Plant extraction solid-liquid separation device for cosmetic preparation

A technology of plant extraction and solid-liquid separation, which is applied in the direction of manufacturing tools, grain processing, presses, etc., can solve the problems of poor liquid composition analysis and insufficient extrusion of plant raw materials, so as to achieve the improvement of solid-liquid Separation effect, convenient and sufficient extrusion, promoting the effect of sufficient refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

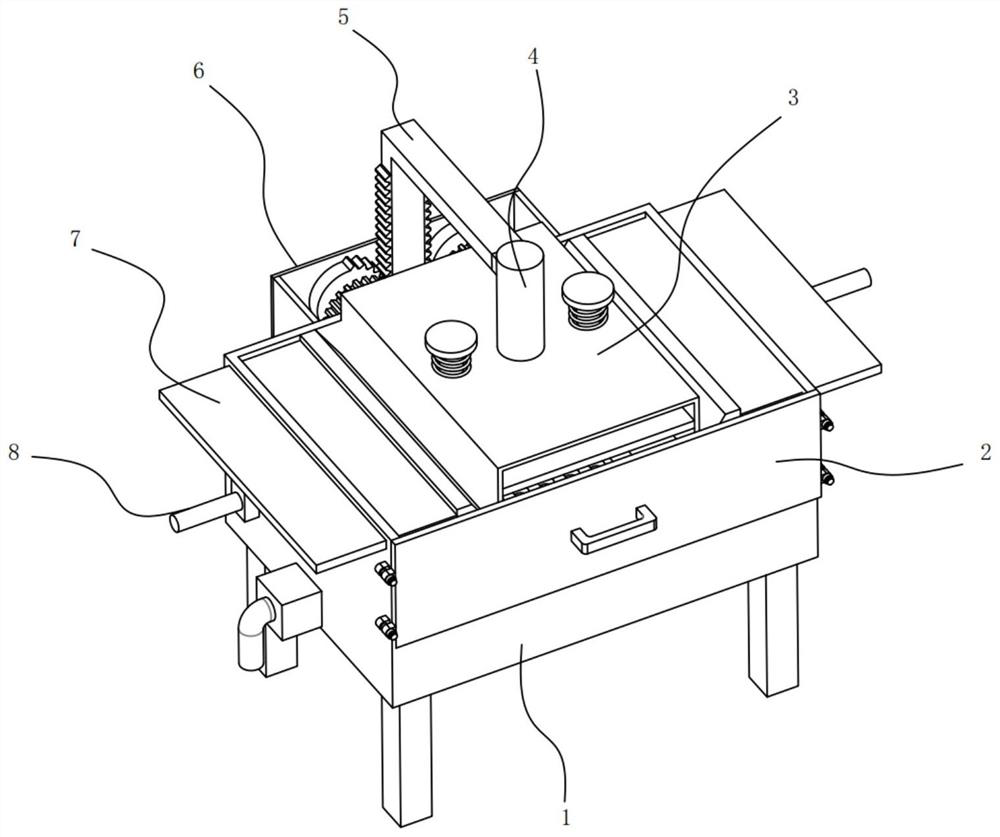

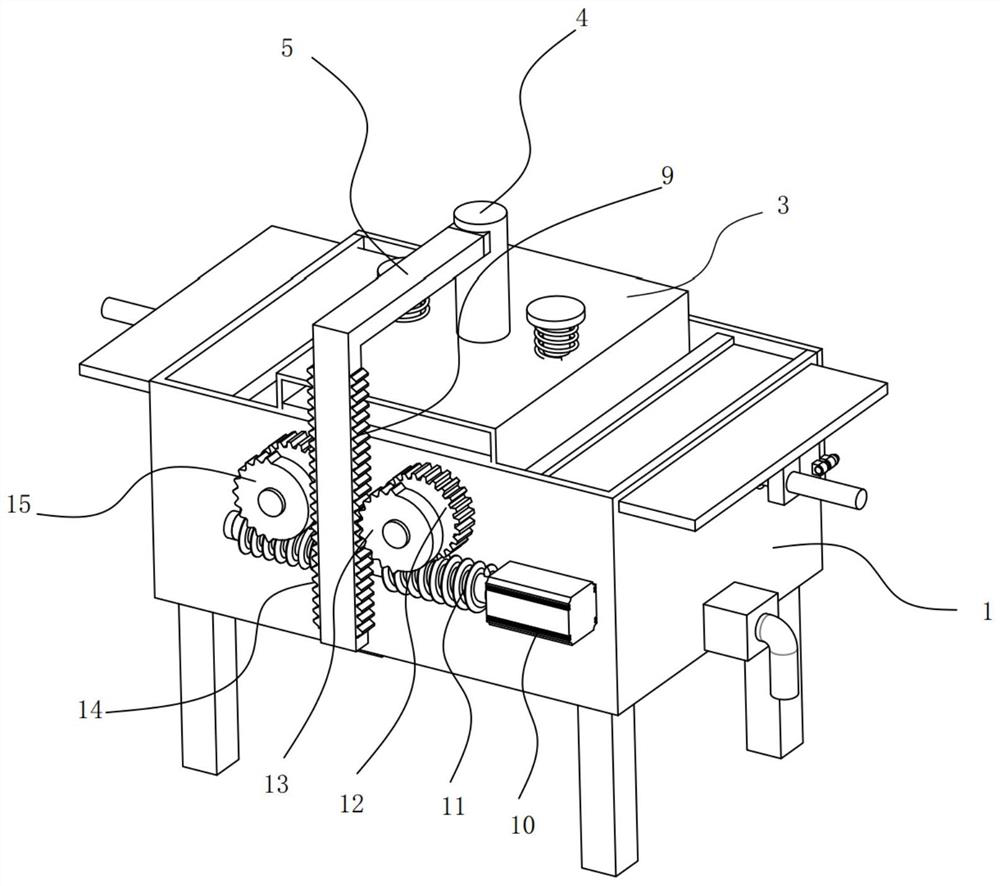

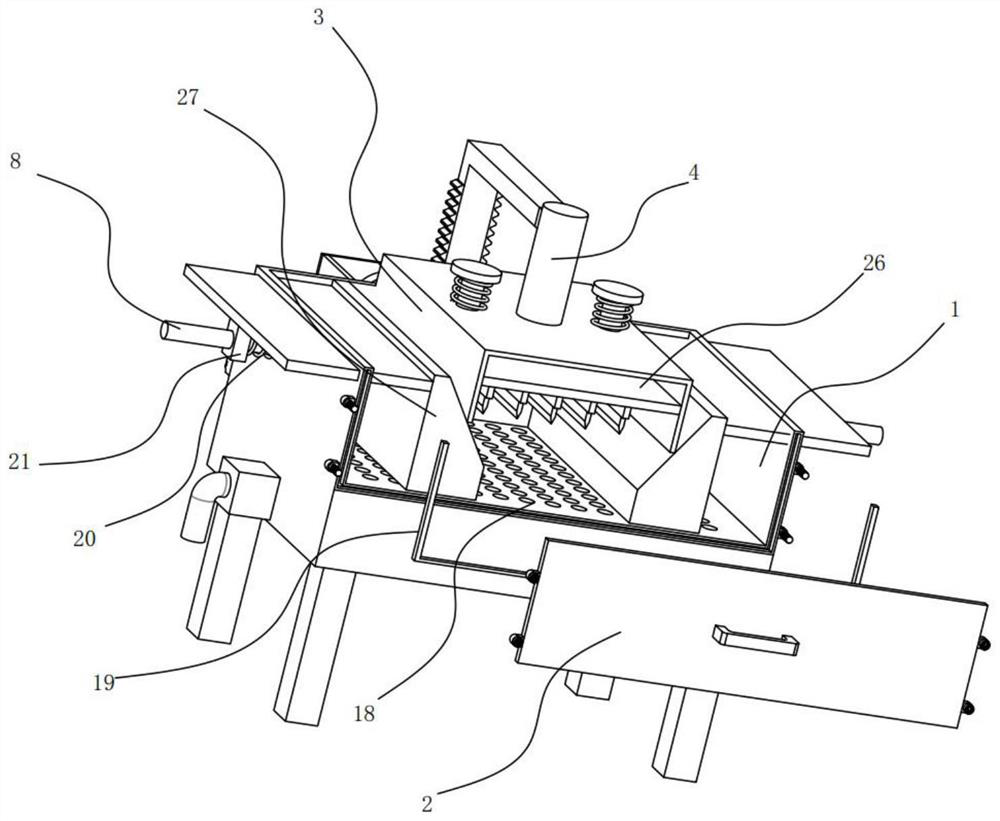

[0023] see Figure 1-5 , a plant extraction solid-liquid separation device for cosmetic preparation, comprising a separation box 1, a transmission box 6 is installed on the separation box 1, a mesh plate 18 is fixed inside the separation box 1, and a lifting transmission mechanism is installed inside the transmission box 6, A vertical rod 4 is installed on the lifting transmission mechanism, a pressure plate 26 is fixed at the bottom of the vertical rod 4, and two wedge-shaped push plates 27 are slidably arranged in the separation box 1, and between the wedge-shaped push plates 27 and the separation box 1 are installed Elastic connection components;

[0024] A portal frame 3 is slidably sleeved on the vertical rod 4, a sliding rod 23 is slidably installed on the portal frame 3, the sliding rod 23 is fixedly connected with the pressing plate 26, and a top plate 22 is installed on the top of the sliding rod 23, and the top plate 22 is connected with the portal frame. A spring r...

Embodiment 2

[0031] see Figure 1-5 , On the basis of Embodiment 1, in addition, the elastic connection component of the device includes a sliding plate 7 fixed with a wedge-shaped push plate 27, a limit seat 21 is fixed on the sliding plate 7, and a separation box is slidably installed on the limit seat 21 1. A fixed limit rod 8, a return spring 20 is connected between the limit seat 21 and the separation box 1.

[0032] During the downward movement of the pressing plate 26 , the pressing plate 26 drives the portal frame 3 to move vertically through the transmission of the sliding rod 23 , the spring ring 17 and the top plate 22 , and the portal frame 3 pushes against the wedge-shaped push plate 27 . Under the action, the wedge-shaped push plates 27 can move toward or away from each other, and when the pressure plate 26 moves up, the two wedge-shaped push plates 27 move toward each other, and when the pressure plate 26 moves down, the two wedge-shaped push plates 27 The plant raw materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com