Patents

Literature

31results about How to "Atomic radius is large" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

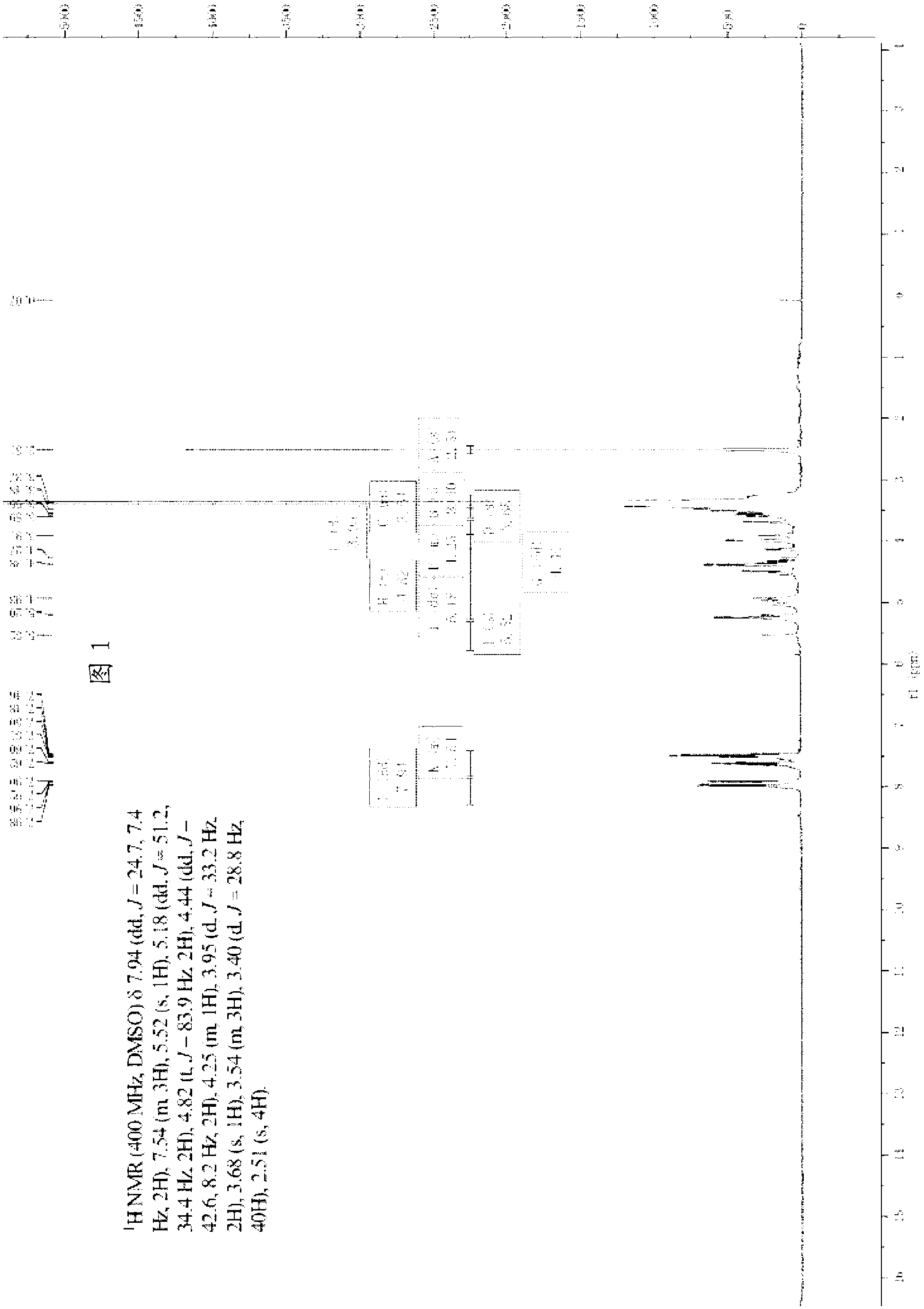

Silicon-containing fluorine conjugated polymer and its preparing process and application

ActiveCN101148495AHigh electron mobilityHigh photothermal oxidation stabilityFinal product manufactureSolid-state devicesHigh energyField-effect transistor

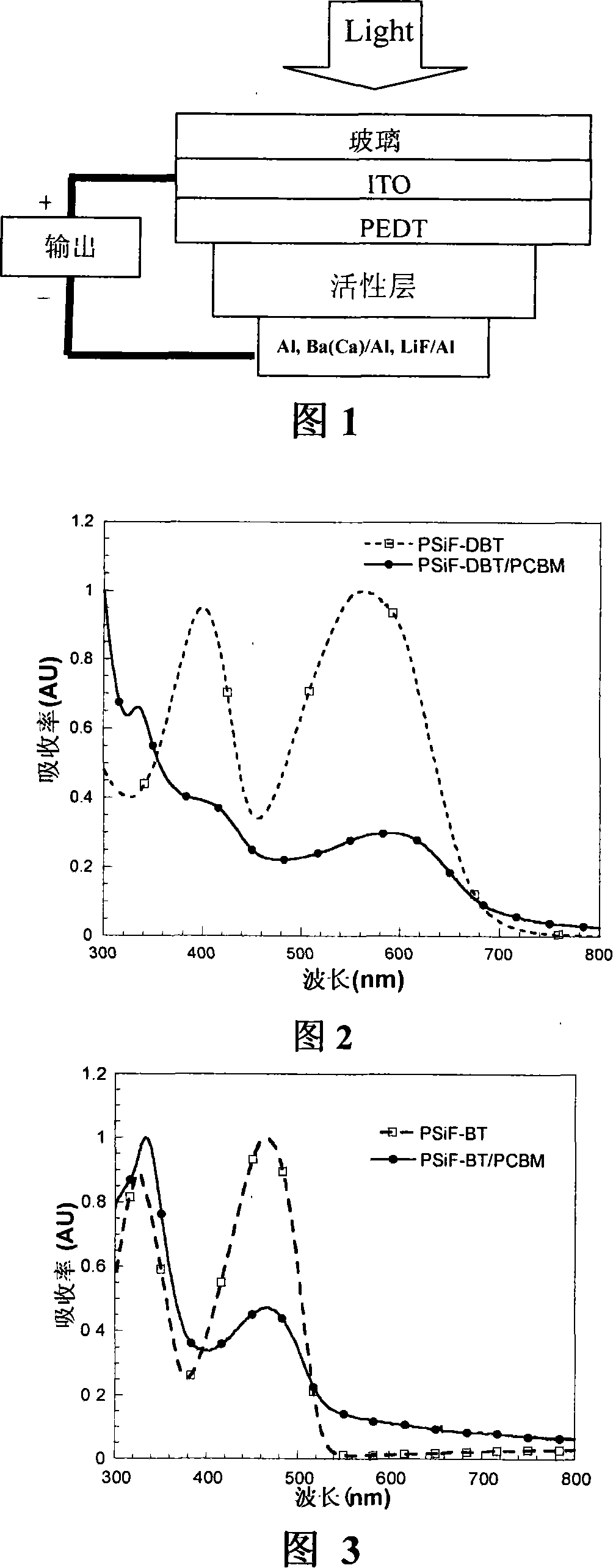

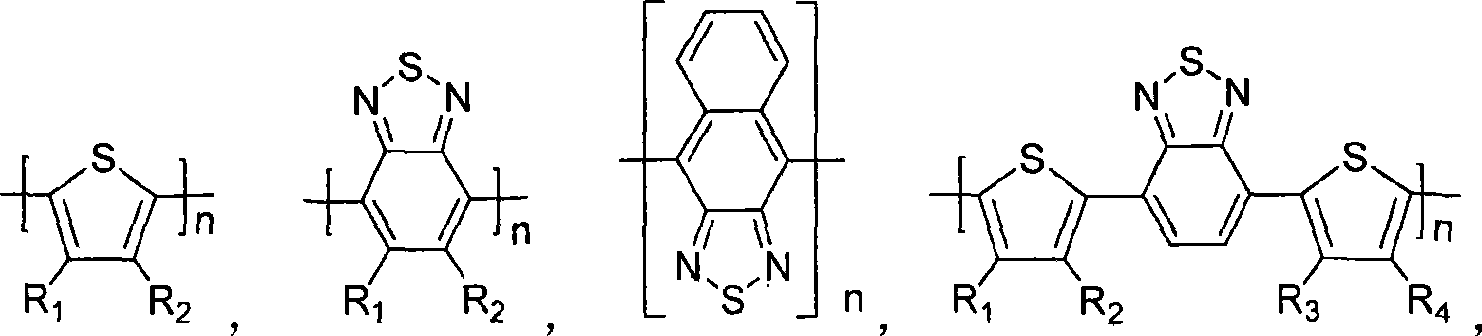

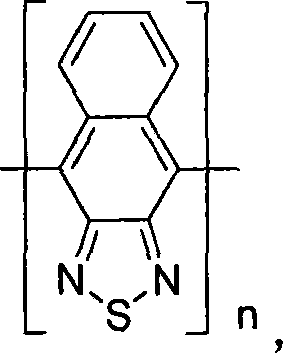

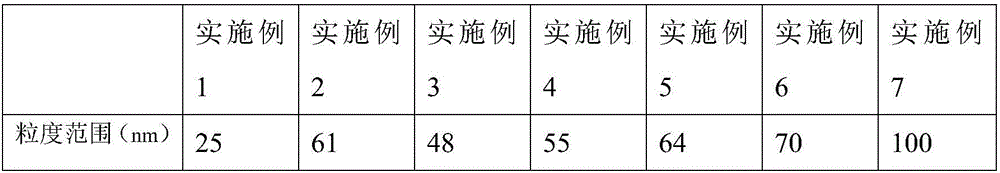

The present invention relates to silico fluorene copolymer and its application. The silico fluorene copolymer is copolymer of 2, 7-silico fluorine and narrow band gap monomer, and has absorption spectrum with absorption side band greater than 500 nm and absorption band side expanded to red light and near infrared region. It is prepared through copolymerizing 2, 7-silico fluorine and narrow band gap monomer containing hetero N and / or S atoms. It may be applied in making polymer solar cell, FET, etc. It has high mobility, high long-term stability and high energy converting efficiency.

Owner:SOUTH CHINA UNIV OF TECH

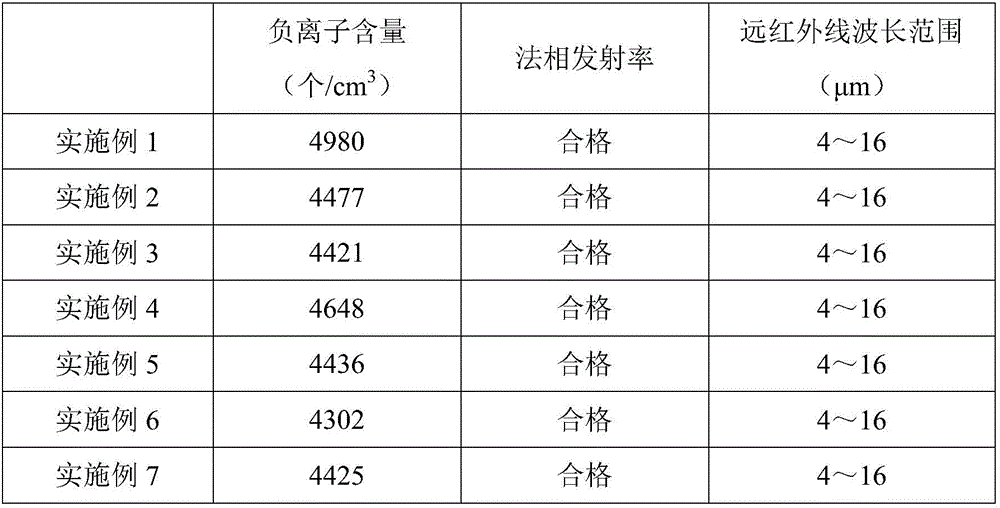

Negative ion far infrared nanometer multifunctional material

ActiveCN106726628AImprove the ability of ionized air to generate negative ionsImprove the ability to generate negative ionsCosmetic preparationsToilet preparationsInfraredAir Ionization

The invention provides a negative ion far infrared nanometer multifunctional material, which comprises the following ingredients in parts by weight: 1 to 86 parts of ore powder, 1 to 115 parts of rare earth powder and 1 to 200 parts of silica gel. The functional material provided by the invention has the advantages that on the basis of the prior art, the functional material capable of obviously improving the capability of generating negative ions of ore and rare-earth salts through air ionization is provided; on the other hand, the infrared ray releasing capability of the ore and the rare-earth salts can be obviously improved.

Owner:惠州市申天地生物科技有限公司

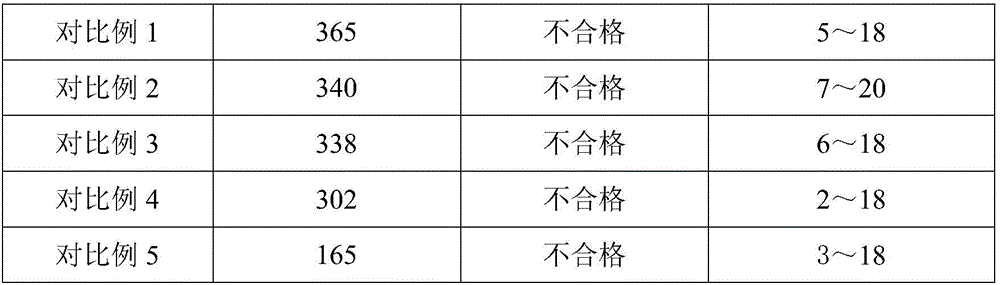

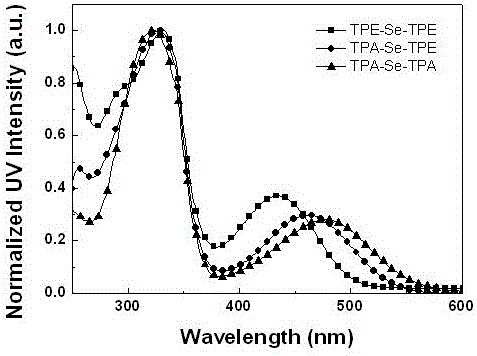

Preparation method and application of 2,1,3-benzoselenadiazole derivative

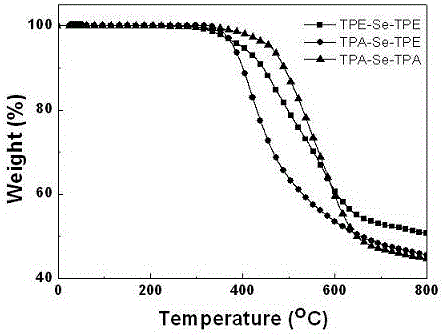

InactiveCN106831650AAtomic radius is largeLow electronegativityOrganic chemistrySolid-state devicesOrganic electroluminescenceQuenching

The invention discloses a preparation method and application of 2,1,3-benzoselenadiazole derivative. The derivative is TPE-Se-TPE, TPA-Se-TPE or TPA-Se-TPA, i.e., tetraphenyl ethylene (TPE) and / or triphenylamine group (TPA) are respectively introduced on a 4 position and a 7 position of the 2,1,3-benzoselenadiazole derivative. The prepared 2,1,3-benzoselenadiazole derivative has the advantages that the phenomena of aggregation and quenching can be effectively avoided, the properties of aggregation, induction and luminescence are achieved, and the luminescence efficiency of the material can be obviously enhanced, so that the 2,1,3-benzoselenadiazole derivative can be applied to an organic electroluminescence device as a luminescent layer.

Owner:JIANGXI NORMAL UNIVERSITY

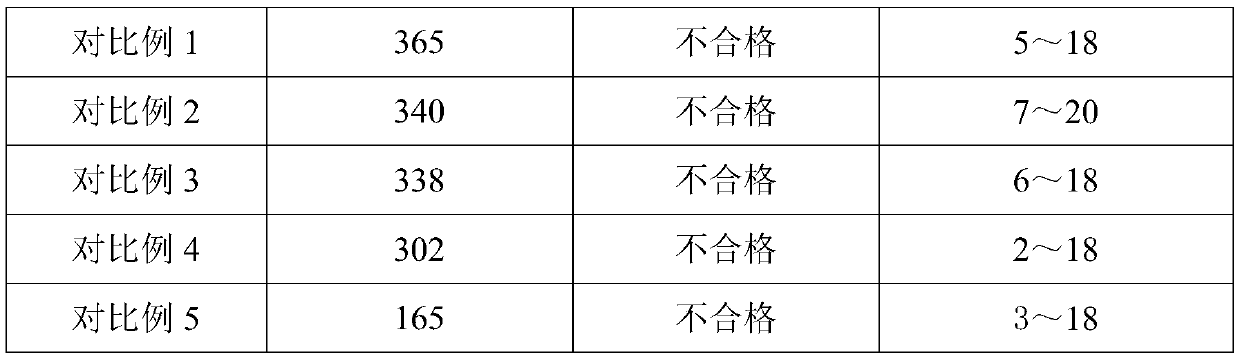

Method for carrying out bonding epitaxial wafer and silicon wafer by indium (In)

InactiveCN102569031AImprove performanceLow melting pointSemiconductor/solid-state device manufacturingIndiumWafer bonding

The invention discloses a method for carrying out epitaxial wafer and silicon wafer bonding by indium (In). The method comprises the steps as follows: an indium (In) layer is deposited on the silicon wafer where a gold (Au) layer is evaporated, and the gold (Au) layer is evaporated on the epitaxial wafer where a reflecting mirror layer is deposited; the two wafers (the indium (In) layer in the middle) face relatively and are put into a bonding machine for bonding, so as to prepare an LED (light-emitting diode) device with the advantages of high efficiency, high brightness, low resistance and steady performance. The epitaxial wafer and silicon wafer bonding is carried out by the method, the bonding area is compact and hole-free, the bonding strength is high, and the bonding rate can reach above 98%. The bonding area of a prepared substrate slice has no pollution layer, polycrystalline layer or oxide layer, so that the performance of the prepared light-emitting diode device is greatly improved.

Owner:BEIJING TIMES HAODING TECH

Method for preparing rhodium-containing catalyst and catalyst prepared according to method

ActiveCN107051438AAtomic radius is largeReduce entryGas treatmentDispersed particle separationSlurryRaw material

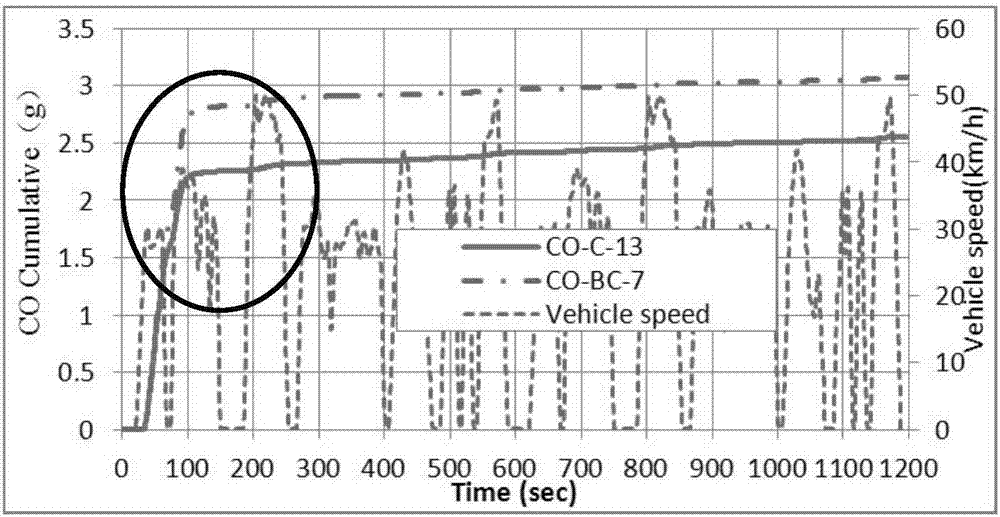

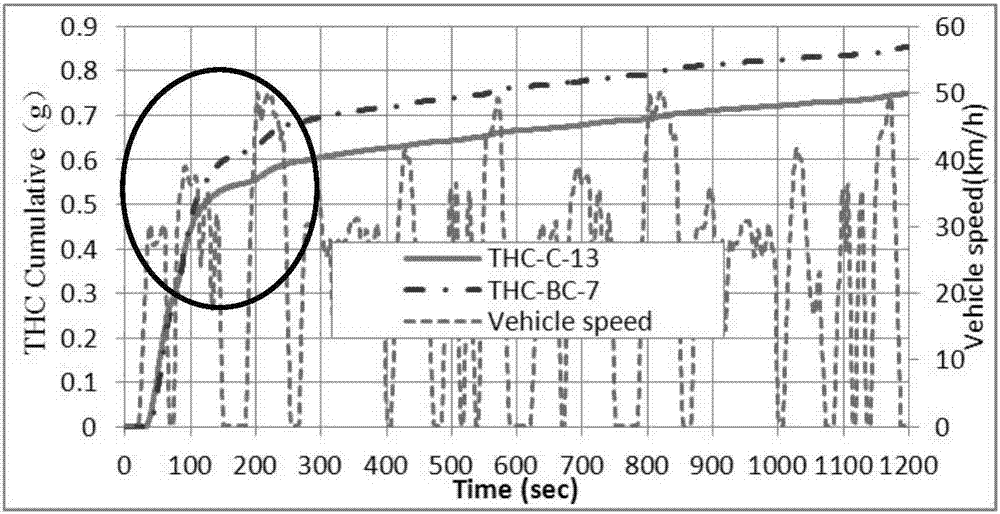

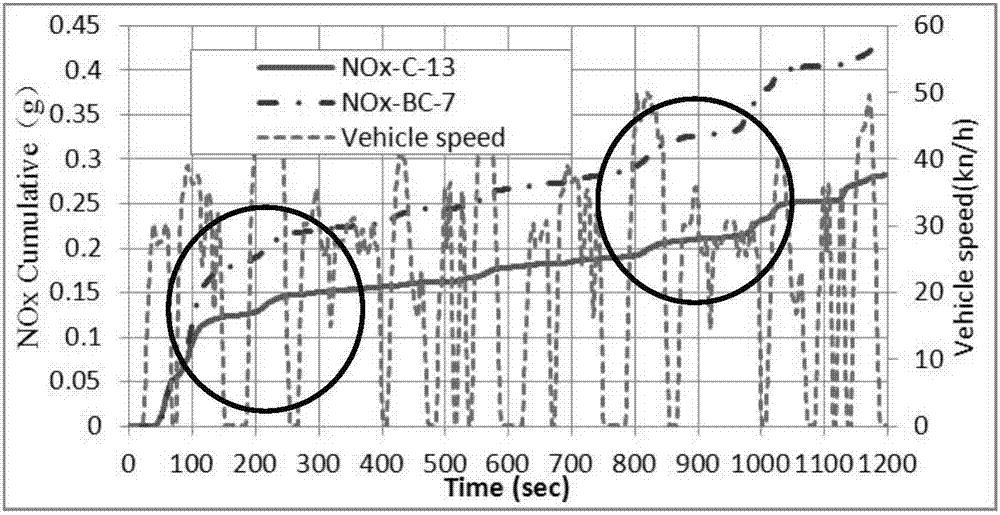

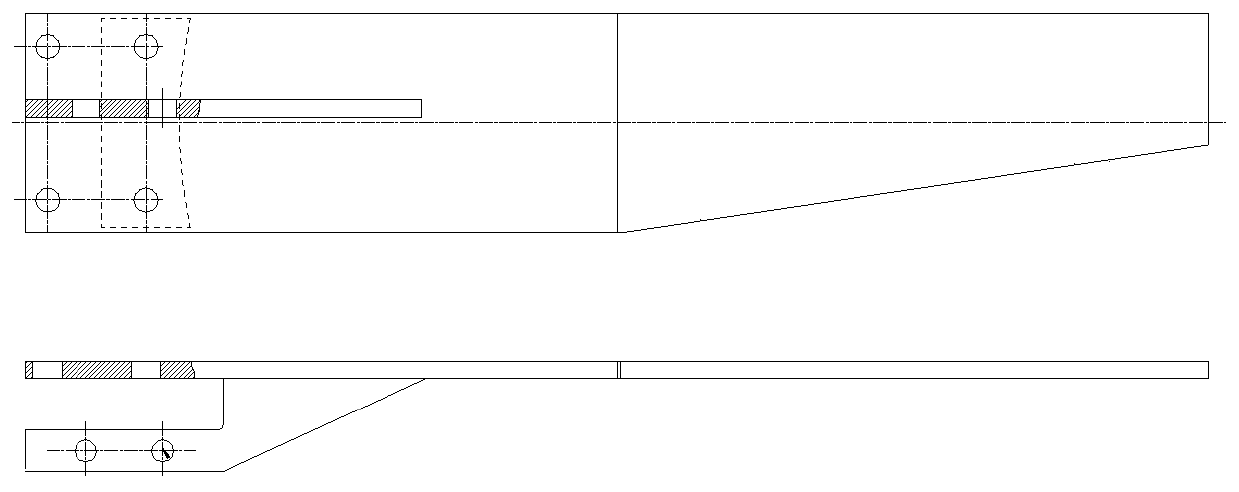

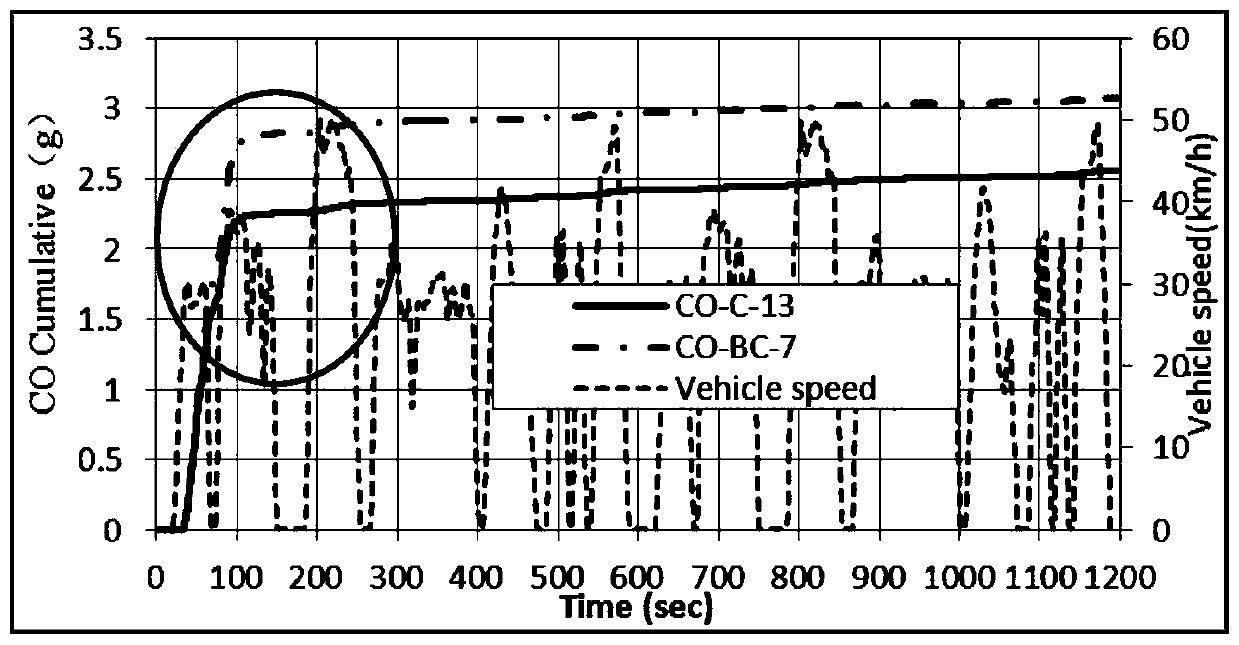

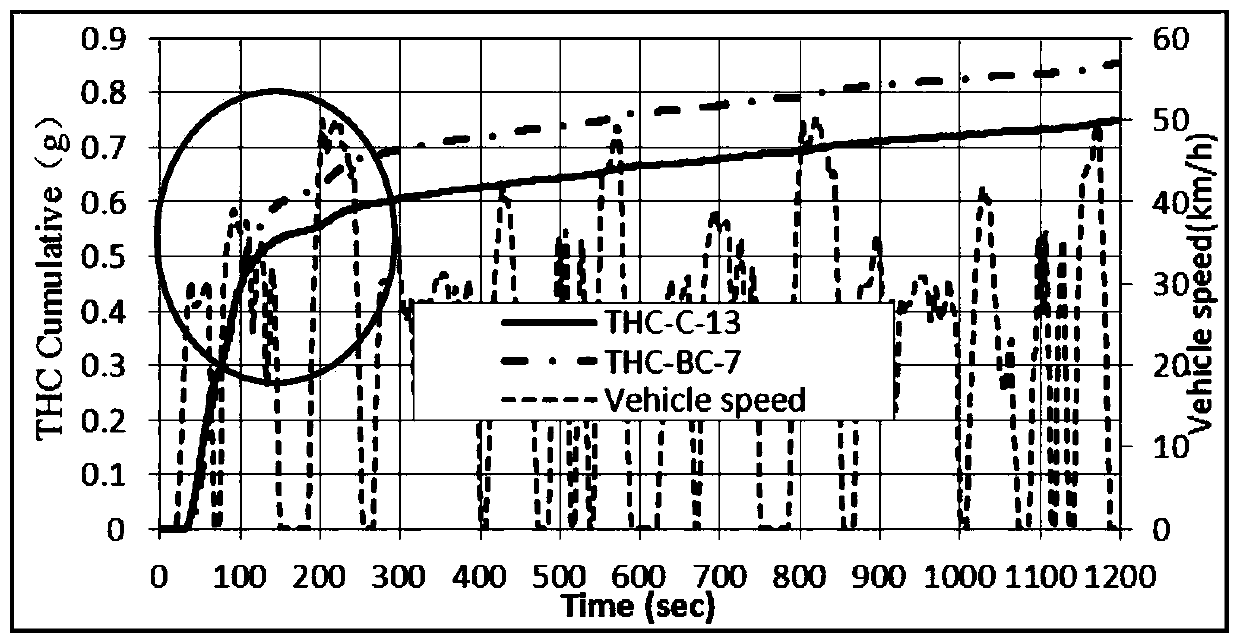

The invention discloses a high-performance rhodium-containing catalyst and a preparation method thereof. The catalyst disclosed by the invention is composed of a matrix and a catalyst coating, wherein the surface of the matrix is coated with the catalyst coating; the catalyst coating is composed of a catalytic material and precious metals; and the catalyst coating at least comprises a rhodium catalyst layer and can further comprise palladium, platinum or a catalyst layer formed by mixing platinum and palladium at a certain ratio. A method for preparing the rhodium catalyst layer comprises the following steps: concentrating a rhodium solution with the mass percentage concentration of 10% until the mass percentage concentration is 40-100% while continuous stirring at the temperature of 40-90 DEG C; adding alcohol, and reacting for 0.5-5 hours, wherein the solution viscosity is 5-50 Pa.s; and adding an alkanolamine solution, regulating the pH value to be 3.5-10.5, continuously stirring for 5-60 minutes, taking out the rhodium solution and adding into the catalytic material so as to form powder / slurry; coating the matrix with the powder or slurry, thereby obtaining the rhodium catalyst layer. The catalyst prepared according to the preparation method is used for treating motorcycle exhaust or gasoline car exhaust, and has the advantages of readily available raw materials, simple preparation process, low initiation temperature and excellent durability.

Owner:SINOCAT ENVIRONMENTAL TECH

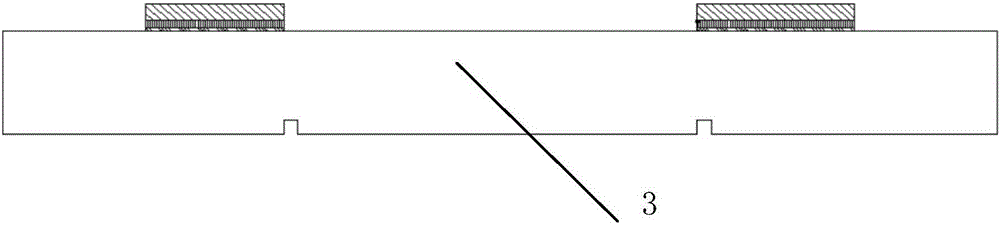

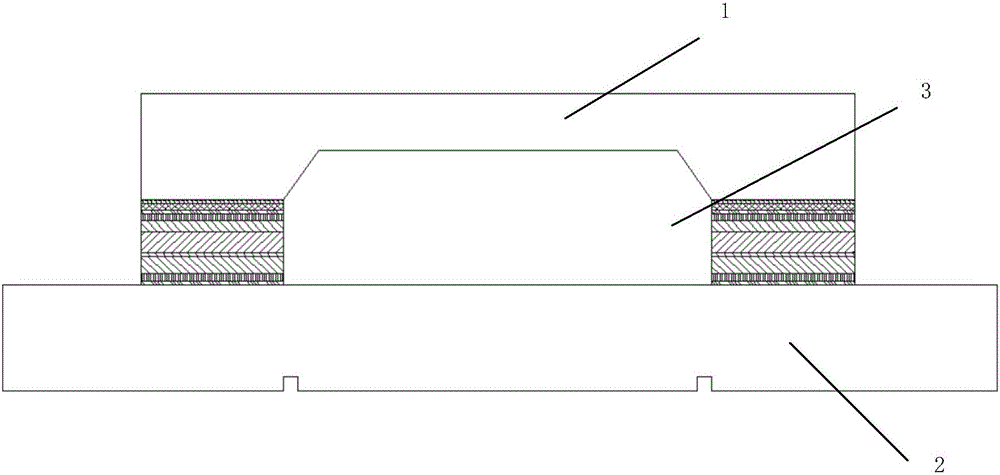

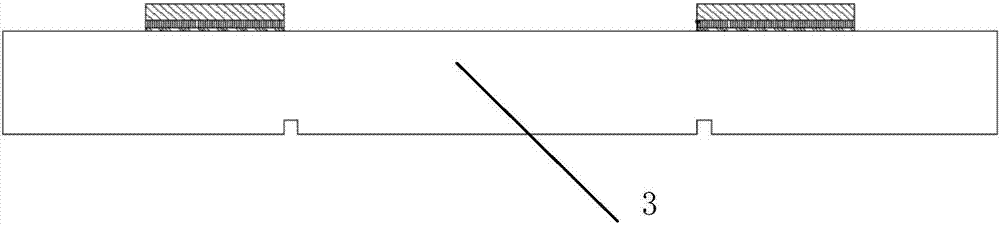

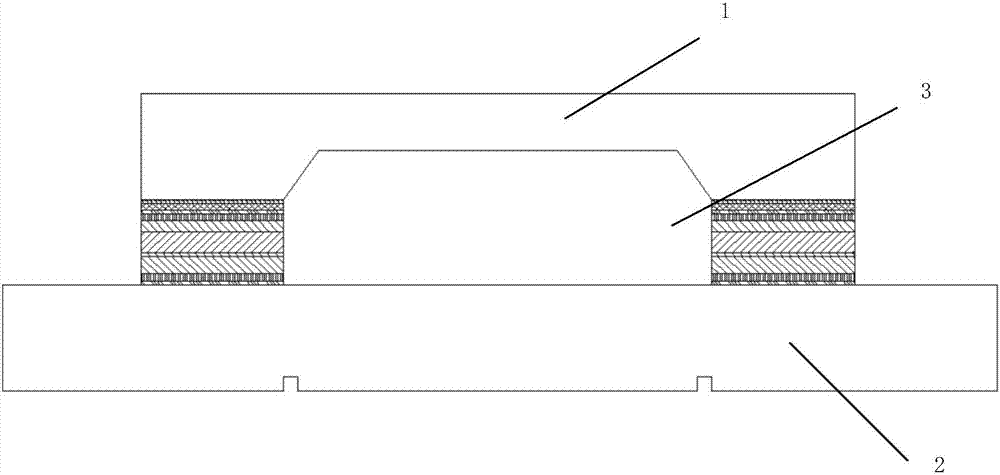

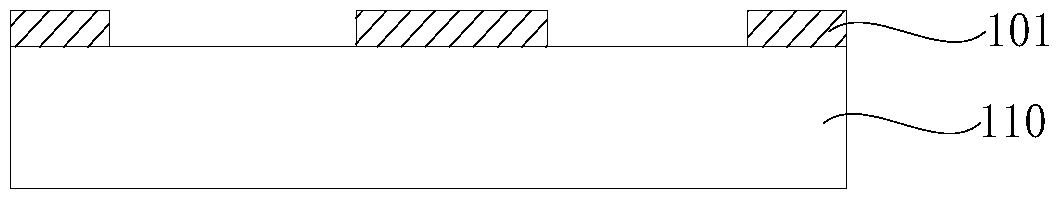

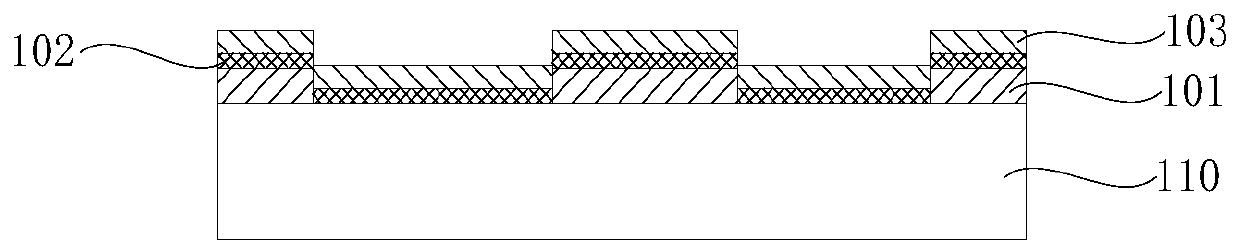

Transverse interconnection low-temperature wafer level packaging method specific to radio-frequency MEMS (Micro Electro Mechanical System) device application

ActiveCN106115608AImprove performanceReduce hardnessDecorative surface effectsSolid-state devicesSurface layerEngineering

The invention relates to a transverse interconnection low-temperature wafer level packaging method specific to a radio-frequency MEMS (Micro Electro Mechanical System) device application. The method is characterized in that a low-temperature packaging process is performed on a radio-frequency device through a process which combines Au and In isothermal solidification low-temperature bonding with organic material bonding, so that the problem of lead transverse interconnection is solved, and high mechanical strength and airtightness are achieved during packaging at the same time. Meanwhile, a metal deposition way of Au and In isothermal solidification bonding is adopted, namely, Cu is taken as a barrier layer material for an Au and In isothermal solidification reaction, and a thin Au layer is deposited on a surface layer of an In layer to serve as a protection layer material for preventing the In surface layer from being oxidized. The manufacturing of a sealing ring mainly focuses on a packaging cover plate, so that the influence of packaging on the performance of a substrate chip is lowered greatly. Meanwhile, the manufacturing of the sealing ring and the manufacturing of a packaging cavity are integrated in process.

Owner:SUZHOU XIMEI MICRO NANO SYST CO LTD

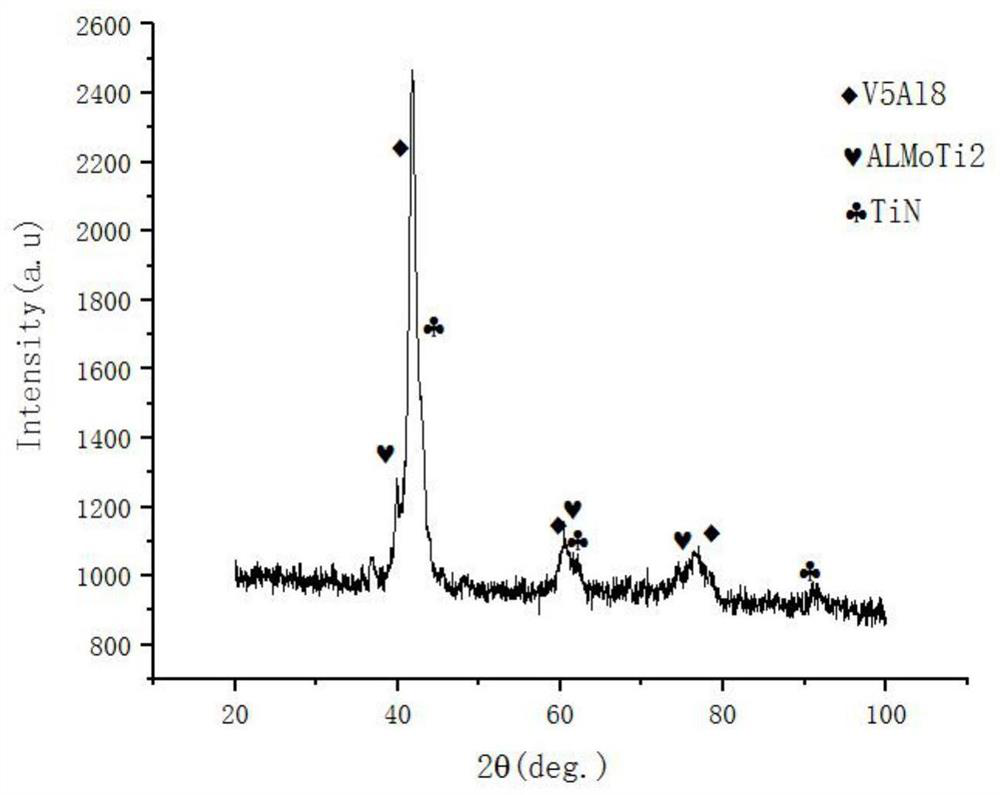

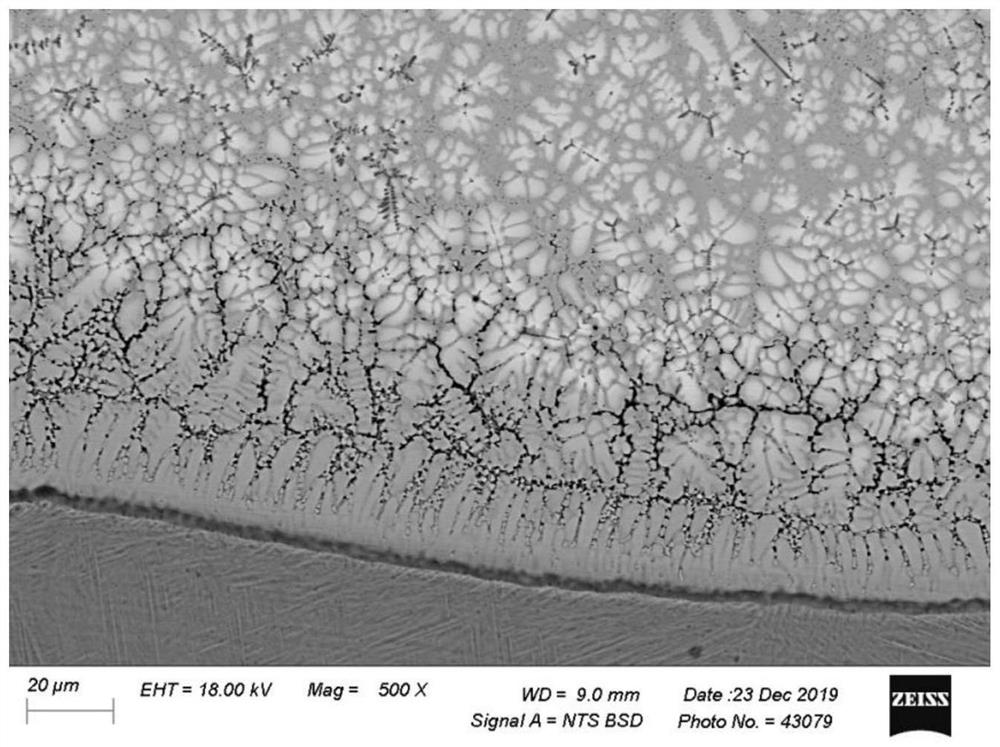

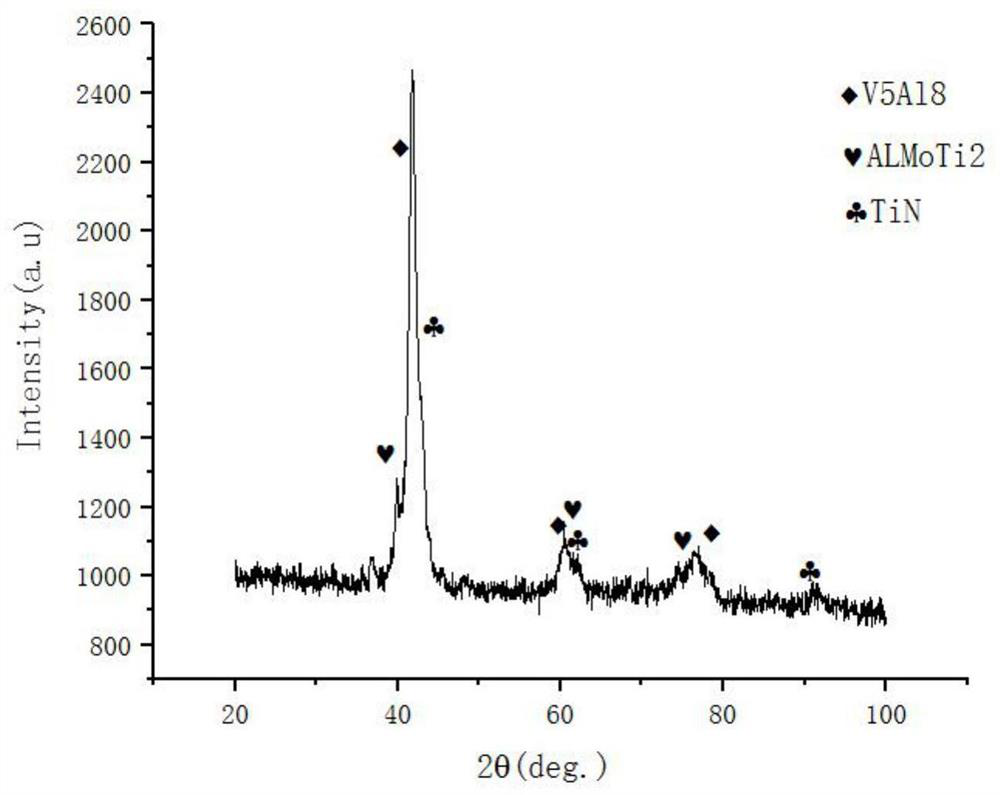

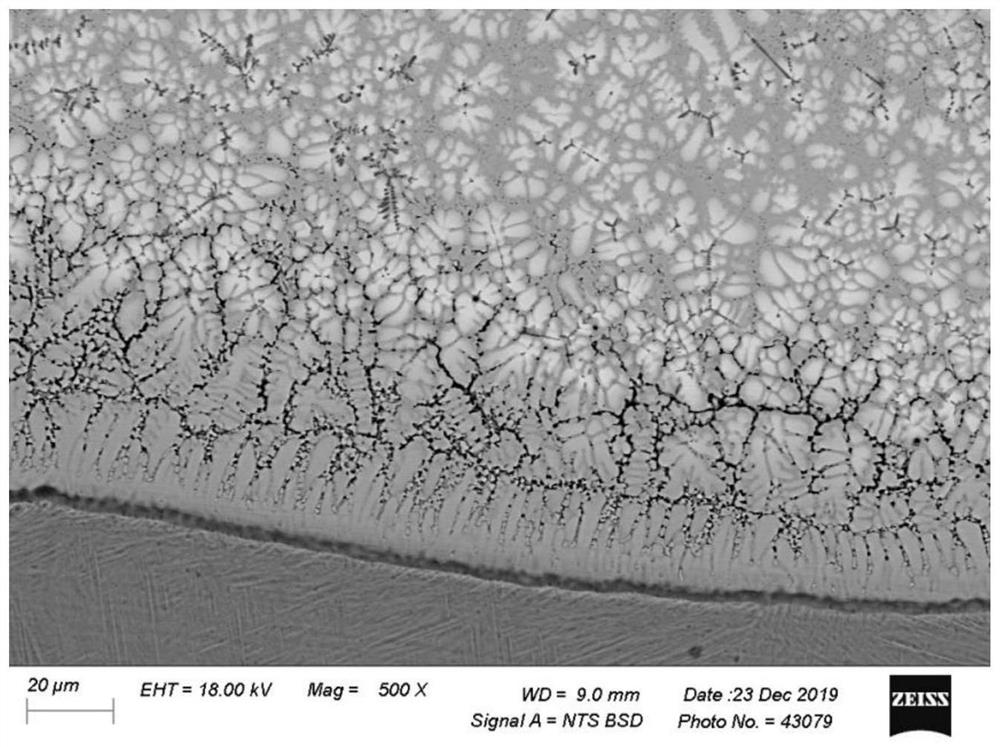

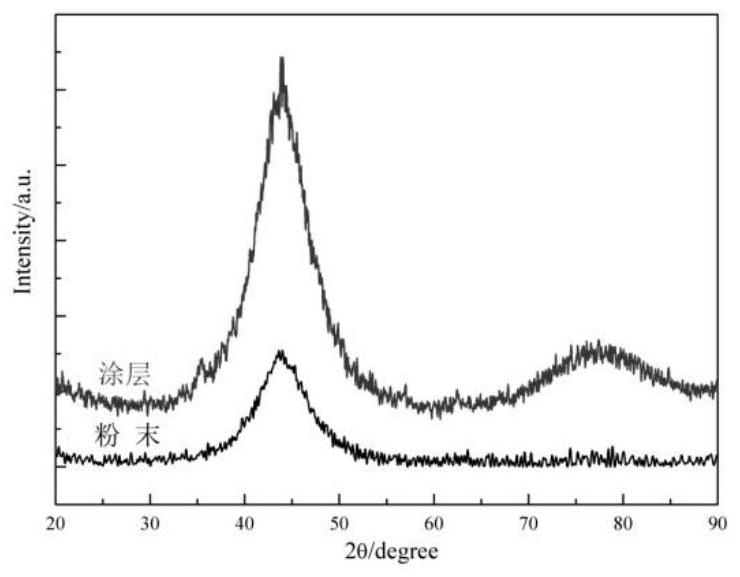

Laser-cladding seven-element high-entropy alloy coating and preparation method thereof

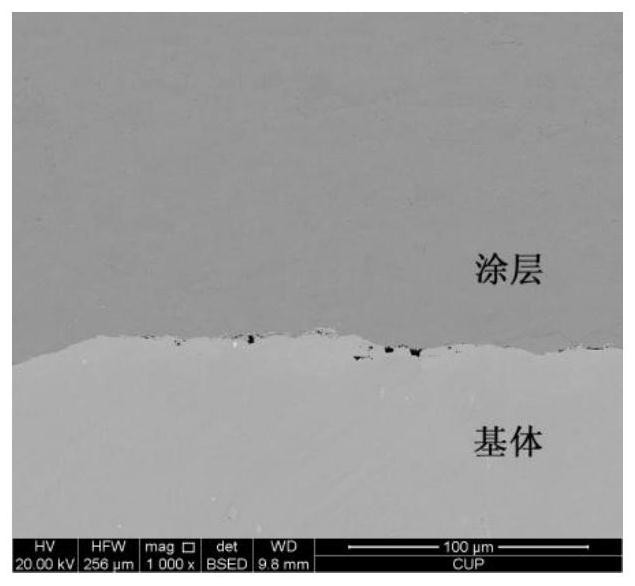

ActiveCN111850543AImprove bindingImprove performanceMetallic material coating processesHigh entropy alloysHigh energy laser beam

The invention discloses a laser-cladding seven-element high-entropy alloy coating and a preparation method thereof, and belongs to the technical field of alloy surface coating modification. High-entropy alloy powder is prepared from Al, Co, Cr, Fe, Mo, V and Ti; a substrate is Ti-6Al-14V(TC4) titanium alloy, the atom fraction of each raw material in the high-entropy alloy powder is Al (10% to 16%), Co (11% to 15%), Cr (9% to 16%), Fe (6% to 15%), Mo (8% to 17%), V (8% to 15%) and Ti (12% to 16%), and the sum of all components is 100%. The high-entropy alloy coating is formed by cladding the prepared alloy powder on the surface of the substrate by a high-energy laser beam emitted from a CO2 laser, the substrate and a cladding layer are metallurgically combined to achieve the purpose of surface modification, thus the hardness, wear resistance and corrosion resistance of titanium alloy are improved, and the service life of the titanium alloy is further prolonged.

Owner:KUNMING UNIV OF SCI & TECH

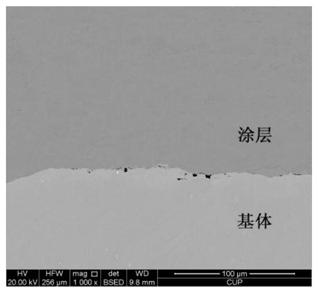

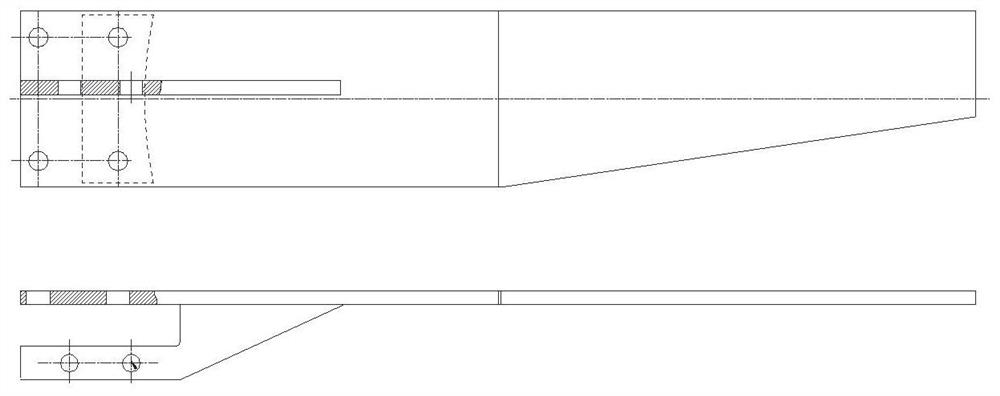

Composite manufacturing method of acid leaching stirrer

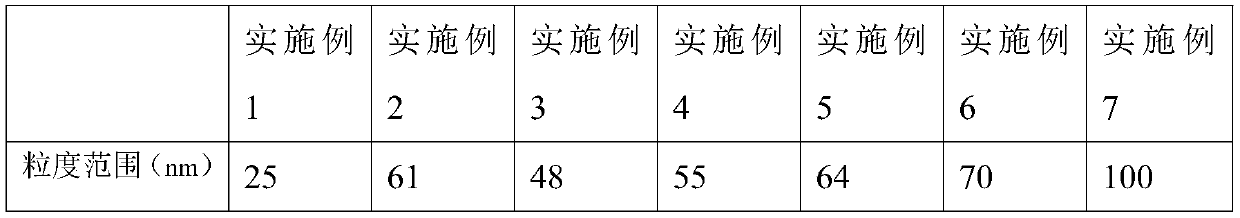

ActiveCN110029300AStrong ability to form amorphous stateEnhanced Amorphous Formation AbilityMolten spray coatingRare-earth elementTungsten

The invention relates to a composite manufacturing method of an acid leaching stirrer. Iron-based amorphous powder is taken as a spraying material, the supersonic flame spraying technology is adoptedto accelerate the heating of the powder, and an iron-based amorphous coating with the thickness of 150-250 [mu]m is prepared on the surface of a stirring shaft or a paddle. The iron-based amorphous powder is prepared from the following components in percentage by mass: 0-25% of chromium, 0-10% of molybdenum, 0-5% of tungsten, 0-12% of niobium, 0-4% of lutetium, 0-7% of manganese, 0-5% of boron, 0-4% of carbon, 0-3% of silicon, 0-2% of rare earth element and the balance of iron. The service life of the prepared composite material stirring shaft and paddle is several times longer than that of traditional stainless steel products.

Owner:INST OF APPLIED PHYSICS JIANGXI ACADEMY OF SCI

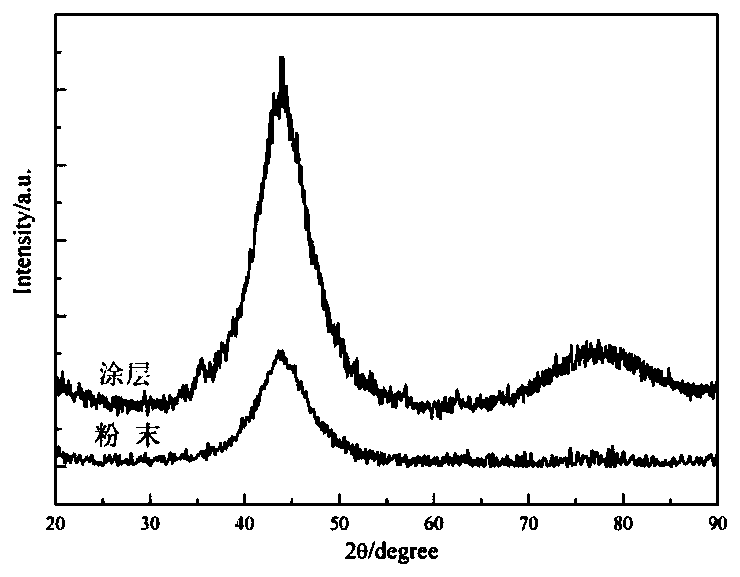

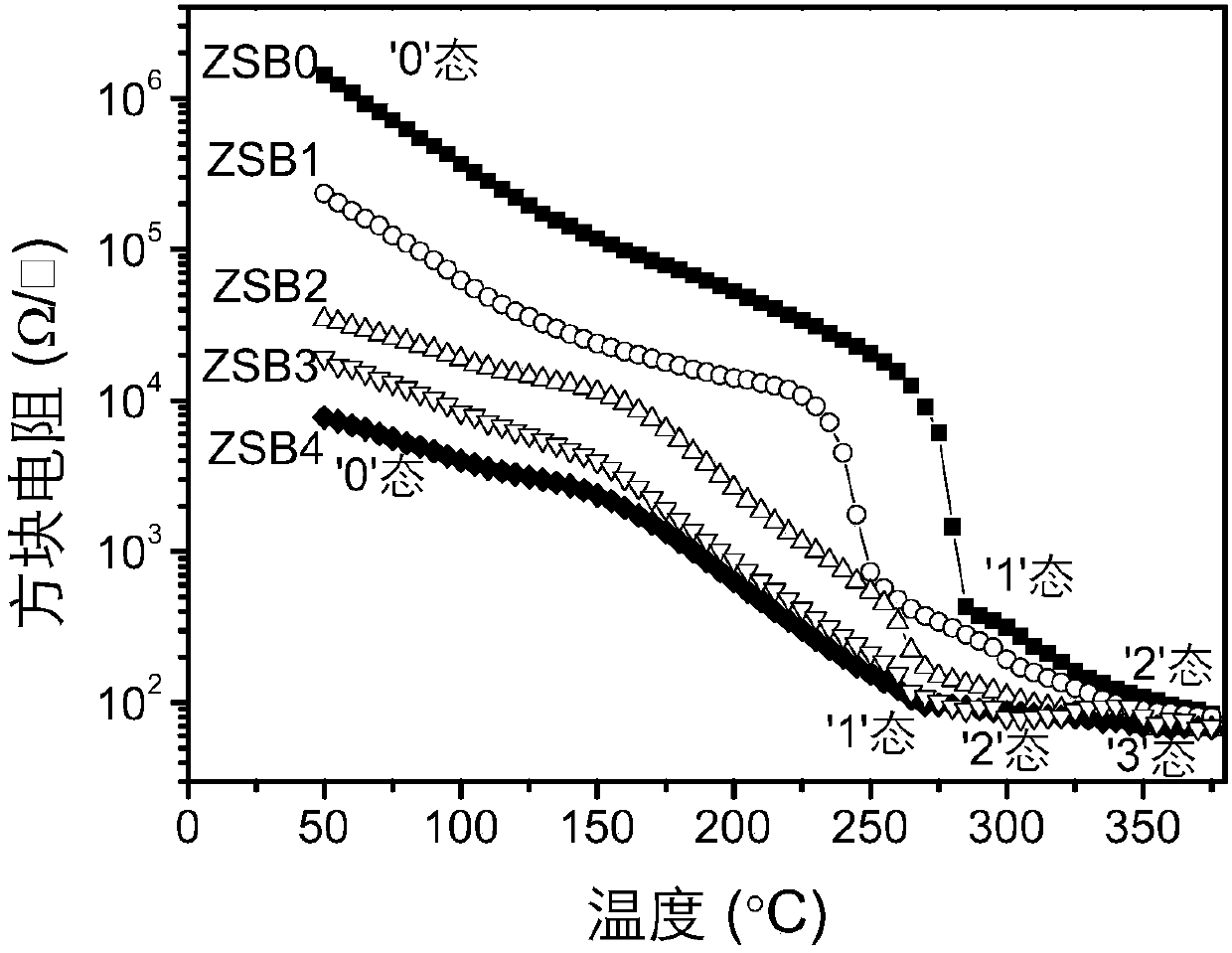

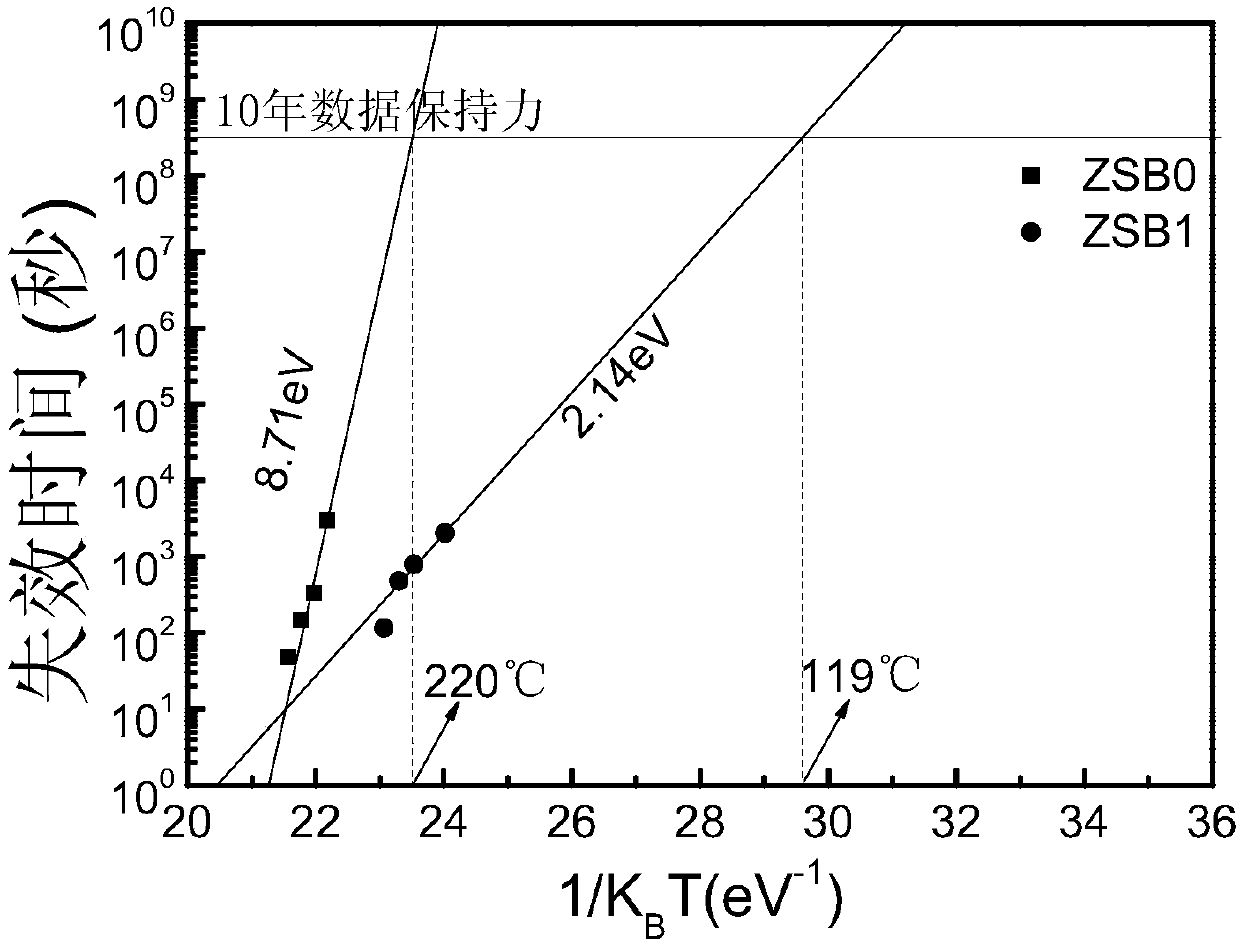

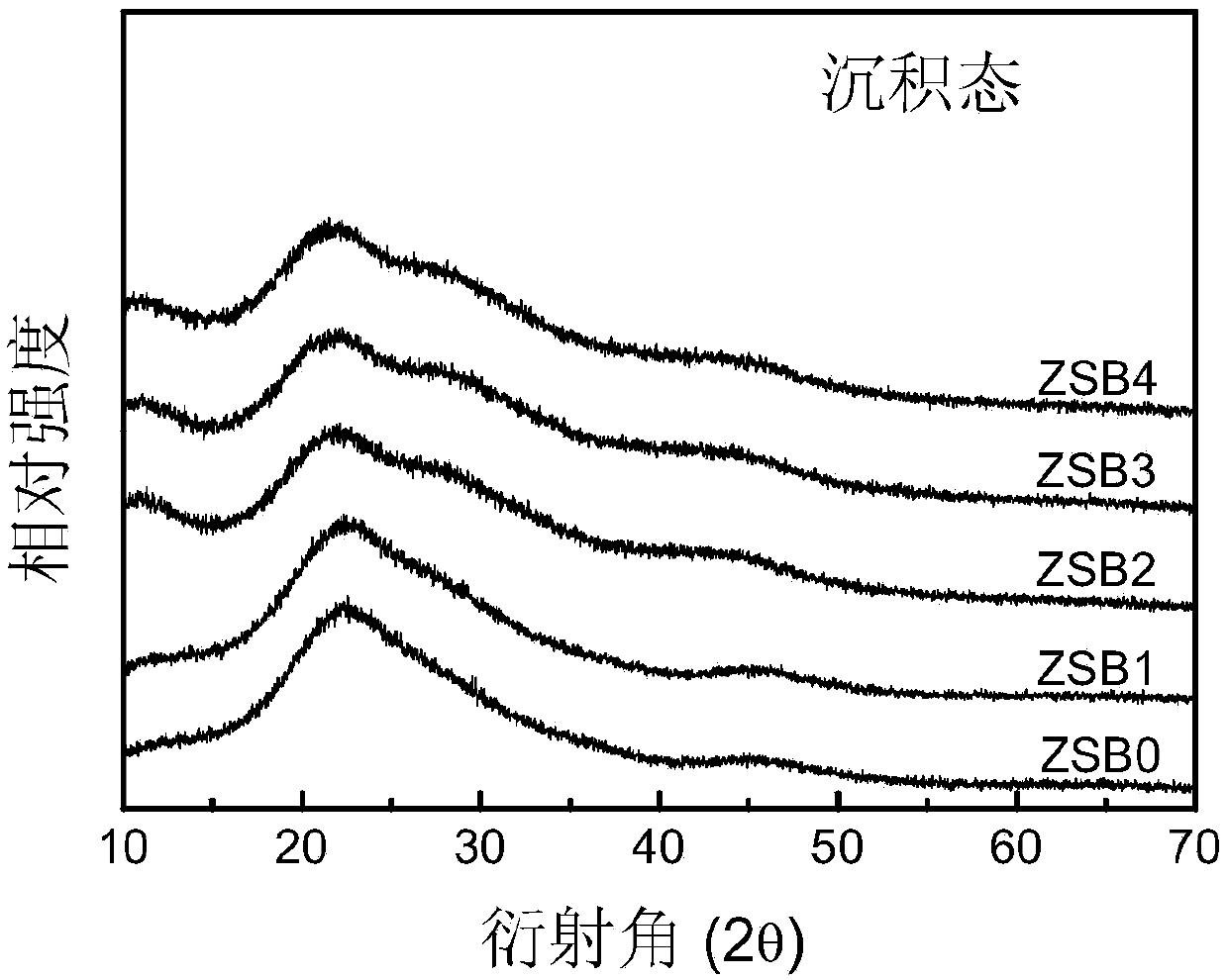

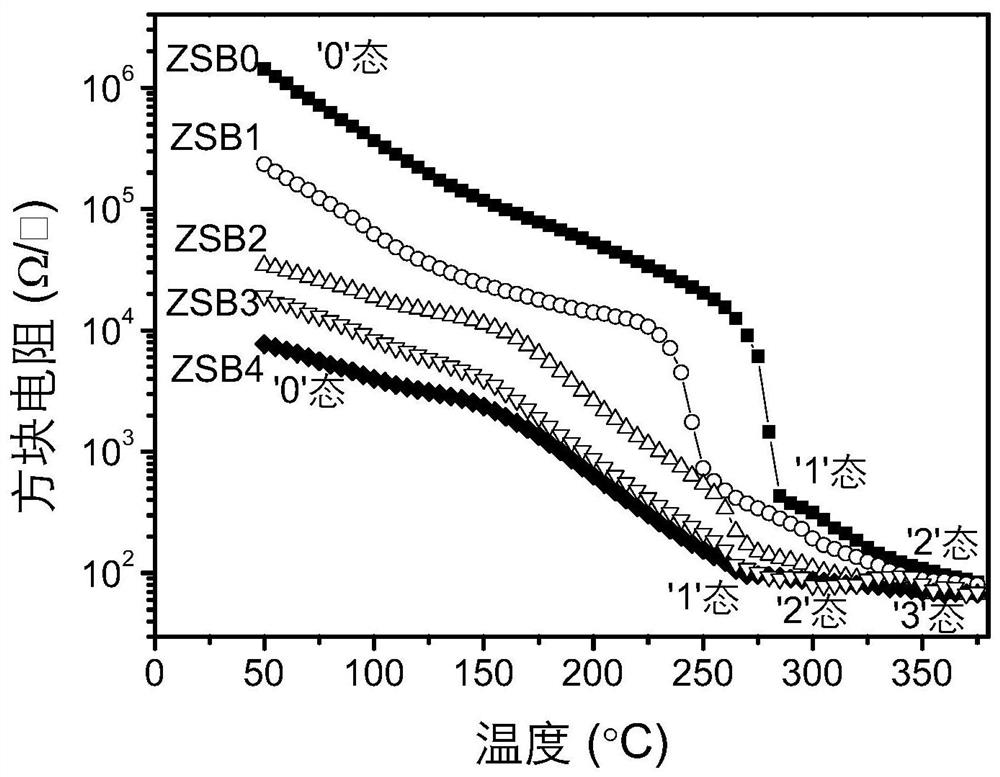

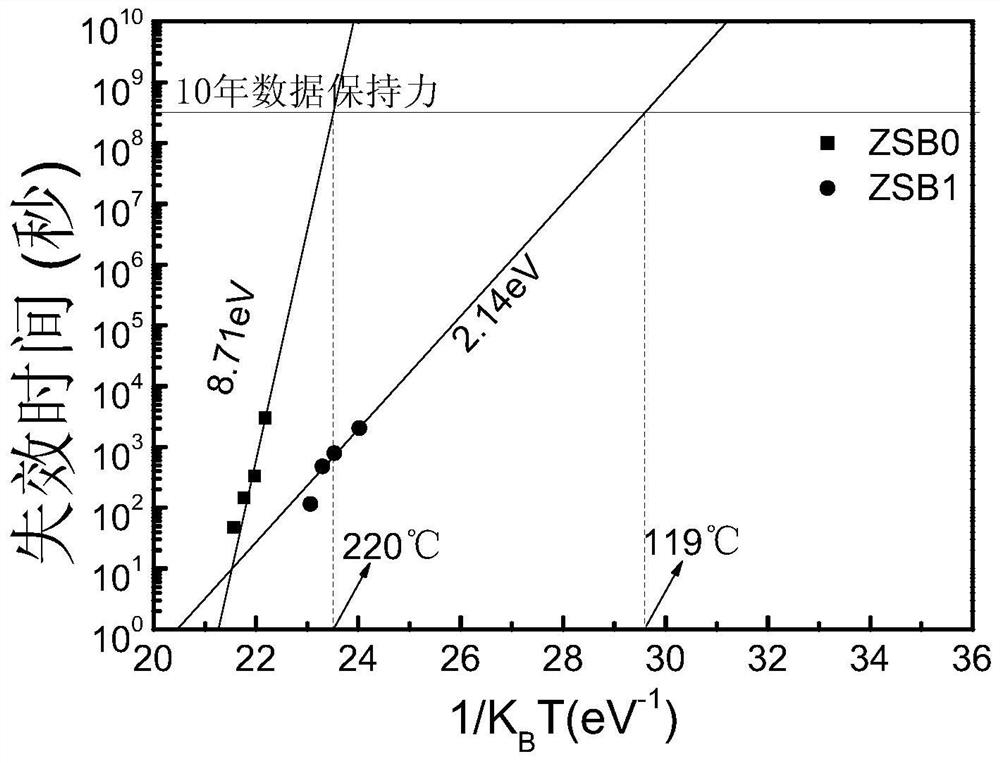

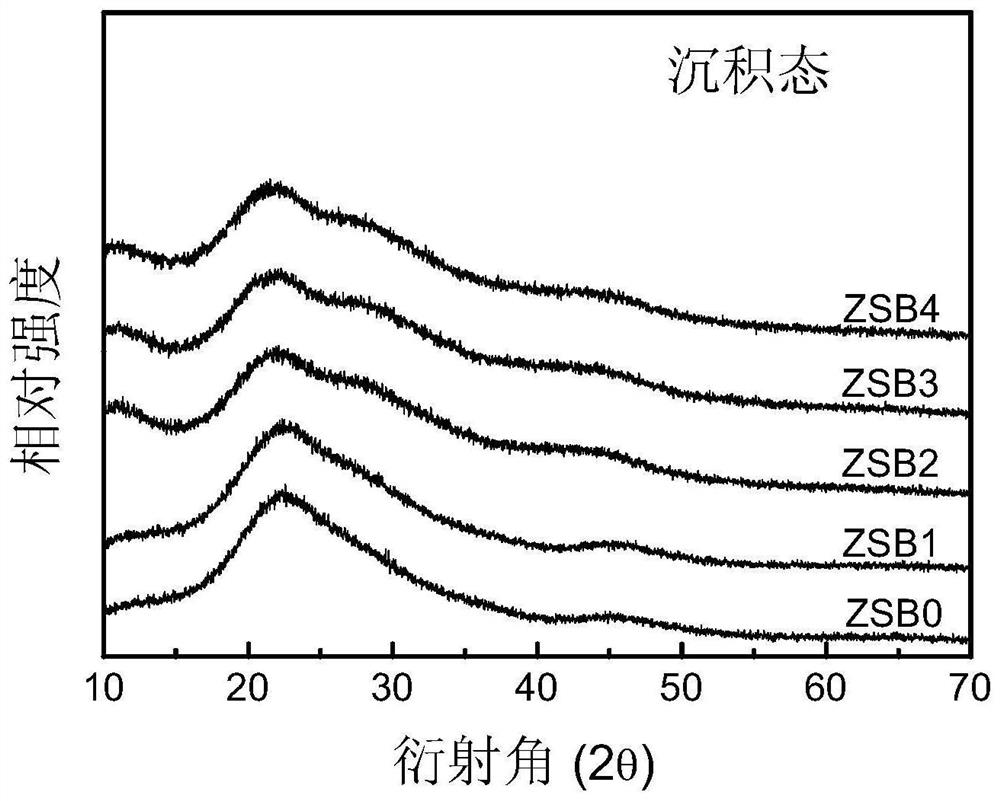

Zn-Sb-Bi thin film material used for multi-state phase change memory, and preparation method of thin film material

ActiveCN107946460AReduced thermal stability of amorphousAtomic radius is largeElectrical apparatusChemical structurePhase-change memory

The invention discloses a Zn-Sb-Bi thin film material used for a multi-state phase change memory, and a preparation method of the thin film material. The thin film material is characterized in that the thin film material is obtained from an elementary metal Bi target and a Zn<2>Sb<3> alloy target in a magnetron sputtering film coating system through dual-target co-sputtering; the thin film material has the chemical structural formula of (Zn<2>Sb<3>)<100-x>Bi<x>, wherein x is greater than or equal to 0 and less than 14, wherein the preferable phase change material Zn<2>Sb<3> and (Zn<2>Sb<3>)<96.8>Bi<3.2> have relatively high crystallization temperature, relatively high crystallization activation energy and relatively high retentivity of data of ten years; and compared with a three-state phase change memory material and the conventional three-state GST phase change material, the thin film material has the advantages of high crystallization temperature and high phase conversion temperature, higher crystalline state resistance and has three resistance states, while the other Zn-Sb-Bi thin film with higher Bi content represents four kinds of resistance states, so that higher multi-bit and multi-valued memory can be realized.

Owner:NINGBO UNIV

Method for manufacturing red ceramic pigment of silicoferrite

ActiveCN101318838ALittle change in chromatic aberrationImprove stabilityCeramic colorantsFerrosilicon

The invention discloses a production method for an environmentally friendly, cheap and stable ceramic colorant which is a ferrosilicon red ceramic colorant. The key point of the method is: lanthanum carbonate is introduced into a formulation and is used to effectively and completely enwrap ferric oxide together with silicon dioxide through high-activity lanthana decomposed from the lanthanum carbonate at a temperature of 900 DEG C and the property of having a greater atomic radius of the lanthanum carbonate, thereby enabling the ferric oxide to show stable colors without impacts from ambient surroundings. In addition, the ferrosilicon red ceramic colorant adapted to different temperatures is manufactured through changing the processing conditions.

Owner:肇庆市欧陶新型材料有限公司

Preparation method of sucrose-6-benzoate

ActiveCN102796145AHigh yieldHigh purityEsterified saccharide compoundsSugar derivativesSucroseMethyl benzoate

The invention provides a preparation method of sucrose-6-benzoate, which comprises the following steps: by using sucrose as a raw material, methyl benzoate as an esterifying reagent and an alkali carbonate as a catalyst, synthesizing sucrose-6-benzoate under vacuum distillation conditions; and by using the polar difference between the sucrose and the sucrose-6-benzoate, adding a low-polarity solvent to precipitate unreacted sucrose, thereby purifying the sucrose-6-benzoate. The method can enhance the yield and purity of the sucrose-6-benzoate and recycle the unreacted sucrose, has the advantages of environment-friendly technique, low facility request and high economical efficiency, provides a new way for synthesizing sucrose-6-benzoate, and is suitable for the demands for large-scale industrial production.

Owner:天津北方食品有限公司

Aluminum-silicon-magnesium casting alloy mechanical property improving method

The invention discloses an aluminum-silicon-magnesium casting alloy mechanical property improving method. Light rare earth is adopted and cooperates with heavy rare earth to process alloy melt, and the iron content is 0.09-0.20 wt% of the alloy melt mass. According to the improving method, based on the difference, in the aspect of physicochemical property, between light rare earth elements and heavy rare earth elements as well as the influence on the alloy crystallization process, the method of utilizing the light rare earth and the heavy rare earth to be combined and modified to control the microstructure and mechanical property of alloy is provided, the light rare earth and the heavy rare earth give play to advantage separately, namely, the light rare earth is focused on enriching on thealpha-Al and Si crystal solidification front and being adsorbed on the surface of crystal, and achieves the effects of refining and modifying; and the heavy rare earth is focused on adsorbing or conducting solid solution on iron-rich Al-Fe and Al-Fe-Si group harmful compound, influencing the microstructure of the compound, impeding growth of crystal, and promoting the compound to be decomposed into short rod-like shape or granular shape at the high temperature; and the light rare earth and the heavy rare earth achieve mutual complementarity in the aspect of controlling the microstructure of the alloy, and substantially, the quite good modifying effect is achieved.

Owner:INNER MONGOLIA UNIV OF TECH

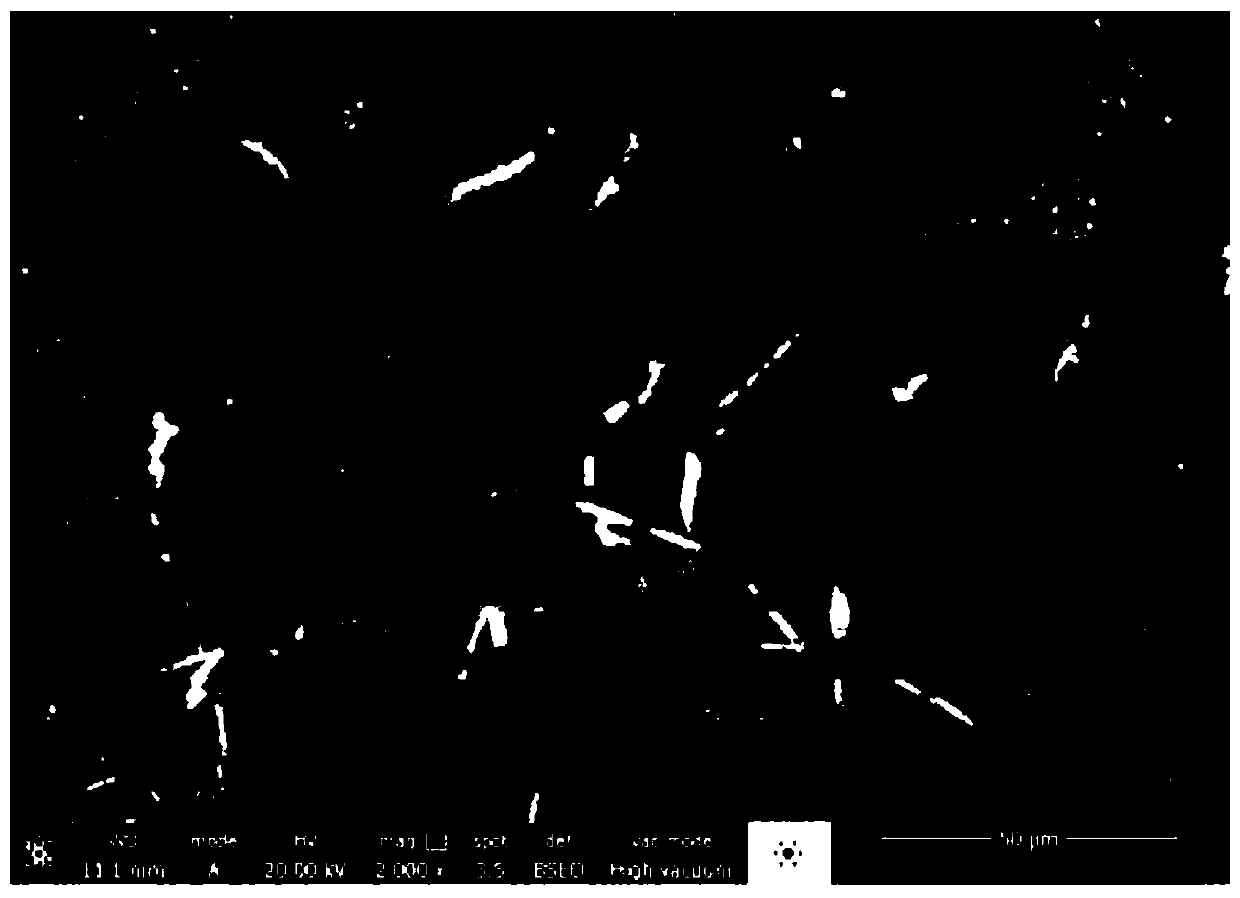

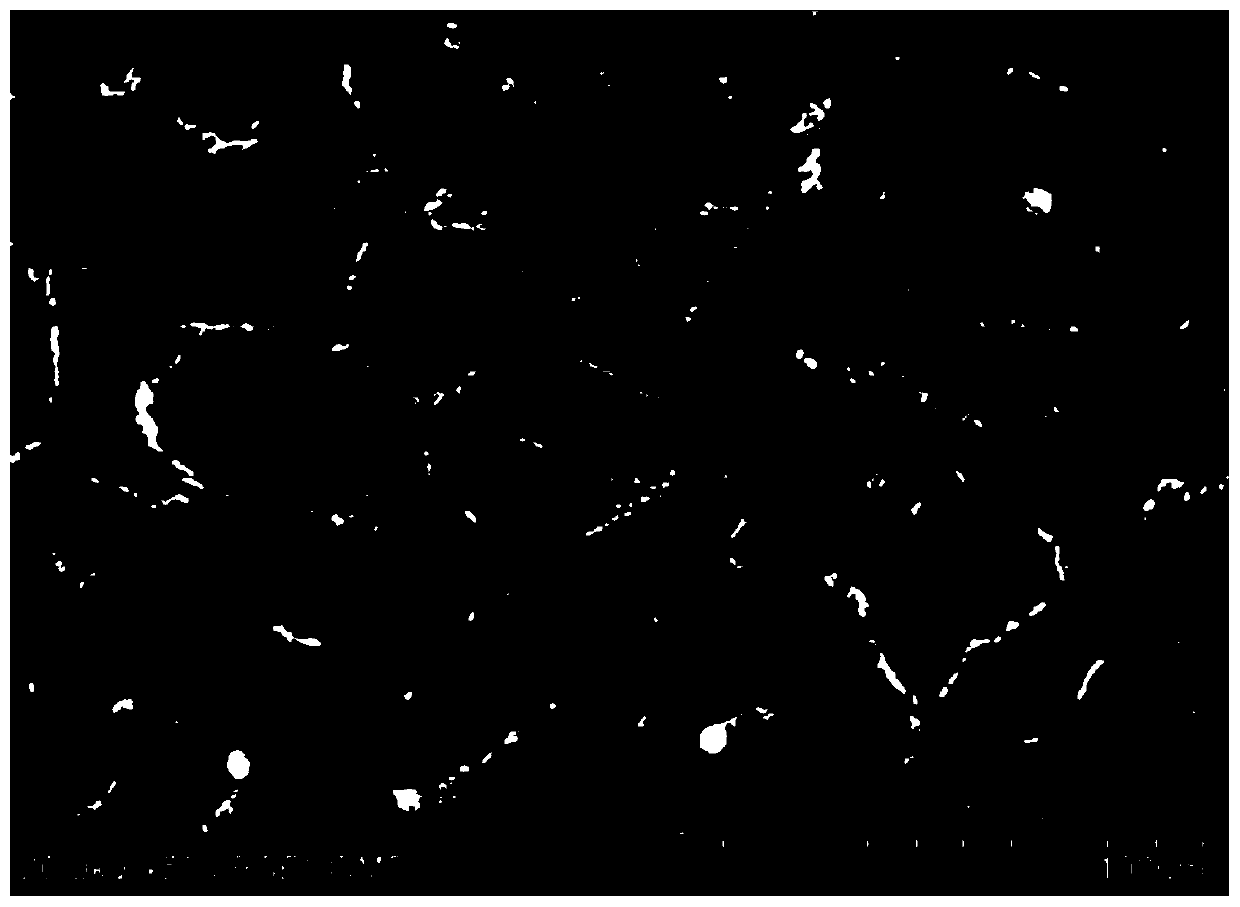

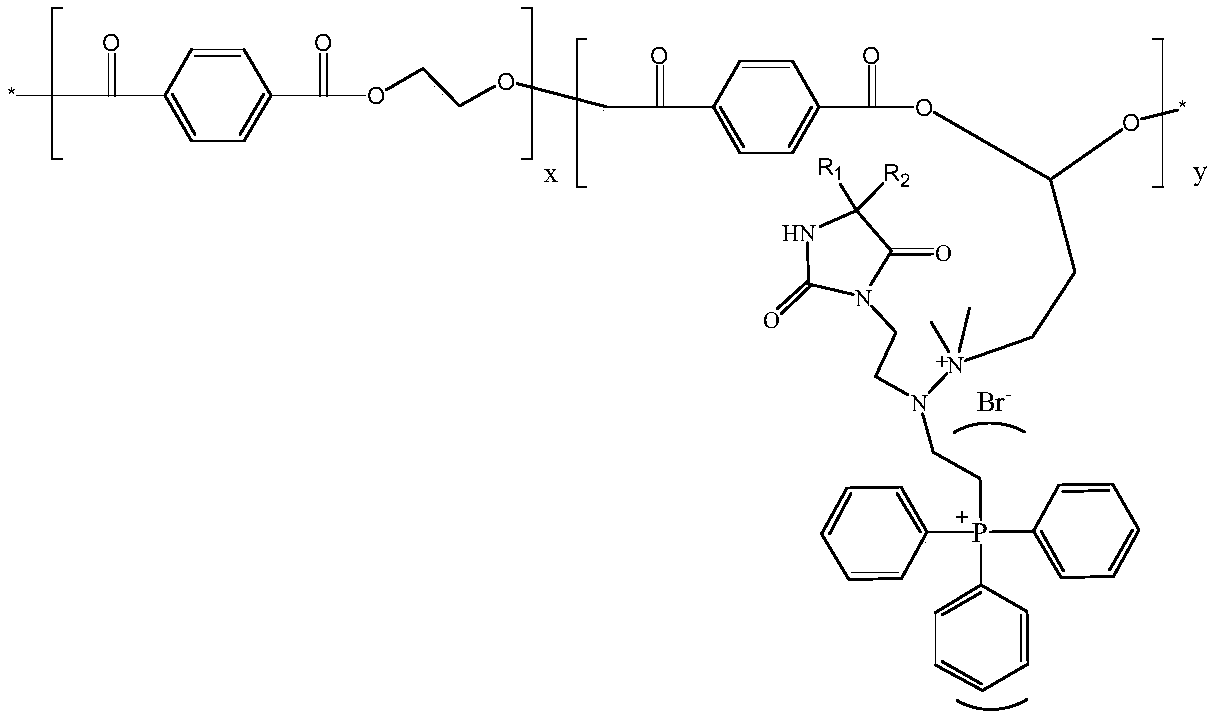

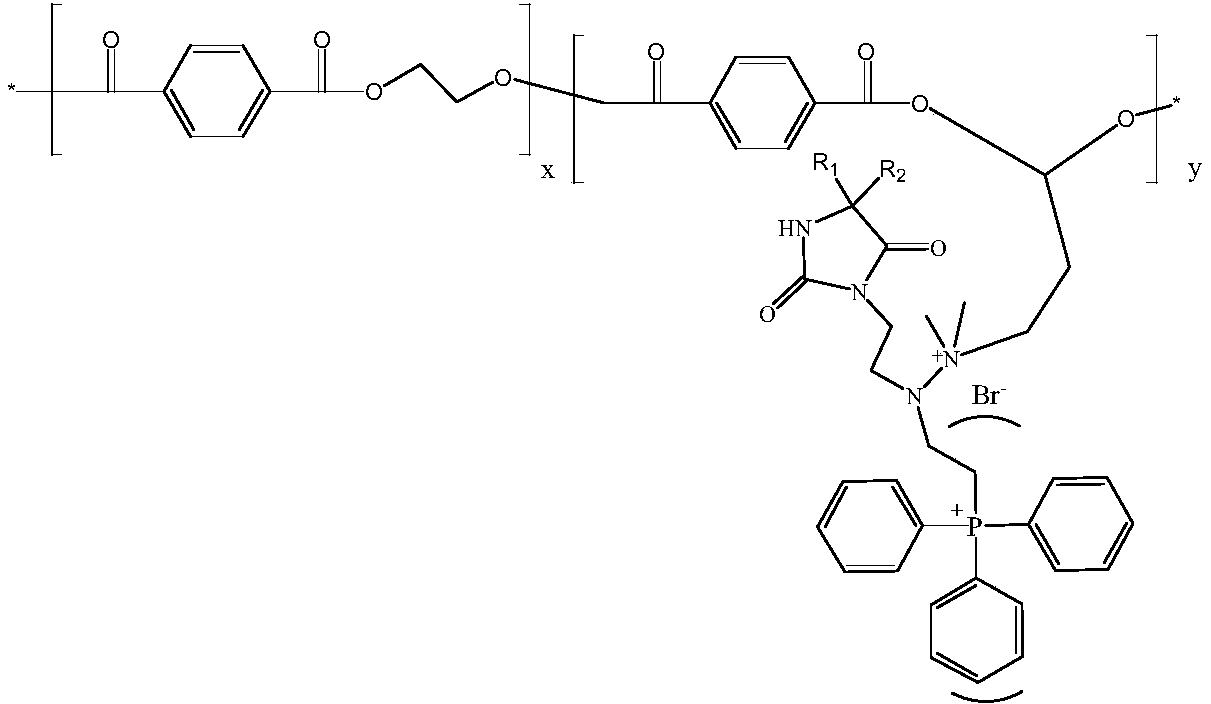

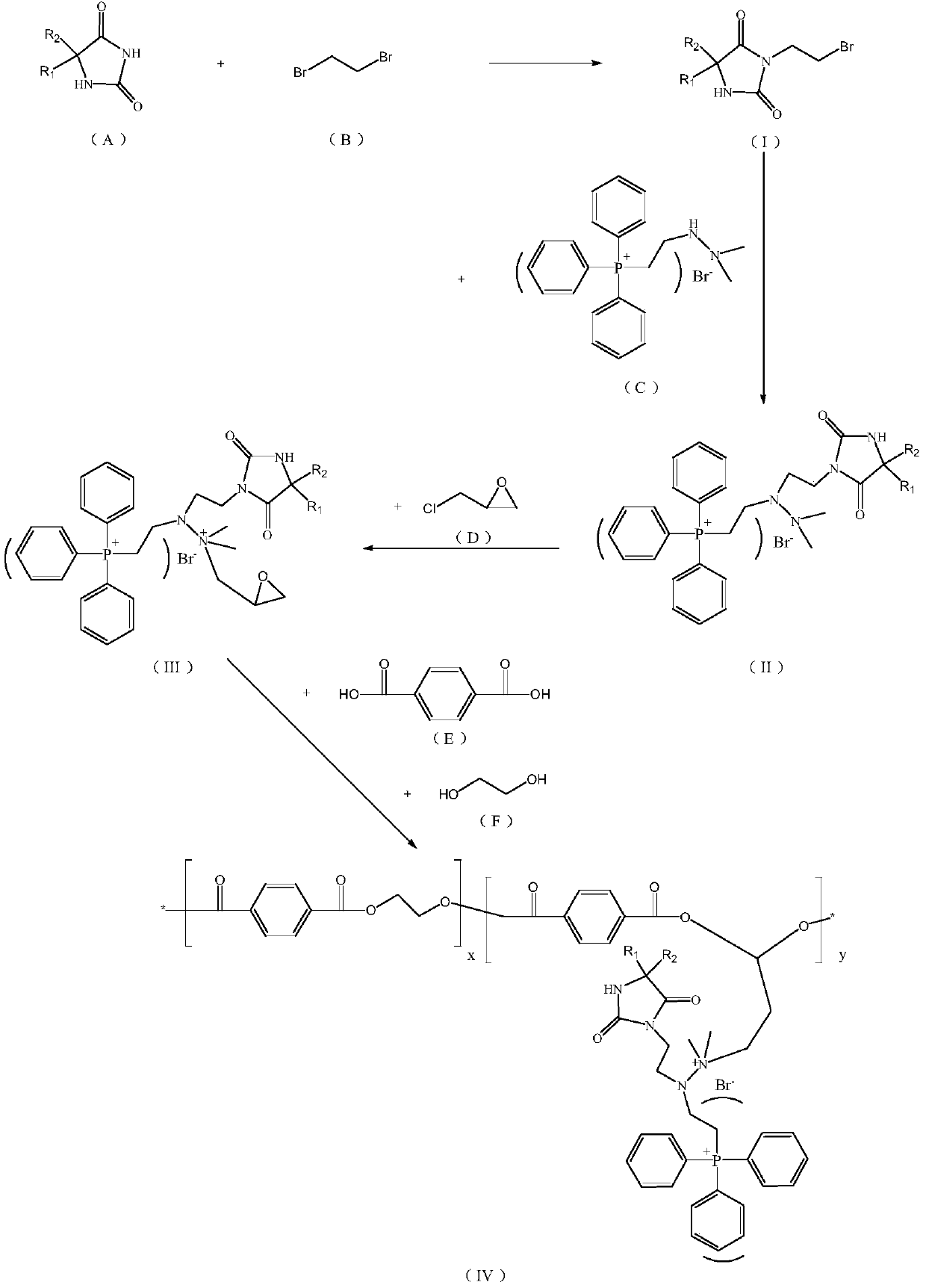

Antibacterial polyester fiber and fabric

InactiveCN111364115AGet rid of the defect of no antimicrobialThe reaction steps are simpleHeating/cooling textile fabricsMonocomponent copolyesters artificial filamentEpoxyFiber

The invention belongs to the field of new materials, and relates to an antibacterial polyester fiber and fabric. The antibacterial polyester fiber and fabric are prepared by taking hydantoin derivatives (A), 1, 2-dibromoethane (B), triphenyl quaternary phosphonium salt (C), epoxy chloropropane (D), terephthalic acid (E) and ethylene glycol (F) as the raw materials through multi-step reactions suchas substitution and polycondensation, a spinning process and a weaving process. The antibacterial polyester fabric effectively overcomes the defect that microorganisms such as bacteria and fungi areprone to breeding after existing polyester is dyed and finished, meanwhile, the antibacterial polyester fabric has high-efficiency flame retardant property and antistatic property, and therefore it can be foreseen that the antibacterial polyester fabric can have a wide market space and is particularly suitable for the fields of clothing and the like.

Owner:华叶莹

A laser cladding seven-element high-entropy alloy coating and its preparation method

ActiveCN111850543BImprove bindingMicroorganizedMetallic material coating processesHigh entropy alloysHigh energy laser beam

The invention discloses a seven-element high-entropy alloy coating prepared by laser cladding and a preparation method thereof, belonging to the technical field of alloy surface coating modification; the high-entropy alloy powders are Al, Co, Cr, Fe, Mo, V, Ti . The matrix material is Ti-6Al-l4V (TC4) titanium alloy, and the atomic fraction of each raw material in the high-entropy alloy powder is Al (10%-16%), Co (11%-15%), Cr (9%-16%) ), Fe (6%-15%), Mo (8%-17%), V (8%-15%), Ti (12%-16%), the sum of all components is 100%. by CO 2 The high-energy laser beam emitted by the laser clads the configured alloy powder on the surface of the substrate to form a high-entropy alloy coating. The substrate and the cladding layer are metallurgically combined to achieve the purpose of surface modification, thereby increasing the hardness of the titanium alloy. , wear resistance and corrosion resistance, thereby extending the service life of titanium alloys.

Owner:KUNMING UNIV OF SCI & TECH

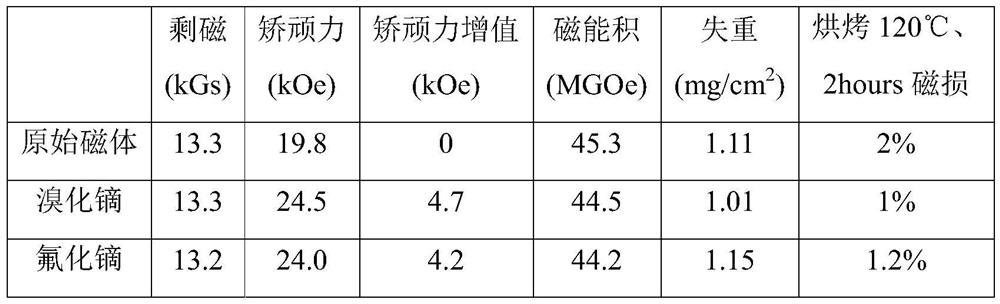

Preparation method of rare earth permanent magnet material

InactiveCN112420372ALittle impact on microstructureImprove coercive forceInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementBromine

The invention discloses a preparation method of a rare earth permanent magnet material, which comprises the following steps: arranging rare earth bromide powder on the surface of a sintered magnet, and carrying out heat treatment on the magnet and the powder at a temperature lower than the sintering temperature of the magnet so as to carry out rare earth diffusion. According to the method, Br witha large atomic radius is used for replacing an F or O element, rare earth bromide is used as a novel grain boundary diffusion source, the surface of the sintered magnet is coated with the novel diffusion source, and rare earth elements are diffused into the magnet through tempering treatment; the rare earth bromide has the characteristics that the rare earth bromide is easy to decompose, the atomic radius of the bromine element is large, the bromine element is easily volatilized into the environment and only slightly diffuses into the magnet, the influence on the microstructure of the magnetis small, rare earth elements are easier to diffuse into the magnet, the diffusion depth is large, and the coercive force of the magnet is obviously improved; and meanwhile, the temperature stabilityand the corrosion resistance of the magnet are improved.

Owner:ZHEJIANG INNUOVO MAGNETICS

Wear-resistant and corrosion-resistant liner plate and preparation method thereof

The invention belongs to the technical field of wear-resistant materials, and particularly relates to a wear-resistant and corrosion-resistant liner plate and a preparation method thereof. The wear-resistant and corrosion-resistant liner plate is prepared from the following components in percentage by weight: 0.6-1% of carbon, 0.4-0.8% of silicon, 0.4-0.85% of magnesium, 0.4-1.0% of manganese, 9-13% of chromium, 1.5-1.9% of molybdenum, 0.1-0.22% of nickel, 0.05-0.20% of titanium, 0.005-0.04% of phosphorus, 0.005-0.04% of sulfur, and the balance of iron. A formula is reasonable, manufacturing is easy, the service life is long, quite high strength, toughness, wear resistance and impact resistance are achieved, the frequency of replacing the wear-resistant and corrosion-resistant liner platein a factory is reduced, the labor intensity is lowered, raw materials are easy to obtain, a manufacturing method is simple, and energy is effectively saved.

Owner:湖北秦鸿新材料有限公司

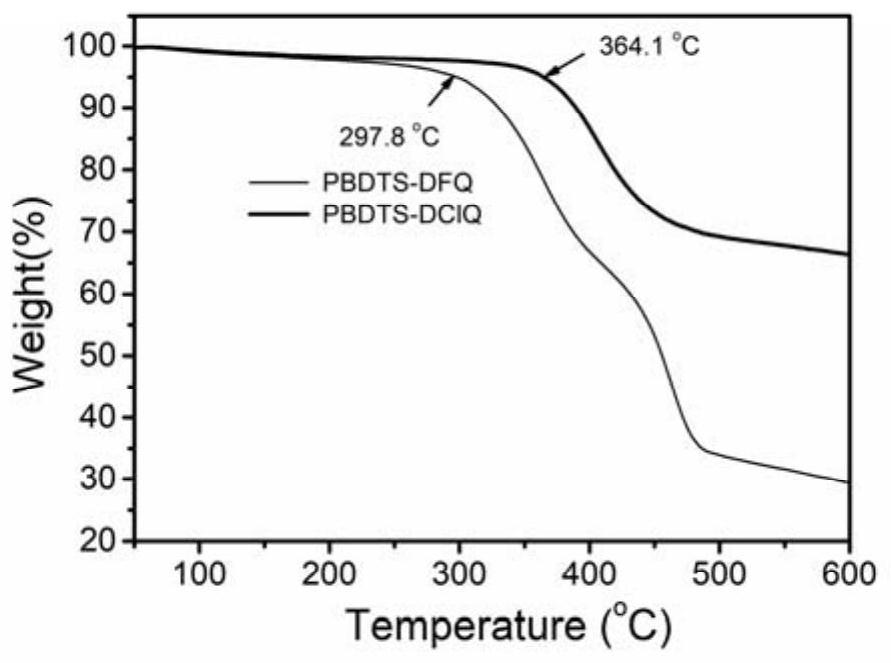

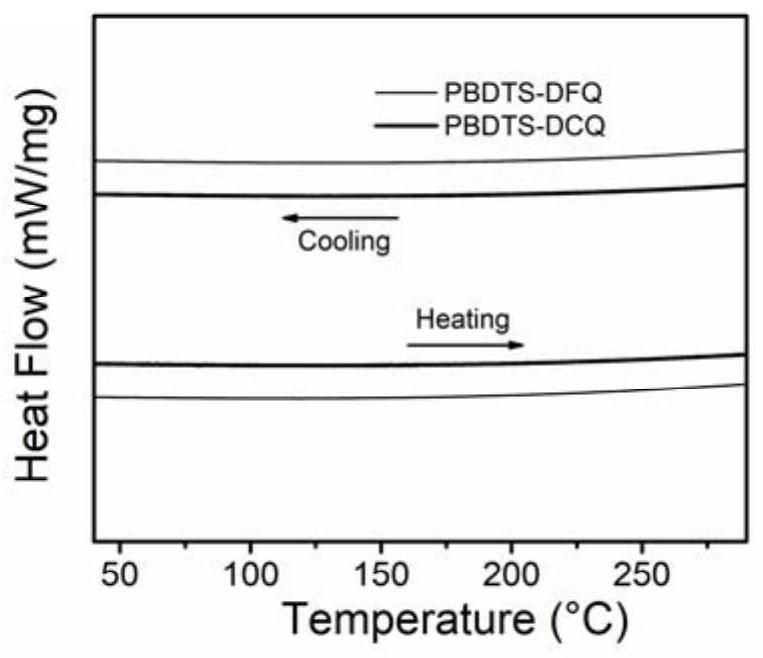

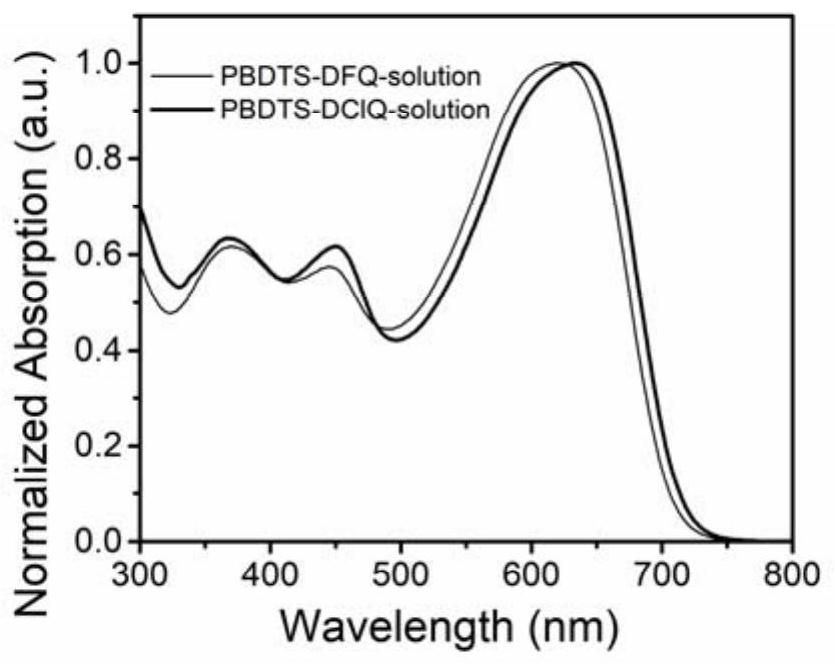

Quinoxaline derivative polymer material based on side chain halogen atom substitution and application

InactiveCN113185674ALower HOMO levelIncrease the open circuit voltageSolid-state devicesSemiconductor/solid-state device manufacturingQuinoxalineSide chain

The invention belongs to the field of polymer solar cells, and particularly relates to a quinoxaline derivative polymer material based on side chain halogen atom substitution and application. The quinoxaline derivatives substituted by side chain halogen atoms (F, Cl) are simple in synthetic route, high in yield and good in stability; and especially, the introduction of the chlorinated side chain can effectively increase the conjugation of material molecules, widen the absorption and ensure that the active layer has good phase separation, thereby achieving the effect of improving the short-circuit current and fill factor of the polymer solar cell. The polymer material is used as an electron donor, Y6 is used as an electron acceptor, the polymer material is applied to a solution processing type polymer solar cell, and the energy conversion efficiency reaches 16.1%. The invention proves that the chlorinated side chain can effectively improve the photovoltaic performance of the polymer solar cell, and the efficient energy conversion of the D-A type polymer material constructed based on the side chain halogen atom substituted quinoxaline derivative in the polymer solar cell is realized.

Owner:CHANGZHOU UNIV

Low-temperature wafer-level packaging method for lateral interconnection for RF mems device applications

ActiveCN106115608BImprove performanceReduce hardnessDecorative surface effectsSolid-state devicesSurface layerMetal device

The invention relates to a transverse interconnection low-temperature wafer level packaging method specific to a radio-frequency MEMS (Micro Electro Mechanical System) device application. The method is characterized in that a low-temperature packaging process is performed on a radio-frequency device through a process which combines Au and In isothermal solidification low-temperature bonding with organic material bonding, so that the problem of lead transverse interconnection is solved, and high mechanical strength and airtightness are achieved during packaging at the same time. Meanwhile, a metal deposition way of Au and In isothermal solidification bonding is adopted, namely, Cu is taken as a barrier layer material for an Au and In isothermal solidification reaction, and a thin Au layer is deposited on a surface layer of an In layer to serve as a protection layer material for preventing the In surface layer from being oxidized. The manufacturing of a sealing ring mainly focuses on a packaging cover plate, so that the influence of packaging on the performance of a substrate chip is lowered greatly. Meanwhile, the manufacturing of the sealing ring and the manufacturing of a packaging cavity are integrated in process.

Owner:SUZHOU XIMEI MICRO NANO SYST CO LTD

A kind of compound manufacturing method of acid leaching stirrer

ActiveCN110029300BSmall atomic radiusAccelerated corrosionMolten spray coatingRare-earth elementLutetium

The invention relates to a compound manufacturing method of an acid leaching stirrer, which uses iron-based amorphous powder as a spraying material, adopts supersonic flame spraying technology to heat and accelerate the powder, and prepares a layer of 150-250 μm thick on the surface of the stirring shaft or blade Iron-based amorphous coating, the chemical ratio of iron-based amorphous powder by mass percentage: chromium 0-25%, molybdenum 0-10%, tungsten 0-5%, niobium 0-12%, lutetium 0-4%, 0-7% manganese, 0-5% boron, 0-4% carbon, 0-3% silicon, 0-2% rare earth elements, and the rest is iron; the service life of the prepared composite stirring shaft and blade is several times For traditional stainless steel products.

Owner:INST OF APPLIED PHYSICS JIANGXI ACADEMY OF SCI

Negative ion far-infrared nanometer multifunctional material

ActiveCN106726628BImprove the ability of ionized air to generate negative ionsImprove the ability to generate negative ionsCosmetic preparationsToilet preparationsInfraredAir Ionization

The invention provides a negative ion far infrared nanometer multifunctional material, which comprises the following ingredients in parts by weight: 1 to 86 parts of ore powder, 1 to 115 parts of rare earth powder and 1 to 200 parts of silica gel. The functional material provided by the invention has the advantages that on the basis of the prior art, the functional material capable of obviously improving the capability of generating negative ions of ore and rare-earth salts through air ionization is provided; on the other hand, the infrared ray releasing capability of the ore and the rare-earth salts can be obviously improved.

Owner:惠州市申天地生物科技有限公司

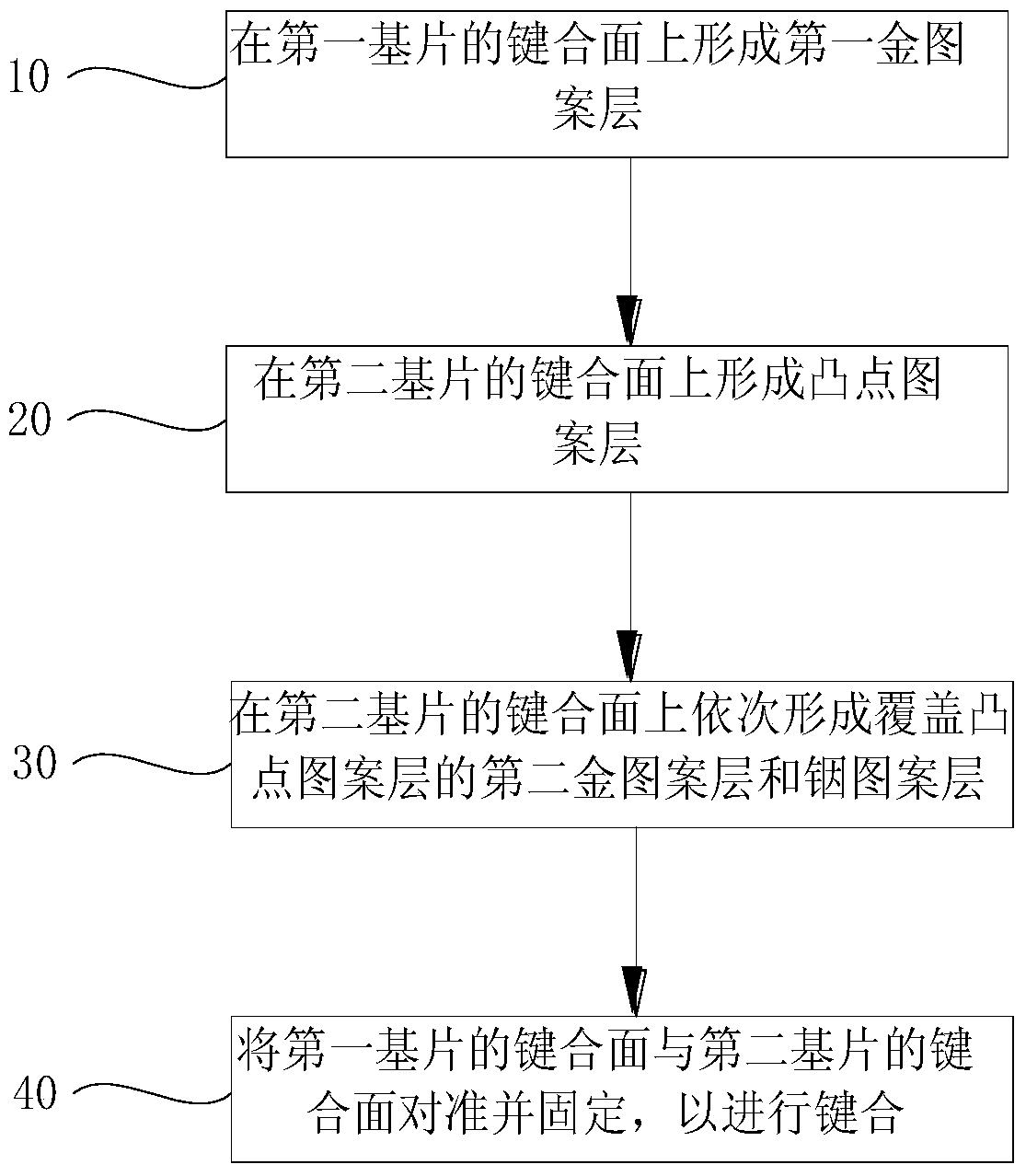

A low-temperature bonding method based on au/in isothermal solidification

ActiveCN106298557BUniform linesReduced Surface Flatness RequirementsSolid-state devicesSemiconductor/solid-state device manufacturingBonding processOptoelectronics

The invention discloses a low-temperature bonding method based on Au / In isothermal solidification, comprising: forming a first gold pattern layer on a bonding surface of a first substrate; forming a bump pattern on a bonding surface of a second substrate layer; on the bonding surface of the second substrate, the second gold pattern layer and the indium pattern layer covering the bump pattern layer are sequentially formed; the bonding surface of the first substrate is bonded to the second substrate Align and secure the bonding surfaces for bonding. The present invention uses a raised dot pattern layer on the bottom layer of the metal film. The raised dot pattern layer not only reduces the bonding alignment accuracy, but also enhances the contact force in the bonding process, which can greatly improve the bonding quality.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

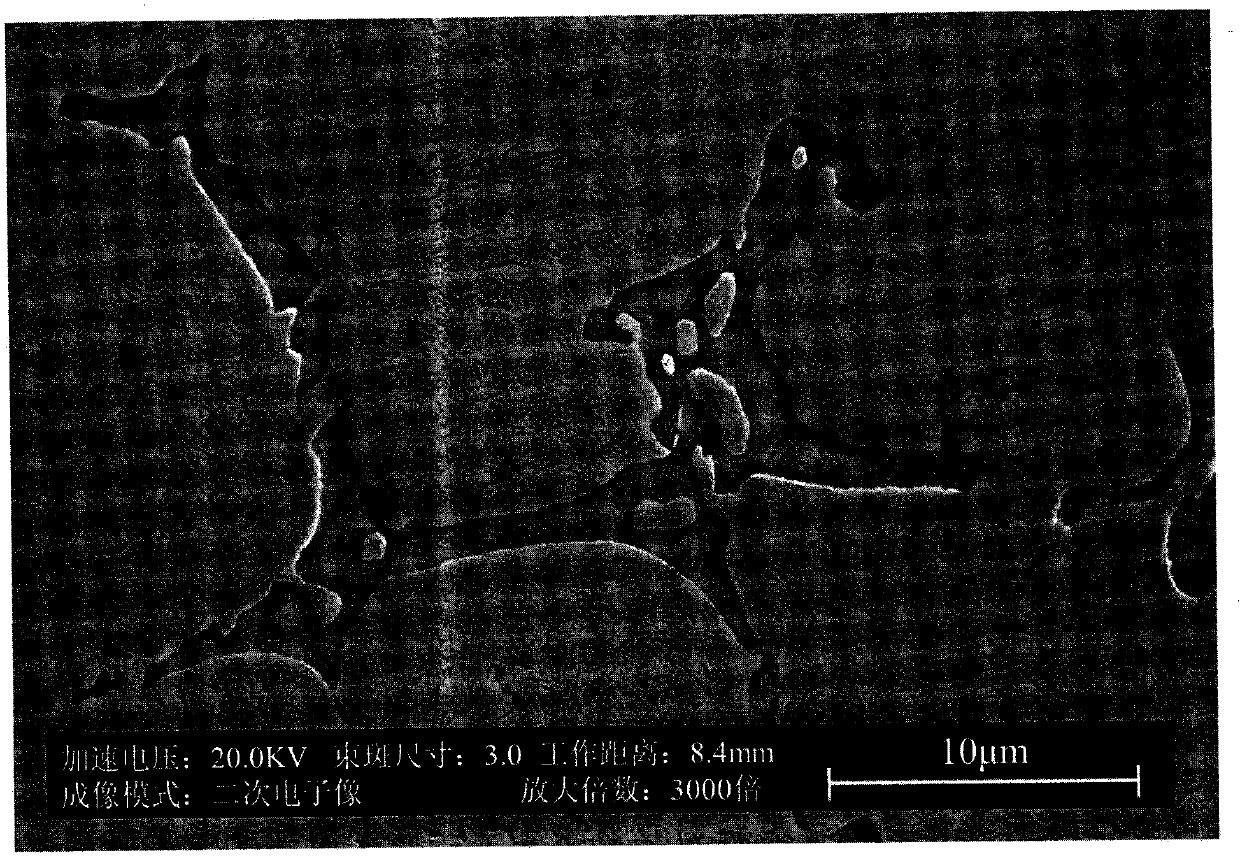

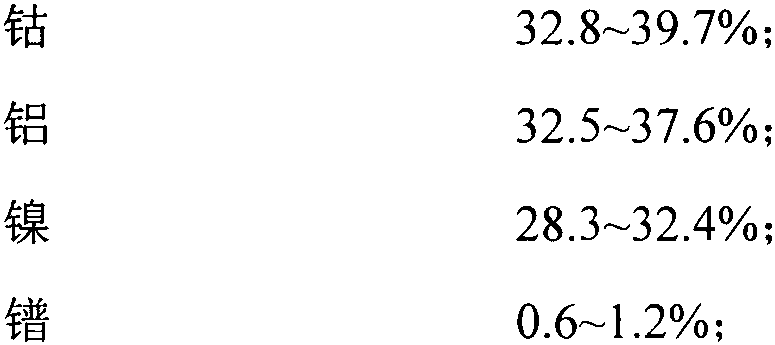

Low start threshold magnetic memory alloy and preparation method thereof

InactiveCN110819871ALow start thresholdExcellent starting thresholdMagnetic memoryShape-memory alloy

The invention provides a low start threshold magnetic memory alloy and a preparation method thereof. Compared with existing materials, the low start threshold magnetic memory alloy has the advantagesof excellent mechanical properties and magnetoelastic strain low start threshold. The chemical formula of the alloy is Co<x>Al<y>Ni<z>Pr<j>, wherein x is greater than or equal to 32.8 and is less thanor equal to 39.7, y is greater than or equal to 32.5 and is less than or equal to 37.6, z is greater than or equal to 28.3 and is less than or equal to 32.4, j is greater than or equal to 0.6 and isless than or equal to 1.2, x plus y plus z and plus j is equal to 100, and x, y, z and j represent molar percentage content. Compared with the existing materials, the magnetically controlled shape memory alloy forms a Co19Pr5 intermetallic compound with a coherent ultrafine dispersion distribution in a matrix phase of the alloy, so that the alloy has both the characteristics of good mechanical properties and magnetic properties, and the alloy is promoted to have the characteristics of both excellent mechanical properties and low start threshold, and the industrial application range of the typeof alloy is greatly broadened.

Owner:NANJING INST OF TECH

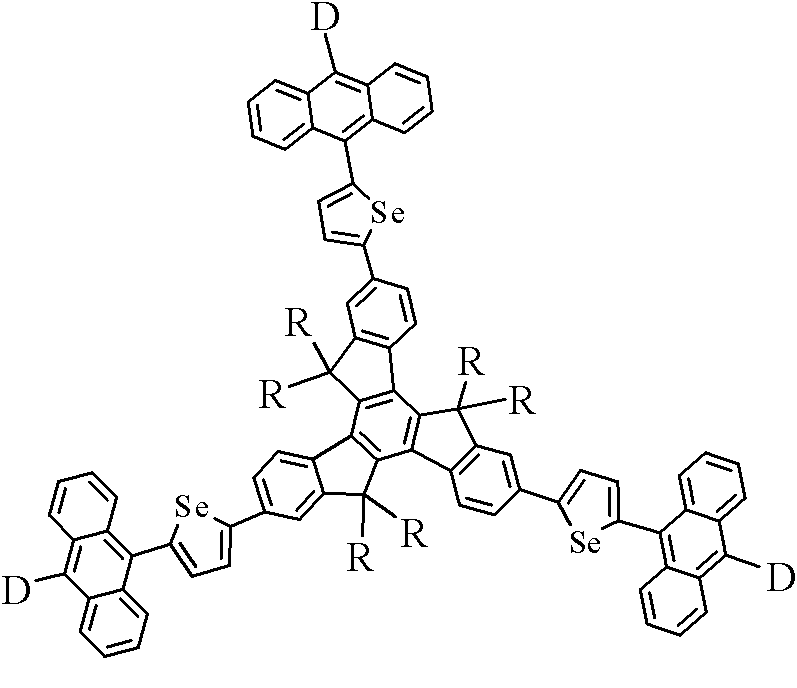

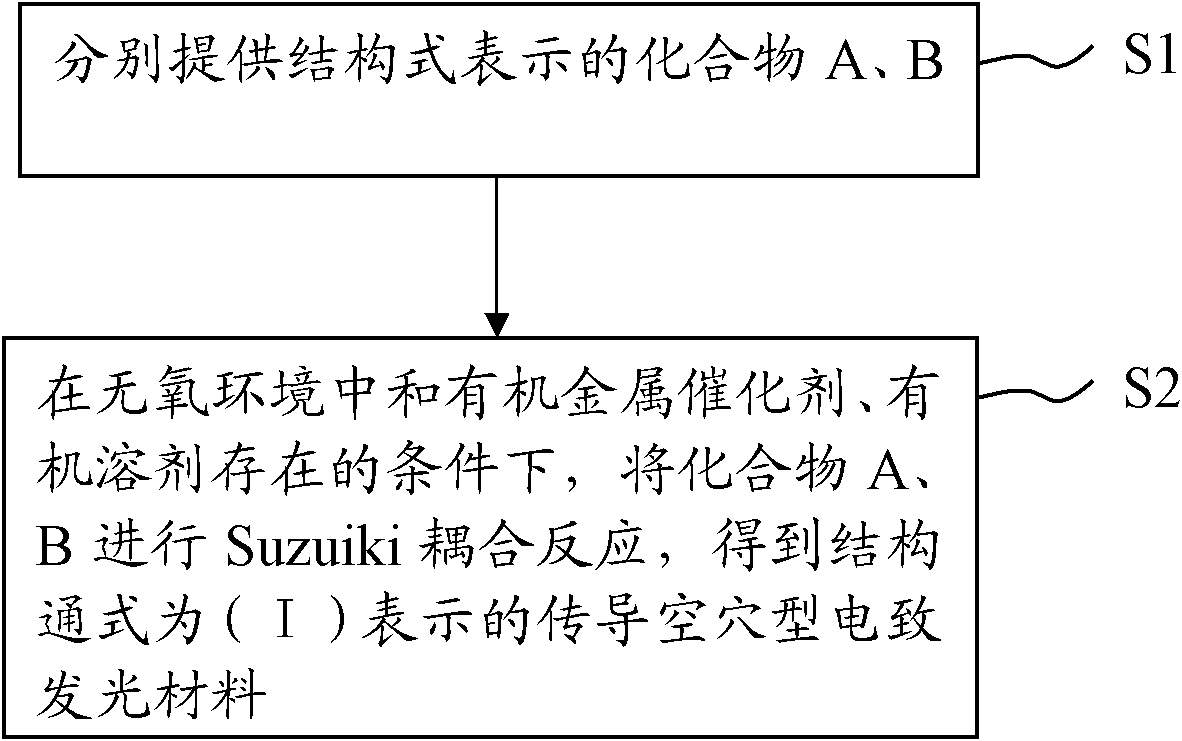

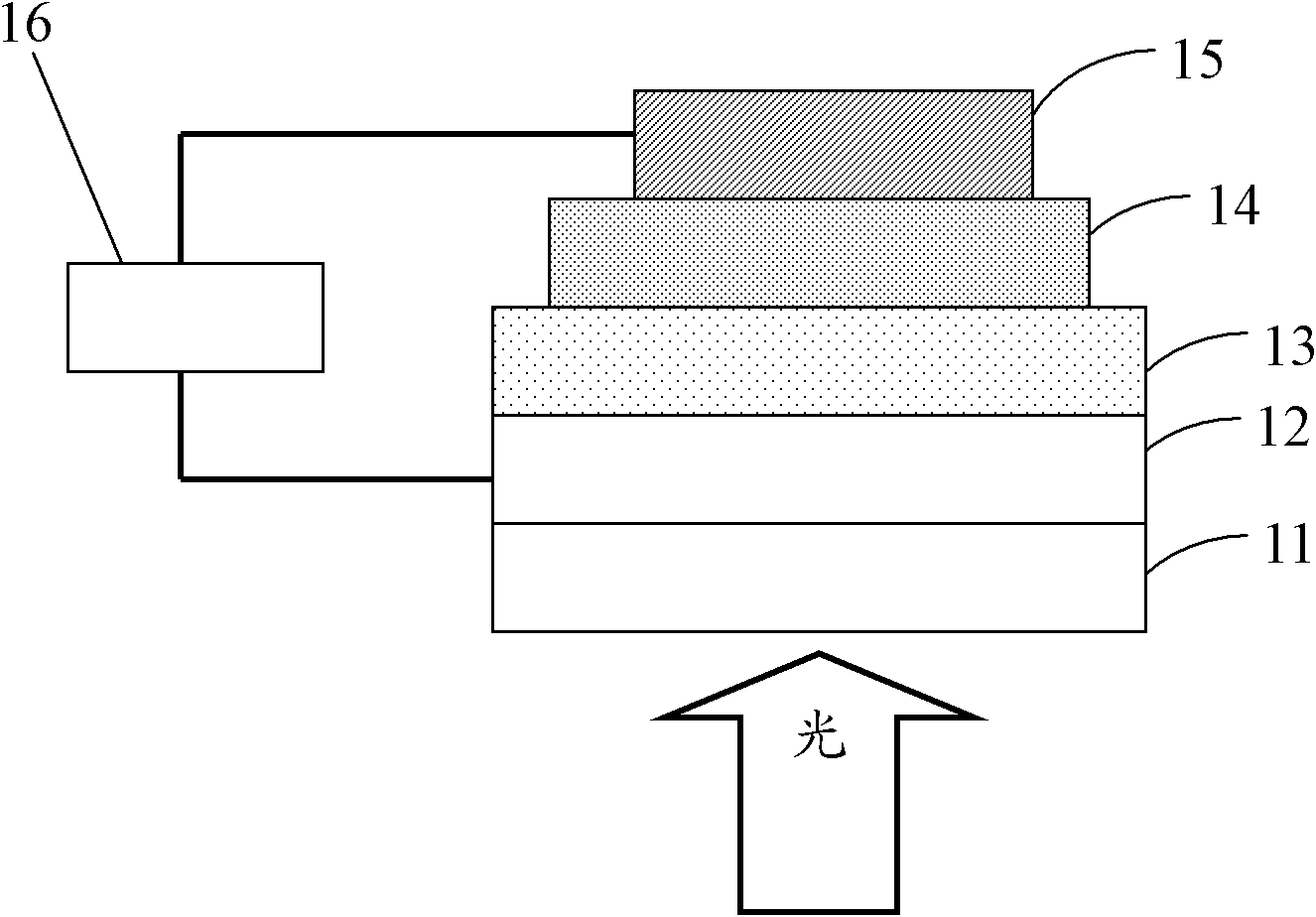

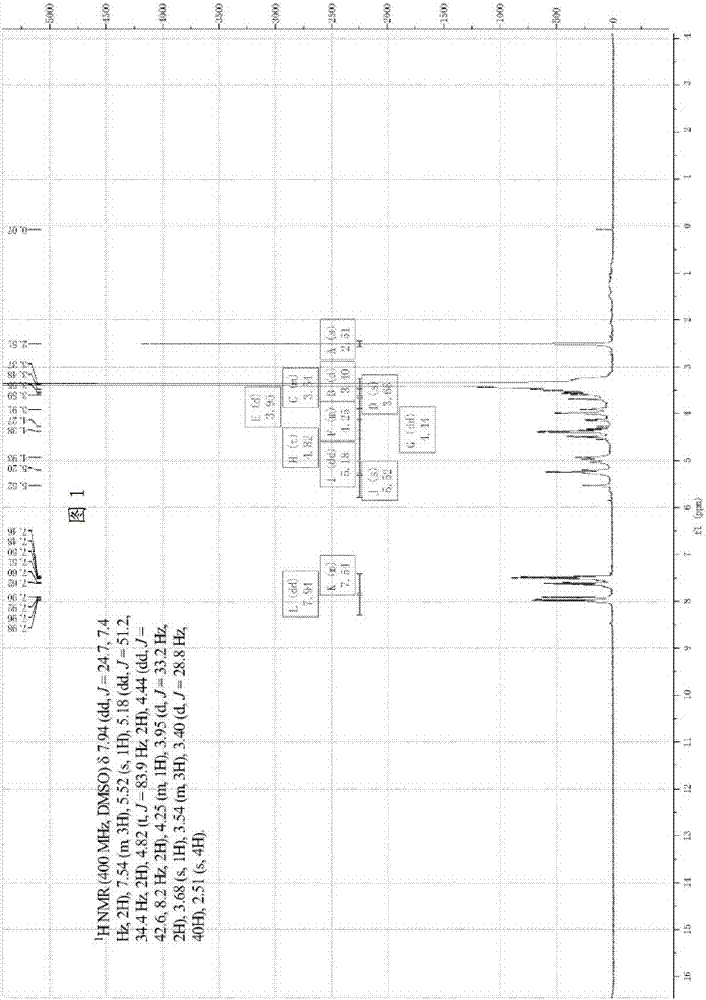

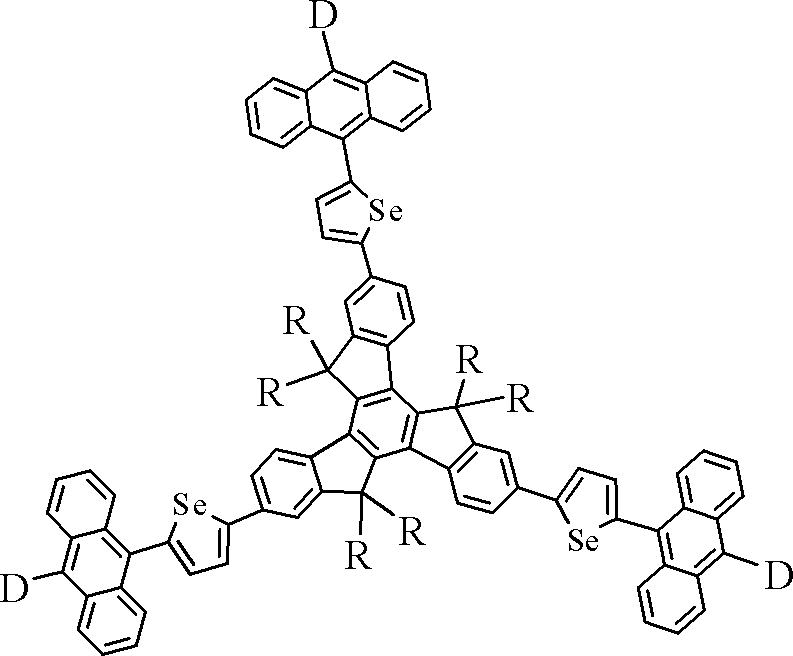

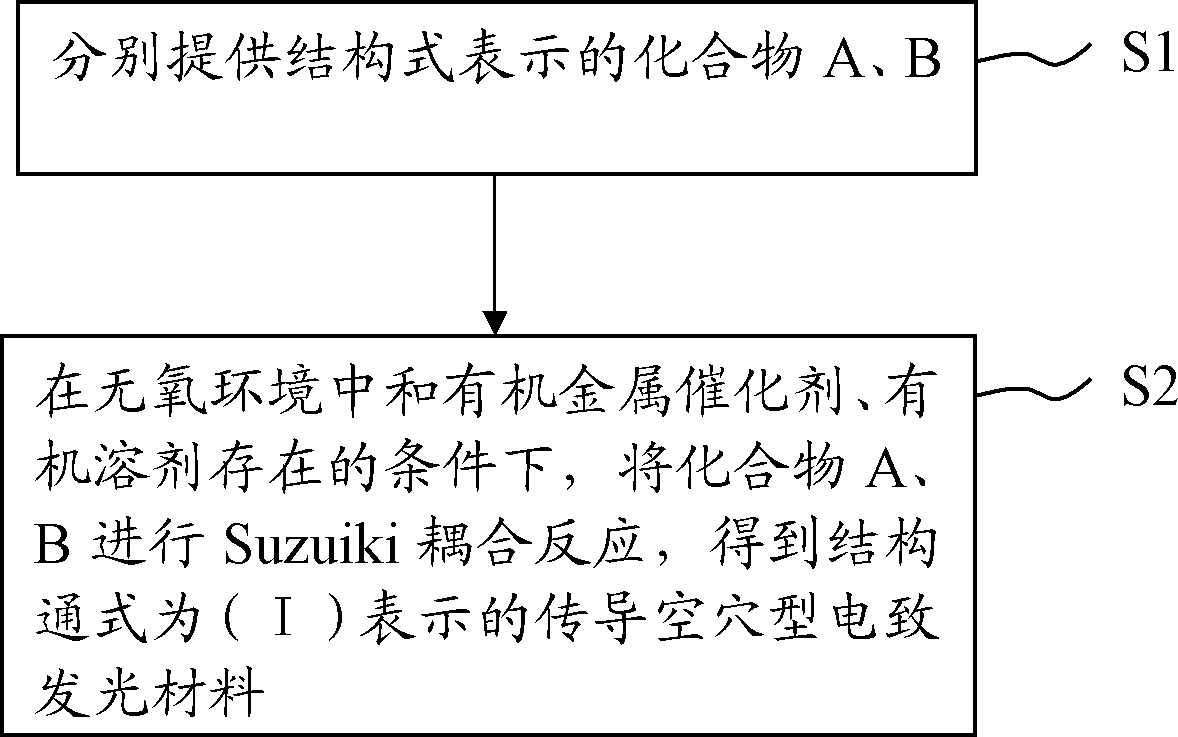

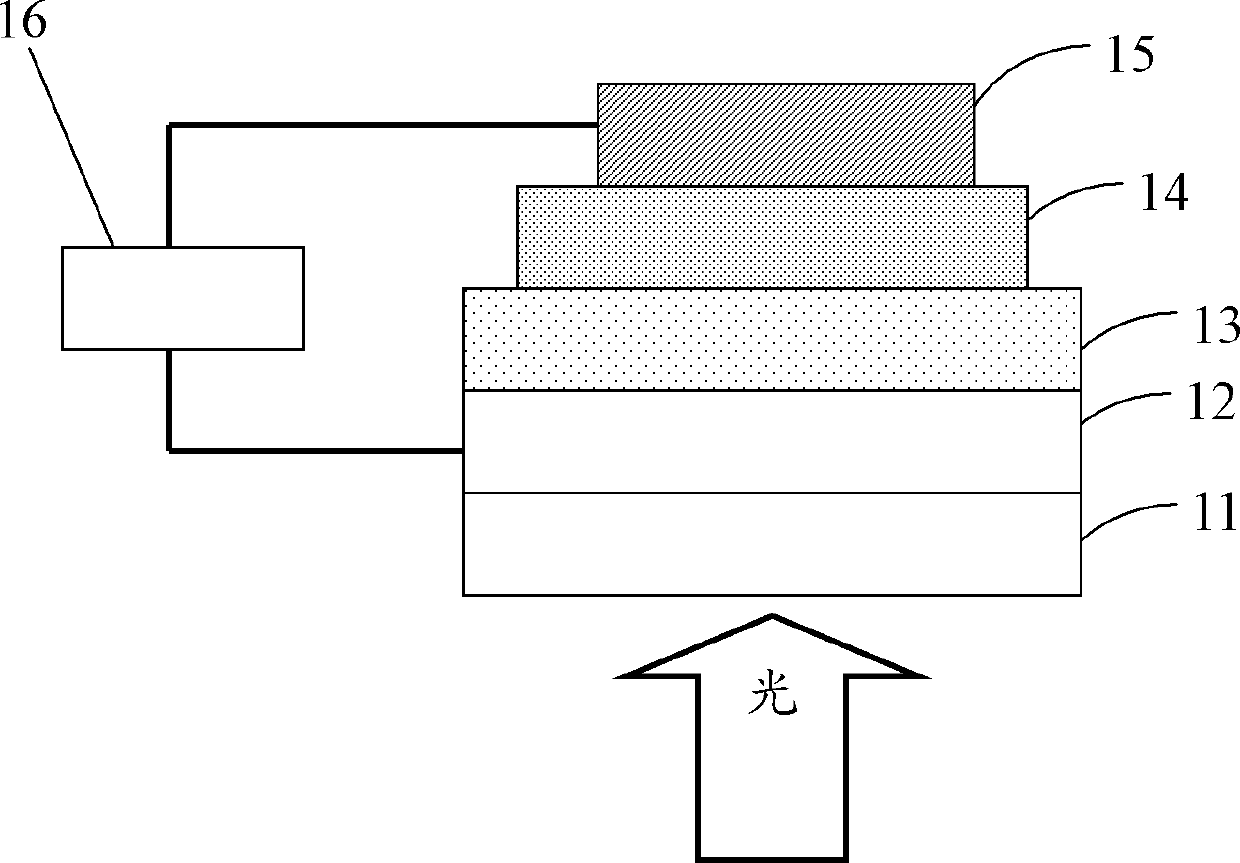

Conduction cavity type electroluminescent material and preparation method and application thereof

InactiveCN102653678AStable structureImprove thermal stabilityLaser active region structureFinal product manufactureElectricityFluorescence

The invention discloses a conduction cavity type electroluminescent material and a preparation method and an application thereof. A molecular structure general formula of the conduction cavity type electroluminescent material is shown as the following formula (I), wherein D is an electron-donating group, and R is a C1-C12 linear chain or alkyl with a branched chain. The conduction cavity type electroluminescent material is prepared by the copolymerization of an anthracene structural unit, a selenophen structural unit and a truxene structural unit, so that the conduction cavity type electroluminescent material is stable in structure and excellent in thermal stability and cavity transmission performance, enhances fluorescence emission, and has great application prospect in the field of photoelectricity. The conduction cavity type electroluminescent material is simple in preparation technology and easy to operate and control, reduces the production cost, and is suitable for industrial production.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

A kind of zn-sb-bi film material and preparation method thereof for multi-state phase change memory

ActiveCN107946460BReduced thermal stability of amorphousAtomic radius is largeElectrical apparatusPhase-change memoryCoating system

The invention discloses a Zn-Sb-Bi thin film material for multi-state phase change memory and a preparation method thereof, which is characterized in that the thin film material is composed of metal single substance Bi target and Zn 2 Sb 3 The alloy target is obtained by double-target co-sputtering in the magnetron sputtering coating system, and its chemical structure is (Zn 2 Sb 3 ) 100‑x Bi x , where 0≤x<14, among which the phase change material Zn is preferred 2 Sb 3 and (Zn 2 Sb 3 ) 96.8 Bi 3.2 It has higher crystallization temperature, larger crystallization activation energy and stronger ten-year data retention. Compared with traditional three-state GST phase change materials, the three-state phase change memory material has higher crystallization temperature and phase transition temperature. , and the crystalline resistance is larger, with 3 resistance states, while other Zn-Sb-Bi films with higher Bi content exhibit 4 resistance states, which can achieve higher multi-bit multi-value storage.

Owner:NINGBO UNIV

A kind of preparation method of rhodium-containing catalyst and catalyst thereof

ActiveCN107051438BAtomic radius is largeReduce entryGas treatmentDispersed particle separationSlurryPt element

The invention discloses a high-performance rhodium-containing catalyst and a preparation method thereof. The catalyst of the present invention consists of a substrate and a catalyst coating coated on the surface of the substrate. The catalyst coating consists of catalytic materials and noble metals. The catalyst coating includes at least a rhodium catalyst layer, and can also include palladium, platinum or platinum-palladium mixed in a certain proportion. Catalyst layer; the preparation method of rhodium catalyst layer comprises: concentration of 10% by weight rhodium solution is concentrated to 40-100% under continuous stirring at 40-90° C., adding alcohols and reacting for 0.5-5h, the solution viscosity is 5-50Pa.s, Then add the alcohol amine solution to adjust the pH to 3.5-10.5, continue to stir for 5-60min, take out the rhodium solution and add it to the catalytic material to form a powder / slurry, and then coat it on the substrate to form a rhodium catalytic layer. The catalyst prepared by the invention is used for treating motorcycle tail gas or gasoline car tail gas, and has the advantages of easy-to-obtain raw materials, simple preparation process, low catalyst light-off temperature and good durability.

Owner:SINOCAT ENVIRONMENTAL TECH

A method for improving the mechanical properties of aluminum-silicon-magnesium casting alloy

Owner:INNER MONGOLIA UNIV OF TECH

Preparation method of sucrose-6-benzoate

ActiveCN102796145BAtomic radius is largeImprove solubilityEsterified saccharide compoundsSugar derivativesSucroseMethyl benzoate

The invention provides a preparation method of sucrose-6-benzoate, which comprises the following steps: by using sucrose as a raw material, methyl benzoate as an esterifying reagent and an alkali carbonate as a catalyst, synthesizing sucrose-6-benzoate under vacuum distillation conditions; and by using the polar difference between the sucrose and the sucrose-6-benzoate, adding a low-polarity solvent to precipitate unreacted sucrose, thereby purifying the sucrose-6-benzoate. The method can enhance the yield and purity of the sucrose-6-benzoate and recycle the unreacted sucrose, has the advantages of environment-friendly technique, low facility request and high economical efficiency, provides a new way for synthesizing sucrose-6-benzoate, and is suitable for the demands for large-scale industrial production.

Owner:天津北方食品有限公司

Conduction cavity type electroluminescent material and preparation method and application thereof

InactiveCN102653678BStable structureImprove thermal stabilityLaser active region structureFinal product manufactureElectron holePolymer science

The invention discloses a conduction cavity type electroluminescent material and a preparation method and an application thereof. A molecular structure general formula of the conduction cavity type electroluminescent material is shown as the following formula (I), wherein D is an electron-donating group, and R is a C1-C12 linear chain or alkyl with a branched chain. The conduction cavity type electroluminescent material is prepared by the copolymerization of an anthracene structural unit, a selenophen structural unit and a truxene structural unit, so that the conduction cavity type electroluminescent material is stable in structure and excellent in thermal stability and cavity transmission performance, enhances fluorescence emission, and has great application prospect in the field of photoelectricity. The conduction cavity type electroluminescent material is simple in preparation technology and easy to operate and control, reduces the production cost, and is suitable for industrial production.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Abrasion-resistant clamping plate and preparation method thereof

The invention belongs to the technical field of abrasion-resistant materials, and particularly relates to an abrasion-resistant clamping plate and a preparation method thereof. The abrasion-resistantclamping plate is prepared from the following chemical components in percentage by weight: 1.5-2.9% of carbon, 0.4-0.8% of silicon, 0.4-0.85% of magnesium, 0.4-1.0% of manganese, 14-17% of chromium, 0.5-1.0% of molybdenum, 0.1-0.22% of nickel, 0.05-0.20% of titanium, 0.005-0.04% of phosphorus, 0.005-0.04% of sulfur, and the balance of iron. The abrasion-resistant clamping plate is reasonable in formula, easy to manufacture and long in service life, and has quite high strength, toughness, abrasion resistance and impact resistance, the frequency for replacing the clamping plate in a factory is decreased, and the labor intensity is lowered.

Owner:湖北秦鸿新材料有限公司

Moving spraying nozzle ring and preparation method thereof

InactiveCN110819887AReasonable formulaEasy to makeProcess efficiency improvementGrain treatmentsCopperWear resistance

The invention belongs to the technical field of wear-resistant materials, and particularly relates to a moving spraying nozzle ring and a preparation method thereof. The moving spraying nozzle ring isprepared from the following chemical components in percentage by weight: 1.5-2.9% of carbon, 1.2-2% of silicon, 0.6-0.9% of copper, 0.4-1.0% of manganese, 14-17% of chromium, 0.05-0.2% of molybdenum,0.1-0.2% of nickel, 0.05-0.20% of boron, 0.005-0.04% of phosphorus, 0.005-0.04% of sulfur, and the balance of iron. A formula is reasonable, manufacturing is easy, the service life is long, quite high strength, toughness, wear resistance and impact resistance are achieved, the frequency of replacing a clamping plate in a factory is reduced, the labor intensity is lowered, raw materials are easy to obtain, a production method is simple, and energy is effectively saved.

Owner:湖北秦鸿新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com