Patents

Literature

1024 results about "Fluorine free" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

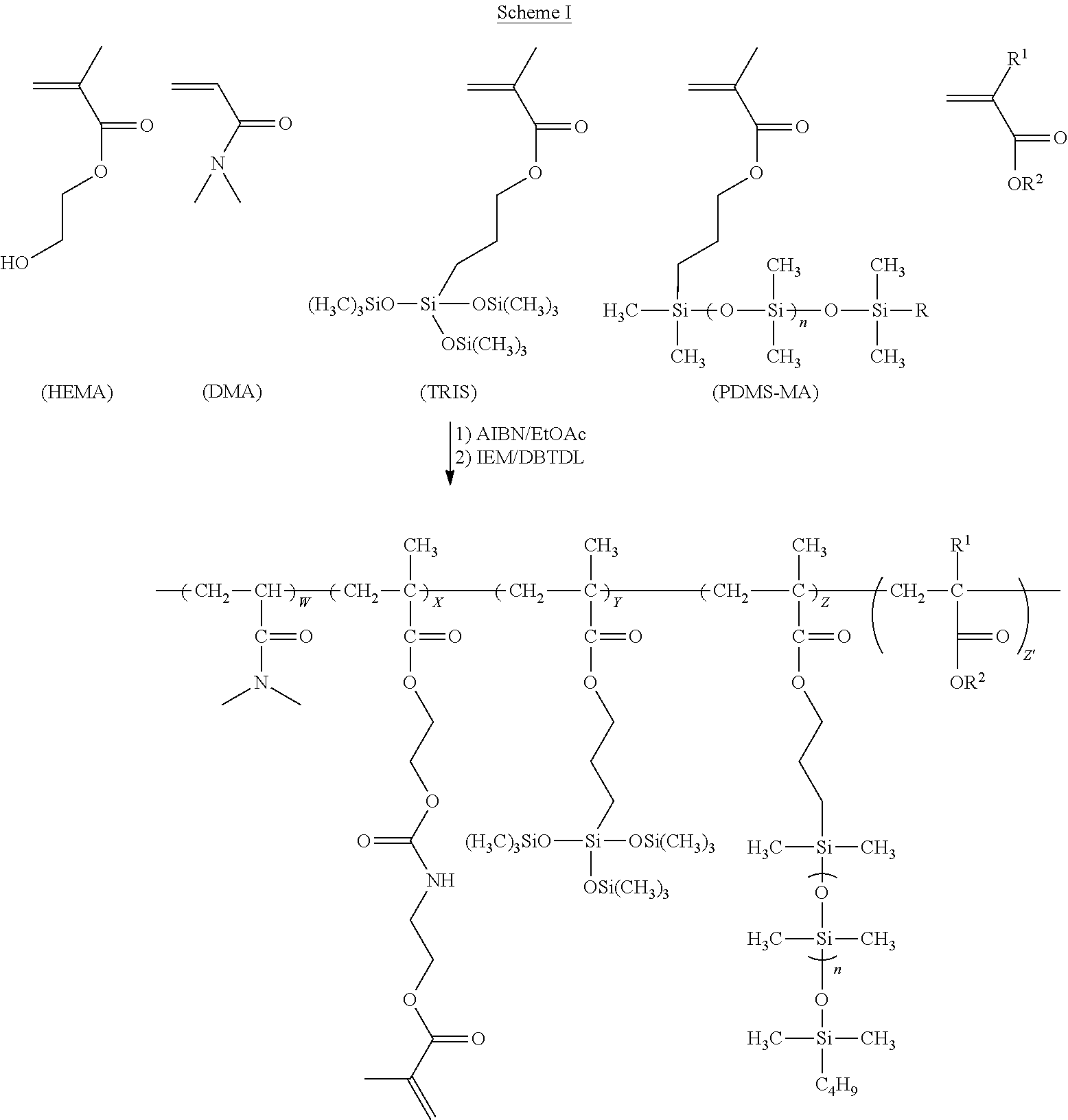

Actinically curable silicone hydrogel copolymers and uses thereof

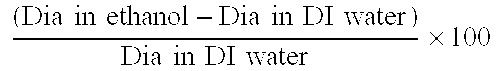

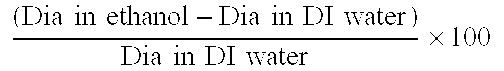

The present invention provides inks and methods for making colored silicone hydrogel contact lenses. The ink of the invention comprises an actinically-curable binder copolymer comprising fluorine-containing segments and is characterized by having capability to be cured actinically or thermally to form a colored film on a molding surface of a mold or a silicone hydrogel contact lens and by having an increased durability in a solvated state in a silicone-hydrogel lens formulation in relation to a control colored film obtained from a control ink including an actinically-curable fluorine-free binder copolymer. The invention also provides methods for making colored silicone hydrogel contact lenses based on print-on-mold processes for producing colored contact lenses.

Owner:ALCON INC

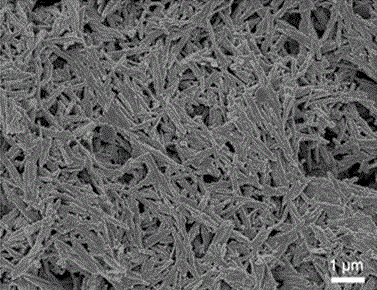

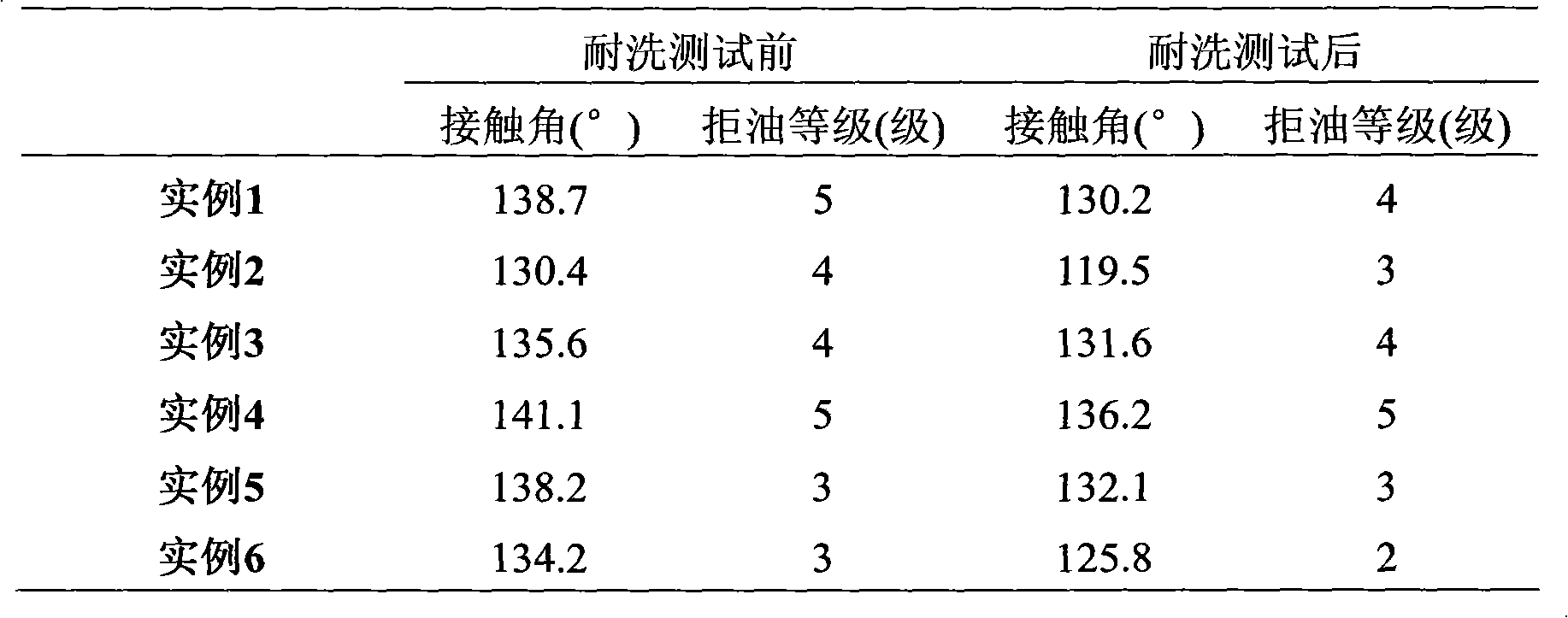

Preparation method of aqueous super-hydrophobic/super-hydrophobic and oileophobic coating

InactiveCN106811114AExcellent superhydrophobicityExcellent super amphiphobic propertiesAntifouling/underwater paintsPaints with biocidesNanoparticles dispersionSolvent

The invention discloses a preparation method of a water-based super-hydrophobic or super-amphiphobic coating. Nano-particles are ultrasonically dispersed into water, the pH of the solution is adjusted to obtain a nano-particle dispersion; The silane coupling agent is hydrolyzed under stirring to obtain an organosilane polymer / nanoparticle composite suspension; and then applied to the surface of the base material by spraying or dipping to obtain a water-based superhydrophobic / superamphiphobic coating. The present invention successfully prepares a water-based super-hydrophobic or super-amphiphobic coating with excellent performance without using any additives (organic solvent, surfactant and water-based solvent), and has many advantages such as water-based environmental protection, low price and excellent performance. , It has broader application prospects in the fields of self-cleaning surface, anti-corrosion coating, oil pollution prevention and oil transportation.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

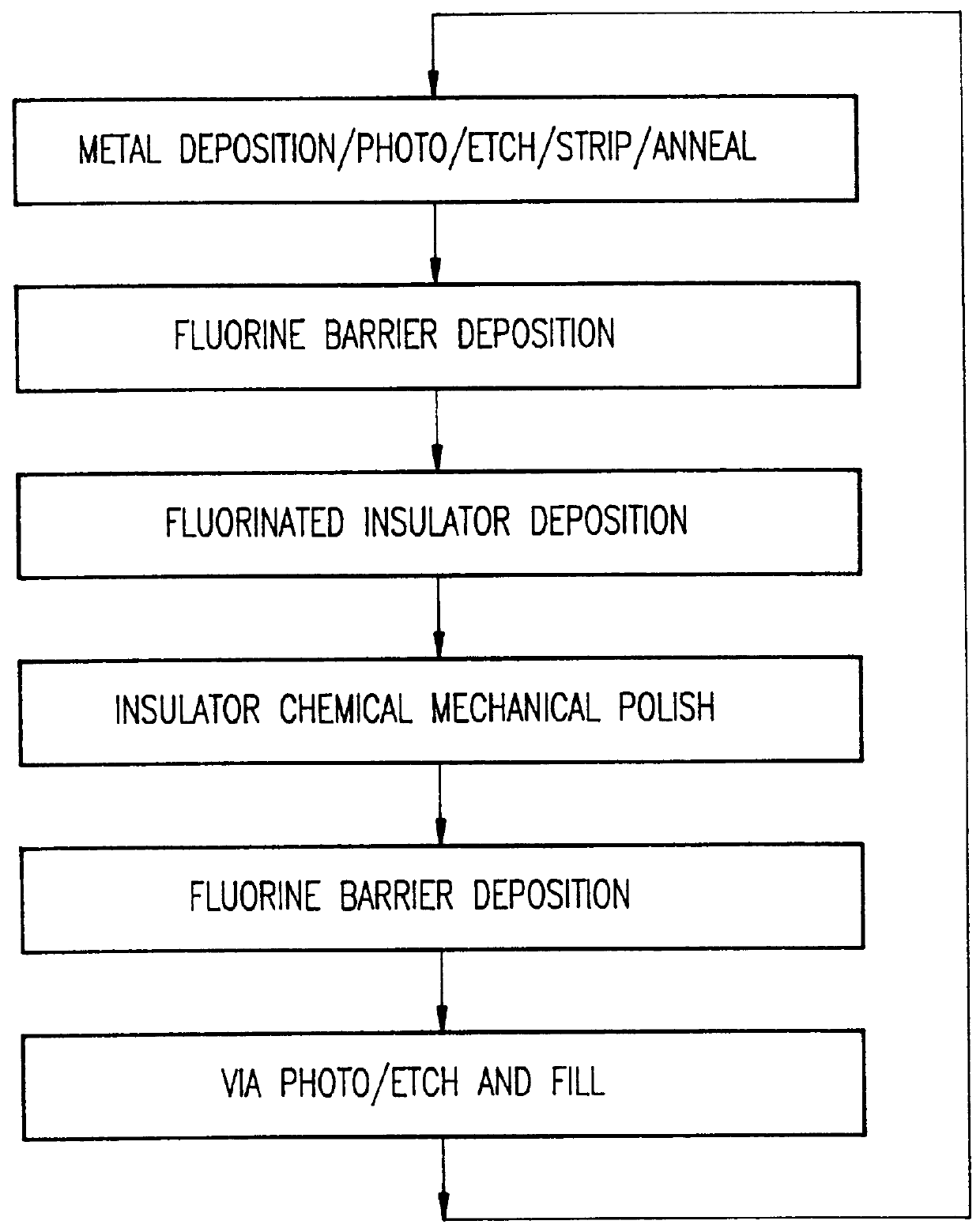

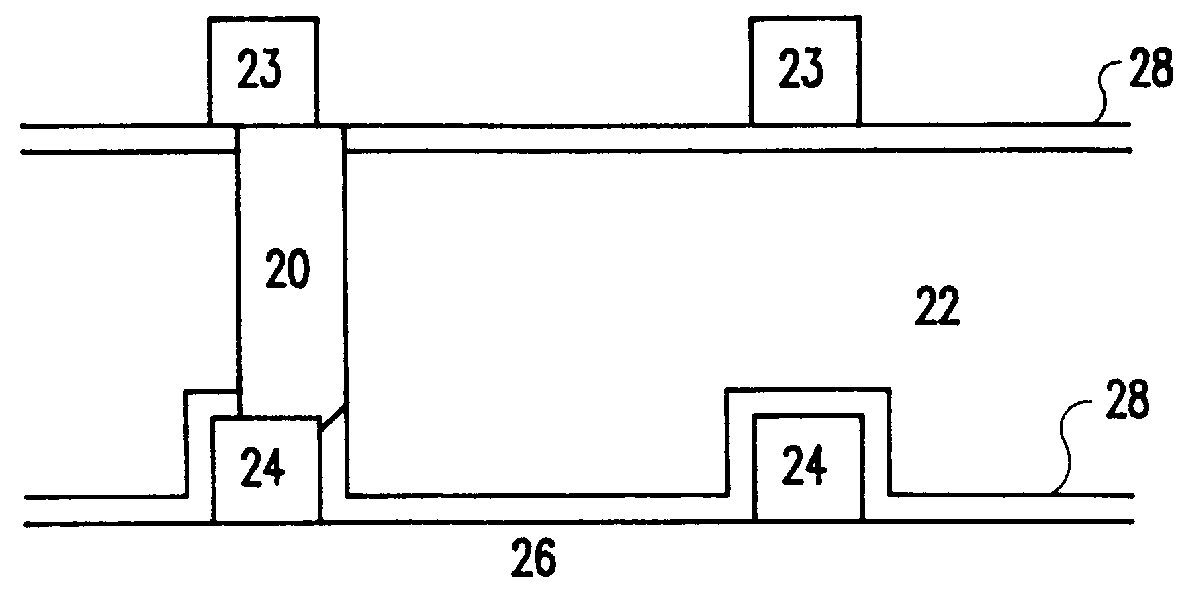

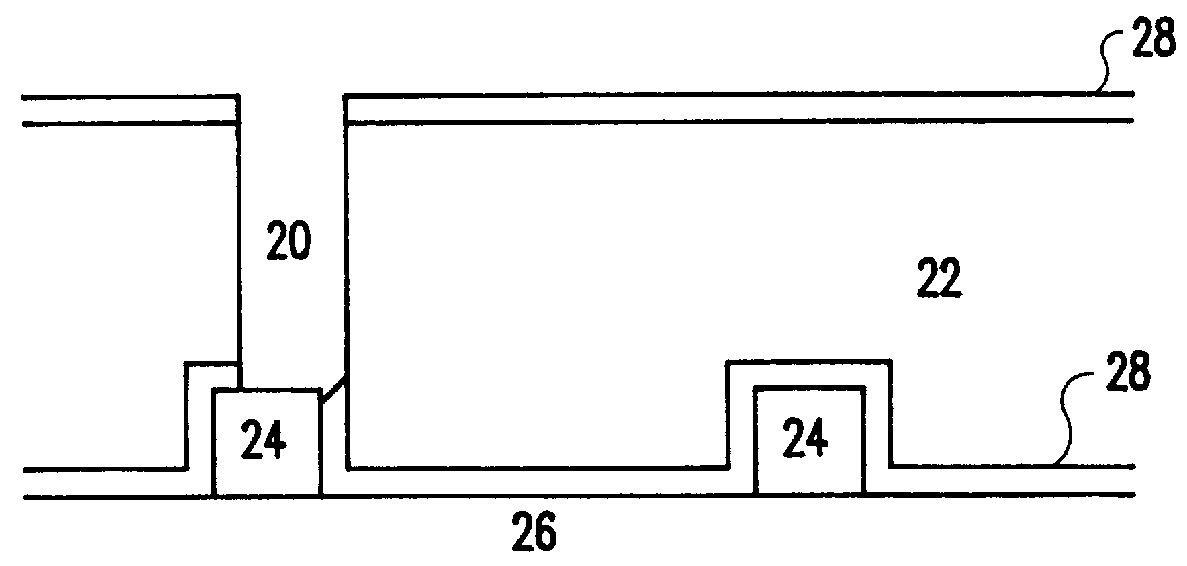

Method for providing fluorine barrier layer between conductor and insulator for degradation prevention

InactiveUS6066577AProvide resistanceEasily integrated into and compatibleSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorSemiconductor structure

Method of improving the resistance of a metal against degradation from exposure to fluorine released from a fluorine-containing material by forming a fluorine-free silicon dioxide barrier layer between the insulator material and the metal. The invention is especially useful in improving corrosion and poisoning resistance of metallurgy, such as aluminum metallurgy, in semiconductor structures. The invention also covers integrated circuit structures made by this method.

Owner:IBM CORP

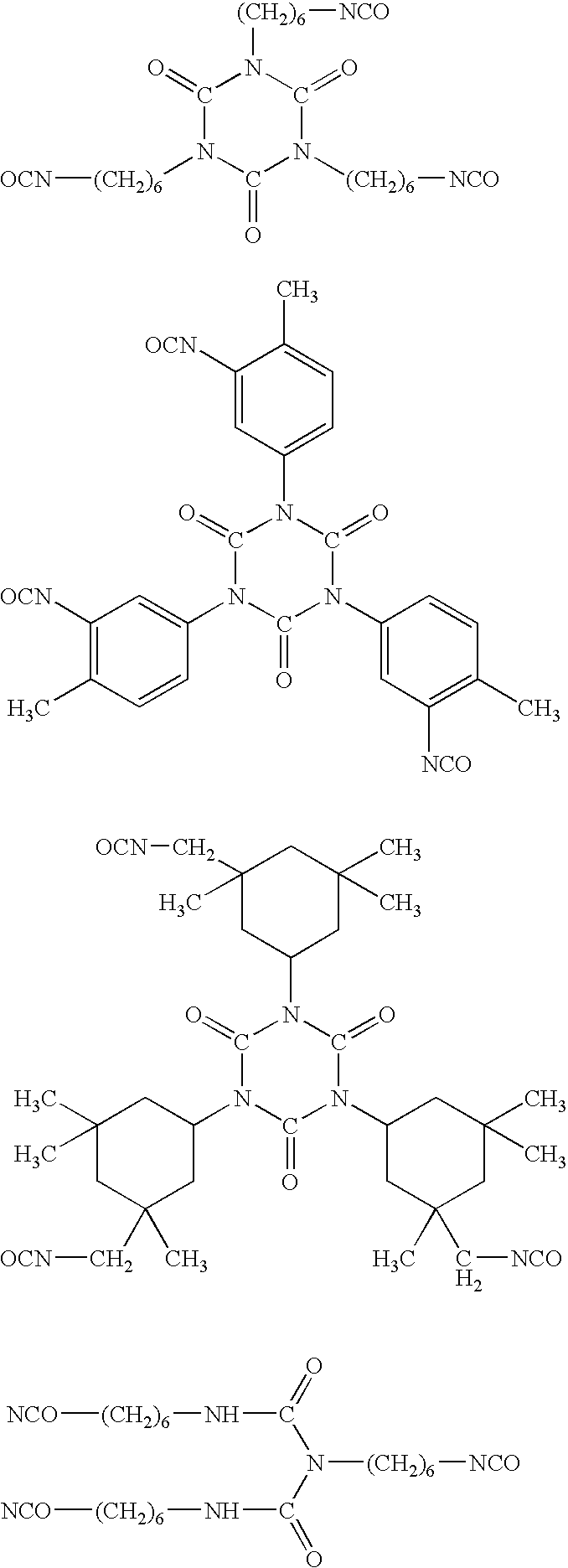

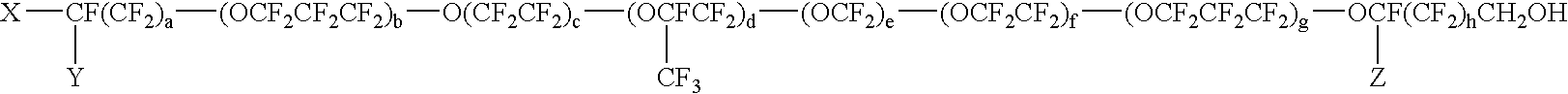

Surface-treating agent composition and process for producing the same

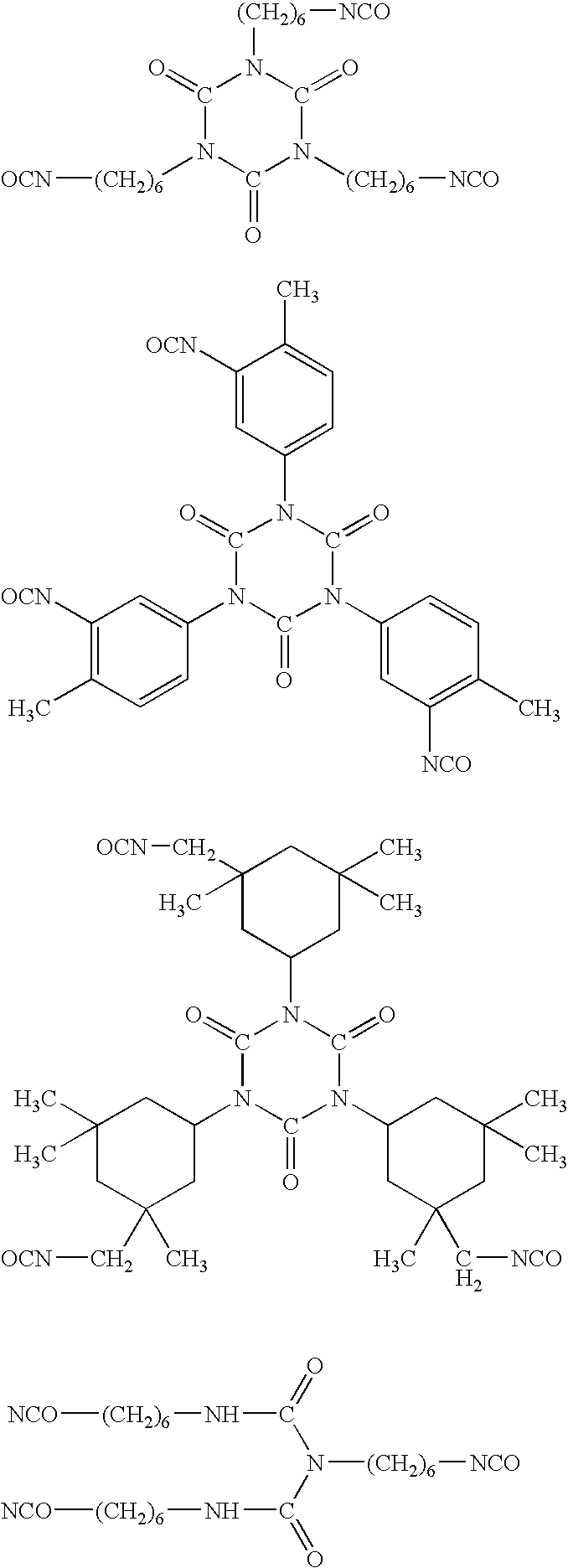

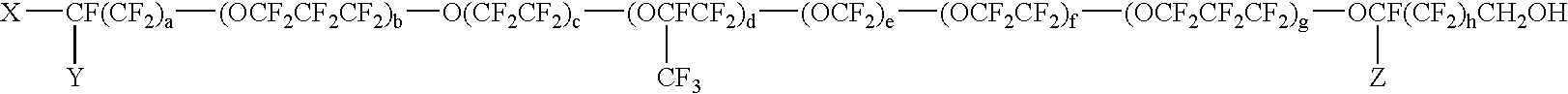

InactiveUS20040181008A1Fit closelySynthetic resin layered productsPolyurea/polyurethane coatingsPolymer sciencePerfluoropolyether

A perfluoropolyether-containing composition, which can easily conform to a fluorine-free substrate and can form a film on a surface of the substrate to fix the composition to the substrate surface, wherein the composition is a carbon-carbon double bond-containing composition comprising (A) a triisocyanate prepared by trimerizing a diisocyanate, and (B) a combination of at least two active hydrogen-containing compounds, and the component (B) comprises (B-1) a perfluoropolyether having at least one active hydrogen, and (B-2) a monomer having active hydrogen and a carbon-carbon double bond.

Owner:DAIKIN IND LTD

Surface treatment composition and preparation thereof

InactiveUS6906115B2Fit closelySynthetic resin layered productsPolyurea/polyurethane coatingsHydrogenPerfluoropolyether

Owner:DAIKIN IND LTD

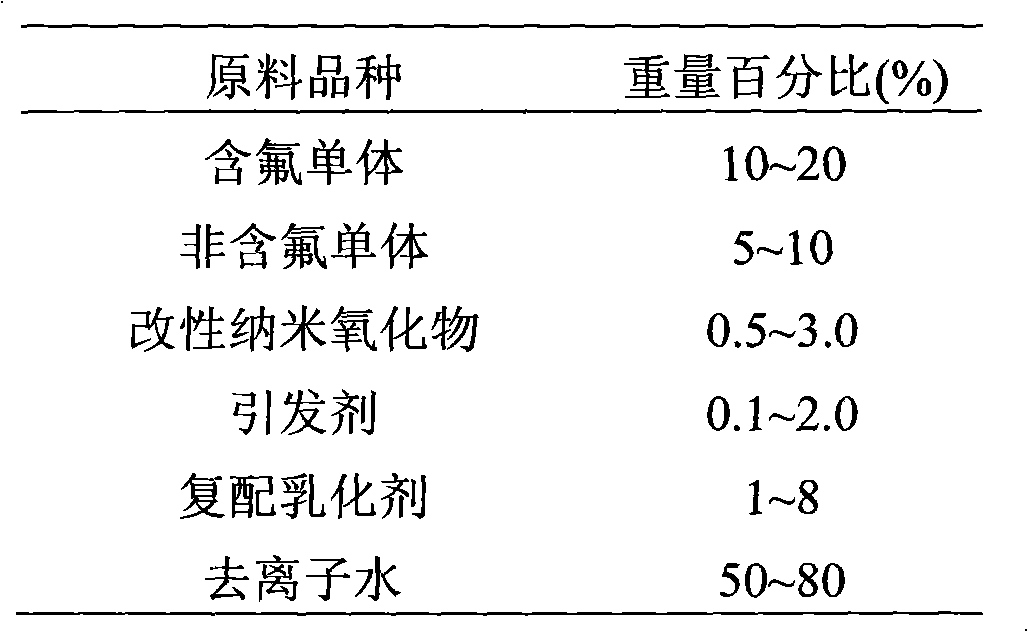

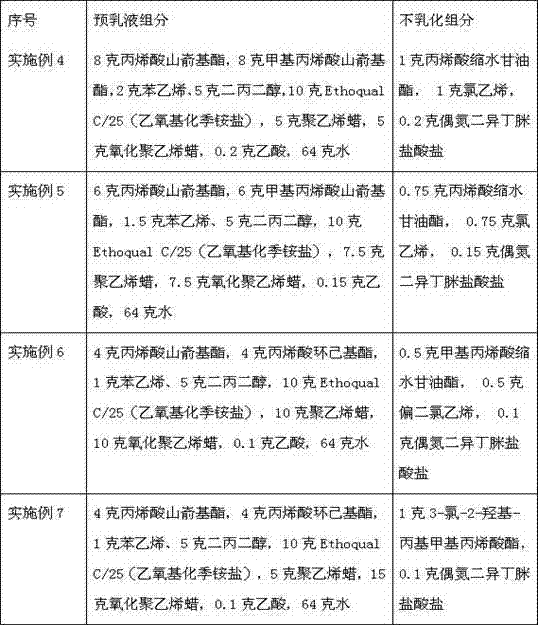

Method for preparing short-chain branch water and oil repellent finishing agent containing modified nano-oxide and fluorine

InactiveCN102041681AImprove securityFeel goodFibre treatmentFunctional monomerEmulsion polymerization

The invention relates to a latex type short-chain branch perfluoroalkyl water and oil repellent finishing agent and a preparation method thereof, belonging to the field of fine chemical industry. The latex type short-chain branch perfluoroalkyl water and oil repellent finishing agent is prepared by the following steps of: pre-emulsifying short-chain branch perfluoroalkyl acrylate monomer (10-20%), fluorine-free functional monomer (5.0-10%), modified nano-oxide (0.5-3.0%), initiator (0.1-2.0%), compound emulsifier (1.0-8.0%) and deioned water (60-80%); and finally heating for emulsion polymerization. The latex type short-chain branch perfluoroalkyl water and oil repellent finishing agent can be used for water and oil repellent finishing of animal and plant natural fiber fabric and chemical fiber fabric and has excellent water and oil repellent performance; fabric finished with the finishing agent has good handfeel and excellent endurance performance. Compared with the traditional fluorine-containing finishing agent , the finishing agent disclosed in the invention does not contain components harmful to human bodies and well accords with environmental protection requirement.

Owner:JIANGNAN UNIV

Fluorine-free superhydrophobic finishing agent containing modified nano silicon dioxide hydrosol and application thereof

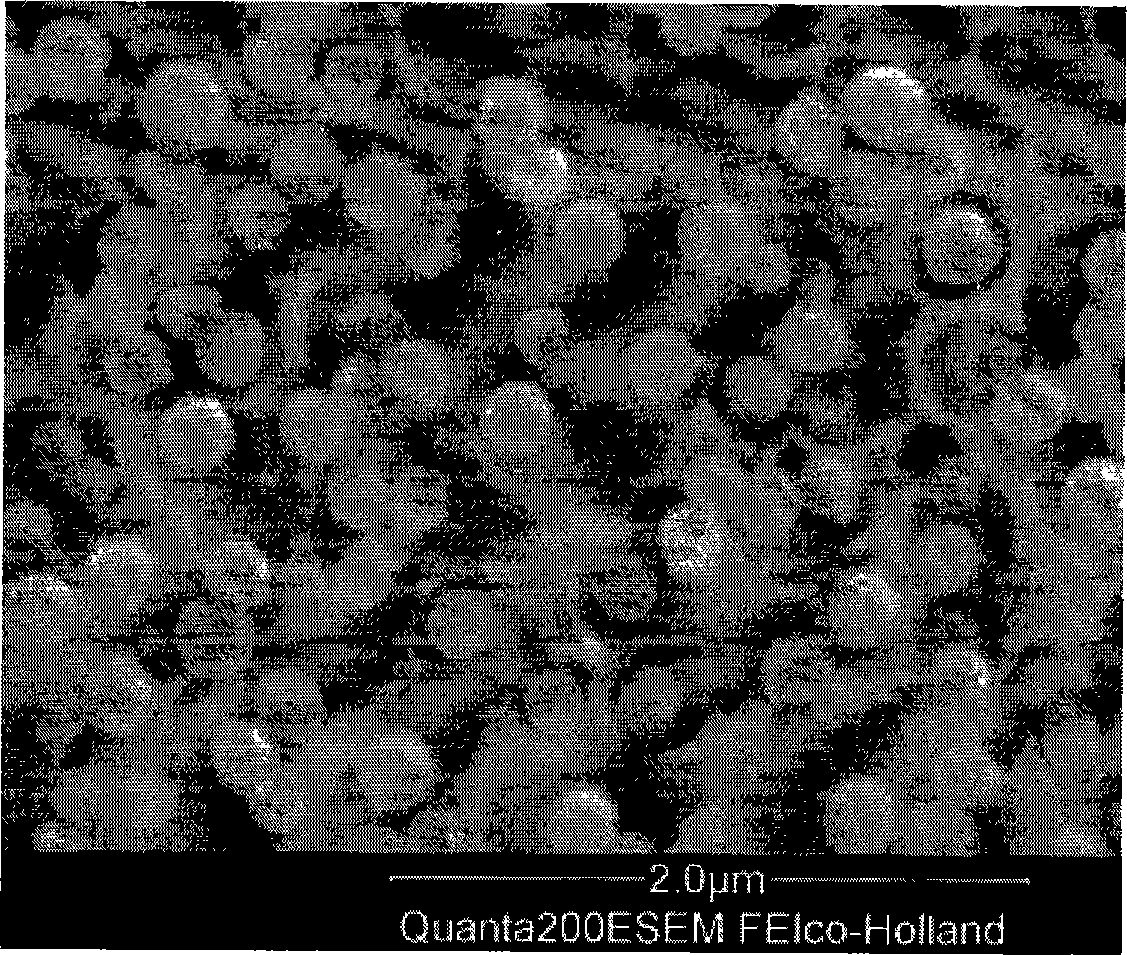

ActiveCN102021819AExcellent water repellencyBasic physical and mechanical propertiesSilicon compoundsVegetal fibresOrganic solventHYDROSOL

The invention relates to a fluorine-free superhydrophobic finishing agent containing modified nano silicon dioxide hydrosol and application thereof. The finishing agent is prepared by the following steps of: (1) mixing a precursor, an anionic surfactant and water and stirring violently at the temperature of between 20 and 50 DEG C; and (2) slowly adding ammonia water serving as a catalyst dropwise, stirring, adding long-chain alkylsiloxane serving as a modifier and stirring continually so as to obtain modified SiO2 hydrosol. The finishing agent has a stable property, avoids the pollution of an organic solvent and has high water repellency when used for performing superhydrophobic finishing on textiles.

Owner:DONGHUA UNIV +1

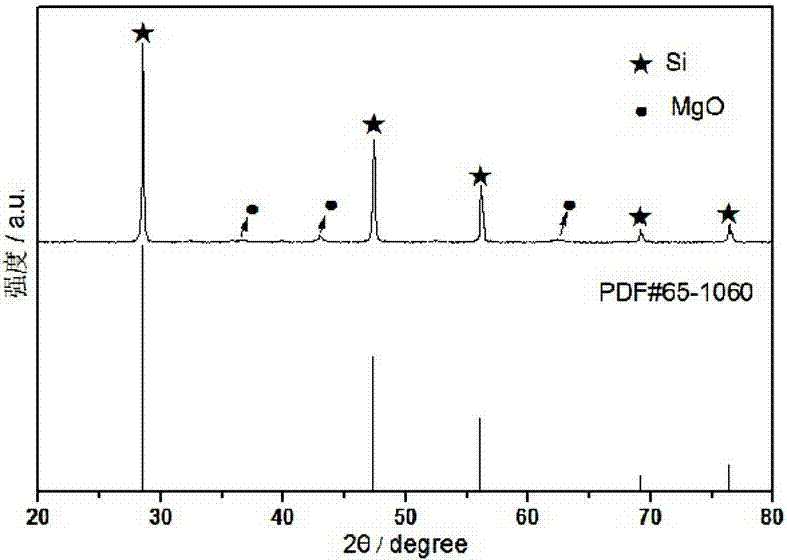

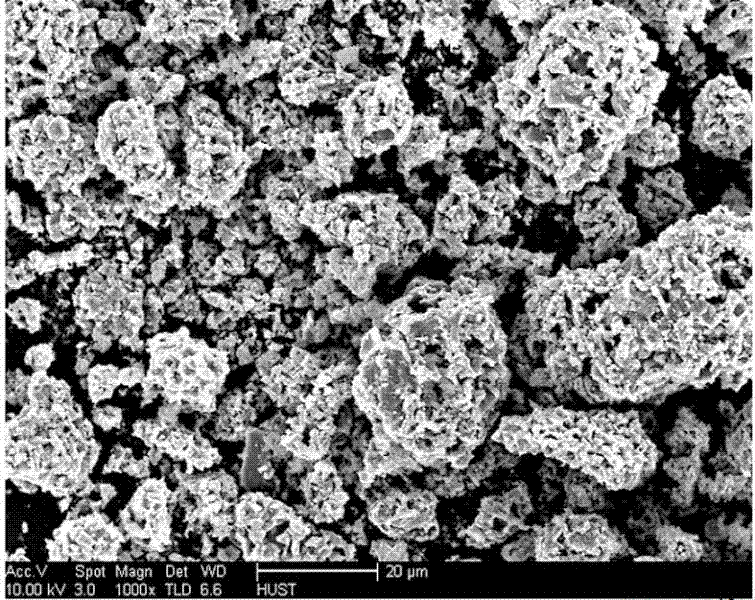

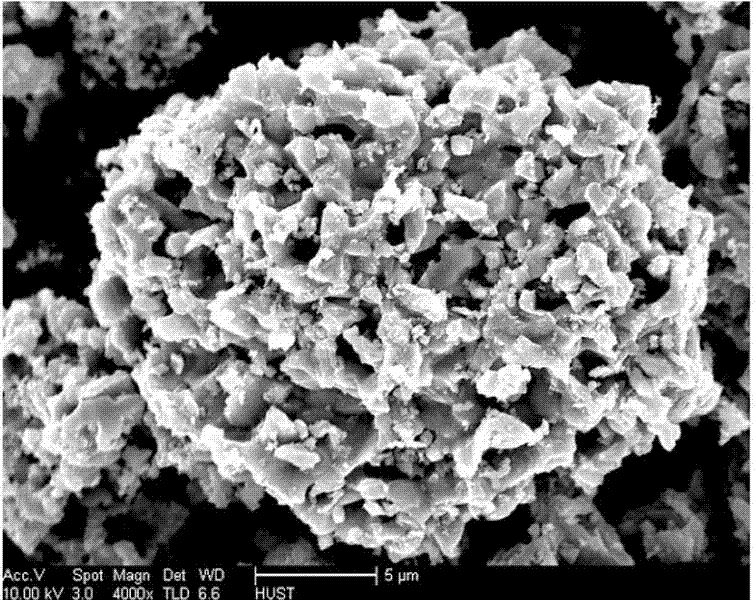

Fluorine-free preparation method for three-dimensional porous silica powder anode material of lithium ion battery

ActiveCN102237519AAvoid pollutionHigh specific capacityCell electrodesSodium-ion batterySilicon particle

The invention discloses a fluorine-free preparation method for a three-dimensional porous silica powder anode material of a lithium ion battery. In the method, combination reaction is performed on ordinary micron-sized silicon and magnesium particles to generate magnesium silicide, and the magnesium silicide is pyrolyzed at high temperature to form magnesium vapor and silica powder with a three-dimensional porous structure. By the fluorine-free preparation method for the three-dimensional porous silica powder anode material of the lithium ion battery, a preparation process is free from fluorine so as to avoid environmental pollutions; the material has the porous structure so as to realize the self-absorption of volume effects of the silicon particles; the specific capacity and recycling stability of the material are improved to a certain extent; and a synthesis process is simple and easy to operate, and the preparation cost of the material is low.

Owner:CHINA THREE GORGES UNIV +1

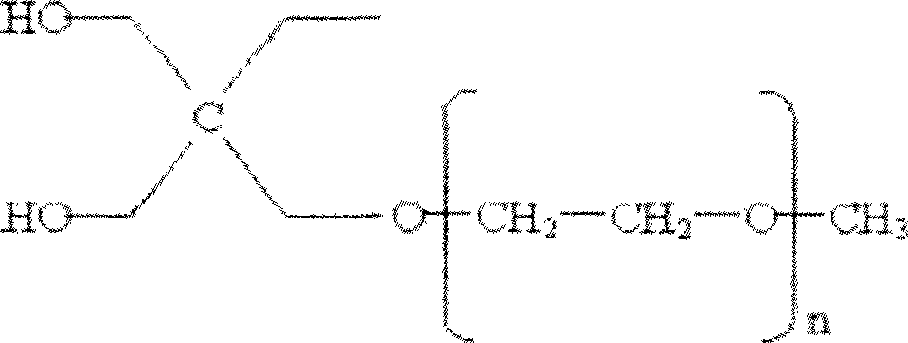

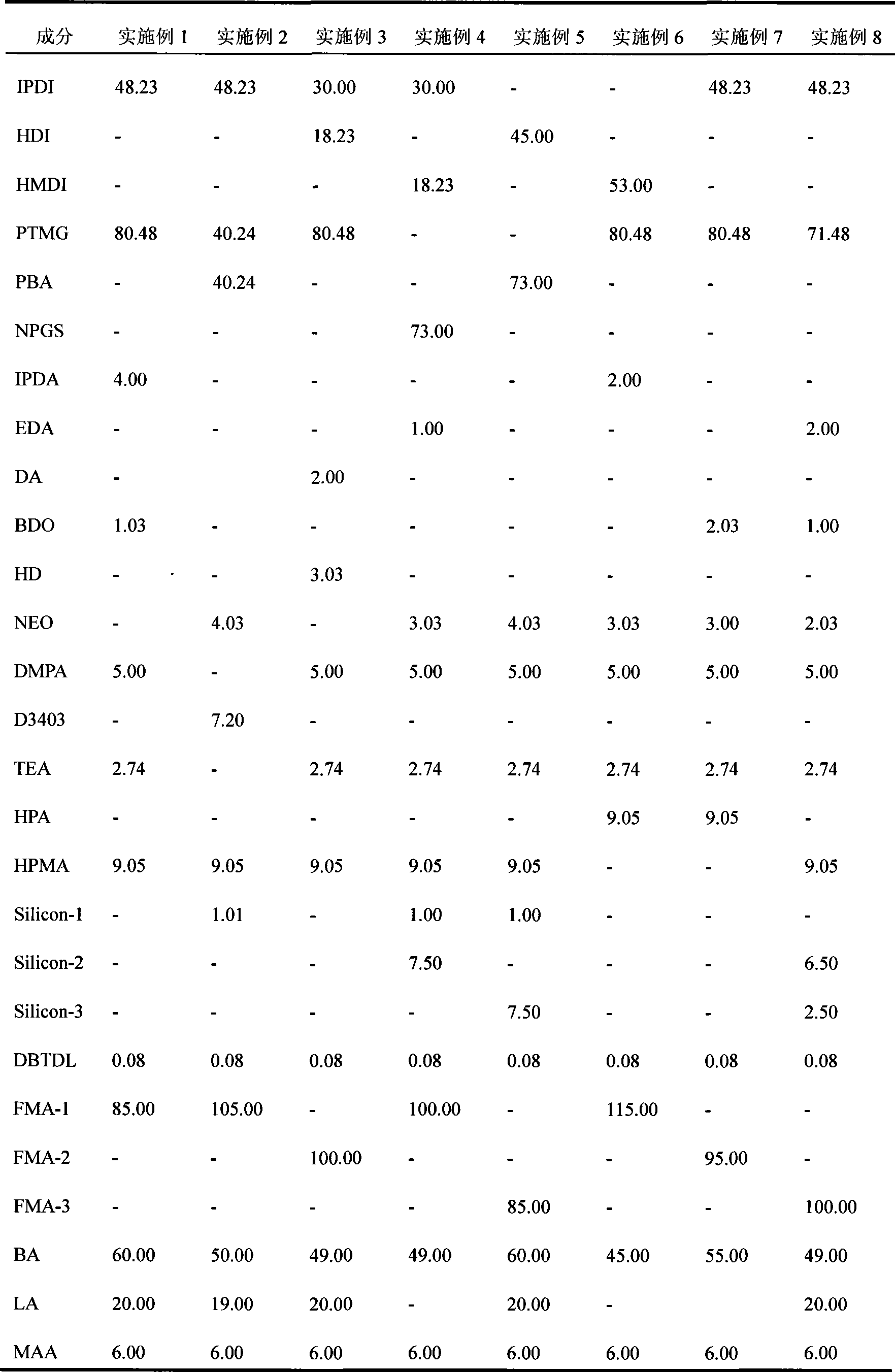

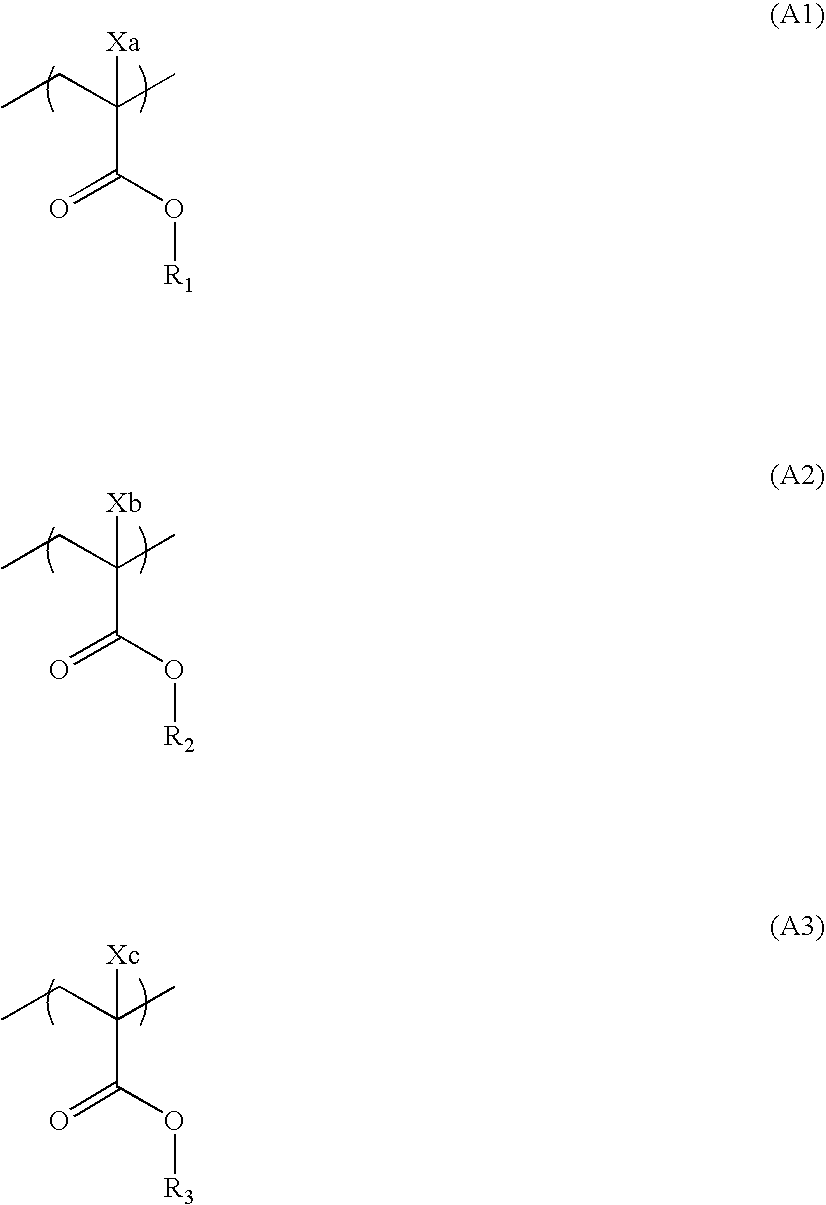

Hybrid polyurethane-polyacrylacid ester dispersion containing fluorine and/or siloxane and preparation method thereof

InactiveCN101362815AGood oil proofImprove waterproof performanceCoatingsDouble bondPhysical property

The invention provides a hybrid polyurethane-polyacrylate dispersoid containing fluorine and siloxane and a preparation method thereof, wherein, an interpenetrating network structure and a nuclear shell structure exist in a dispersoid particle simultaneously. The hybrid polyurethane-polyacrylate dispersoid is polymerizing a polyurethane dispersoid containing double bonds (10-20 percent), a fluorine-containing monomer (5-15 percent), a fluorine-free monomer (10-30 percent), an initiating agent (0.1-2.0 percent), an emulsifying agent (0.5-5 percent), a chain transfer agent (0.01-0.5 percent) and deionized water (50-70 percent) by emulsion. The dispersoid is white lacteal liquid, contains no organic solvent, and has a solid content of 30-50 percent, a molecular weight of 10,000-100,000, a pH value of 7-9, a viscosity of 30-300cp and a stationary phase of more than 1 year. Paint films prepared by the dispersoid have good physical property and relatively low surface energy and can be applied to providing surface coatings with excellent water-proof / antifouling performance.

Owner:大连振邦氟涂料股份有限公司

Preparation method of lithium hexafluorophosphate

ActiveCN102009972ARich sourcesReduce manufacturing costPhosphorus compoundsPhosphoric acidNitrogen gas

The invention relates to a preparation method of lithium hexafluorophosphate. The preparation method comprises the following steps of: (1) distilling to obtain hydrogen fluoride liquid of which the purity is over 99.99 weight percent; (2) reacting the high-purity hydrogen fluoride liquid with phosphorus pentachloride to obtain mixed gas of the phosphorus pentafluoride and hydrogen chloride; (3) introducing the mixed gas of the phosphorus pentachloride and the hydrogen chloride into hydrogen fluoride and lithium fluoride, reacting at a certain temperature and under certain pressure to obtain solution of lithium hexafluorophosphate, exhausting hydrogen chloride gas at regular time, and absorbing by using water to prepare byproduct hydrochloric acid; and (4) crystallizing and separating, namely filtering the solution of lithium hexafluorophosphate, delivering filtrate into a crystallizing slot, separating the lithium hexafluorophosphate out at the temperature of between -70 and 80 DEG C, filtering, and performing primary drying and secondary drying to obtain a lithium hexafluorophosphate product, wherein the residual hydrogen fluoride gas is displaced by nitrogen. The preparation method has readily available raw materials and is easy to operate, the purity of the obtained lithium hexafluorophosphate product is over 99.9 percent, the moisture is lower than 10ppm, and the production requirements of lithium ion electrolytic cells are met.

Owner:MORITA NEW ENERGY MATERIALS ZHANGJIAGANG CO LTD

Pattern forming method

Owner:FUJIFILM CORP

Resist protective film material and pattern formation method

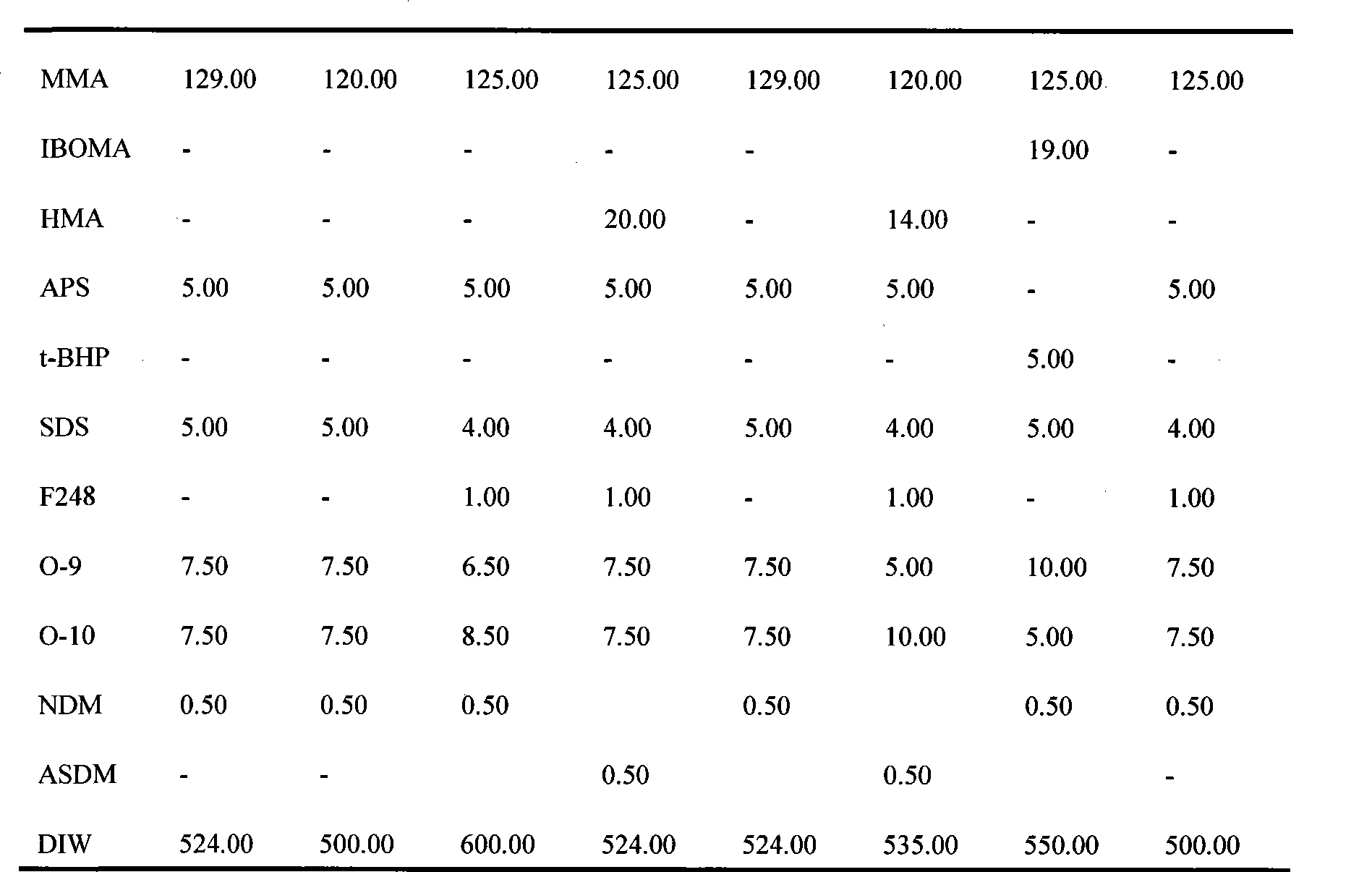

InactiveUS20070122736A1Photosensitive materialsPhotosensitive materials for photomechanical apparatusTectorial membranePhotoresist

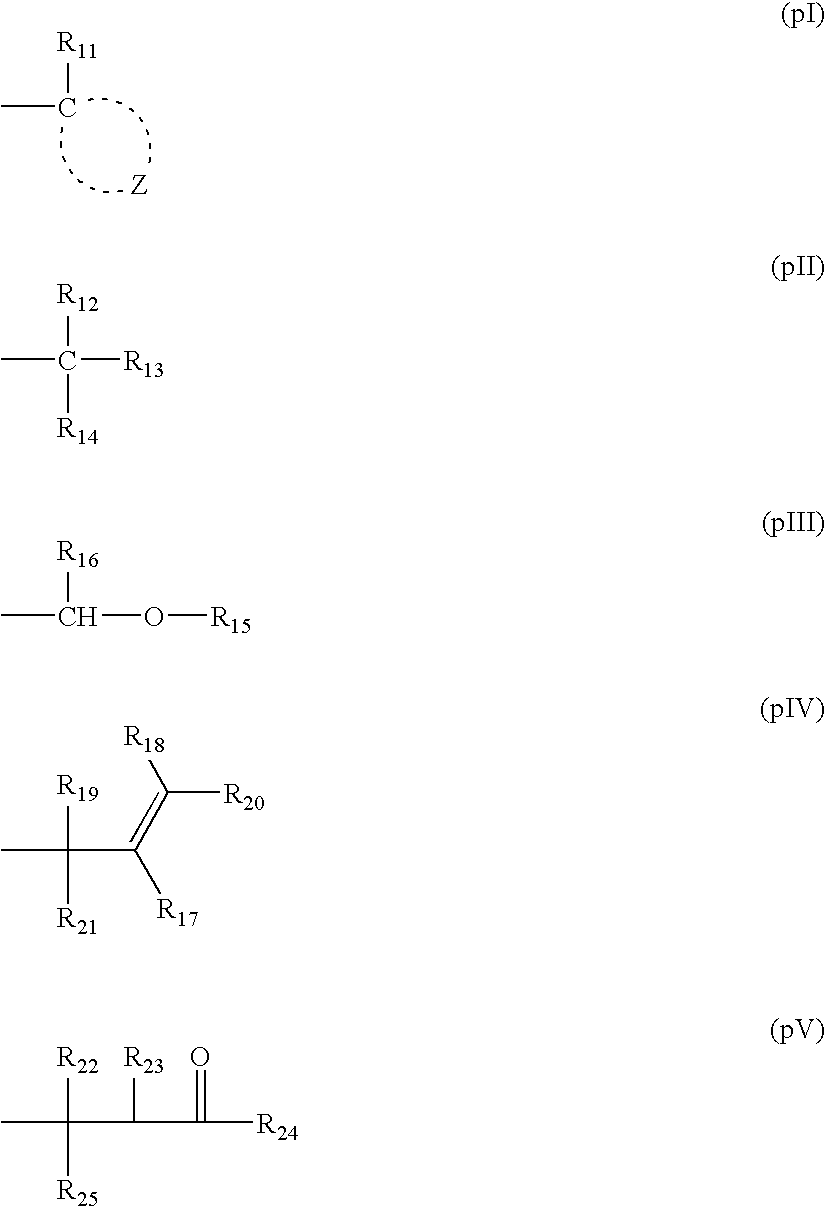

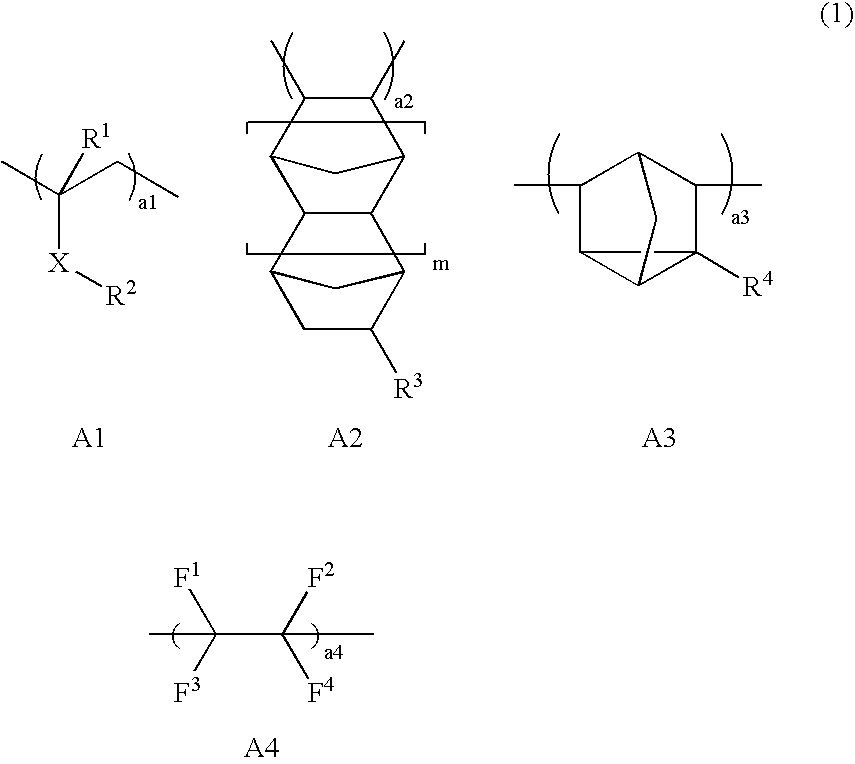

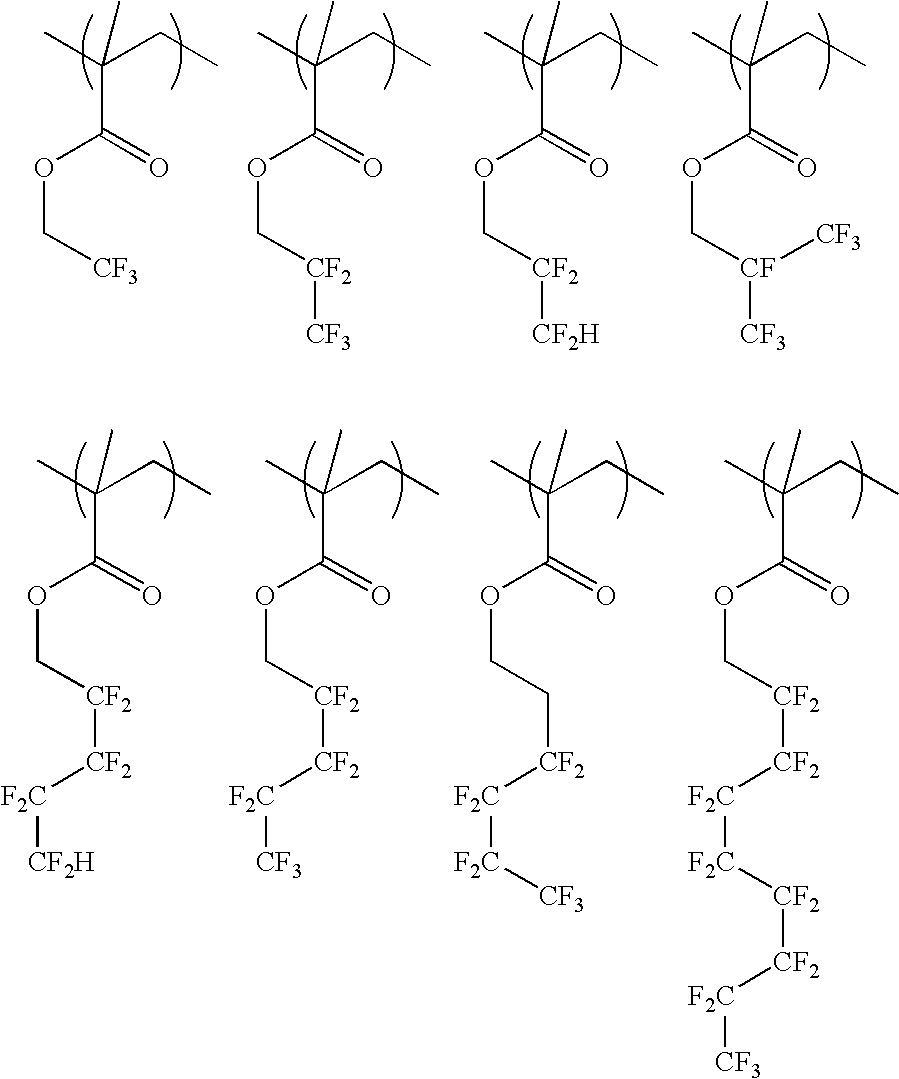

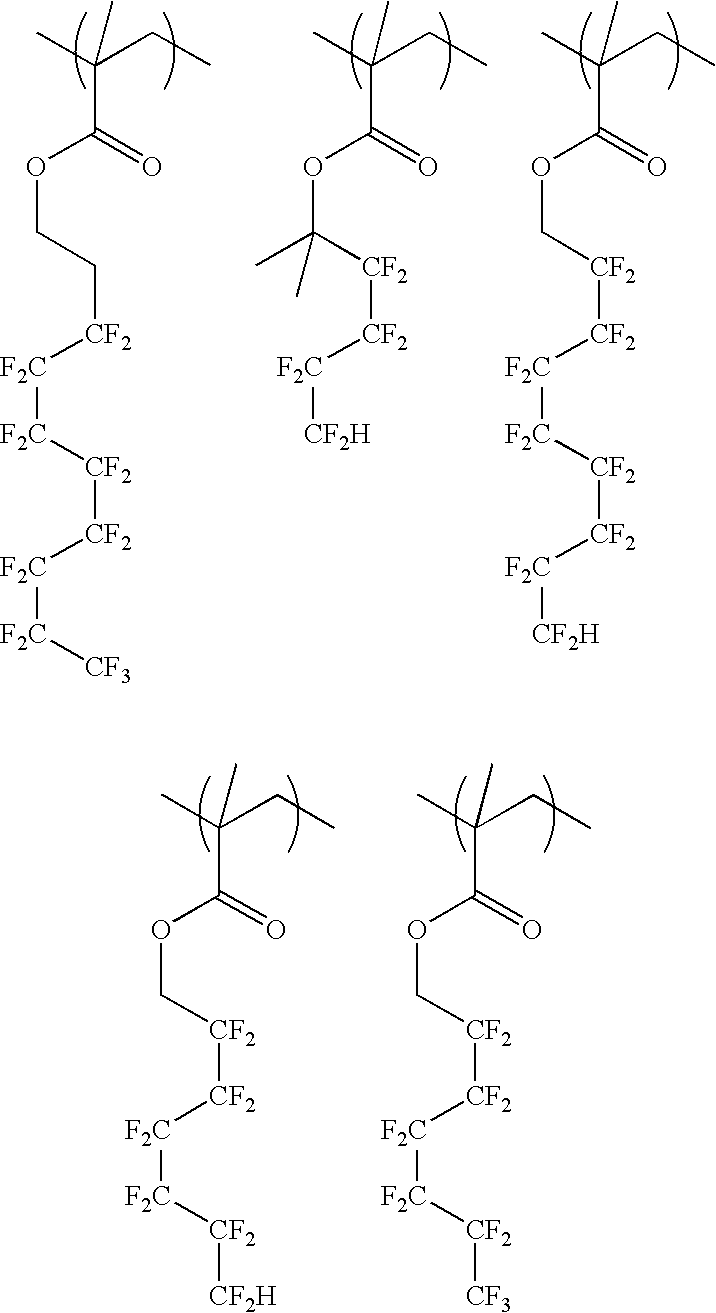

The invention is a protective film material for immersion lithography that enables desirable immersion lithography, can be removed simultaneously with development of a photoresist layer, and has excellent process adaptability. The invention also includes a method for forming a pattern using the material. More specifically, the invention is a protective film material comprising (i) a blend of a polymer comprising a repeating unit having a fluorine-containing alkyl or alkylene group which contains at least one fluorine atom and an optional alkali soluble repeating unit and a polymer comprising a repeating unit having a fluorine-free alkyl group and an optional alkali soluble repeating unit, or (ii) a polymer comprising a repeating unit having a fluorine-containing alkyl or alkylene group which contains at least one fluorine atom and a repeating unit having a fluorine-free alkyl group and an optional alkali-soluble repeating unit.

Owner:SHIN ETSU CHEM IND CO LTD

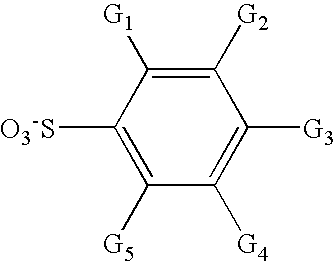

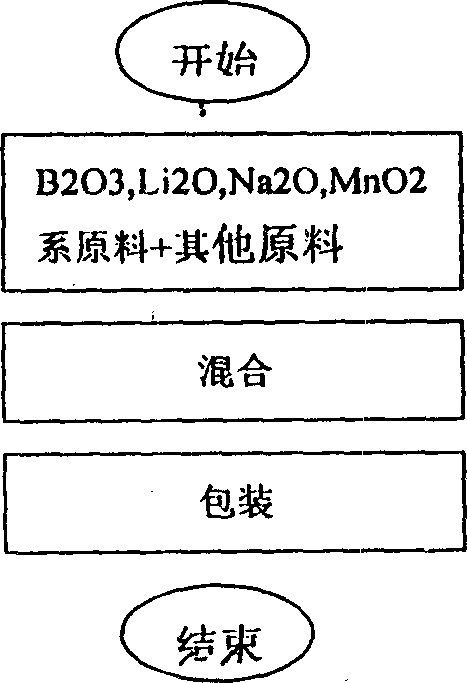

Fluorine-free environment-friendly type continuous casting protecting slag for the blast furnace slag containing titanium and the manufacturing process of the same

The present invention relates to steel-making crystallizer protecting dregs, and is environment protecting fluoride-free protecting dregs suitable for continuous casting of plate billet and square billet. The protecting dregs consist of sintering base material, titanium-containing blast slag, manganese ore powder, bentone, carbon black, clay shaped graphite, etc. Its production process includes the synthesis of base material and the compounding of protecting dregs. The protecting dregs may be molten in the crystallizer homogeneously to produce cast billet lubricating and heat insulating effect and has no corrosion to casting machine and no pollution to water.

Owner:CHONGQING UNIV

Fluorine-free water-proofing agent and preparation method thereof as well as textile

InactiveCN103628324AImprove bindingImprove waterproof performanceFibre treatmentPolymer scienceActive agent

Owner:DYMATIC CHEM

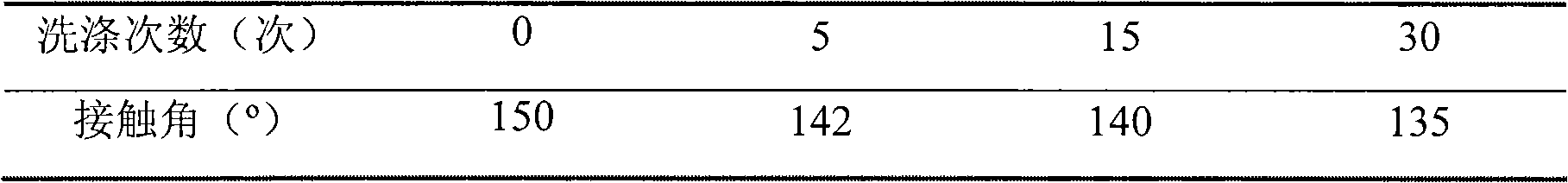

Treatment method and treatment liquid for preparing fluoride-free super-hydrophobic cotton fabric

ActiveCN103290674AMeet the requirementsWide variety of sourcesVegetal fibresTetraethyl orthosilicateFluorine free

The invention provides a treatment method and treatment liquid for preparing a fluoride-free super-hydrophobic cotton fabric. The treatment liquid comprises the following components: 1-8ml of ammonia water of which the mass percent concentration is 25-28%, 80-140ml of ethanol, 5-6ml of tetraethyl orthosilicate, 2-4ml of hexadecyl trimethoxy siloxane, 0.5-3ml of alkane siloxane and 0-4ml of 3-glycidol ether oxy-propyl trimethoxysilane. According to the treatment method, a large amount of modified silicon dioxide nano-particles with water repellency are modified on the surface of the fabric by dipping the fabric in the treatment liquid of modified silicon dioxide sol, so that the contact angle between the prepared fabric and a water drop is more than 150 degrees, the fabric has super-hydrophobic performance, and the physical and mechanical properties of the fabric are not affected. The treatment method and treatment liquid for preparing the fluoride-free super-hydrophobic cotton fabric are environment-friendly in process, simple, convenient, effective and in accordance with ecological textiles, and can meet requirements for industrial mass production.

Owner:MYPOLYMER JIAXING

Copolymer for cosmetics

A copolymer for cosmetics, which is obtained by polymerizing (A) 5 to 95% by weight of a fluorine-containing (meth)acrylate, and (B) 5 to 95% by weight of at least one fluorine-free monomer selected from the group consisting of (i) a silicone macromonomer, (ii) a polyalkylene glycol (meth)acrylate, (iii) an alkyl (meth)acrylate, and (iv) an alkyl (meth)acrylate macromonomer, can be easily incorporated in cosmetics and can form a film excellent in water resistance, water- and oil-repellency, feeling when used, and safety. This copolymer for cosmetics can improve the drawbacks of powder treated with a fluorine-containing compound.

Owner:DAIKIN IND LTD

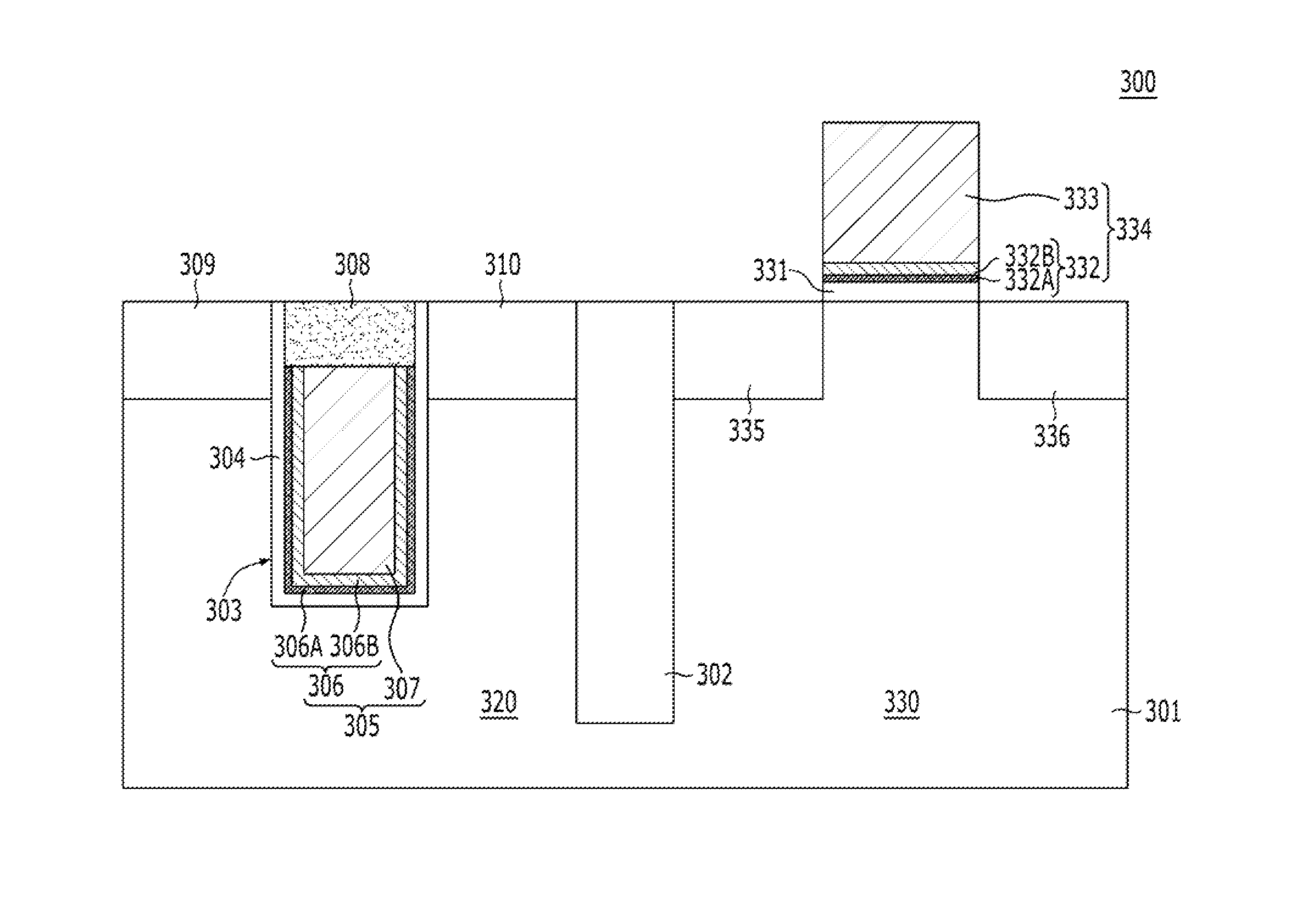

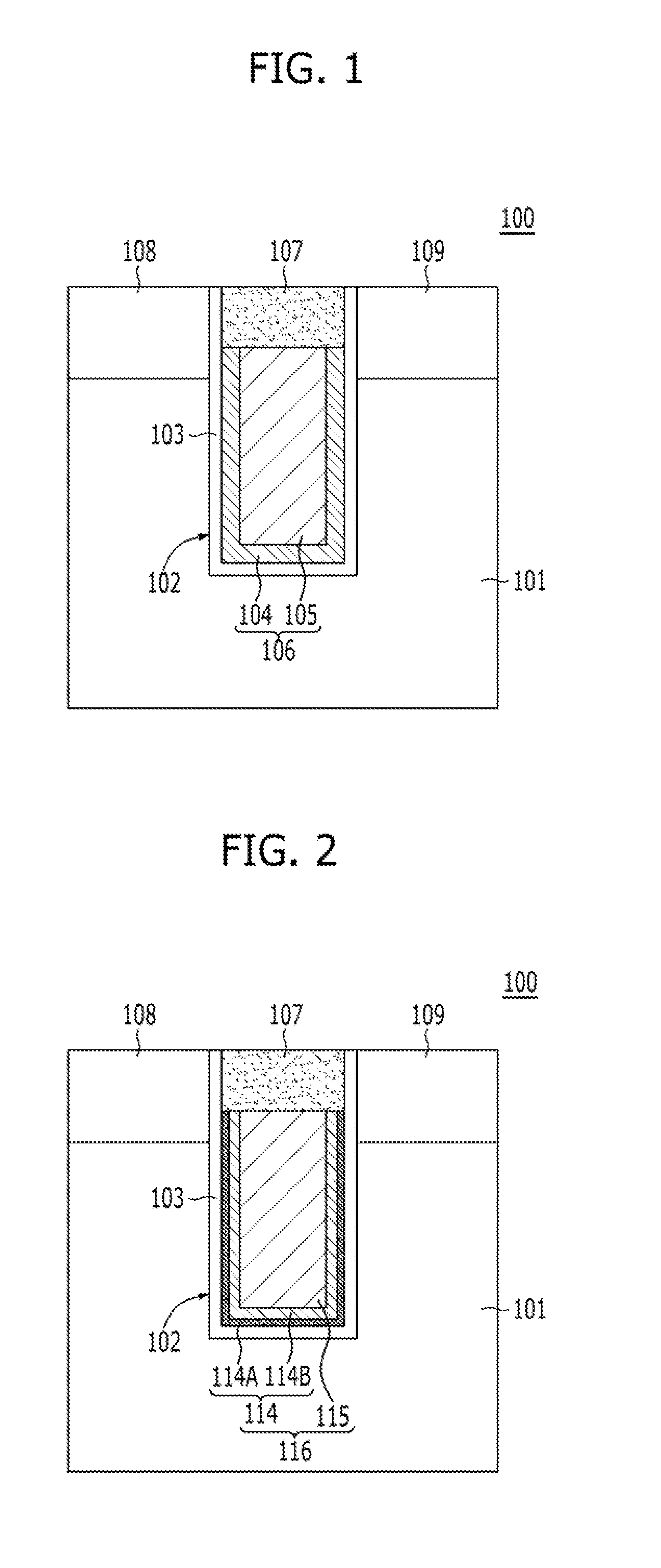

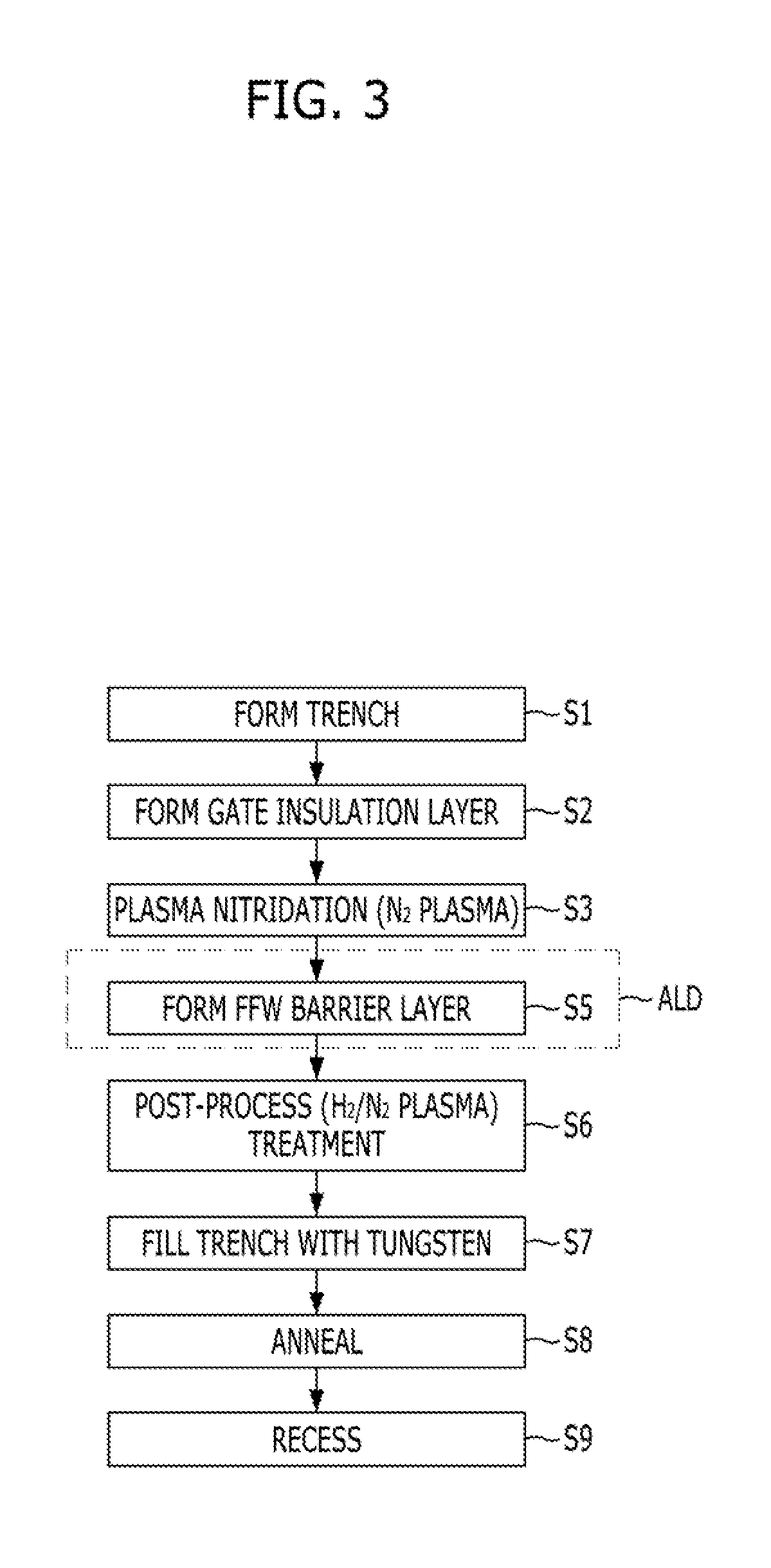

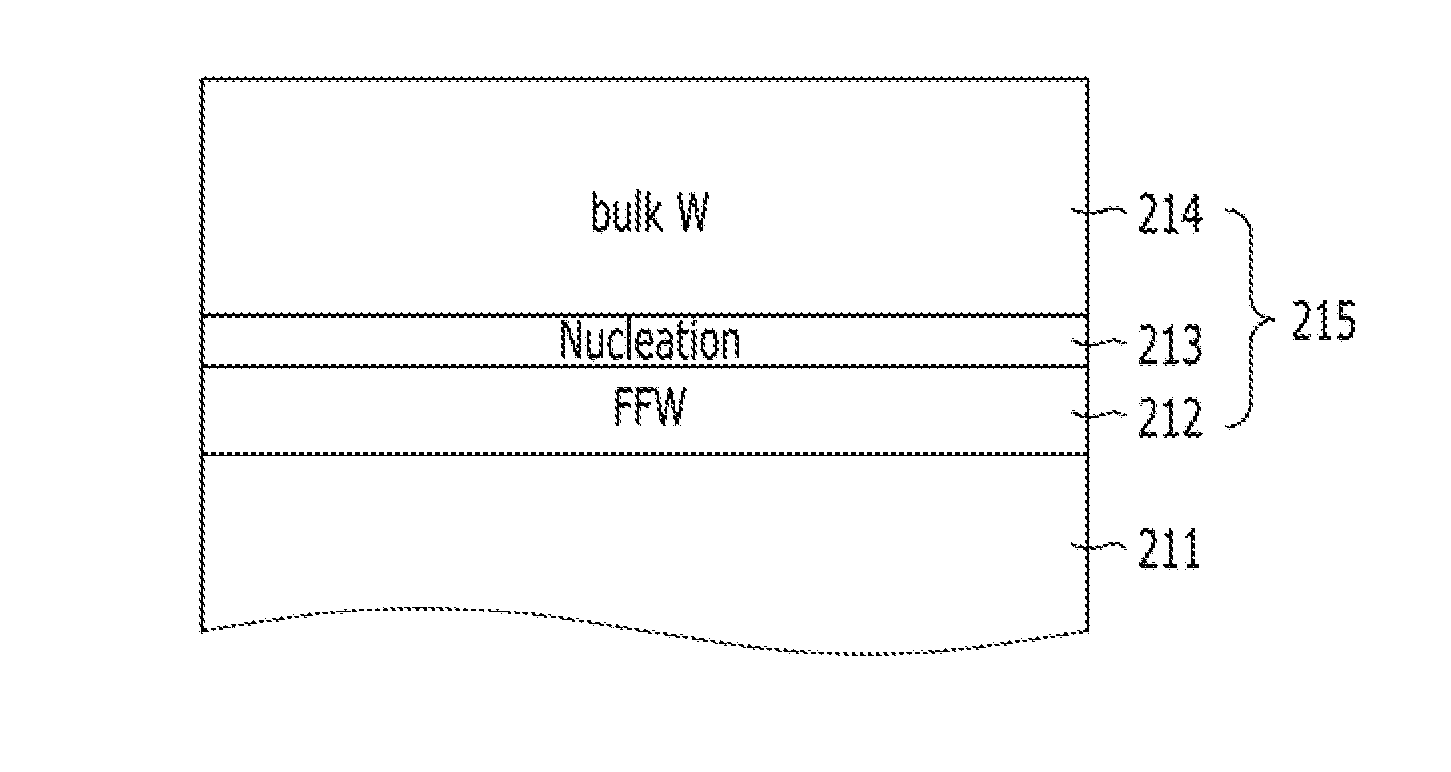

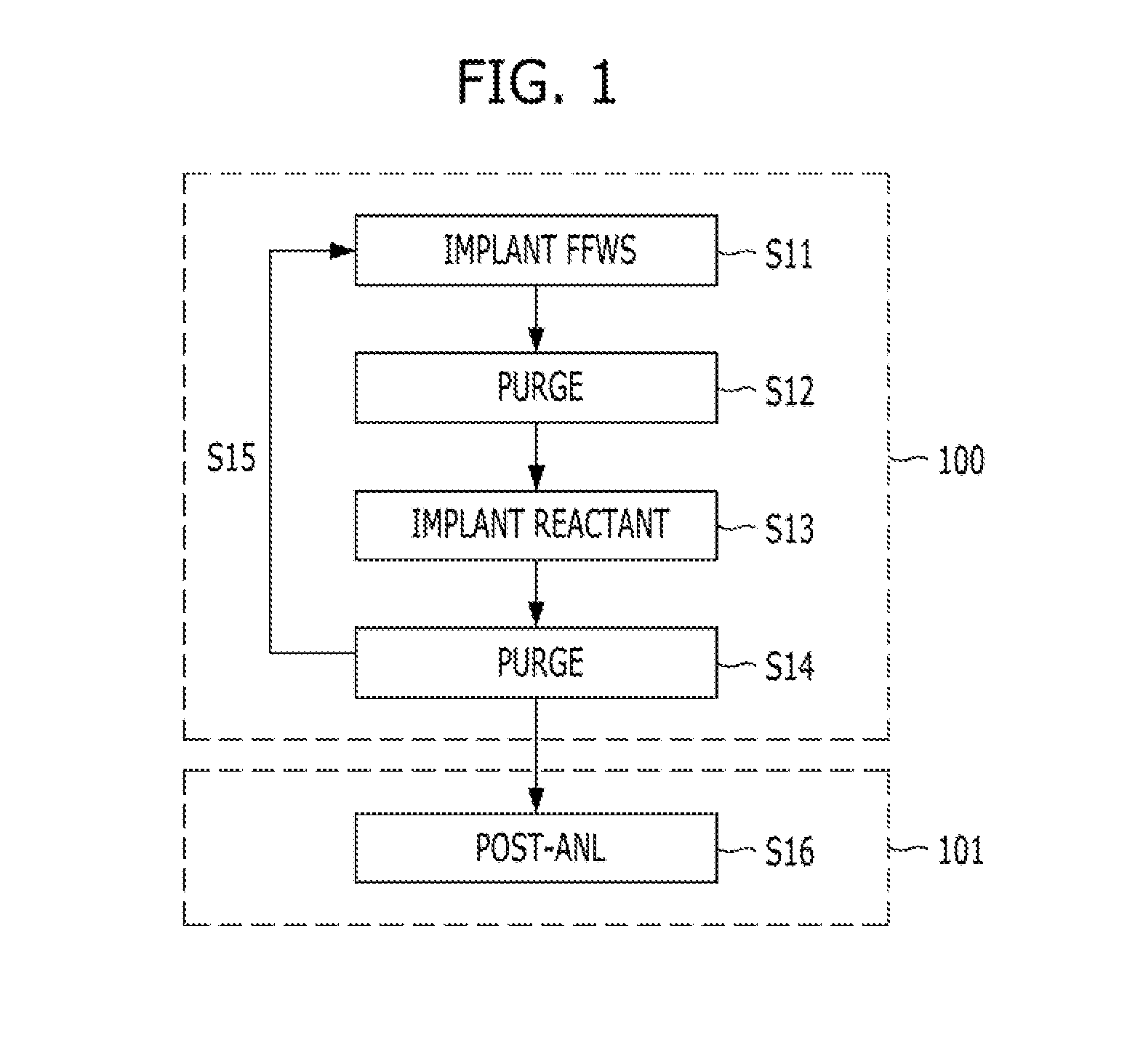

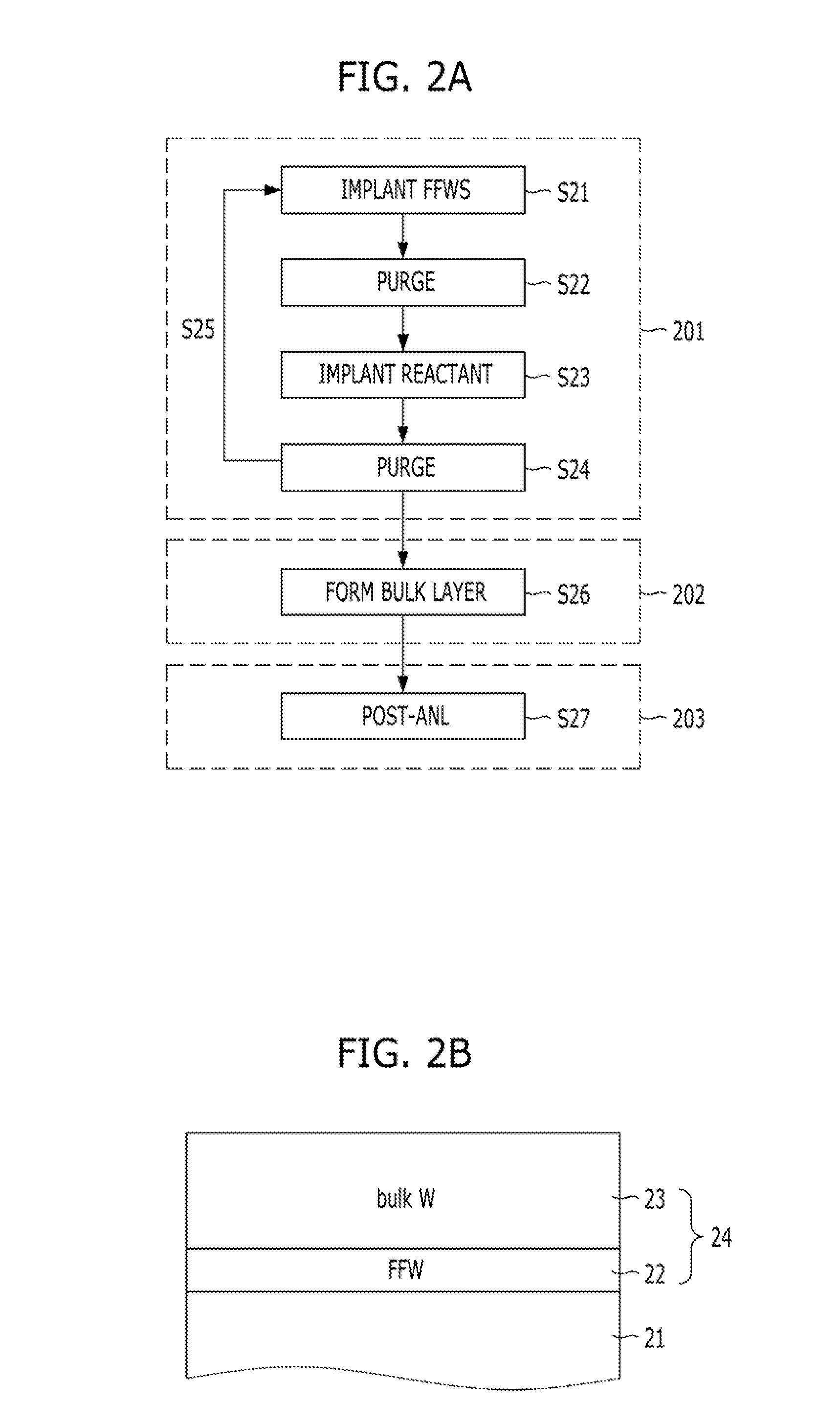

Transistor having tungsten-based buried gate structure, method for fabricating the same

ActiveUS20150228491A1Lower resistanceSemiconductor/solid-state device manufacturingSemiconductor devicesGate dielectricTungsten

A method for fabricating a transistor that includes forming a trench in a substrate, forming a gate dielectric layer on a surface of the trench, forming a first fluorine-free tungsten layer as an interface stabilization layer over the gate dielectric layer, forming a second fluorine-free tungsten layer as a barrier layer over the first fluorine-free tungsten layer, forming a bulk tungsten layer as a gate electrode over the second tungsten layer to fill the trench, and selectively recessing the third tungsten layer, the second tungsten layer and the first tungsten layer to form a buried gate structure.

Owner:SK HYNIX INC

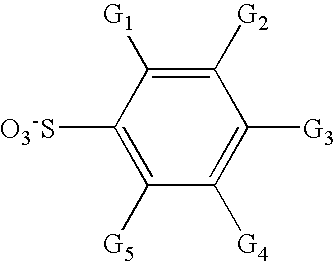

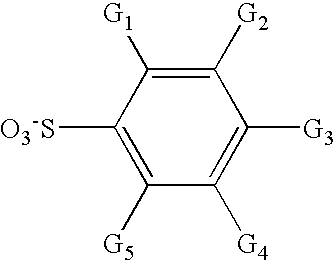

Aromatic fluorine-free photoacid generators and photoresist compositions containing the same

InactiveUS20090181319A1Good optical clarityImprove thermal stabilityOrganic chemistryOrganic compound preparationSulfonatePhotoacid generator

Fluorine-free photoacid generators and photoresist compositions containing fluorine-free photoacid generators are enabled as alternatives to PFOS / PFAS photoacid generator-containing photoresists. The photoacid generators are characterized by the presence of a fluorine-free aromatic sulfonate anionic component having one or more electron withdrawing groups. The photoacid generators preferably contain a fluorine-free onium cationic component, more preferably a sulfonium cationic component. The photoresist compositions preferably contain an acid sensitive imaging polymer having a lactone functionality. The compositions are especially useful for forming material patterns using 193 nm (ArF) imaging radiation.

Owner:GLOBALFOUNDRIES INC

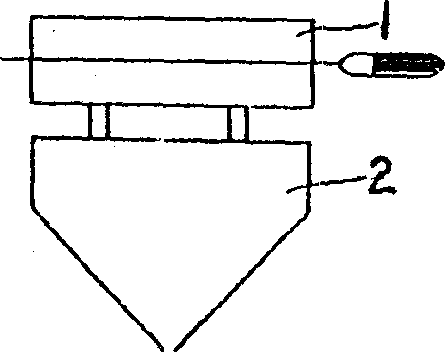

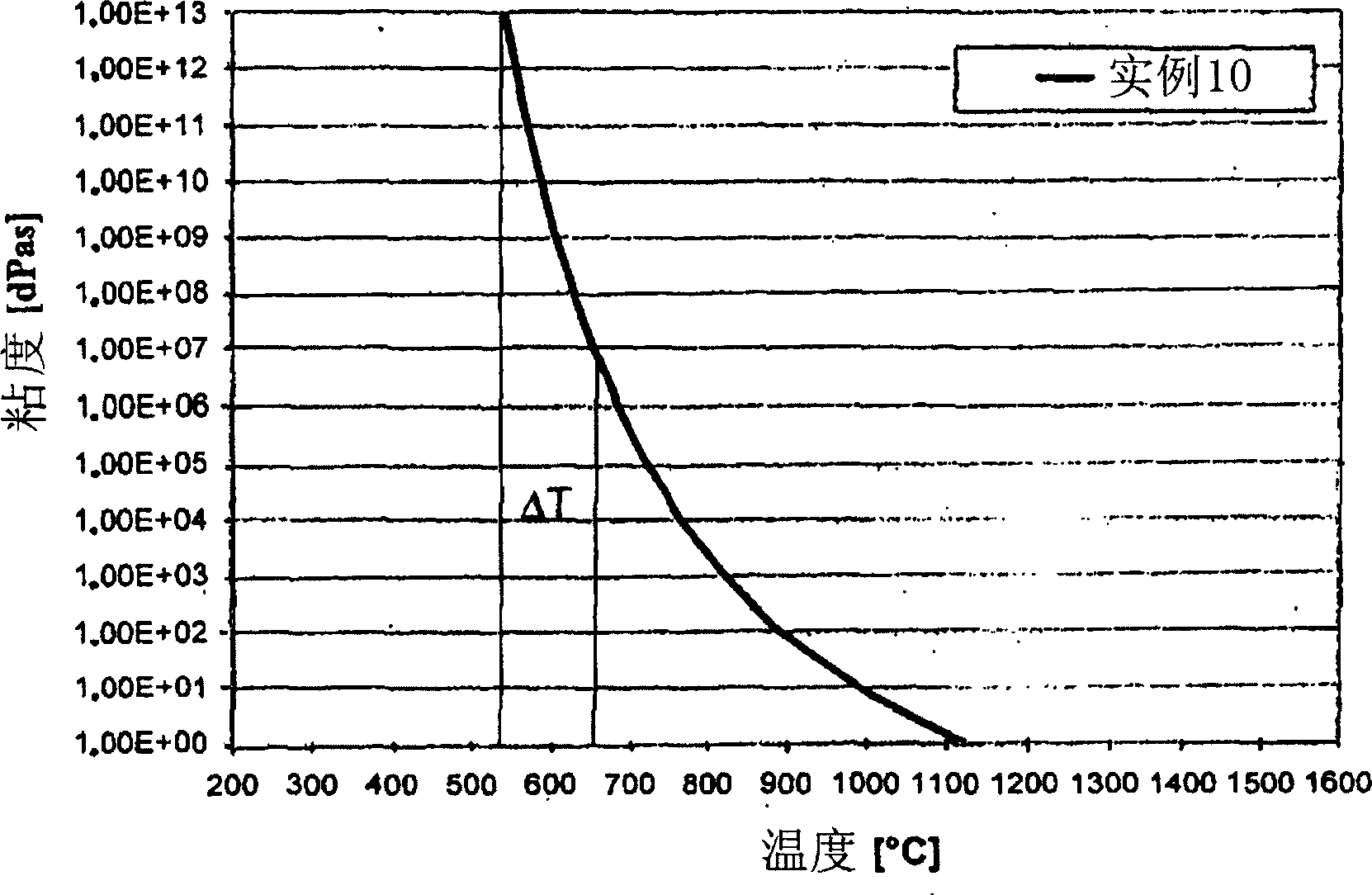

Fluorine free protecting slag for steelmaking and continuous casting and method for manufacturing same

A fruorine-free mold flux for the continuous casting of steel and method for producing the same relates to a mold flux for the continuous casting of new steel grade, which accord with the requirement of protecting natural environment. The characteristic is in that the mold flux contains the fellowing compositions and performance range: 23-40% SiO2, 20-4-% CaO, 0.5-10% MgO, 0.5-10% Al2O3, 0.5-10% MnO2, 2-15% Na2O, 5-15% B2O3, and 0.5-10% C; the melting point is 800-1200 DEG C, the viscosity is 0.2-5 pt, and the crystallizer rate is 0.1-30%. The advantages of the invention are in that the fruorine-free mold flux can alternatively act the role of the fluorine component, according with the continuous casting conditions (steel grade, casting speed, and the like). In this way, uniform fusing characteristic, fluidity and viscosity are improved or promoted, and the mold flux is contributed to the improvement of the operational stability and the product quality with the smooth workability in the continuous casting process by singly or in combination use.

Owner:SANYI METALLURGICAL MATERIAL

Fluoride-free waterproof agent, preparation method and textile

InactiveCN103572602AHigh molecular weightHigh melting pointFibre treatmentPolymer scienceFunctional monomer

The invention discloses a fluoride-free waterproof agent. The fluoride-free waterproof agent comprises the following components according to mass percent: 10%-20% of fluoride-free hydrophobic polymer, 10%-20% of (modified) polyethylene wax, 1%-10% of surfactants, 0.001%-10% of auxiliaries and the balance being water, wherein the fluoride-free hydrophobic polymer is formed through free radical polymerization of fluoride-free hydrophobic monomers with hydrocarbon hydrophobic groups and double bonds and functional monomers; the functional monomers are selected from one or more of monomers with a functional group besides double bonds; the (modified) polyethylene wax is selected from polyethylene wax and oxidized polyethylene wax with the softening point of above 100 DEG C; free radicals are generated by thermal decomposition of initiators. The fluoride-free waterproof agent provided by the invention has a good waterproof effect, does not contain fluorine and has an environment-friendly effect. Compared with the prior art, adopting the (modified) polyethylene wax with a high melting point, the fluoride-free waterproof agent has a better waterproof effect.

Owner:DYMATIC CHEM

Semiconductor device including fluorine-free tungsten barrier layer and method for fabricating the same

ActiveUS20140061931A1Low resistivitySemiconductor/solid-state device detailsSolid-state devicesDiffusion barrierSemiconductor

A method of forming a fluorine-free tungsten diffusion barrier layer having a reduced resistivity, and a semiconductor device, and method for forming such semiconductor device, using the fluorine-free tungsten diffusion barrier layer.

Owner:SK HYNIX INC

Freon-free super hydrophobic UV resistant cotton fabric and method for preparing same

The invention belongs to the field of water repellent finishing and processing of fabric, and particularly relates to freon-free super hydrophobic UV resistant cotton fabric and a method for preparing the same. The freon-free super hydrophobic UV resistant cotton fabric is prepared by padding a fabric with nanometer titanium dioxide sol and processing the fabric by using a long-chain freon-free alkyl compound. The titanium dioxide content of the titanium dioxide sol is 0.2 to 5.0 weight percent, and the number of long-chain carbon atoms of the long-chain freon-free alkyl compounds is 6 to 18. The contact angle between the prepared cotton fabric and water drops is over 150 degrees, so that the cotton fabric has a super hydrophobic property; and the UV resistant factor of the prepared cotton fabric is over 50+, so that the cotton fabric has high UV resistance.

Owner:SHAANXI UNIV OF SCI & TECH

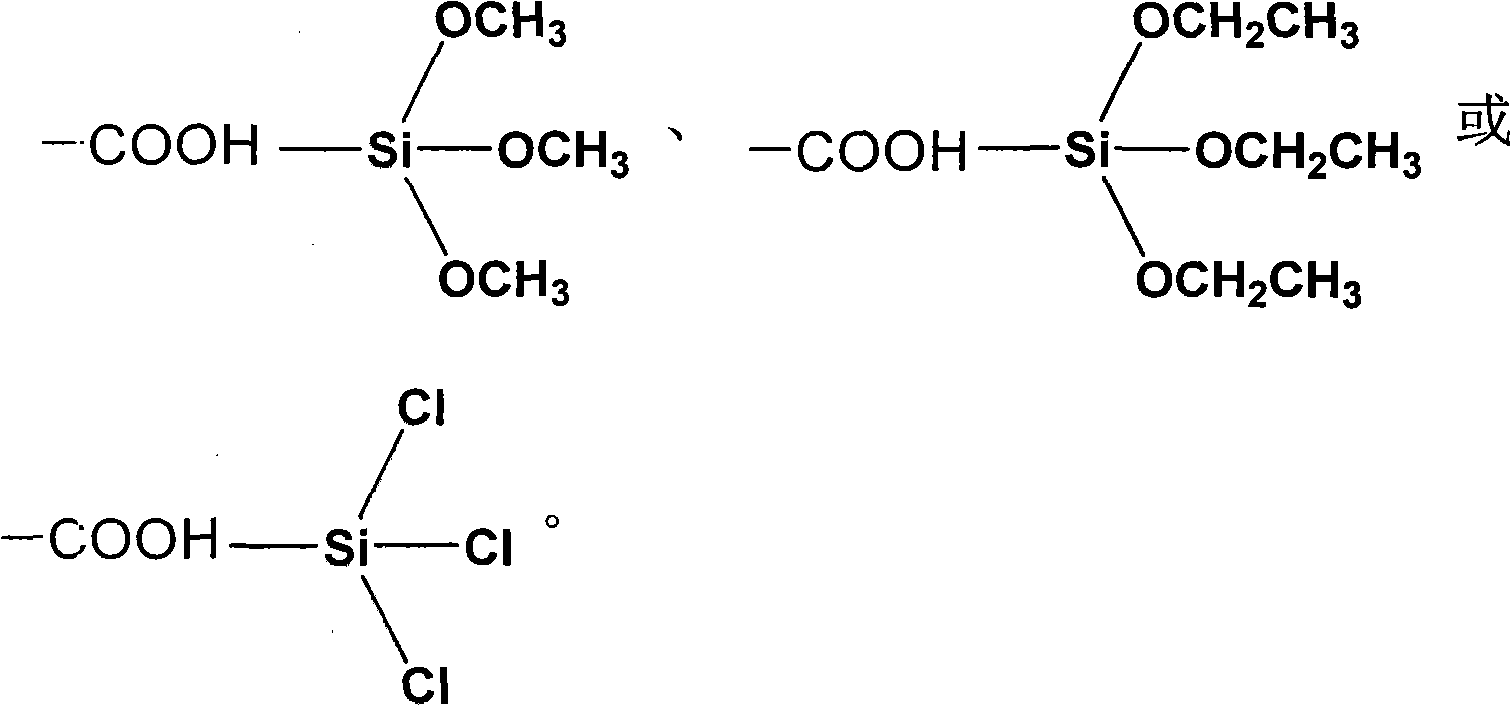

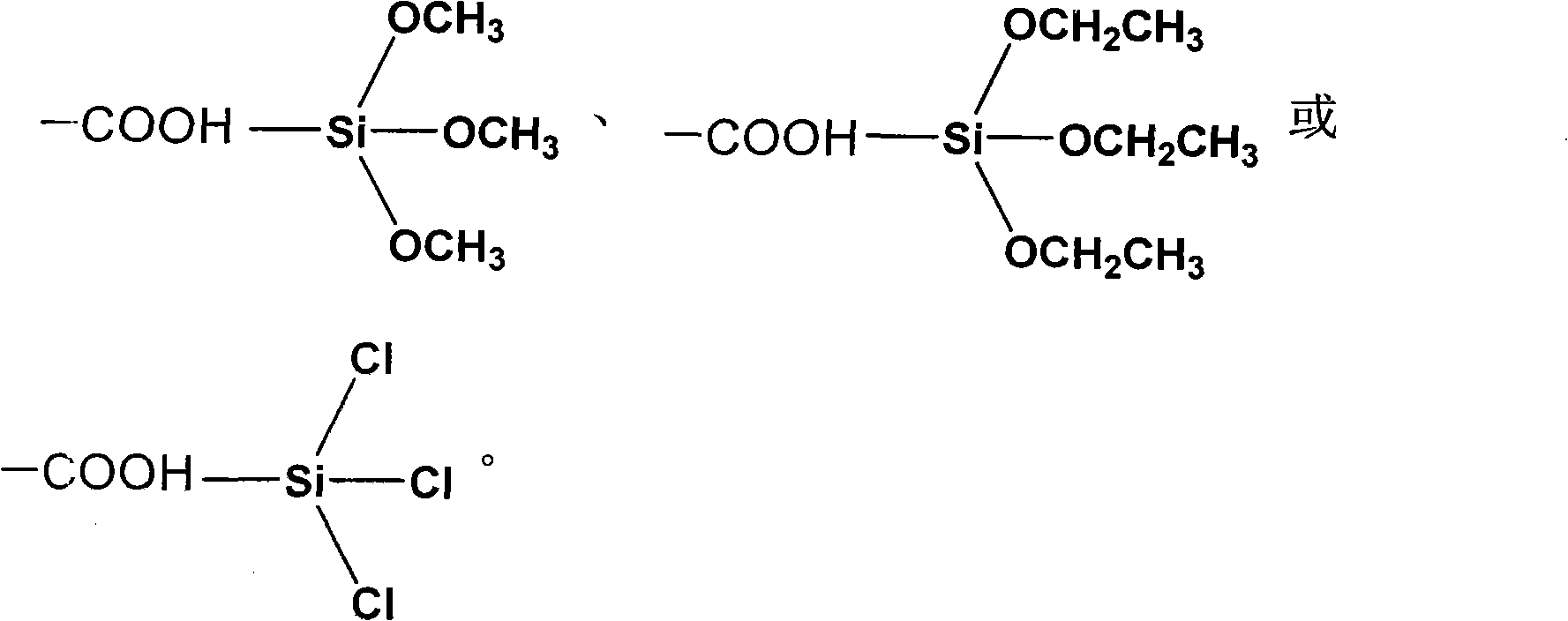

Fluorine-free nano durable super hydrophobicity finishing method for cellulose fabric

InactiveCN101591853AEasy to prepareThe preparation method is safeVegetal fibresCelluloseOrganic acid

The invention relates to a fluorine-free nano durable super hydrophobicity finishing method for cellulose fabric, which comprises the following steps: (1) preparing hydrous medium solution containing tetra-alkyl ester silicate, polycarboxylic acid and a crosslinked catalyst, oscillating and stirring the hydrous medium solution to obtain SiO2 sol, soaking and rolling the cellulose fabric twice respectively, and curing the cellulose fabric; and (2) preparing non-aqueous solvent solution of alkyl siloxane catalyzed and hydrolyzed by using inorganic acid or organic acid water solution, soaking the cellulose fabric in the solution, and curing the cellulose fabric. The method is simple and safe, has low performance requirement on equipment, is easy for industrialization, and is particularly applicable to the hydrophobicity finishing of the cellulose fabric.

Owner:DONGHUA UNIV

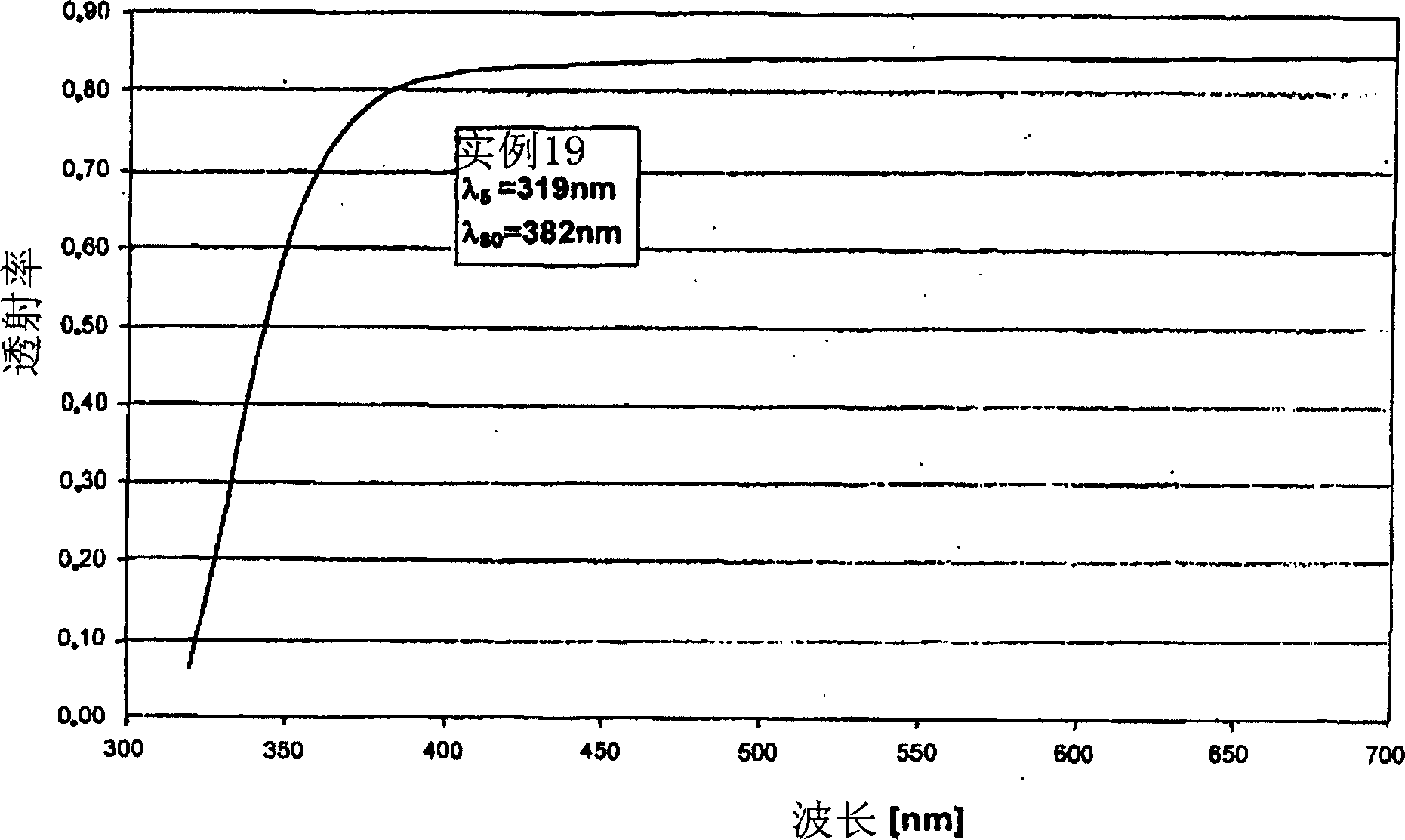

Lead and arsenic free optical lanthanum borate glass

The present invention describes lead and arsenic free and preferably gadolinium and further preferably also fluorine free optical glasses for the application fields mapping, projection, telecommunication, optical communication engineering, mobile drive and / or laser technology with a refractive index of 1.75<=Nd<=1.85, an Abbe number of 34<=Vd<=44 and have a low transformation temperature, namely lower than or equal to 560 DEG C. and preferably lower than or equal to 550 DEG C., as well as good producability and processability and crystallisation stability. The glasses according to the present invention within the following composition range (based on oxide in % by weight) contain the following component B2O3, ZnO, La2O3, Ta2O5.

Owner:SCHOTT AG

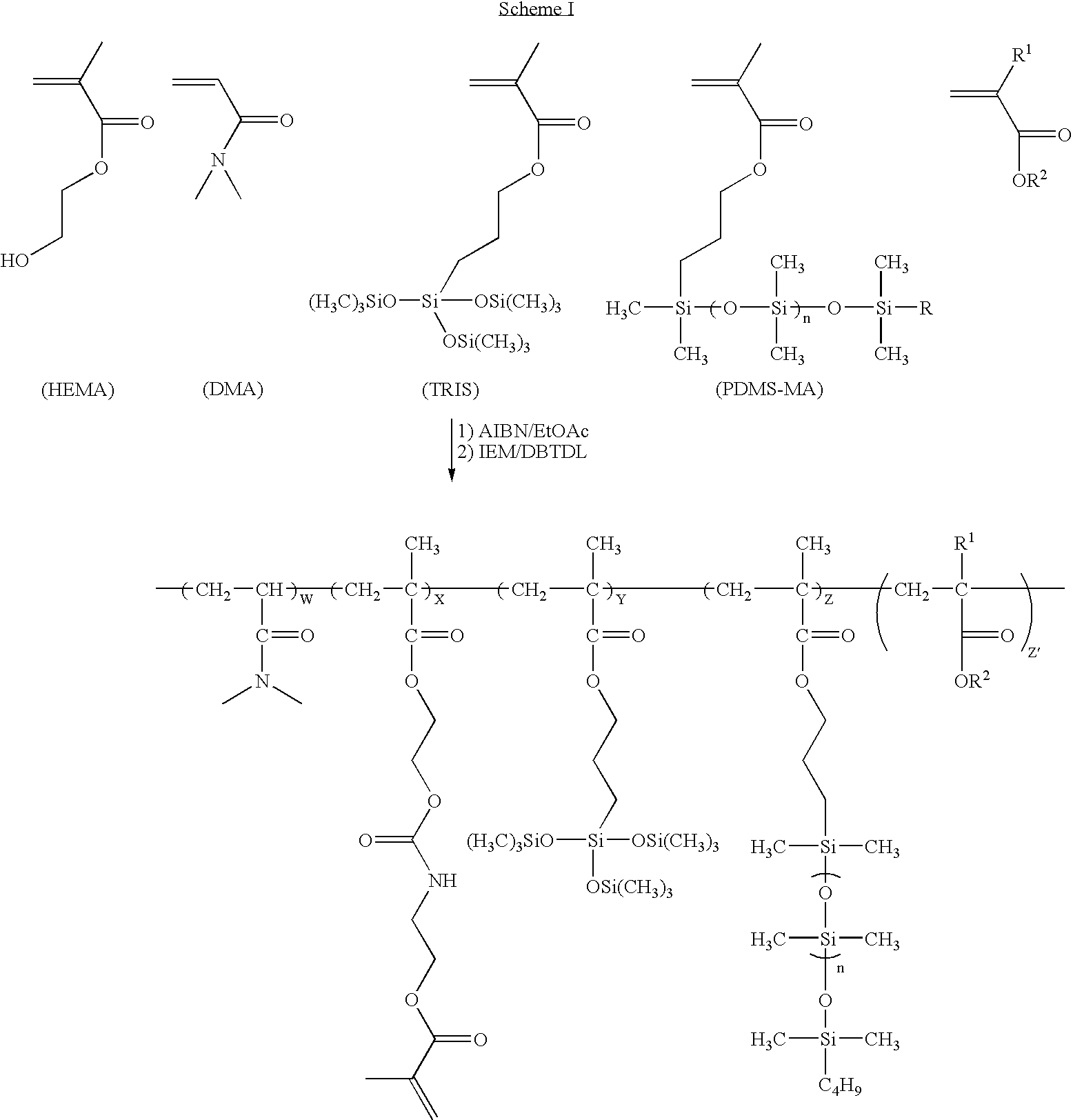

Actinically curable silicone hydrogel copolymers and uses thereof

The present invention provides inks and methods for making colored silicone hydrogel contact lenses. The ink of the invention comprises an actinically-curable binder copolymer comprising fluorine-containing segments and is characterized by having capability to be cured actinically or thermally to form a colored film on a molding surface of a mold or a silicone hydrogel contact lens and by having an increased durability in a solvated state in a silicone-hydrogel lens formulation in relation to a control colored film obtained from a control ink including an actinically-curable fluorine-free binder copolymer. The invention also provides methods for making colored silicone hydrogel contact lenses based on print-on-mold processes for producing colored contact lenses.

Owner:ALCON INC

Laminate

The present invention provides a laminate in which at least one fluororesin is used and which is highly impermeable to fuels. The present invention is a laminate having a layer (A) comprising a fluororesin and a layer (B) comprising a fluorine-free organic material, wherein said laminate has a fuel permeation rate of not higher than 1.5 g / m2 / day.

Owner:DAIKIN IND LTD

Lignin and waste rigid foam powder fluorine-free polyurethane heat insulation material and preparing method

InactiveCN101012332AHigh strengthImprove environmental friendlinessOther chemical processesPolyolFoaming agent

The invention discloses non-fluorine polyurethane insulating material and making method, which comprises the following steps: allocating raw material with 10-16% isocyanate, 6-10% polyether polyol, 0.05-0.25% water, 2-.35% foamer, 0.05-0.2% foam-even agent, 0.04-0.08% initiator, 0.1-3% lignin and 0.1-2% waste hard foaming powder; blending each component together under normal temperature and normal pressure; stirring evenly; casting into mould or plastic filling space immediately; foaming; obtaining the product.

Owner:HEILONGJIANG INST OF TECH

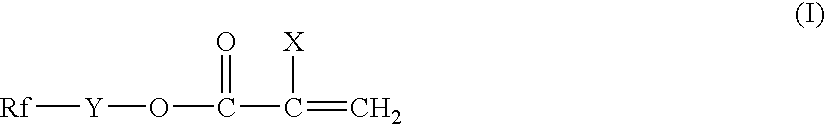

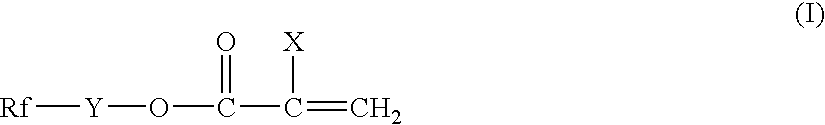

Silicon-containing fluorochemical surface-treating agent

ActiveUS20060134439A1Improve soil resistancePowerful shearing energyOther chemical processesLiquid repellent fibresPolymeric surfacePolymer science

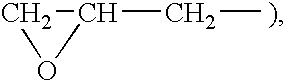

There is provided a surface treatment agent which comprises a fluoropolymer having repeating units derived from a fluorine-containing monomer of the formula: wherein (a) the fluoropolymer contains a silicon atom, and / or (b) the surface treatment agent contains a fluorine-free polymer which is different from the fluoropolymer and which is a silicon-containing polymer. The surface treatment agent imparts excellent water- and oil-repellency and soil resistance to textiles while retaining the feeling of the textiles, even if the surface treatment agent contains a fluorine-containing acrylate polymer substituted at its α-position by a fluorine atom, a chlorine atom or the like.

Owner:DAIKIN IND LTD

Method for comprehensively recycling rare earth and fluorine in process of treating bastnaesite

The invention provides a method for comprehensively recycling rare earth and fluorine in a process of treating bastnaesite. The method comprises the steps of: carrying out oxidizing roasting on the bastnaesite, leaching a roasted mixture by adopting hydrochloric acid to obtain a rare earth chloride solution containing less cerium and fluorine-containing and cerium-rich slag, wherein a roasting additive is added in the bastnaesite in the roasting process and / or a catalytic leaching additive is added in the mixture in a hydrochloric acid leaching process; and then separating and recycling rare earth chloride from the fluorine-containing and cerium-rich slag. According to the method provided by the invention, the consumption of a large quantity of chemical raw materials can be reduced, the pollution to the environment in a use process is greatly reduced, and the production cost is also greatly lowered. According to the method, the procedures of multiple times of solid-liquid separation and the like are eliminated, the process is simplified, the manipulation strength is reduced, the rare earth loss is reduced, the rare earth yield is increased, and especially the hydrochloric acid leaching recycling rate of high-valent non-cerium rare earth is increased. The method provided by the invention realizes fluorine-free emission in the whole process, and has the characteristics of low consumption, high efficiency and the like.

Owner:GRIREM ADVANCED MATERIALS CO LTD

Non-fluorin environment protection opacifiedglass material and method for manufacturing same

InactiveCN101244889AGood opacification effectHigh opacityGlass furnace apparatusGlass furnacePhosphate

The invention relates to a fluorine-free environmental opaque glass material and a preparation method thereof and belongs to the new material field of glass. Composition of the glass material is SiO2-Al2O3-B2O3P2O5-MgO-CaO-SrO-BaO-Li2O-Na2O-K2O. The preparation method comprises that raw materials are mixed to make an even batch, then the batch is put into a corundum crucible, and then the batch is casted and molded after being melted and insulated under 1500 DEG C to 1520 DEG C for 3 hours, and then the batch is insulated and annealed under 550 DEG C to 560 DEG C for 1 hour. The preparation of the invention replaces the fluoride with a small amount of phosphate to generate opaque effect, and no environmental pollution can be caused in the industrial production of the opaque glass, and the short service life of glass furnaces and safety problems caused by fluorine can be avoided, and a compact net structure reconstruction technology is adopted to adjust the relative contents of SiO2 and P2O5, meanwhile, alkali metals or alkaline earth metal oxides are introduced, and the glass produces significant opaque effect under the spontaneous phase separation in the process of cooling, and a small amount of B2O3 is introduced to enhance the opaque effect of the glass, meanwhile, a certain amount of Al2O3 is introduced to endow the glass with excellent chemical stability.

Owner:QILU UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com