A heat treatment method for improving the microstructure and properties of 7xxx series aluminum alloys

A heat treatment method and aluminum alloy technology, which is applied in the heat treatment of 7xxx series aluminum alloys, and in the field of heat treatment to improve the structure and performance of 7xxx series aluminum alloys, can solve the problems of large quenching residual stress, machining deformation of alloy structural parts out of tolerance, etc., to achieve Reduction of quenching residual stress, improvement of production efficiency, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

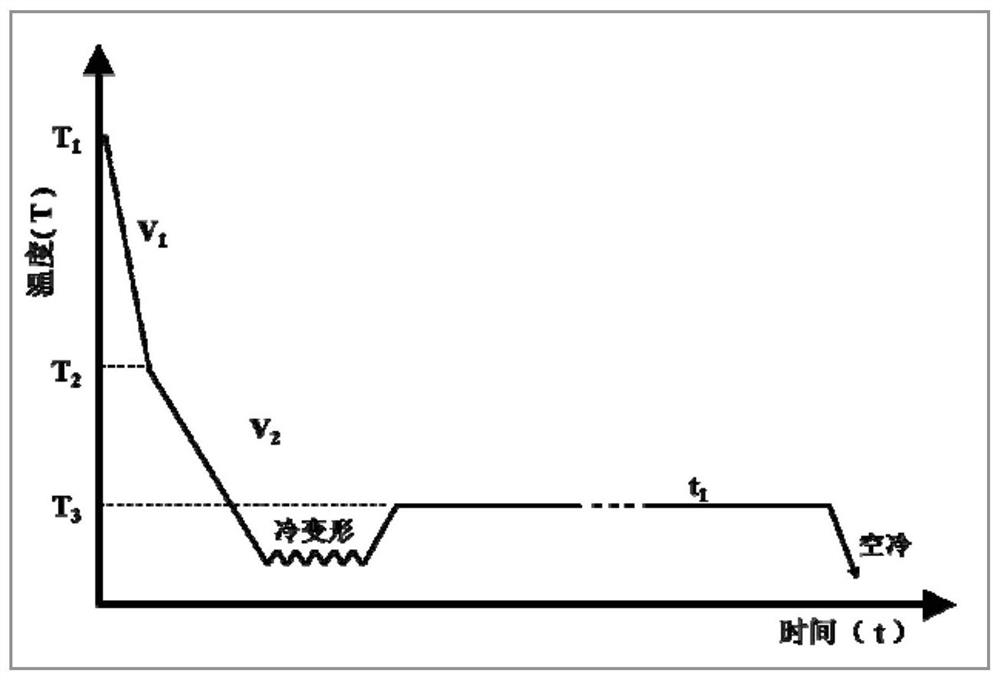

Method used

Image

Examples

Embodiment 1

[0037] In this embodiment, a 25mm plate of 7055 alloy (Al-8.0Zn-2.3Cu-2.0Mg-0.16Zr) is used as the research object. The solution treatment system of the hot-rolled 7055 alloy plate is 470°C / 2h+475°C / 2h, the pre-stretch deformation is 2.0%, and different schemes of staged quenching and single-stage aging heat treatment are adopted. The heat treatment system is shown in Table 3 . The properties of the plates after different heat treatments were tested, and the results are shown in Table 4.

[0038] table 3

[0039]

[0040] Table 4

[0041]

Embodiment 2

[0043] In this embodiment, a 78mm plate of 7050 alloy (Al-6.2Zn-2.3Cu-2.2Mg-0.12Zr) is used as the research object. The solution treatment system of the hot-rolled 7055 alloy plate is 470°C / 3h+480°C / 1h, the pre-stretch deformation is 2.3%, and different schemes of staged quenching and single-stage aging heat treatment are adopted. The heat treatment system is shown in Table 5 . The properties of the plates after different heat treatments were tested, and the results are shown in Table 6.

[0044] table 5

[0045]

[0046] Table 6

[0047]

Embodiment 3

[0049] In this embodiment, a 152mm plate of 7085 alloy (Al-7.5Zn-1.6Cu-1.5Mg-0.12Zr) is used as the research object. The solution treatment system of the hot-rolled 7085 alloy plate is 475°C / 2h, and the pre-stretching deformation is 2.5%. Different schemes of staged quenching and single-stage aging heat treatment are adopted. The heat treatment system is shown in Table 7. The properties of the plates after different heat treatments were tested, and the results are shown in Table 8.

[0050] Table 7

[0051]

[0052] Table 8

[0053]

[0054]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com