Patents

Literature

34results about How to "Fully detailed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

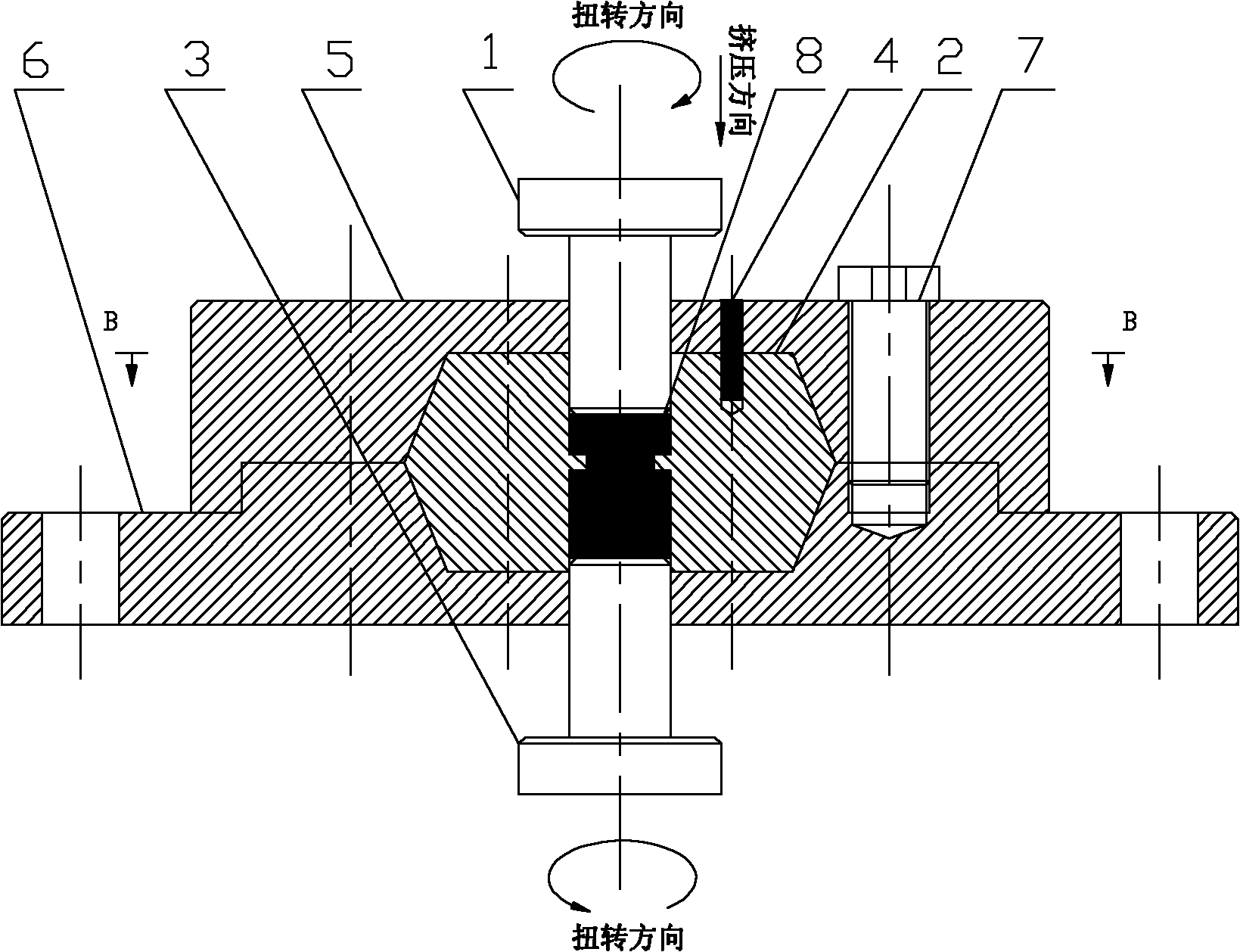

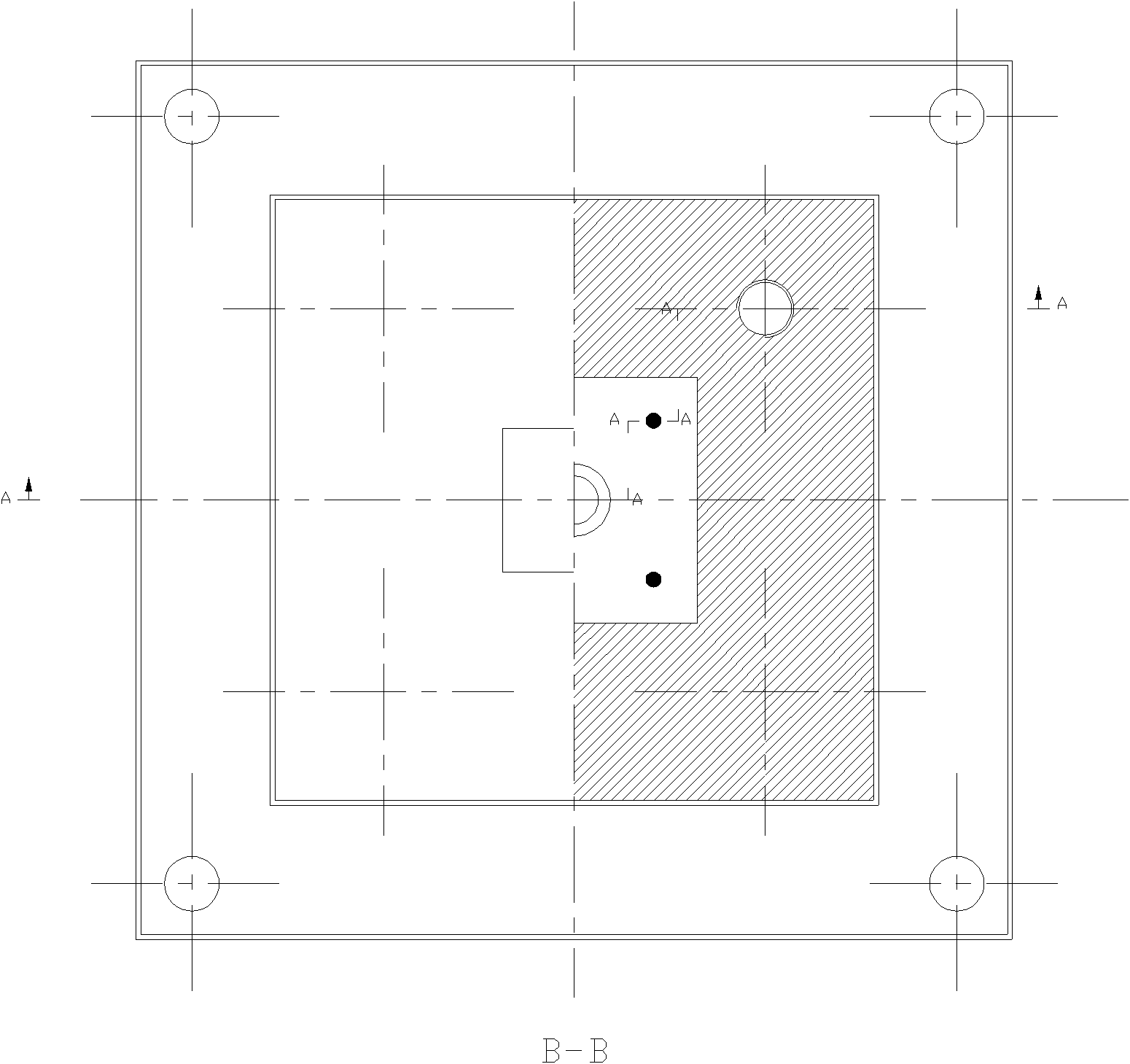

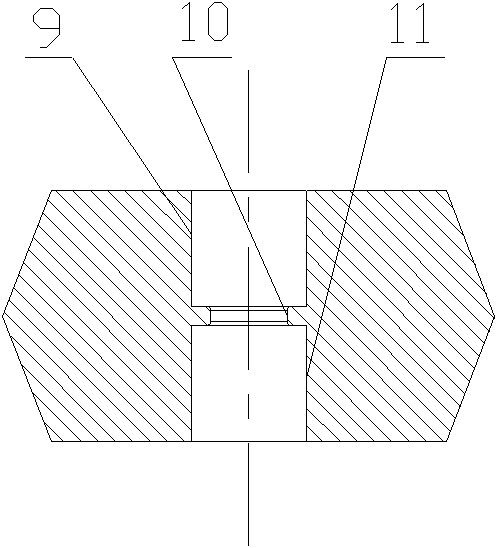

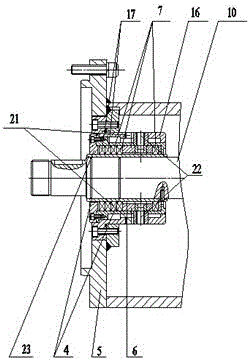

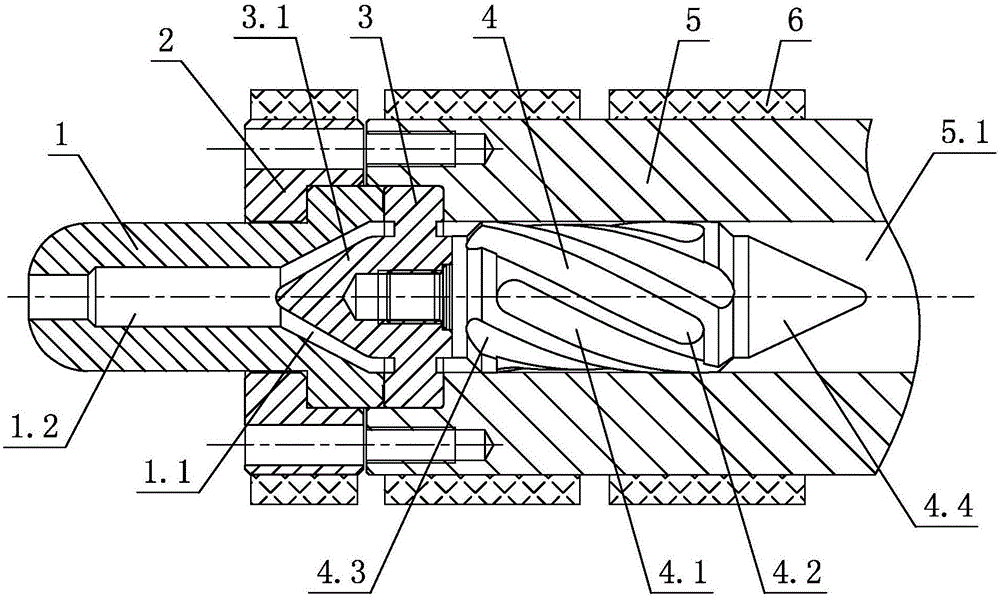

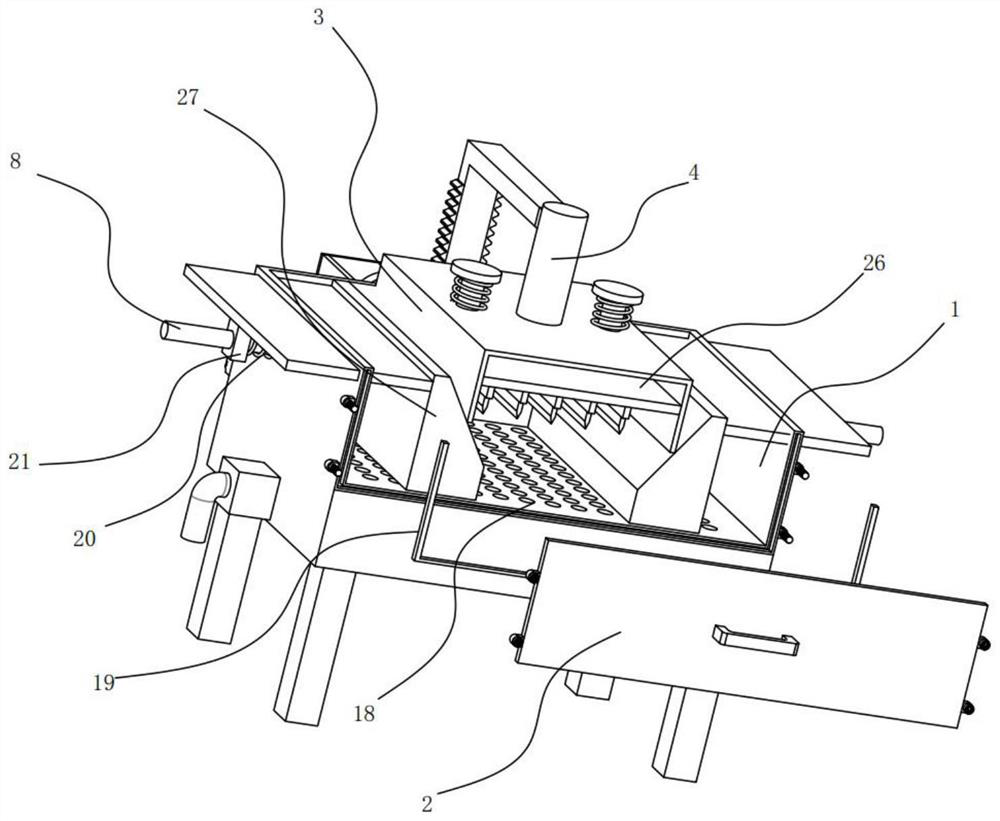

Torsion type reciprocating extrusion device and process method thereof

ActiveCN101966536AAddressing Smaller Size LimitationsImprove toughnessExtrusion profiling toolsExtrusion control devicesEngineeringUltra fine

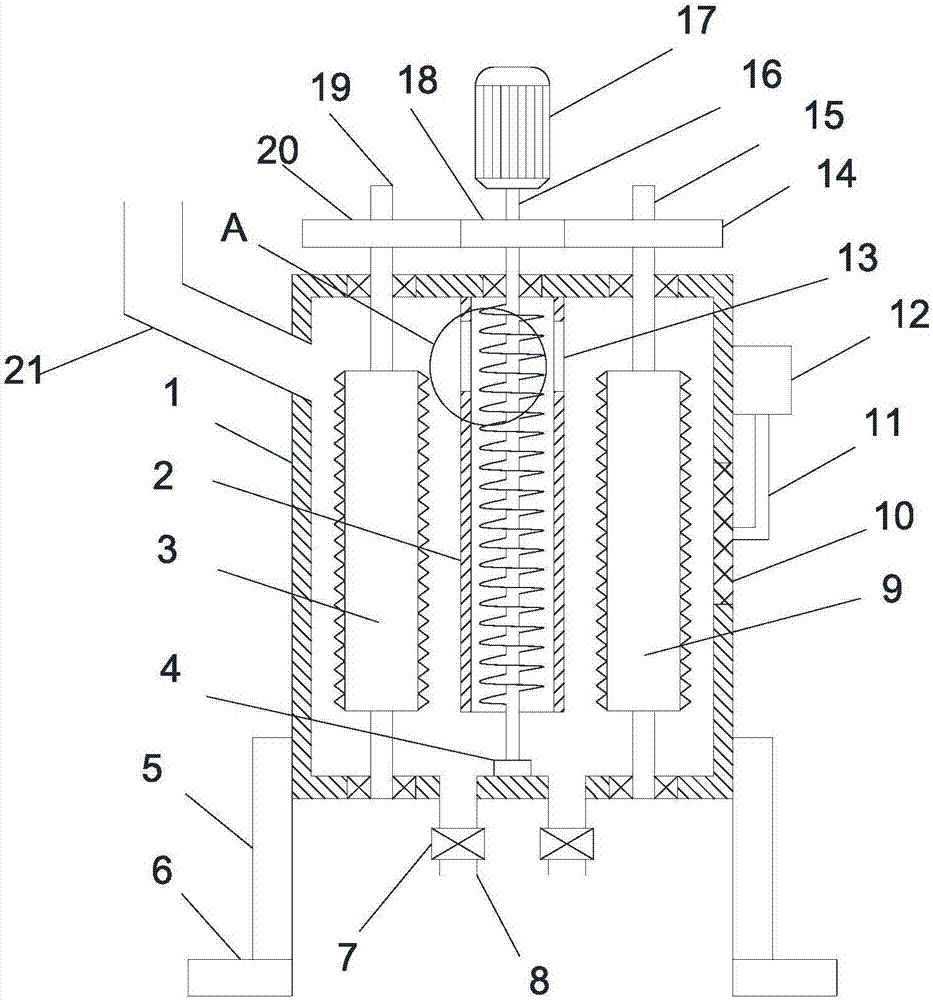

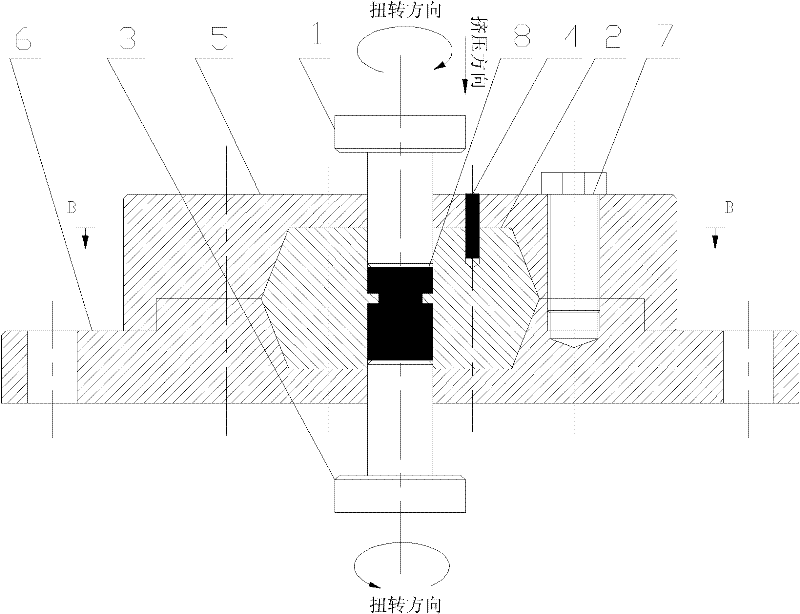

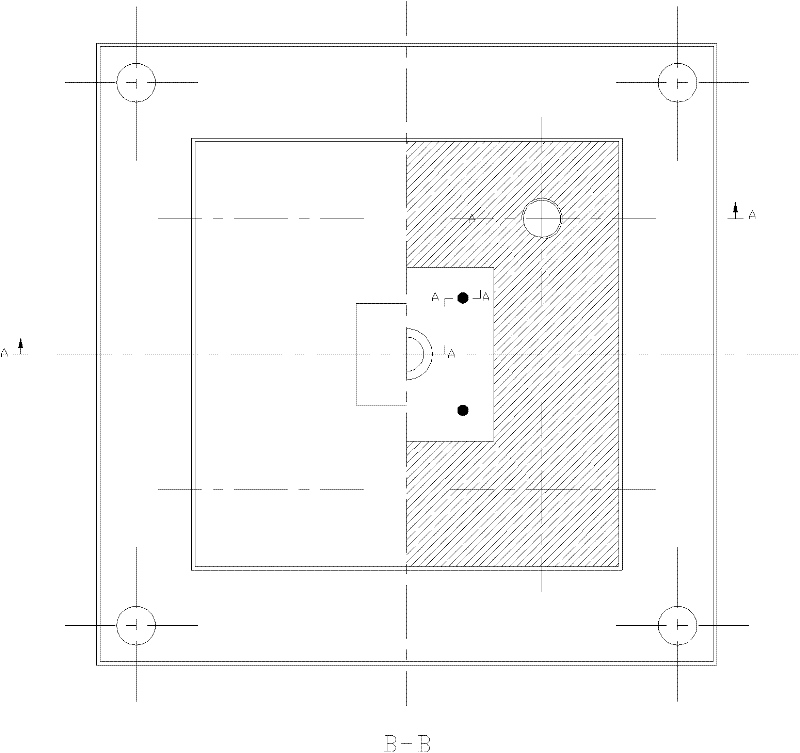

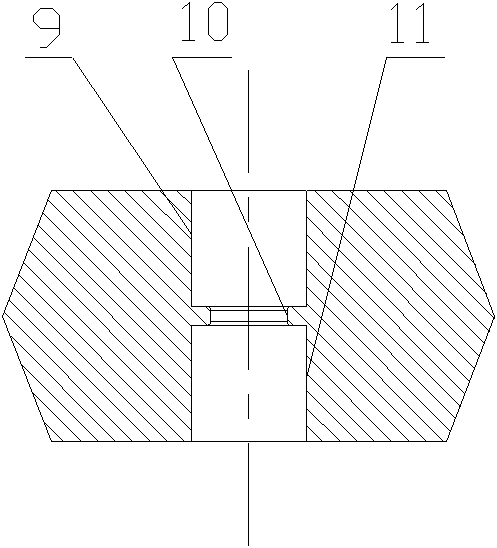

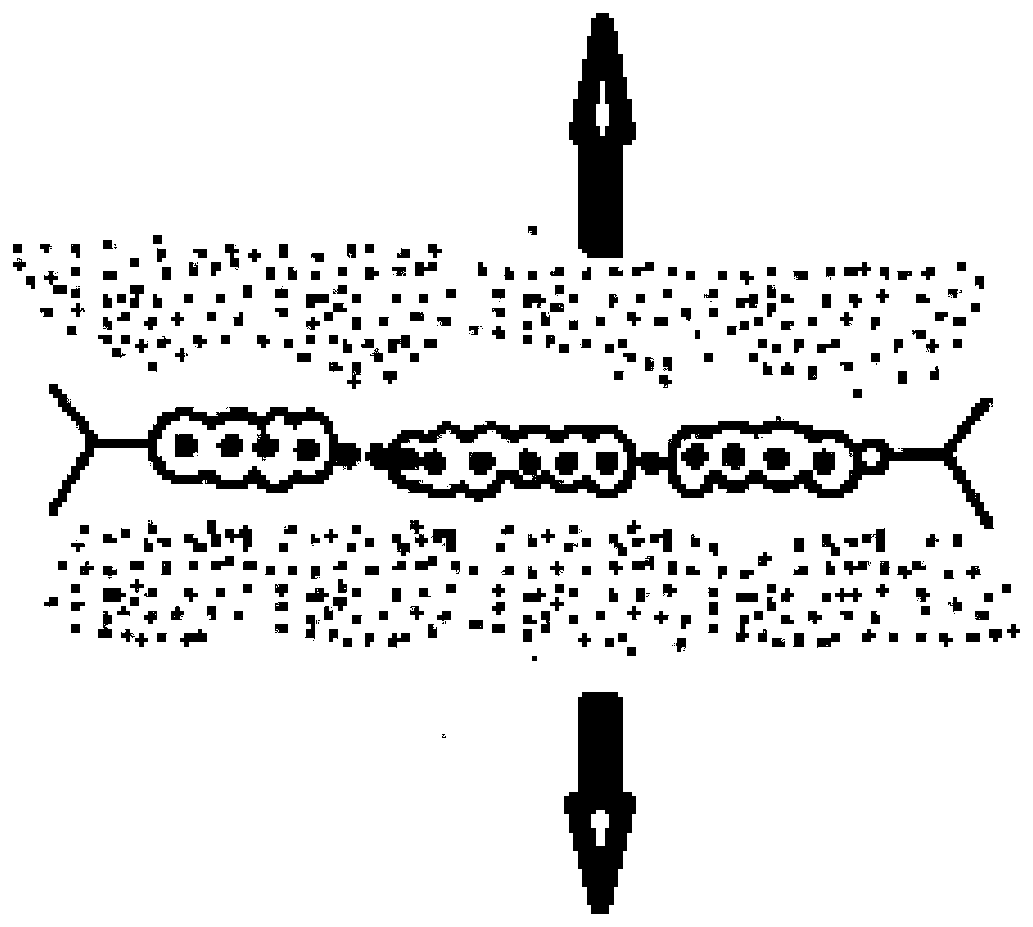

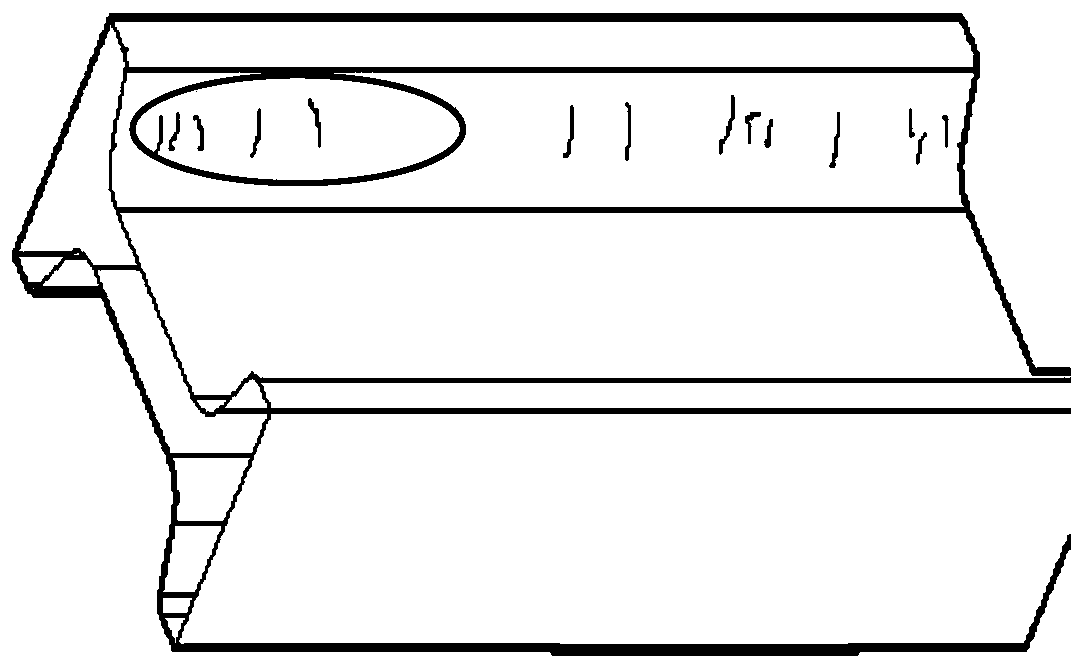

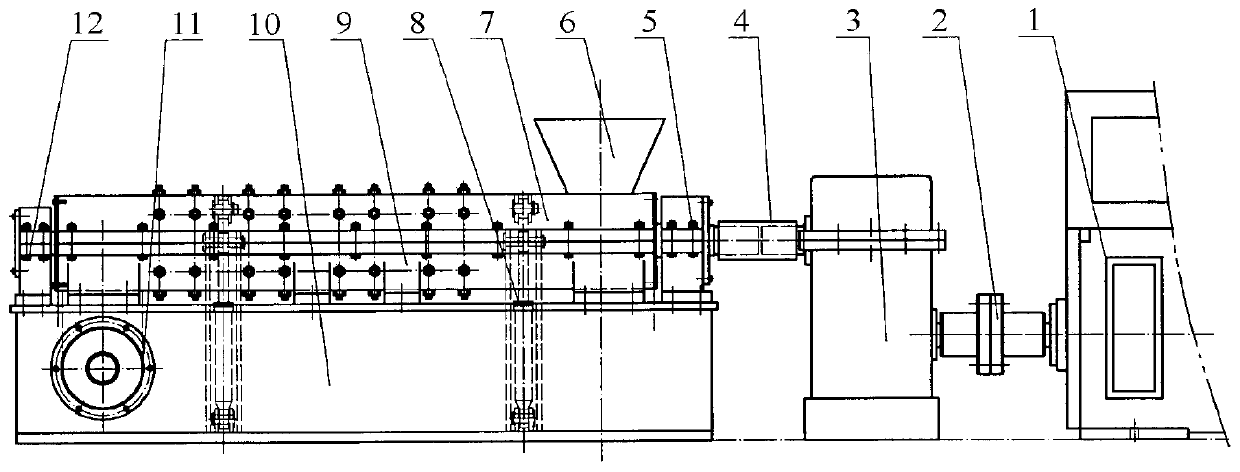

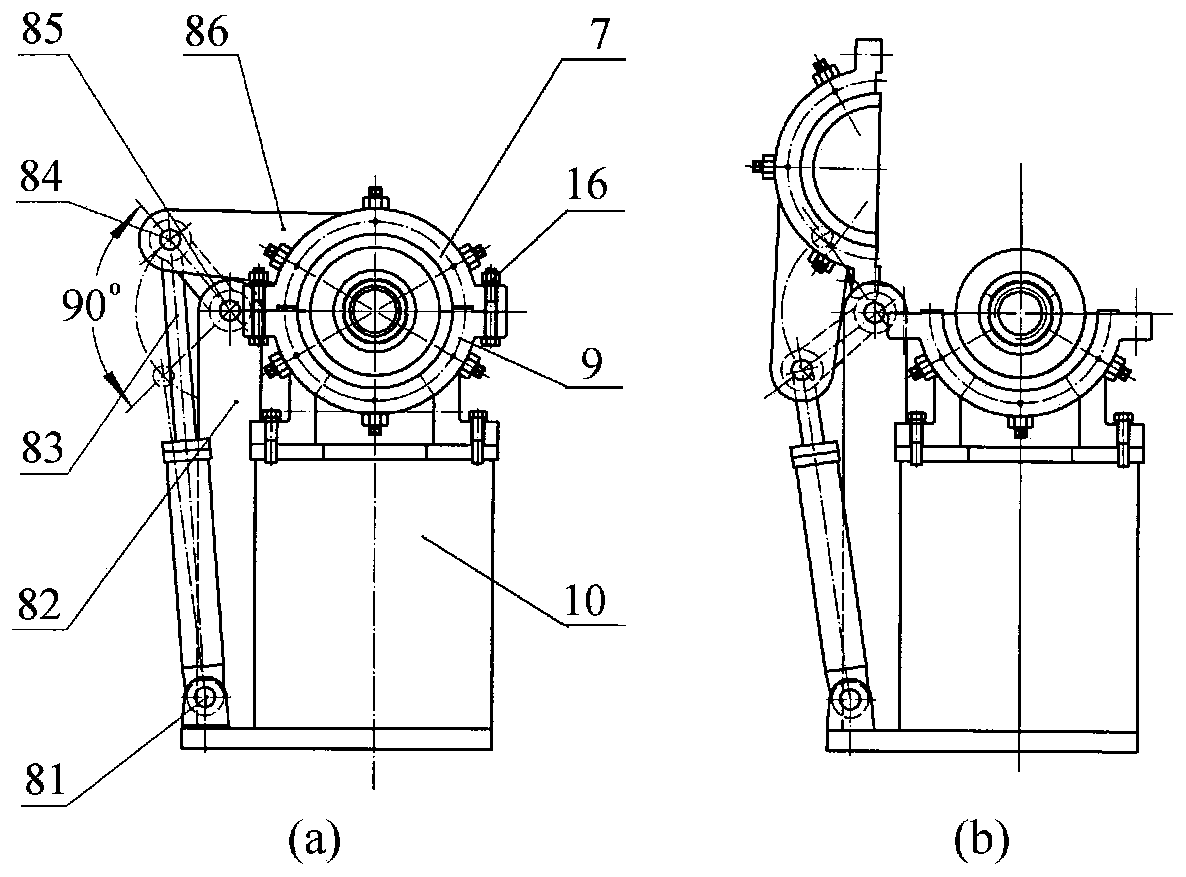

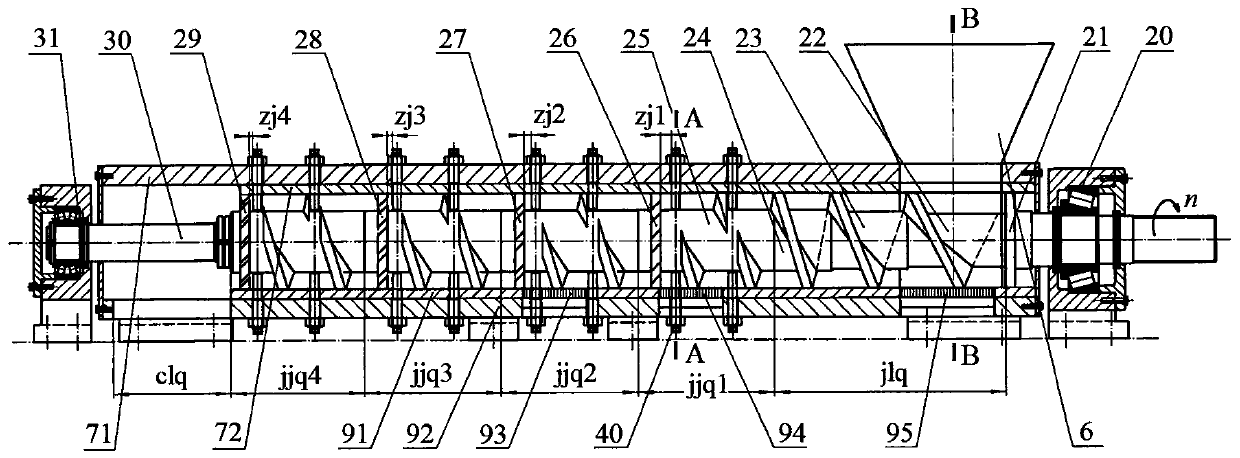

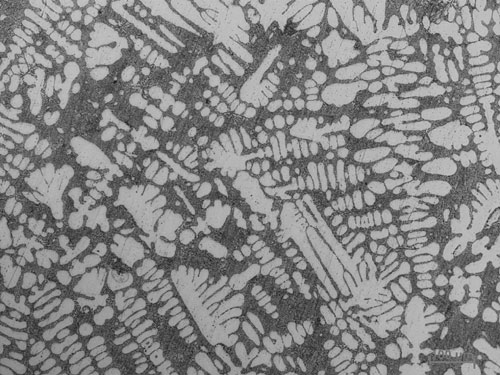

The invention discloses a torsion type reciprocating extrusion device and a process method thereof, belonging to the technical field of plastic formation. The device comprises a cavity die, a cavity die cover plate and a cavity die fixing plate, wherein the cavity die fixing plate is fixed on a work table, and the cavity die with a variable section spindle structure is arranged between the cavity die fixing plate and the cavity die cover plate. The process method makes materials generate the compound formation of reciprocating extrusion and torsion shearing so as to prepare ultra-fine grained materials with larger volume and uniform tissue.

Owner:SHANGHAI JIAO TONG UNIV

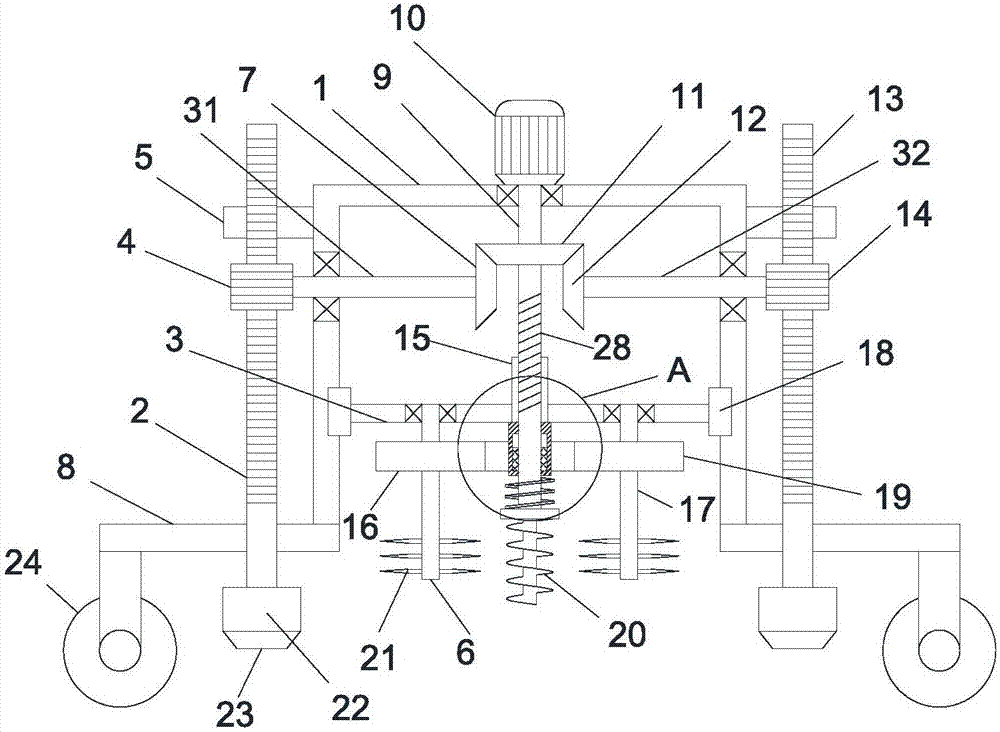

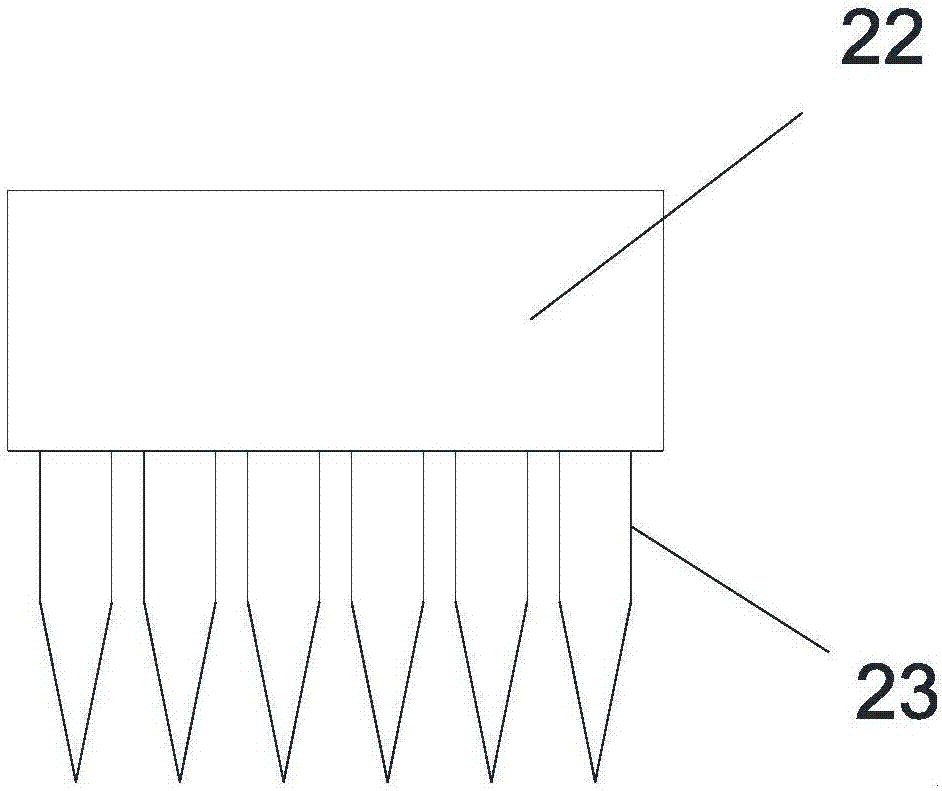

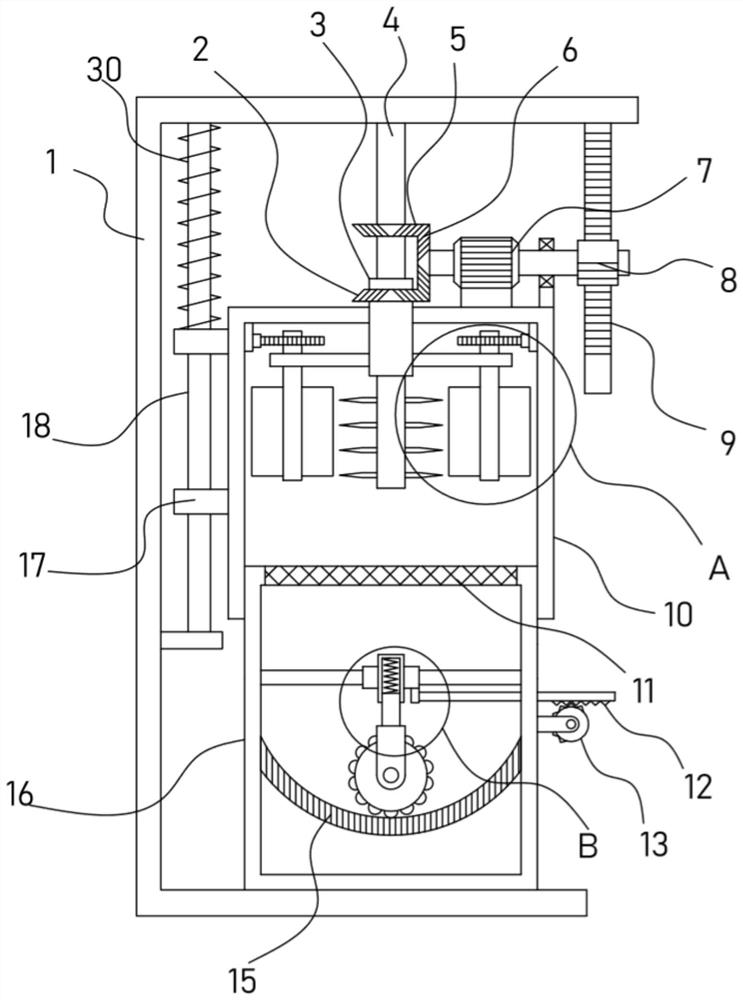

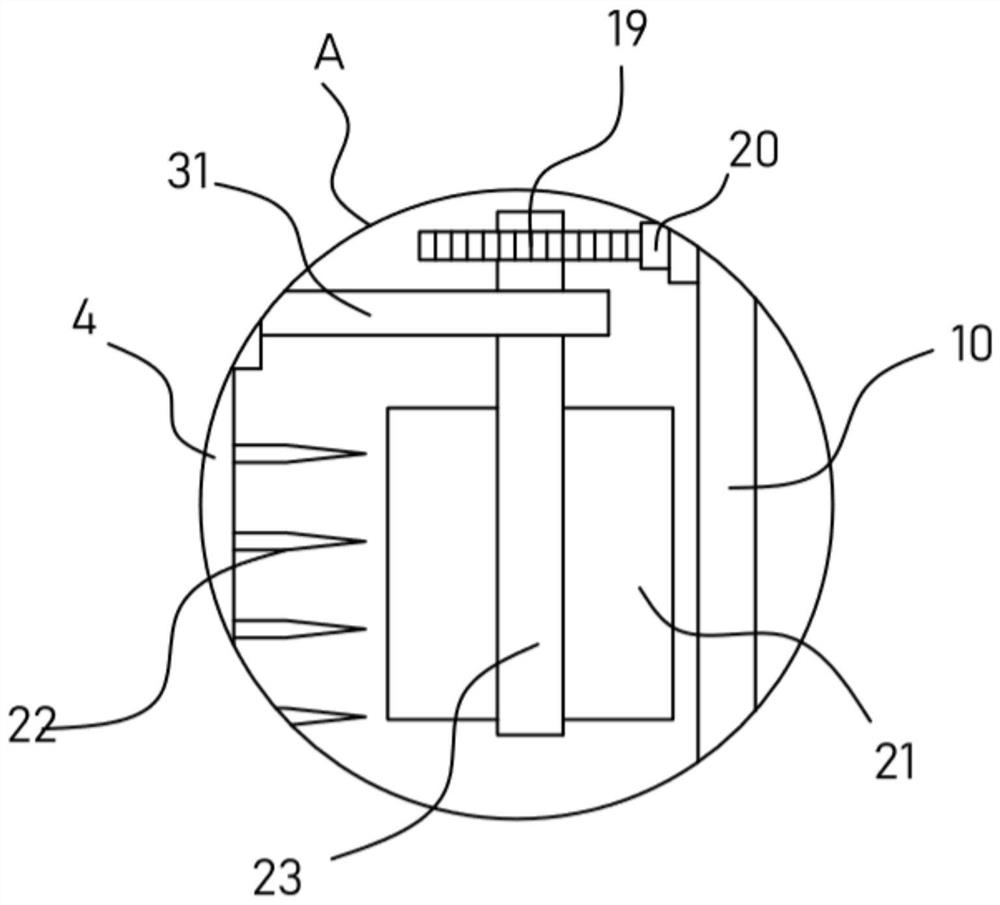

Soil loosening trolley used for garden planting

The invention discloses a soil loosening vehicle for garden planting, which comprises a support frame, two limit blocks are symmetrically arranged on the left side wall of the support frame, and a left rack and a left rack are respectively vertically slidable on the limit blocks. Right rack, the right end of the first rotating shaft is provided with the first driven bevel gear meshed with the driving bevel gear, the drive shaft passes through the inside of the threaded sleeve vertically, and the surface of the drive shaft is tapped with an external thread that is threadedly connected with the threaded sleeve , two connection blocks are arranged symmetrically on the side wall of the drive shaft, and a vertically opened sliding cavity matching with the connection block is arranged on the limit sleeve, and the surfaces of the first driven shaft and the second driven shaft are provided with Several crushing blades; the design of the present invention is reasonable, the rotation of the driving shaft drives the spiral blade to rotate and rotate and lift the soil to realize the soil turning, and at the same time, the first driven shaft and the second driven shaft drive the crushing blade to lift the soil upward by the spiral blade Rotary cutting and crushing are carried out, and the soil is turned and crushed in one step, and the crushing effect is more sufficient.

Owner:雷晓琴

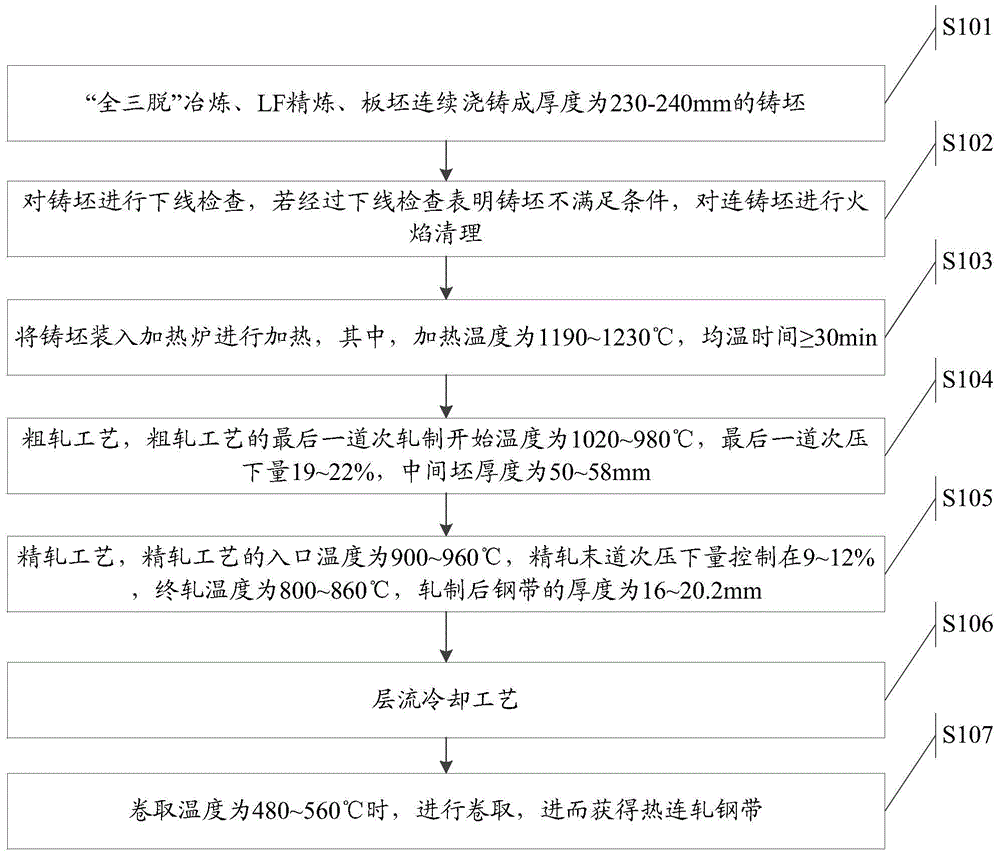

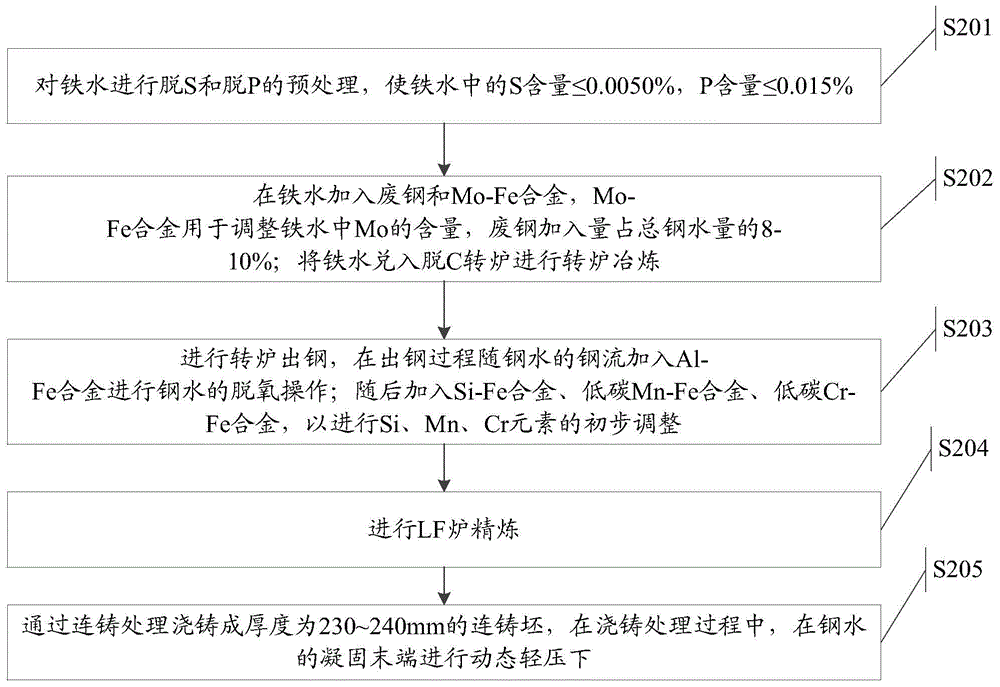

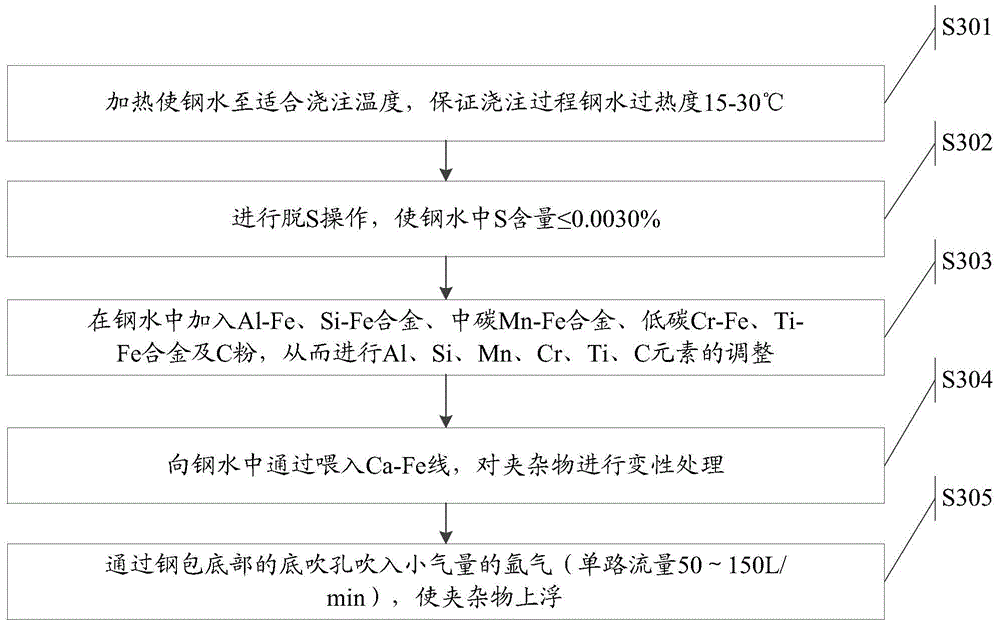

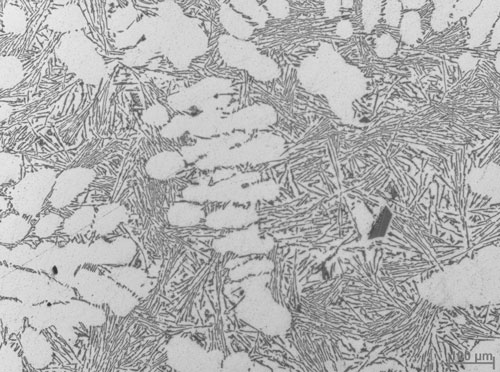

Thick-gauge hot continuous rolling steel belt with excellent ultralow temperature CTOD (Crack Tip Opening Displacement) performance and production method of thick-gauge hot continuous rolling steel belt

ActiveCN104561486AGuaranteed surface qualityImprove purityCrack tip opening displacementHeating furnace

The invention relates to the technical field of hot continuous rolling steel belts for use in submarine oil / gas transmission pipelines and provides a thick-gauge hot continuous rolling steel belt with excellent ultralow temperature CTOD (Crack Tip Opening Displacement) performance and a production method of the thick-gauge hot continuous rolling steel belt. According to the thick-gauge hot continuous rolling steel belt and the production method, the technical problem of high technical difficulty in the production of the thick-gauge hot continuous rolling steel belt with the excellent ultralow temperature CTOD performance in the prior art is solved. The production method comprises the following steps: (1) continuously casting a plate blank into a casting blank with the thickness of 230mm-240mm by virtue of 'complete pretreatment' smelting and LF refining; (2) carrying out offline detection on the casting blank; (3) putting the casting blank in a heating furnace, and heating, wherein the heating temperature is 1190-1230 DEG C, and the temperature equalizing time is more than or equal to 30 minutes; (4) carrying out a rough rolling process; (5) carrying out a precision rolling process, wherein the thickness of the rolled steel belt is 16mm-20.2mm; (6) carrying out a laminar flow cooling process; and (7) reeling at the temperature of 480-560 DEG C. The production method can be used for producing the thick-gauge hot continuous rolling steel belt with the excellent ultralow temperature CTOD at relatively low difficulties.

Owner:SHOUGANG CORPORATION +1

Rolling technology for high-carbon steel in thin slab casting and rolling

ActiveCN104438326AIncrease nucleation sitesUniform nucleationTemperature control deviceTension/compression control deviceThree stageSlow cooling

The invention provides a rolling technology for high-carbon steel in thin slab casting and rolling. The rolling technology includes the processes of continuous casting, heat evening, scale removing, rolling, inter-stand cooling, laminar cooling, reeling and insulation cover slow cooling. The rolling technology is characterized in that the rolling process includes three stages of Austenite perfect recrystallization rolling, non-recrystallization area Austenite rolling and two-phase area rolling. Medium-and-high-carbon steel structures rolled through the rolling technology are even and fine ferrite and particular pearlite, banded structures can be improved, the mechanical property is good, the annealing process does not need to be conducted before forming, cost is reduced, and quite high practicability is achieved.

Owner:武汉钢铁有限公司

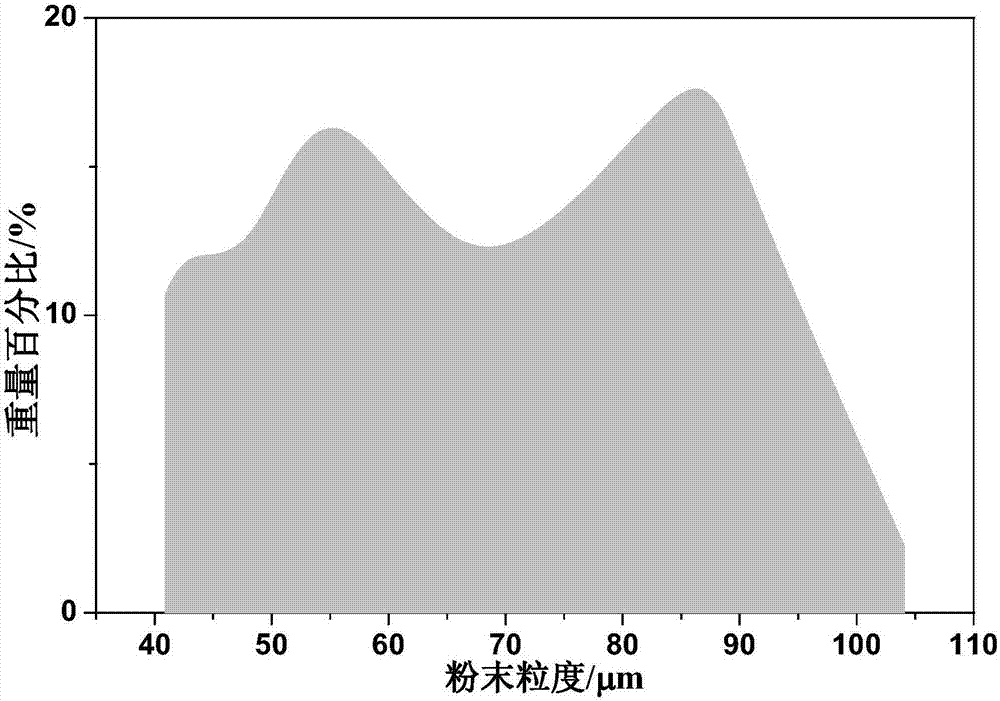

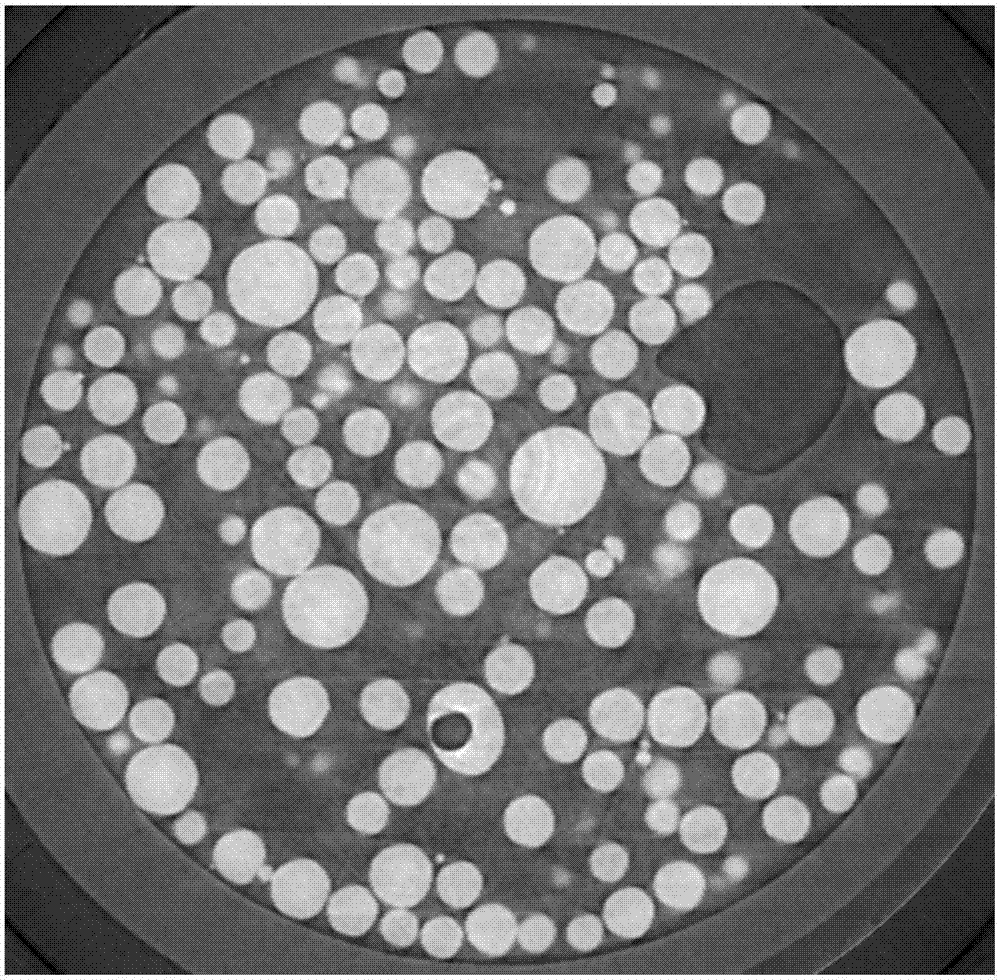

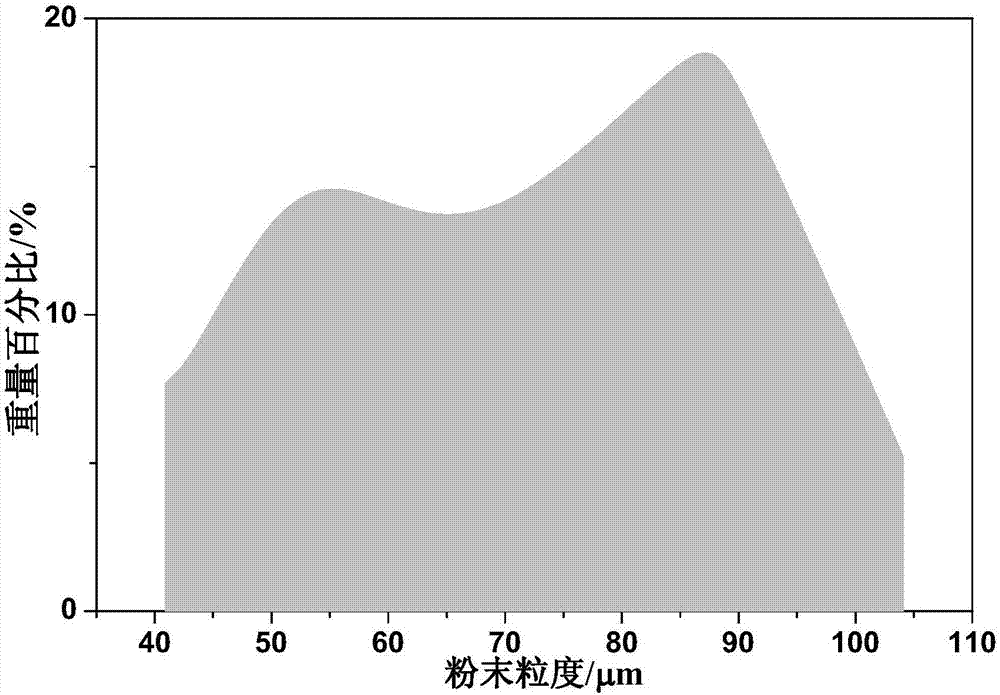

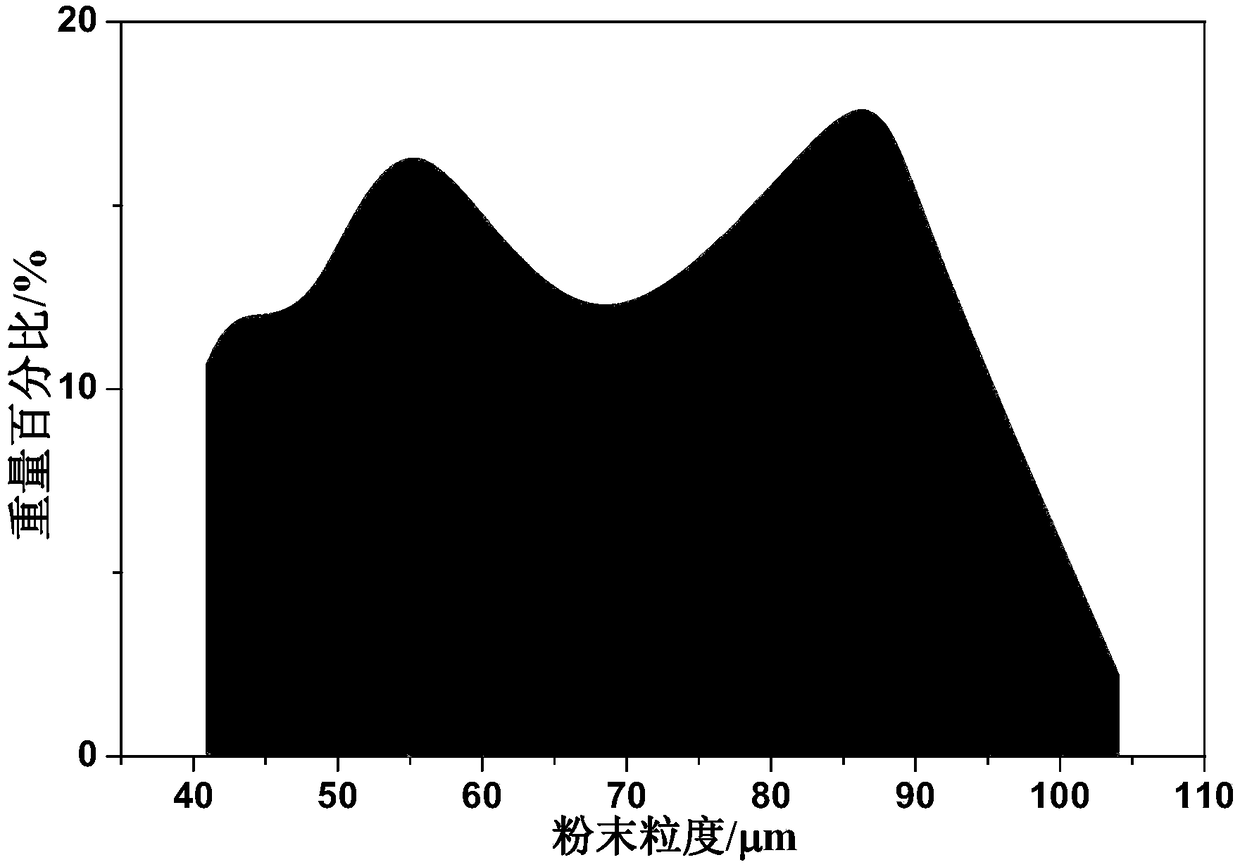

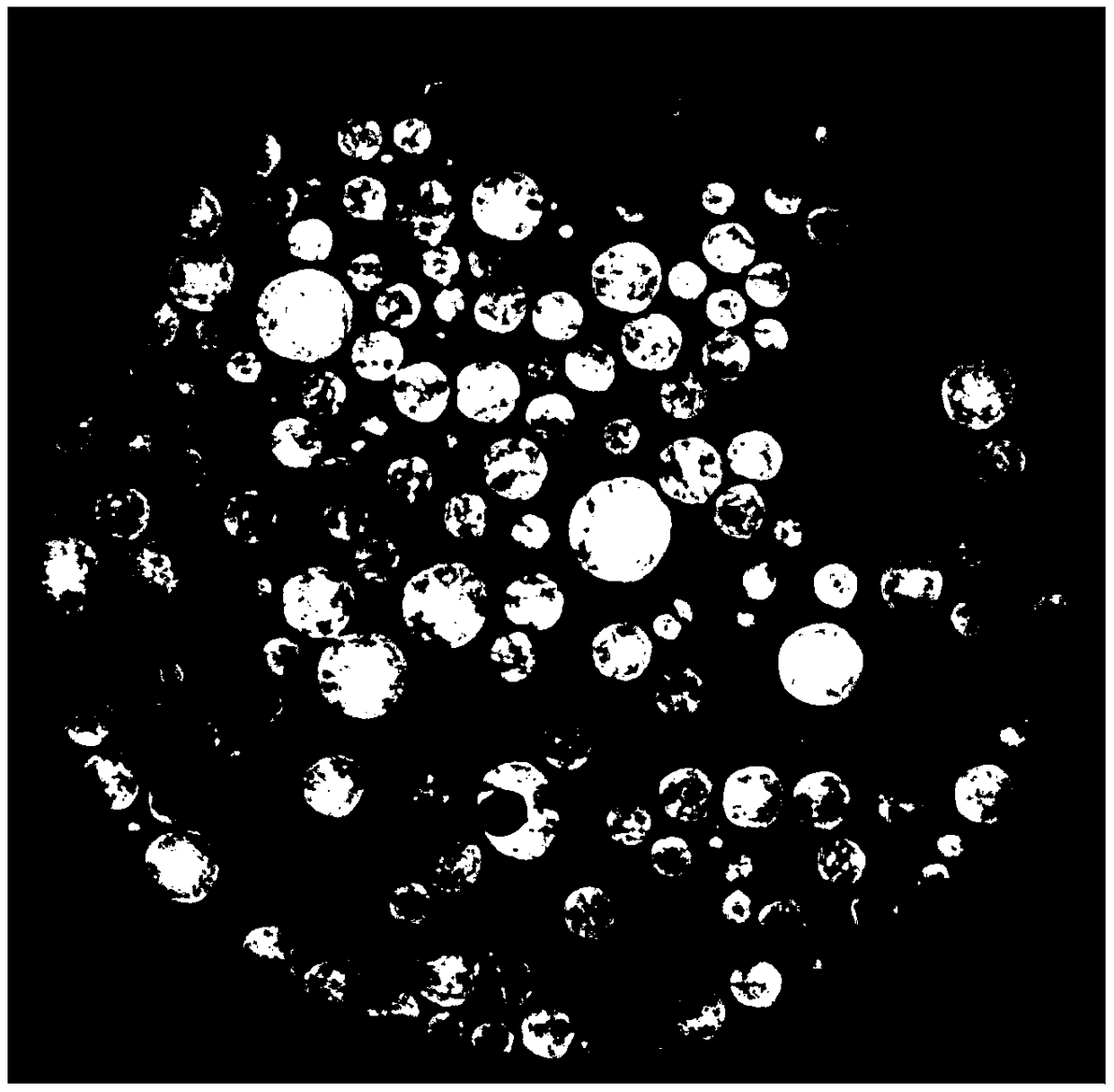

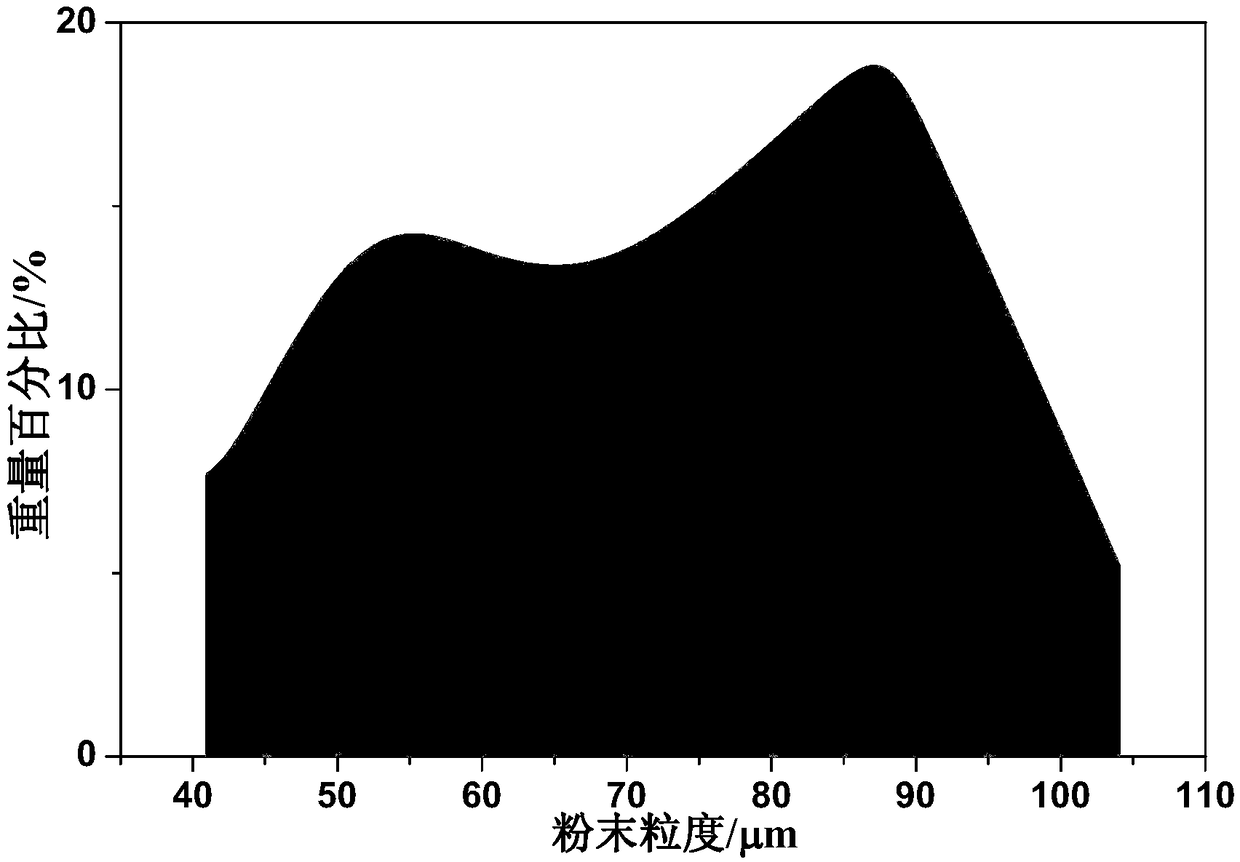

Method for preparing titanium based spherical powder with reduced particle size through gas atomization

ActiveCN107498059AGood physical propertiesLarge particle sizeTransportation and packagingMetal-working apparatusCrucibleGlobular shaped

The invention discloses a method for preparing titanium based spherical powder with reduced particle size through gas atomization. The method comprises steps as follows: step one, a titanium based raw material and a tin material are placed in a smelting crucible, and the smelting crucible is put in a smelting chamber of a vacuum induction melting gas atomization equipment for vacuum induction melting; step two, after the titanium based raw material and the tin material are melted through vacuum induction melting, argon is introduced for protection, a graphite diversion pipe located at the bottom of the smelting crucible is heated, a melted liquid produced after melting of the titanium based raw material and the tin material freely falls into an atomization chamber through the graphite diversion pipe and subjected to vacuum induction melting gas atomization treatment, atomized powder is obtained, and titanium based spherical powder is obtained from a collecting tank. According to the method, tin is introduced into the titanium raw material or a titanium alloy raw material for reducing viscosity of the melted liquid obtained after smelting, so that the raw materials are easy to break during gas atomization, the particle size of the prepared powder becomes small, wherein the yield of the powder with the particle size smaller than 45 mu m in the titanium based spherical powder is not lower than 28%, pores in the powder are reduced, and the amount of hollow powder is reduced.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

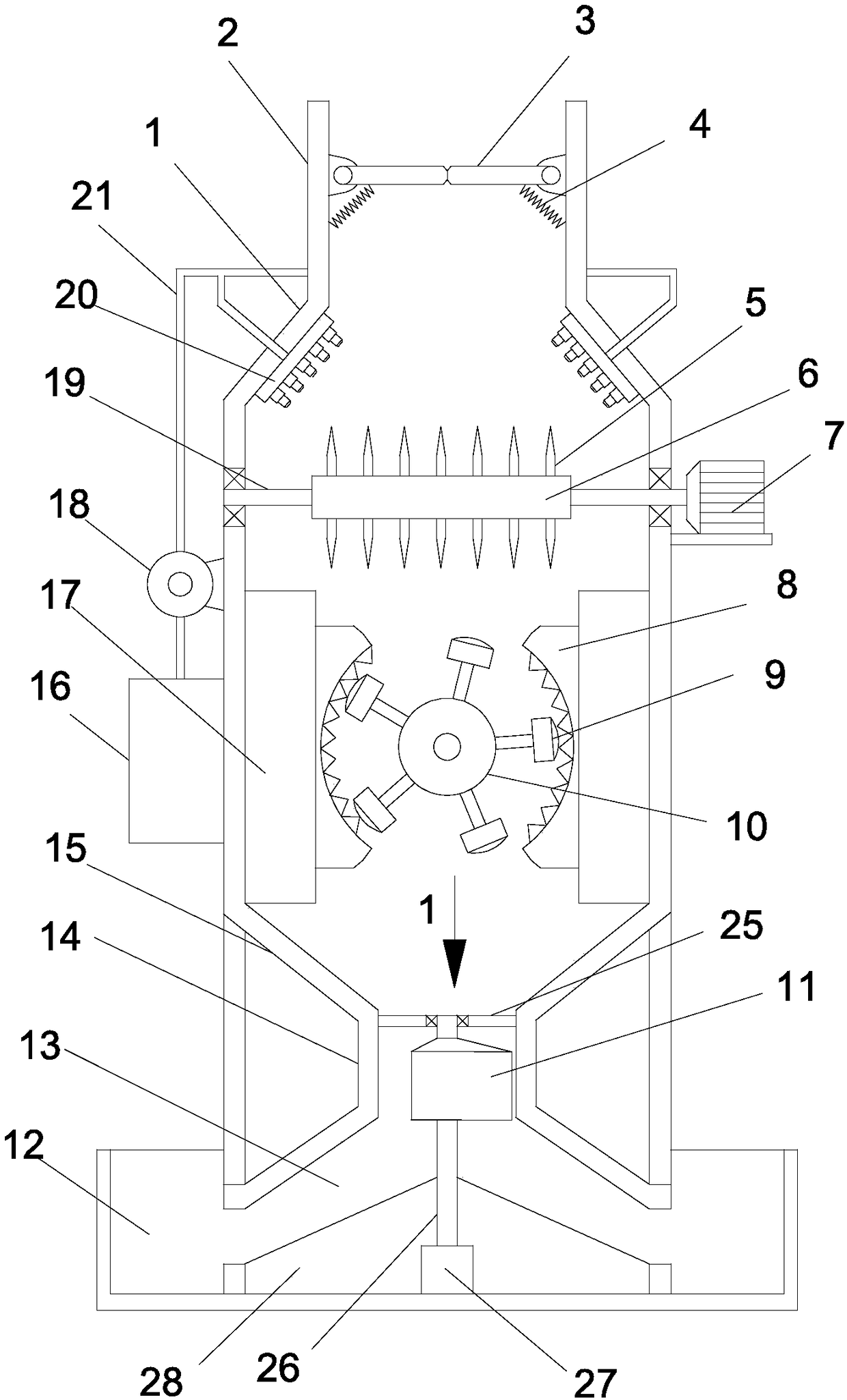

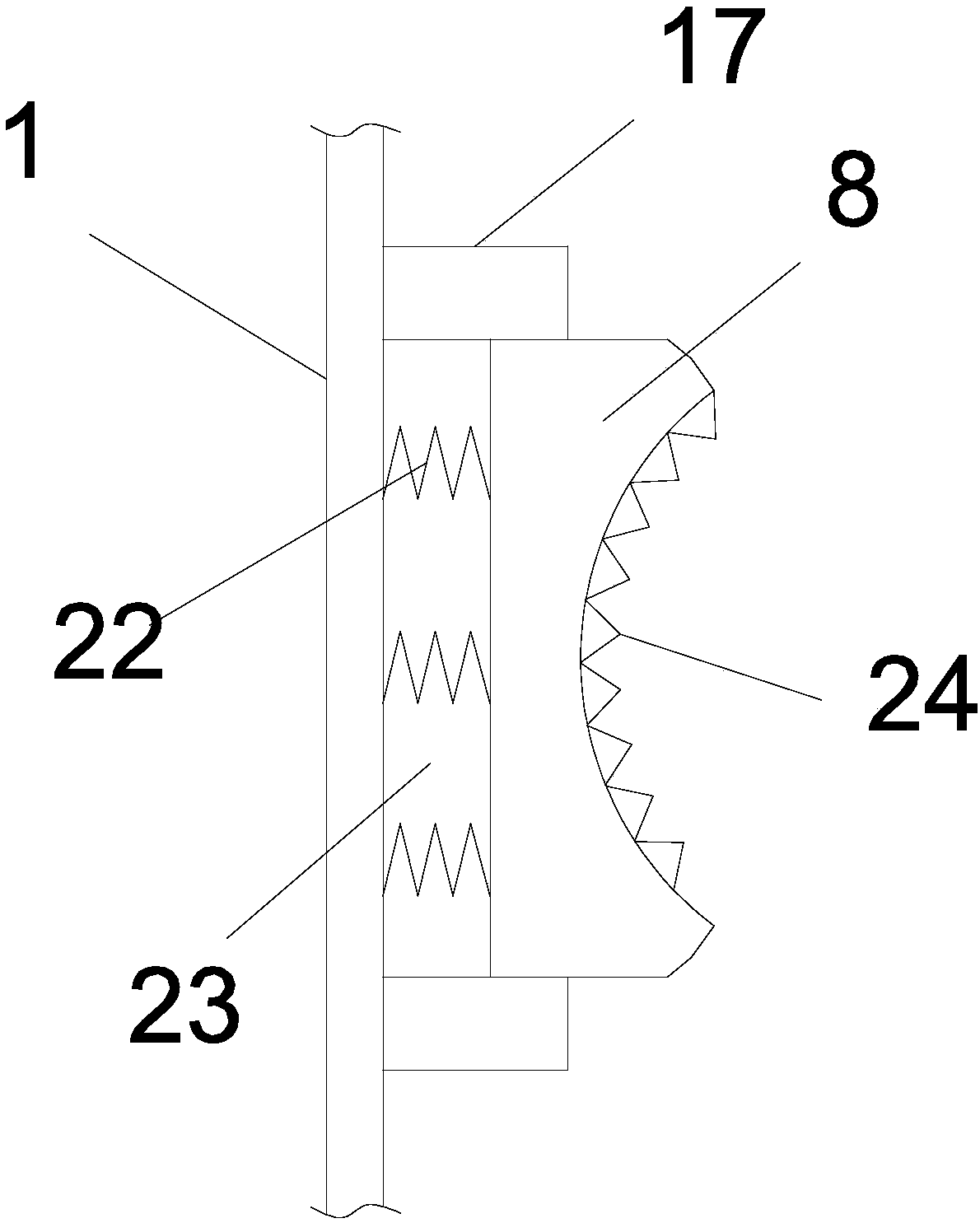

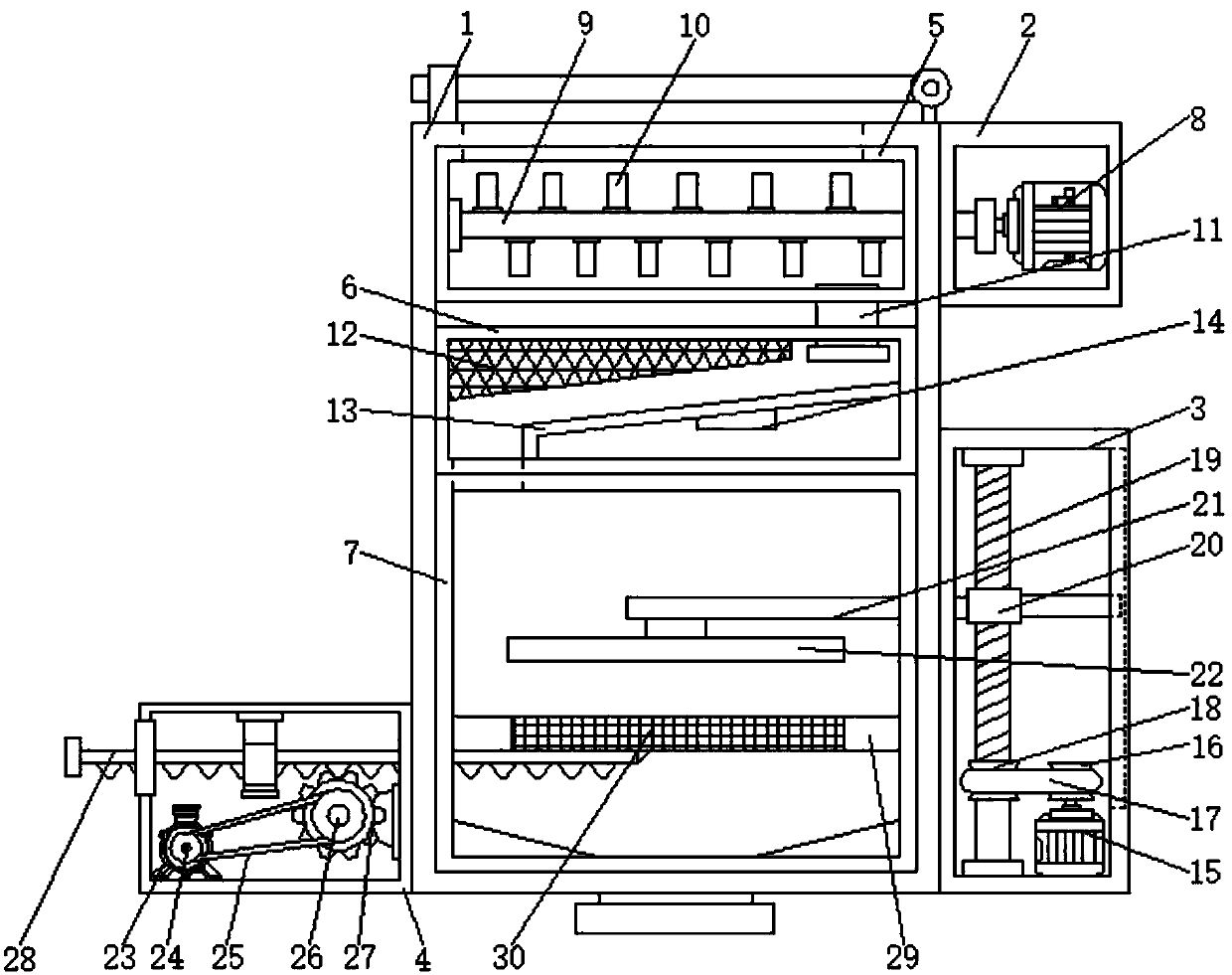

Disinfecting and crushing device for medical waste disposal

InactiveCN108176479AImprove refinementFully detailedMedical waste disposalGrain treatmentsDrive shaftMedical waste

The invention discloses a disinfecting and crushing device for medical waste disposal. The disinfecting and crushing device for medical waste disposal comprises a processing tank; the upper end of theprocessing tank is fixedly provided with a feeding pipe; the inner side wall of the feeding pipe is rotationally provided with two rotating baffles with the end portions abutting against each other;and reset springs are fixedly connected between the rotating baffles and the feeding pipe. Medical waste is subjected to primary rotary crushing by rotating a smashing blade, a rotary wheel rotates todrive a grinding head to be matched with an arc crushing trough to achieve further rotary grinding of the medical waste, and refining of the medical waste is promoted; a drive shaft drives an eccentric grinding roller to rotate so that the medical waste can be eccentrically ground again, and accordingly the medical waste is sufficiently and thoroughly refined; and in the smashing process, the rotating baffles abut against each other, so that the smashing space is relatively sealed, and by spraying disinfectant fluid into the processing tank through a spraying plate, the medical waste can be disinfected and sterilized, dust spreading is avoided, and the disinfecting and crushing device is more environmentally friendly.

Owner:丁小标

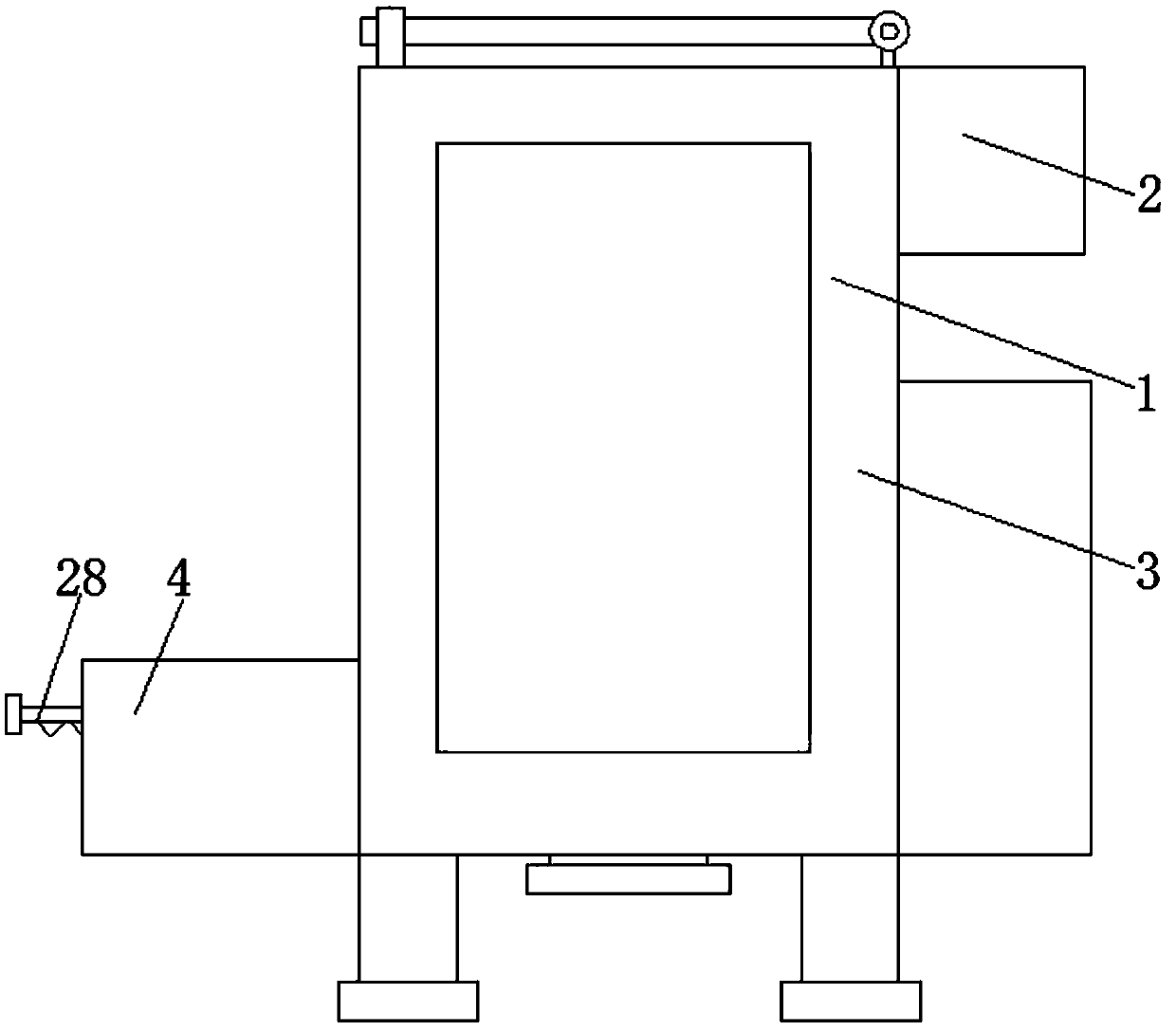

Solid waste treatment device

InactiveCN107891052AEasy to handleGuaranteed treatment effectSolid waste disposalMedical waste disposalCouplingEngineering

The invention discloses a solid waste treatment device. The solid waste treatment device comprises a box; the top of the right side of the box is fixedly connected with a top box; the bottom of the right side of the box is fixedly connected with a bottom box; the bottom of the left side of the box is fixedly connected with a motor box; the top of the inner wall of the box is fixedly connected witha crushing box; a disinfection box is fixedly connected between two sides of the inner wall of the box at the bottom of the crushing box; an extrusion box is fixedly connected between two sides of the inner wall of the box at the bottom of the disinfection box; one side of the inner wall of the top box is fixedly connected with a first motor through a first motor base; an output shaft of the first motor is fixedly connected with a crushing shaft through a coupling; and the solid waste treatment device relates to the technical field of waste treatment. The solid waste treatment device can extrude wastes to guarantee that the wastes can pass through a filter screen, so that the later treatment is convenient, the treatment effect is guaranteed, and the stability of the device is greatly improved; and the device is simple in structure and high in operability, and saves the treatment cost.

Owner:易亮

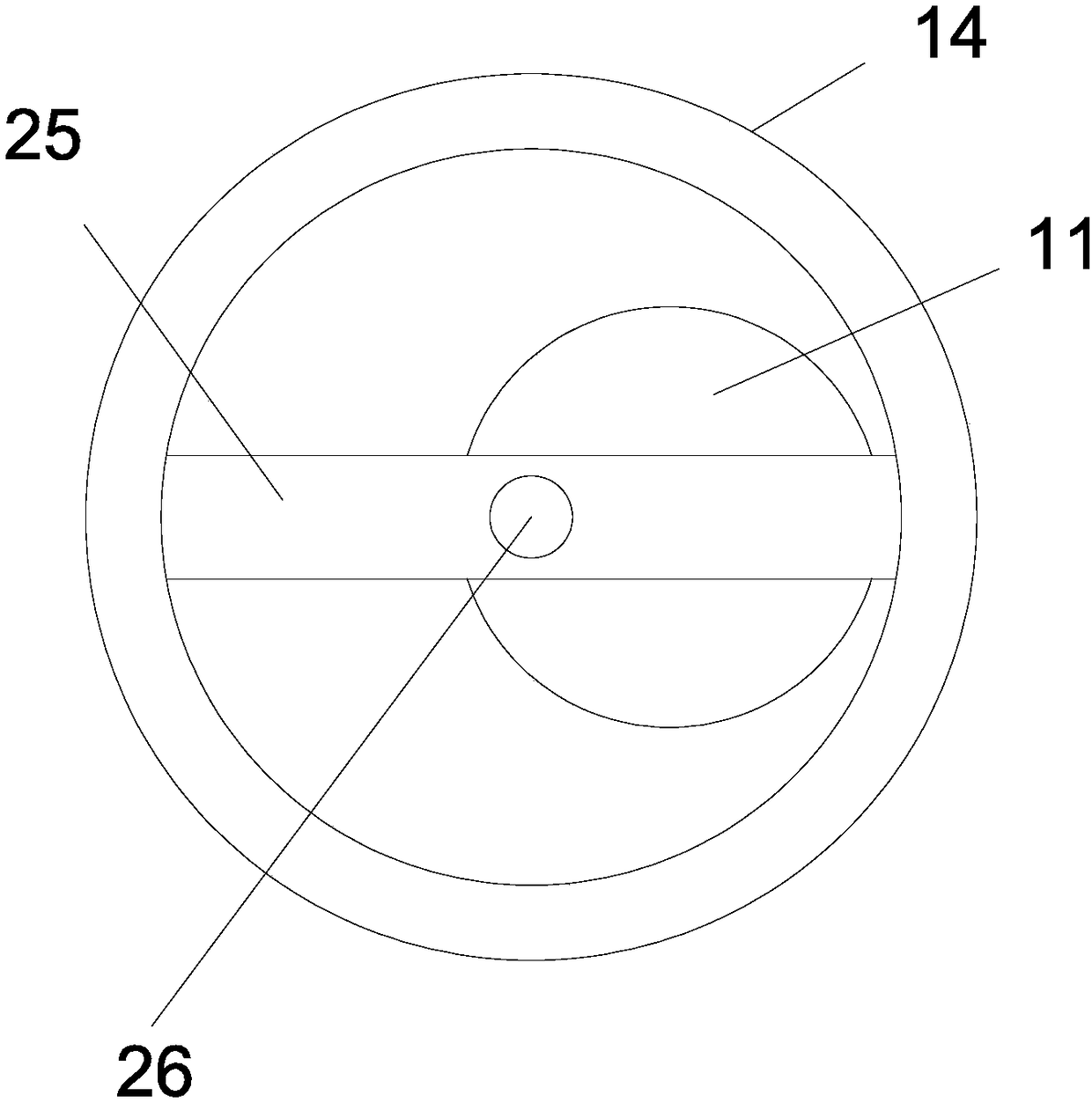

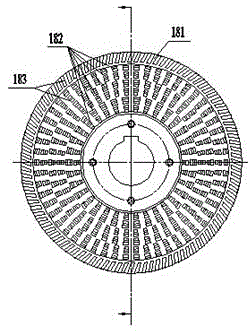

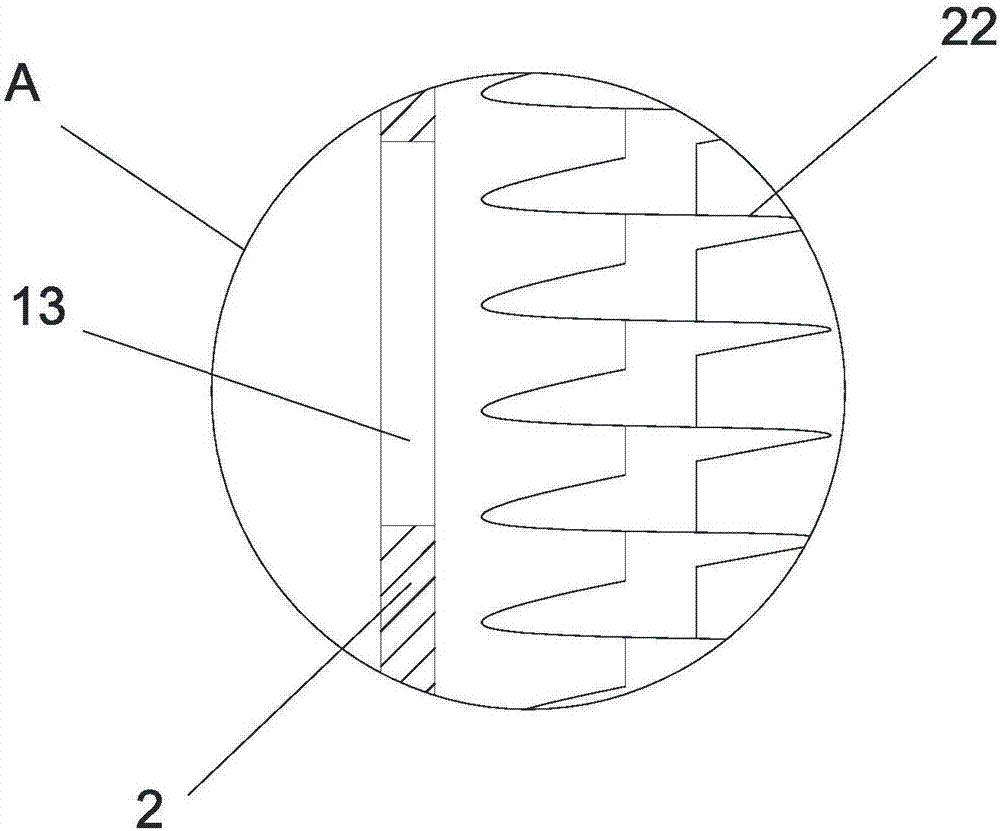

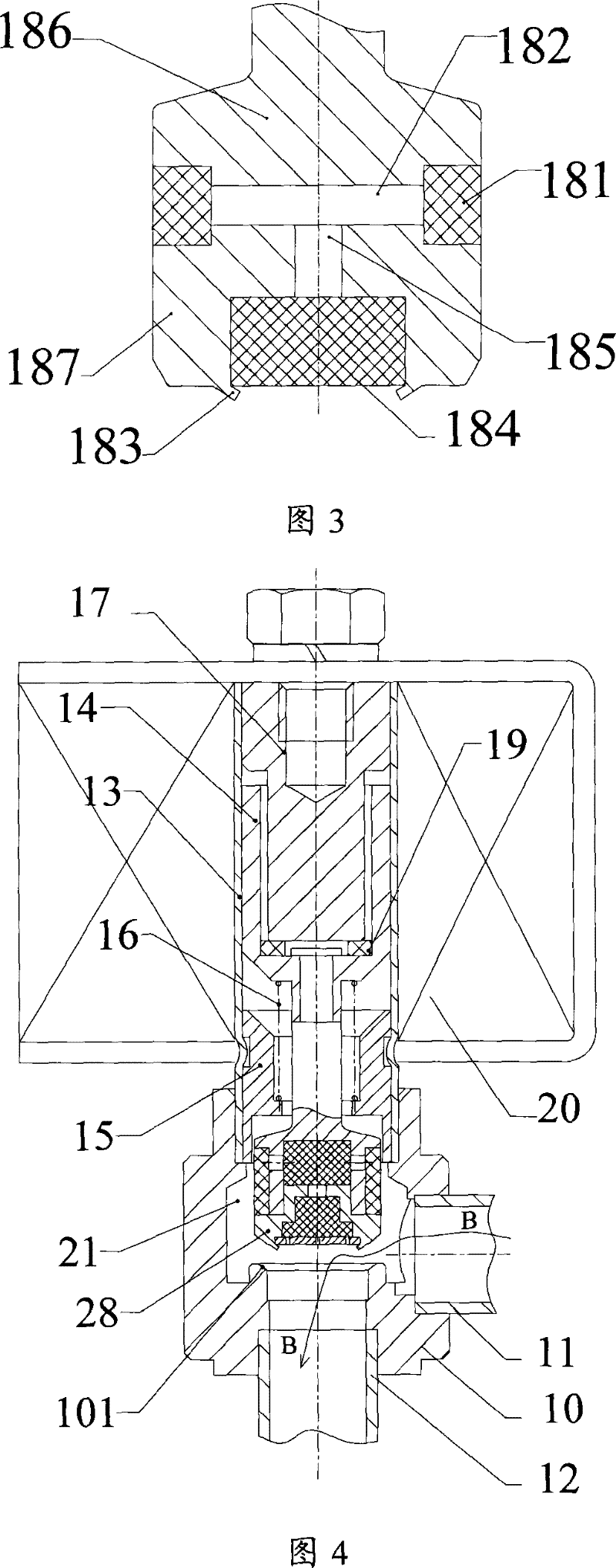

Colloid mill stator and rotor and colloid mill comprising stator and rotor

The invention discloses a colloid mill stator and rotor and a colloid mill comprising the stator and rotor, and belongs to the field of machinery. According to the colloid mill stator and rotor provided by the invention, the end surface of a stator disc and the end surface of a rotor disc are provided with concentric annular distribution toothed sections; a sluice channel is formed between adjacent toothed sections; straight teeth are arranged on the toothed section at the outermost layer of the end surface of the static disc; trapezoidal teeth are arranged on the toothed sections at the other layers of the end surface of the stator disc; the tooth height of each straight tooth is smaller than the tooth height of each trapezoidal tooth on the end surface of the stator disc; a blind groove is formed in the outer edge of the sluice channel between two adjacent straight teeth; inclined teeth are arranged on the toothed section at the outermost layer of the end surface of the rotor disc; trapezoidal teeth are arranged on the other various layers of the end surface of the rotor disc; the tooth height of each inclined tooth is smaller than the tooth height of each trapezoidal tooth of the end surface of the rotor disc; and a blind groove is formed in the inner edge of the sluice channel between two adjacent inclined teeth. The colloid mill comprising the stator and rotor disclosed by the invention is simple in structure, high in shearing efficiency and long in service life.

Owner:SHANDONG DASHAN ROAD & BRIDGE ENG

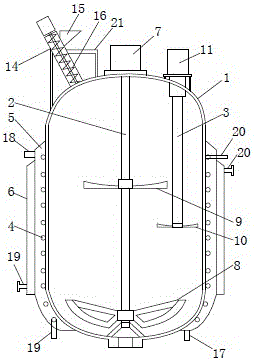

Stirring tank for coating production

InactiveCN106492669AMix well and evenlyFully detailedRotary stirring mixersTransportation and packagingBiochemical engineeringCooling coil

The invention discloses a stirring tank for coating production and belongs to the technical field of coating production equipment. The stirring tank comprises a tank body, a stirring shaft, a dispersing rotating shaft, a cooling coil, a heating jacket and a cooling jacket, wherein the stirring shaft and the dispersing rotating shaft are arranged in the tank body; the cooling coil is arranged on an outer wall of the tank body; the heating jacket is arranged on the exterior of the cooling coil; the cooling jacket is arranged on the exterior of the heating jacket; a feeding port and a discharging port are arranged on the tank body; the lower end of the stirring shaft is supported at the bottom in the tank body in a rotatable form; a stirring paddle is arranged at the lower end of the stirring shaft; a big dispersing plate is arranged on the middle part of the stirring shaft; a small dispersing plate is arranged at the lower end of the dispersing rotating shaft; a rotating shaft driving motor on the exterior of the tank body is connected with the upper end of the dispersing rotating shaft; the big dispersing plate and the small dispersing plate both include base plates and arc-shaped slices peripherally arrayed on the base plates; a feeding drum which is bias arranged is arranged at the feeding port; a feeding hopper is arranged on the feeding drum; a feeding screw rod is arranged in the feeding drum. The powder is fully refined and is uniformly mixed under the effect of the stirring paddle, so that the powder and the liquid material are integrally dissolved.

Owner:成都市红鑫科技有限公司

Efficient crushing device for grain processing

The invention discloses a high-efficiency crushing device for grain processing, which includes a crushing box, the lower end of the driving shaft is connected to the crushing box through a bearing seat in a rotational manner, the upper end of the driving shaft is installed with a driving motor, and the output shaft of the driving motor is connected to the driving shaft through a coupling The first driven gear is coaxially fixedly installed on the first driven shaft, and the first driven gear is engaged with the driving gear. An air guide pipe is connected with the air guide cover; the invention has an ingenious structure and a reasonable design, and the grain is crushed by two crushing rollers, the first crushing roller and the second crushing roller, which improves the crushing efficiency, and the grain falls from the dispersing hole to the In the crushing box, the re-rotating crushing effect of the second crushing roller and the first crushing roller is obtained, which realizes the circulation and repeated crushing of grain particles, greatly enhances the crushing effect, improves the crushing efficiency, and is faster and more efficient.

Owner:ZHENGZHOU AIMOFU INFORMATION TECH CO LTD

Grain crushing and grinding device for food processing

InactiveCN112108227AFully brokenFully detailedGrain treatmentsReciprocating motionAgricultural engineering

The invention discloses a grain crushing and grinding device for food processing, and relates to the technical field of food processing. The grain crushing and grinding device comprises a fixing frame, an arc-shaped mesh plate is arranged in a grinding box, a dispersing mechanism is in transmission connection with a crushing mechanism, and a lifting mechanism for driving a crushing box to vertically lift is in transmission connection with a double-shaft motor; a translation mechanism is arranged on the fixing frame, and a grinding mechanism abutting against the arc-shaped mesh plate is installed on the translation mechanism. According to the grain crushing and grinding device for the food processing, grains inside the crushing box are rotationally crushed and refined through the arranged crushing mechanism, the arranged lifting mechanism can drive the crushing box to vertically lift, namely the crushing mechanism can vertically lift to be continuously adjusted, and the effect of fullycrushing the grains in different position areas in the crushing box is achieved; and the arranged dispersing mechanism can achieve the dispersing effect of the grains, the crushing sufficient degree is higher, the arranged grinding mechanism can be driven by the translation mechanism to do transverse reciprocating motion and repeatedly grind the grains, and sufficient refining of the grains is effectively guaranteed.

Owner:盐池县荣桂昌食品科技有限公司

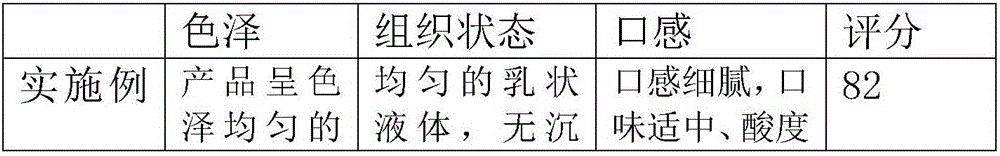

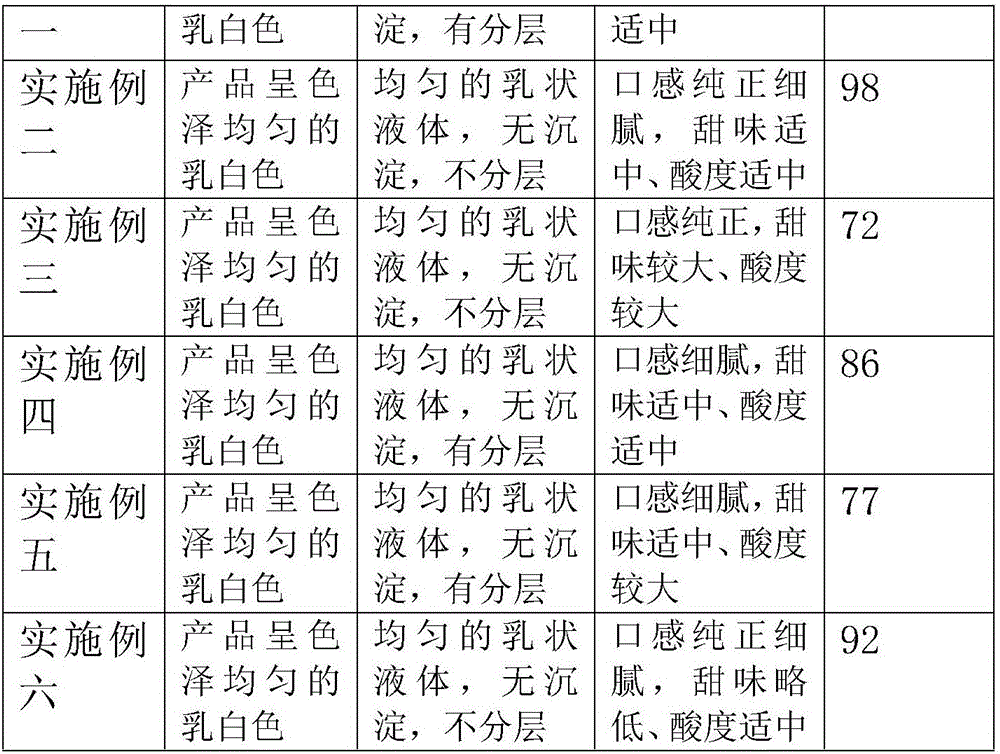

Stirring type preparation process of stirring type active probiotic flavored fermented milk

PendingCN106615101AHigh biological valueHigh protein efficiencyMilk preparationIsomaltooligosaccharideSucrose

The invention discloses a stirring type preparation process of active probiotic flavored fermented milk. The active probiotic flavored fermented milk is prepared from raw milk, white granulated sugar, whey protein powder, isomalto-oligosaccharide, a compound stabilizer, anhydrous cream, sucralose and strains; the strains comprise streptococcus thermophilus, lactobacillus bulgaricus, lactobacillus plantarum and lactobacillus rhamnosus; the preparation process comprises the following steps: checking the raw milk, purifying the milk, standardizing and temporarily storing; adding all the materials and blending; pre-heating and carrying out high-temperature homogenization; raising the temperature and sterilizing; cooling and inoculating; after fermenting, putting the milk into a jar, cooling and temporarily storing; stirring, filling and packaging in sequence; finally, putting into a freezer and freezing to carry out after-ripening. According to the flavored fermented milk disclosed by the invention, types and quantities of the strains are enriched through four types of lactic acid bacteria, and intestinal harmful bacteria are effectively inhibited; one part of sucrose is replaced with the isomalto-oligosaccharide, so that the calories of the fermented milk are reduced and the content of active probiotics in the final finished-product fermented milk is extremely great; intestinal probiotics can easily become a dominant population.

Owner:HENAN SANSE PIGEON DAIRY CO LTD

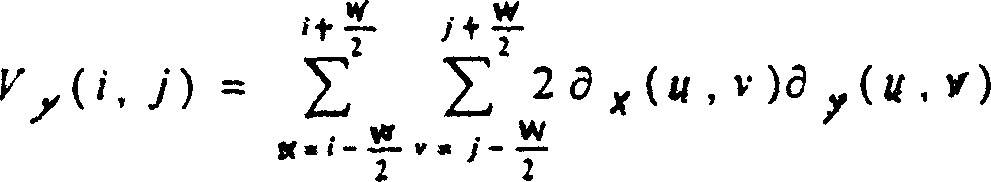

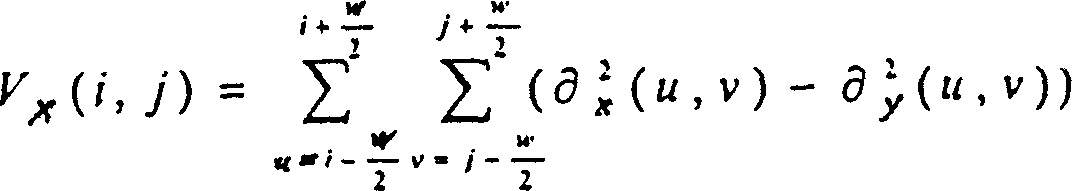

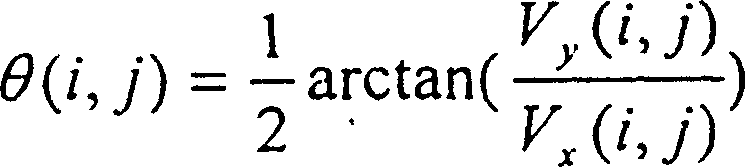

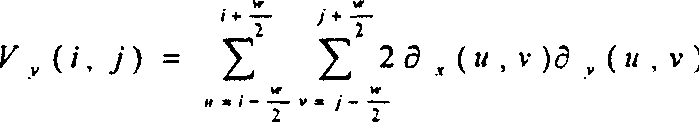

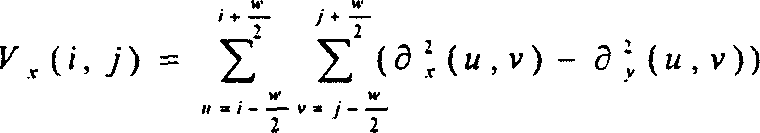

Automatic fingerprint identifying technology under verification mode

InactiveCN1484189AThorough refinementFully detailedCharacter and pattern recognitionAlgorithmDirection information

The invention discloses a kind of automatic fingerprint recognition technology under confirmation pattern, especially points to the problem that the picture has bifurcation which is not thinned completely and has burrs after the improved OPTA algorithm is thinned. The incomplete thin is caused by incomplete eliminating of template, thus the invention constructs eliminate template and the retention template to process the situation. The burr is generated by the asymmetry of retention template, thus, on base of the 6 retention templates of improved OPTA algorithm, reduces the templates which have upwards, leftwards and rightwards burrs, and eliminates the burrs. The invention also proposes a new method for withdrawing the fingerprint picture direction information with multistage division.

Owner:NANJING UNIV +1

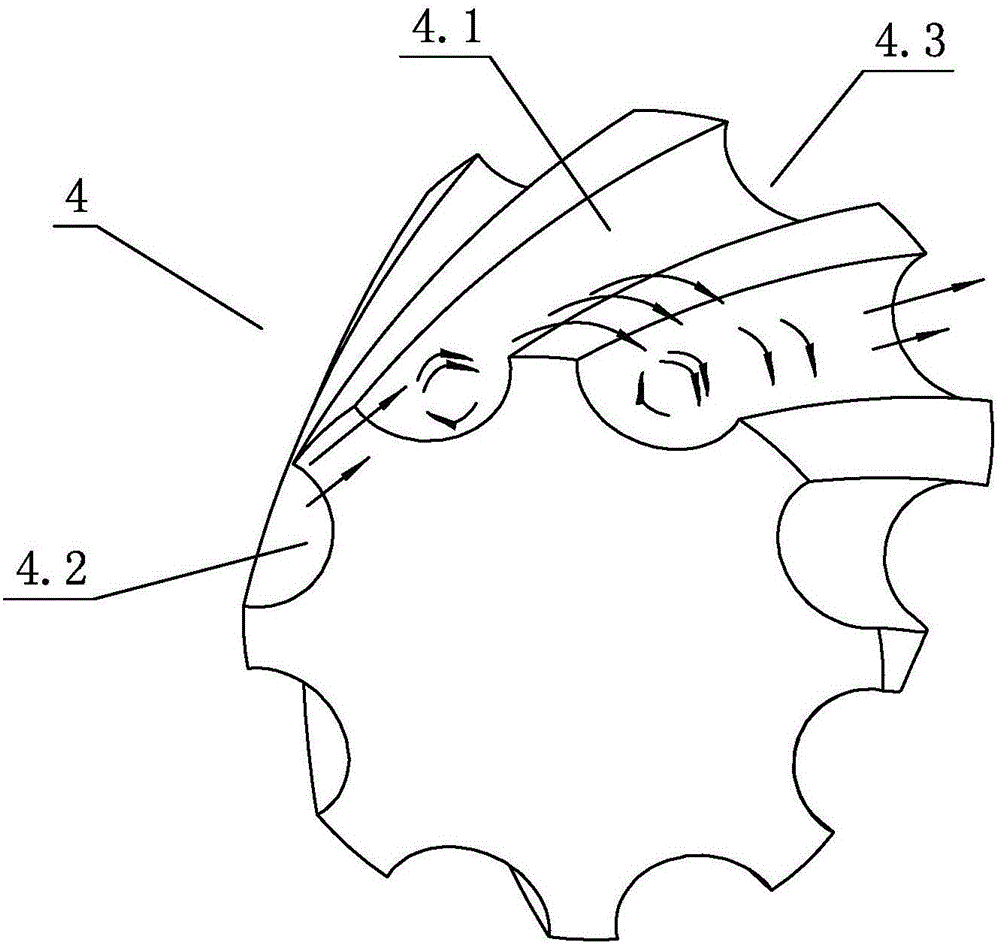

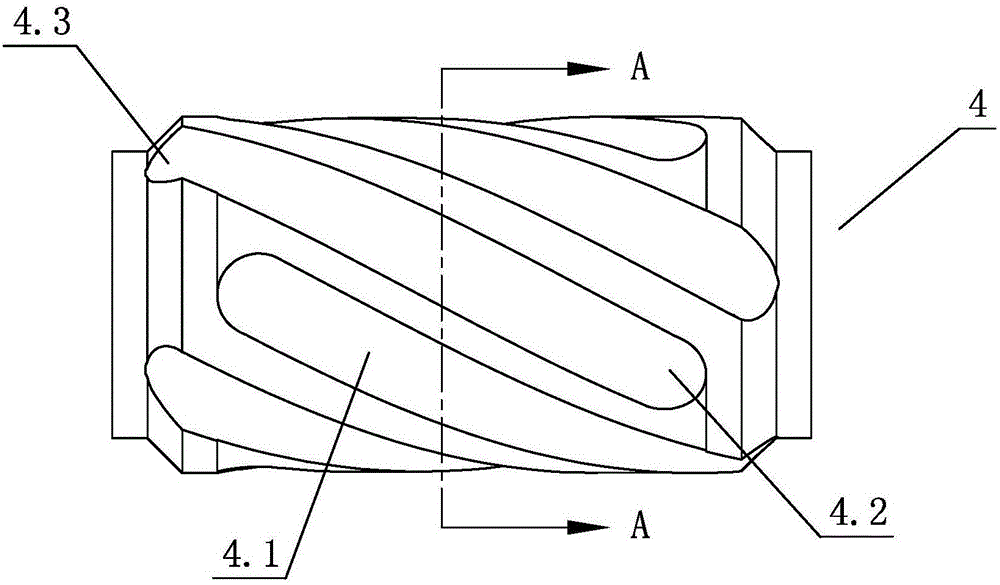

Static barrier mixing device for semi-solid-state alloy pulp-making

The invention discloses a static barrier mixing device for semi-solid-state alloy pulp-making. The static barrier mixing device comprises a barrier mixing head, a flow concentrating comb plate, a material barrel, a spray nozzle, a spray nozzle flange and a heater, wherein the barrier mixing head is statically arranged in a cavity; and a plurality of inclined slots are spirally formed in the outer wall of the barrier mixing head. Through the improvement on the structure, the plurality of inclined slots are spirally formed in the outer wall of the screen mixing head, metal melt is pushed to the barrier mixing head by utilizing pressure, and crystal nucleus of the metal melt is refined through the shearing action of the barrier mixing head and the material barrel, so that the semi-solid-state pulp preparation requirements are met. The static barrier mixing device has the characteristics of being simple and reasonable in structure, excellent in performance, quick to assemble, convenient to operate, low in manufacturing cost, easy to produce and realize, safe and reliable, and the like, and is high in practicability.

Owner:GUANGDONG YIZUMI PRECISION MACHINERY

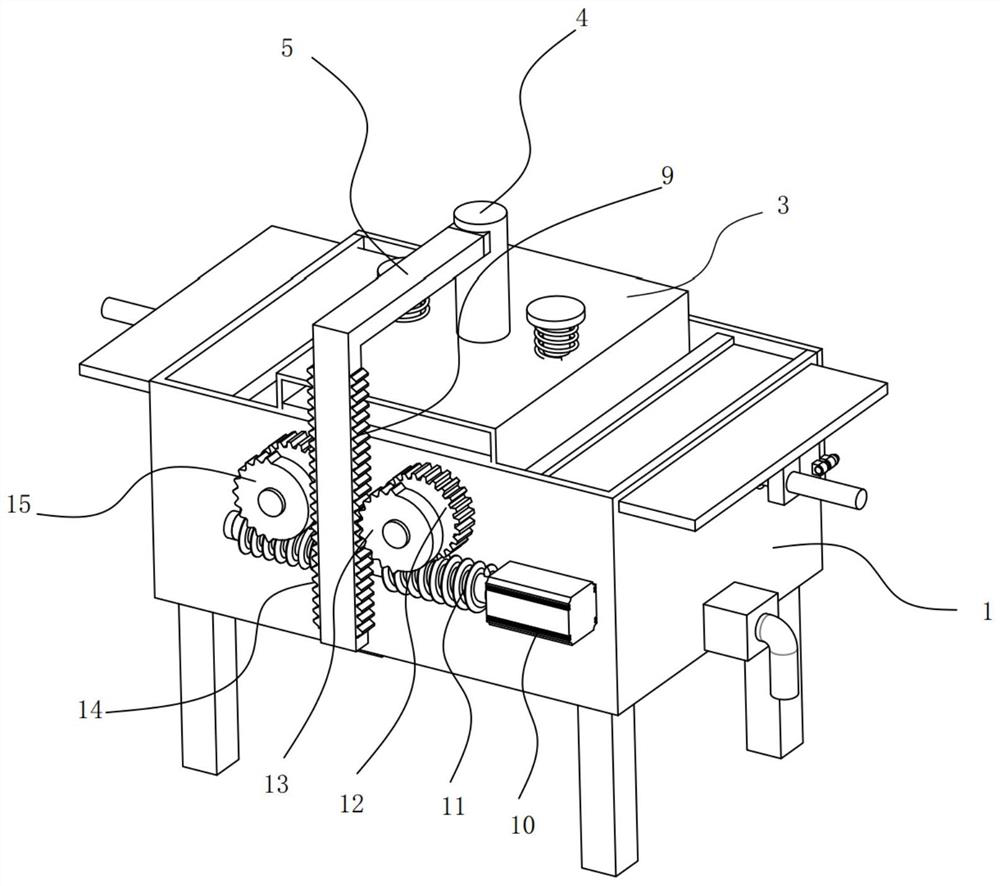

Soil crushing device for agricultural research

InactiveCN110898935AGuaranteed finenessFully detailedContaminated soil reclamationGrain treatmentsAgricultural engineeringAgricultural science

The invention discloses a soil crushing device for agricultural research, belongs to the technical field of agricultural experiments, and solves the problem of small contact area between a crushing rod and soil in an existing device. The device is technically characterized in that the device is characterized by comprising a base and a stirring cavity. A plurality of supporting legs used for supporting the base are fixedly installed at the bottom of the base; the stirring cavity is formed in the upper portion of the base; a driving assembly is arranged at the left side of the stirring cavity;a stirring assembly is arranged in the stirring cavity; the stirring assembly and the driving assembly are fixedly connected through a shaft coupler; and the driving assembly comprises a stirring motor and a storage battery, wherein the storage battery is arranged at the bottom of the stirring motor and electrically connected with the stirring motor through a wire. According to the embodiment of the invention, a hammer crushing assembly and a second crushing knife are arranged, so that sufficient refining of soil in the middle of the stirring cavity is guaranteed; meanwhile, a striking block is arranged, so that blocky soil in the stirring cavity can be crushed, and the fineness of the soil is guaranteed; and the soil crushing device further has a soil remediation function.

Owner:长沙市天珍科技有限公司

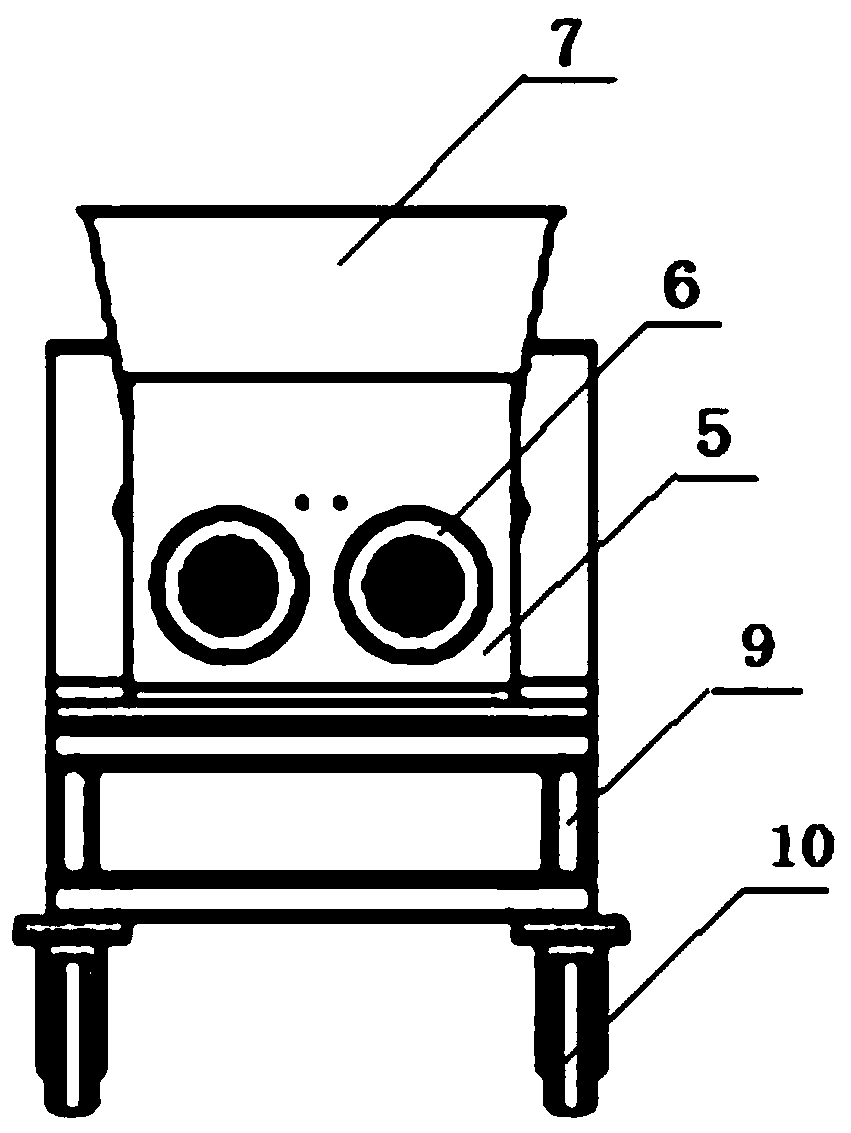

Anti-blocking control device of bulking machine

InactiveCN108685139AFully detailedAffect the discharge workFood shapingPulp and paper industryEngineering

The invention discloses an anti-blocking control device of a bulking machine. The anti-blocking control device of the bulking machine comprises an operation support platform, a puffing bin and fittedcolumns, wherein horizontal bottom bars are fixed at the left and right ends of the bottom of the operation support platform, and the end of each horizontal bottom bar is connected with a frosted sleeve, a hollow chute is fixed at the middle ends of the horizontal bottom bars, the top of the hollow chute is connected with a drawing plate, the puffing bin is arranged right above the operation support platform, the outer surface of the puffing bin is provided with a limiting clamping ring, a feed inlet is arranged at the middle end of the top of the puffing bin, the middle end of the inner sideof the feed inlet is fixedly provided with an inlaid frame, and the inner side of the inlaid frame is provided with a drawing material ramming rod. The anti-blocking control device of the bulking machine is provided with the drawing material ramming rod, and when the feed inlet is blocked by materials, the materials blocking the bottom of the feed inlet are rammed by the drawing material rammingrod in a T-shaped structure under the action of the inlaid frame and springs, so that the materials can be further processed after entering the puffing bin.

Owner:金学芳

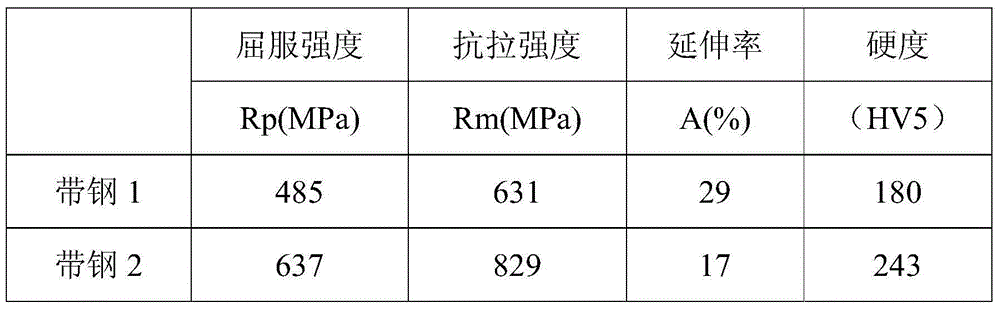

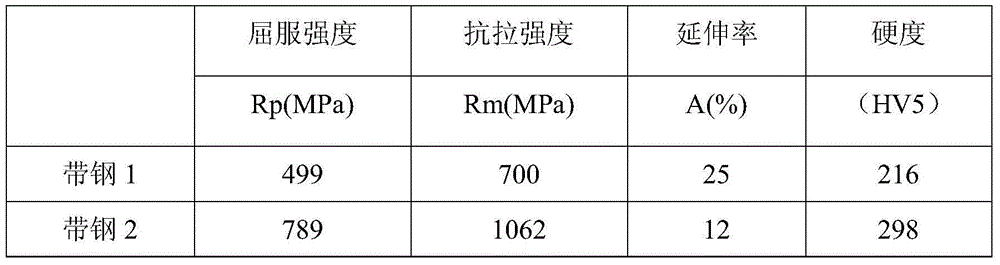

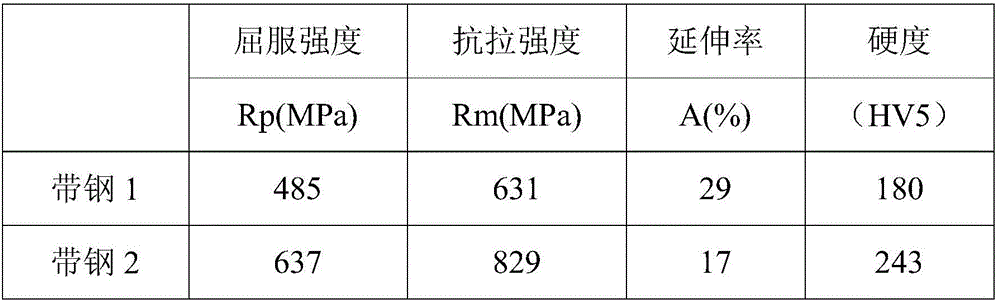

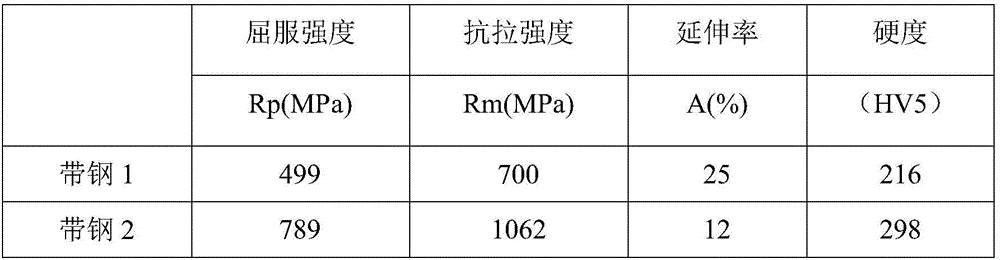

Hot-rolled steel strip for cold drawing and production method thereof

The invention belongs to the technical field of hot continuous rolling steel strips, and discloses a hot-rolled steel strip for cold drawing and a production method. The method comprises the following steps: a casting blank is obtained through a full tri-stripping process, a ladle refining furnace LF refining process, an RH refining process and slab skin continuous casting in sequence; the thickness of the casting blank is 230-240 mm; the casting blank is heated; the heating temperature is 1190-1250 DEG C, and the soaking time is longer than and equal to 30 min; the heated casting blank is roughly rolled, wherein the rolling ending temperature of the final pass of rough rolling is 960-1060 DEG C, the rolling reduction is controlled within 19-22% and the thickness of an intermediate slab is controlled within 35-40 mm; the rough-rolled casting blank is finely rolled, wherein the final rolling temperature of fine rolling is controlled within 800-860 DEG C, and the thickness of the rolled steel strip is 6-10 mm; laminar cooling is performed on the fine-rolled casting blank; and the laminar-cooled casting blank is rolled as the hot continuous rolling steel strip, wherein the rolling temperature is 580-660 DEG C. The invention provides the hot-rolled steel strip for cold drawing with excellent performance and the production method.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

Torsion type reciprocating extrusion device and process method thereof

ActiveCN101966536BAddressing Smaller Size LimitationsImprove toughnessExtrusion profiling toolsExtrusion control devicesUltra fineEngineering

The invention discloses a torsion type reciprocating extrusion device and a process method thereof, belonging to the technical field of plastic formation. The device comprises a cavity die, a cavity die cover plate and a cavity die fixing plate, wherein the cavity die fixing plate is fixed on a work table, and the cavity die with a variable section spindle structure is arranged between the cavitydie fixing plate and the cavity die cover plate. The process method makes materials generate the compound formation of reciprocating extrusion and torsion shearing so as to prepare ultra-fine grainedmaterials with larger volume and uniform tissue.

Owner:SHANGHAI JIAOTONG UNIV

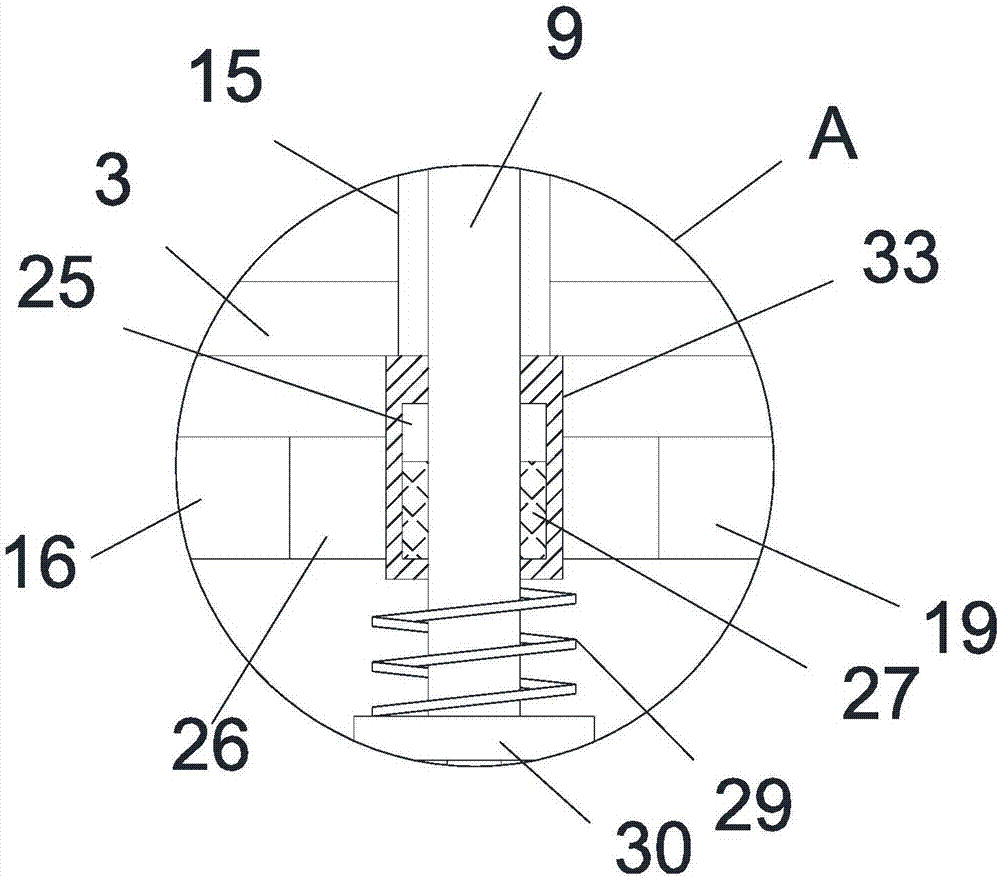

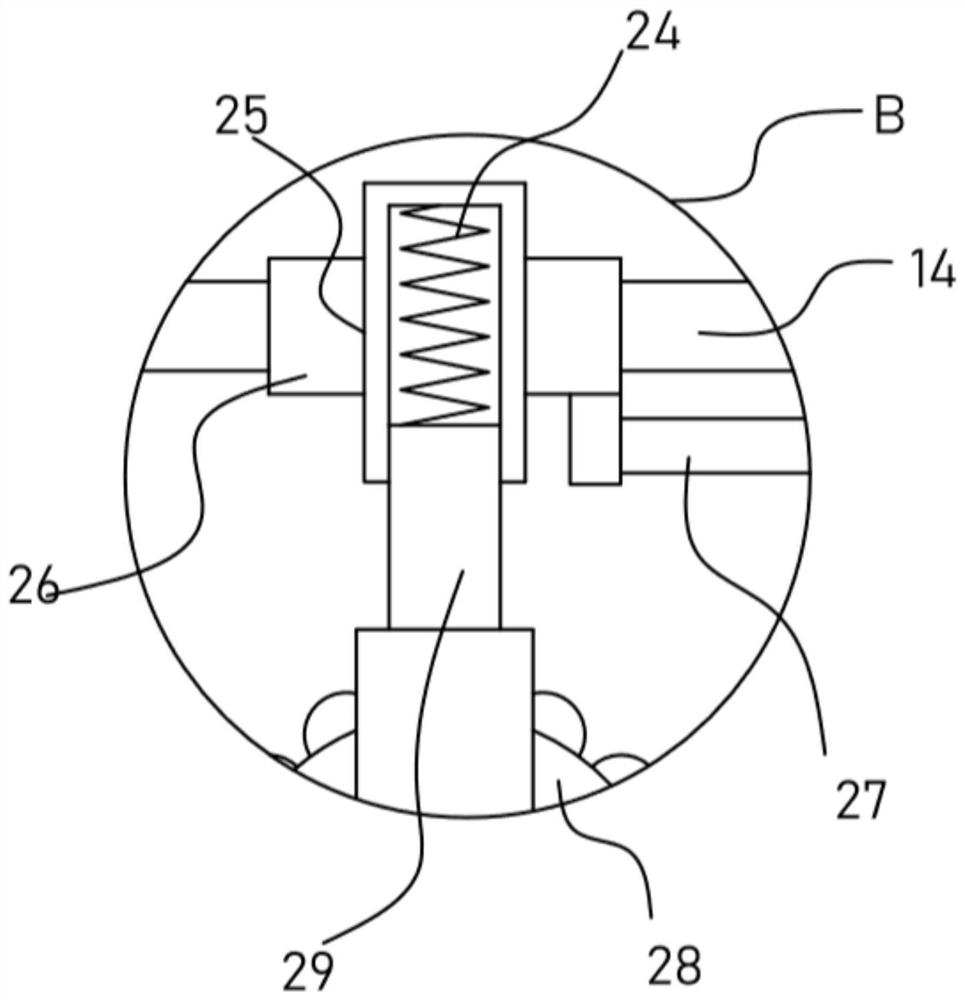

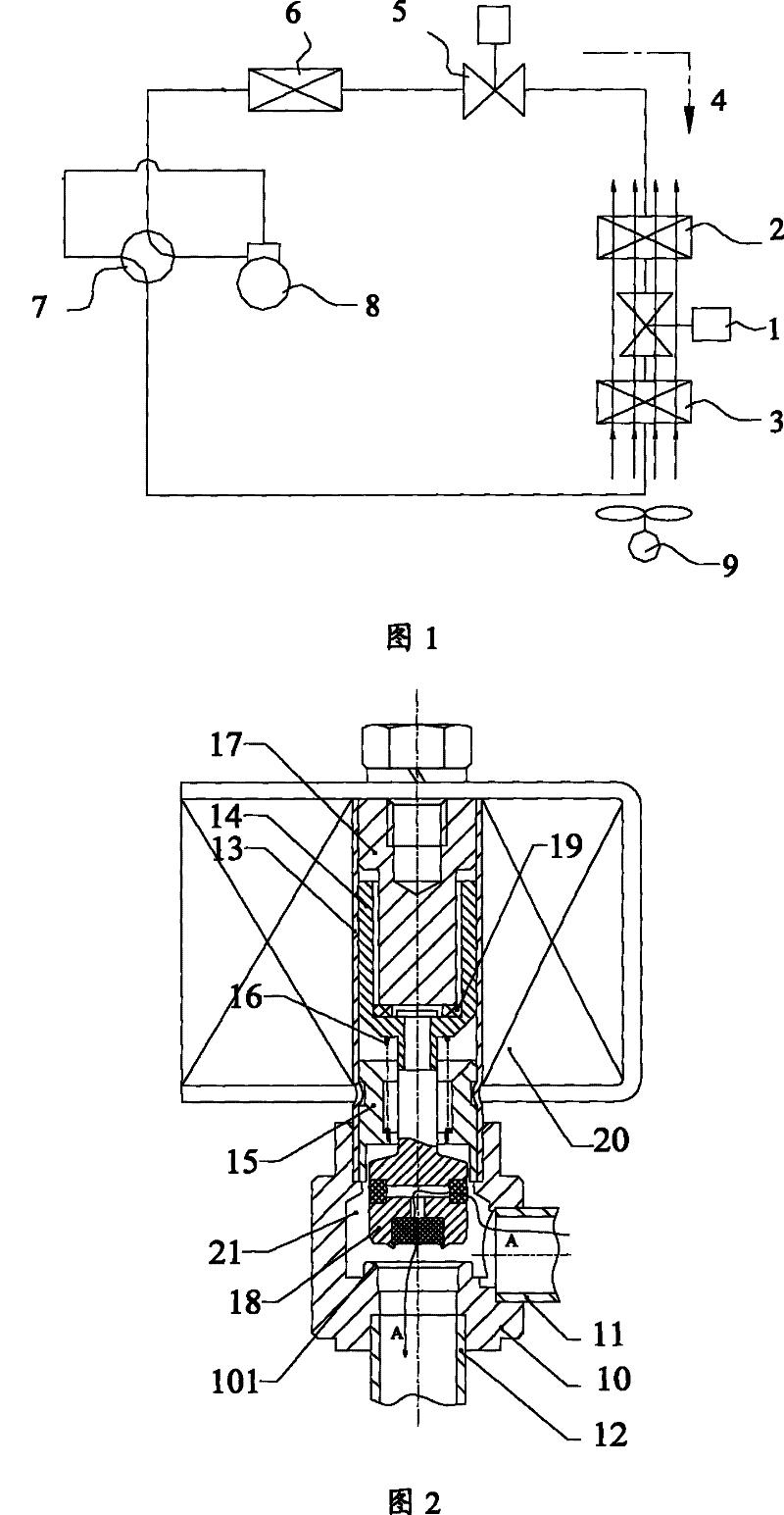

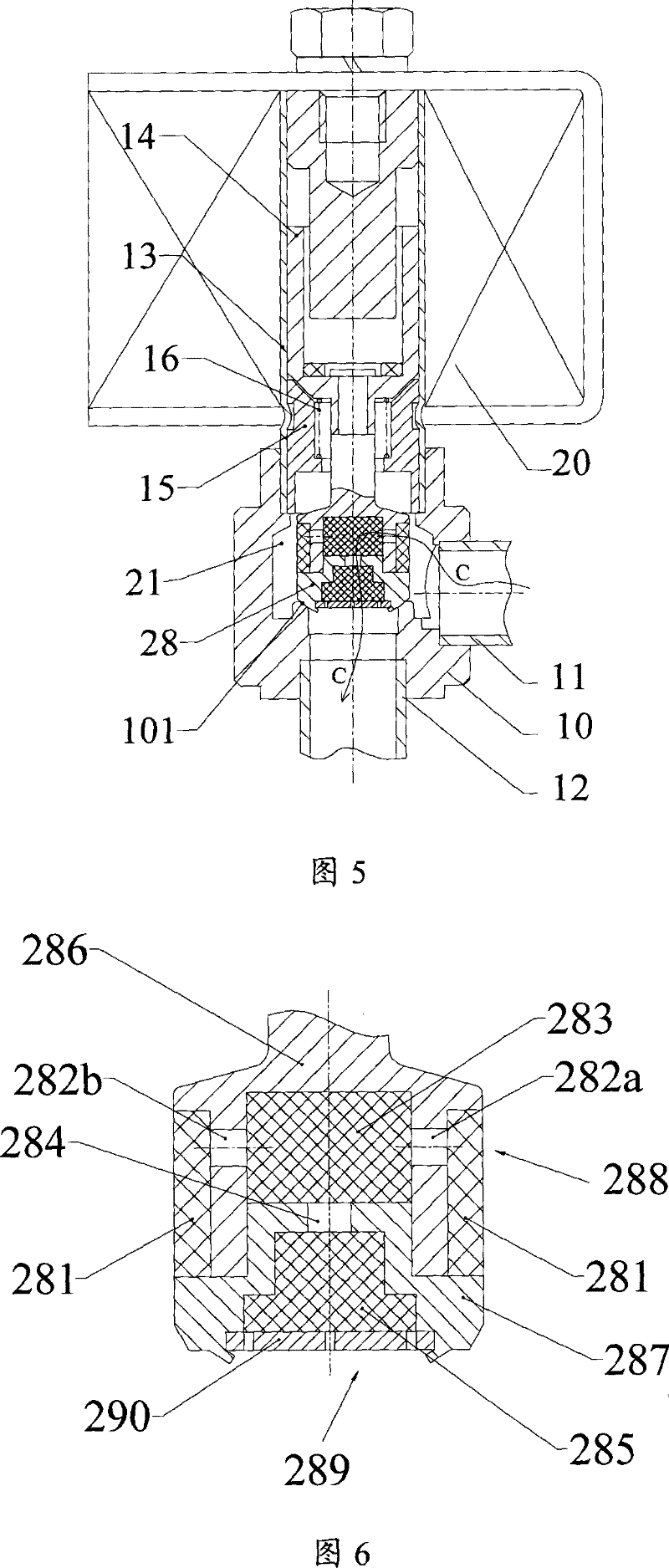

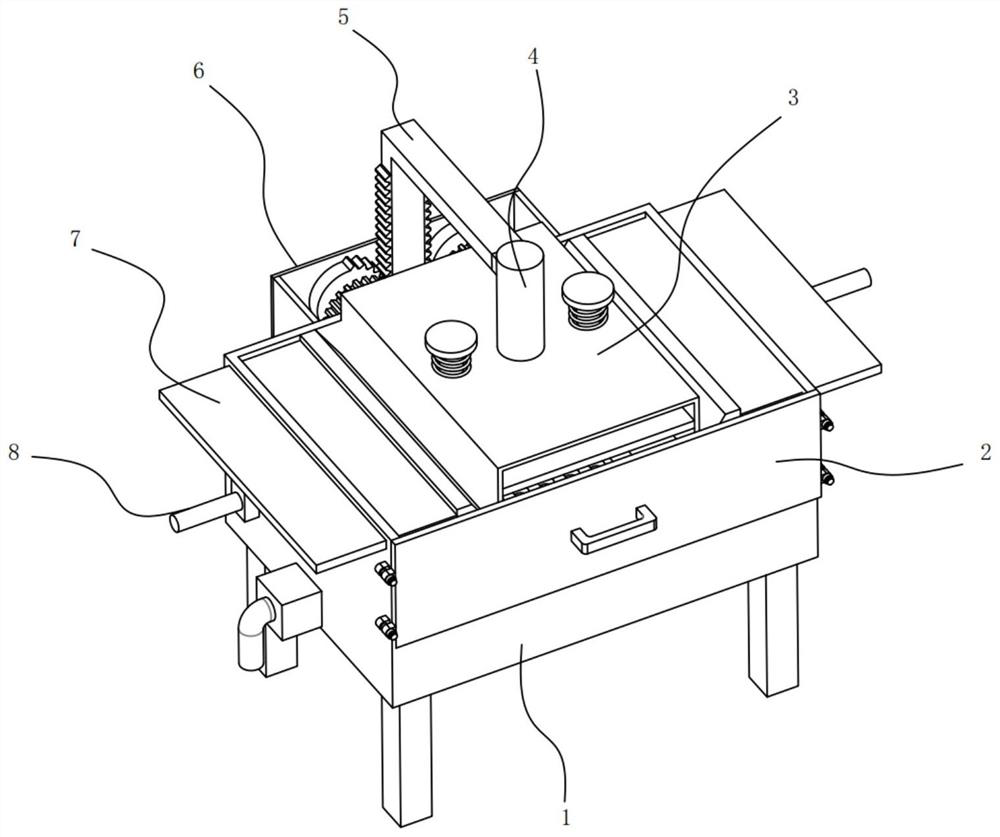

Electromagnetic valve

ActiveCN101520107BLarge access areaImprove noise reductionOperating means/releasing devices for valvesValve members for absorbing fluid energyElectromagnetic valveVALVE PORT

The invention discloses an electromagnetic valve, which comprises a valve seat, a valve port on the valve seat, an inlet pipe and an outlet pipe that are fixed through the valve seat, a sleeve connected with the valve seat as a whole, a moving iron core and a static iron core in the sleeve, a spring between the moving iron core and the static iron core, and a sealing element that is integrated with the moving iron core through a connecting part. The sealing element comprises: a sealing part right opposite to the outlet pipe, a filter element, a first holding part that faces to a chamber on the sealing element and is used for placing the filter element, an erasure part at an end part and a second holding part that is right opposite to the outlet pipe on the sealing part of the sealing element and used for placing the erasure part at the end part. Under the closed condition of the electromagnetic valve, the inlet pipe and the outlet pipe form an access through the sealing element and the access at least comprises the filter element, a first throttle access, a middle erasure part, a second throttle access, the erasure part at the end part and a spacer with a through hole which are sequentially arranged; and the end erasure part is a rotating body whose cross-sectional area increases along the direction of the flowing medium. The electromagnetic valve has excellent erasure effect.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

Plant extraction solid-liquid separation device for cosmetic preparation

PendingCN114832917ARealize repeated shreddingFully detailedGrain treatmentsPressesStructural engineeringManufacturing engineering

The invention discloses a plant extraction solid-liquid separation device for cosmetic preparation, and relates to the technical field of cosmetic production, the plant extraction solid-liquid separation device comprises a separation box, a screen plate is fixed in the separation box, a lifting transmission mechanism is mounted in a transmission box, a pressing plate is fixed at the bottom of a vertical rod, and an elastic connecting assembly is mounted between a wedge-shaped push plate and the separation box; the vertical rod is slidably sleeved with a door-shaped frame, a sliding rod is slidably installed on the door-shaped frame and fixedly connected with the pressing plate, a top plate is installed at the top of the sliding rod, a spring ring is connected between the top plate and the door-shaped frame, and the lower end of the door-shaped frame abuts against the wedge face of the wedge-shaped push plate. According to the device, through vertical reciprocating motion of the door-shaped frame, the effect of repeatedly chopping plant raw materials by the blades is achieved, sufficient refining of the plant raw materials is promoted, through vertical reciprocating motion of the pressing plate, the effect of extruding the raw materials is achieved, liquid components in the raw materials are promoted to be sufficiently separated out, and solid-liquid separation is achieved.

Owner:HENAN VOCATIONAL COLLEGE OF APPLIED TECH

A method for preparing titanium-based spherical powder with fine particle size by gas atomization

ActiveCN107498059BGood physical propertiesLarge particle sizeTransportation and packagingMetal-working apparatusTitanium alloyMoisture

The invention discloses a method for preparing titanium-based spherical powder with fine particle size by gas atomization. The method is as follows: 1. Put titanium-based raw materials and tin materials into a melting crucible, and then place them in vacuum induction melting gas atomization equipment Vacuum induction smelting is carried out in the smelting chamber; 2. After the titanium-based raw material and tin material are melted by vacuum induction smelting, they are filled with argon for protection, and then the graphite guide tube at the bottom of the melting crucible is heated, and the titanium-based raw material is The molten liquid produced after melting with the tin material falls freely into the atomization chamber through the heated graphite guide tube, and the atomized powder is obtained after the vacuum induction melting gas atomization treatment, and the titanium-based spherical powder is obtained in the collection tank. In the present invention, the tin element is introduced into the titanium raw material or titanium alloy raw material to reduce the viscosity of the molten liquid obtained after smelting, so that it is easy to be broken during gas atomization, and the particle size of the obtained powder becomes finer. Among them, the titanium-based spherical powder The yield of powder with a medium particle size less than 45 μm is not less than 28%, the internal pores of the powder are reduced, and the number of hollow powders is reduced.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

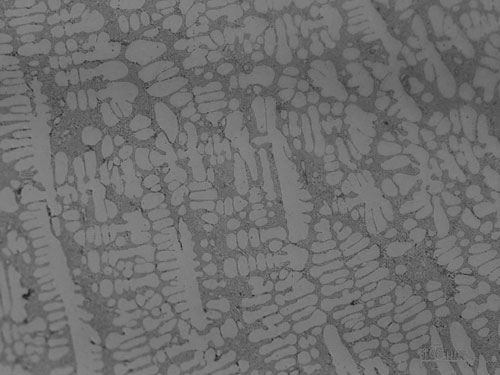

Casting method of metal alloy casting

InactiveCN110340297AReduced activityAvoid pinhole defectsFoundry mouldsFoundry coresChemical reactionInvestment casting

The invention provides a casting method of a metal alloy casting. The casting method comprises the following steps that a corresponding mould shell is prepared according to the shape of the metal alloy casting, a corresponding alloy raw material is prepared according to the material of the metal alloy casting, the alloy raw material is smelted to prepare alloy metal liquid, a proper amount of grain refiner is added into the alloy metal liquid, a mould material is obtained after uniform mixing, the mould material is poured into the mould shell through an investment casting process, and the metal alloy casting is obtained. Preferably, the composition of the grain refiner is aluminum titanium boron. By adopting the technical scheme, the aluminum titanium boron is used as the grain refiner toreplace an aluminum strontium modifier commonly used in the prior art, the elements such as aluminum, titanium and boron in the aluminum titanium boron grain refiner are lower in activity so as not likely to chemically react with other elements in the alloy raw material, so that the grains can be more fully refined, corresponding pinhole defects generated in the casting forming process of the casting can be avoided, and the forming quality, the mechanical property and the mechanical property of the finished casting are improved.

Owner:GUIZHOU ANJI AVIATION PRECISION CASTING

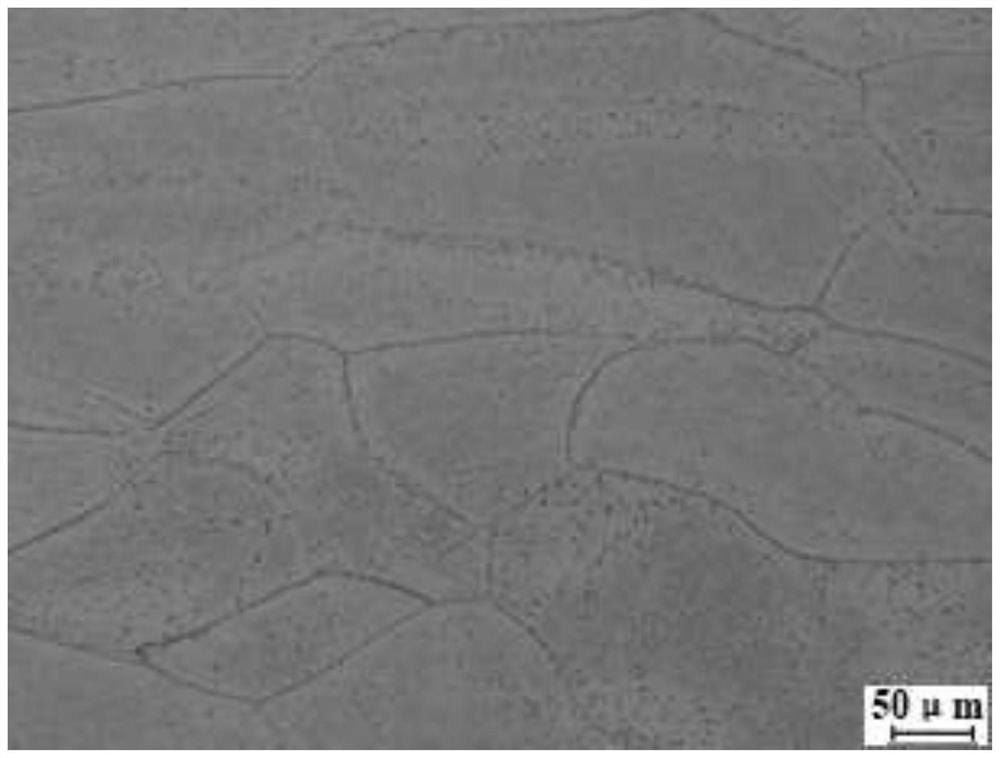

A kind of low-temperature resistant micro-alloyed steel and its production process

Owner:CENT IRON & STEEL RES INST +1

Rolling Process of Thin Slab Continuous Casting and Rolling Medium and High Carbon Steel

ActiveCN104438326BIncrease nucleation sitesUniform nucleationTemperature control deviceTension/compression control deviceThin slabHigh carbon

The invention provides a rolling technology for high-carbon steel in thin slab casting and rolling. The rolling technology includes the processes of continuous casting, heat evening, scale removing, rolling, inter-stand cooling, laminar cooling, reeling and insulation cover slow cooling. The rolling technology is characterized in that the rolling process includes three stages of Austenite perfect recrystallization rolling, non-recrystallization area Austenite rolling and two-phase area rolling. Medium-and-high-carbon steel structures rolled through the rolling technology are even and fine ferrite and particular pearlite, banded structures can be improved, the mechanical property is good, the annealing process does not need to be conducted before forming, cost is reduced, and quite high practicability is achieved.

Owner:武汉钢铁有限公司

Preparation method of low-density Nb-Ti-Al-V-Zr-C niobium alloy bar

ActiveCN114855107AHigh elongationSmall sizeNuclear energy generationMetal-working apparatusCarbideIngot

The invention discloses a preparation method of a low-density Nb-Ti-Al-V-Zr-C niobium alloy bar. The method comprises the following steps: 1, carrying out primary extrusion on a low-density Nb-Ti-Al-V-Zr-C niobium alloy ingot to obtain a primary extruded bar; 2, performing secondary extrusion to obtain a secondary extrusion rod; 3, quenching treatment; 4, free forging processing; and fifthly, vacuum annealing is conducted, and the low-density Nb-Ti-Al-V-Zr-C niobium alloy bar is obtained. According to the method, the low-density niobium alloy bar is prepared through the technology of two-time extrusion, quenching and forging, the quenching treatment technology and the secondary extrusion technology are added, the carbide reinforced phase TiC is separated out and nucleated again after redissolution and is dispersed and distributed in a matrix, the size of the carbide reinforced phase is effectively reduced, and the dispersity of the carbide reinforced phase is improved; the elongation after fracture of the low-density niobium alloy bar is improved, so that the low-density niobium alloy bar shows room-temperature high-strength and high-plasticity mechanical properties.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

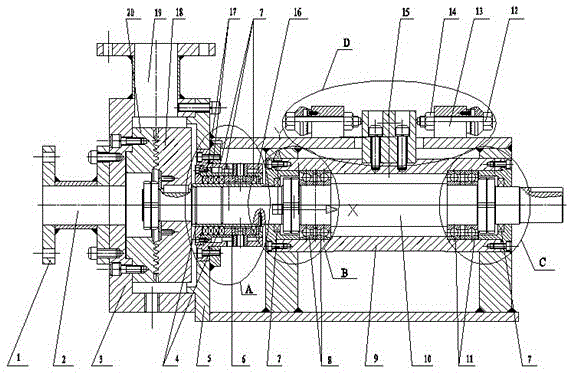

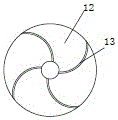

A single-screw refiner

InactiveCN108867137BSimple structural designSimple structurePulp beating/refining methodsFiberImpeller

The invention relates to a pin barrel single-screw refiner. According to the pin barrel single-screw refiner, a motor drives a threaded rod to rotate after a speed reducer reduces the speed, the threaded rod is arranged in a cylindrical barrel with a radial pin, and a feeding port performing feeding tangentially is formed in the front end of the threaded rod; a fiber raw material is forcibly put into the refiner through a spiral propeller, and under the squeezing action of the threaded rod, the fiber raw material passes through a feeding area of the threaded rod, a plurality of squeezing and cutting areas and is discharged from a discharging area of the tail section of the threaded rod; in a refining process, a main cutting pin set is combined with a plurality of impellers to form a main cutting element respectively, an auxiliary cutting pin set is combined with a transport spiral notch to form an auxiliary cutting element, then the squeezing and cutting functions are applied on a material, so that the fiber raw material is processed into required pulp step by step. The pin barrel single-screw refiner has the advantages of simple structure, lower manufacturing cost, reduced no-loadpower consumption, and convenient use and maintenance.

Owner:TIANJIN UNIV OF SCI & TECH

Automatic fingerprint identifying technique under verification mode

InactiveCN1229755CThorough refinementFully detailedCharacter and pattern recognitionAlgorithmDirection information

The invention discloses a kind of automatic fingerprint recognition technology under confirmation pattern, especially points to the problem that the picture has bifurcation which is not thinned completely and has burrs after the improved OPTA algorithm is thinned. The incomplete thin is caused by incomplete eliminating of template, thus the invention constructs eliminate template and the retention template to process the situation. The burr is generated by the asymmetry of retention template, thus, on base of the 6 retention templates of improved OPTA algorithm, reduces the templates which have upwards, leftwards and rightwards burrs, and eliminates the burrs. The invention also proposes a new method for withdrawing the fingerprint picture direction information with multistage division.

Owner:NANJING UNIV +1

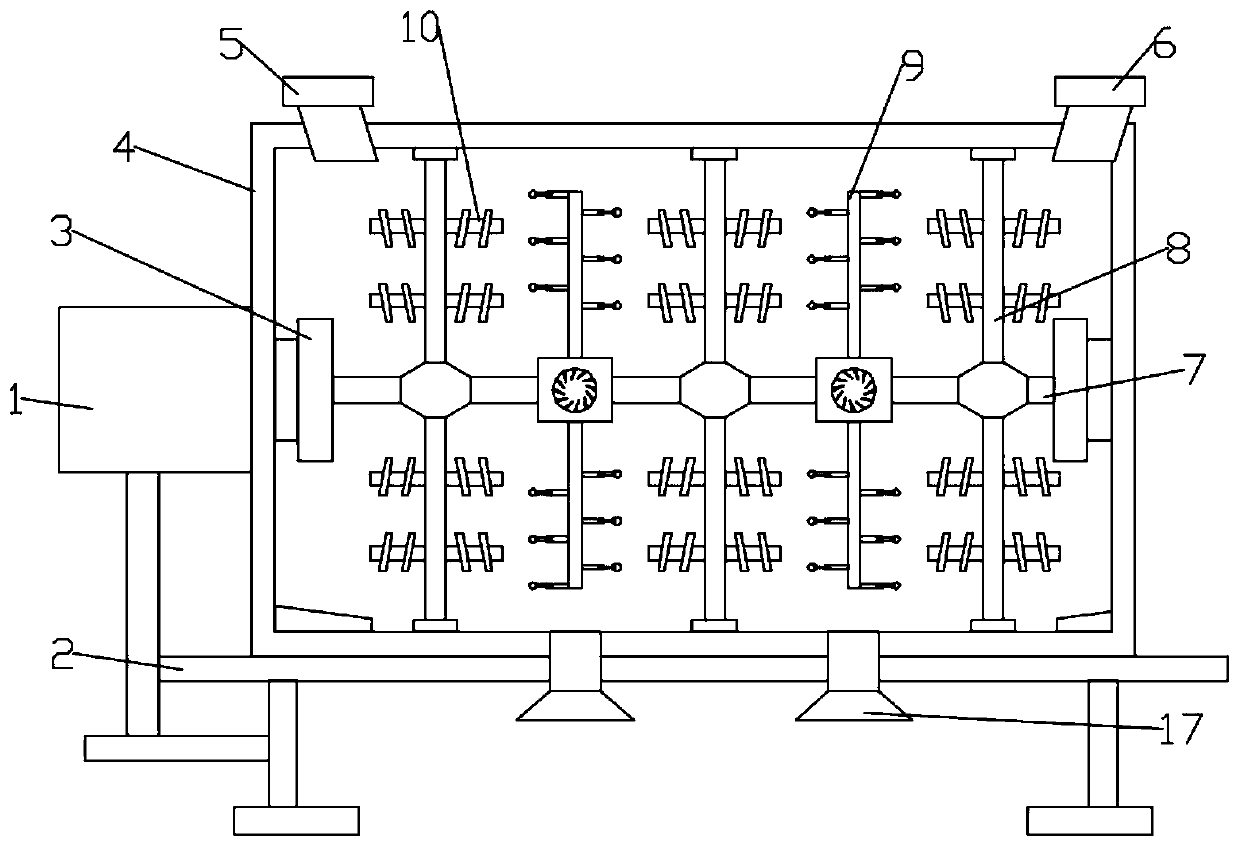

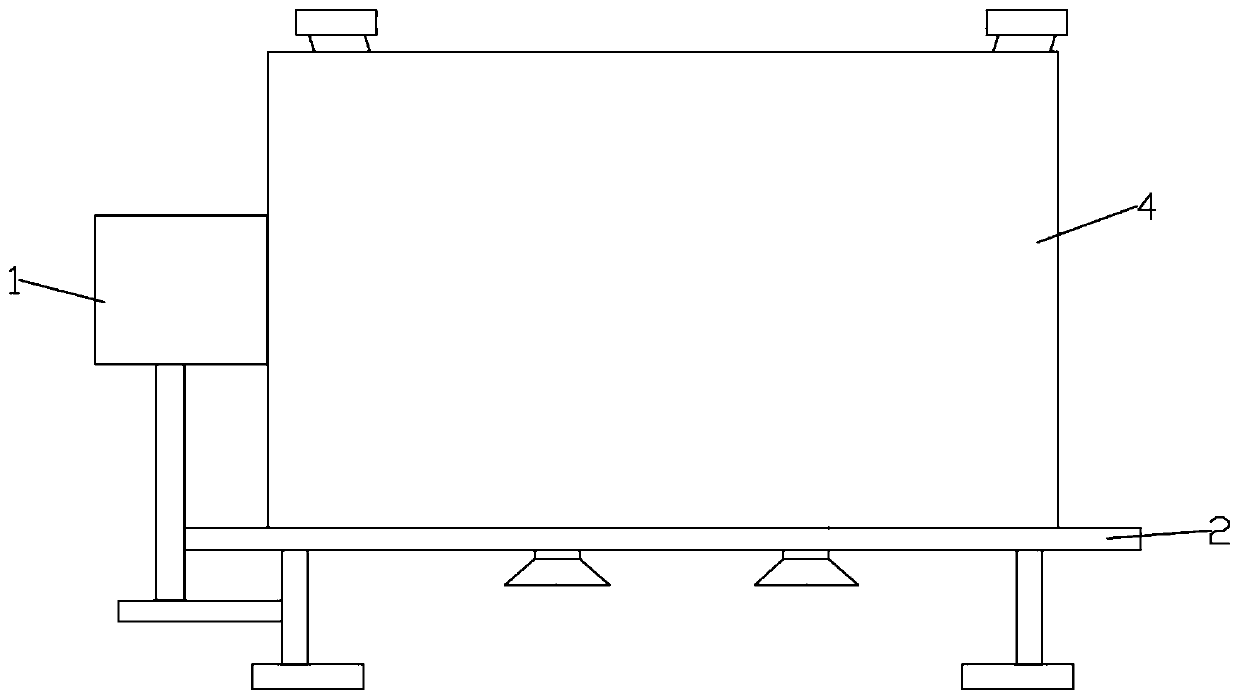

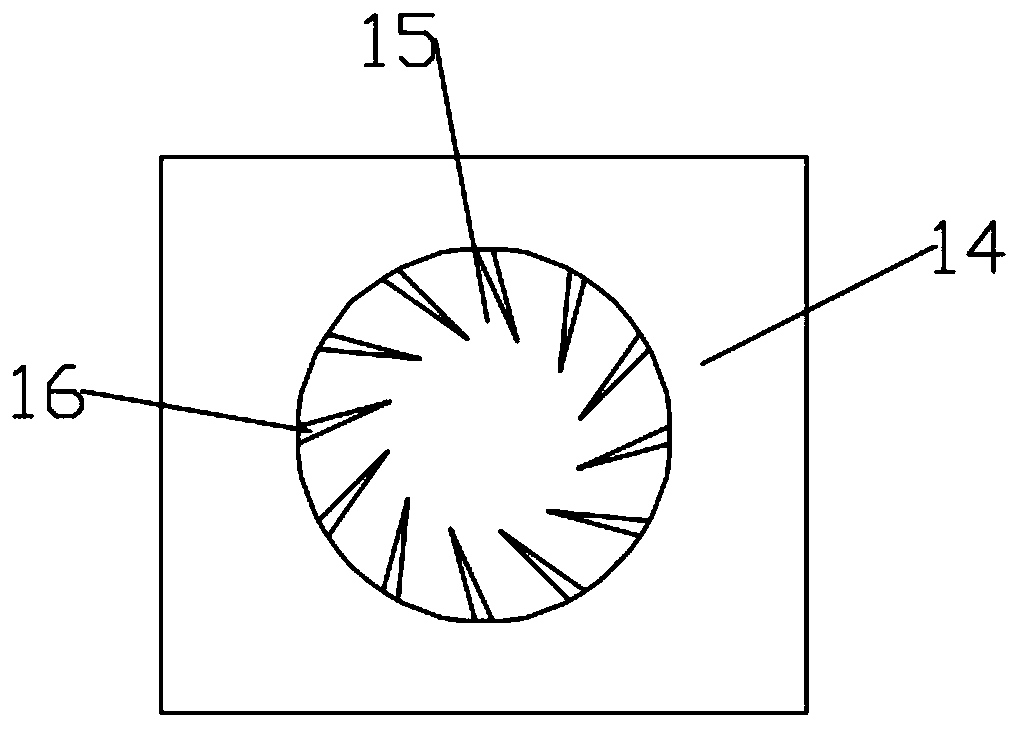

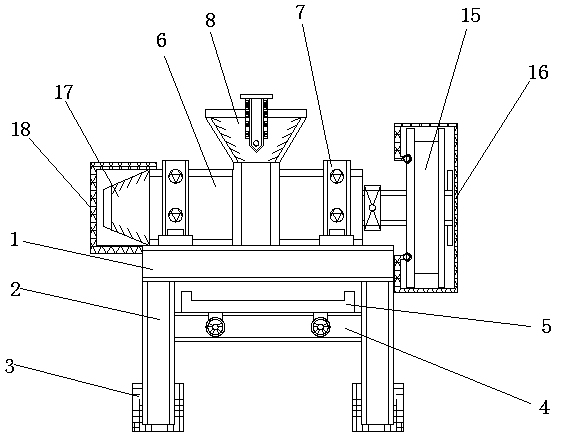

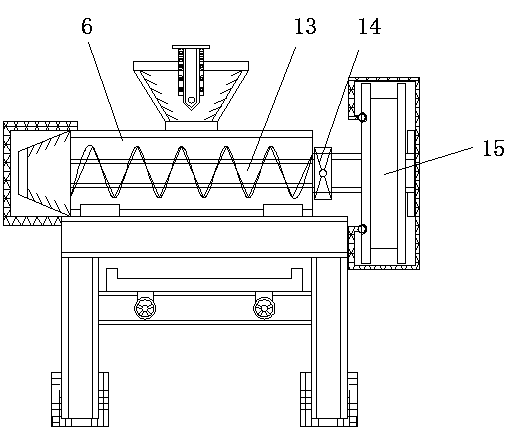

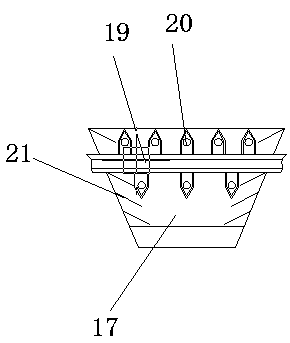

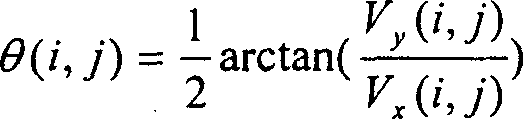

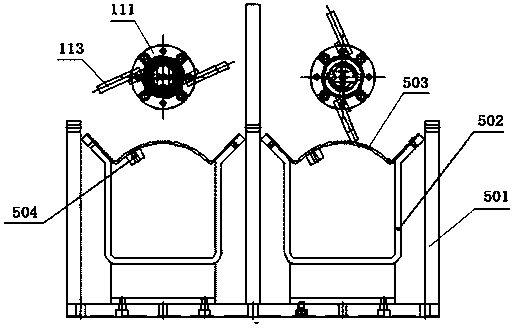

Biomass feed extruder

InactiveCN105962398BFully detailedModerate propulsion speedFeeding-stuffPropellerMechanical engineering

Owner:长春长拖农业科技开发有限公司

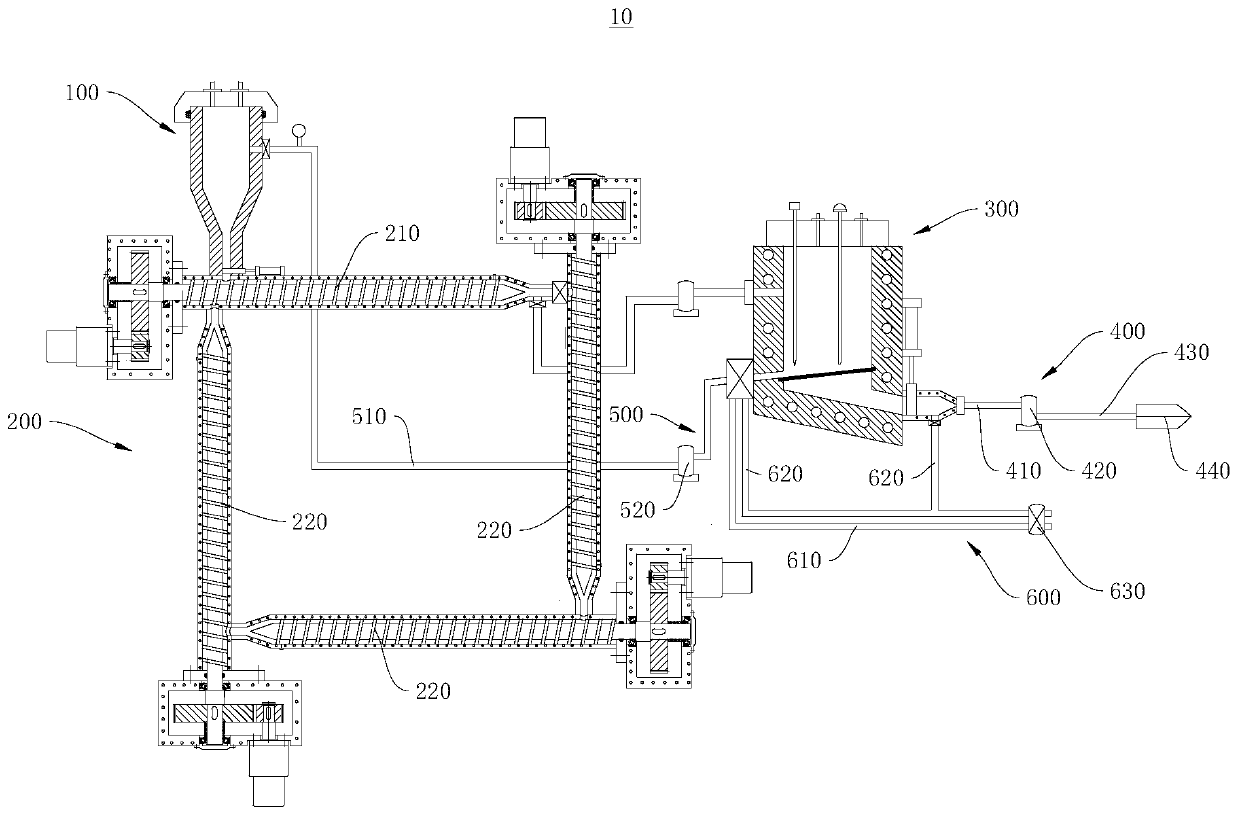

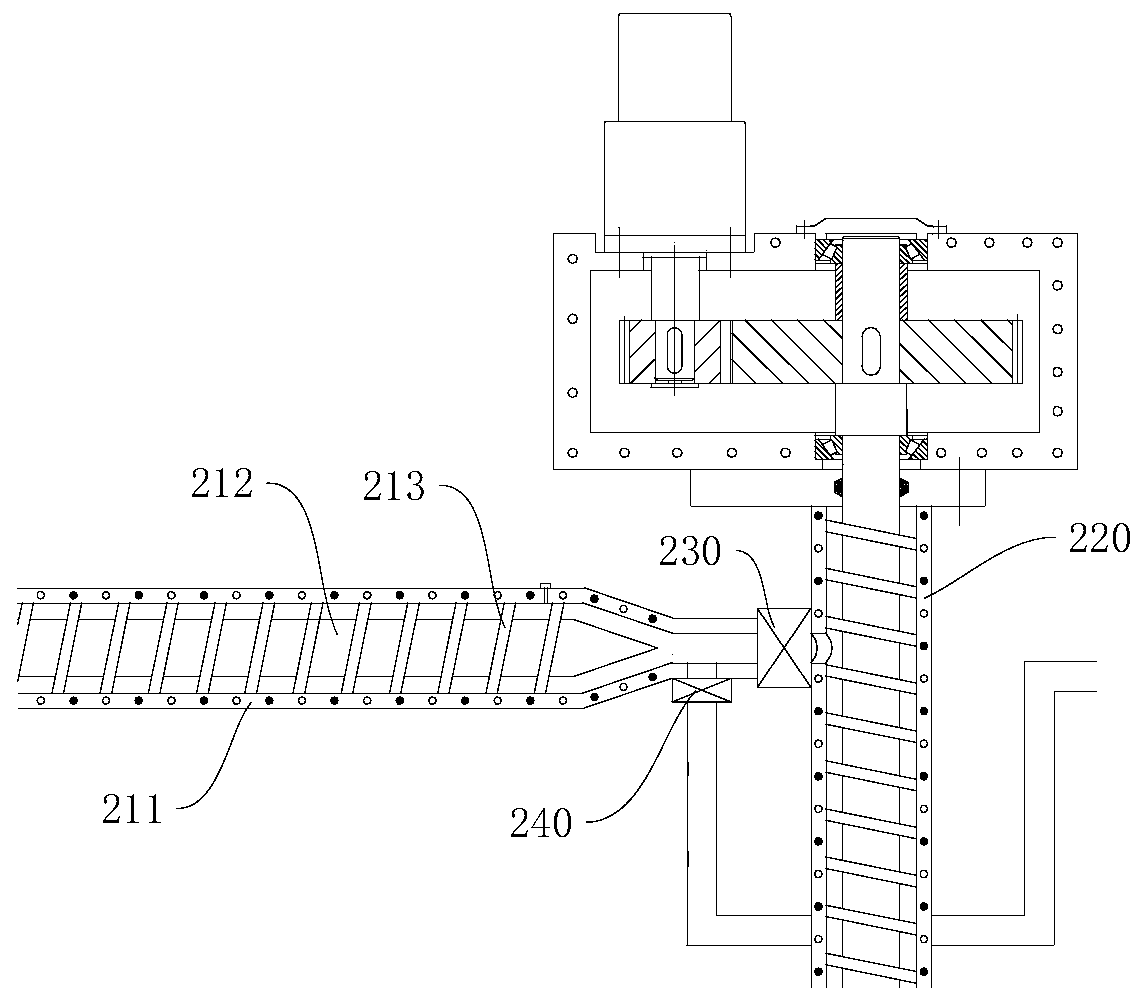

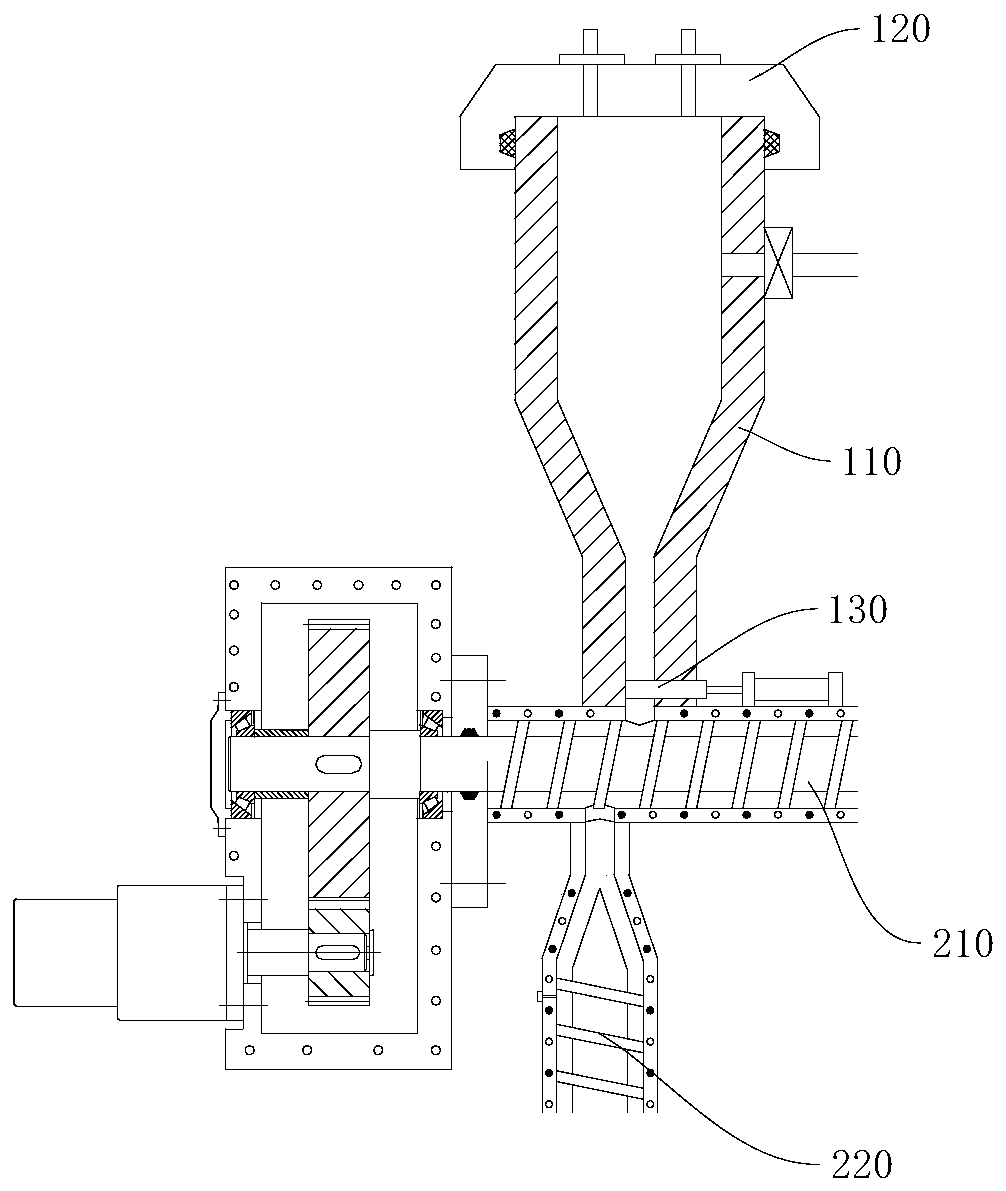

Lithium ion battery slurry spiral circulating stirring processing integrated system

PendingCN111203370AStir wellFully detailedLiquid surface applicatorsTransportation and packagingEngineeringLithium-ion battery

The invention provides a lithium ion battery slurry spiral circulating stirring processing integrated system and relates to the technical field of battery processing. The system comprises a feeding component, a circulating stirring component and a coating device, wherein the circulating stirring component comprises a first spiral stirring device and a second spiral stirring device; a conveying blade for spiral conveying and stirring lithium ion battery slurry is arranged in each of the first spiral stirring device and the second spiral stirring device; the feeding component is connected with the input end of the first spiral stirring device; the output end of the first spiral stirring device is connected with the coating device; the output end of the second spiral stirring device is connected with the input end of the first spiral stirring device; and the input end of the second spiral stirring device is connected with the output end of the first spiral stirring device and is used forreceiving the lithium ion battery slurry guided out by the first spiral stirring device. The integrated system can fully and uniformly stir the lithium ion battery slurry.

Owner:SHENZHEN GEESUN INTELLIGENT TECHNOLOGY CO LTD

High-efficiency low-strontium-consumption 4004 aluminum alloy modification method

The invention discloses a high-efficiency low-strontium-consumption 4004 aluminum alloy modification method, which comprises the following steps that a blocky aluminum-strontium intermediate alloy is adopted as a modifier to be added into a 4004 aluminum alloy melt, and the adding amount of the strontium element is 0.008-0.01 wt%, so that the residual quantity of strontium is 0.001-0.003 wt% before casting, aiming at a high-silicon aluminum alloy, the adding amount of Sr and the refining time during smelting are controlled, and the content of strontium in the high-silicon aluminum alloy is controlled. The purpose of alloy structure modification is achieved, a silicon phase is prevented from being in a thick sheet shape or a needle shape, the line size of the silicon phase is controlled to be within 50 microns, a serious cutting effect on a matrix is prevented, the mechanical property of the alloy is improved, and the defects in the composite rolling process are avoided, so that the ideal modification effect is achieved.

Owner:DALISHEN ALUMINUM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com