Rare-earth-added ultra-fine grain high-toughness WC-10Co hard alloy material and preparation method

A cemented carbide, ultra-fine grain technology, applied in the field of powder metallurgy, to achieve the effect of simple and convenient process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

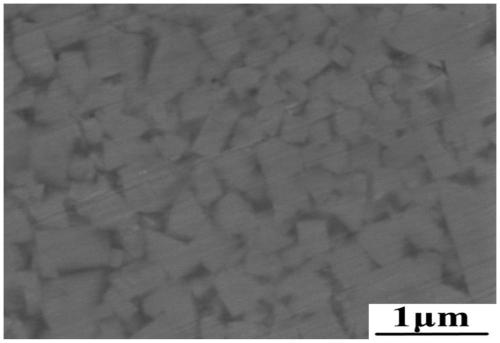

Embodiment 1

[0035] According to mass fraction WC89%, Co10%, VC0.5%, Cr 3 C 2 0.3% and Pr 6 o 110.2% for batching, with absolute ethanol as the ball milling medium, its addition amount is 240ml / kg, paraffin wax addition amount is 80g / kg, zirconia pellets are added as 500g each of Φ10 and Φ6, put into the polyester ball mill jar, and The ball milling process was carried out for 8 hours at a rotational speed of 150r / min. Then the ball-milled mixture was rinsed through an 80-mesh sieve with absolute ethanol; the sieved mixed powder was placed in a ventilated drying oven for 12 hours to dry. Then put the dried mixed powder directly into the molding die, and use 70MPa pressure to keep the pressure for 2 minutes to prepare the green body. In the vacuum sintering furnace, after the vacuuming is completed, the temperature is raised to 500°C at a rate of 2°C / min and kept for 60 minutes, then the temperature is raised to 1380°C at a rate of 4°C / min, kept for 90 minutes, and finally cooled with t...

Embodiment 2

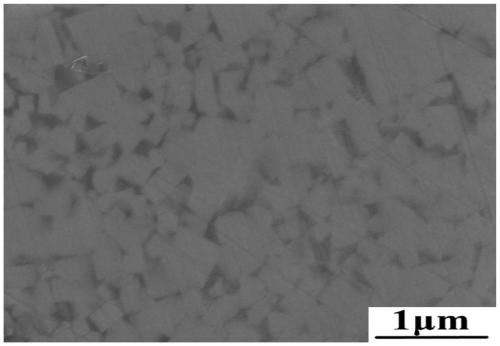

[0037] According to mass fraction WC88.8%, Co10%, VC0.5%, Cr 3 C 2 0.3% and Pr 6 o 11 0.4% for batching, with absolute ethanol as the ball milling medium, its addition amount is 240ml / kg, paraffin wax addition amount is 80g / kg, zirconia pellets are added as 500g each of Φ10 and Φ6, put into the polyester ball mill jar, and The ball milling process was carried out for 8 hours at a rotational speed of 150r / min. Then the ball-milled mixture was rinsed through an 80-mesh sieve with absolute ethanol; the sieved mixed powder was placed in a ventilated drying oven for 12 hours to dry. Then put the dried mixed powder directly into the molding die, and use 70MPa pressure to keep the pressure for 2 minutes to prepare the green body. In the vacuum sintering furnace, after the vacuuming is completed, the temperature is raised to 500°C at a rate of 2°C / min and kept for 60 minutes, then the temperature is raised to 1380°C at a rate of 4°C / min, kept for 90 minutes, and finally cooled wit...

Embodiment 3

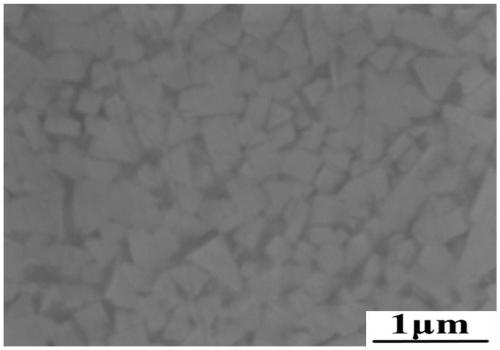

[0039] According to mass fraction WC89.1%, Co10%, VC0.5%, Cr 3 C 2 0.3% and Nd 2 o 3 0.1% for batching, with absolute ethanol as the ball milling medium, its addition amount is 240ml / kg, paraffin wax addition amount is 80g / kg, zirconia pellets are added as 500g each of Φ10 and Φ6, put into the polyester ball mill jar, and The ball milling process was carried out for 8 hours at a rotational speed of 150r / min. Then the ball-milled mixture was rinsed through an 80-mesh sieve with absolute ethanol; the sieved mixed powder was placed in a ventilated drying oven for 12 hours to dry. Then put the dried mixed powder directly into the molding die, and use 70MPa pressure to keep the pressure for 2 minutes to prepare the green body. In the vacuum sintering furnace, after the vacuuming is completed, the temperature is raised to 500°C at a rate of 2°C / min and kept for 60 minutes, then the temperature is raised to 1380°C at a rate of 4°C / min, kept for 90 minutes, and finally cooled with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fracture toughness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com