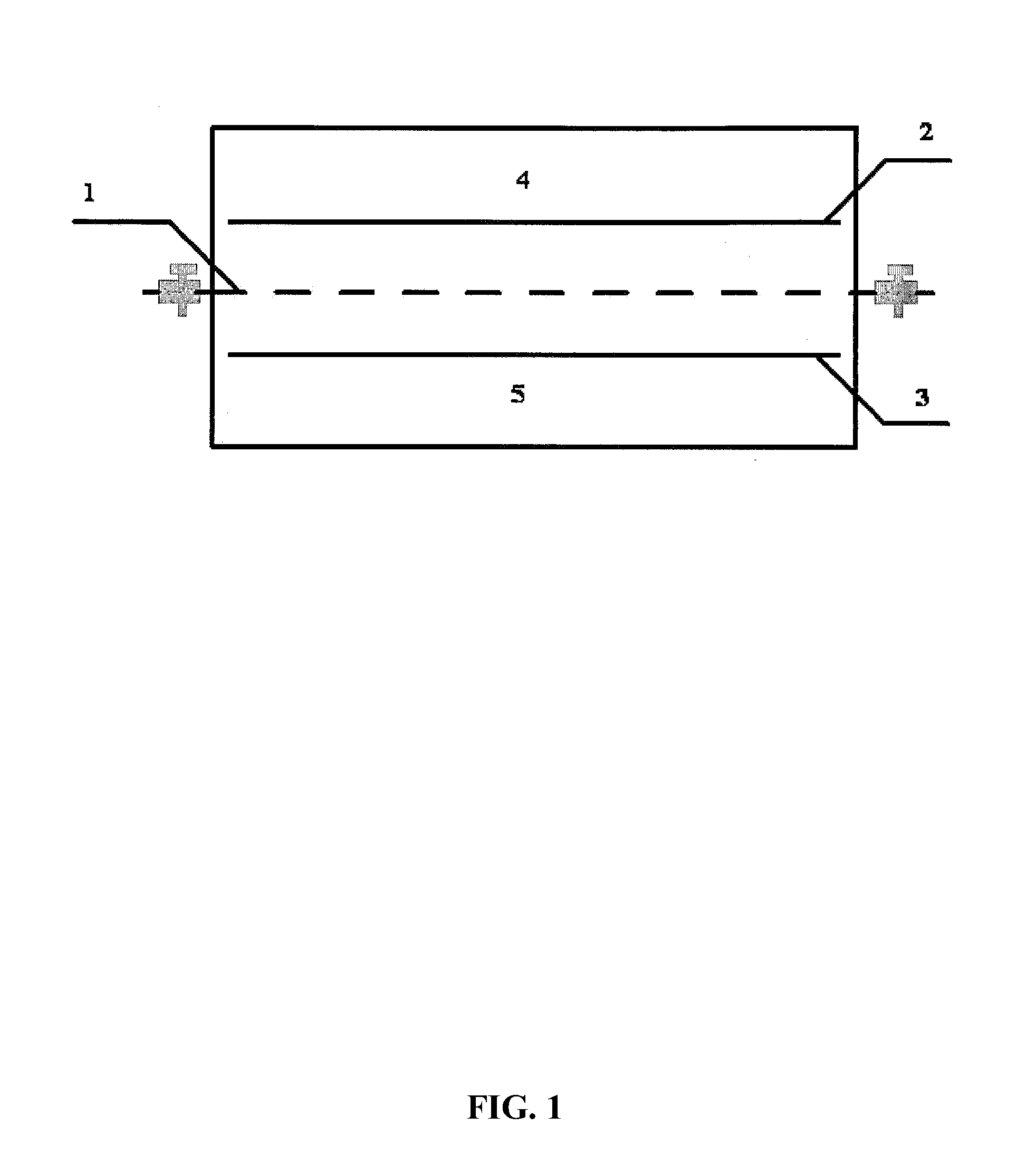

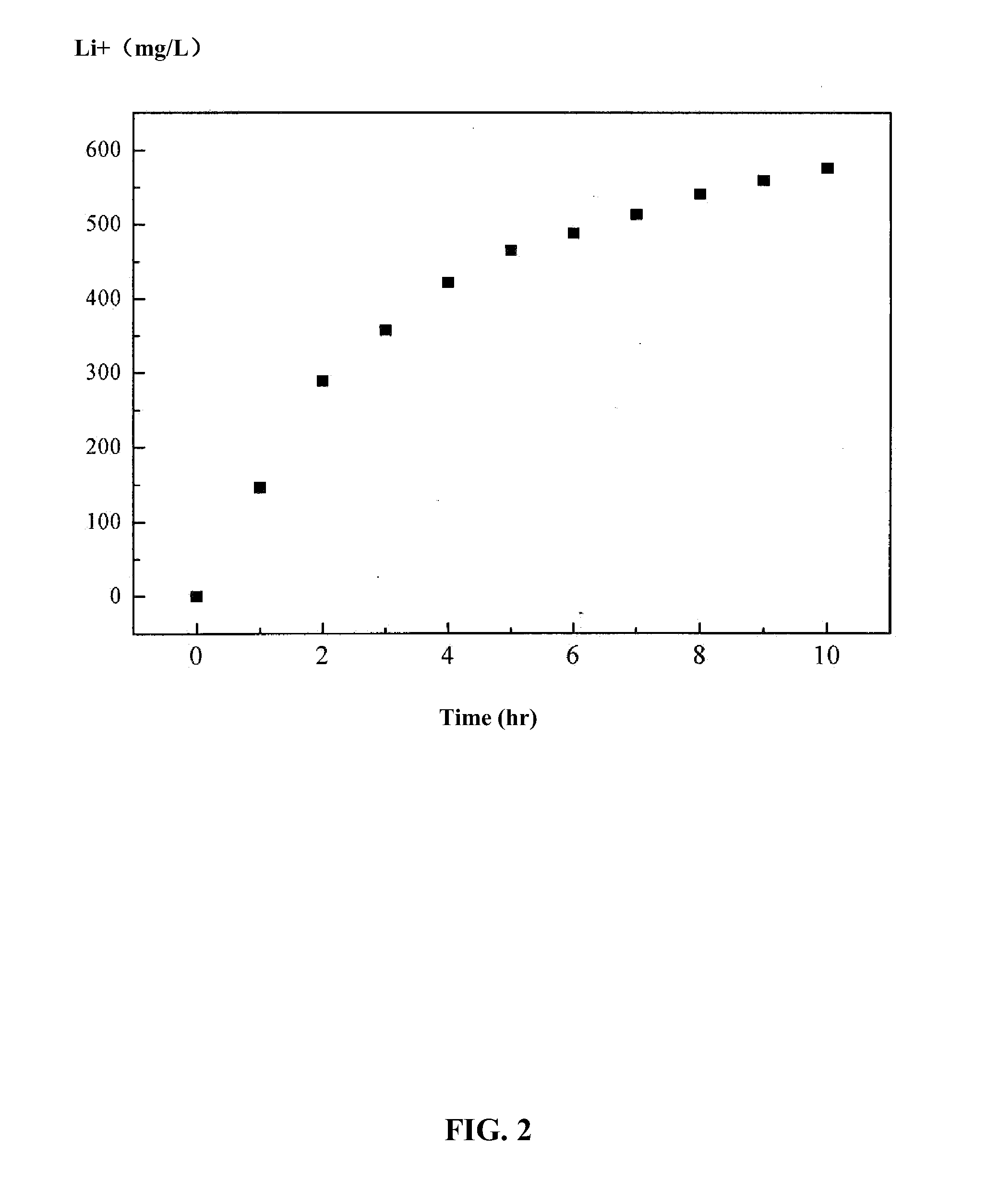

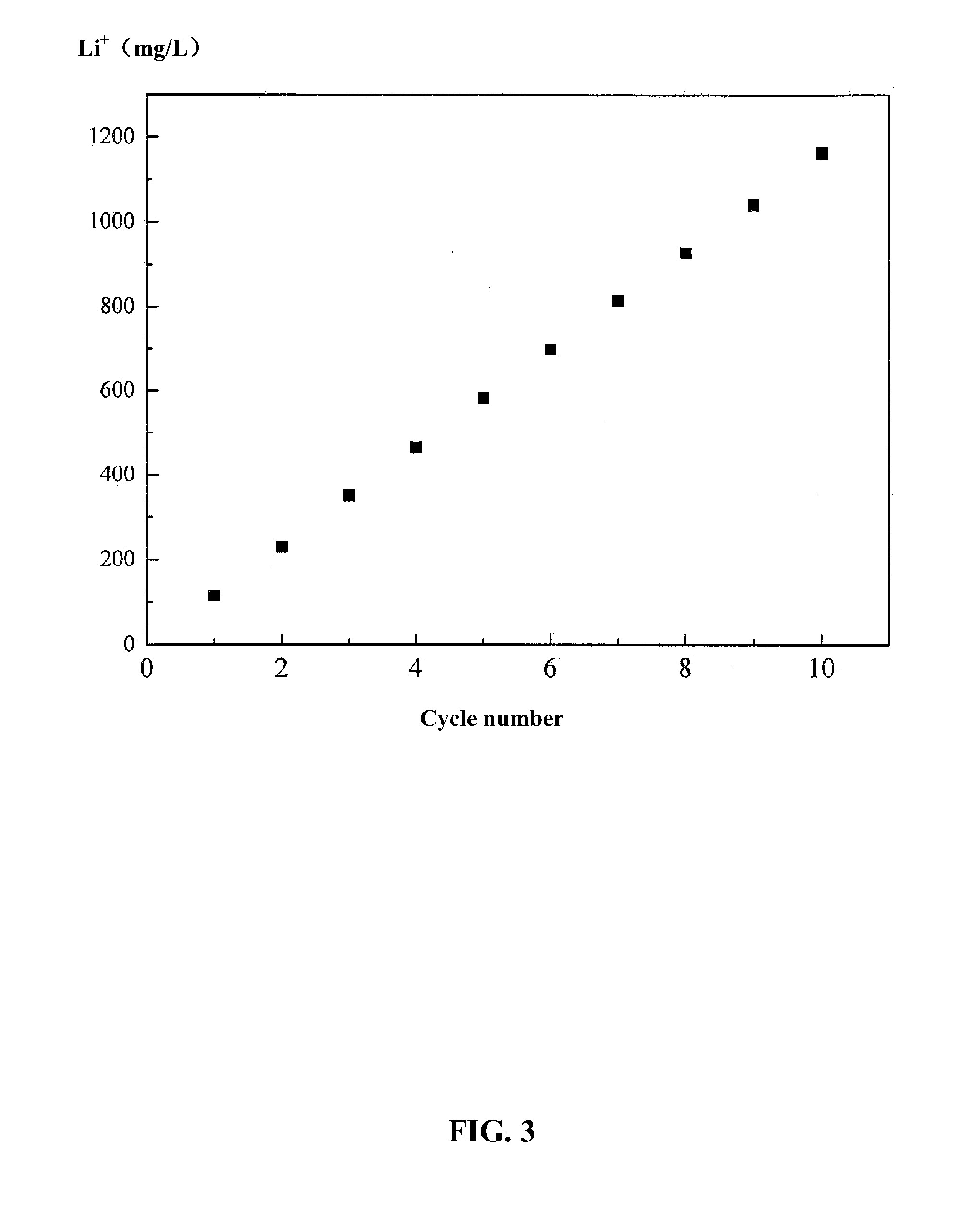

ActiveUS9062385B2Efficient separationShort processing flowSludge treatmentVolume/mass flow measurementSupporting electrolyteIon-exchange membranes

A method for extracting and enriching lithium, including: (a) providing an electrodialysis device including an electrodialysis cell; (b) dividing the electrodialysis cell into a lithium salt chamber and a brine chamber using an anion exchange membrane; (c) filling the brine chamber with salt lake brine; (d) filling the lithium salt chamber with a Mg2+ free supporting electrolyte solution; (e) placing a conductive substrate coated with an ion sieve in the brine chamber to operate as a cathode; (f) placing a conductive substrate coated with a lithium-intercalated ion sieve in the lithium salt chamber to operate as an anode; and (g) carrying out an electrodialysis.

Owner:CENT SOUTH UNIV

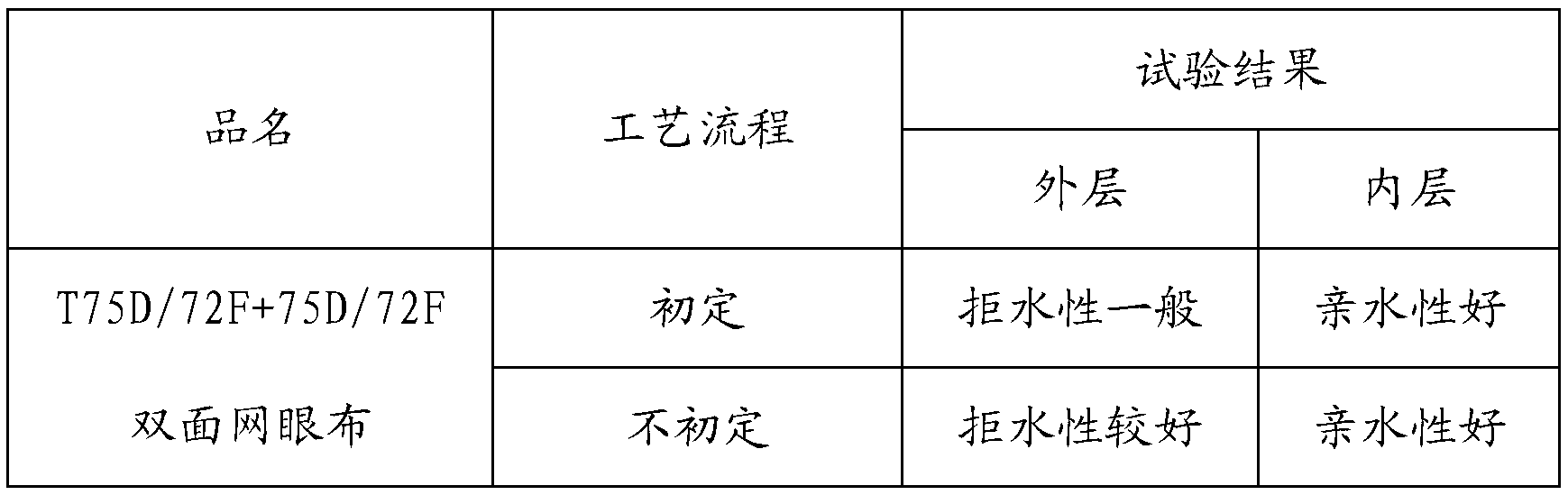

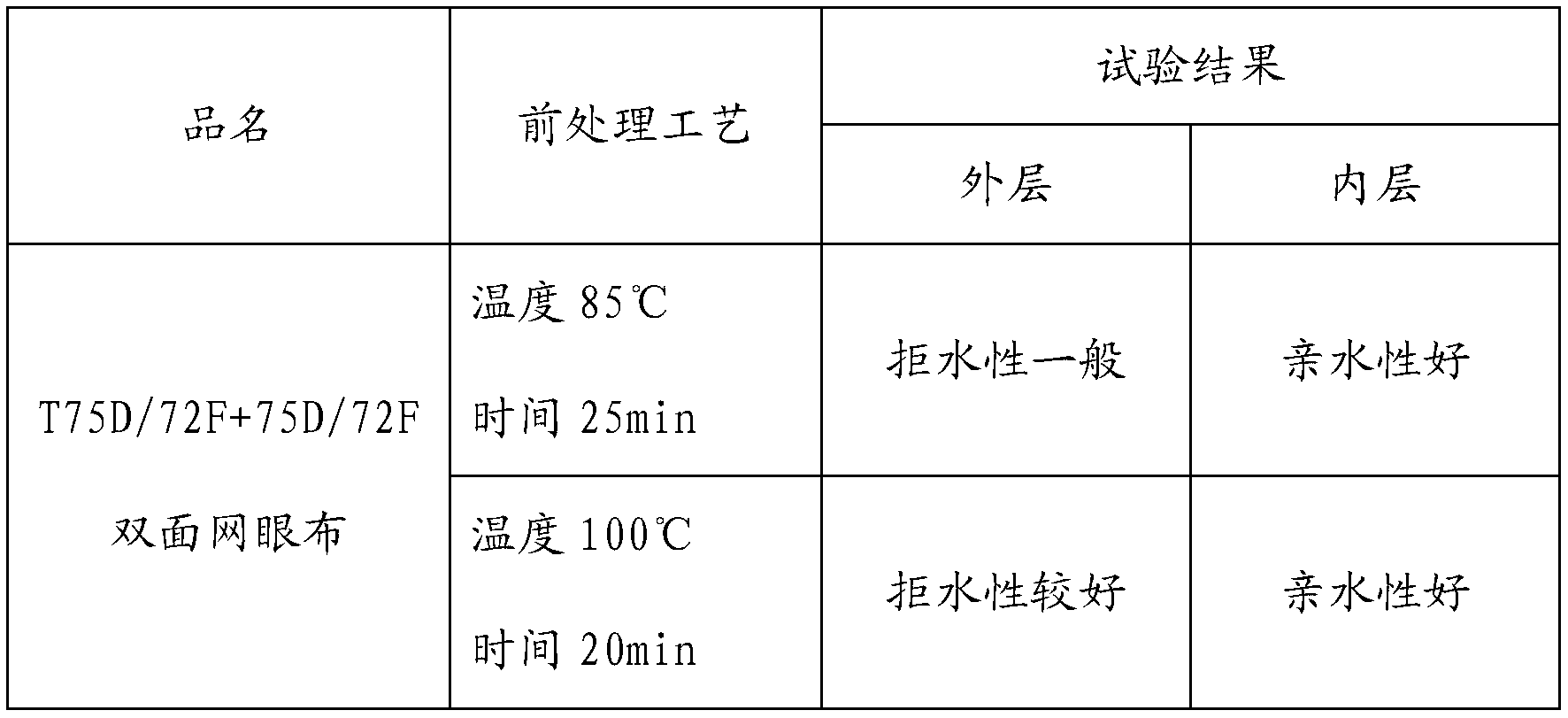

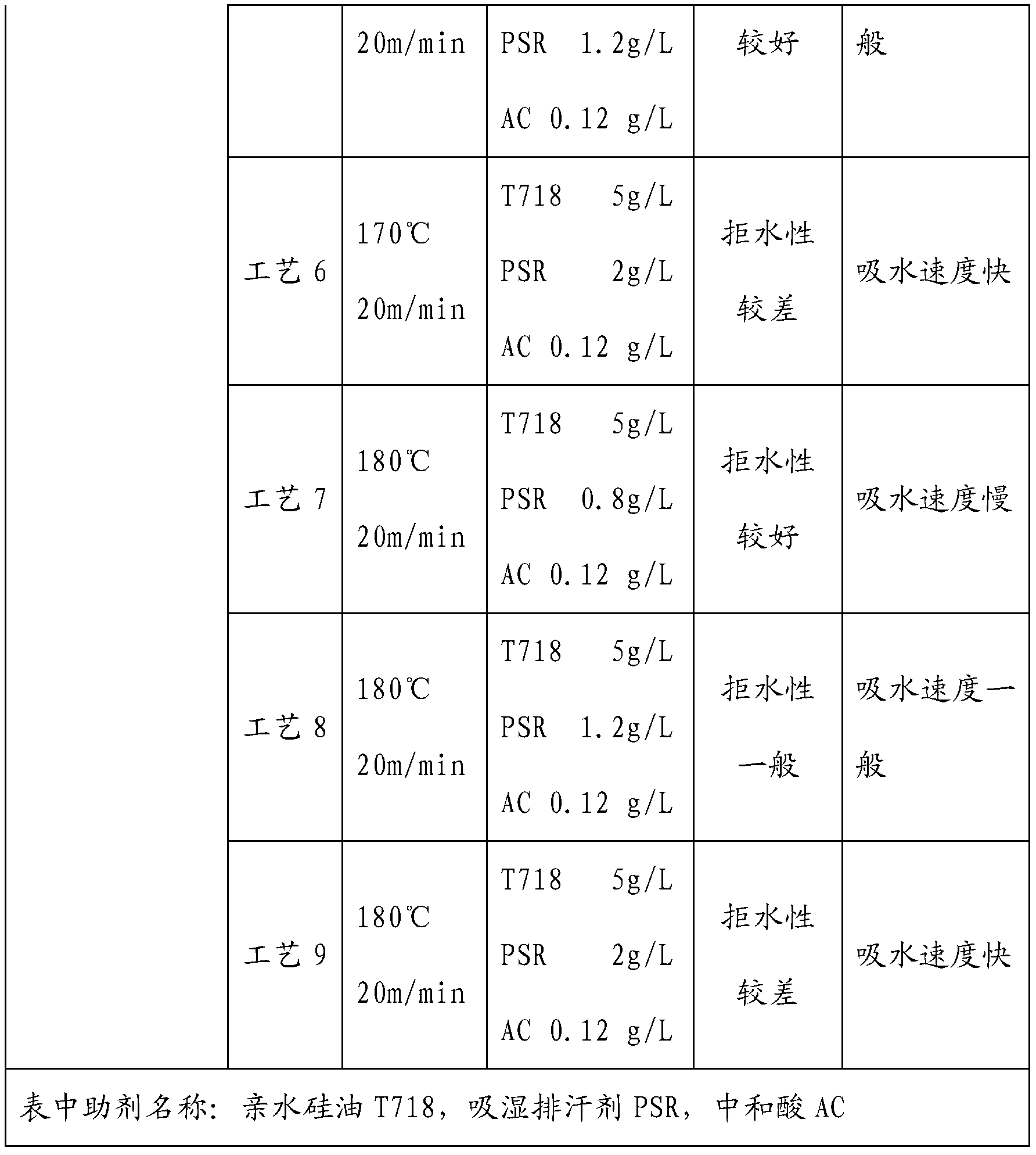

Anti-permeability and moisture absorption different-function knitted fabric and production process thereof

InactiveCN103233317AGood water repellencyWater repellency is not affectedSucessive textile treatmentsWeft knittingTextile designMoisture absorption

The invention discloses an anti-permeability and moisture absorption different-function knitted fabric and a production process thereof. The anti-permeability and moisture absorption different-function knitted fabric is of a double-layer structure, a middle connection tuck is connected between the outer layer and the inner layer, the outer layer and the middle connection tuck are made of water-repellency terylene subjected to surface modification processing, and the inner layer is made of terylene with irregular sections and having moisture absorption and sweat releasing functions. The production process of the anti-permeability and moisture absorption different-function knitted fabric includes steps of performing weaving to obtain grey fabric according to the double-layer textile design; performing preprocessing, dyeing, softening, dewatering and wet cutting for the grey fabric; and performing after finishing through a setting machine. According to the anti-permeability and moisture absorption different-function knitted fabric and the production process thereof, two different functions are combined in the inner layer and the outer layer of the fabric, and requirements of sports knitwear for combining inner layer moisture absorption and sweat releasing functions with outer layer sweat stain prevention function are met.

Owner:FUJIAN FYNEX TEXTILE SCI & TECH

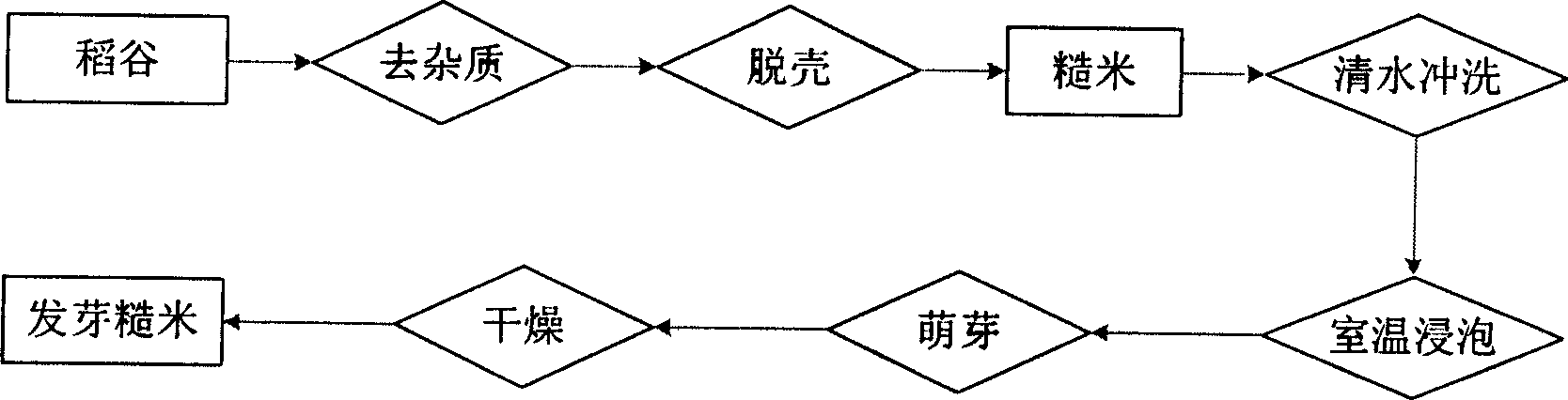

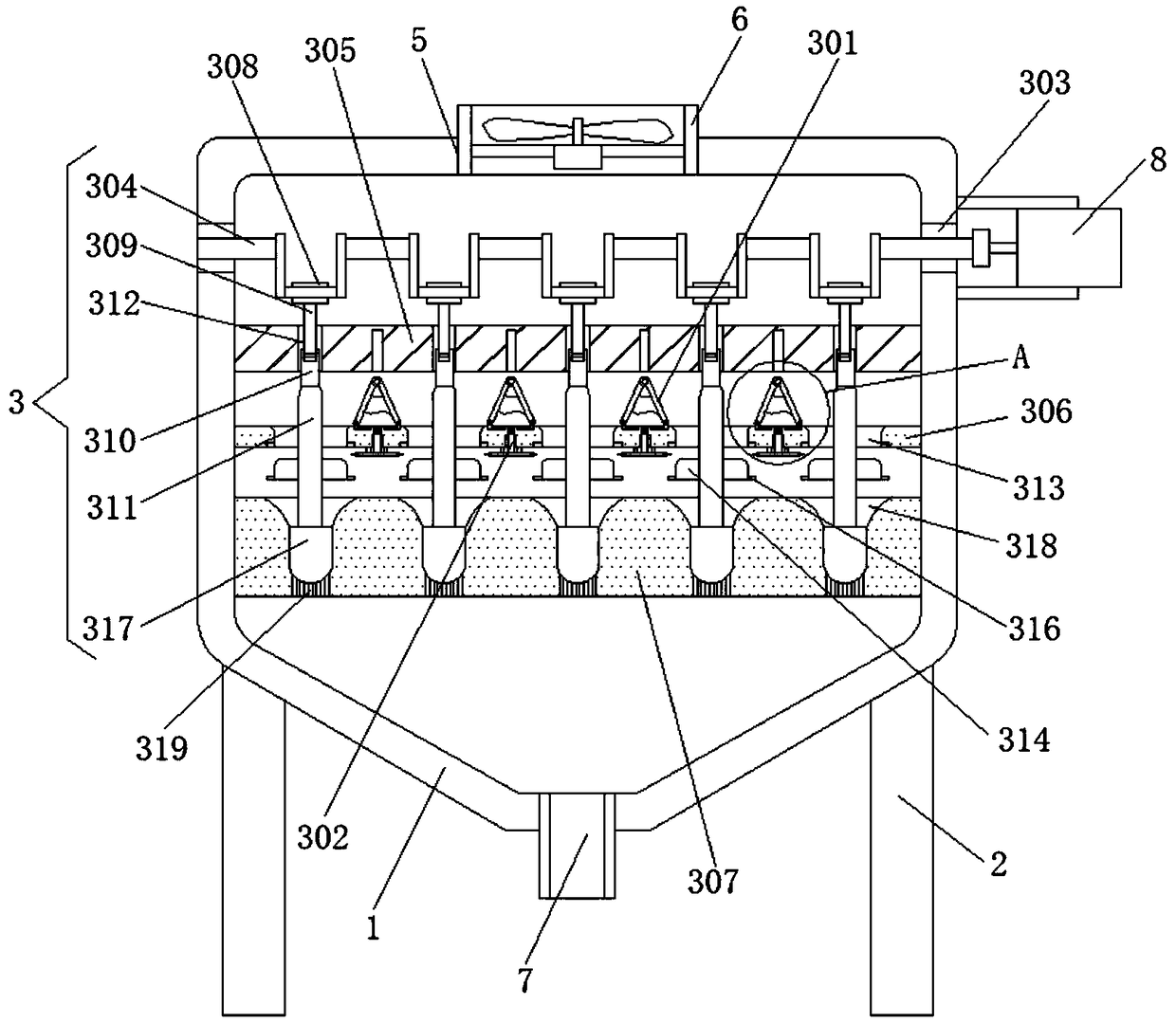

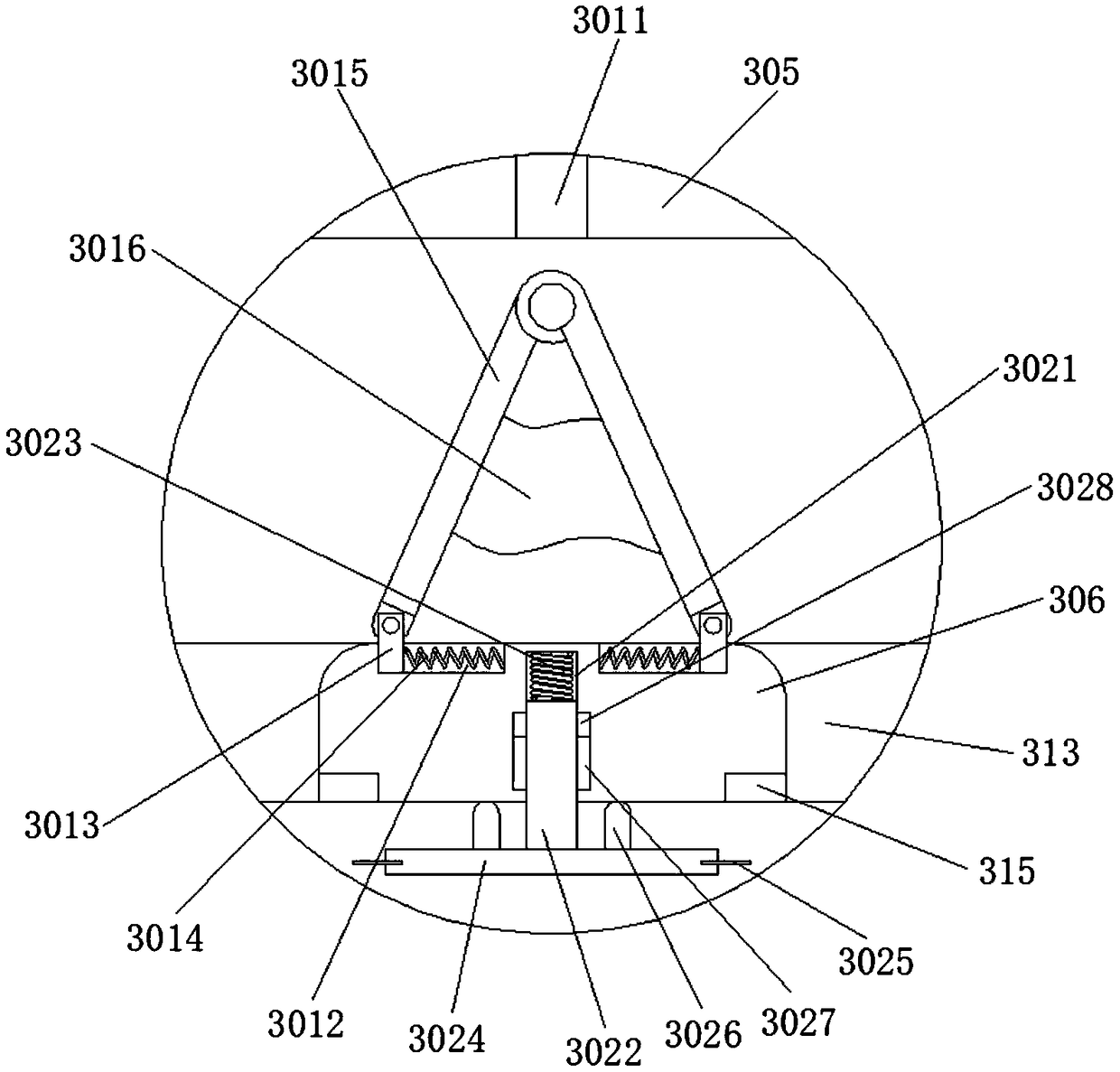

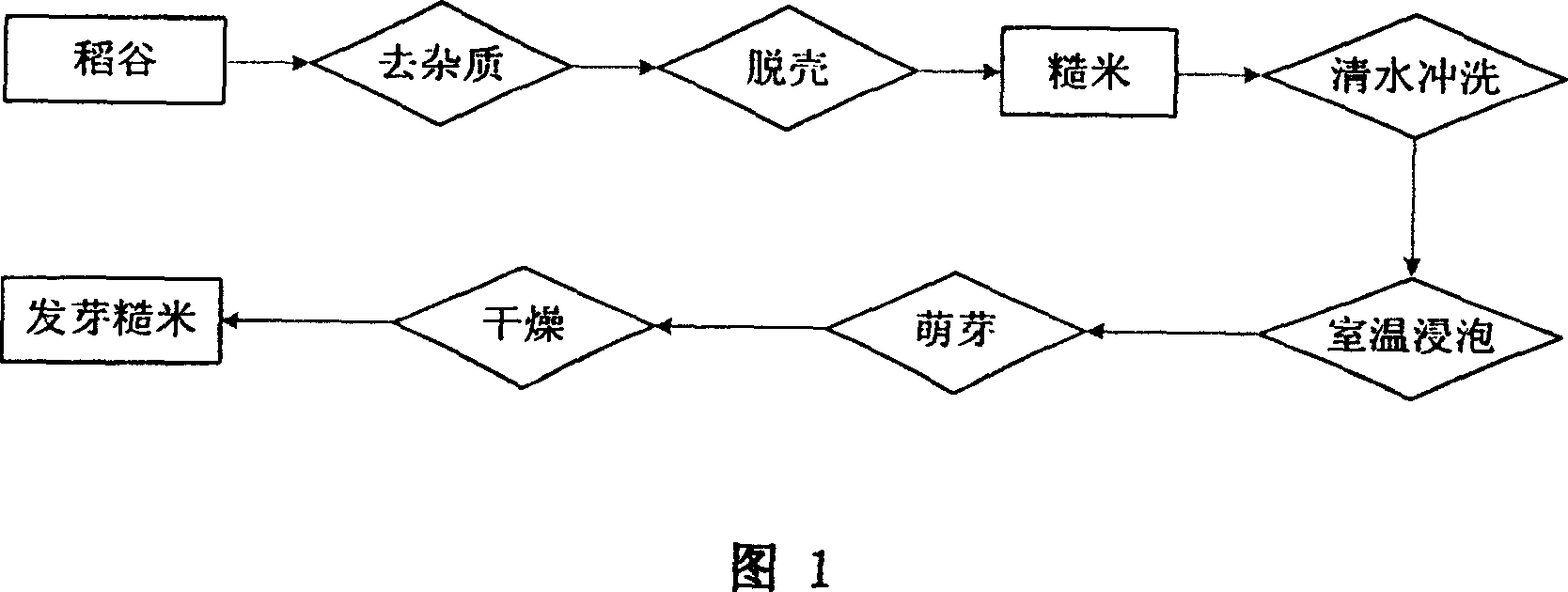

Processing method of sprouted half-polished and obtained sprouted half-polished rice

ActiveCN1596603AShort processing flowReduce the impact of intrinsic qualityCultivating equipmentsFood preparationAmino acidClean water

A process for preparing sprouted half-polished rice, which is rich in amino acids, includes such steps as flushing raw long-grained non-glutinous rice, immersing in clean water at 18-24 deg.C for 2-4 hr, germinating at 35-45 deg.C for 11-25 hr while exchanging water every 8-12 hr, and drying at 40-50 deg.C for 4-12 hr.

Owner:江苏海奥生物科技有限公司

Method and device for extracting and enriching lithium

ActiveUS20130186760A1Efficient separationShort processing flowSludge treatmentVolume/mass flow measurementSupporting electrolyteSalt lake brine

A method for extracting and enriching lithium, including: (a) providing an electrodialysis device including an electrodialysis cell; (b) dividing the electrodialysis cell into a lithium salt chamber and a brine chamber using an anion exchange membrane; (c) filling the brine chamber with salt lake brine; (d) filling the lithium salt chamber with a Mg2+ free supporting electrolyte solution; (e) placing a conductive substrate coated with an ion sieve in the brine chamber to operate as a cathode; (f) placing a conductive substrate coated with a lithium-intercalated ion sieve in the lithium salt chamber to operate as an anode; and (g) carrying out an electrodialysis.

Owner:CENT SOUTH UNIV

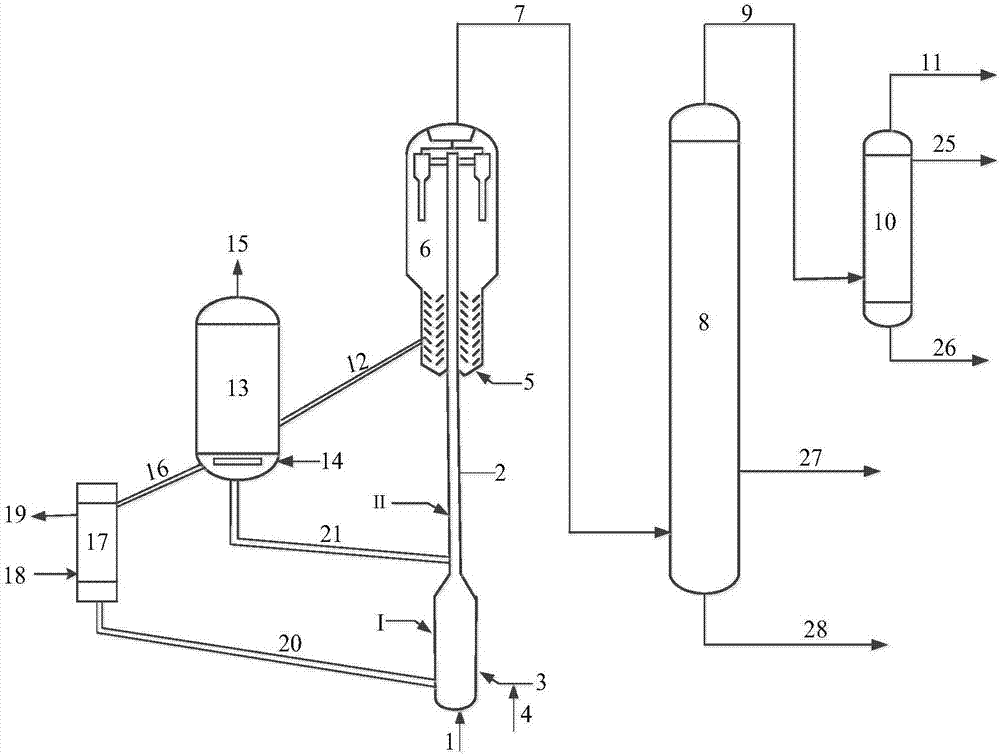

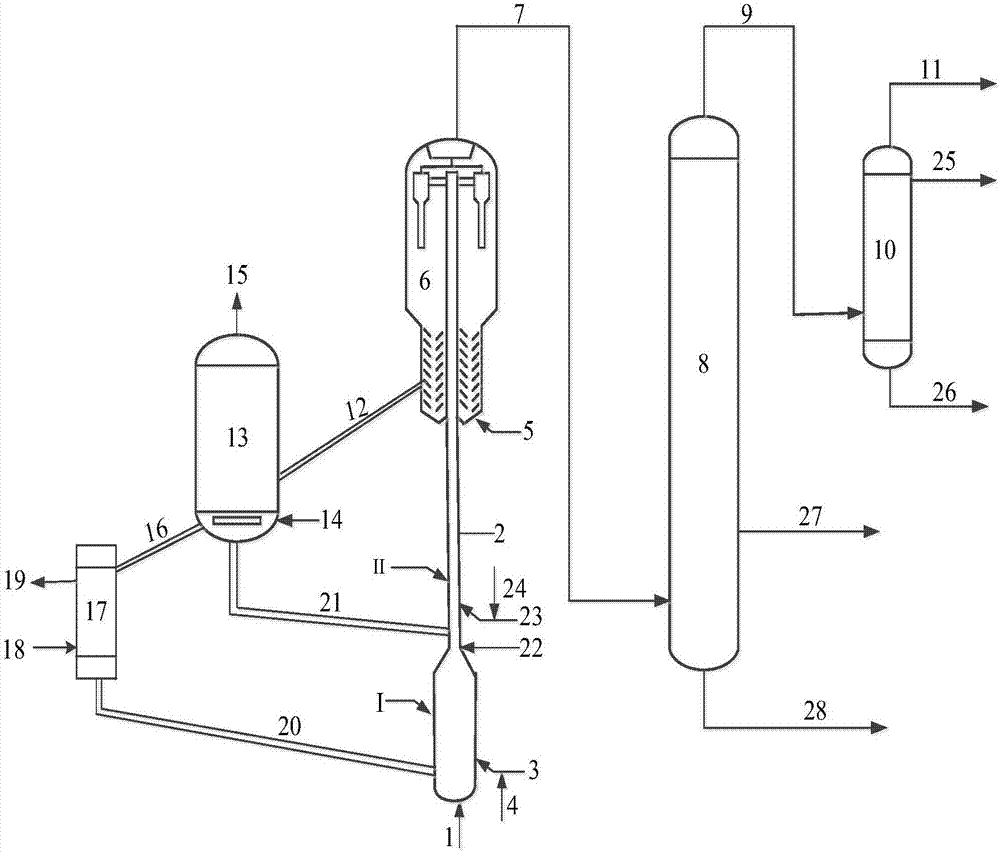

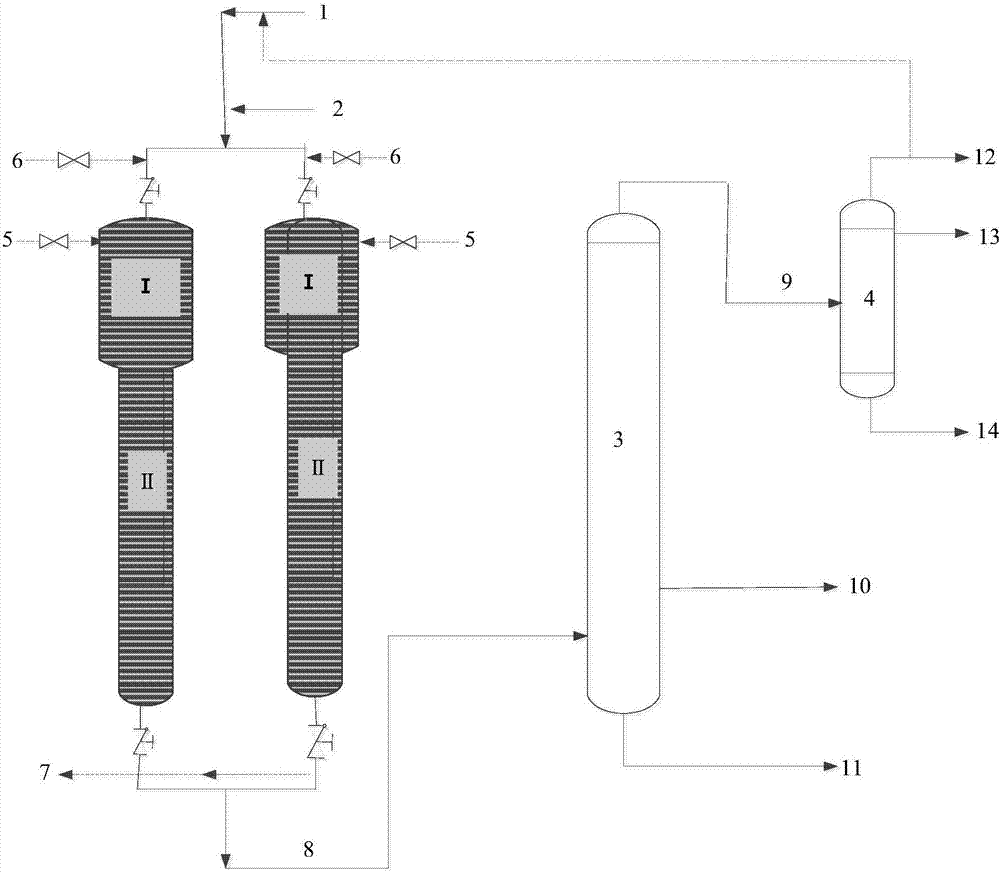

Processing method and system for inferior crude oil

ActiveCN107267211AEliminates rich gas compressorReduce device energy consumptionTreatment with hydrotreatment processesChemistryDry gas

The invention discloses a processing method and system for inferior crude oil. The method comprises the steps as follows: a, feeding hydrogen-containing gas and the inferior crude oil into a fluidized bed hydrogen absorption zone (I) of a fluidized bed riser reactor for contact with a first catalytic cracking catalyst and a hydrogen adsorption reaction to obtain a hydrogen absorption product; b, feeding the hydrogen absorption product obtained in the step a into a riser cracking zone (II) of the fluidized bed riser reactor for contact with a second catalytic cracking catalyst and a catalytic cracking reaction to obtain catalytic cracked oil-gas. The inferior crude oil processed by the system with the method has the advantages that the conversion rate of the inferior crude oil can be increased substantially, the yield of dry gas and coke is reduced, and accordingly, clean and efficient use of the inferior crude oil is realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

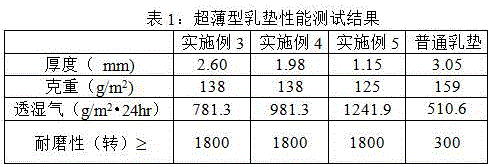

Ultra-thin breast pad and preparation method thereof

ActiveCN105970489AEliminates the defect of easy hair lossImprove wear resistanceLiquid surface applicatorsLayered productsPhysiologyHot melt

The invention discloses an ultra-thin breast pad and a preparation method thereof and relates to the field of female lactation products. The ultra-thin breast pad is composed of a surface layer hydrophilic non-woven fabric, an intermediate absorbing layer and an impermeable bottom film. The surface layer hydrophilic non-woven fabric is a soft type double-component filament non-woven fabric composed of core layer PP / skin layer PE; and the intermediate absorbing layer is a hot melting non-woven fabric formed by blending core layer PP / skin layer PE and superabsorbent fibers. According to the method for preparing the ultra-thin breast pad, the surface layer hydrophilic non-woven fabric for preparing the ultra-thin breast pad is selected through a PE / PP double-component filament non-woven fabric soft bulkiness processing method, the superabsorbent fibers and the PE / PP double-component fibers are blended, the intermediate absorbing layer is prepared through a plain net hot air reinforcing method, so that the prepared ultra-thin breast pad has the advantages of being not subjected to fiber slip, being ultra-thin and breathable, having moisture breathability and being safe and healthy, and the problems that a breast pad not subjected to fiber slip is poor in comfort, unsafe, high in moisture content and high in material cost are solved.

Owner:CHANGSHU GOLD SPRING CHEM FIBERS & KNITTINGS

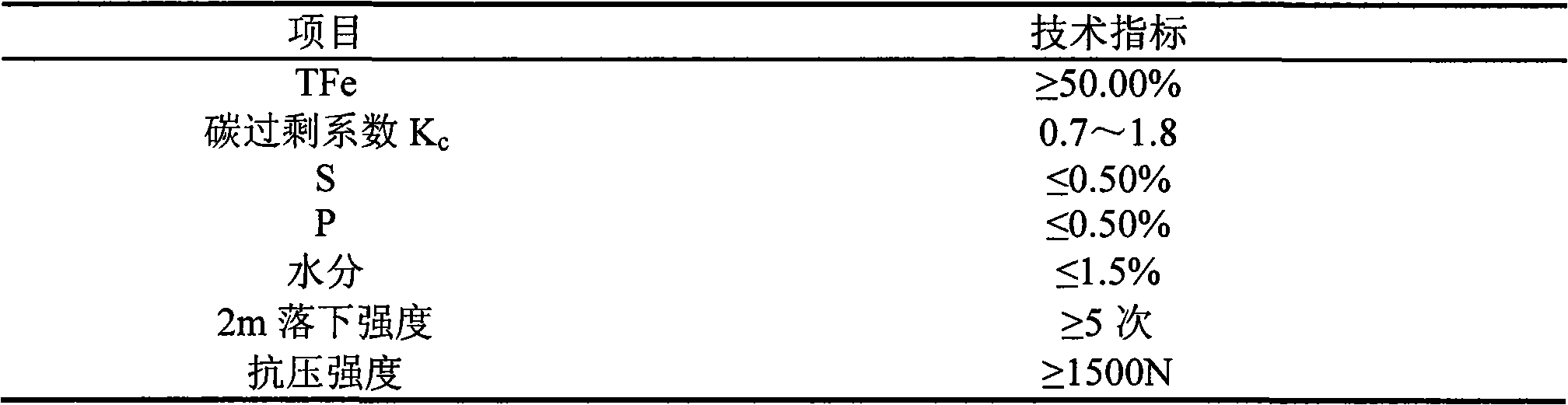

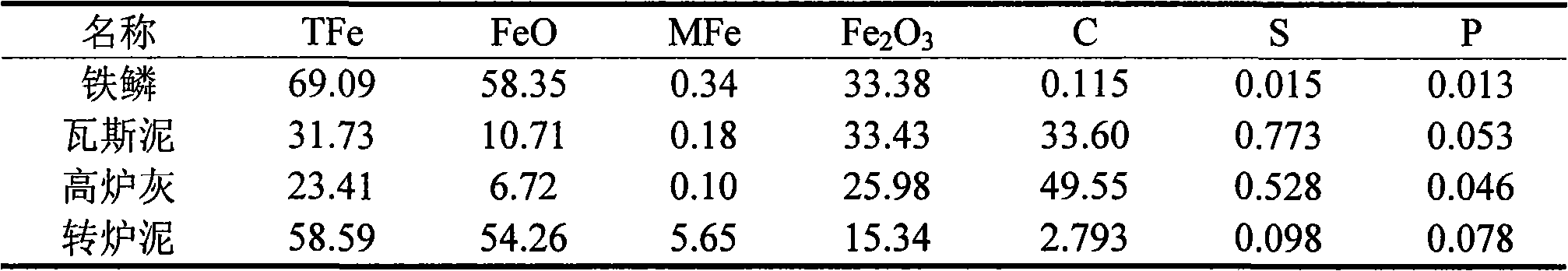

Rotary furnace cooling agent made of metallurgical waste material product and using method thereof

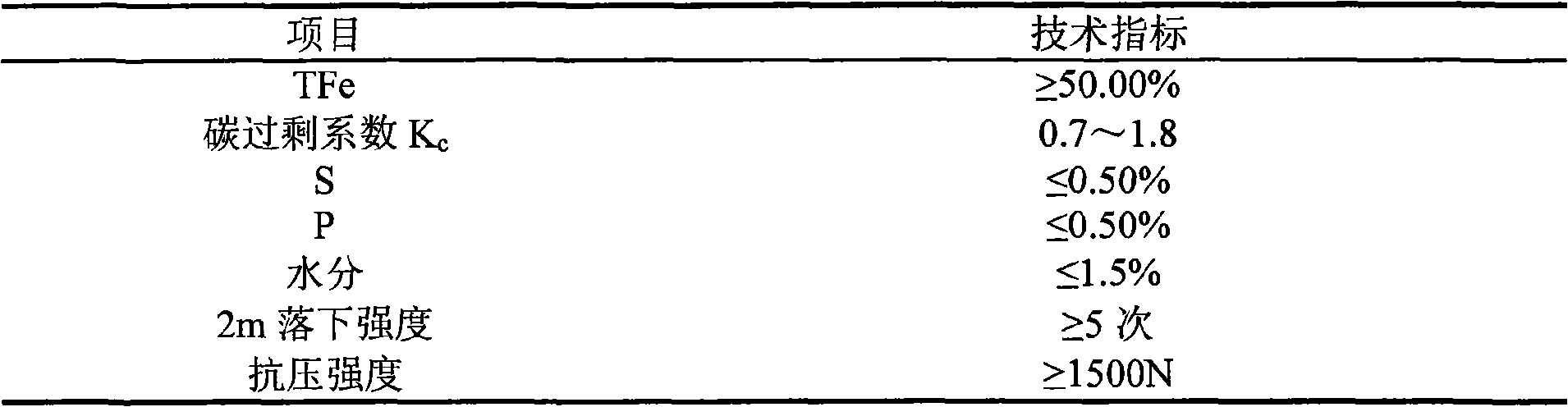

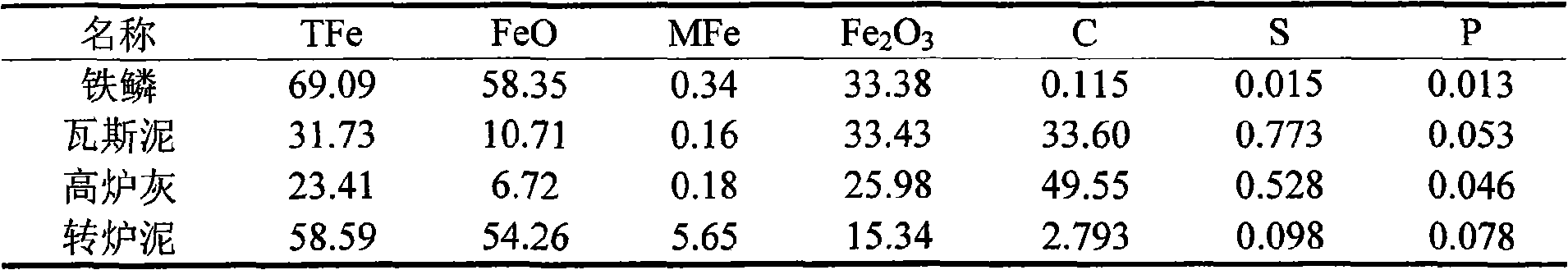

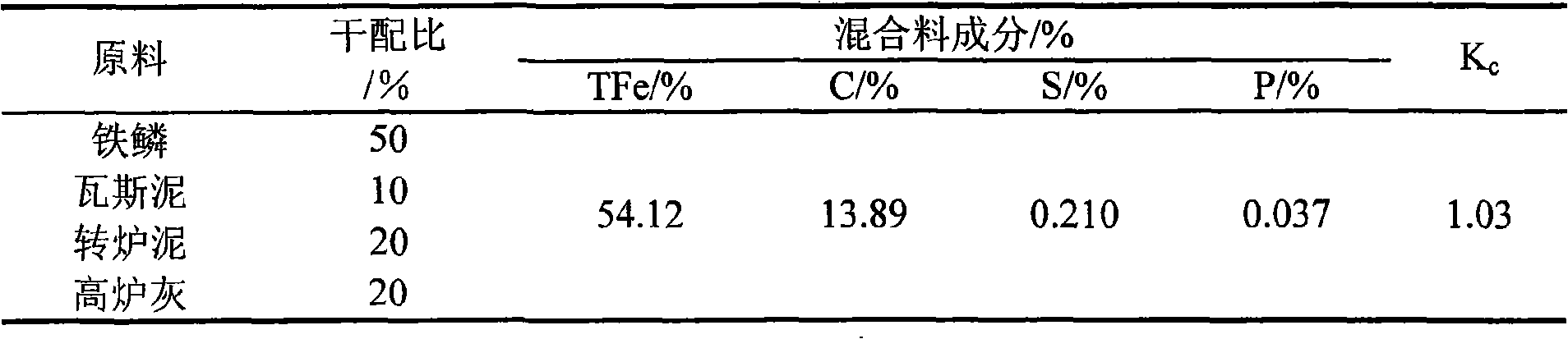

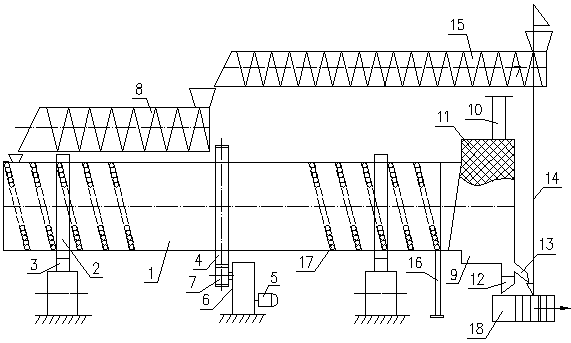

ActiveCN101560583AImprove slag removal effectEmission reductionManufacturing convertersProcess efficiency improvementChemical compositionEconomic benefits

The invention provides a rotary furnace cooling agent and a manufacturing method thereof. The cooling agent is a carbonic and ferreous conglomeration which mainly takes iron scale, carbonic waste material and ferreous waste material as raw materials, and prepared by additionally adding caking agent into the raw materials. The weight percentage of the main chemical compositions of the cooling agent meets the following condition: the carbon content is 5-25%, the content of TFe is more than or equal to 50%, the content of S is less than or equal to 0.50% and the content of P is less than or equal to 0.50%. The manufacturing method comprises: the wet materials in the carbonic waste material and the ferreous waste material are firstly dried and crushed by a crusher, and then enters a blending machine to be mixed together with the dry materials such as the iron scale and the like; the mixture is added with the caking agent to be evenly mixed, and the mixed material is sent into a mixing mill and then into a twin-roller ball press machine to be pressed into conglomeration; the pressed conglomeration is screened by a sieving machine, and the qualified screened conglomeration can be sent into a dry furnace to be dried, so that the finished product conglomeration can be obtained. The rotary furnace cooling agent completely uses the waste materials generated in the steel production, and can be used for replacing the common waste steel to be applied in smelting of a rotary furnace, so that no special reduction plant is needed for use, the process flow is short, the cost is low, the using method is flexible, the adding quantity is large, the recovery rate is high, the field operation is seldom affected, the economic benefit and the environmental protection benefit are remarkable, and the promotion and application values are excellent.

Owner:ANGANG STEEL CO LTD

Production method of pure silk quilt with jasmine flower fragrance

The invention provides a production method of a pure mulberry silk quilt with jasmine flower fragrance. The production method comprises the following steps: (1) putting matured silkworms on a spinning net; (2) stripping silk to obtain a crude soft piece; (3) degumming the crude soft piece; (4) cleaning with clean water and then dehydrating; (5) removing impurities, reshaping, and drying for later use; (6) picking and storing jasmine flowers; (7) taking the flowers and waiting for scenting; (8) parqueting and scenting by piling; (9) weighing the soft piece and pulling to be fluffy; (10) cutting the soft piece; (11) pulling the cut soft pieces open one by one, laying in a criss-cross manner, after laying is completed, checking and finishing, and removing impurities; (12) placing a silk-escape-preventing gauze above and below a finished soft bat respectively, so that silk escape is avoided; (13) covering the soft bat with a bat cover; and (14) quilting a seam between the bat cover and a silk floss bat and shaping. The mulberry silk quilt obtained by adopting the production method provided by the invention has no rib strip, no pupal fat and no chemical residue and is more natural and environment-friendly compared with the traditional silk quilt produced from silk floss; and the mulberry silk quilt has jasmine flower fragrance and also maintains the characteristics of the silk quilt of softness, breathability, closed fit and comfort.

Owner:GUANGXI GUIHUA SILK CO LTD

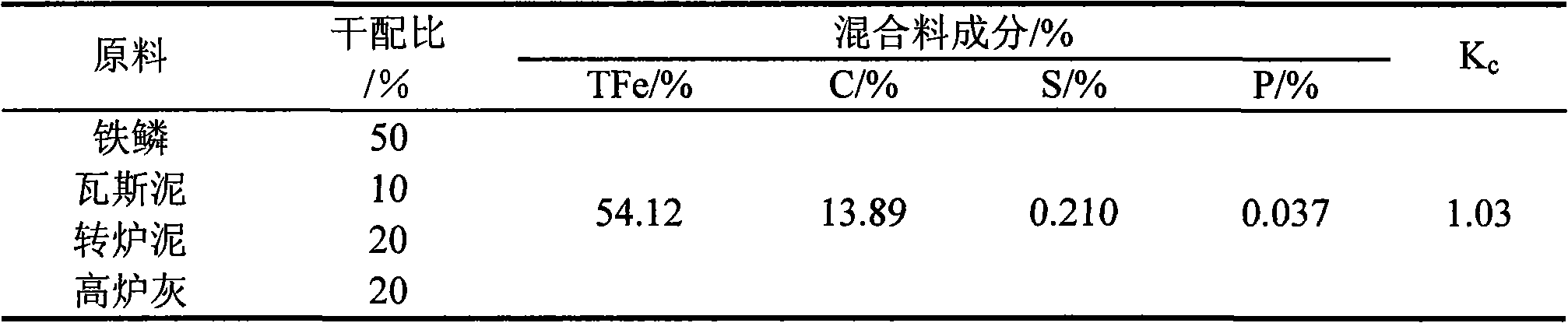

High-permeability diversion layer material and preparation method thereof

ActiveCN106937902AReduce heavinessGood moisture permeabilityAbsorbent padsBaby linensFiberReverse osmosis

The invention discloses a high-permeability diversion layer material and a preparation method thereof, and relates to the field of disposable sanitary products. The preparation method of the high-permeability diversion layer material is characterized in that by compound-superimposing and selecting an upper layer vertical net and a bottom layer direct laying net, matching coarse denier profiled cross-section fibers and fine denier hydrophilic double components in the upper layer vertical net, reasonably matching hydrophilic and water-repellent double-component fiber in the bottom layer direct laying net, selecting a hot air penetration thermal stabilization mode and reasonably selecting lustring and setting technological parameters of a hot pressing roll, the high-permeability diversion layer material with good permeability is prepared. Therefore, the technical problems of poor diversion performance, inability in storing liquid, poor transient sucking effect, complex technology, poor permeability and difficulty in quantity production of a diversion layer material are solved, and the effects of enabling the diversion layer material to have good abilities of transient suction property, diversion property, barrier property and temporary liquid storage and to have good effects of ventilation, moisture permeation and reverse osmosis prevention are achieved.

Owner:CHANGSHU GOLD SPRING CHEM FIBERS & KNITTINGS

Preparation method of pure mulberry silk quilt with aglaia odorata lour fragrance

The invention provides a preparation method of a pure mulberry silk quilt with aglaia odorata lour fragrance. The preparation method comprises the following steps: (1) putting ripe silkworms on a spinning net; (2) stripping silks so as to obtain rough cotton sheets; (3) performing degelatinization treatment on the rough cotton sheets; (4) cleaning the rough cotton sheets with clear water, and then performing dehydration; (5) removing impurities, reshaping, and then drying for later use; (6) picking and maintaining aglaia odorata lour; (7) scenting the aglaia odorata lour ; (8) weighing the cotton sheets, and pulling the cotton sheets into a fluffy state; (9) cutting the cotton sheets; (10) stretching the cotton sheets one by one, laying the cotton sheets in a crisscross manner, then performing inspection and tidying, and removing impurities; (11) respectively placing one layer of silk-leakage gauze on the upper and lower surfaces of a tidied batt core so as to avoid silk leakage; (12) sleeving the batt core with a batt sleeve; and (13) performing tailor tacking and setting on the batt sleeve and the silk batt core. The obtained silk quilt has no fillets, chrisalis oil and chemical residues; compared with a silk quilt made of traditional silk floss, the pure mulberry silk quilt is relatively natural and environmentally friendly; the pure mulberry silk quilt has aglaia odorata lour fragrance, and also keeps the characteristics of lightness, softness, permeability and body-contact comfort of the silk quilt per se.

Owner:GUANGXI GUIHUA SILK CO LTD

Method for preparing aromatic hydrocarbon with carbon dioxide hydrogenation

ActiveUS20190071374A1Low selectivityHigh selectivityHydrocarbon from carbon oxidesMolecular sieve catalystsMolecular sieveHydrogen

A method for preparing aromatic hydrocarbons with carbon dioxide hydrogenation, comprising: directly converting a mixed gas consisting of carbon dioxide and hydrogen with the catalysis of a composite catalyst under reaction conditions of a temperature of 250-450° C., a pressure of 0.01-10.0 MPa, a feedstock gas hourly space velocity of 500-50000 mL / (h·gcat) and a H2 / CO2 molar ratio of 0.5-8.0, to produce aromatic hydrocarbons. The composite catalyst is a mixture of a first component and a second component. The first component is an iron-based catalyst for making low-carbon olefin via carbon dioxide hydrogenation, and the second component is at least one of metal modified or non-modified molecular sieves which are mainly used for olefin aromatization. In the method, CO2 conversion per pass may be above 33%, the hydrocarbon product selectivity may be controlled to be above 80%, the methane content is lower than 8%, C5+ hydrocarbon content is higher than 65% and the proportion of the aromatic hydrocarbons in C5+ hydrocarbons may be above 63%.

Owner:ZHUHAI FUTIAN ENERGY TECH CO LTD

Preparation method of natural fibroin mask

ActiveCN105919910ANot easy to damageShort processing flowCosmetic preparationsToilet preparationsMicrowave sterilizationImpurity

The invention relates to the field of cosmetics and concretely relates to a preparation method of a natural fibroin mask. The method comprises 1, after matured silkworms for spitting silk defecation, putting the matured silkworms on a silk spitting net so that the matured silkworms uniformly spit 5-8 layers of silks on the silk spitting net, 2, after the matured silkworms finish silk spitting, removing dust and impurities on the silks and separating the silks from the silk spitting net, 3, cutting the separated silks according to a mask shape to obtain mask-shaped silks, 4, arranging the mask-shaped silks on the position for water steaming and steaming the silks through vapor at a temperature of 100-105 DEG C for 3-5min, 5, putting the steamed mask-shaped silks into a microwave sterilization machine and carrying out microwave sterilization for 5-6min, and 6, packaging the mask-shaped silks subjected to sterilization through a traditional mask packaging technology to obtain a pure fibroin mask. The preparation method has short mask processing processes, does not damage silks and has good skin care effects.

Owner:上海缇曼生物科技有限公司

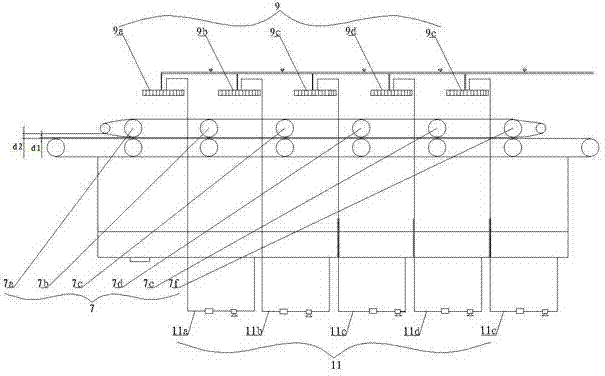

Spray-rolling type loose fiber dyeing machine

ActiveCN103774360AFast absorptionFacilitated DiffusionLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsFiberMechanical engineering

The invention relates to a spray-rolling type loose fiber dyeing machine, and belongs to the technical field of loose fiber dyeing. The spray-rolling type loose fiber dyeing machine comprises a transmission component and a spray component. The transmission component comprises a pair of upper drive rollers and a pair of lower drive rollers. The upper drive rollers and the lower drive rollers are sleeved with an upper guide belt and a lower guide belt respectively to be used in a cooperative mode. The upper guide belt is provided with a first leak hole, the upper guide belt and the lower guide belt operate synchronously, a plurality of upper rollers are arranged in an upper guide belt loop, and a plurality of lower rollers matched with the upper rollers to be used are arranged in a lower guide belt loop. The upper guide belt and the lower guide belt are matched with the upper rollers and the lower rollers to achieve synchronous clamping transportation of the loose fibers. The spray component comprises a dyeing liquid pipe and sprayer heads. One end of the dyeing liquid pipe is communicated with dyeing liquid, the other end of the dyeing liquid pipe is connected with the sprayer heads, the sprayer heads are located above the upper guide belt between adjacent upper rollers, and the dyeing liquid in the dyeing liquid pipe is sprayed downwards onto the loose fibers through the sprayer heads. By means of the spray-rolling type loose fiber dyeing machine, continuous production can be carried out, cost can be lowered to 1 / 3-1 / 5 of that in the prior art.

Owner:SHAOXING JINYU TEXITLE NEW TECH CO LTD

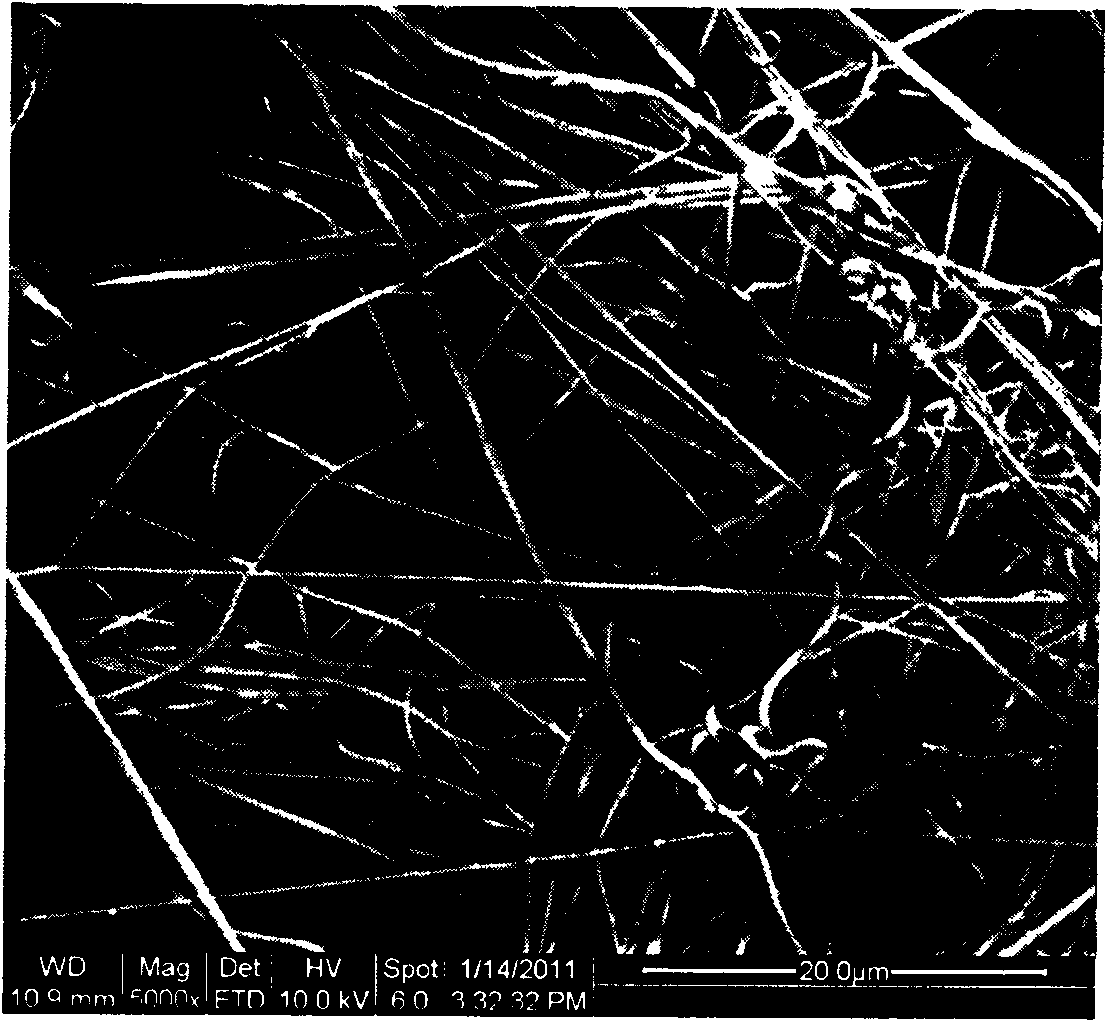

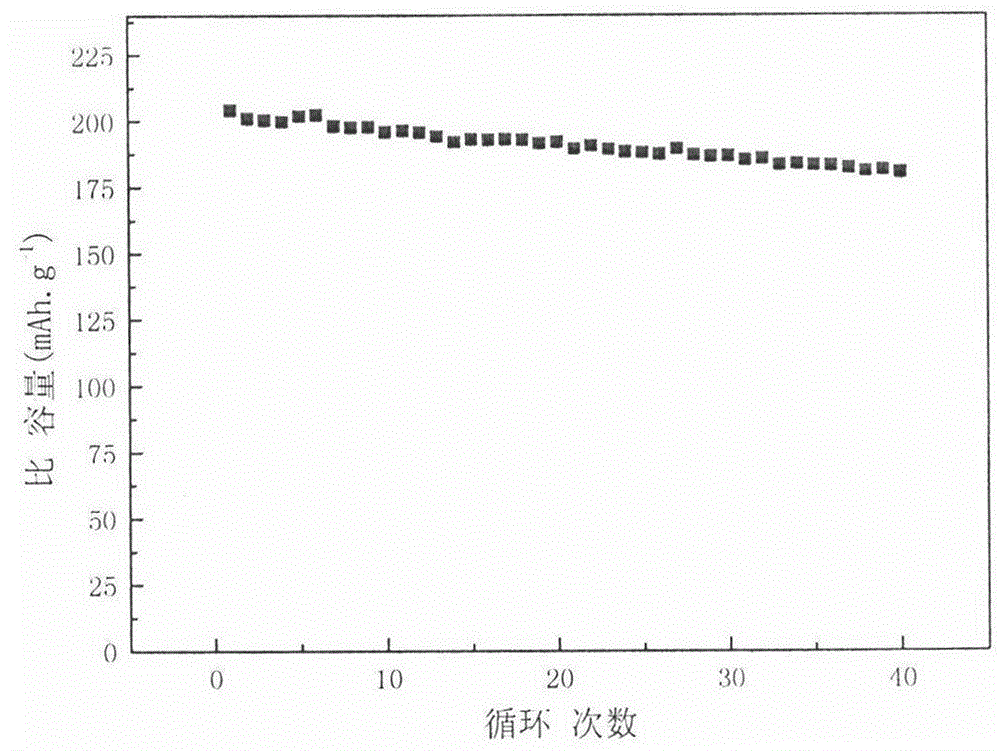

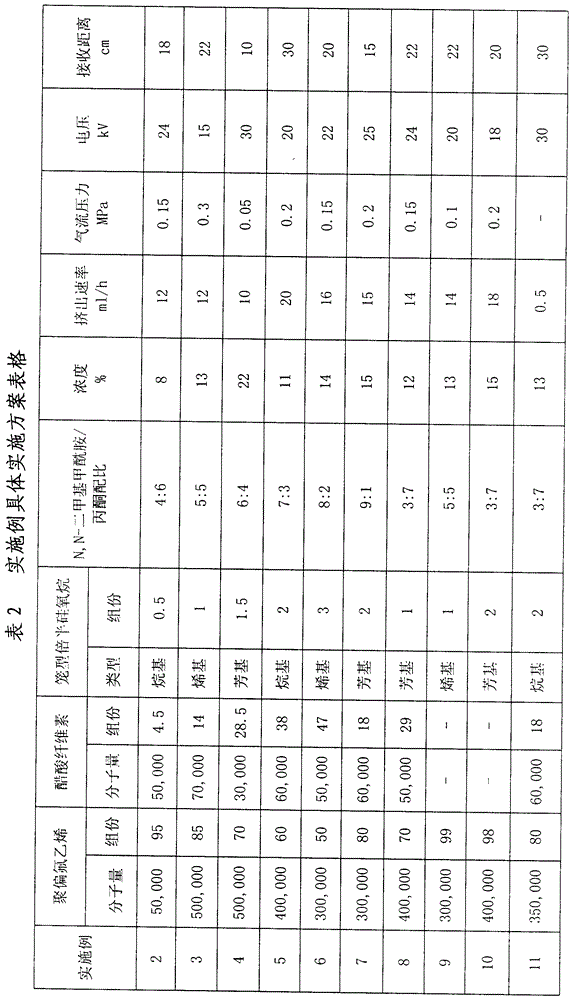

Blend superfine fiber diaphragm for lithium ion battery

InactiveCN104362280AShort processing flowSimple processSecondary cellsCell component detailsFiberCellulose acetate

The invention relates to a blend superfine fiber diaphragm for a lithium ion battery. The blend superfine fiber diaphragm is characterized by comprising polyvinylidene fluoride, cellulose acetate and polyhedral oligomeric silsesquioxane. The polyhedral oligomeric silsesquioxane is one of alkyl silsesquioxane, alkenyl silsesquioxane or aryl silsesquioxane. The blend superfine fiber diaphragm provided by the invention has good hydrophilcity, high strength and excellent thermal size stability; the solution absorbing rate of the blend superfine fiber diaphragm is 300-900 percent, the thermal shrinkage rate of the blend superfine fiber diaphragm is smaller than 5 percent, the specific capacity of a gel polymer lithium ion battery assembled by adopting the blend superfine fiber diaphragm reaches 200-220 mAh.g<-1>, and the lithium intercalation utilization rate of an anode material LiCoO2 can reach above 70 percent.

Owner:TIANJIN POLYTECHNIC UNIV

Plasticity machining method for metal composite pipe

ActiveCN106670258AReduce inputImprove processing stabilityLarge deformationUltimate tensile strength

The invention relates to a plasticity machining method for a metal composite pipe. A heating spinning method is adopted for conducting powerful spinning on an assembled composite pipe blank, a laser is used for conducting local heating on the composite pipe blank in the forming process, interface combination of an inner pipe body and an outer pipe body of the composite pipe blank is achieved under the joint action of the temperature and the large deformation, and a formed interface has high bonding strength. According to the provided plasticity machining method for the metal composite pipe, the production technology is simple, the machining efficiency is high, the technology stability is good, and the production cost is low.

Owner:JIANGSU UNIV OF TECH

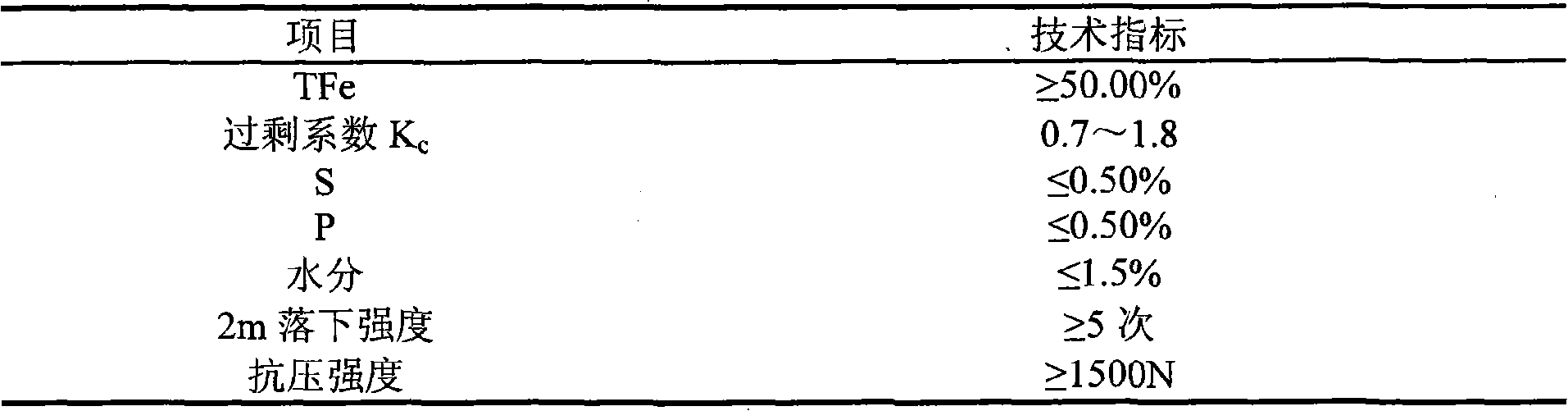

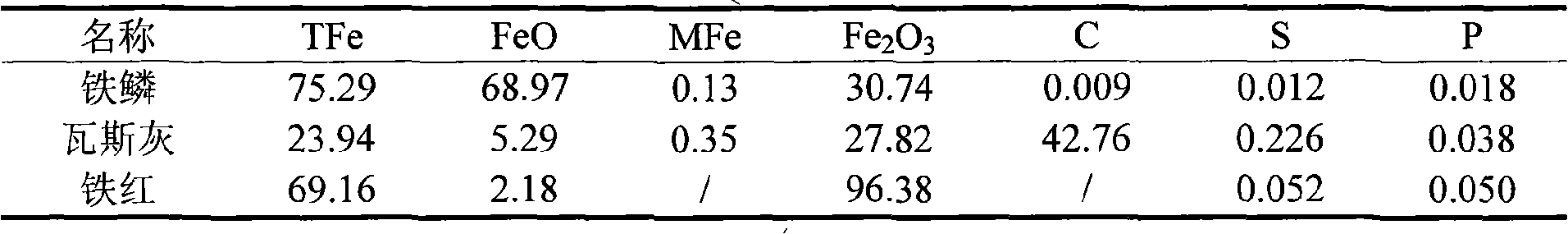

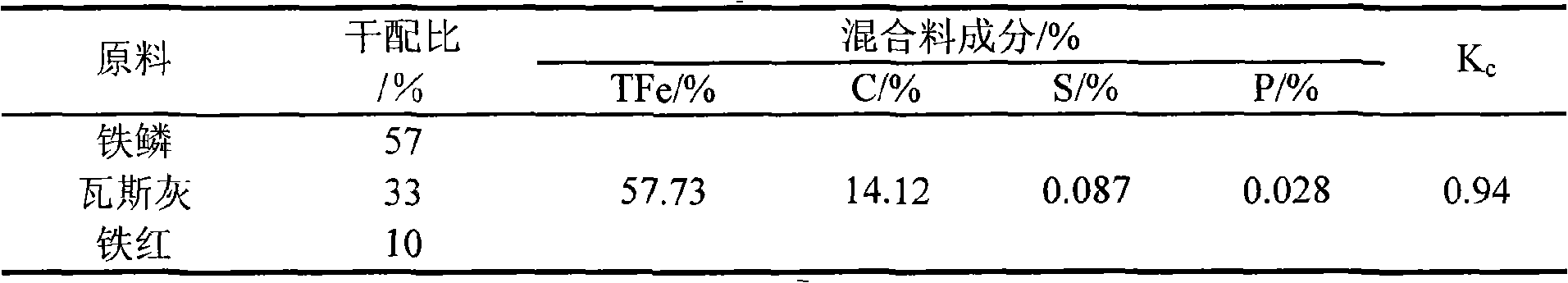

Rotary furnace cooling agent and manufacturing method thereof

ActiveCN101560581AEmission reductionHigh yieldManufacturing convertersProcess efficiency improvementChemical compositionEconomic benefits

The invention provides a rotary furnace cooling agent and a manufacturing method thereof. The cooling agent is a carbonic and ferreous conglomeration which mainly takes iron scale, carbonic dry ash and ferreous dry waste material as raw materials, and prepared by additionally adding caking agent into the raw materials. The weight percentage of the main chemical compositions of the cooling agent meets the following condition: the carbon content is 5-25%, the content of TFe is more than or equal to 50%, the content of S is less than or equal to 0.50% and the content of P is less than or equal to 0.50%. The manufacturing method comprises: the iron scale, the carbonic dry ash and the ferreous dry waste material are firstly sent into a blending machine to be mixed together and evenly mixed with the caking agent; after being evenly mixed, the materials are sent into a mixing mill and then into a twin-roller ball press machine to be pressed into conglomeration; the pressed conglomeration is screened by a sieving machine, and the qualified screened conglomeration can be sent into a dry furnace to be dried, so that the finished product conglomeration can be obtained. The rotary furnace cooling agent can be used for replacing the common waste steel to be applied in smelting of a rotary furnace; compared with the prior art, the cooling agent completely uses the waste materials generated in the steel production, so that the process flow is short, the cost is low, the using method is flexible, the adding quantity is large, the recovery rate is high, the field operation is seldom affected, the economic benefit and the environmental protection benefit are remarkable, and the promotion and application values are excellent.

Owner:ANGANG STEEL CO LTD

Method for continuously synthesizing N-butylthiophosphoric triamide by microreactors

InactiveCN108084224AEvenly dispersedImprove solubilityGroup 5/15 element organic compoundsChemical/physical/physico-chemical processesSolventDistributor

The invention discloses a method for preparing N-butylthiophosphoric triamide by continuous reaction in microreactors. The method comprises the following steps: uniformly mixing n-butylamine and triophosphoryl chloride with a solvent respectively at first, then adding a mixture into a membrane dispersion microreactor through a charging pump, dispersing the n-butylamine into a mixture solution of the triophosphoryl chloride in a micro-droplet form, performing reaction at certain temperature to obtain N-butylthiophosphoric dichloride, and simultaneously introducing ammonia as an acid binding agent of hydrogen chloride; delivering the reactant to a tubular microreactor, and continuously introducing ammonia into the reactor through a gas distributor to obtain the N-butylthiophosphoric triamideand ammonium chloride; finally collecting a product through a collection kettle, and executing operations of crystallization, filtering, drying and the like to obtain a product. The method has the advantages of short processing flow, mild reaction condition, simplicity for process operation, few byproducts, low energy consumption, high yield, low cost and the like, and is suitable for large-scaleindustrial production.

Owner:NORTH HUAJIN CHEM IND CO LTD

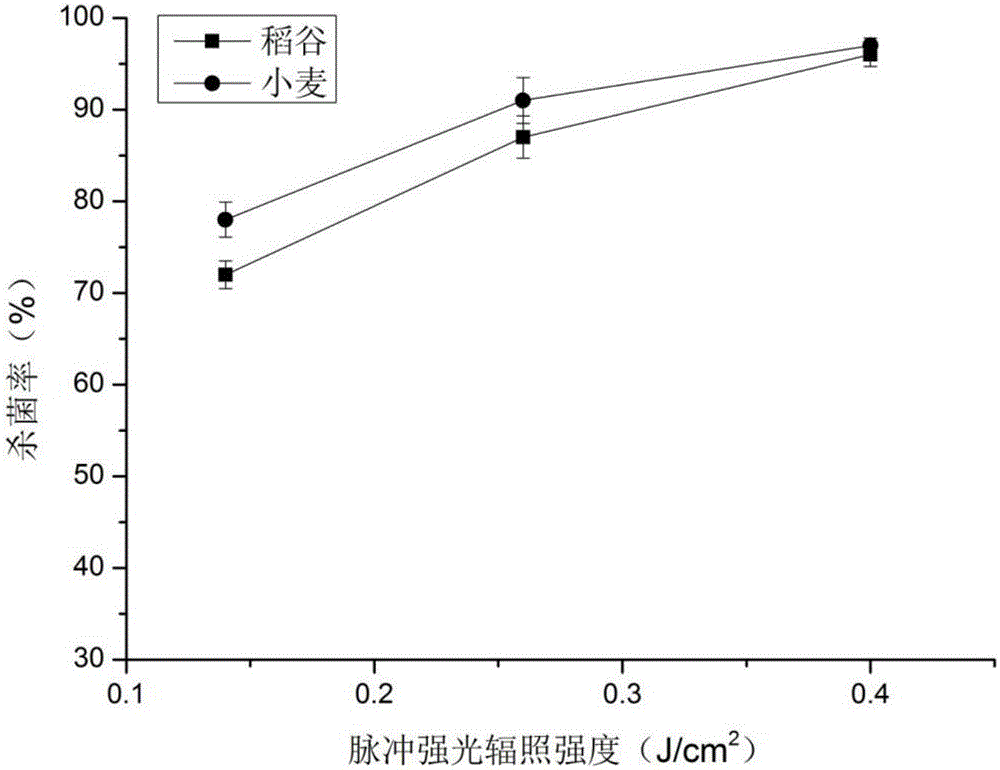

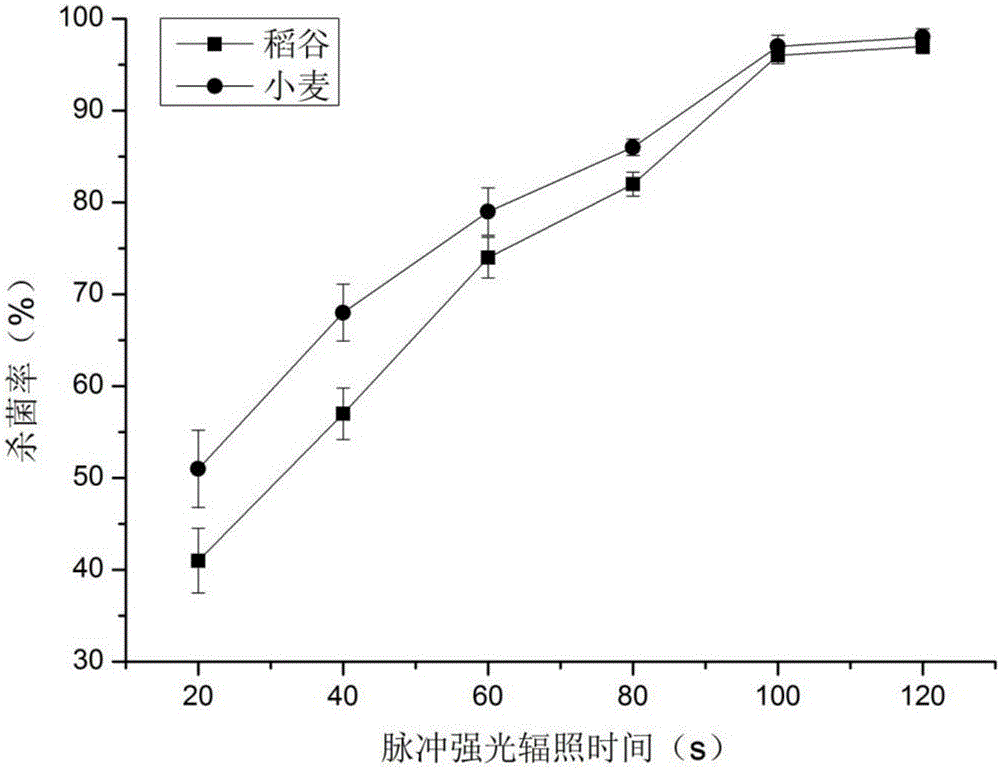

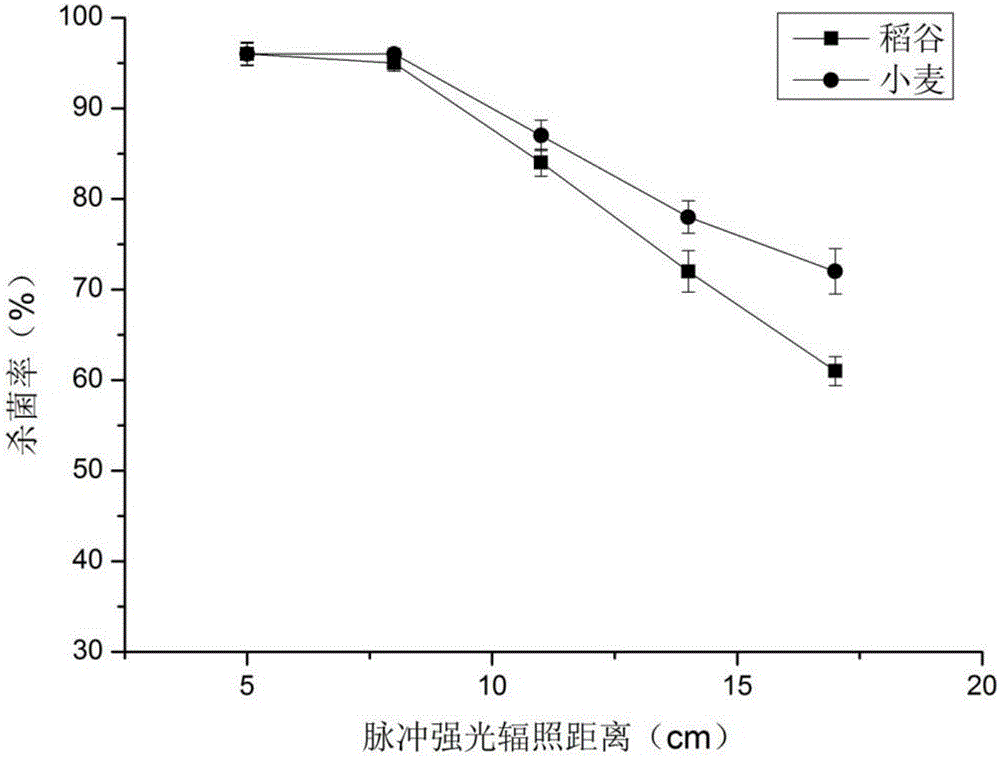

Physical method for preventing and controlling mould fungi of grain

InactiveCN106819098AExtended shelf lifeStrong light sterilization effect is remarkableSeed preservation by irradiation/electric treatmentSeed preservation by dryingLight treatmentIrradiation

The invention discloses a physical method for preventing and controlling mould fungi of grain, and belongs to the technical field of farm product storage and processing. The method concretely comprises the following steps of A, quantificationally and uniformly laying the grain onto a container with good reflectivity or a conveying belt provided with a reflecting material to form a thin grain layer; B, performing pulse strong light treatment: putting a tray or a flat plate containing the grain onto a support frame; putting the tray or the flat plate into a pulse strong light device to be subjected to irradiation treatment; C, after the irradiation, controlling the moisture of the grain subjected to the pulse treatment to be lower than 14 percent by cooperating with other physical drying methods; conveying the grain into a cabin or a warehouse to be stored, or directly selling the grain. The method has the advantages that the pulse strong light sterilization effect on various grain such as cereals is obvious; the growth and the breeding of the mould fungi on the surface of the grain are controlled; the processing flow process is short; the technical process is simple and convenient; the implementation is easy; meanwhile, the environment-friendly performance is better.

Owner:NANJING UNIV OF FINANCE & ECONOMICS

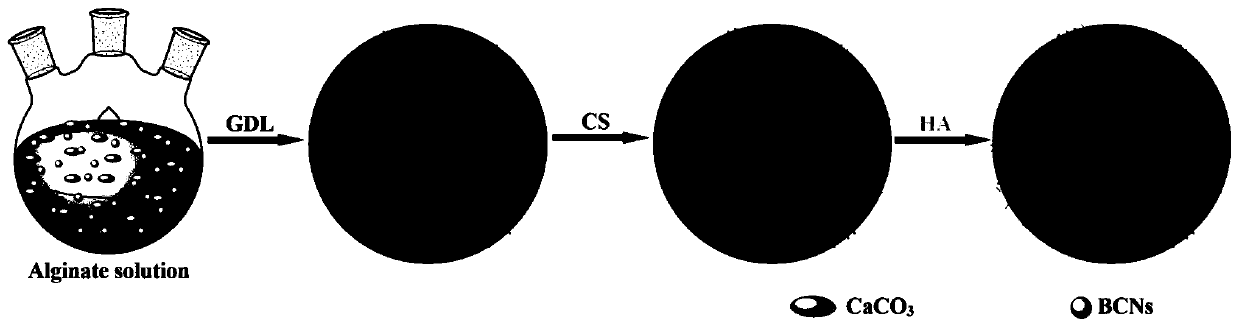

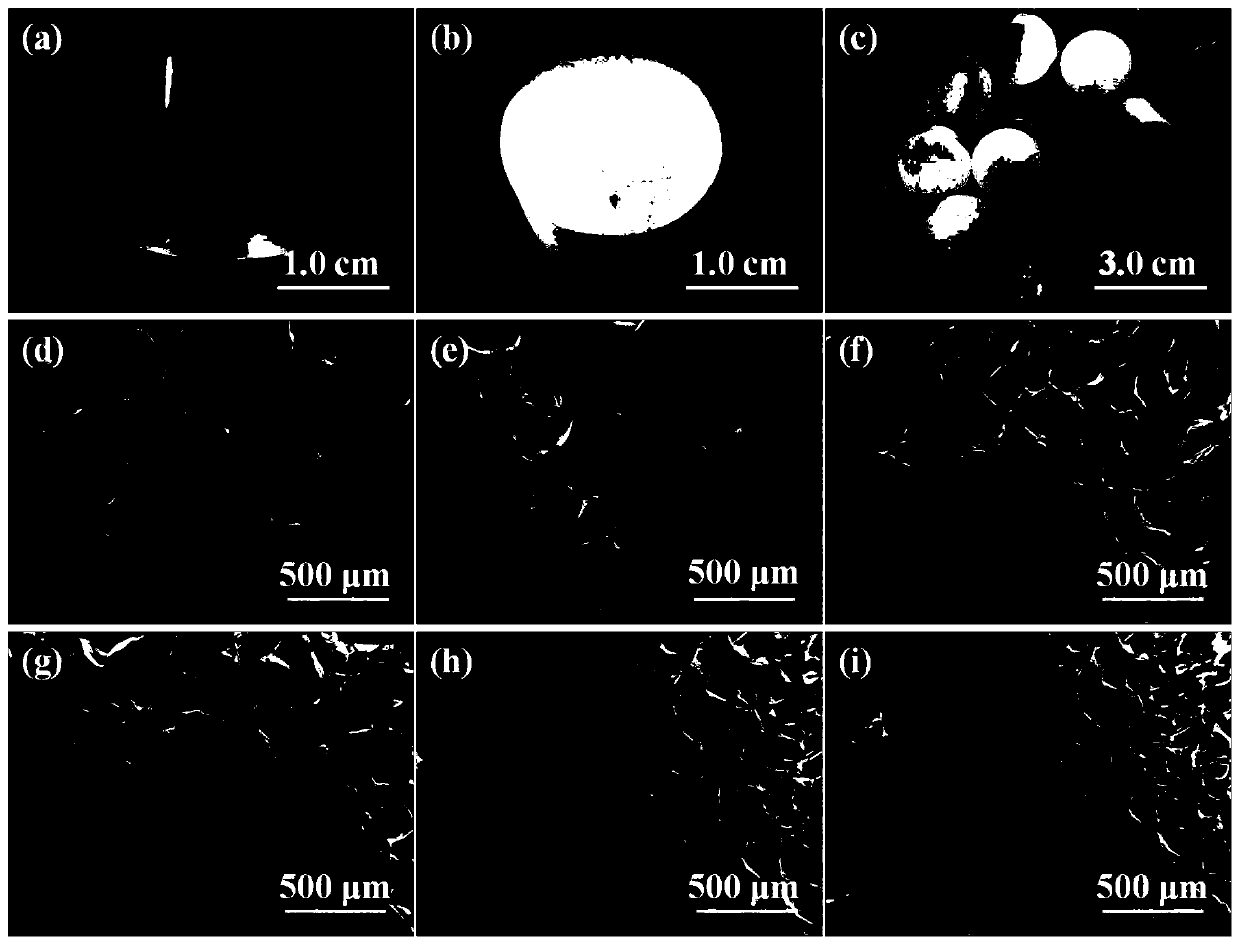

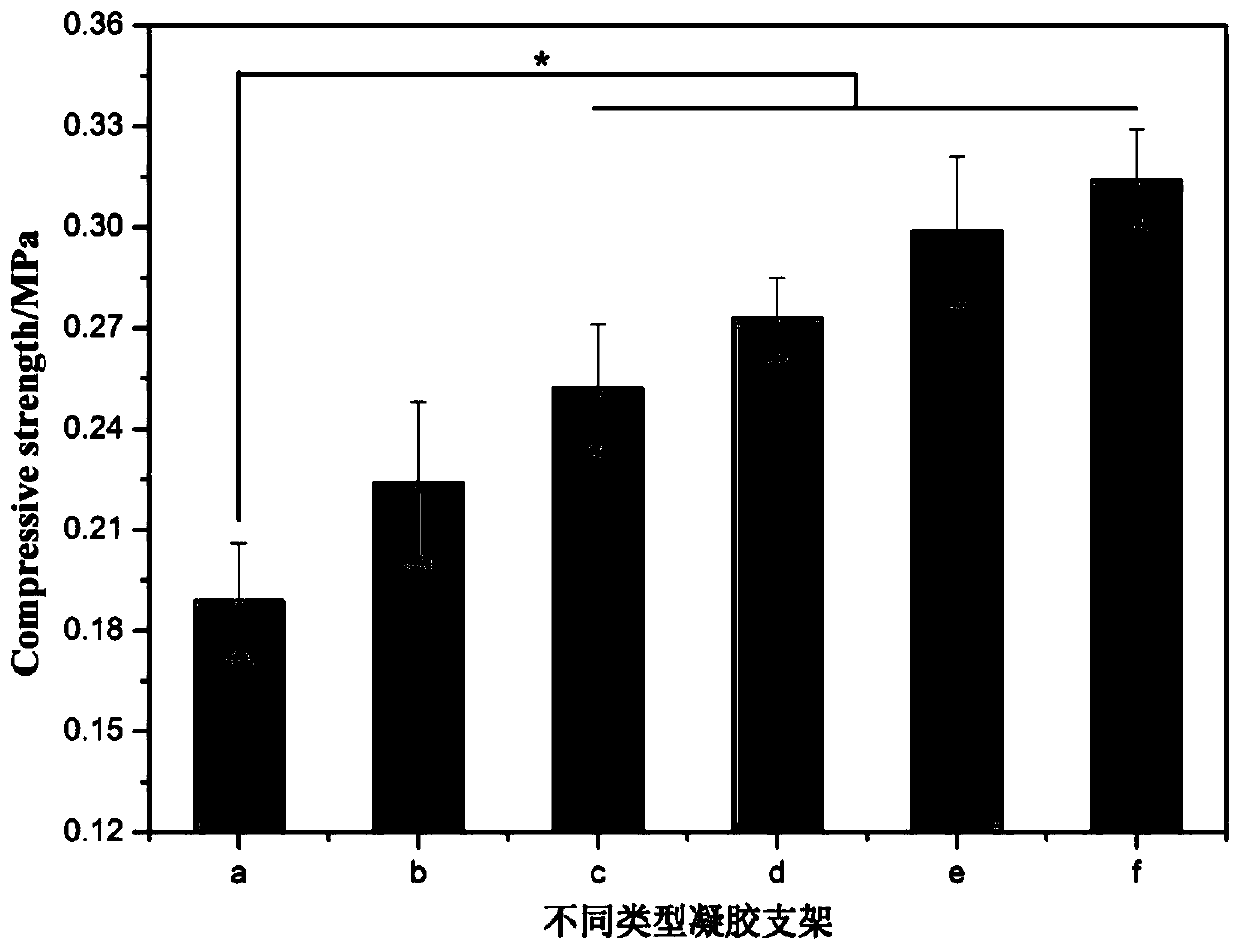

Functional drug-sustained-release medical dressing constructed by alginic acid aminated derivative/bacterial cellulose nanocrystal composite gel

The invention relates to medical dressings, particularly relates to a functional drug-sustained-release medical dressing constructed by alginic acid aminated derivative / bacterial cellulose nanocrystalcomposite gel and belongs to the technical field of medical treatment. The functional drug-sustained-release medical dressing provided by the invention is prepared through loading an antibiotic druginto an alginic acid aminated derivative by a physical blending method through taking CaCO3 / GDL as an ion cross-linking system of RAOA and taking bacterial cellulose nanocrystals (BCNs) prepared through hydrolyzing bacterial cellulose by sulfuric acid as a reinforcer, constructing an alginic acid aminated derivative / bacterial cellulose nanocrystal composite gel matrix under the action of ion cross-linking of the CaCO3 / GDL, coating the surface of a matrix material sequentially with positive-charge chitosan (CS) and negative-charge hyaluronic acid (HA) through a layer-by-layer assembling method,and carrying out cross-linking by a chemical cross-linker. A technical support is provided for development and utilization of renewable resources and research and development of the medical dressings.

Owner:HAINAN NORMAL UNIV

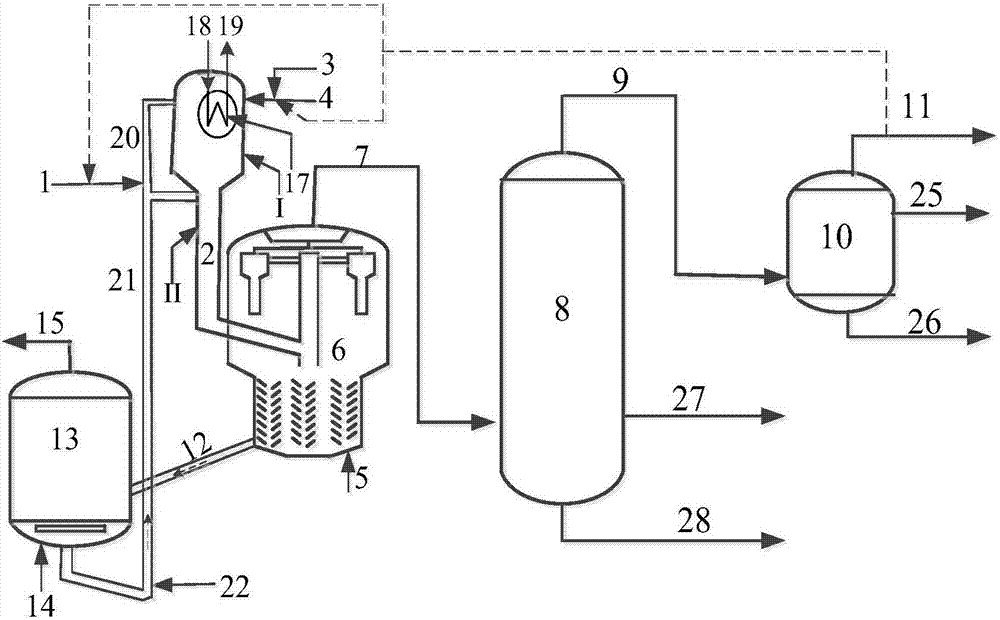

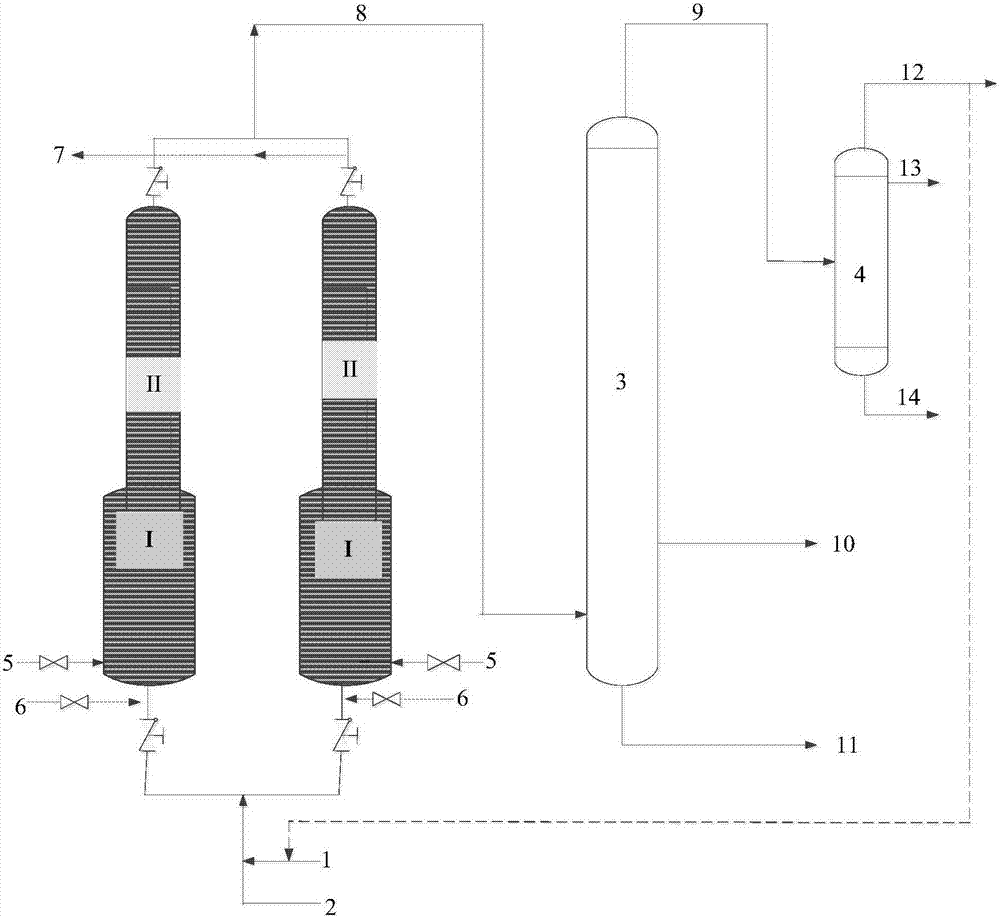

Processing method and system for inferior crude oil

ActiveCN107267207ARestore activityIncrease pressureTreatment with hydrotreatment processesHydrogenSorbent

The invention discloses a processing method and system for inferior crude oil. The method comprises the steps as follows: a, feeding hydrogen-containing gas and the inferior crude oil into a hydrogen absorption zone (I) of a fixed bed reactor for contact with an adsorbent and a hydrogen adsorption reaction to obtain a hydrogen absorption product; b, feeding the hydrogen absorption product obtained in the step a into a cracking zone (II) of the fixed bed reactor for contact with a catalytic cracking catalyst and a catalytic cracking reaction to obtain catalytic cracked oil-gas. The inferior crude oil processed by the system with the method has the advantages that the conversion rate of the inferior crude oil can be increased substantially, the yield of dry gas and coke is reduced, and accordingly, clean and efficient use of the inferior crude oil is realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

Rotary furnace cooling agent made of metallurgical waste material product and using method thereof

ActiveCN101560582AEmission reductionImprove the level of comprehensive utilizationManufacturing convertersProcess efficiency improvementChemical compositionEconomic benefits

The invention provides a rotary furnace cooling agent made of metallurgical waste material product and a using method thereof. The cooling agent is a carbonic and ferreous conglomeration which mainly takes iron scale, carbonic waste material and ferreous waste material as raw materials, and prepared by additionally adding caking agent into the raw materials. The weight percentage of the main chemical compositions of the cooling agent meets the following condition: the carbon content is 5-25%, the content of TFe is more than or equal to 50%, the content of S is less than or equal to 0.50% and the content of P is less than or equal to 0.50%, 2m drop strength is more than or equal to 5 times, and the compression strength is more than or equal to 1500N. The adding methods of the carbonic and ferreous conglomeration which is taken as the rotary furnace cooling agent comprises: adding before Fe is mixed, adding after Fe is mixed as well as adding respectively before and after Fe is mixed. The recovery rate of iron of the carbonic and ferreous conglomeration is 85-93%. Compared with the prior art, the rotary furnace cooling agent completely uses the waste materials generated in the steel production, so that the process flow is short, the cost is low, the using method is flexible, the adding quantity is large, the recovery rate is high, the field operation is seldom affected, the economic benefit and the environmental protection benefit are remarkable, and the promotion and application values are excellent.

Owner:ANGANG STEEL CO LTD

Aqueous gypsum drying and calcining device and process

PendingCN108709408AEliminate liquidationEliminate knotsRotary drum furnacesCharge treatment typeReduction driveReducer

The invention discloses an aqueous gypsum drying and calcining device. The aqueous gypsum drying and calcining device comprises a roller, rolling rings connected to the roller, supporting wheel sets,a ring gear, a motor, a reducer and a gear, wherein the motor is connected with the reducer. A discharge hole of a screw conveyor is connected with a feed inlet of the roller, and the discharge end ofthe roller is connected with a discharge chamber. An exhaust outlet is formed in the upper end of the discharge chamber, and two discharge openings are formed in the lower end of the discharge chamber. One of the discharge openings is connected with a feed inlet of a returning charge screw conveyer, and a discharge hole of the returning charge screw conveyor is connected with a feed inlet of thescrew conveyor. A spiral pipe is arranged in the roller, the rear end of the spiral pipe is connected with steam inlets, and the front end of the spiral pipe is located outside the roller. The invention further discloses aqueous gypsum drying and calcining process. The aqueous gypsum drying and calcining device has the advantages of multi-function, less equipment, small land occupation, low energyconsumption and high thermal efficiency, has high production efficiency and reliable performance, and can safely operate for a long time.

Owner:自贡市德明电站锅炉有限公司

Vertical-linkage and reciprocating rolling-type mashed potato preparing device

The invention belongs to the technical field of food processing, and discloses a vertical-linkage and reciprocating rolling-type mashed potato preparing device. The vertical-linkage and reciprocatingrolling-type mashed potato preparing device comprises a box, wherein the section of the bottom wall of the box is funnel-shaped; supporting legs are fixedly connected to four corners of the bottom wall of the box; the discharge end of a feed hopper is fixedly communicated with the front surface of the box; a mounting hole is formed in the middle part of the top wall of the box; an exhaust fan is fixedly mounted inside the mounting hole; the feed end of a discharge pipe is fixedly communicated with the middle part of the bottom wall of the box; a driving motor is fixedly mounted at the top endof the right side surface of the box through a mounting rod; a rolling mechanism is arranged inside the box. Through arrangement of the rolling mechanism, the vertical-linkage and reciprocating rolling-type mashed potato preparing device can quickly roll potatoes after feeding to quickly destroy the structures of the potatoes, so that rapid mashing of the potatoes is achieved and improvement on the preparation efficiency of mashed potato is facilitated.

Owner:曾早生

Processing method of anti-mosquito polyester knitted fabric

InactiveCN106498783AUse low concentrationHigh exhaustion rateHeating/cooling textile fabricsDyeing processChemistrySetting time

The invention discloses a processing method of an anti-mosquito polyester knitted fabric. The processing method comprises the following steps of 1 dyeing, wherein a gray fabric is put into a dye vat to be dyed, dispersing dye, a leveling agent DB-212 with the concentration of 1G / L, a deoiling agent DB-808 with the concentration of 1G / L and glacial acetic acid are added, the dyeing temperature is 130 DEG C, the bath ratio is 1:12, and the PH value is 5.5; 2 setting and drying, wherein the dyed fabric is taken out, cleaned in a clean water tank and then put into a setting and drying oven to be dried, the setting temperature ranges from 150 DEG C to 160 DEG C, and the setting time is 1 minute; 3 anti-mosquito padding finishing, wherein an anti-mosquito auxiliary solution is added in a rolling groove of a setting machine, the dried polyester knitted fabric passes through the padding solution contained in the rolling groove and then is delivered into the setting machine to be subjected to anti-mosquito finishing for 2 minutes, the polyester knitted fabric is taken out, and then the finished anti-mosquito polyester knitted fabric product is obtained. According to the processing method, the processing process is short, operation is easy, novel environment-friendly pyrethrin is low inconcentration and high in exhaustion rate, and the environment-friendly requirements are met.

Owner:JIANGSU XINKAISHENG ENTERPRISE DEV

Preparation method of high-gamma-aminobutyric acid germinated brown rice and selenium-enriched germinated brown rice

ActiveCN104351660AEasy cookingHigh nutritional valueMulti-step food processesFood preparationPhytaseRice grain

The invention discloses a preparation method of germinated brown rice with high gamma-aminobutyric acid content. The preparation method comprises the following steps: by adopting brown rice prepared by husking rice which is harvested within half a year as a raw material, soaking the brown rice for 2-4 hours by using a soaking solution, germinating soaked brown rice in a container filled with nitrogen, performing water washing on the germinated brown rice by using a deionized aqueous solution containing cell growth factors and sodium salicylate, treating the germinated brown rice subjected to water washing by using phytase, and then performing microwave drying on the treated germinated brown rice to prepare the germinated brown rice with the water weight content of 8-10%. The preparation method of the germinated brown rice disclosed by the invention is short in processing flow and simple, convenient and feasible in technological process, can be used for reducing the influences of a processing course to the inherent quality of the germinated brown rice to a highest extent, and ensures that 'original taste and flavor' of rice grains can be kept to the highest extent; the prepared germinated brown rice is high in nutritional value, is easy to stew and absorb, and is excellent in taste; and the GABA content of 100g of a product is more than 200mg, so that the germinated brown rice has a very good health effect.

Owner:南京远望富硒农产品有限责任公司

Processing method of sprouted half-polished and obtained sprouted half-polished rice

ActiveCN100345479CShort processing flowReduce the impact of intrinsic qualityCultivating equipmentsHorticulture methodsAmino acidClean water

A process for preparing sprouted half-polished rice, which is rich in amino acids, includes such steps as flushing raw long-grained non-glutinous rice, immersing in clean water at 18-24 deg.C for 2-4 hr, germinating at 35-45 deg.C for 11-25 hr while exchanging water every 8-12 hr, and drying at 40-50 deg.C for 4-12 hr.

Owner:江苏海奥生物科技有限公司

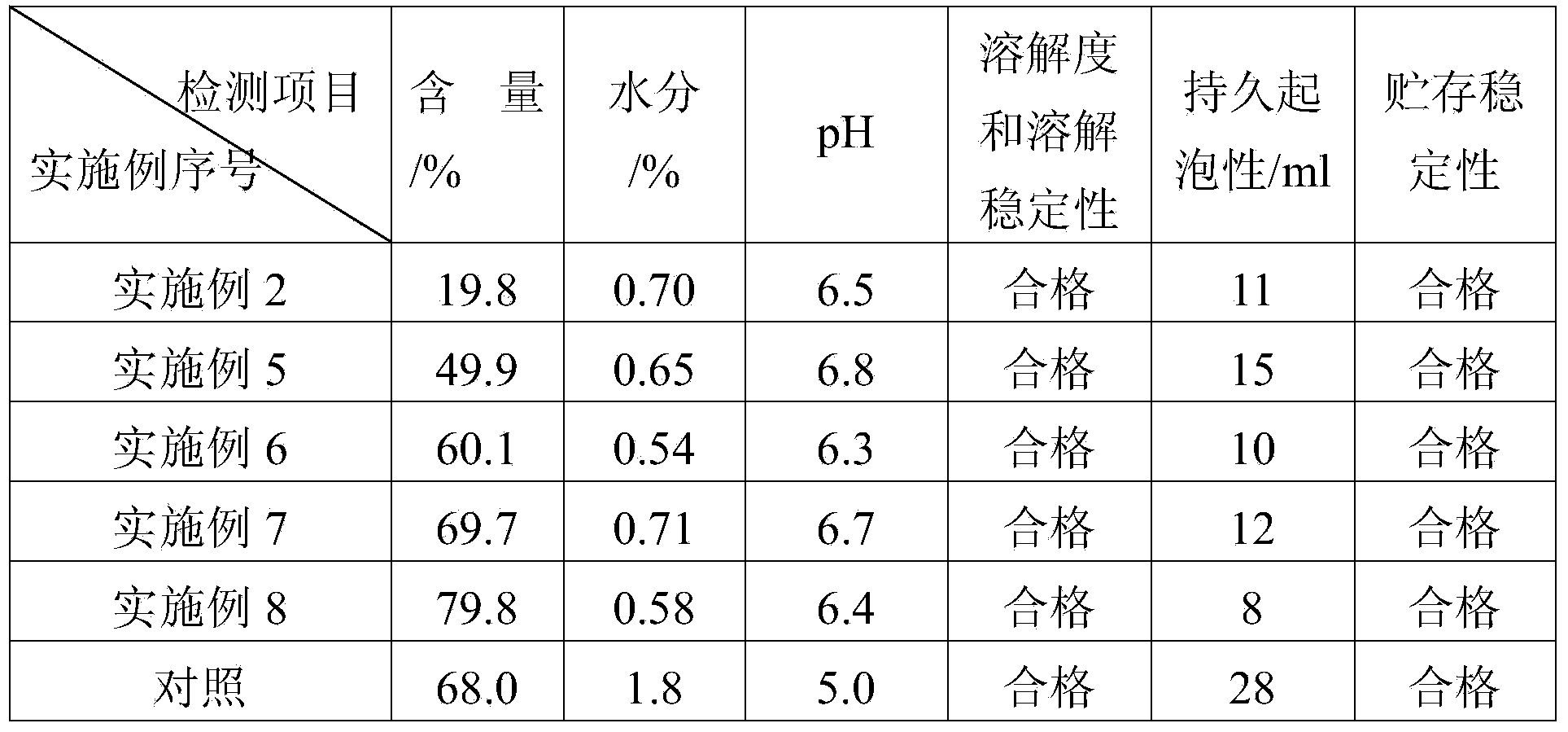

Method for preparing dicamba sodium salt preparations and prepared dicamba sodium salt preparations

ActiveCN103461331AHigh suspension rateImprove conversion rateBiocideAnimal repellantsSolid reactionSurface-active agents

The invention relates to the technical field of pesticides, in particular to a method for preparing dicamba sodium salt preparations and the prepared dicamba sodium salt preparations. The preparation method comprises the following steps that 10-80 parts of dicamba, 5-85 parts of inorganic fillers and 5-35 parts of alkaline substances are taken and are mixed with water, and solid-solid reactions are carried out under the temperature ranging from 45 DEG C to 55 DEG C to prepare wet dicamba sodium salt; the wet dicamba sodium salt is mixed with 5-20 parts of surface active agents, and the dicamba sodium salt preparations are prepared through granulation, drying and screening. Because the solid-solid reactions are adopted and are carried out in a moderate mode, dicamba sodium salt reactions, kneading and granulation can be simultaneously carried out, and the technical process is short. Experiments indicate that the suspension rate of the dicamba sodium salt preparations is obviously higher than that of existing products and the disintegration time of the dicamba sodium salt preparations is obviously shorter than that of the existing products.

Owner:SHANDONG WEIFANG RAINBOW CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com