Preparation method of super-hydrophobic flame-retardant recycled paper

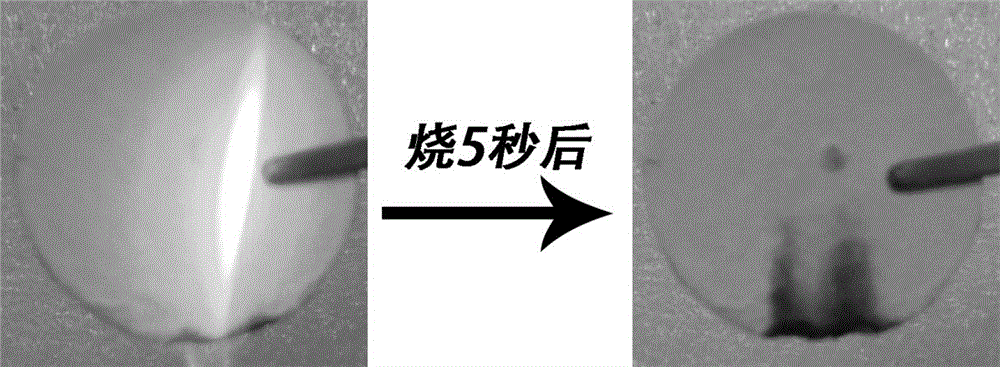

A super-hydrophobic and recycled paper technology, which is applied in the direction of paper, water-repellent agent addition, fireproof agent addition, etc., can solve the problems of paper loss of use value, inability to be used for outdoor packaging, pollution and energy consumption, etc., and achieve low cost and good fire resistance non-toxic, good water-repellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

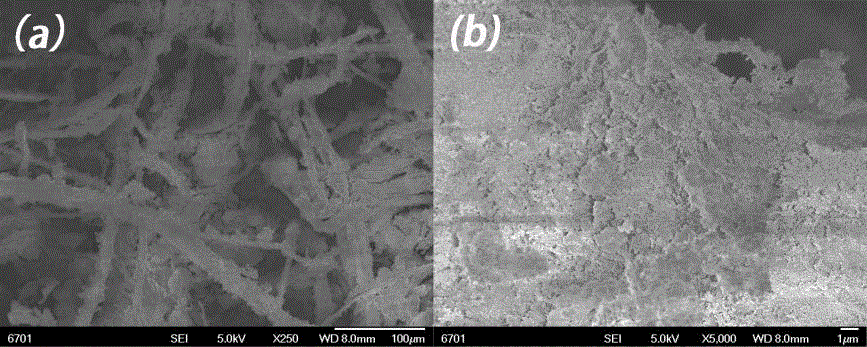

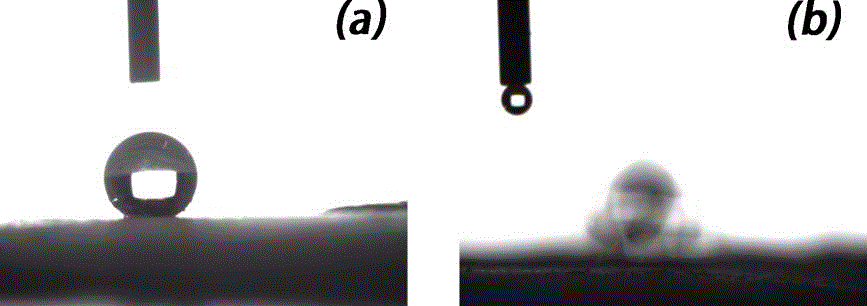

[0027] (1) Preparation of inorganic-organic composite superhydrophobic filler: add 0.02M ammonia water to the methanol solution of ethyl orthosilicate, and then add 0.1M hydrochloric acid to adjust the pH value of the solution to 5. Add 0.02g of dopamine hydrochloride powder to this solution, stir for 5 hours, then drop 3.5ml of 25% ammonia water into the system, and age for 10 hours to obtain polydopamine-silica gel. The obtained composite gel was transferred to a reaction kettle, n-hexane solvent and hexamethyldisilazane (volume ratio: 20:3) were added, and reacted at 80°C for 10 hours. Take it out, filter it with suction and wash it with n-propanol several times, so as to complete the step of modifying the hydrophobic substance. The superhydrophobic gel was then placed in an oven and dried at 60°C for 6 hours in order to remove the solvent and residual reactants. Then grind the dry gel to obtain inorganic-organic composite superhydrophobic filler powder.

[0028] (2) Prep...

Embodiment 2

[0032] (1) Preparation of inorganic-organic composite superhydrophobic filler: add 0.02M ammonia water to the methanol solution of ethyl orthosilicate, and then add 0.1M hydrochloric acid to adjust the pH value of the solution to 5. Add 0.02g of dopamine hydrochloride powder to this solution, stir for 5 hours, then drop 3.5ml of 25% ammonia water into the system, and age for 14 hours to obtain polydopamine-silica gel. The obtained composite gel was transferred to a reaction kettle, n-hexane solvent and hexamethyldisilazane (volume ratio: 20:3) were added, and reacted at 80°C for 10 hours. Take it out, filter it with suction and wash it with n-propanol several times, so as to complete the step of modifying the hydrophobic substance. The superhydrophobic gel was then placed in an oven and dried at 60°C for 6 hours in order to remove the solvent and residual reactants. Then grind the dry gel to obtain inorganic-organic composite superhydrophobic filler powder.

[0033] (2) Prep...

Embodiment 3

[0036](1) Preparation of inorganic-organic composite superhydrophobic filler: add 0.02M ammonia water to the methanol solution of ethyl orthosilicate, and then add 0.1M hydrochloric acid to adjust the pH value of the solution to 5. Add 0.02g of dopamine hydrochloride powder to this solution, stir for 5 hours, then drop 3.5ml of 25% ammonia water into the system, and age for 10 hours to obtain polydopamine-silica gel. The obtained composite gel was transferred to a reaction kettle, n-hexane solvent and hexamethyldisilazane (volume ratio: 20:3) were added, and reacted at 80°C for 10 hours. Take it out, filter it with suction and wash it with n-propanol several times, so as to complete the step of modifying the hydrophobic substance. The superhydrophobic gel was then placed in an oven and dried at 60°C for 6 hours in order to remove the solvent and residual reactants. Then grind the dry gel to obtain inorganic-organic composite superhydrophobic filler powder.

[0037] (2) Prepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com