Patents

Literature

46results about How to "Microorganized" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

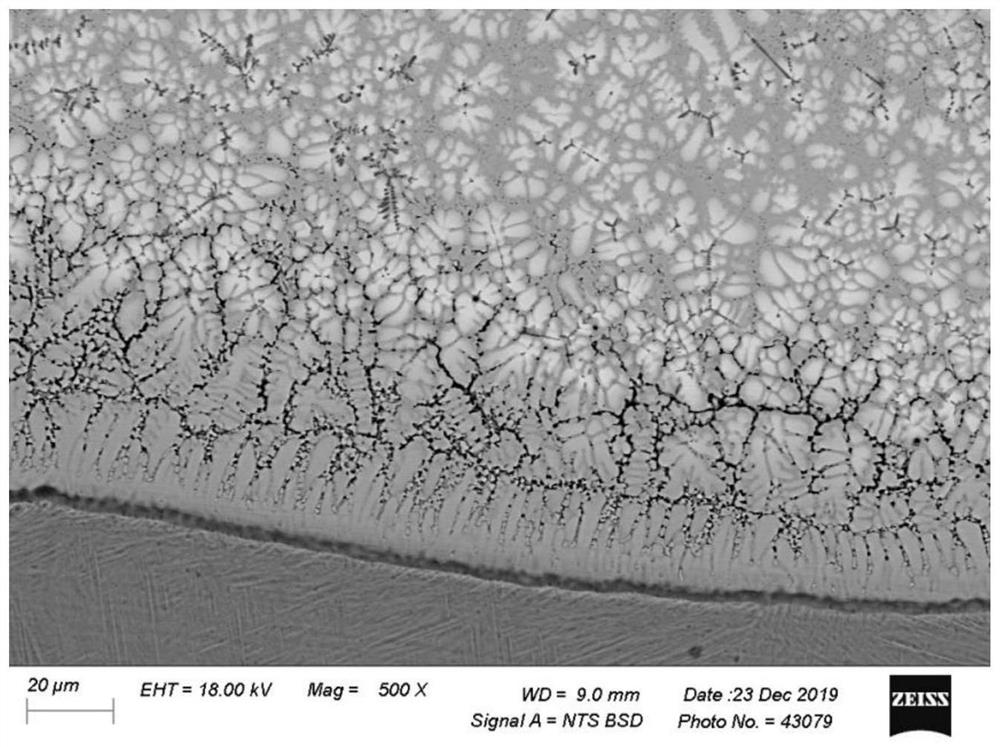

Low-pressure casting method of aluminum alloy automobile hub

ActiveCN102366828AOptimization of process parameters and heat treatment parametersImprove performanceHubsThermal treatmentAluminium alloy

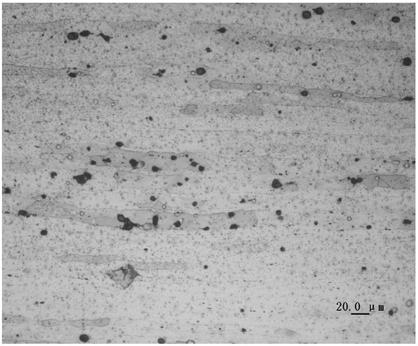

The invention discloses a low-pressure casting method of an aluminum alloy automobile hub. In the method, by optimizing alloy component design, adding a proper amount of Al-Ti-B-C refining agent and rare-earth modifying agent, low-pressure casting process parameters and thermal treatment parameters are optimized, so that the prepared automobile hub is provided with a tissue consisting of fine and uniform a dendritic crystal and fine and uniform worm-shaped or spherical silicon, and the performance of the aluminum alloy automobile hub is improved.

Owner:QINHUANGDAO XINGLONG WHEEL HUB

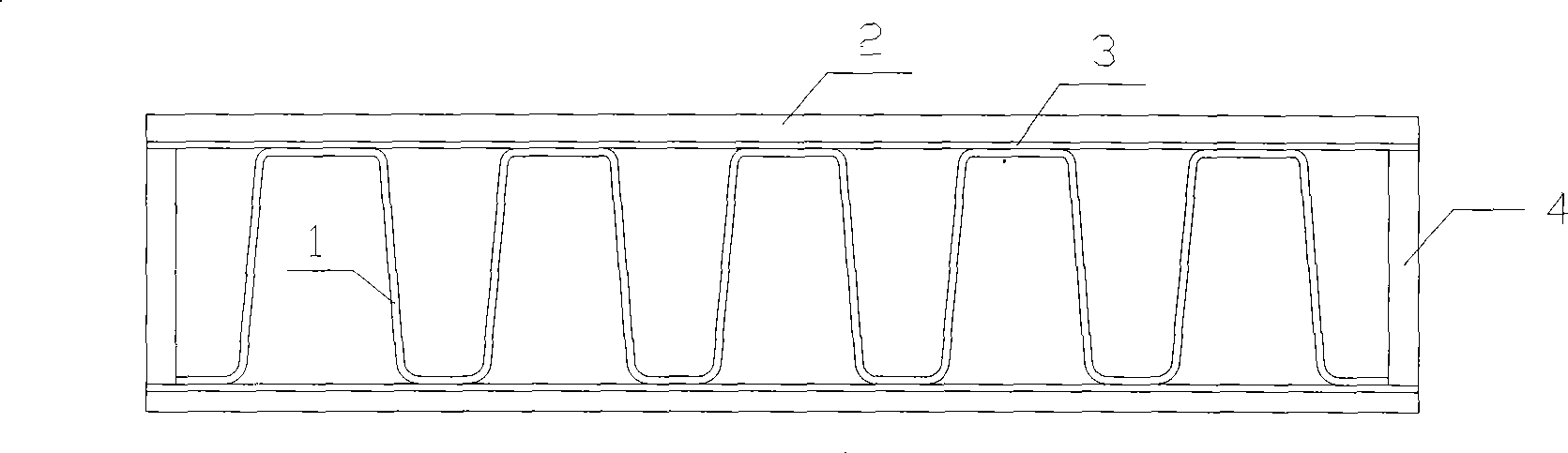

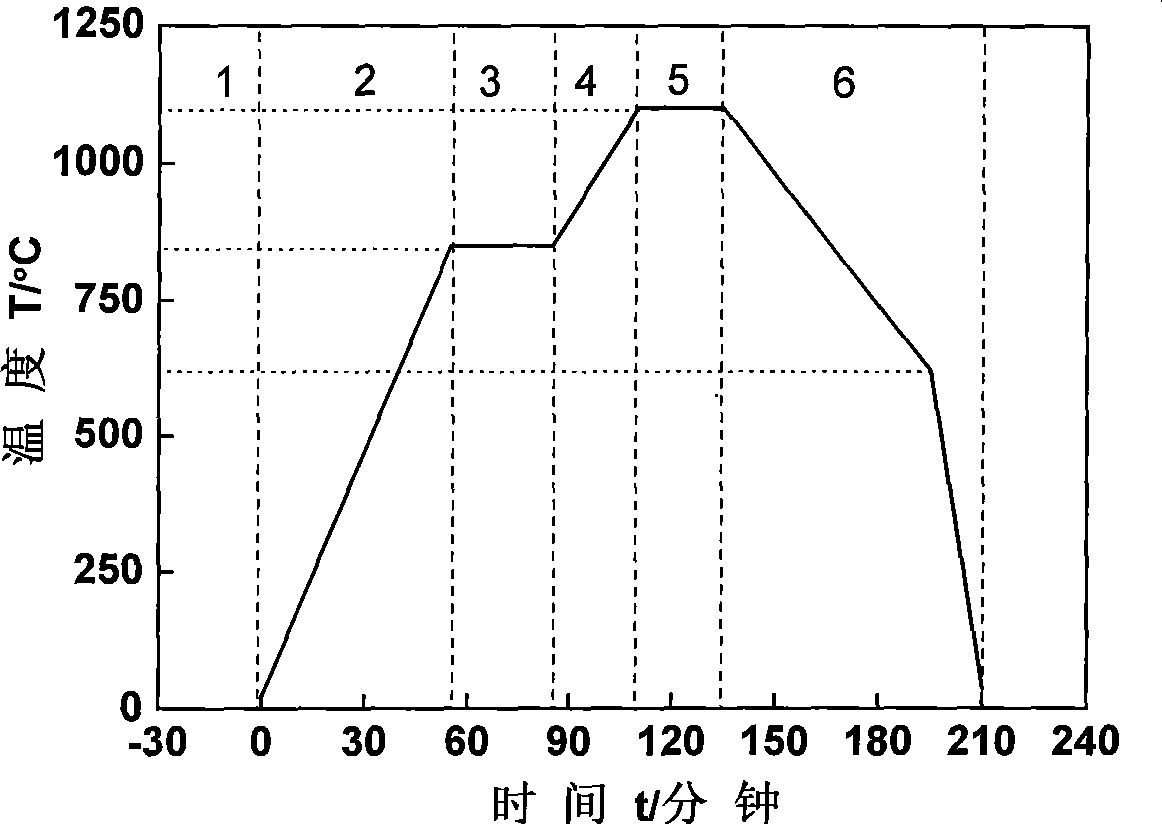

Vacuum brazing technique of stainless steel plate fin structure

InactiveCN101391329AOptimizing the Vacuum Brazing ProcessHigh strengthSoldering apparatusNitrogenNitrogen gas

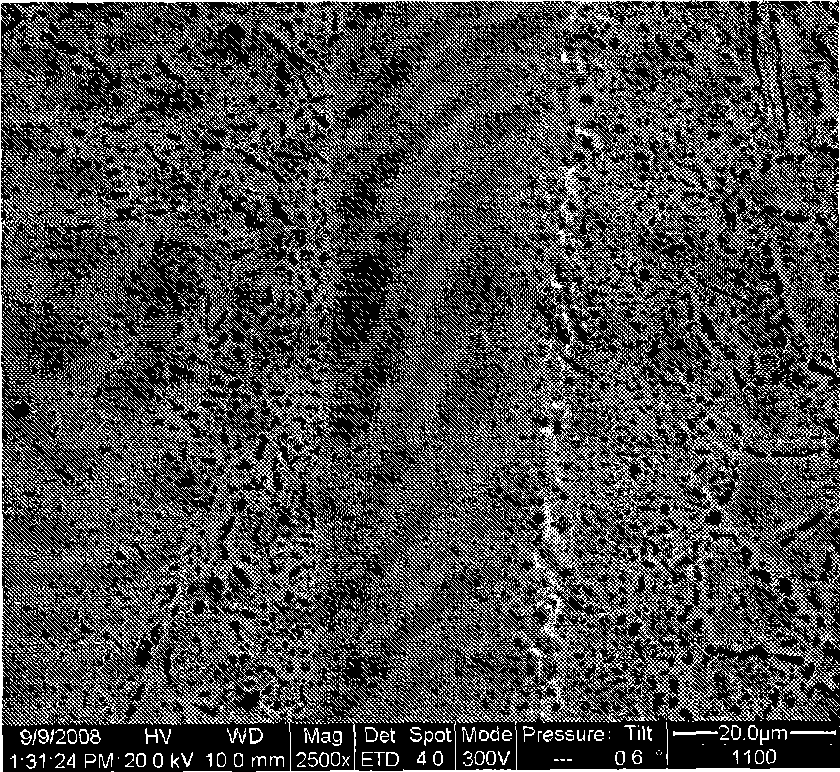

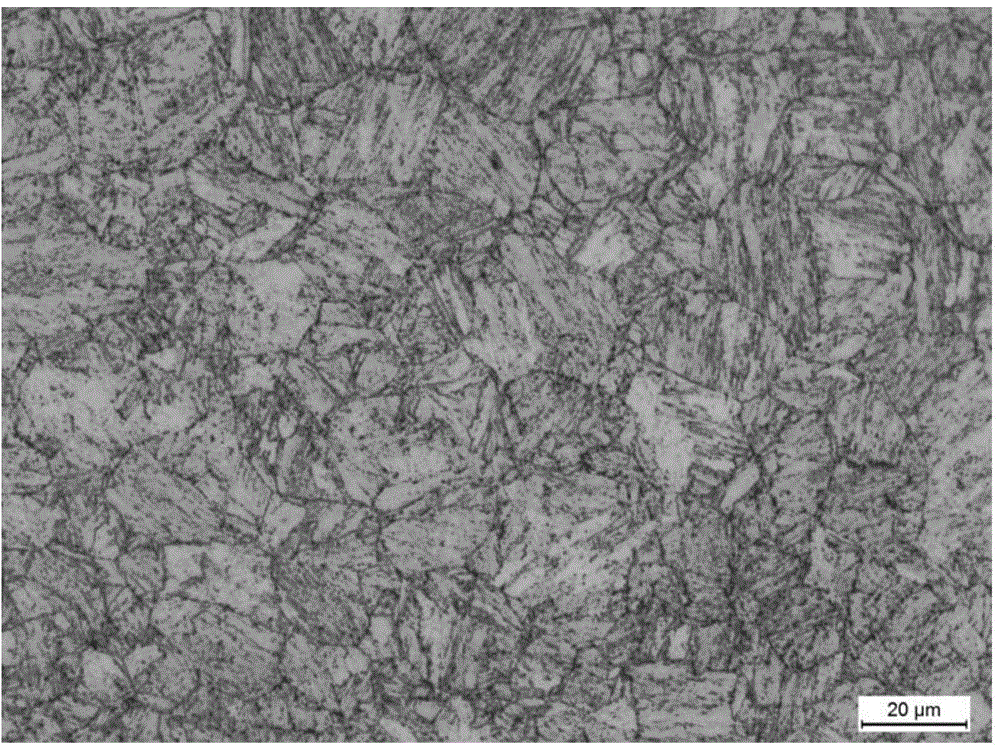

The invention discloses a vacuum brazing process of a stainless steel plate-fin structure, comprising: firstly placing a fin on a baffle and then placing a baffle thereon, placing a solder foil between the fin and the baffles, and then sealing the two sides by edge sealing tapes to form an elementary unit; stacking up a plurality of elementary units according to the design requirements, then using a special jig to clamp and firm the units and exerting pressure on the units, and placing the units in a vacuum brazing furnace; vacuumizing the brazing furnace firstly; then heating the stainless steel plate-fin structure to 850 to 870DEG C and then preserving the heat; and again heating the stainless steel plate-fin structure to the brazing temperature of 1070 to 1100DEG C and then preserving the heat; and then self-cooling the structure slowly in vacuum from the brazing temperature of 1070 to 1100DEG C to 620 to 640DEG C, then filling nitrogen into the furnace, starting up a fan to cool the structure to 40 to 60DEG C so as to take out the structure, and finally obtaining the stainless steel plate-fin structure. The stainless steel plate-fin structure acquired through the brazing process has excellent microstructures and rather high strength.

Owner:NANJING UNIV OF TECH

800MPa grade low-welding crack sensitive tempering type hydroelectric steel plate

InactiveCN104532148AImprove low temperature impact toughnessMicroorganizedMaterials scienceImpact toughness

The invention relates to an 800MPa grade low-welding crack sensitive tempering type hydroelectric steel plate. The steel plate comprises the following components in percentage by weight: 0.09-0.14% of C, 0.24-0.35% of Si, 0.7-1.45% of Mn, less than or equal to 0.013%, less than or equal to 0.002% of S, less than or equal to 0.035% of Nb, 0.012-0.02% of Ti, 0.30-0.50% of Ni, 0.020-0.070% of Alt, 0.035-0.060% of V, 0.25-0.60% of Cr, 0.25-0.55% of Mo, 0.15-0.30% of Cu, less than or equal to 0.0060% of N, less than or equal to 0.00030% of H, 0.0008-0.002% of B and the balance of Fe. The preparation method comprises the following steps: smelting and casting to a cast blank according to set compositions; heating and rolling in two stages; and quickly cooling to temper and thermally treat to obtain excellent strength, plasticity and low-temperature impact toughness which are matched, so that the request on hydroelectric steel is satisfied.

Owner:NANJING IRON & STEEL CO LTD +1

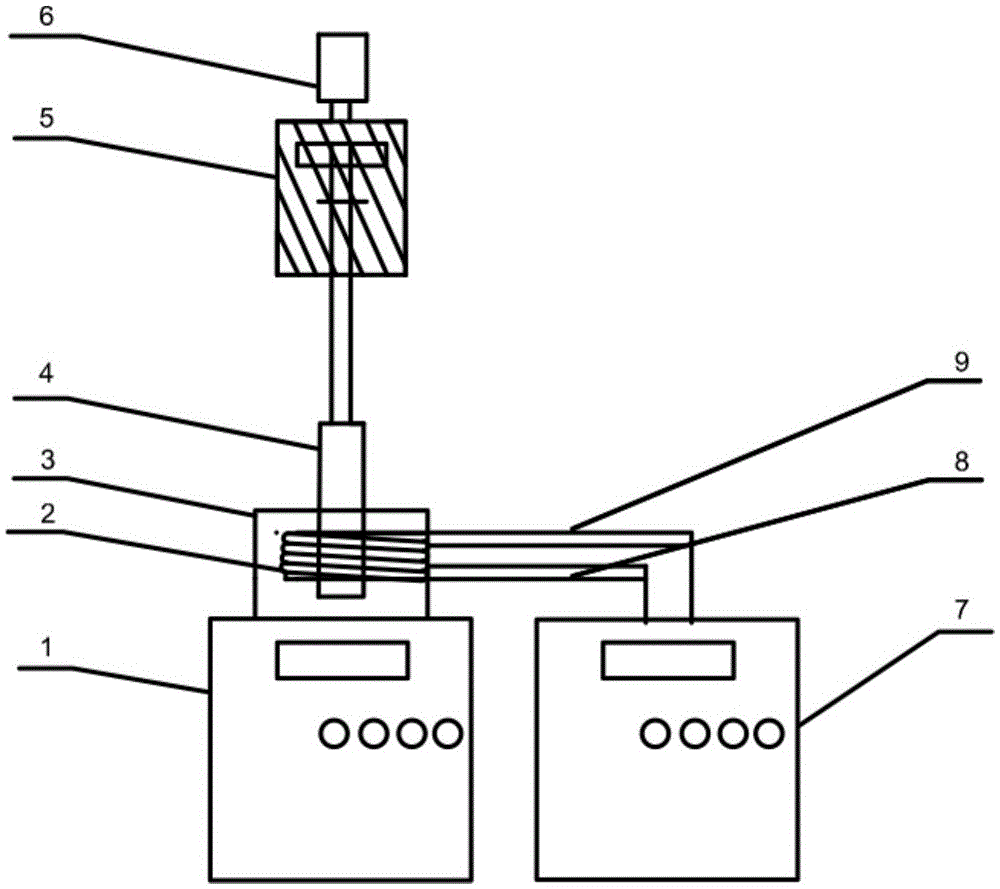

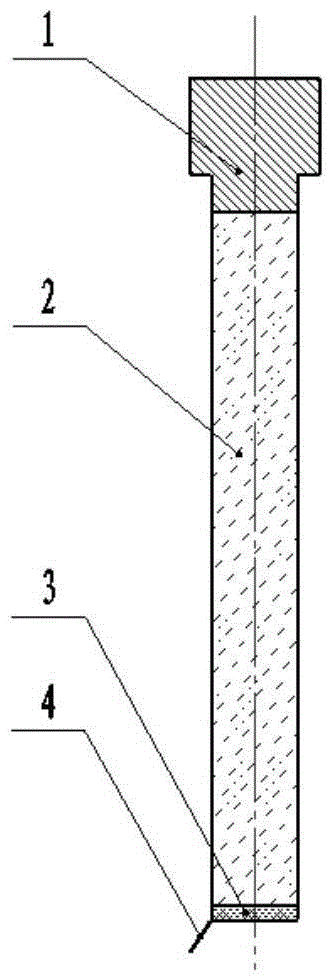

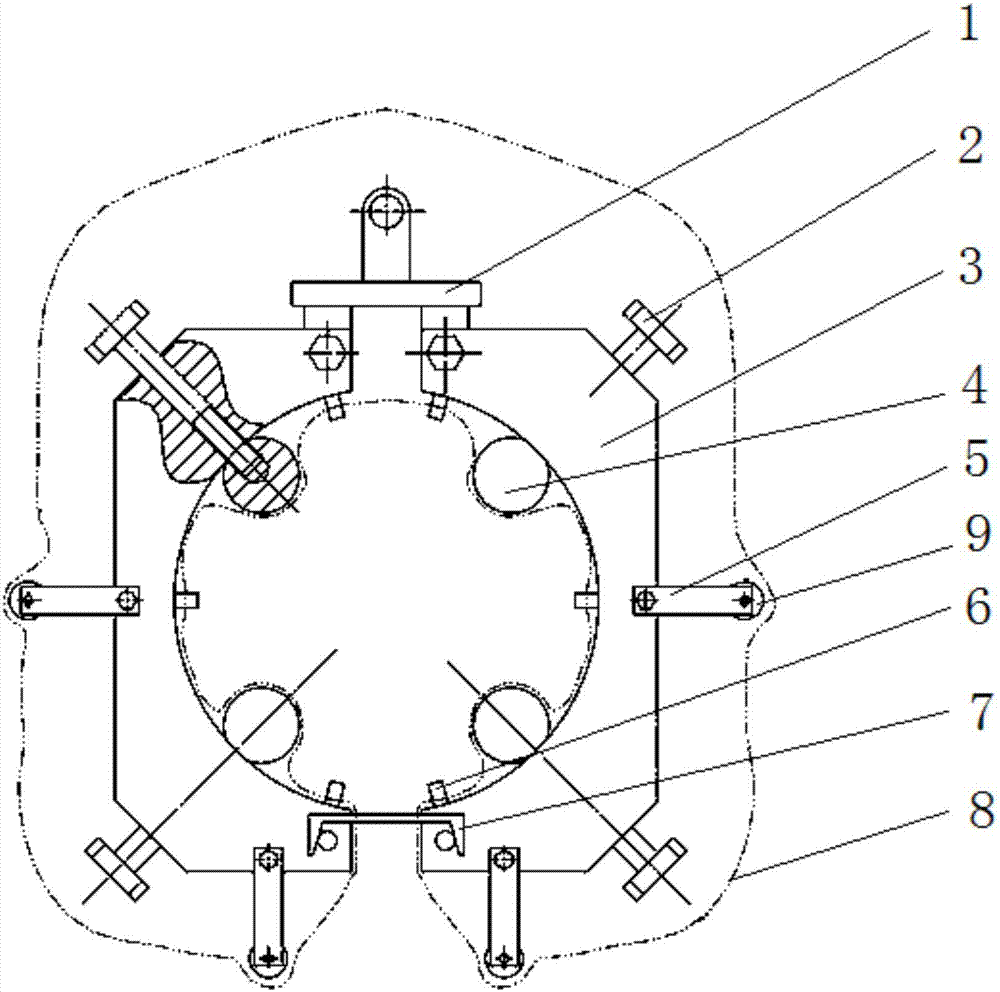

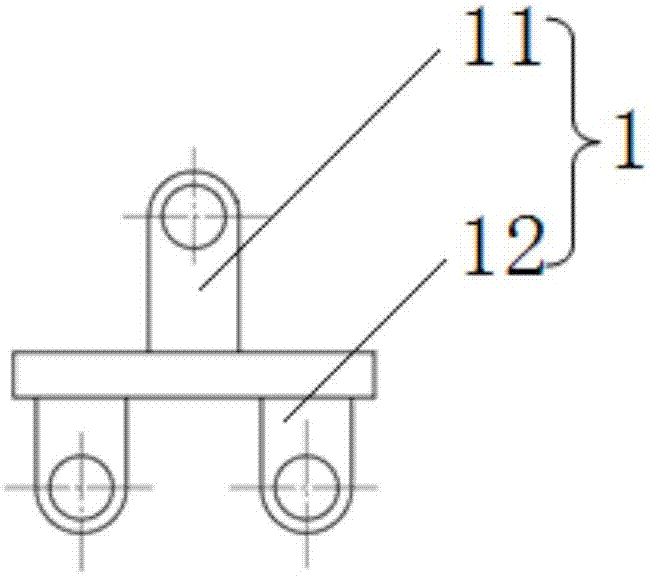

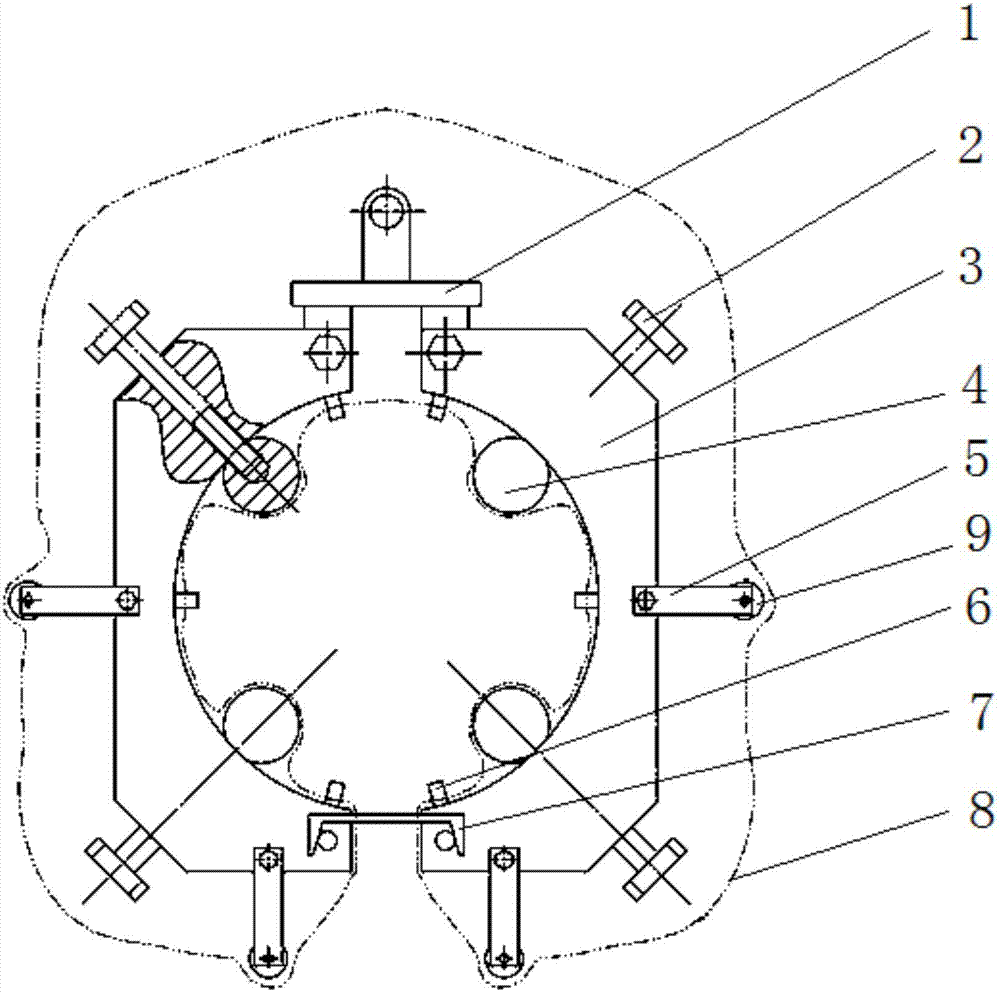

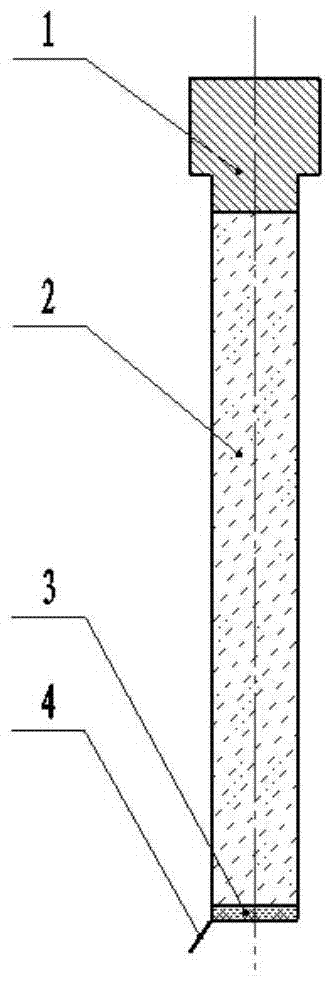

Directional solidification apparatus for preparation of porous ceramics based on ice template method and preparation method thereof

InactiveCN105541369AUniform sizePrecise Control of MorphologyCeramicwareSlurryDirectional solidification

The invention discloses a directional solidification apparatus for preparation of porous ceramics based on an ice template method and a preparation method thereof. The directional solidification apparatus comprises a servo mechanism, a motor, a low temperature circulator, a constant temperature bath and a die. A refrigeration mode with refrigeration at one end and heating at the other end is used for generating a uniform temperature field, the motor and the servo mechanism are controlled for providing a solidification rate which is higher than 500 [mu]m / s, so that a better microscopic structure of the product is provided with better mechanical properties. Two independent technological parameters including temperature gradient and withdrawal rate are regulated separately, so that solidification process of a ceramic slurry is controlled, the regulation and control scope of the withdrawal rate is wide, and the regulated scope is 1-3000 [mu]m / s. A more uniform temperature field is generated by using the high-speed directional solidification method, the cooling rate is higher, the dimension of ice crystal with orientated growth is more uniform, and the porous ceramics with an oriented structure is obtained; form, structure and porosity of the prepared oriented porous ceramic pores are accurately controlled.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

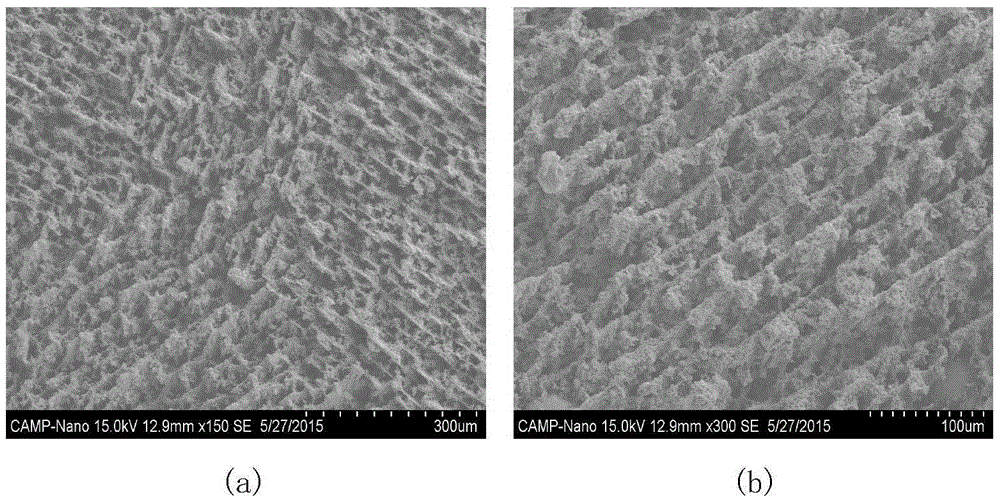

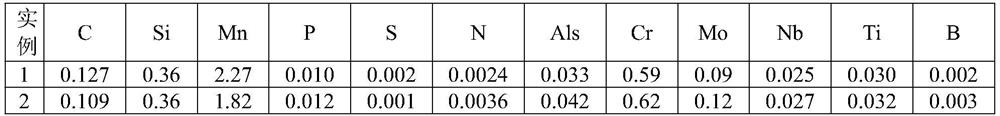

Low-carbon-equivalent 1180 MPa-grade hot galvanizing dual-phase steel and production method thereof

ActiveCN112522623AReduce contentImprove hardenabilityHot-dipping/immersion processesUltimate tensile strengthMechanical properties of carbon nanotubes

The invention discloses low-carbon-equivalent 1180 MPa-grade hot galvanizing dual-phase steel and a production method thereof, and belongs to the technical field of cold-rolled plate strip production.The low-carbon-equivalent 1180 MPa-grade hot galvanizing dual-phase steel comprises the following chemical components including, by mass percent, 0.05-0.14% of C, 0.05-0.40% of Si, 1.20-2.50% of Mn,less than or equal to 0.020% of P, less than or equal to 0.010% of S, 0.015-0.070% of Als, less than or equal to 0.0060% of N, 0.006-0.20% of Mo, 0.010-0.040% of Nb, 0.010-0.040% of Ti, 0.20-0.67% ofCr, larger than 0 and less than 0.005% of B, and the balance Fe and inevitable impurities. The production method comprises the processes of smelting, hot rolling, acid rolling, hot galvanizing and thelike. According to the low-carbon-equivalent 1180 MPa-grade hot galvanizing dual-phase steel and the production method thereof, the steel has excellent mechanical properties, the yield strength is 880-960 MPa, the tensile strength is 1193-1276 MPa, the elongation A80 is 6.0-10.0%, and the problem that the steel cannot meet the requirements of high strength, high yield strength and low cost at thesame time can be effectively solved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

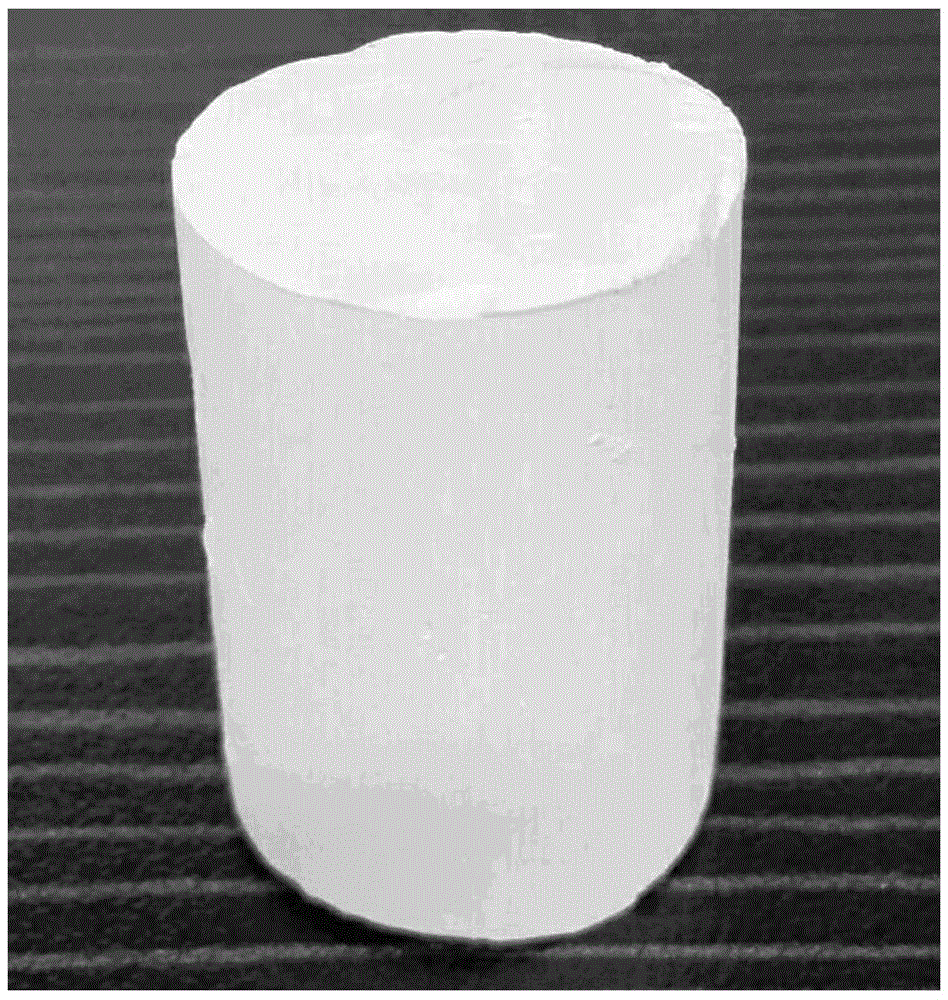

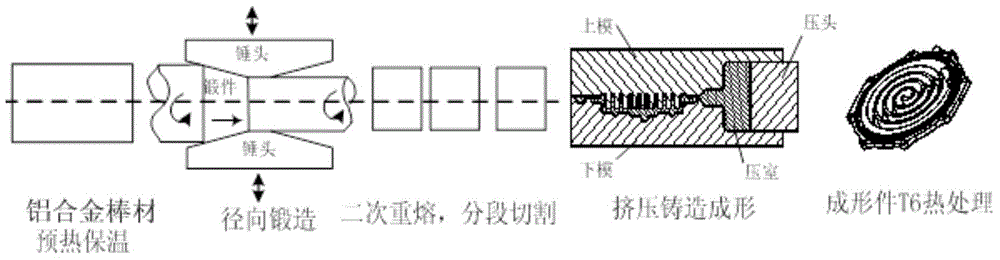

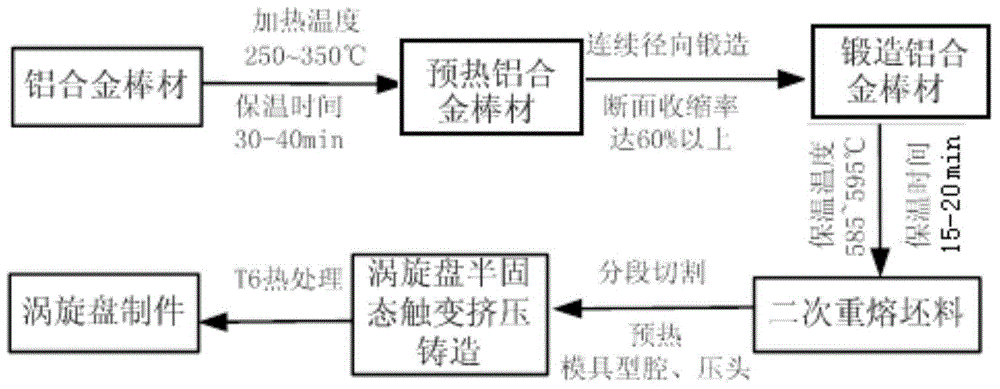

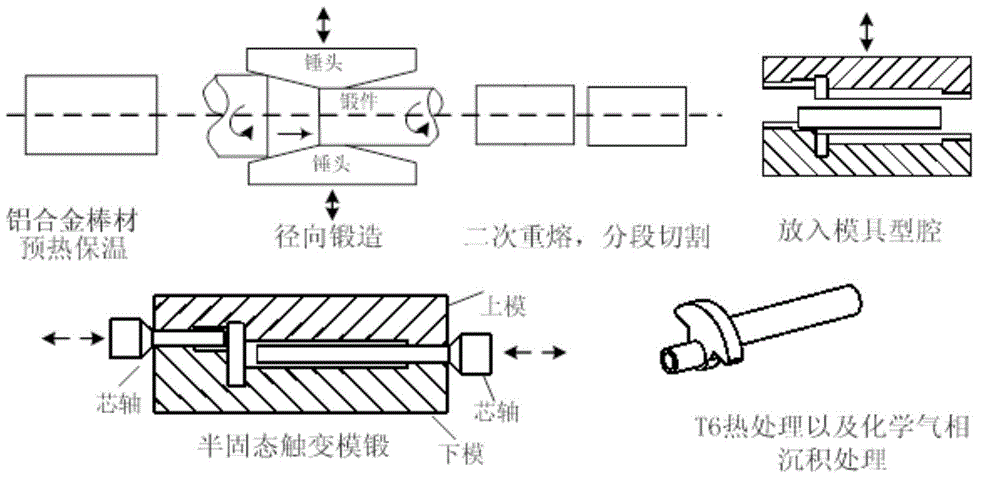

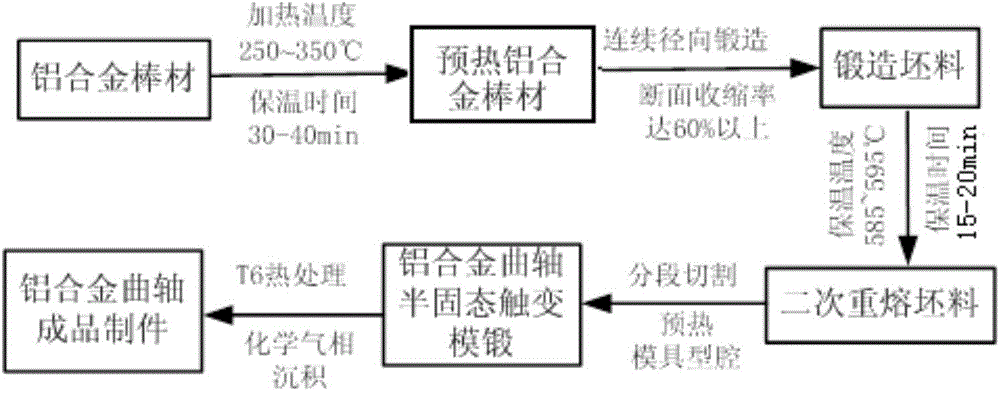

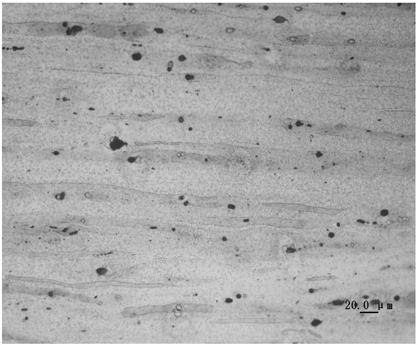

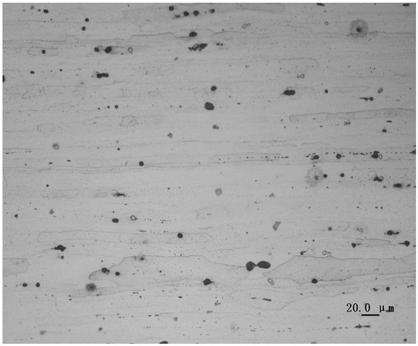

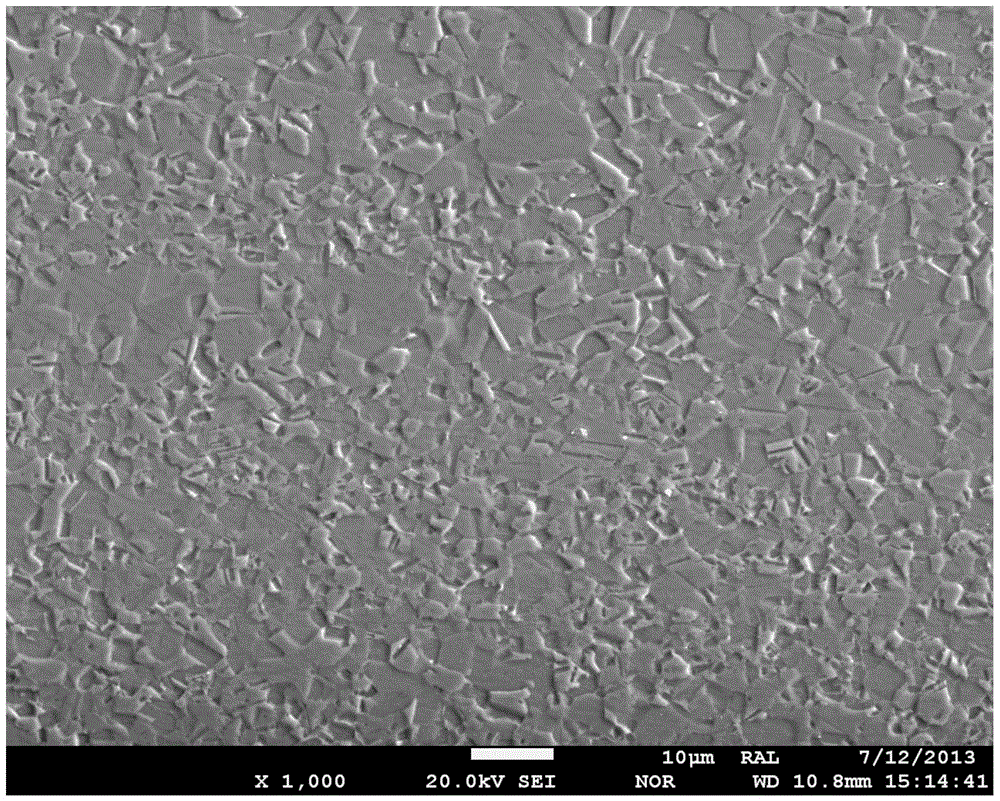

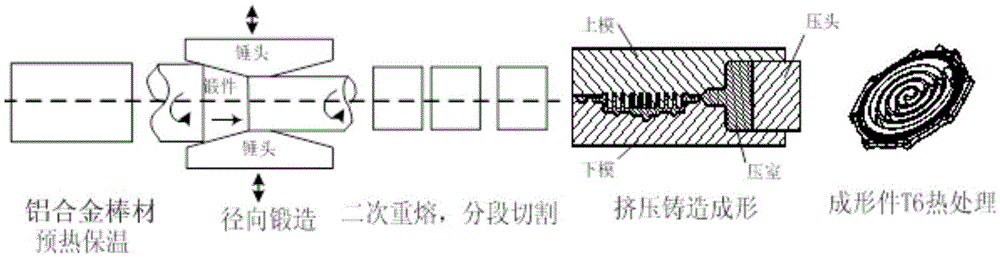

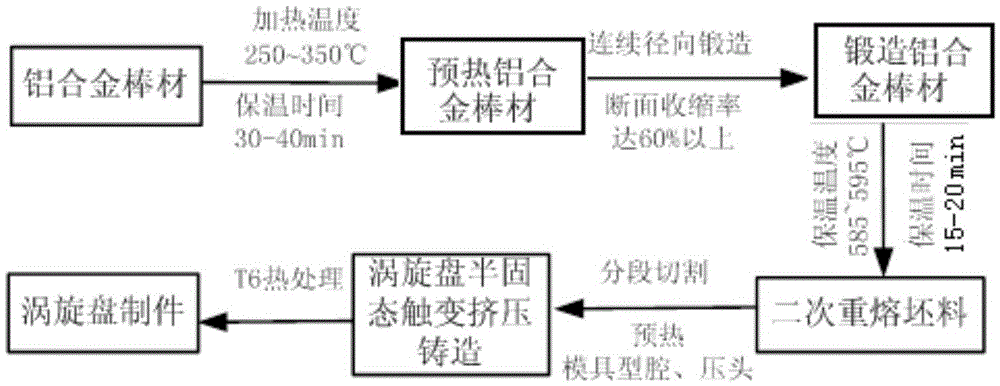

Process for preparing semi-solid state aluminum alloy scroll plate by radial forging strain induction method

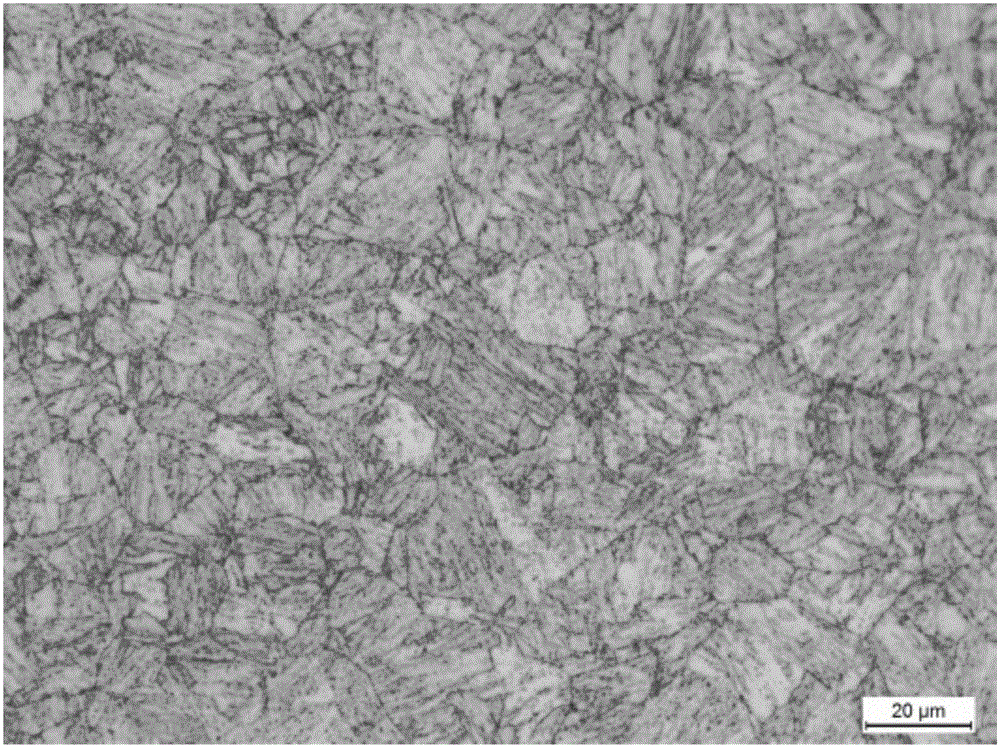

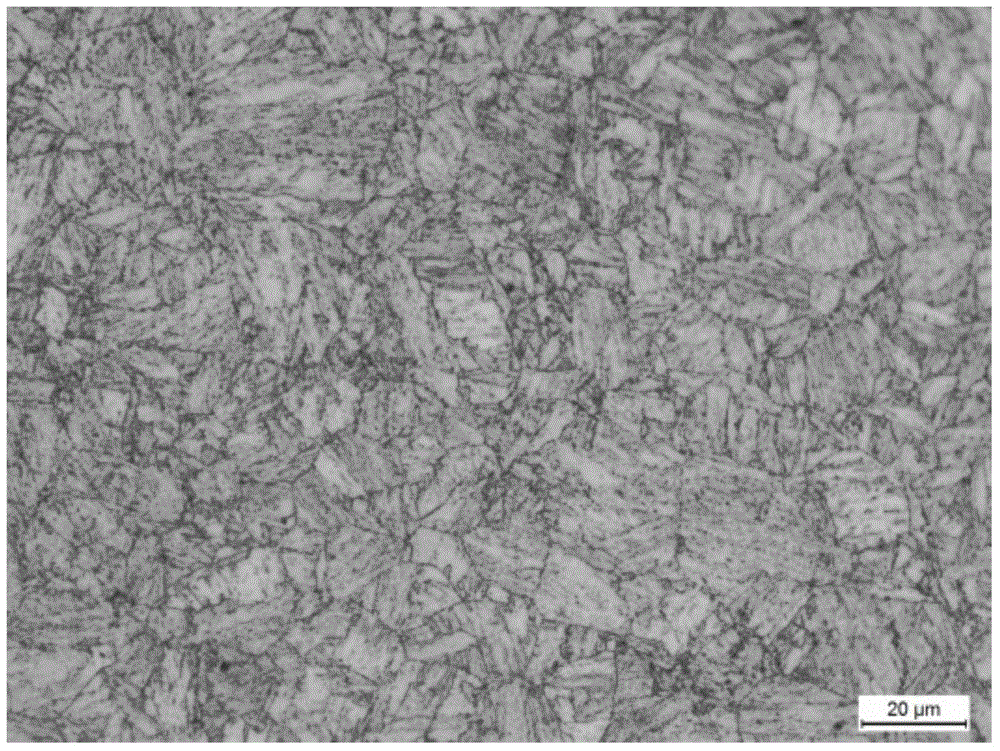

InactiveCN104561852AAvoid uneven defectsReduce plastic forming forceIncreasing energy efficiencySemi solidInduction method

The invention discloses a process for preparing a semi-solid state aluminum alloy scroll plate by a radial forging strain induction method. The method comprises the following steps: pre-heating an aluminum alloy rods at first; performing radial forging on the aluminum alloy rods; performing secondary remelting on blanks subjected to radial forging; performing extrusion casting on the aluminum alloy scroll plate; performing T6 heat treatment on the aluminum alloy scroll plate acquired by extrusion casting in a semi-solid state to increase the mechanical property. According to the process, the aluminum alloy semi-solid state blanks which are uniform and free of microdefect are prepared and are subjected to extrusion casting to form a scroll plate workpiece with less microdefects and high mechanical performance, and the process is simple and easy to operate.

Owner:XI AN JIAOTONG UNIV

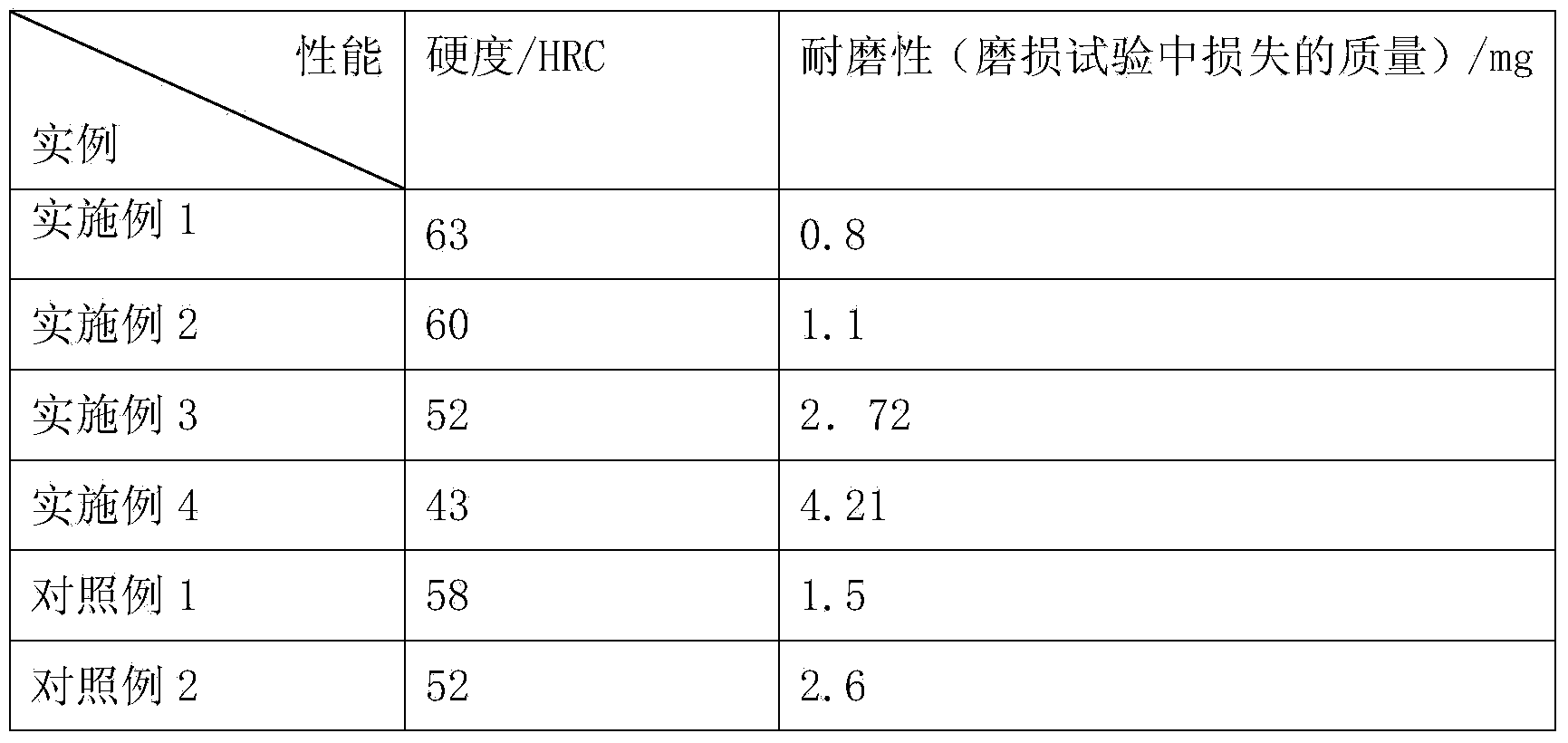

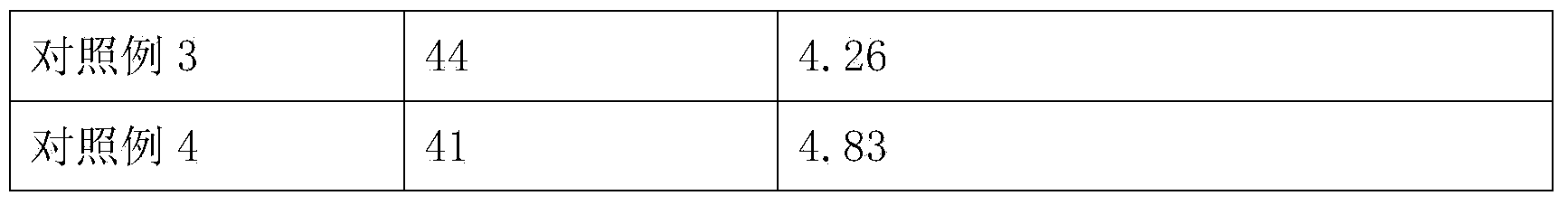

Heat treatment technique of large-size GCr15 steel

The invention relates to the field of metal working, and discloses a heat treatment technique of large-size GCr15 steel, which comprises the following steps: a) heating large-size GCr15 steel with the diameter of 20-150mm to 835-850 DEG C, and keeping the temperature for 30-60 minutes; b) carrying out water quenching at the water temperature of 20-60 DEG C; c) when the color on the product surface darkens and red completely disappears, immediately taking the product out of water and carrying out oil quenching; and d) after quenching, tempering the product. The heat treatment technique adopts a double quenching method; in the GCr15 steel heat treatment quenching process, the material is firstly subjected to pre-quenching with the water medium with favorable thermal conductivity, and then subjected oil quenching after the surface layer is hardened, thereby completing the final quenching technique; and finally, the material is tempered. The technique can enable the surface layer of the large-size GCr15 steel to reach high hardness, and enhances the abrasion resistance of the material as compared with the existing technique.

Owner:SHANGHAI UNIV OF ENG SCI

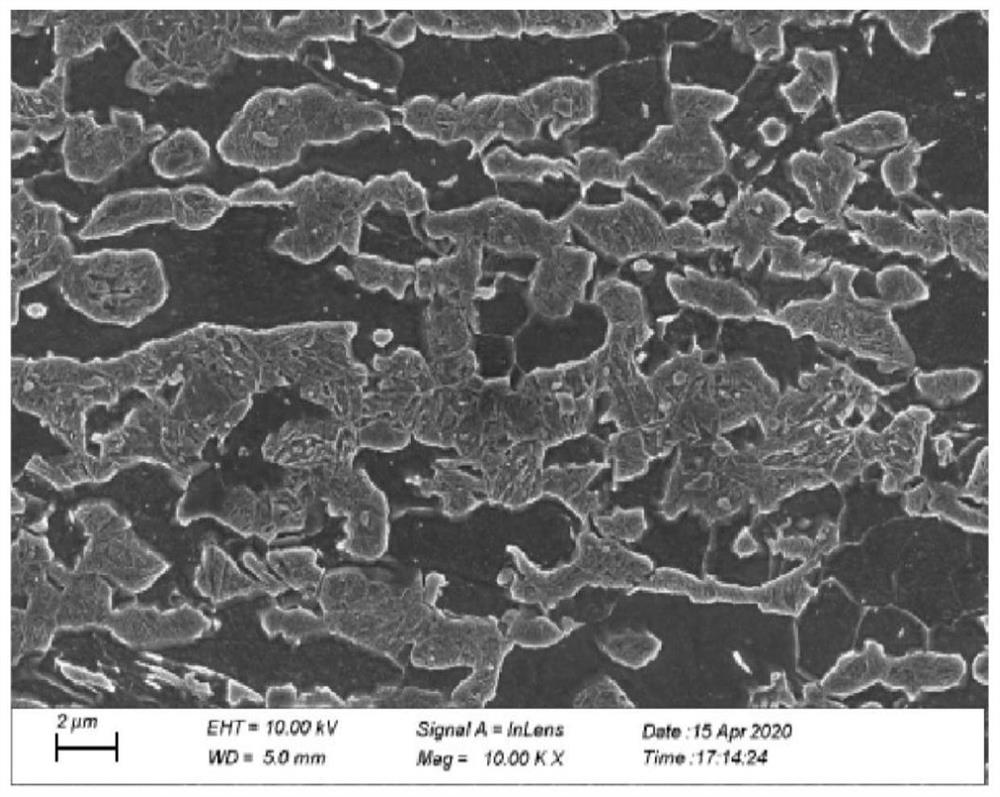

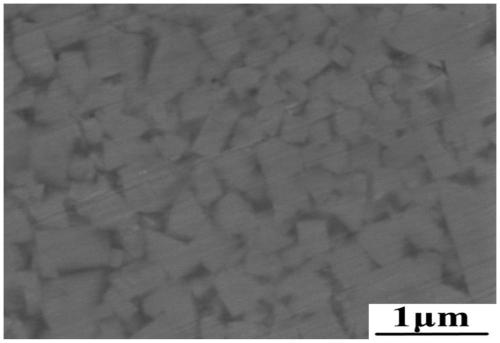

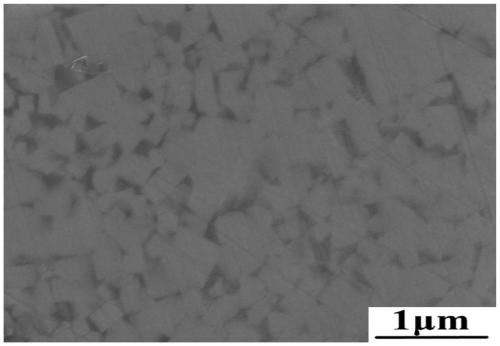

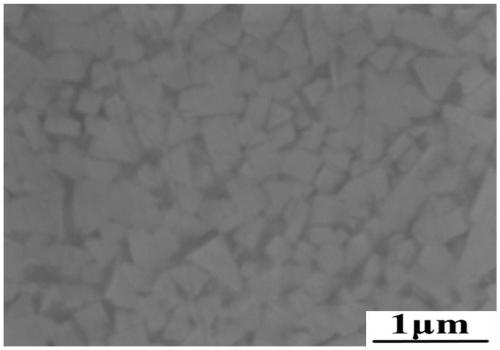

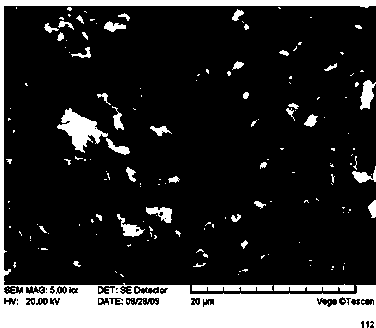

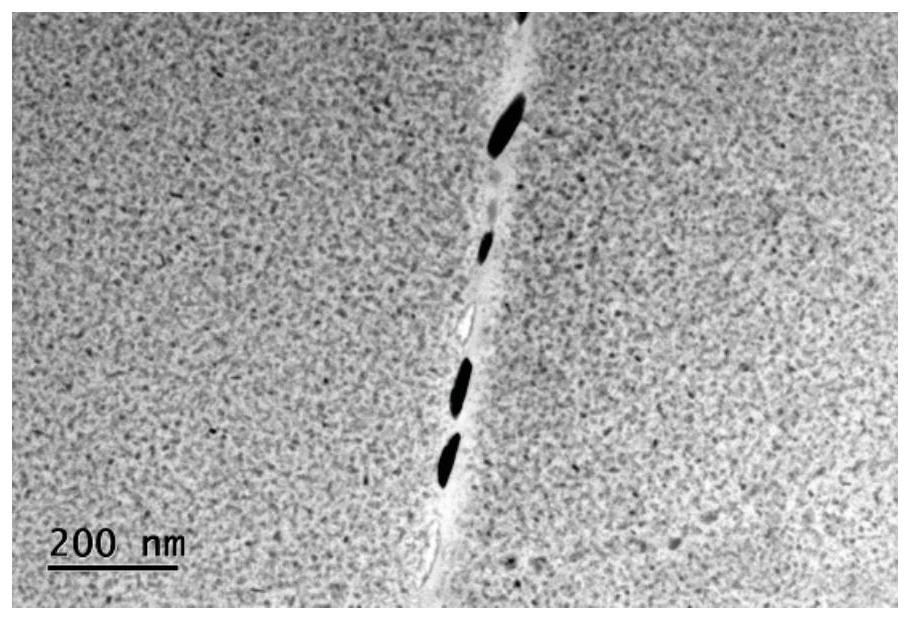

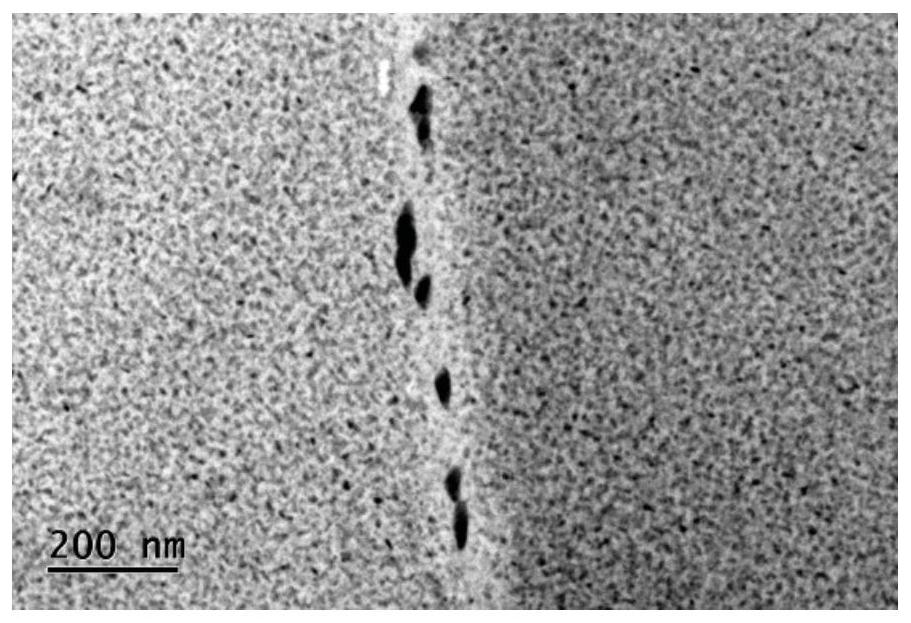

Rare-earth-added ultra-fine grain high-toughness WC-10Co hard alloy material and preparation method

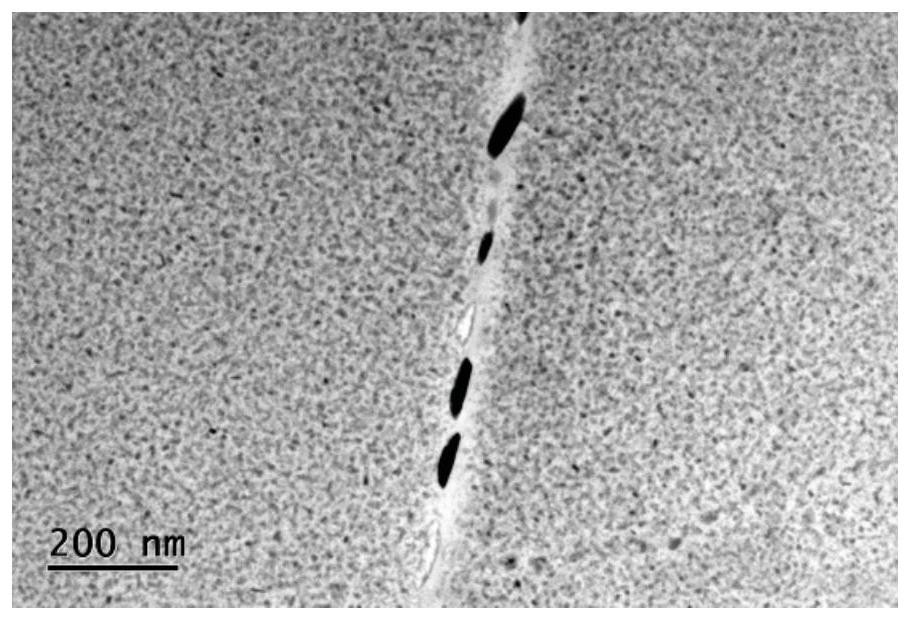

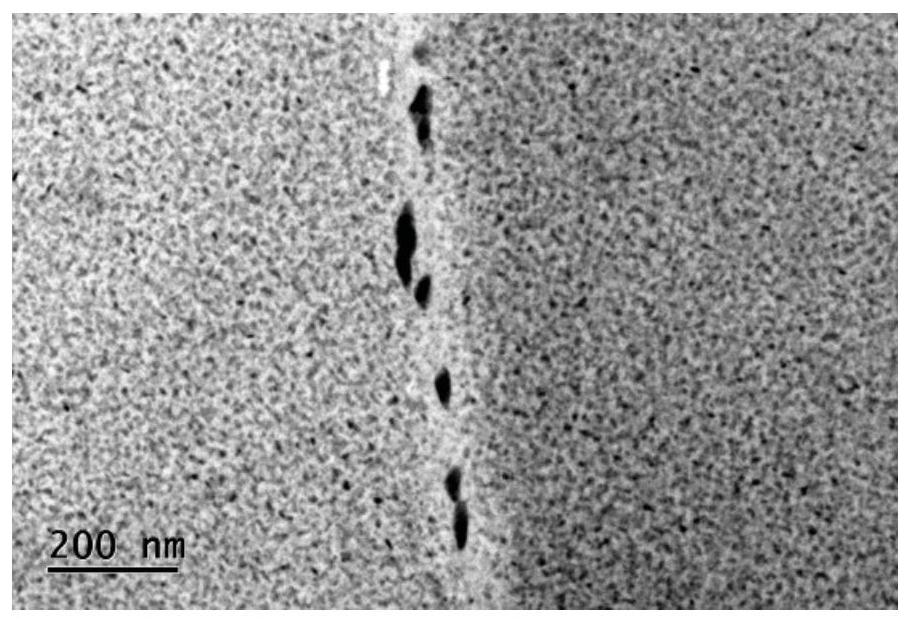

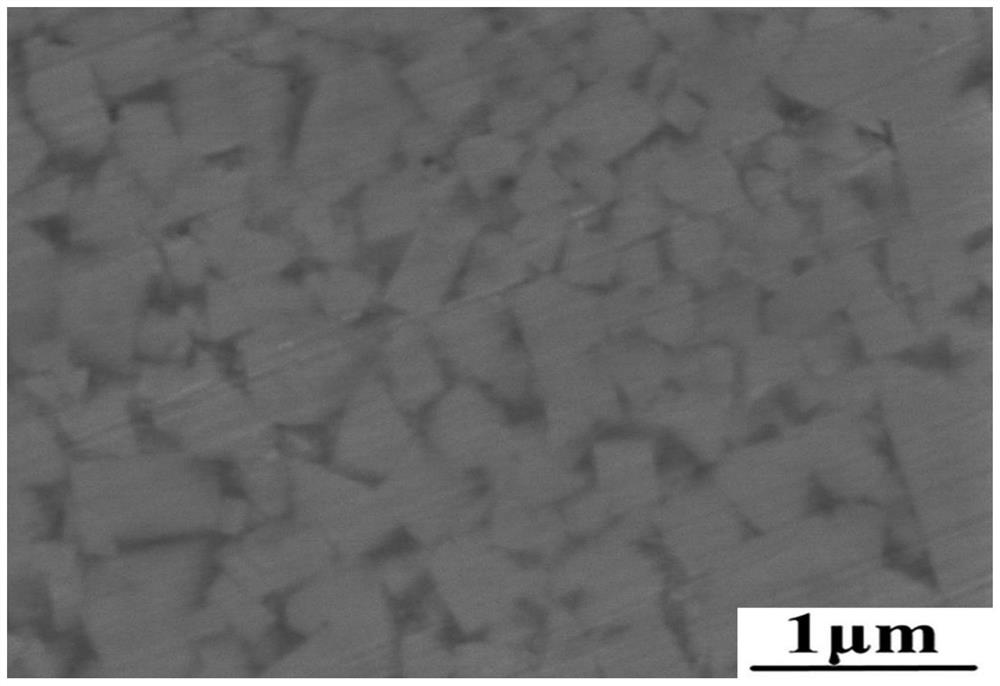

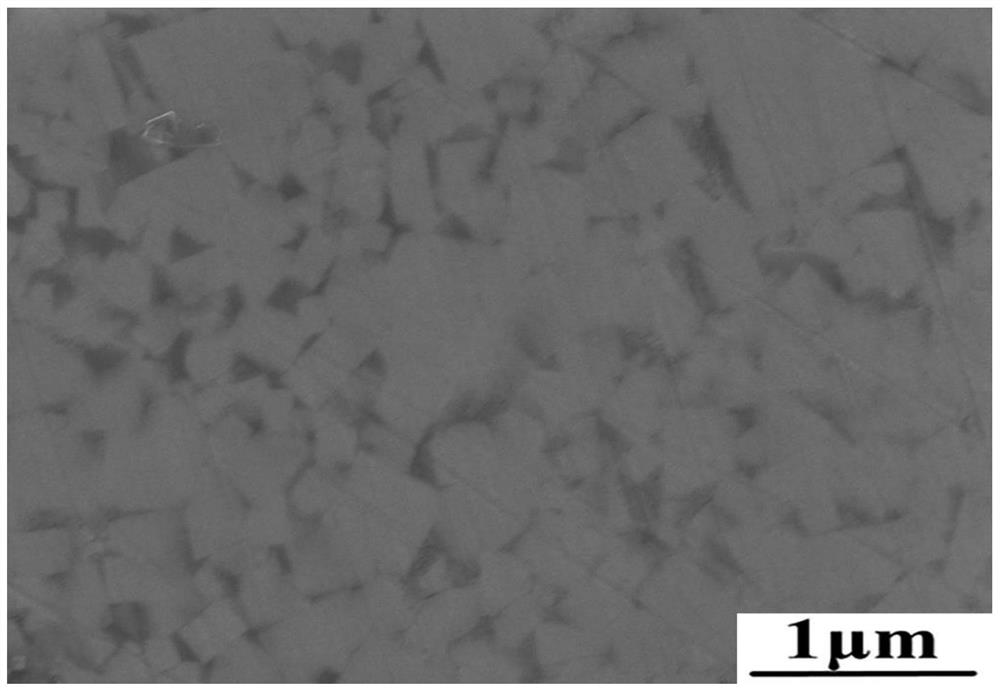

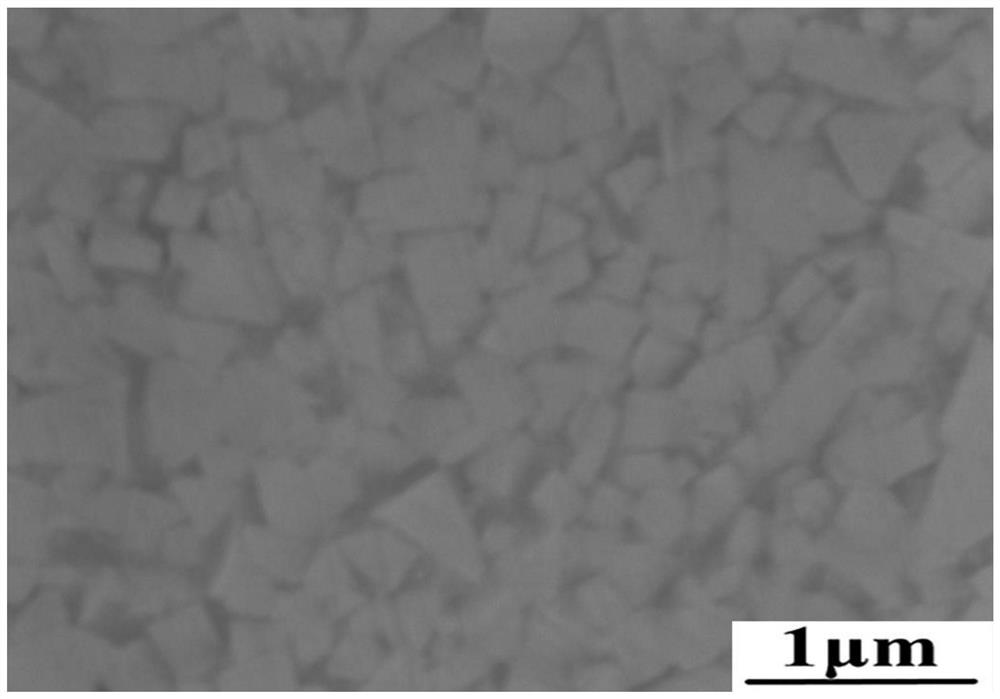

The invention relates to a rare-earth-added ultra-fine grain high-toughness WC-10Co hard alloy material and a preparation method, and belongs to the field of powder metallurgy. The hard alloy comprises the components: 88.7 percent to 89.1 percent of tungsten carbide, 10 percent of cobalt, 0.5 percent of vanadium carbide, 0.3 percent of chromium carbide, and 0.1 percent to 0.5 percent of praseodymium oxide (or 0.1 percent to 0.5 percent of neodymium oxide). Rare earth oxide can be used for refining WC grains through influencing the content of W elements in binding-phase Co and influencing the liquid phase temperature in sintering, so that the hardness of the hard alloy is improved; and in addition, the rare earth oxide can be used for enhancing the toughness through acting on a Co phase. The alloy continuity can be worsened along with the increase of the content of the rare earth oxide, so that the adding content of the rare earth oxide is limited within a certain range. The rare-earth-added ultra-fine grain high-toughness WC-10Co hard alloy is prepared through ball milling, briquetting and vacuum sintering. The hard alloy provided by the invention is fine in grain size which reaches to 190nm minimally, higher in hardness which reaches up to 2100HV, and favorable in toughness which reaches up to 28.17MPa.m1 / 2 at the same time. A hard alloy product with high hardness and high toughness at the same time is not publicly reported.

Owner:UNIV OF SCI & TECH BEIJING

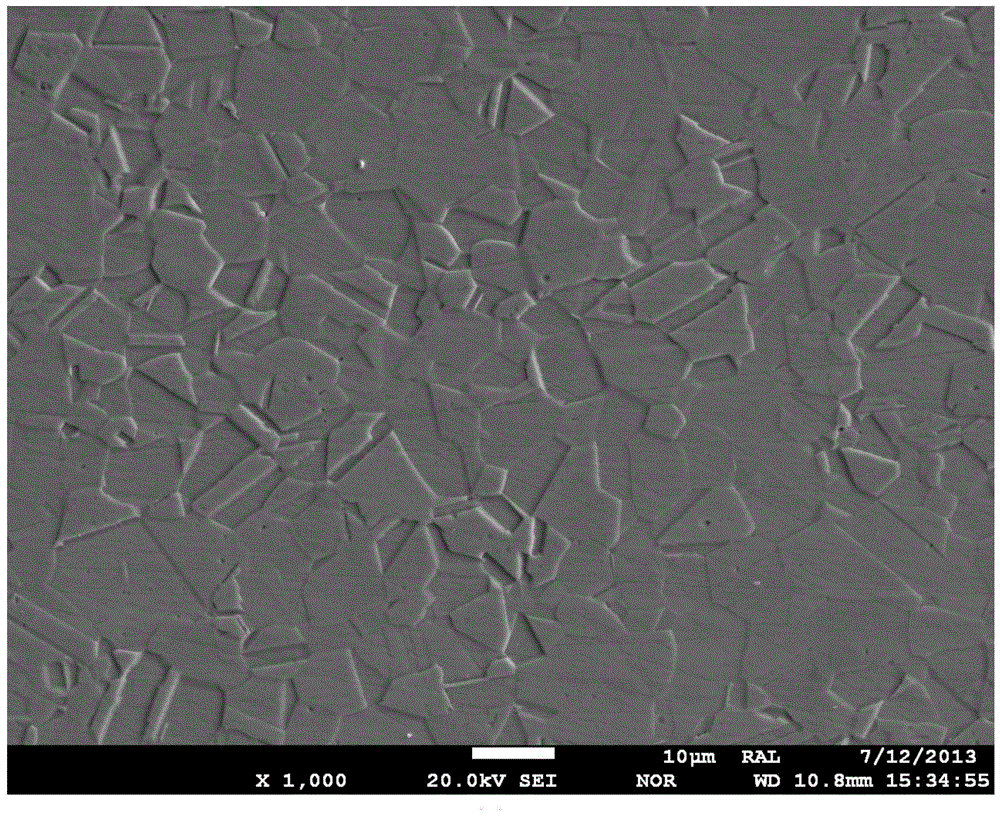

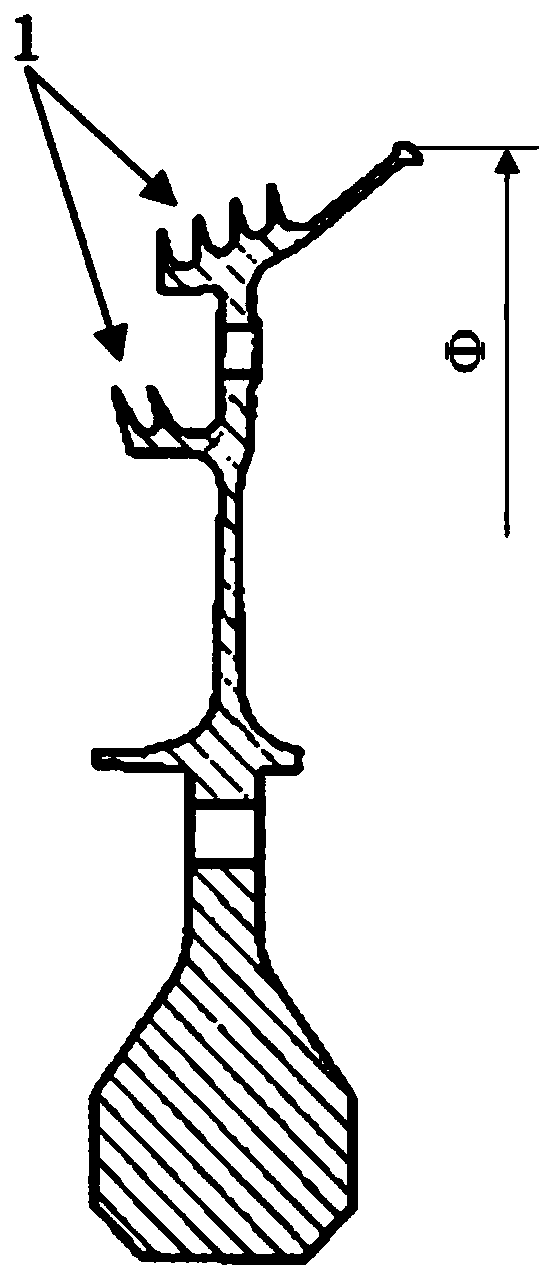

Radial forging strain-induced semi-solid state process for manufacturing aluminum alloy crankshaft of air condition compressor

InactiveCN104525829AGood microstructureGood formabilityMetal-working apparatusEngine componentsCast ironRadial forging

A radial forging strain-induced semi-solid state process for manufacturing an aluminum alloy crankshaft of an air condition compressor comprises the steps that an aluminum alloy bar material is preheated, radial forging is carried out on the aluminum alloy bar material, secondary remelting is carried out on a bank after radial forging, then semi-solid thixotropy forging of the aluminum alloy crankshaft is carried out, and subsequent processing of the aluminum alloy crankshaft is carried out. The uniform aluminum alloy semi-solid blank without mirodefects can be manufactured and the aluminum alloy crankshaft with fewer microstructure defects and good mechanical performance is formed and replaces a cast iron crankshaft through the process, the process is simple, and operation is easy.

Owner:XI AN JIAOTONG UNIV

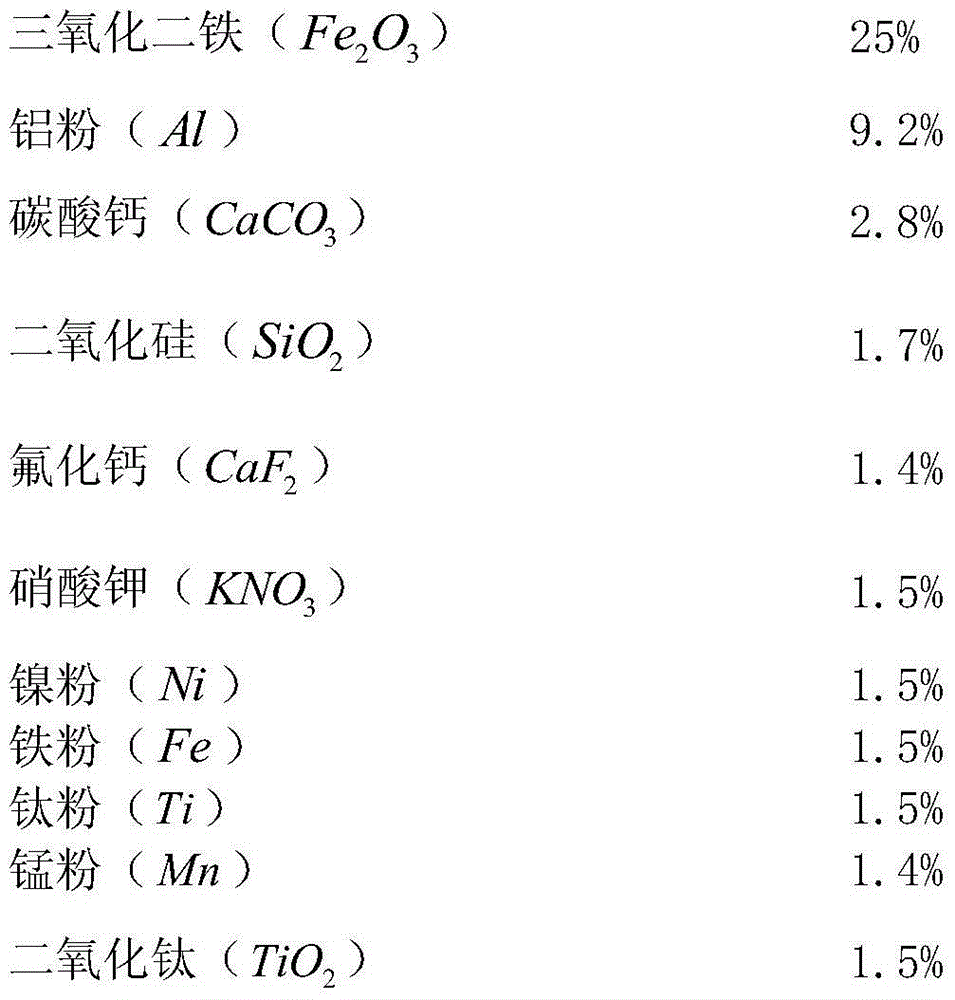

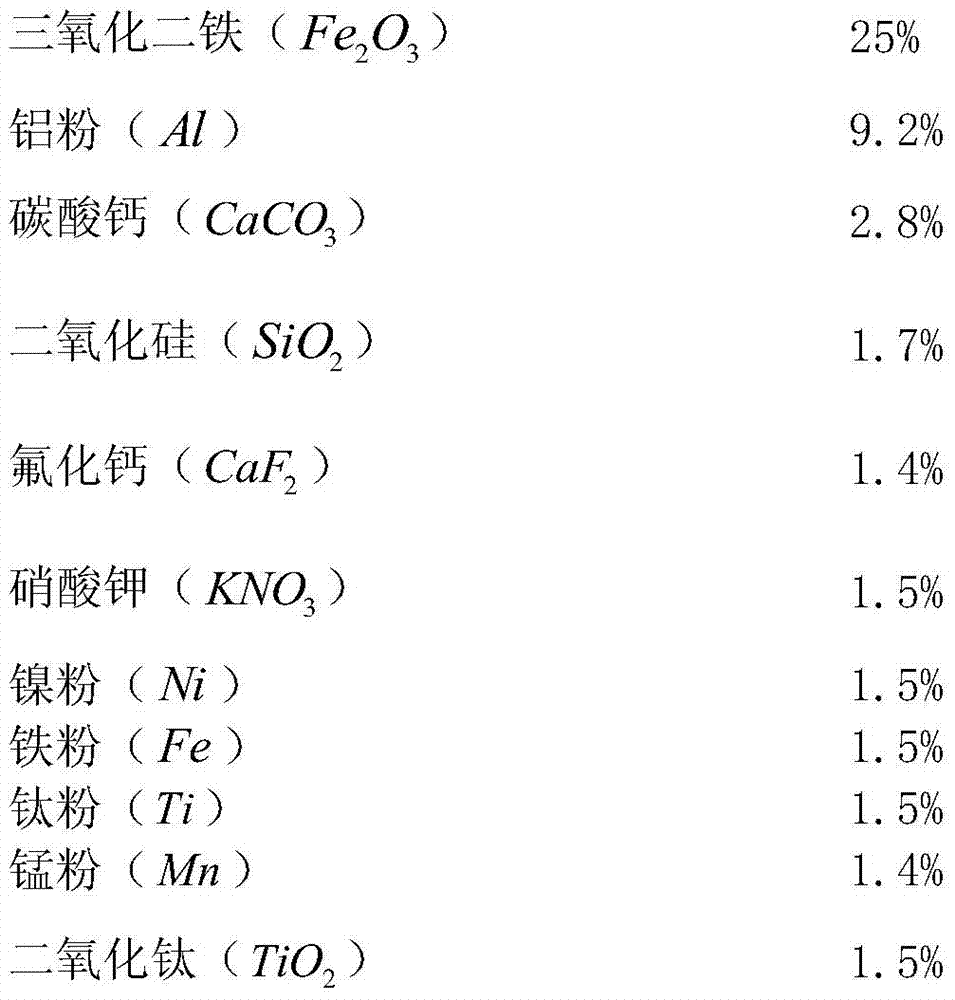

Non-electric welding agent applicable to emergency welding repair of low-carbon steel thin-walled sheet parts below 5mm and welding pen containing same

ActiveCN104907739AAvoid slag inclusion defectsMicroorganizedWelding/cutting media/materialsSoldering mediaSlagReaction temperature

The invention relates to a non-electric welding agent applicable to emergency welding repair of low-carbon steel thin-walled sheet parts below 5mm. The welding agent is formed by mixing powdery thermite, slagging constituents, alloying agents and thinners. The welding agent generates the self-propagating reaction after being ignited, the thermite in the welding agent reacts to generate heat for maintaining reaction and also provide enough heat to enable parent metal to melt, and the metal part generated by the thermite and the melting part of the parent metal jointly form a molten bath to be subjected to metallurgic reaction at high temperature; the slagging constituents and Al2O3 generated by the thermite jointly form slag low melting point and viscosity, the slag is effectively separated from metal ingredients in the molten bath, Al2O3 is taken out, and the defect of slag inclusion in weld metal is overcome; alloy ingredients in the alloying agents enter the molten bath at high temperature generated by the thermite and participate in the metallurgic reaction of the molten bath jointly, so that the weld metal has the ideal microstructure and reasonable mechanical property; the thinners are used for adjusting the self-propagating reaction speed and reaction temperature of the welding agent, so that operation is convenient.

Owner:山东军浩苑环保科技有限公司

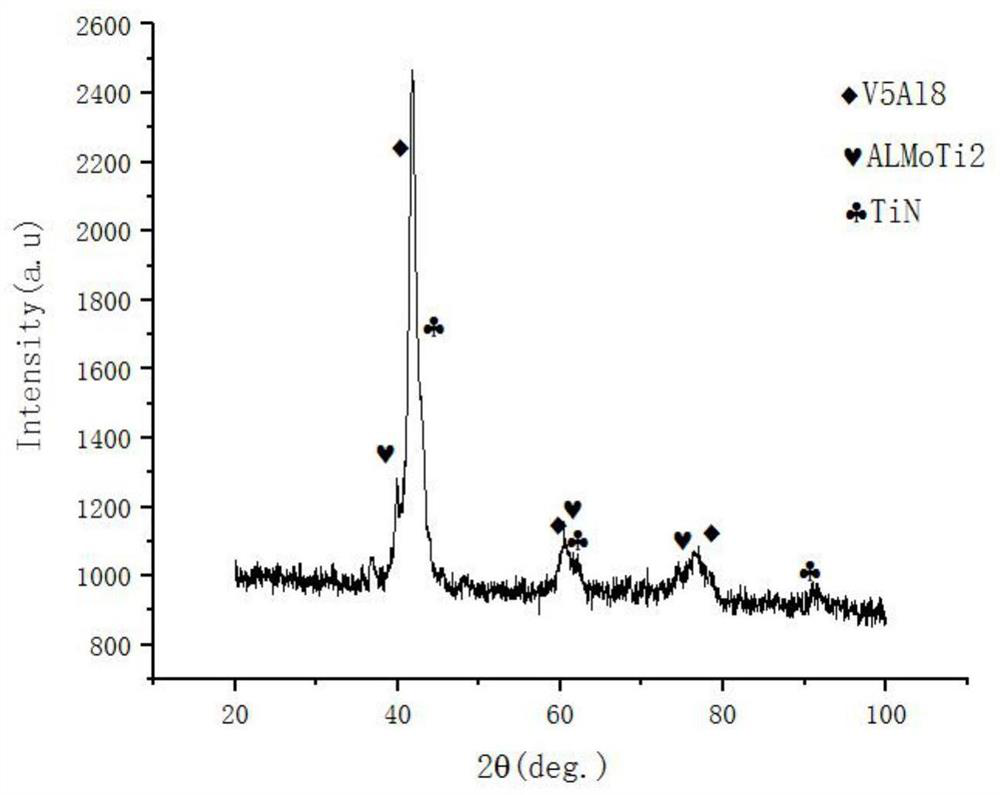

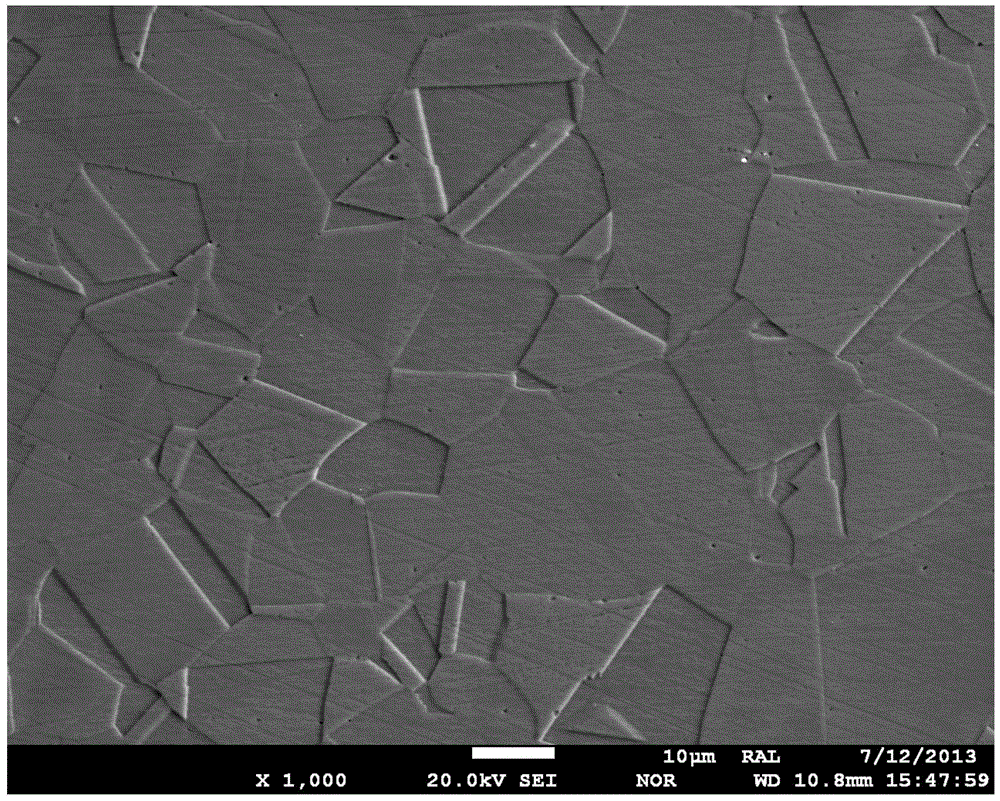

Laser-cladding seven-element high-entropy alloy coating and preparation method thereof

ActiveCN111850543AImprove bindingImprove performanceMetallic material coating processesHigh entropy alloysHigh energy laser beam

The invention discloses a laser-cladding seven-element high-entropy alloy coating and a preparation method thereof, and belongs to the technical field of alloy surface coating modification. High-entropy alloy powder is prepared from Al, Co, Cr, Fe, Mo, V and Ti; a substrate is Ti-6Al-14V(TC4) titanium alloy, the atom fraction of each raw material in the high-entropy alloy powder is Al (10% to 16%), Co (11% to 15%), Cr (9% to 16%), Fe (6% to 15%), Mo (8% to 17%), V (8% to 15%) and Ti (12% to 16%), and the sum of all components is 100%. The high-entropy alloy coating is formed by cladding the prepared alloy powder on the surface of the substrate by a high-energy laser beam emitted from a CO2 laser, the substrate and a cladding layer are metallurgically combined to achieve the purpose of surface modification, thus the hardness, wear resistance and corrosion resistance of titanium alloy are improved, and the service life of the titanium alloy is further prolonged.

Owner:KUNMING UNIV OF SCI & TECH

Preparation method of titanium alloy seamless pipe

The invention provides a preparation method of a titanium alloy seamless pipe. The preparation method comprises the following steps: step 1, smelting titanium sponge and intermediate alloy for multiple times to obtain a titanium alloy cast ingot; step 2, heating the titanium alloy cast ingot obtained by smelting, carrying out drawing forging, and carrying out multi-heating-number upsetting and drawing above the transformation temperature of the titanium alloy and below the transformation temperature of the titanium alloy in a staggered manner to obtain a titanium alloy bar blank; step 3, punching a through hole in a titanium alloy bar, and performing boring to obtain a titanium alloy hollow bar blank; step 4, coating the inner surface and the outer surface of the heated titanium alloy hollow rod blank with lubricating agent, and then extruding the titanium alloy hollow rod blank to obtain a titanium alloy extruded pipe blank; step 5, performing one-time forming precision forging on thetitanium alloy extruded pipe blank to obtain a precision forging finished pipe blank; and step 6, conducting straightening and machining after overall heat treatment to obtain the titanium alloy seamless pipe. The titanium alloy seamless pipe manufactured by the preparation method has the advantages of being adjustable in pipe outer diameter and shape, high in size precision, high in structural uniformity and the like.

Owner:湖南湘投金天科技集团有限责任公司 +1

Semisolid process for manufacturing engine aluminum alloy cam shaft through radial forging strain provocation method

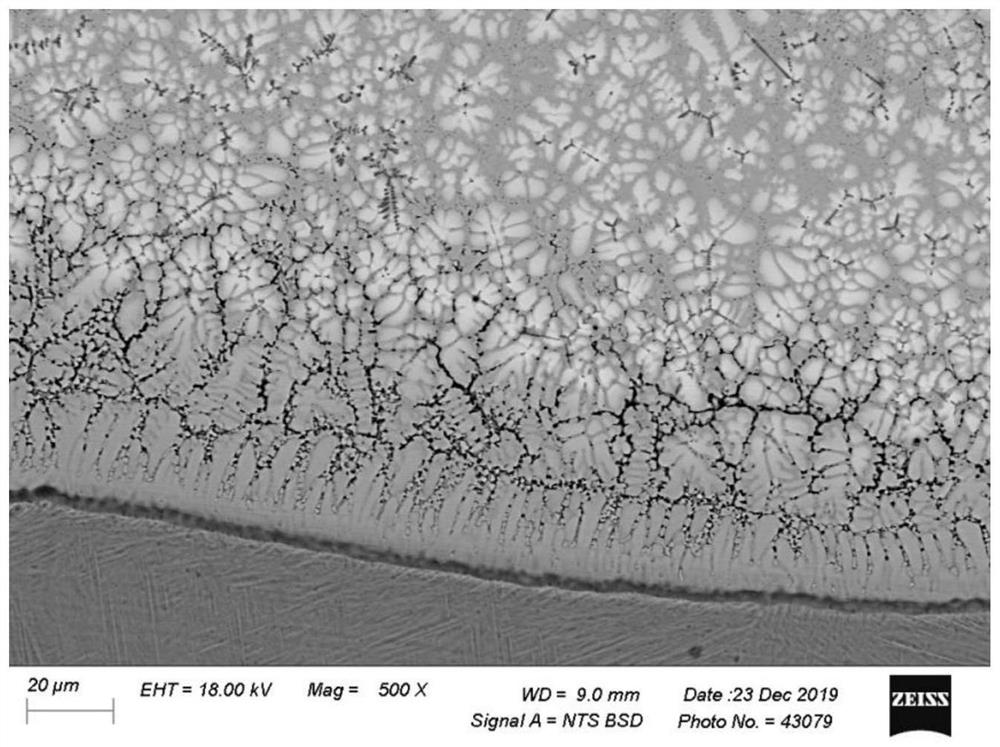

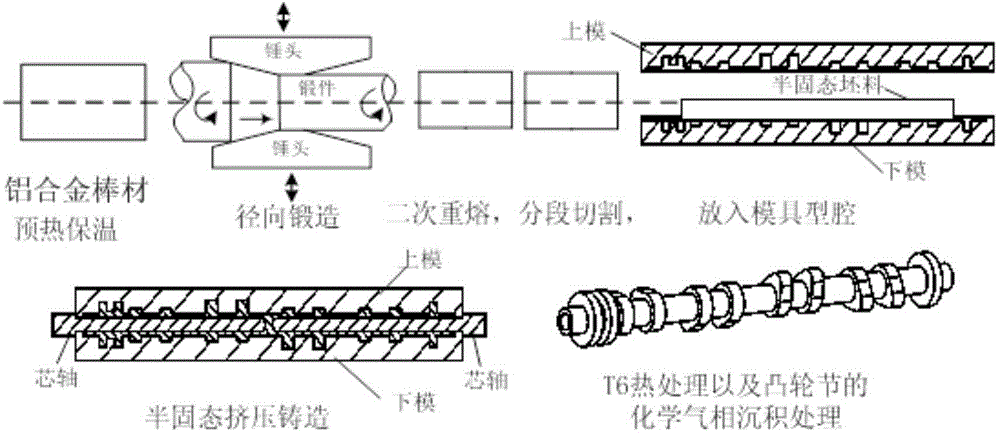

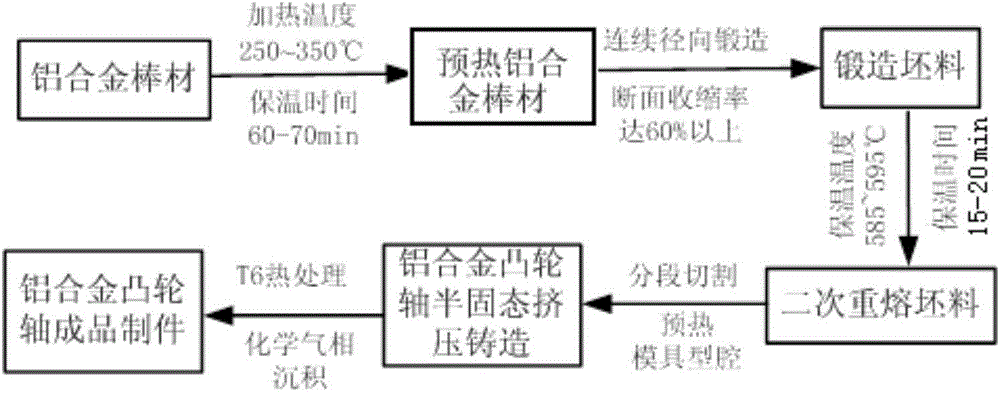

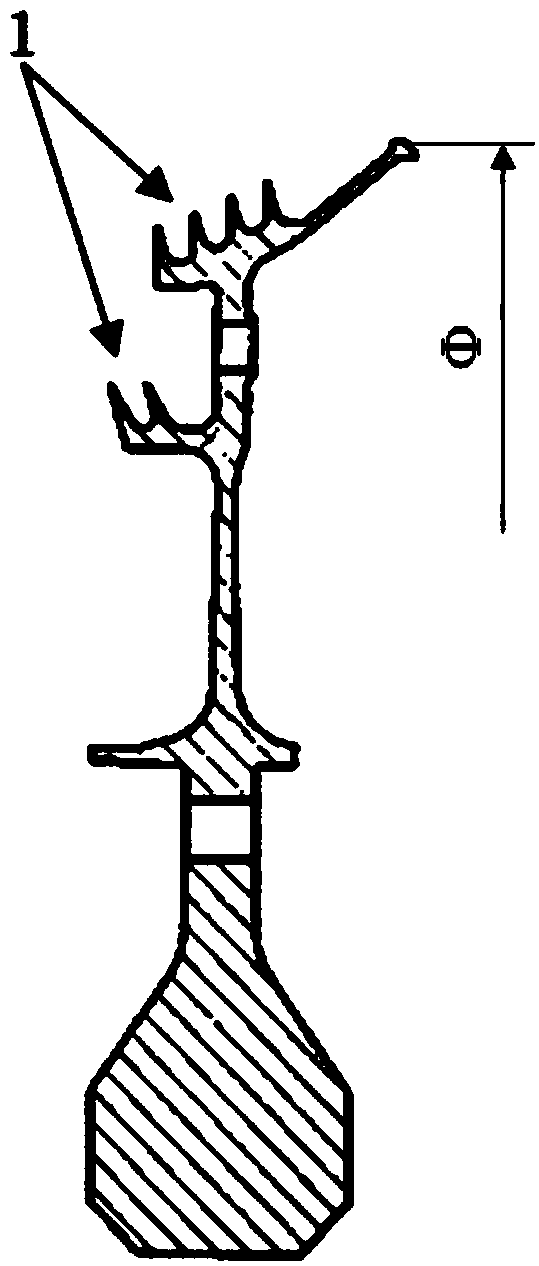

InactiveCN104624914AAvoid composition segregation and uneven microstructure defectsAvoid uneven defectsMetal-working apparatusEngine componentsMicro structureCam

Disclosed is a semisolid process for manufacturing an engine aluminum alloy cam shaft through a radial forging strain provocation method. Aluminum alloy rod materials are preheated and then forged in the radial direction, a blank is remelted again after radial forging, the aluminum alloy cam shaft is extruded and cast, and finally follow-up treatment is carried out on the aluminum alloy cam shaft in the radial direction. Through the process, the uniform aluminum alloy semisolid blank without micro defects can be manufactured, the aluminum alloy cam shaft which has a few micro structure defects and is good in mechanical performance can be formed, and the process is simple and easy to operate.

Owner:XI AN JIAOTONG UNIV

Laser cladding repairing technical method for labyrinth seal of turbine disc

ActiveCN107805806AImprove bindingEasy dischargeMetallic material coating processesSpray nozzleEngineering

The invention discloses a laser cladding repairing technical method for a labyrinth seal of a turbine disc. The laser cladding repairing technical method for the labyrinth seal of the turbine disc comprises the following steps that the turbine disc is clamped in an inert atmosphere protection box, the to-be-repaired labyrinth seal is cleaned and then subjected to laser cladding, and the repaired portion is machined, specifically, cleaning of the to-be-repaired labyrinth seal includes matrix pre-melting and powder supply cladding which are conducted in sequence, as for matrix pre-melting, a laser unit is adopted for irradiating the to-be-repaired labyrinth seal of the turbine disc so that a matrix of the to-be-repaired labyrinth seal can be molten, and as for powder supply cladding, laser cladding is conducted on the to-be-repaired labyrinth seal of the turbine disc in a mode that a powder supply nozzle conducts lateral powder supply. By means of the technical method, the abraded labyrinth seal can recover to the initial geometric shape and technical indexes and can be reused.

Owner:AECC AVIATION POWER CO LTD

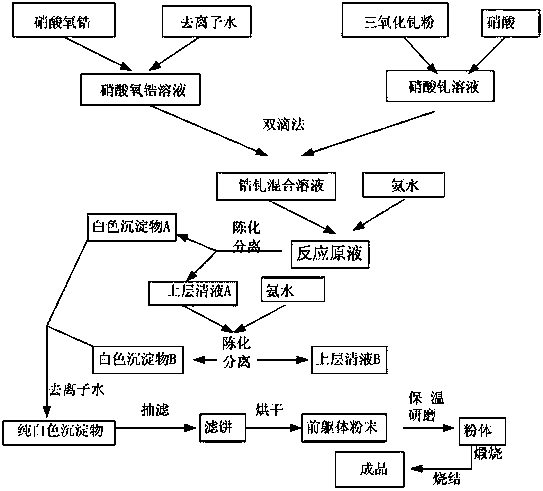

Co-precipitation preparation method of ZrO2/Gd203 composite ceramic material for nuclear power

ActiveCN103449811ANo stringent requirementsEasy to implementNuclear energy generationComposite ceramicNuclear power

The invention discloses a co-precipitation preparation method of a ZrO2 / Gd203 composite ceramic material for nuclear power. The co-precipitation preparation method comprises a pre-preparation process of a zirconium-gadolinium mixed solution, a preparation process of zirconium-gadolinium mixed precipitates and the like. The co-precipitation preparation method comprises the following steps of: firstly dissolving and mixing zirconyl nitrate deionized water, gadolinium oxide powder, nitric acid and ammonia water which are used as raw materials, then precipitating and mixing so as to form uniformly mixed preparation raw materials, and finally carrying out follow-up reduction treatment so as to obtain the ZrO2 / Gd203 Gd2O3 composite ceramic material. The co-precipitation preparation method has no strict requirements on processing equipment and is easy to realize. The vacuum sintering is carried out, and the sintering temperature is controlled at 1500 DEG C to 1650 DEG C. The ZrO2 / Gd203 composite ceramic material prepared by the method has good sintering property and relatively good microstructure, mechanical strength and density (theoretical density greater than 96% T.D).

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Titanium nitride ceramic reinforced copper-based composite material and preparation method thereof

Owner:XIAN SPECIAL EQUIP INSPECTION INST

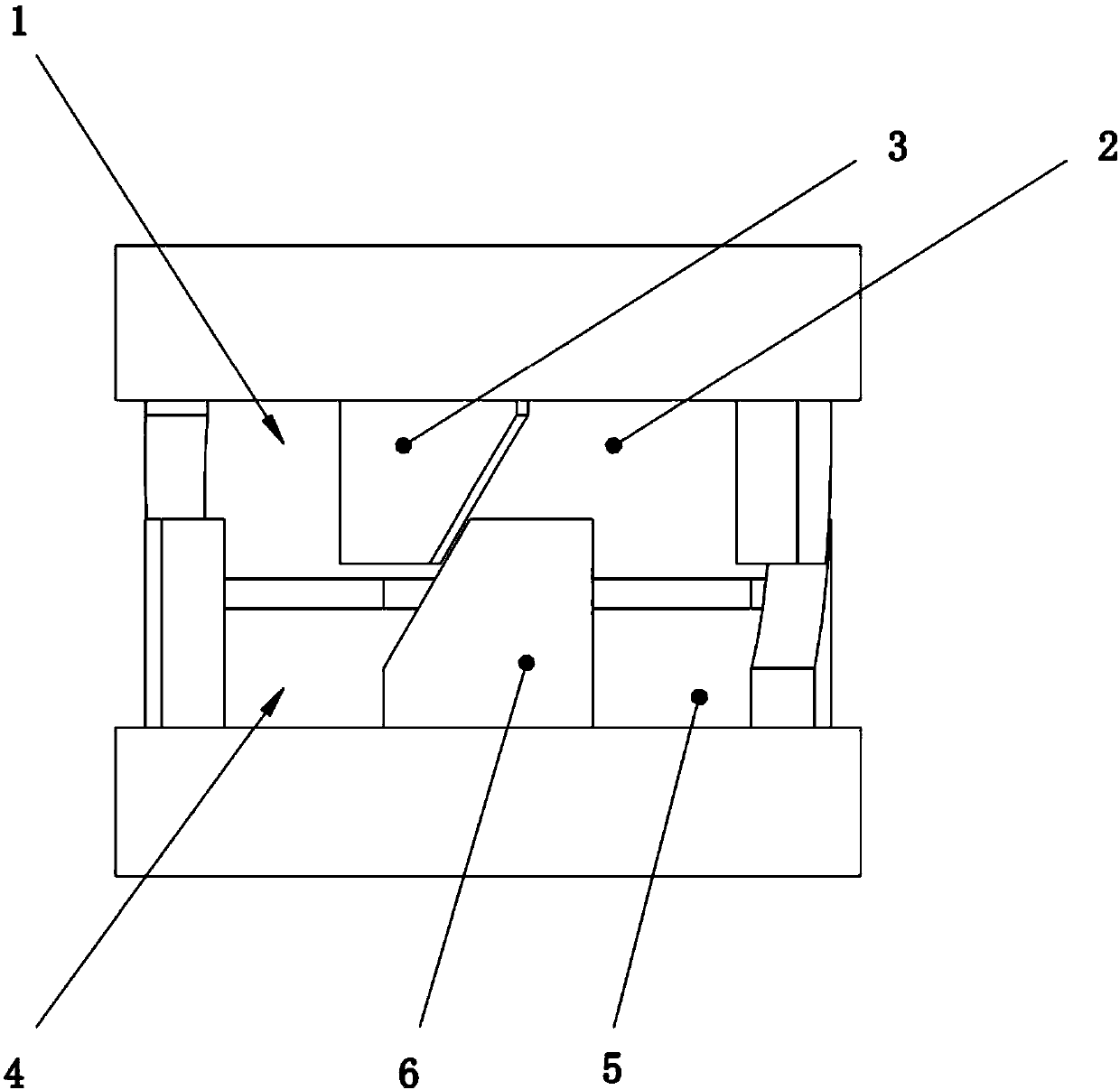

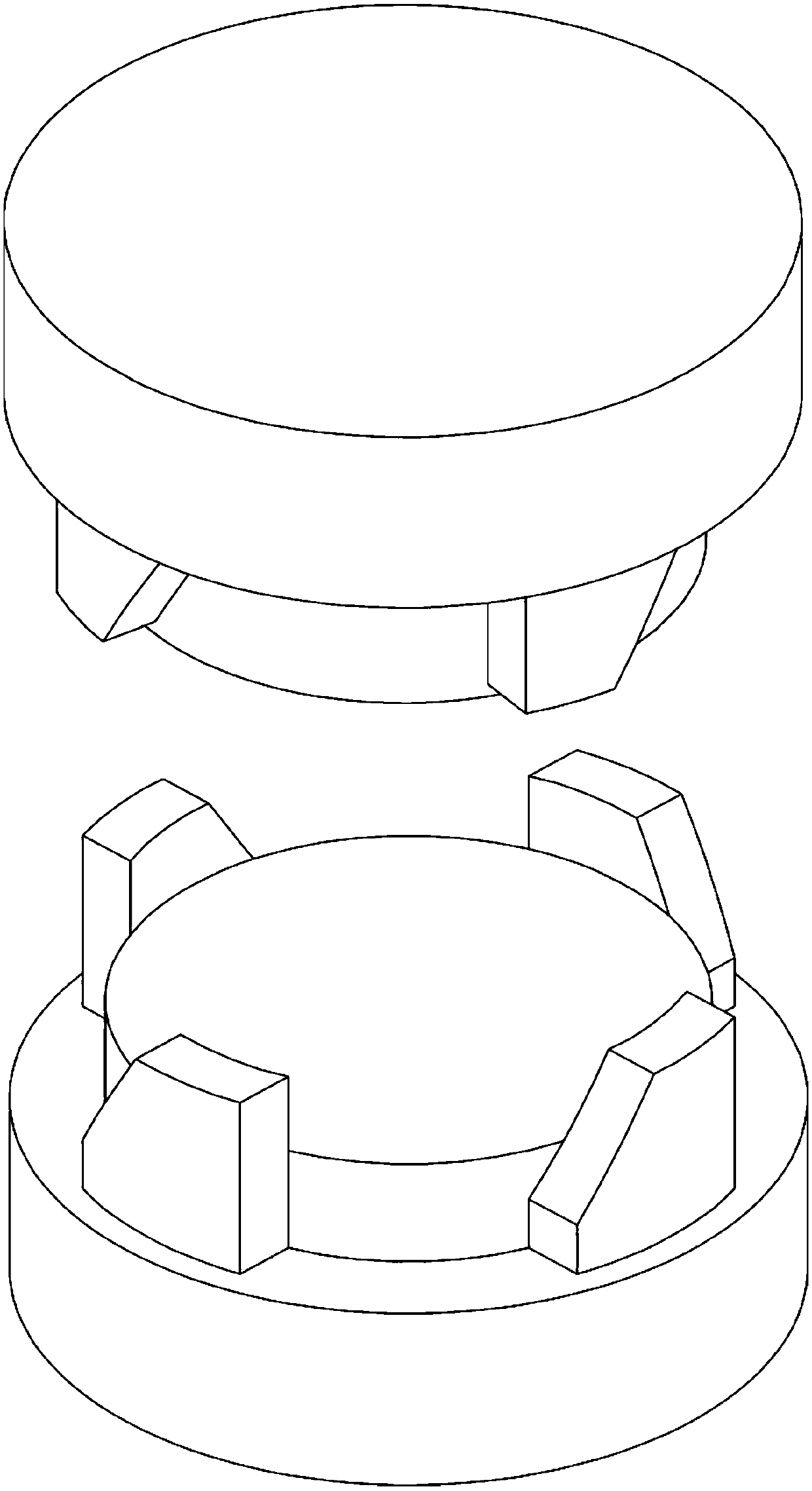

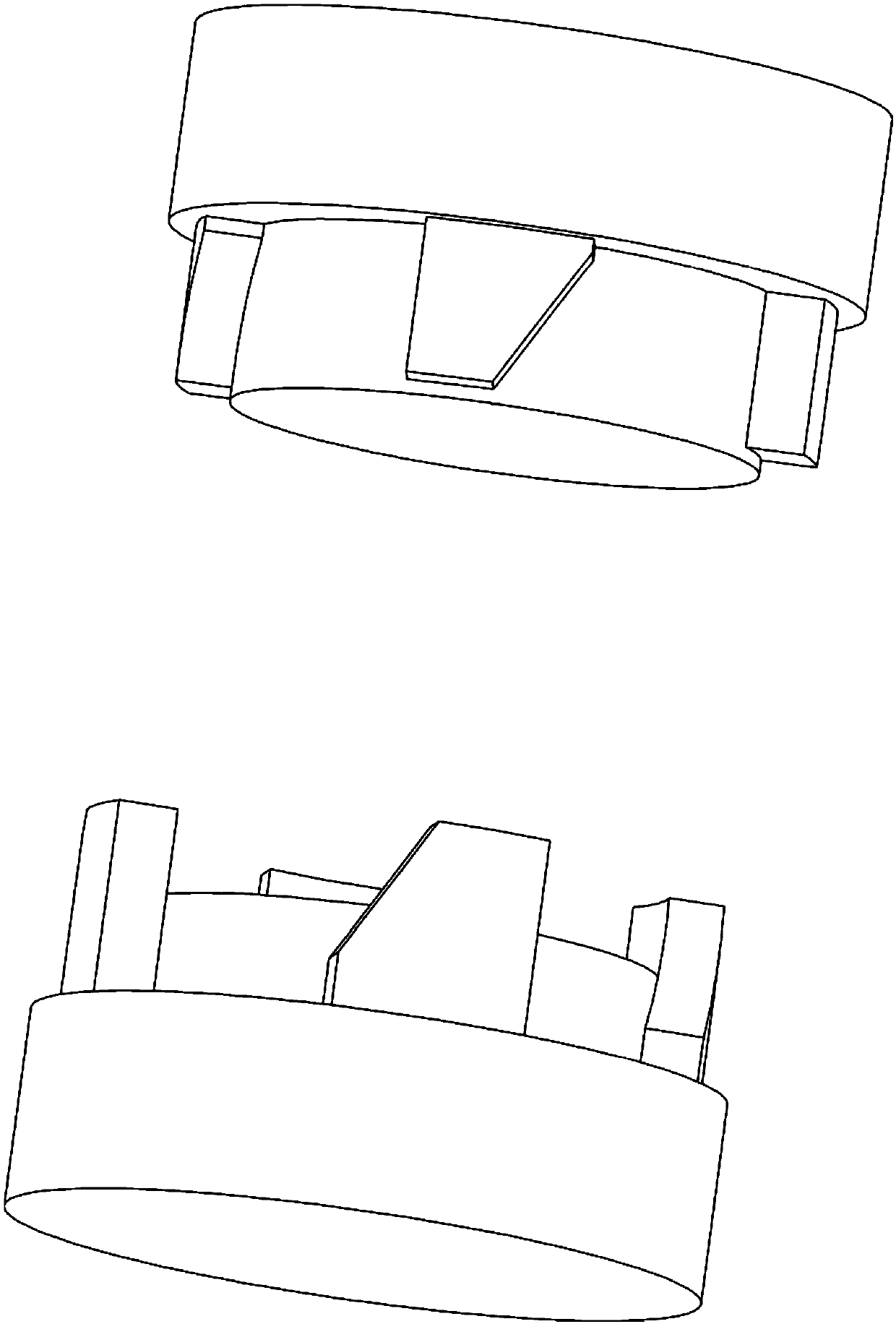

Pressure-torsion die, pressure-torsion machining equipment and pressure-torsion machining method of difficult-to-deform metal materials

InactiveCN109570297AFine grainMicroorganizedShaping toolsForging/hammering/pressing machinesEngineeringMachining

The invention relates to a pressure-torsion die. The pressure-torsion die is provided with an upper pressing die and a lower pressing die. The upper pressing die can drive the lower pressing die to rotate when the upper pressuring die is close to the lower pressing die so that upsetting machining and pressure-torsion machining can be carried out on the cake-like difficult-to-deform metal materialsclamped between the upper pressuring die and the lower pressuring die. The invention further relates to pressure-torsion machining equipment using the pressure-torsion die and a machining method of the pressure-torsion for pressure-torsion machining the difficult-to-deform metal materials with the pressure-torsion machining equipment. The pressure-torsion die can be used for simultaneous composite loading of upsetting and torsion of the difficult-to-deform metal materials.

Owner:XIAMEN UNIV OF TECH +1

Efficient abrasive belt grinding special grinding apparatus for high surface integrity machining

The present invention provides an efficient abrasive belt grinding special grinding apparatus for high surface integrity machining. The efficient abrasive belt grinding special grinding apparatus comprises polishing blocks; a fixing device for fixing the polishing blocks to a grinding machine; abrasive belt fixing devices disposed at an inner side wall of an installing cavity and outer side wallsof the polishing blocks and used for fixing an abrasive belt; and radial compressing assemblies for compressing the abrasive belt to the outer periphery of a to-be-machined workpiece and capable of moving in a radial direction of the installing cavity. According to the abrasive belt grinding special grinding apparatus, a winding mode is adopted, the abrasive belt is fixed to the outer periphery ofthe to-be-machined workpiece by the abrasive belt fixing devices installed at the inner side wall of the installing cavity and the outer side walls of the polishing blocks, and the abrasive belt canbe effectively prevented from falling off; machining requirements of the workpieces having different diameters are satisfied by adjusting radial positions of the radial compressing assemblies; and different positions of the to-be-machined workpiece are simultaneously ground and polished by the plurality of radial compressing assemblies, and machining efficiency of the workpiece can be higher. Thegrinding apparatus is simple in structure, high in machining efficiency and good in mechanical property, and the abrasive belt is fixed firmly.

Owner:NANJING TRIZ INST OF LASER APPL TECH CO LTD

A kind of low-pressure casting method of aluminum alloy automobile wheel hub

The invention discloses a low-pressure casting method for an aluminum alloy automobile hub. The method of the present invention optimizes the alloy composition design, adds appropriate content of Al-Ti-B-C refiner and rare earth modifier, and optimizes the low-pressure casting process parameters and heat treatment parameters, so that the prepared automobile wheel hub has fine and uniform a branch Crystal and fine uniform worm-like or spherical silicon structure, improve the performance of aluminum alloy automobile wheels.

Owner:QINHUANGDAO XINGLONG WHEEL HUB

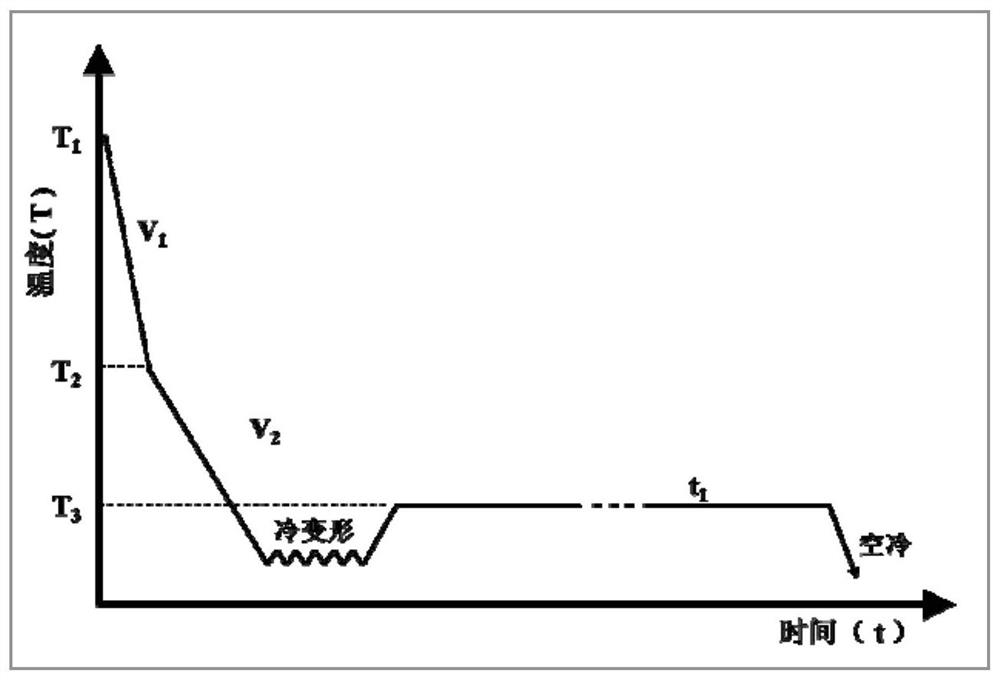

Heat treatment method for improving structure and performance of 7xxx series aluminum alloy

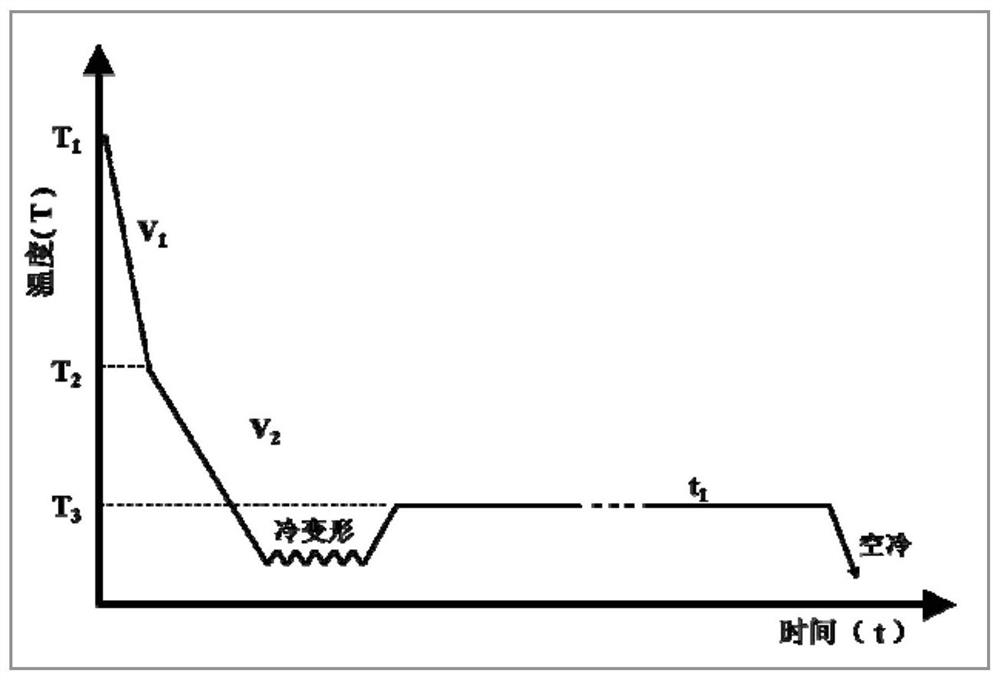

Provided is a heat treatment method for improving the structure and performance of a 7xxx series aluminum alloy. The method includes the steps that firstly, single-stage or graded solid solution heat preservation heat treatment is conducted on a deformation form, and the final solid solution heat preservation temperature is T1, wherein T1 is greater than or equal to 460 DEG C and less than or equal to 485 DEG C; the alloy is cooled from T1 to T2 at an average cooling rate V1, and then from T2 to room temperature at an average cooling rate V2, wherein T2 is greater than or equal to 150 DEG C and less than or equal to 190 DEG C, V1 is greater than or equal to 20 DEG C / s and less than or equal to 60 DEG C / s, and V2 is greater than or equal to 3 DEG C / s and less than or equal to 10 DEG C / s; and 1-5% of cold deformation treatment is conducted on the quenched aluminum alloy, and then aging heat treatment is conducted at the temperature T3 for the heat preservation time t1, wherein T3 is greater than or equal to 110 DEG C and less than or equal to 140 DEG C, and t1 is greater than or equal to 10 h and less than or equal to 32 h. According to the heat treatment method for improving the structure and performance of the 7xxx series aluminum alloy, under the condition that the residual stress is controlled, the 7xxx series aluminum alloy can obtain an ideal precipitated phase structure form, and good matching of obdurability and corrosion resistance is obtained. Compared with the prior art, the method greatly shortens the heat treatment time, and has the characteristics of simplicity and convenience in operation, high efficiency and feasibility.

Owner:GRIMAT ENG INST CO LTD

A 500MPa-level low-Cu Mg-free aluminum alloy and a preparation method thereof

The invention relates to a 500MPa-level low-Cu Mg-free aluminum alloy and a preparation method. The 500MPa-level low-Cu Mg-free aluminum alloy comprises the following chemical components in percentageby weight: 3.3-3.8% of Cu, 0.6-0.9% of Mn, 0.4-0.7% of Zn, 0.5-0.8% off Fe, 0%-0.5% of Si, 0%-0.15% of Ti, 0%-0.1% of Ni, and the balance being Al and inevitable impurities. The method includes: annealing the casting blank by adopting a standardized complete annealing process system; carrying out hot rolling on the homogenizing annealed casting blank, carrying out solid solution treatment, immediately quenching, and carrying out cold rolling to obtain a thin plate; performing classified aging process for thin plates as in the following: 200 DEG C / 11-14h+230-250 DEG C / 30-60min+180-200 DEG C / 10-14 h, the 500 MPa-level low-Cu Mg-free aluminum alloy plate with the thickness of 1.5 + / -0.5 mm is obtained.

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

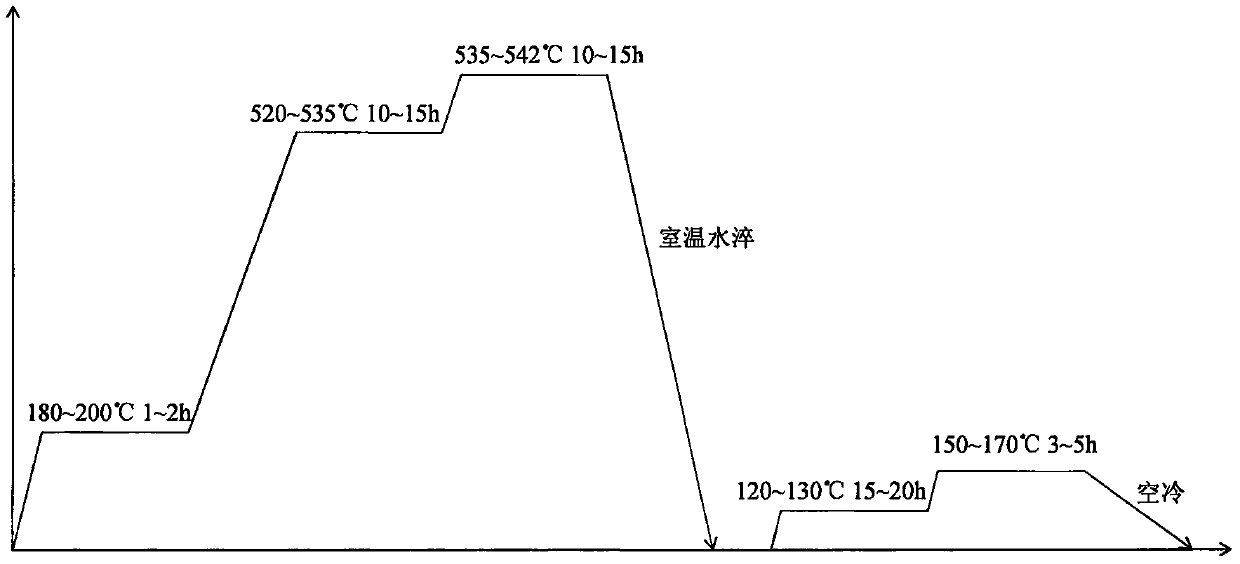

Heat treatment method for cast aluminium alloy

The invention provides a heat treatment method for a cast aluminium alloy. The heat treatment method is characterized in that the cast aluminium alloy is subjected to low-temperature short-time agingtreatment at first, then subjected to two-step solution treatment and room-temperature quenching, and finally subjected to two-step aging treatment. The heat treatment method provided by the inventionhas the following beneficial effects: with the adoption of the heat treatment method provided by the invention, the casting produced from the alloy is high in mechanical property, and the productioncost is greatly lowered.

Owner:北京世联信诺科技有限公司

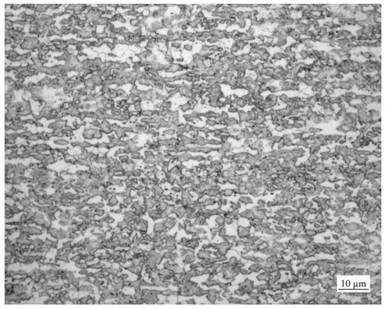

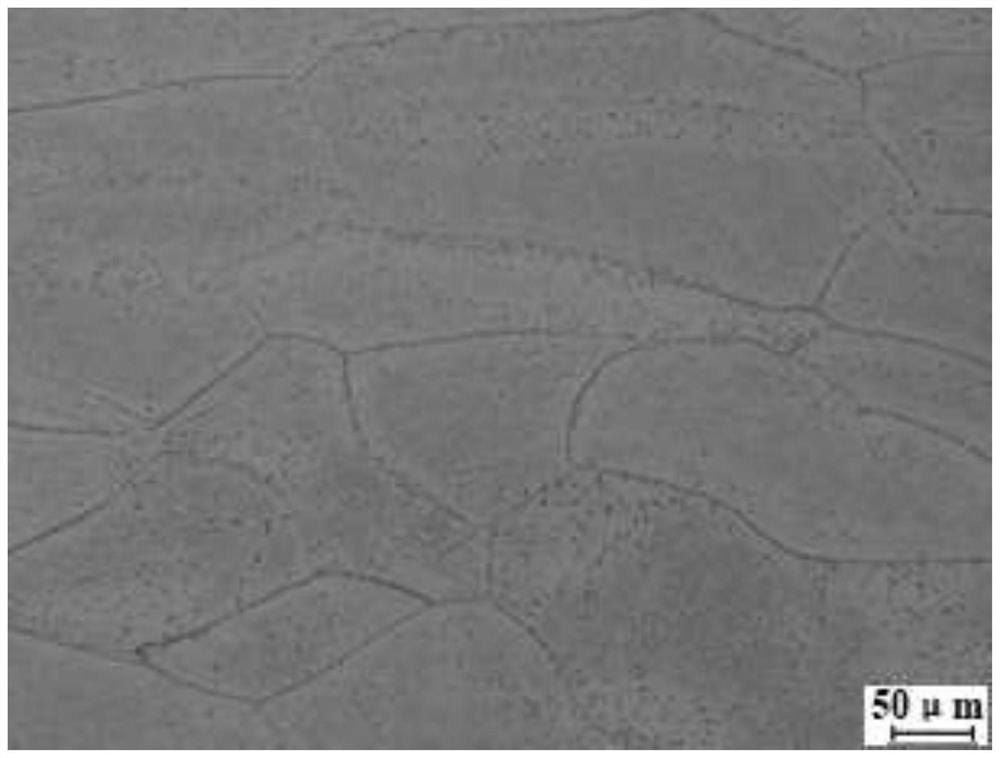

A kind of cr, n-type high manganese austenitic steel plate and preparation method thereof

ActiveCN105177439BOptimal Design Chemical CompositionMicroorganizedSolution treatmentChemical composition

The invention discloses a Cr / N-containing high-manganese austenitic steel plate and a preparation method thereof. The Cr / N-containing high-manganese austenitic steel plate comprises the following chemical components in percentage by weight: 0.28-0.32% of C, 24.8-25.2% of Mn, 2.8-3.2% of Cr, 2.8-3.2% of Al, 0.02-0.20% of N, at most 0.015% of P, at most 0.005% of S and the balance of Fe. The preparation method comprises the following steps: smelting molten steel according to set components, casting into an ingot, heating to 1200 DEG C, keeping the temperature for 2 hours, forging into a plate blank, carrying out hot rolling until the thickness is 6mm, carrying out homogenizing treatment, carrying out cold rolling to the thickness of 1mm or so, and finally, carrying out solution treatment, thereby obtaining favorable strength-plasticity compatibility and having certain oxidation resistance and corrosion resistance.

Owner:XUZHOU SHENGHAI MACHINERY MFG TECH

A laser cladding seven-element high-entropy alloy coating and its preparation method

ActiveCN111850543BImprove bindingMicroorganizedMetallic material coating processesHigh entropy alloysHigh energy laser beam

The invention discloses a seven-element high-entropy alloy coating prepared by laser cladding and a preparation method thereof, belonging to the technical field of alloy surface coating modification; the high-entropy alloy powders are Al, Co, Cr, Fe, Mo, V, Ti . The matrix material is Ti-6Al-l4V (TC4) titanium alloy, and the atomic fraction of each raw material in the high-entropy alloy powder is Al (10%-16%), Co (11%-15%), Cr (9%-16%) ), Fe (6%-15%), Mo (8%-17%), V (8%-15%), Ti (12%-16%), the sum of all components is 100%. by CO 2 The high-energy laser beam emitted by the laser clads the configured alloy powder on the surface of the substrate to form a high-entropy alloy coating. The substrate and the cladding layer are metallurgically combined to achieve the purpose of surface modification, thereby increasing the hardness of the titanium alloy. , wear resistance and corrosion resistance, thereby extending the service life of titanium alloys.

Owner:KUNMING UNIV OF SCI & TECH

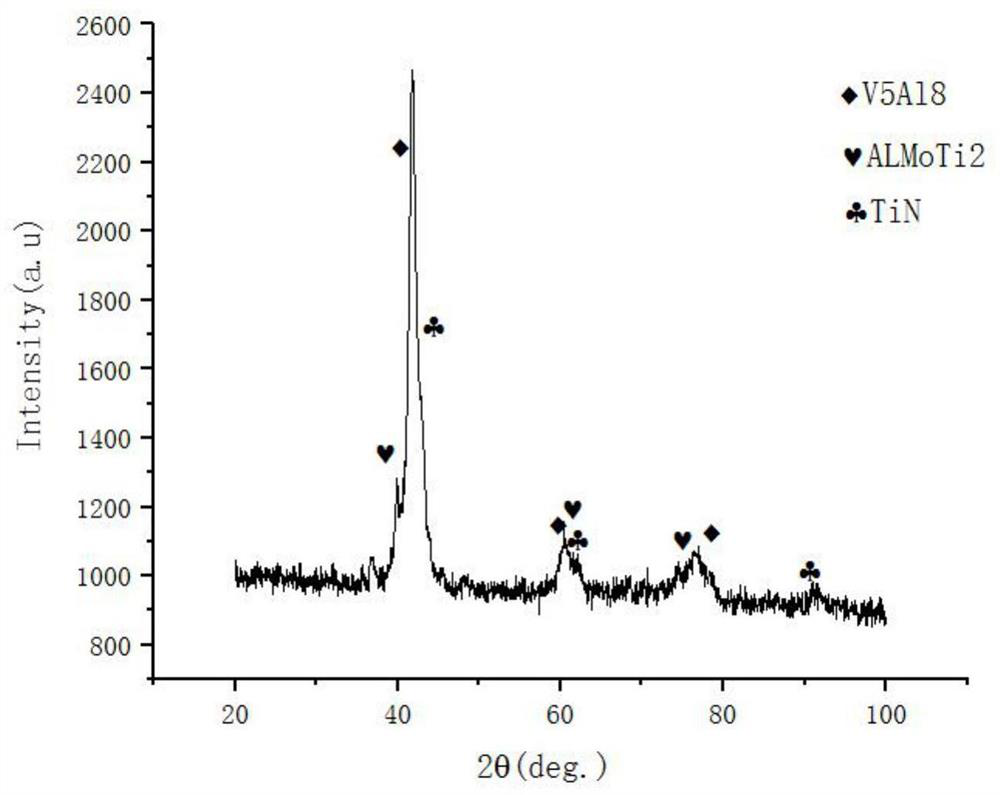

Preparation method of low-density Nb-Ti-Al-V-Zr-C niobium alloy bar

ActiveCN114855107AHigh elongationSmall sizeNuclear energy generationMetal-working apparatusCarbideIngot

The invention discloses a preparation method of a low-density Nb-Ti-Al-V-Zr-C niobium alloy bar. The method comprises the following steps: 1, carrying out primary extrusion on a low-density Nb-Ti-Al-V-Zr-C niobium alloy ingot to obtain a primary extruded bar; 2, performing secondary extrusion to obtain a secondary extrusion rod; 3, quenching treatment; 4, free forging processing; and fifthly, vacuum annealing is conducted, and the low-density Nb-Ti-Al-V-Zr-C niobium alloy bar is obtained. According to the method, the low-density niobium alloy bar is prepared through the technology of two-time extrusion, quenching and forging, the quenching treatment technology and the secondary extrusion technology are added, the carbide reinforced phase TiC is separated out and nucleated again after redissolution and is dispersed and distributed in a matrix, the size of the carbide reinforced phase is effectively reduced, and the dispersity of the carbide reinforced phase is improved; the elongation after fracture of the low-density niobium alloy bar is improved, so that the low-density niobium alloy bar shows room-temperature high-strength and high-plasticity mechanical properties.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

A heat treatment method for improving the microstructure and properties of 7xxx series aluminum alloys

A heat treatment method for improving the microstructure and properties of 7xxx series aluminum alloys, comprising: first performing single-stage or hierarchical solid solution heat preservation heat treatment on the deformed form, and the final solution heat treatment heat preservation temperature is T 1 , where, 460℃≤T 1 ≤485℃; the alloy is cooled at an average cooling rate V 1 by T 1 The temperature point is cooled to temperature T 2 , followed by an average cooling rate V 2 from T 2 The temperature point is cooled to room temperature, where, 150℃≤T 2 ≤190℃, 20℃ / s≤V 1 ≤60℃ / s, 3℃ / s≤V 2 ≤10°C / s; the quenched aluminum alloy is subjected to 1-5% cold deformation treatment, and then at T 3 Holding time at temperature t 1 Carry out aging heat treatment, where 110℃≤T 3 ≤140℃, 10h≤t 1 ≤32h. The method of the invention can make the 7xxx series aluminum alloy obtain a relatively ideal precipitated phase structure under the condition of controlling the residual stress, and obtain a good match between strength, toughness and corrosion resistance. Compared with the existing technology, the method greatly shortens the heat treatment time, and has the characteristics of simple operation, high efficiency and feasibility.

Owner:GRIMAT ENG INST CO LTD

A non-electric welding flux suitable for emergency welding maintenance of low-carbon steel sheet parts below 5mm and a welding pen containing the flux

ActiveCN104907739BAvoid slag inclusion defectsMicroorganizedWelding/cutting media/materialsSoldering mediaSlagMolten bath

The invention relates to a non-electric welding agent applicable to emergency welding repair of low-carbon steel thin-walled sheet parts below 5mm. The welding agent is formed by mixing powdery thermite, slagging constituents, alloying agents and thinners. The welding agent generates the self-propagating reaction after being ignited, the thermite in the welding agent reacts to generate heat for maintaining reaction and also provide enough heat to enable parent metal to melt, and the metal part generated by the thermite and the melting part of the parent metal jointly form a molten bath to be subjected to metallurgic reaction at high temperature; the slagging constituents and Al2O3 generated by the thermite jointly form slag low melting point and viscosity, the slag is effectively separated from metal ingredients in the molten bath, Al2O3 is taken out, and the defect of slag inclusion in weld metal is overcome; alloy ingredients in the alloying agents enter the molten bath at high temperature generated by the thermite and participate in the metallurgic reaction of the molten bath jointly, so that the weld metal has the ideal microstructure and reasonable mechanical property; the thinners are used for adjusting the self-propagating reaction speed and reaction temperature of the welding agent, so that operation is convenient.

Owner:山东军浩苑环保科技有限公司

Fabrication process of semi-solid aluminum alloy scroll disk by radial forging strain induction method

InactiveCN104561852BAvoid uneven defectsReduce plastic forming forceIncreasing energy efficiencyMechanical propertyInduction method

Owner:XI AN JIAOTONG UNIV

A laser cladding repair method for turbine disc grate teeth

ActiveCN107805806BImprove bindingEasy dischargeMetallic material coating processesErbium lasersTurbine

The invention discloses a laser cladding repairing technical method for a labyrinth seal of a turbine disc. The laser cladding repairing technical method for the labyrinth seal of the turbine disc comprises the following steps that the turbine disc is clamped in an inert atmosphere protection box, the to-be-repaired labyrinth seal is cleaned and then subjected to laser cladding, and the repaired portion is machined, specifically, cleaning of the to-be-repaired labyrinth seal includes matrix pre-melting and powder supply cladding which are conducted in sequence, as for matrix pre-melting, a laser unit is adopted for irradiating the to-be-repaired labyrinth seal of the turbine disc so that a matrix of the to-be-repaired labyrinth seal can be molten, and as for powder supply cladding, laser cladding is conducted on the to-be-repaired labyrinth seal of the turbine disc in a mode that a powder supply nozzle conducts lateral powder supply. By means of the technical method, the abraded labyrinth seal can recover to the initial geometric shape and technical indexes and can be reused.

Owner:AECC AVIATION POWER CO LTD

A kind of rare earth added ultra-fine grain high toughness WC-10CO cemented carbide material and preparation method

The invention discloses a rare earth-added ultra-fine grain high-toughness WC-10Co hard alloy material and a preparation method thereof, which belong to the field of powder metallurgy. The cemented carbide composition is: tungsten carbide 88.7%-89.1%, cobalt 10%, vanadium carbide 0.5%, chromium carbide 0.3%, praseodymium oxide 0.1%-0.5% (or neodymium oxide 0.1%-0.5%). Rare earth oxides can refine the WC grains by affecting the W element content in the binder phase Co and the liquidus temperature during sintering, thereby improving the hardness of the cemented carbide; and the rare earth oxides can enhance the toughness by acting on the Co phase. As the content of rare earth oxides increases, the continuity of the alloy will be deteriorated, so the content of rare earth oxides is limited within a certain range. The invention prepares rare earth-added superfine-grain high-toughness WC-10Co cemented carbide through ball milling, pressing and vacuum sintering. The hard alloy grain size of the present invention is fine, the minimum reaches 190nm, not only has high hardness, the maximum can reach 2100HV, but also has good toughness, the maximum can reach 28.17MPa·m 1 / 2 , There is no public report that cemented carbide products can have such high hardness and high toughness at the same time.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com