Anti-permeability and moisture absorption different-function knitted fabric and production process thereof

A technology of knitted fabric and manufacturing process, which is applied in knitting, weft knitting, textiles and papermaking, etc. It can solve the problems that the water repellency effect is greatly affected by the number of washings, poor wearing comfort, and high surface density of fabrics. The effect of water is not affected, good water repellency and air permeability, good effect of double-sided heterosexual function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

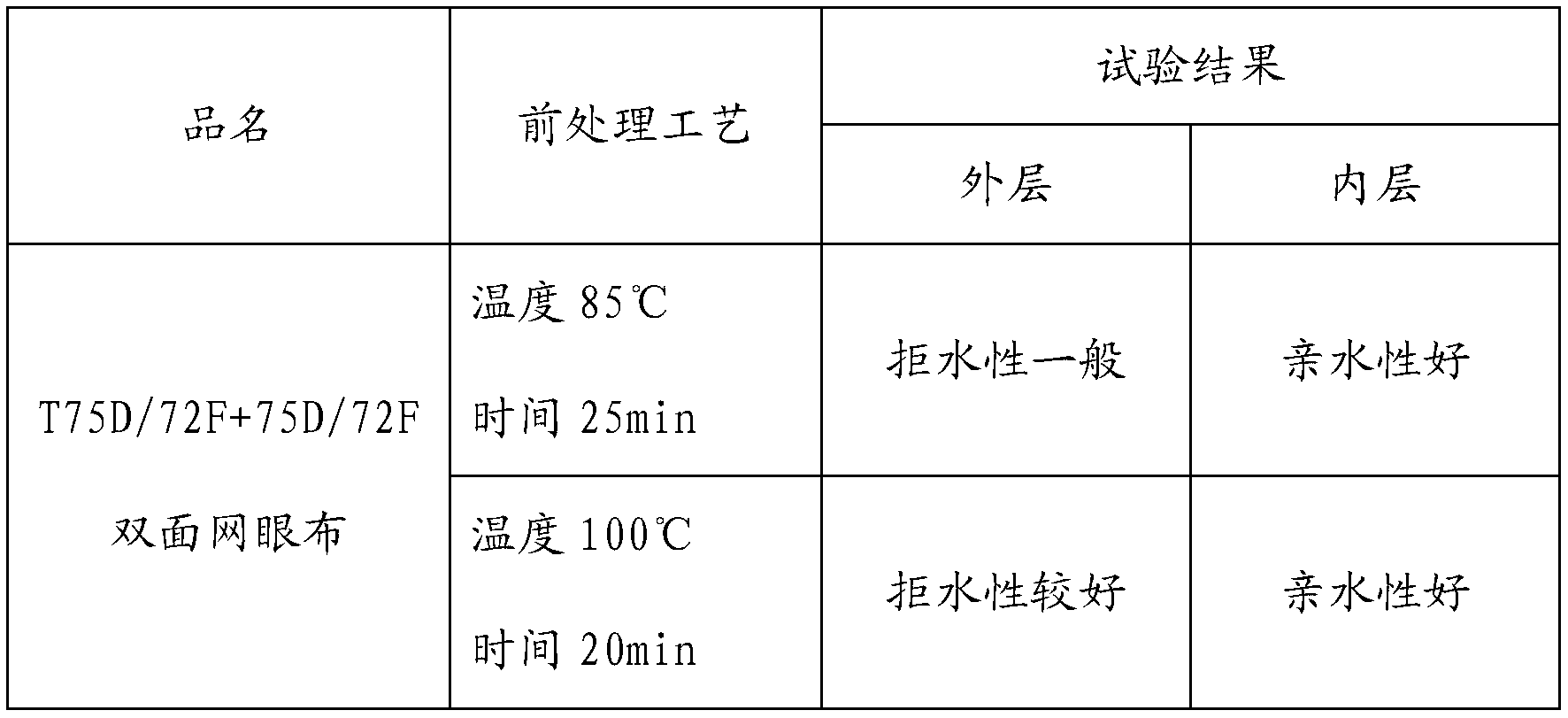

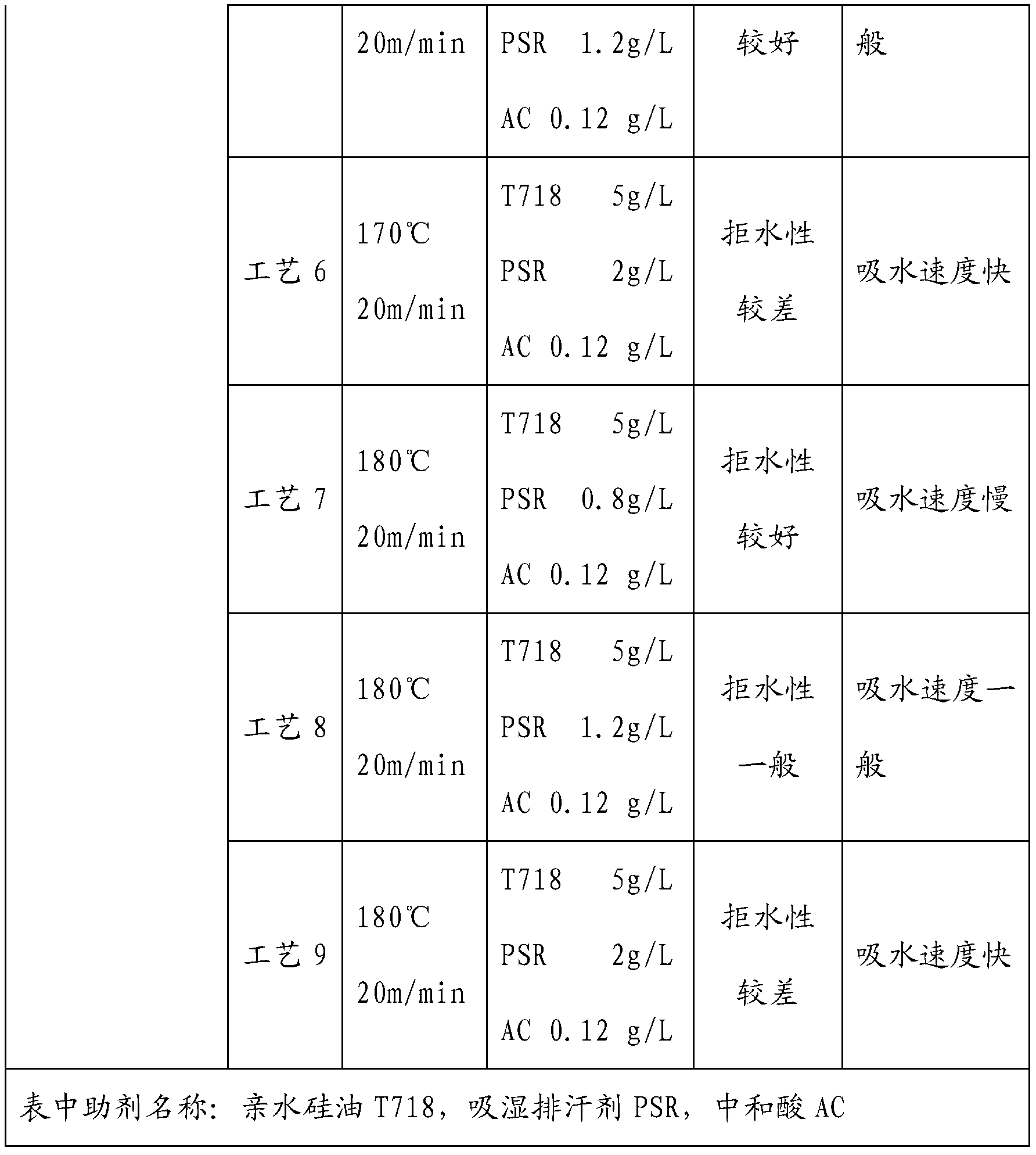

[0034] In order to explore which dyeing and finishing factors will affect the functional effect of anti-permeable and moisture-absorbing heterofunctional fabrics, experiments and comparisons were carried out from the aspects of process flow, pre-treatment process, setting process, and additive dosage, etc., and a set of anti-permeable and moisture-absorbing heterofunctional knitted fabrics was summarized. The most stable dyeing and finishing production process parameters. The following tests were carried out based on the technical solutions described in the Summary of the Invention of the present invention.

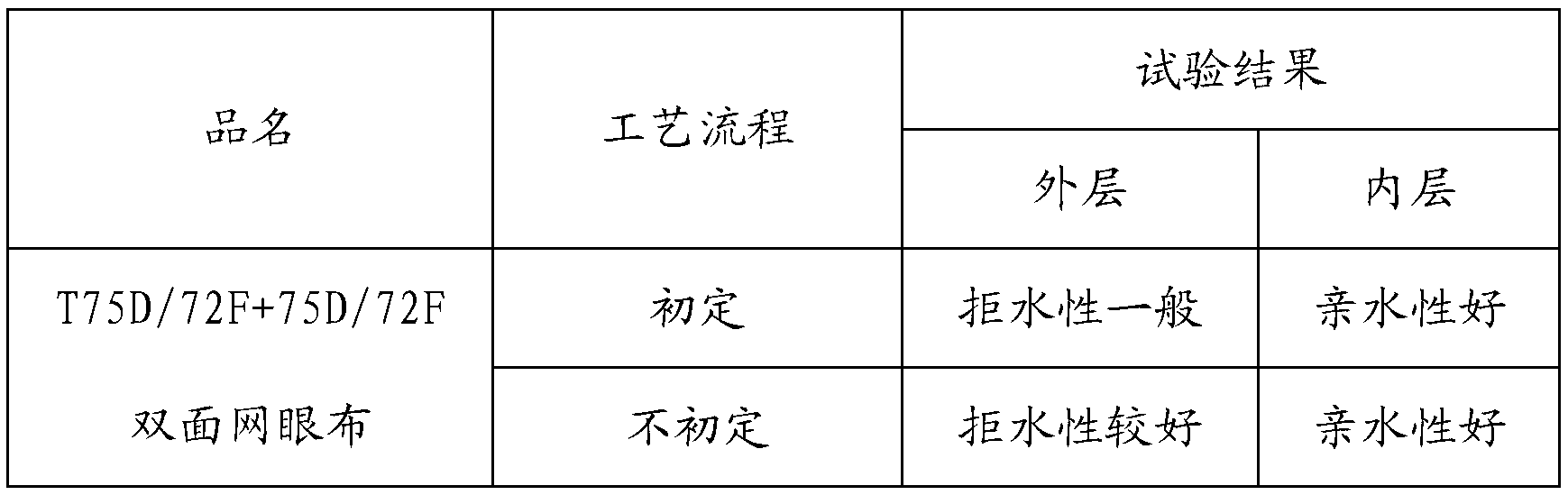

[0035] (1) Effects of different technological processes on the hydrophilicity of different functional fabrics

[0036] It mainly studies whether the preliminary process of gray fabrics affects the hydrophilicity of anti-permeable and moisture-absorbing fabrics. Through small samples and pilot tests, two production processes, preliminary and non-preliminary, are used to dye ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com