Water repellent and oleophylic composite needling non-woven fabric and preparation method thereof

A technology of composite needles and non-woven fabrics, which is applied in the direction of non-woven fabrics, textiles and papermaking, general water supply saving, etc., can solve the problems of poor absorption capacity, high product cost, complicated production process, etc., and achieve the effect of preventing water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

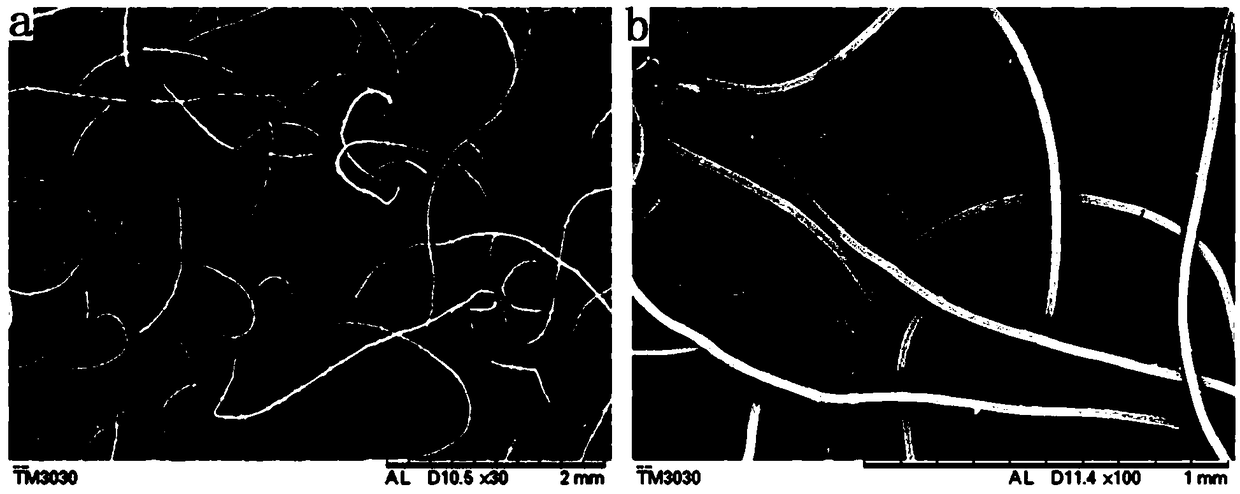

[0044] (1) Preparation of PET / ES needle-punched non-woven fabric: fully mix PET fiber and ES fiber at a mass ratio of 3:1, and then process the blended fiber by needle punching process: PET / ES Opening and mixing → carding into web → lapper → pre-needling → main needling to obtain PET / ES needle-punched non-woven fabric. In order to increase the strength of the non-woven fabric, the pre-needled material was laminated for main needling, and the power frequency was set to 13Hz.

[0045] (2) Take part of the PET / ES needle-punched non-woven fabric prepared in step (1) for heat-drying treatment, put the sample into an oven, and heat-dry it for 60 minutes at a temperature of 120°C.

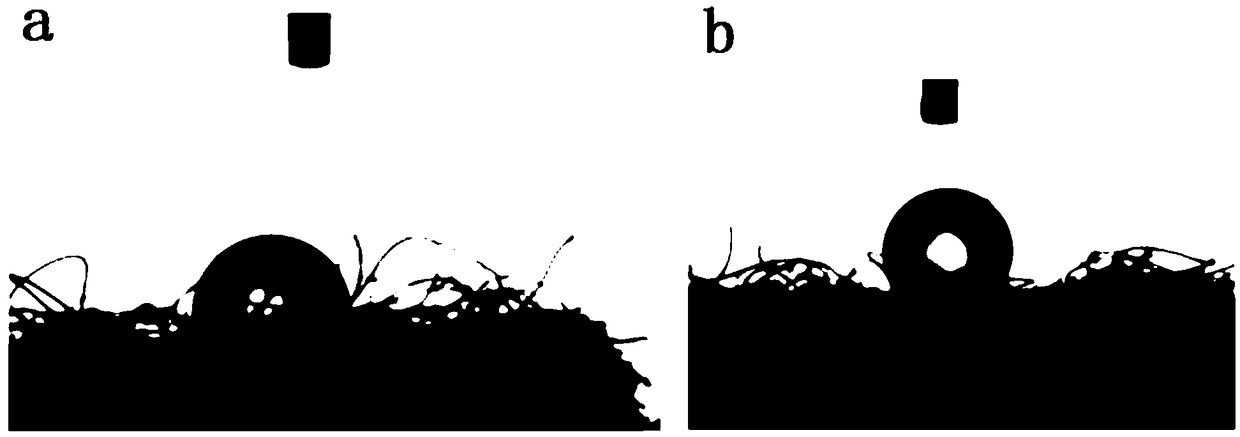

[0046] (3) Then use a fluorine-free water repellent aqueous solution with a concentration of 50mL / L to perform water-repellent treatment on the sample that has been heated and baked. The bath ratio of the fluorine-free water repellent aqueous solution to the sample is 10:1-20:1. Process flow: PET / ES need...

Embodiment 2

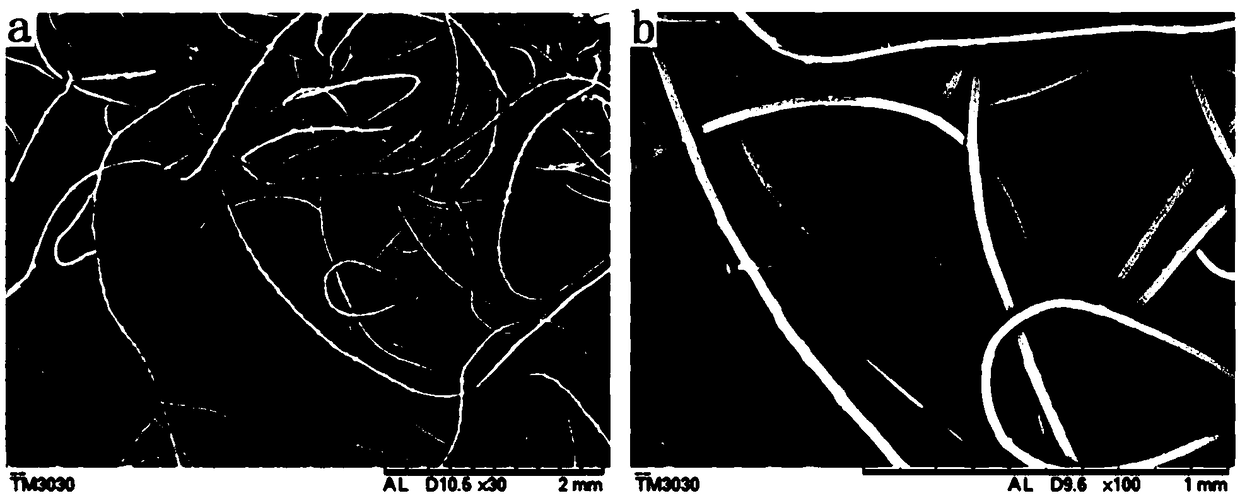

[0048] Hydrophobic and lipophilic composite needle-punched nonwoven fabrics were prepared according to the method of Example 1, except that in step (1), the mass ratio of PET fibers to ES fibers was 1:1.

Embodiment 3

[0050] Hydrophobic and lipophilic composite needle-punched nonwoven fabrics were prepared according to the method of Example 1, except that in step (1), the mass ratio of PET fibers to ES fibers was 1:3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oil absorption | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com