Super-hydrophobic aluminium and preparation method thereof

A super-hydrophobic and water-aluminum technology, which is applied in the coating process of metal materials, devices for coating liquid on the surface, special surfaces, etc., can solve the problems of restricting the practical application of metal surfaces, time-consuming, and toxic pollution to the environment during the preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

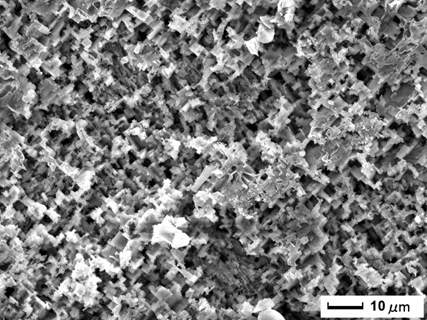

[0021] First, the aluminum sheet was immersed in absolute ethanol and acetone for 10 minutes, then ultrasonically cleaned, then taken out, rinsed with deionized water, and dried with nitrogen to obtain a pretreated aluminum sheet; then the above pretreated aluminum sheet was immersed in a concentration of React in 3.5mol / L hydrochloric acid solution at 45°C for 8 minutes, take it out, wash it with deionized water, then put it in boiling water for 20 minutes, take it out, dry it with nitrogen gas, and get an aluminum surface with a rough structure; Finally, soak the above-mentioned aluminum sheet with a rough structure in 0.01 mol / L perfluorooctanoic acid aqueous solution, take it out after 60 minutes, and dry it with nitrogen to obtain superhydrophobic aluminum.

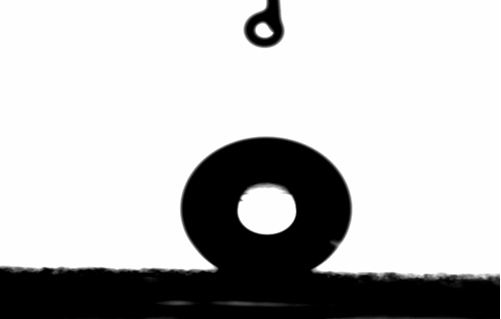

[0022] see figure 1 , using OCAH200 contact angle tester to test the wettability of the aluminum surface, the results show that the contact angle of the surface with water is 168o, and the rolling angle is less than ...

Embodiment 2

[0029] First, the aluminum sheet was immersed in absolute ethanol and acetone for 10 minutes, then ultrasonically cleaned, then taken out, rinsed with deionized water, and dried with nitrogen to obtain a pretreated aluminum sheet; then the above pretreated aluminum sheet was immersed in a concentration of 4mol / L and a temperature of 30 ℃ hydrochloric acid solution for 8 minutes, take it out, wash it with deionized water, then put it in boiling water for 20 minutes, take it out, dry it with nitrogen, and get an aluminum surface with a rough structure; finally Soak the above-mentioned aluminum sheet with a rough structure in 0.008mol / L perfluorooctanoic acid aqueous solution, take it out after 60 minutes, and dry it with nitrogen to obtain a superhydrophobic aluminum surface.

[0030] The wettability of the aluminum surface was tested by OCAH200 contact angle tester, and the results showed that the contact angle between the surface and water was 165°, and the rolling angle was le...

Embodiment 3

[0037] First, the aluminum sheet was immersed in absolute ethanol and acetone for 10 minutes, then ultrasonically cleaned, then taken out, rinsed with deionized water, and dried with nitrogen to obtain a pretreated aluminum sheet; then the above pretreated aluminum sheet was immersed in a concentration of React in 2.5mol / L hydrochloric acid solution with a temperature of 75°C for 8 minutes, take it out, wash it with deionized water, then put it in boiling water for 20 minutes, take it out, dry it with nitrogen, and get an aluminum surface with a rough structure; Finally, soak the above-mentioned aluminum sheet with a rough structure in 0.02 mol / L perfluorooctanoic acid aqueous solution, take it out after 40 minutes, and dry it with nitrogen to obtain a superhydrophobic aluminum surface.

[0038] The wettability of the aluminum surface was tested by OCAH200 contact angle tester, and the results showed that the contact angle between the surface and water was 155o, and the rolling...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roll angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com