Preparation method of low-density Nb-Ti-Al-V-Zr-C niobium alloy bar

A nb-ti-al-v-zr-c, niobium alloy technology, applied in the field of preparation of low-density Nb-Ti-Al-V-Zr-C niobium alloy rods, can solve the problem of low-density niobium alloy rods Brittle fracture and insufficient elongation, etc., to achieve the effect of excellent microstructure, improved elongation, and increased single deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

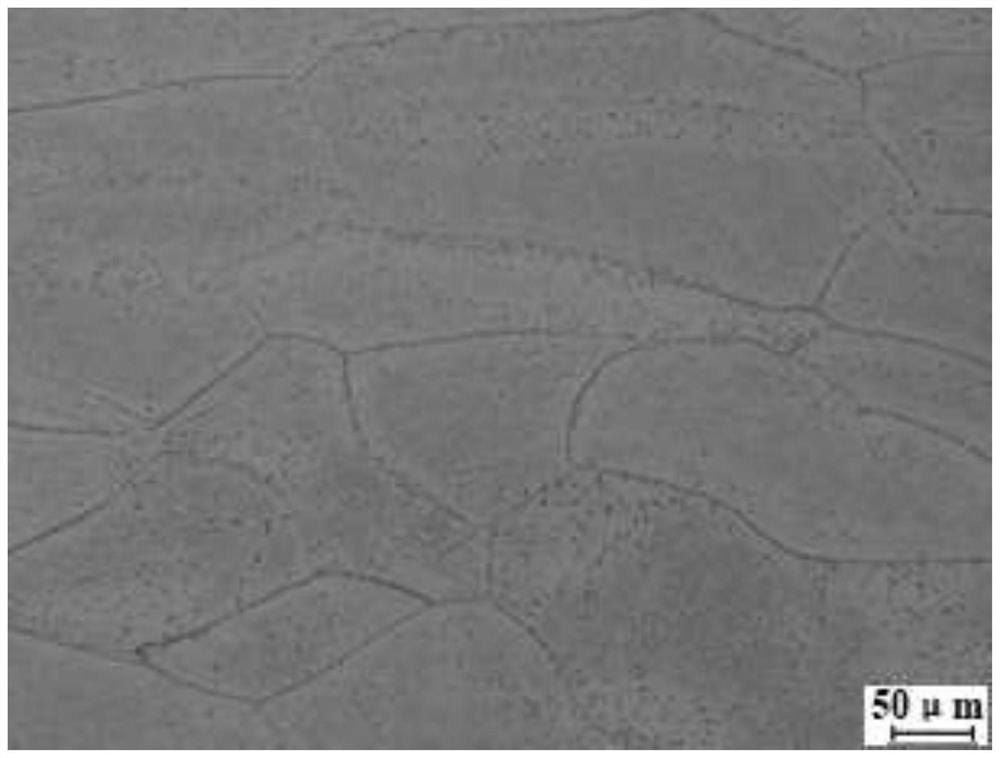

Image

Examples

Embodiment 1

[0029] The preparation method of this embodiment comprises the following steps:

[0030] Step 1. The surface of the low-density Nb-30Ti-6Al-9V-1Zr-0.07C niobium alloy ingot with a specification (diameter×length) of Φ260mm×600mm is turned clean, until there are no visible pits, impurities and micro-cracks. , and then apply a high-temperature anti-oxidation coating on the surface of the ingot and air-dry it naturally, put it into a box-type resistance furnace for heating, heat it up to 1300 ℃ with the furnace, and then keep it for 2 hours, and then quickly put it into the extruder for one extrusion, one time The diameter of the extrusion cylinder used for extrusion is Φ280mm, and the extrusion ratio is 4.5. After taking it out, it is cooled to room temperature in the air to obtain a primary extrusion rod with a specification (diameter×length) of Φ130mm×2400mm;

[0031] The low-density Nb-30Ti-6Al-9V-1Zr-0.07C niobium alloy ingot is prepared by a vacuum arc melting method, and th...

Embodiment 2

[0047] The preparation method of this embodiment comprises the following steps:

[0048] Step 1. Turn the surface of the low-density Nb-30Ti-7Al-8V-1Zr-0.07C niobium alloy ingot with a specification (diameter×length) of Φ260mm×600mm to clean, until there are no visible pits, impurities and micro-cracks. , and then apply a high-temperature anti-oxidation coating on the surface of the ingot and air-dry it naturally, put it into a box-type resistance furnace for heating, heat it up to 1300 ℃ with the furnace, and then keep it for 2 hours, and then quickly put it into the extruder for one extrusion, one time The diameter of the extrusion cylinder used for extrusion is Φ280mm, and the extrusion ratio is 4.0. After taking it out, it is cooled to room temperature in the air to obtain a primary extrusion rod with a specification (diameter×length) of Φ140mm×2070mm;

[0049] The low-density Nb-30Ti-7Al-8V-1Zr-0.07C niobium alloy ingot is prepared by a vacuum arc melting method, and the ...

Embodiment 3

[0056] The preparation method of this embodiment comprises the following steps:

[0057] Step 1. Clean the surface of the low-density Nb-28Ti-9Al-6V-1Zr-0.07C niobium alloy ingot with a specification (diameter×length) of Φ260mm×600mm, until there are no pits, impurities and micro-cracks visible to the naked eye. , and then apply a high-temperature anti-oxidation coating on the surface of the ingot and air-dry it naturally, put it into a box-type resistance furnace for heating, heat it up to 1300 ℃ with the furnace, and then keep it for 2 hours, and then quickly put it into the extruder for one extrusion, one time The diameter of the extrusion cylinder used for extrusion is Φ280mm, and the extrusion ratio is 5.0. After taking it out, it is cooled to room temperature in the air to obtain a primary extrusion rod with a specification (diameter×length) of Φ125mm×3000mm;

[0058] The low-density Nb-28Ti-9Al-6V-1Zr-0.07C niobium alloy ingot is prepared by a vacuum arc melting method,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com