Freon-free super hydrophobic UV resistant cotton fabric and method for preparing same

A cotton fabric, super-hydrophobic technology, applied in plant fibers, textiles, papermaking, fiber treatment, etc., can solve the problems of high price of organic fluorine materials, environmental hazards, etc., and achieve good UV protection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

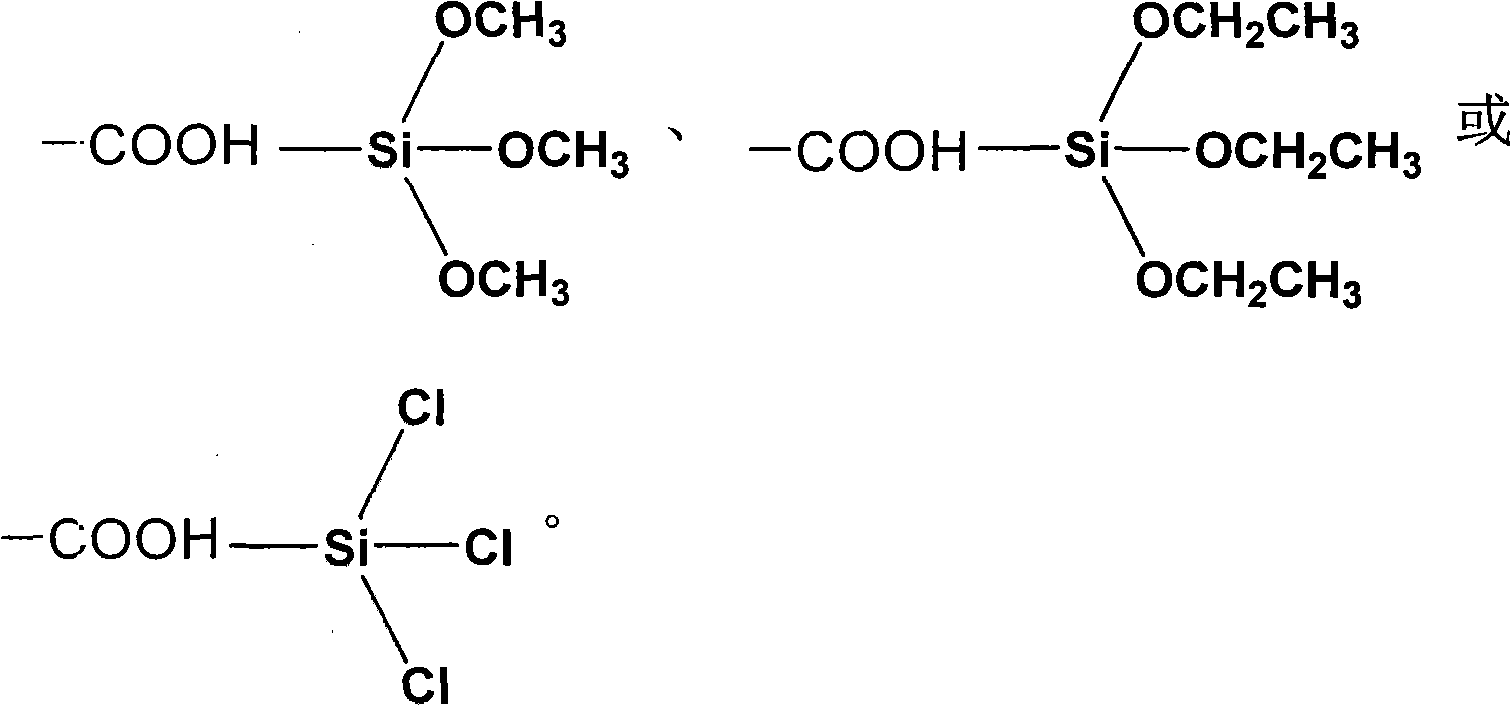

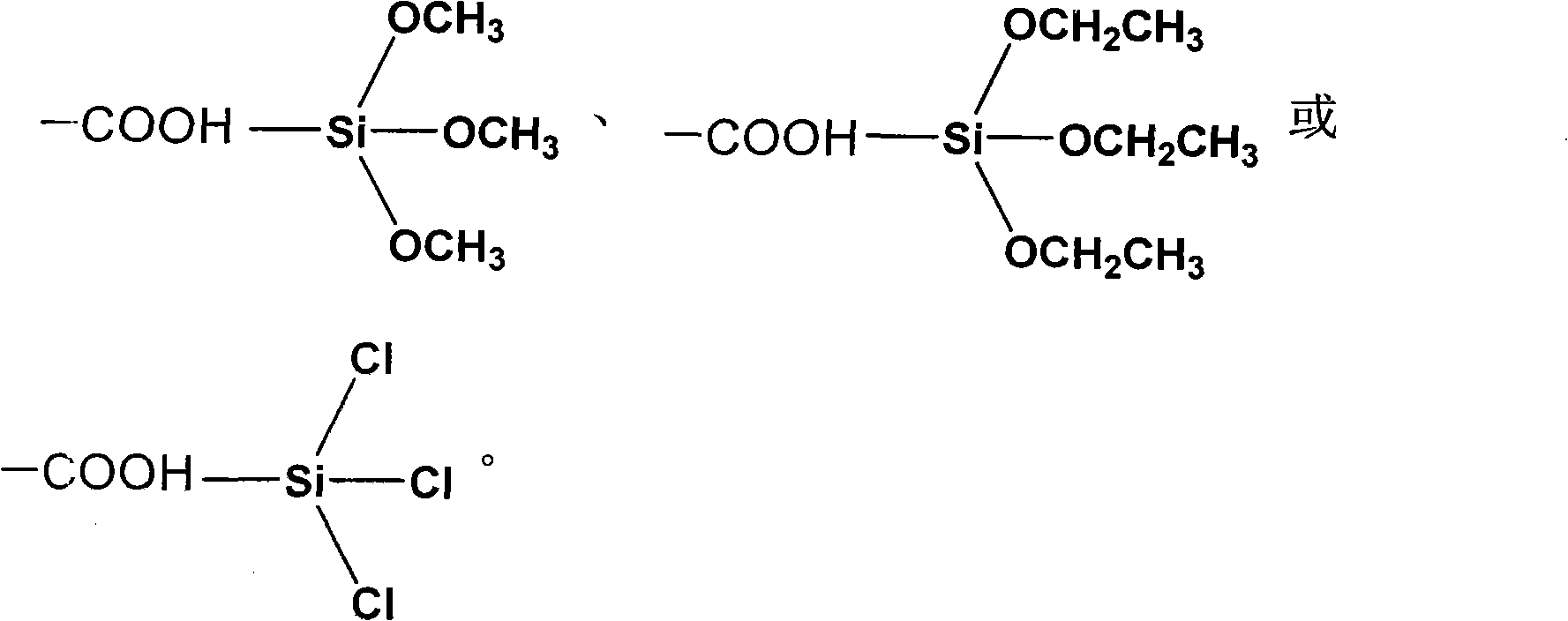

Method used

Image

Examples

Embodiment 1

[0019] Example 1: First, slowly add 8.5 mL of butyl titanate to 20 mL of absolute ethanol under stirring to obtain solution A; stir and mix 1.5 mL of deionized water, 5 mL of acetic acid and 20 mL of absolute ethanol to obtain solution B The A solution is slowly added in the B solution in 1 hour and constantly stirred, and then stirred at room temperature for 24 hours to obtain a transparent light yellow nano-titanium dioxide sol; the mass concentration of titanium dioxide in the nano-titanium dioxide sol is diluted to 0.4%, then the cotton fabric is dipped in the nano-titanium dioxide sol of 0.4% by mass concentration for 8 minutes, and the excess solution is rolled off by a padder, and the excess rate is 80wt%. After repeating the padding process 1 time, the cotton The fabric was baked at 110° C. for 8 minutes; the cotton fabric after padding with nano-titanium dioxide sol was immersed in acetone solution with a mass concentration of 1% stearic acid for 10 minutes, and the re...

Embodiment 2

[0020] Example 2: First, slowly add 10 mL of butyl titanate to 20 mL of absolute ethanol under stirring to obtain solution A; stir and mix 1 mL of deionized water, 4 mL of acetic acid and 20 mL of absolute ethanol to obtain solution B; Solution A was slowly added to solution B within 3 hours and kept stirring, and then stirred at room temperature for 8 hours to obtain a transparent light yellow nano-titanium dioxide sol; dilute the mass concentration of titanium dioxide in the nano-titanium dioxide sol to 2.0% with absolute ethanol , then the cotton fabric is immersed in the nano-titanium dioxide sol with a mass concentration of 2.0% for 5 minutes, and the excess solution is rolled off by a paddle car, and the excess rate is 70wt%. After repeating the padding process 1 time, the cotton fabric is Bake at 150°C for 2 minutes; soak the cotton fabric after padding with nano-titanium dioxide sol in an ethanol solution with a mass concentration of 1.5% dodecyltrimethoxysilane for 10 ...

Embodiment 3

[0021] Example 3: First, slowly add 7 mL of butyl titanate to 20 mL of absolute ethanol under stirring to obtain solution A; stir and mix 2 mL of deionized water, 6 mL of acetic acid and 20 mL of absolute ethanol to obtain solution B; Solution A was slowly added to solution B within 0.5 hours and kept stirring, and then stirred at room temperature for 15 hours to obtain a transparent light yellow nano-titanium dioxide sol; dilute the mass concentration of titanium dioxide in the nano-titanium dioxide sol to 0.2% with absolute ethanol , and then the cotton fabric is immersed in the nano-titanium dioxide sol of 0.2% for 10 minutes, and the excess solution is rolled off by a paddle car, and the excess rate is 75wt%. After repeating the padding process 1 time, the cotton fabric is Bake at 110°C for 10 minutes; immerse the cotton fabric after padding with nano-titanium dioxide sol in an ethanol solution with a mass concentration of 0.5% dodecyltriethoxysilane for 10 minutes, remove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com