Preparation method of super-hydrophobic coating with phase change function

A superhydrophobic coating and superhydrophobic technology, which is applied in the direction of microsphere preparation, coating, microcapsule preparation, etc., can solve the problems of undisclosed preparation methods, achieve superhydrophobic phase change heat preservation, simple preparation method, convenient and large area The effect of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

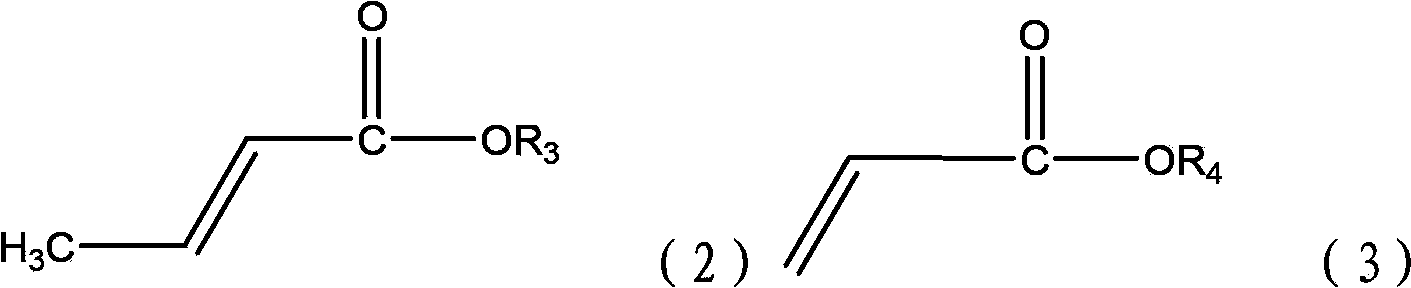

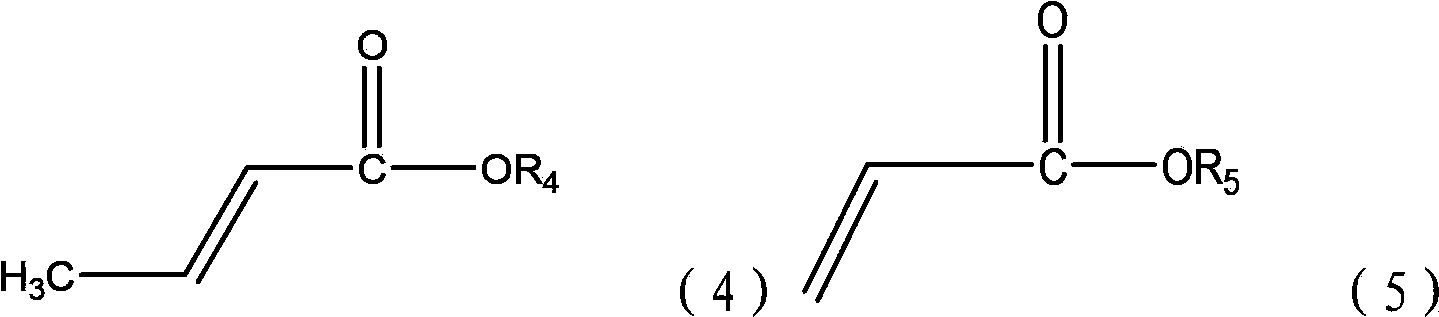

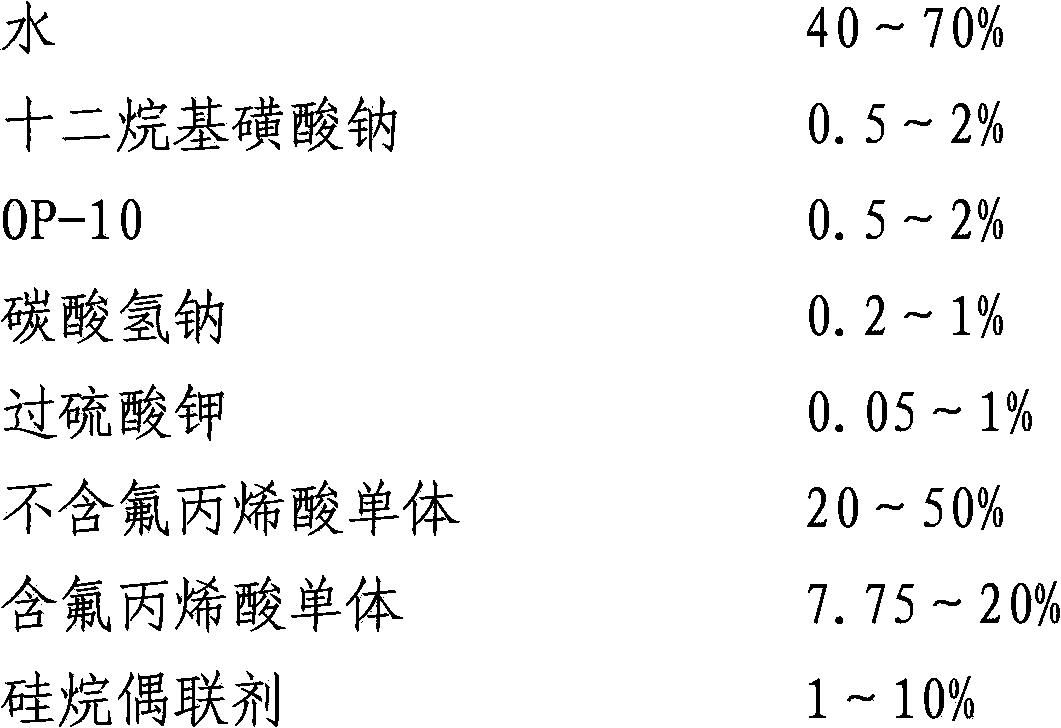

Method used

Image

Examples

Embodiment 1

[0030] 1) Add 20g deionized water, emulsifier (a mixture of 0.08g sodium dodecylsulfonate and 0.08g OP-10), 0.2g sodium bicarbonate into a four-neck bottle, heat up to 75°C after isolating oxygen, add 3g of methyl methacrylate and 4g of 0.5% potassium persulfate aqueous solution until a faint blue light appears in the reaction to form a seed emulsion. After keeping warm for 0.5 hours, raise the temperature to 80°C, slowly add a mixture of 3g methyl methacrylate, 3g butyl acrylate and 0.4g hydroxyethyl methacrylate, at the same time, continue to drop 6g of 0.5% potassium persulfate aqueous solution. After the dropwise addition and reaction for 0.5 hours, slowly add 1g methyl methacrylate, 3g butyl acrylate, 0.6g methacryloxypropyl triisopropoxysilane and 4g dodecafluoroheptyl methacrylate dropwise At the same time, continue to dropwise add 12g0.5% potassium persulfate aqueous solution. After the dropwise addition was completed, the reaction was continued for 3 to 4 hours. Th...

Embodiment 2

[0034] 1) Add 20g deionized water, emulsifier (a mixture of 0.06g sodium dodecylsulfonate and 0.06g OP-10), 0.2g sodium bicarbonate into a four-neck bottle, heat up to 75°C after isolating oxygen, add 2g of methyl methacrylate and 3g of 0.5% aqueous solution of potassium persulfate until a faint blue light appears in the reaction to form a seed emulsion. After 0.5 hours of heat preservation, the temperature was raised to 80° C., and a mixture of 3 g of methyl methacrylate and 0.7 g of hydroxyethyl methacrylate was slowly added. At the same time, 6 g of 0.5% potassium persulfate aqueous solution was continued to be added dropwise. After the dropwise addition was completed and reacted for 0.5 hours, slowly add dropwise a mixture of 2g methyl methacrylate, 4g butyl acrylate, 1g methacryloxypropyl triisopropoxysilane and 3g trifluorooctyl methacrylate. Mixed solution, at the same time, continue to dropwise add 12g of 0.5% potassium persulfate aqueous solution. After the dropwise ...

Embodiment 3

[0038] 1) Add 20g of deionized water, emulsifier (a mixture of 0.08g of sodium dodecylsulfonate and 0.08g of OP-10), and 0.2g of sodium bicarbonate into a four-necked bottle, and heat up to 75°C after blocking oxygen, and add 3g of methyl methacrylate and 4g of 0.5% potassium persulfate aqueous solution until a faint blue light appears in the reaction to form a seed emulsion. After 0.5 hours of heat preservation, the temperature was raised to 80° C., and a mixture of 6 g of butyl methacrylate and 1 g of hydroxyethyl methacrylate was slowly added. At the same time, 6 g of 0.5% potassium persulfate aqueous solution was continued to be added dropwise. After the dropwise addition was completed and reacted for 0.5 hours, a mixed solution of 6g butyl methacrylate, 2g vinyltriethoxysilane and 4g trifluorooctyl methacrylate was slowly added dropwise, and at the same time, 12g0. 5% potassium persulfate in water. After the dropwise addition was completed, the reaction was continued for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com