Patents

Literature

55results about How to "Increase nucleation sites" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

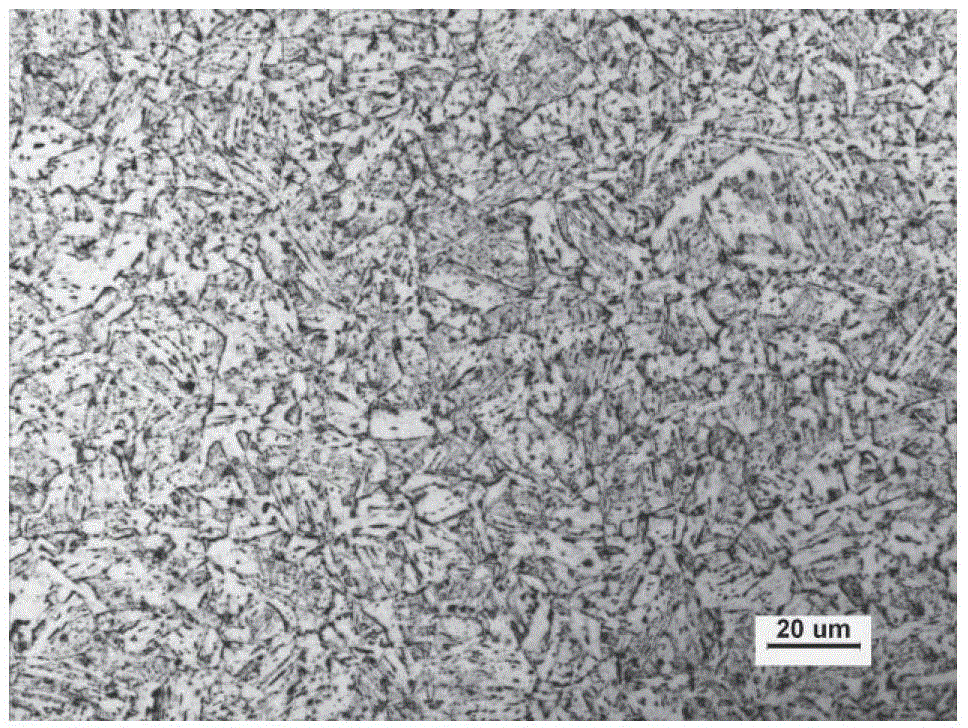

Economic-type pipe fitting steel with high strength and low yield ratio and production method thereof

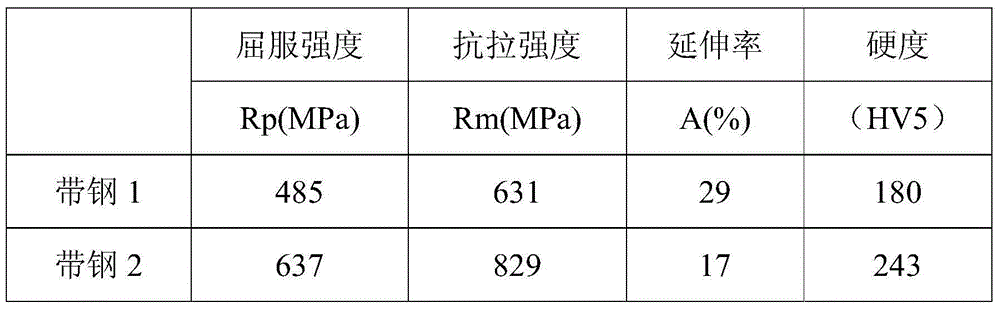

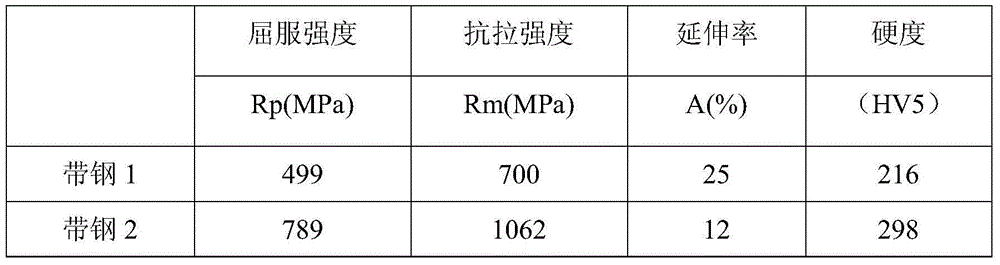

The invention discloses an economic-type pipe fitting steel with high strength and low yield ratio, which comprises the following elements: 0.10%-0.18% of C, 0.25%-0.55% of Si, 1.40%-1.90% of Mn, 0.02%-0.05% of Nb, 0.008%-0.020% of Ti, 0.02%-0.05% of V, 0.010%-0.040% of Als, smaller than or equal to 0.10% of Nb, V and Ti, 0-0.25% of Mo, 0-0.30% of Ni, 0-0.35% of Cu, 0-0.30% of Cr, smaller than or equal to 0.55% of Mo, Ni, Cu and Cr, and the balance of ferrum and unavoidable impurities. The yield strength after heat treatment can reach more than 630MPa or 690MPa, the tensile strength reaches more than 775MPa or 870MPa, the yield ratio is lower than 0.85, the impact ductility at minus 46 DEG C is not lower than 80J, and the technical requirements for X90 level and X100 level pipe fitting steel are completely satisfied.

Owner:ANGANG STEEL CO LTD

High-strength weather-proof bridge steel and preparation method thereof

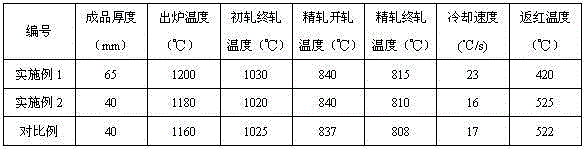

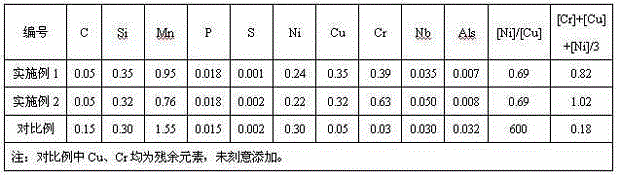

The invention discloses high-strength weather-proof bridge steel. The high-strength weather-proof bridge steel is composed of, by mass, 0.03-0.06% of C, 0.20-0.50% of Si, 0.70-1.00% of Mn, 0-0.030% of P, 0-0.003% of S, 0.25-0.60% of Cu, 0.18-0.45% of Ni, 0.30-0.70% of Cr, 0.030-0.080% of Nb, 0-0.010% of Als and the balance Fe and inevitable impurities. Meanwhile, the corresponding elements meet the requirements that 0.6<=[Ni] / [Cu]<=1.5, and 0.80%<=[Cr]+[Cu]+[Ni] / 3<=1.30%. Raw materials are obtained through the steps of smelting, continuous casting, rolling and stacking for slow-cooling. The high-strength weather-proof bridge steel has the advantages of being high in strength, excellent in low-temperature tenacity, low in yield ratio, excellent in welding performance and good in weather-proof performance.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

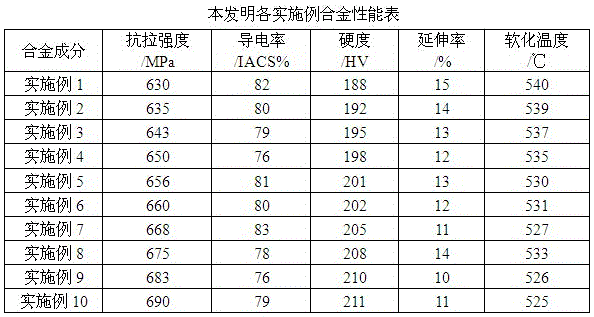

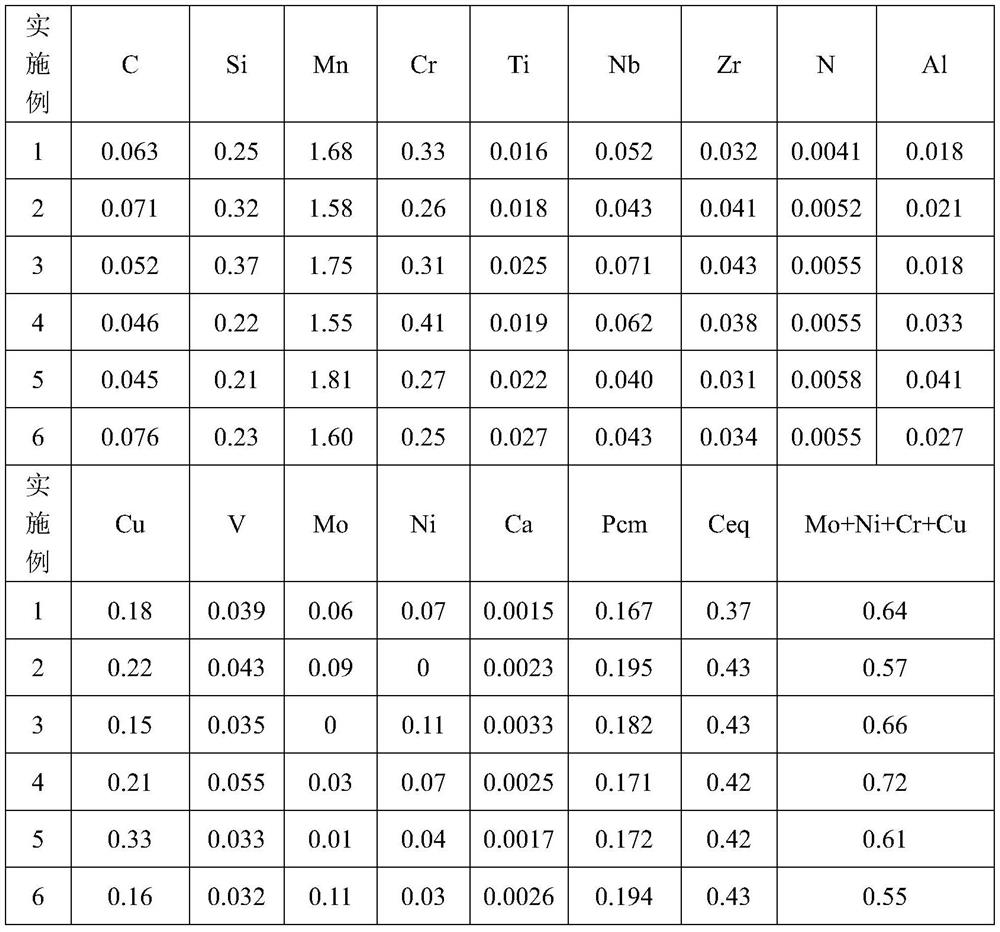

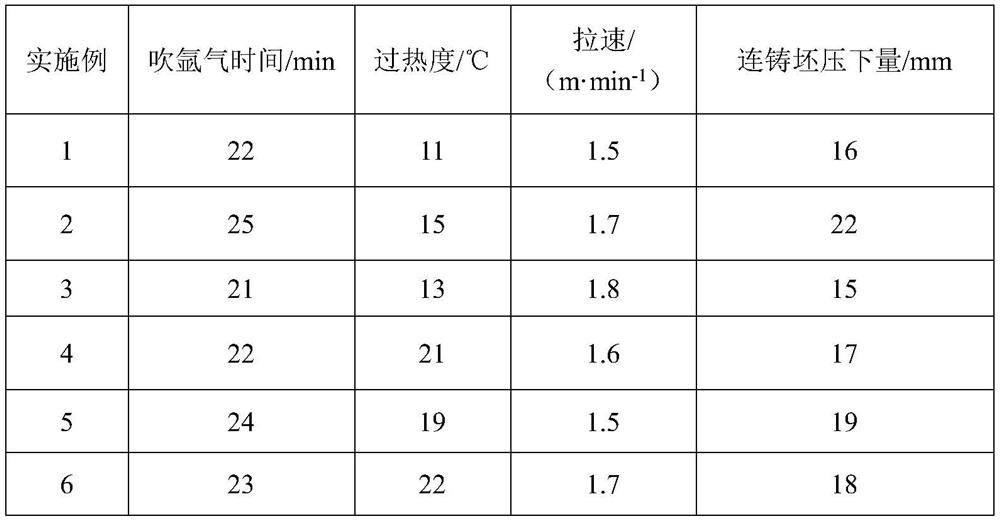

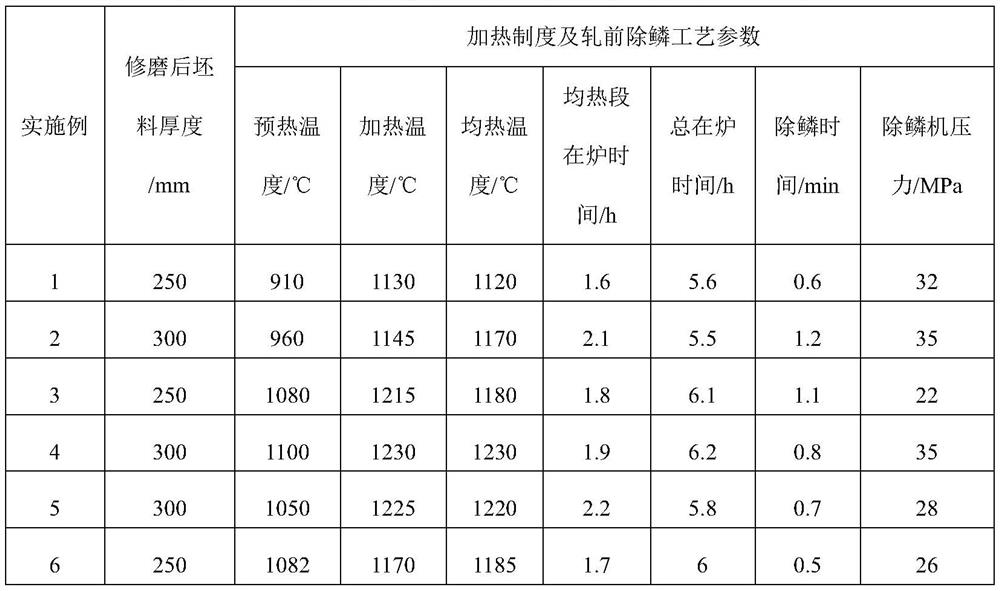

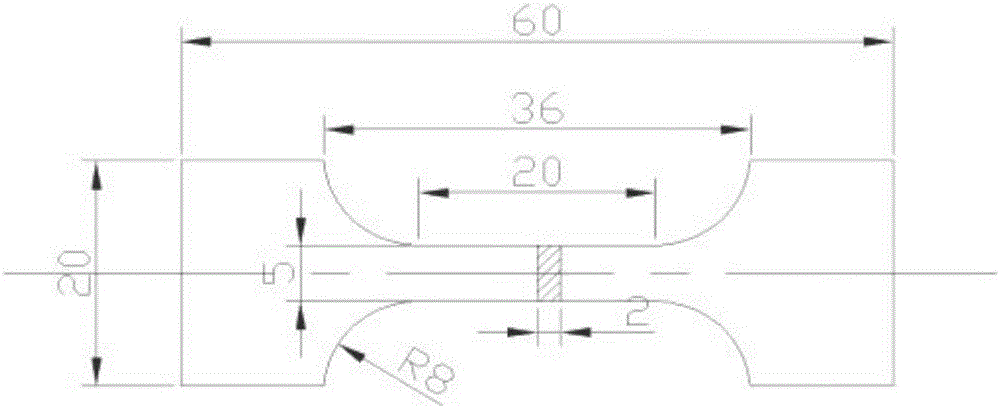

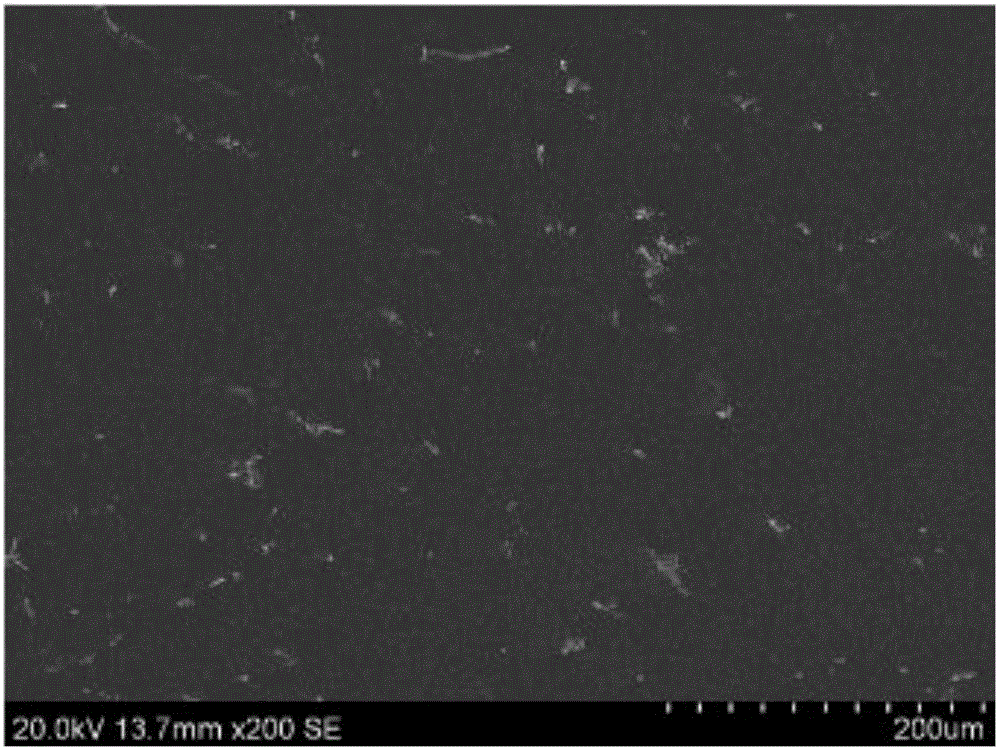

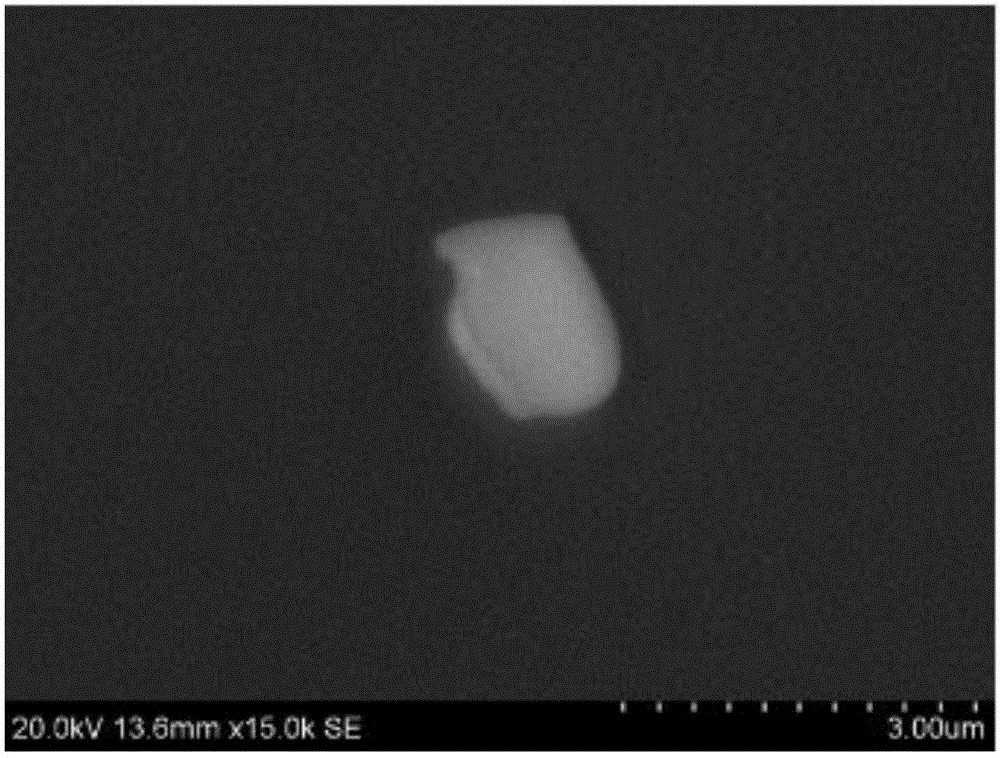

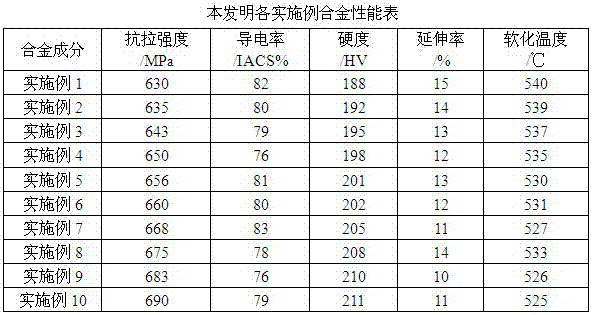

High-strength and high-conductivity rare earth copper alloy for contact lines and preparation method thereof

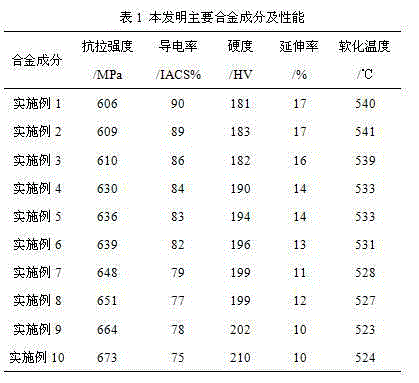

The invention relates to a high-strength and high-conductivity rare earth copper alloy for contact lines and a preparation method thereof. The rare earth copper alloy is composed of chromium, zirconium, zinc, titanium, silver, copper, rare earth elements and inevitable impurity elements, wherein during preparation, a Cu-Zr intermediate alloy and a Cu-rare earth intermediate alloy are prepared at first, and then the Cu-Zr intermediate alloy and the Cu-rare earth intermediate alloy are smelted and subjected to mould casting with copper, zinc, silver and titanium to form a cast ingot, the cast ingot is subjected to hot extrusion to obtain a bar billet, the bar billet is subjected to solution treatment, the treated alloy is subjected to drawing deformation, and then subjected to aging treatment to prepare the high-strength and high-conductivity rare earth copper alloy. The conductivity, elongation, strength and softening temperature of the alloy disclosed by the invention can be greatly improved; the machining performances of the alloy are remarkably improved; the manufacturability of the alloy can be changed, thus benefiting refining, degassing and microalloying; and the requirements of a material for the industrial field of contact lines on the performances of copper alloys can be met well. The alloy disclosed by the invention is simple in preparation process, short in process flow, high in strength, good in conductivity and excellent in hot-working property.

Owner:HENAN UNIV OF SCI & TECH

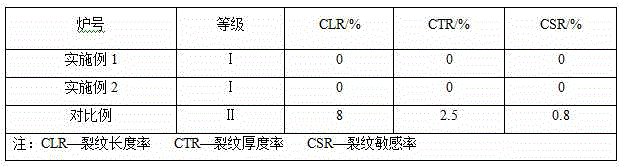

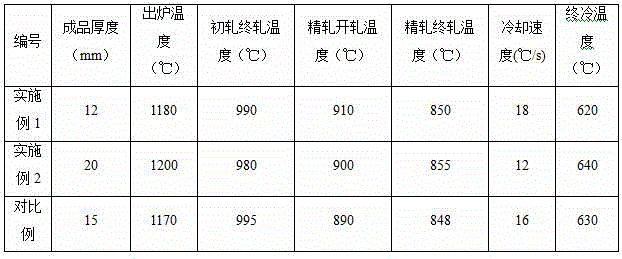

Thick specification hot-rolled steel sheet for roll forming high intensity metal sheet pile and manufacturing technology

ActiveCN101451216AAvoid formingMeet demanding requirementsTemperature control deviceMetal rolling arrangementsChemical compositionSheet steel

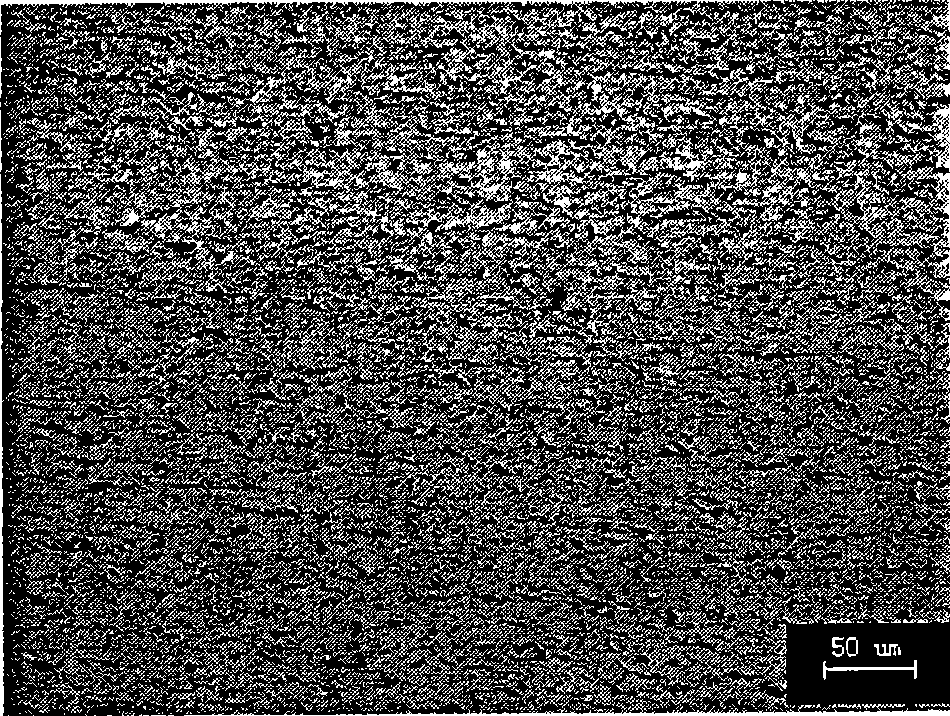

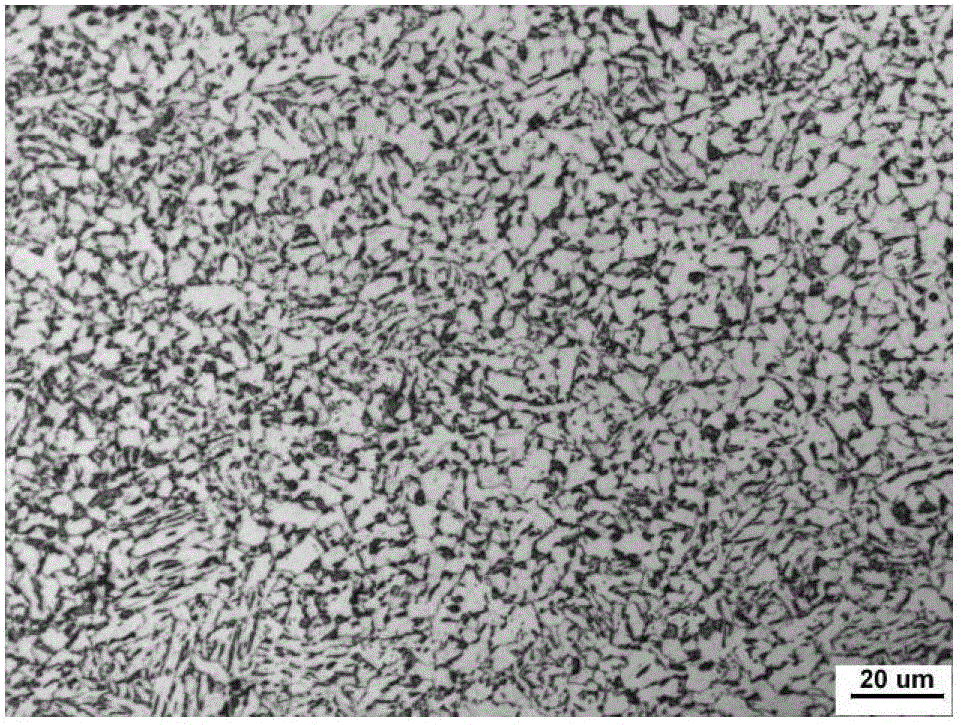

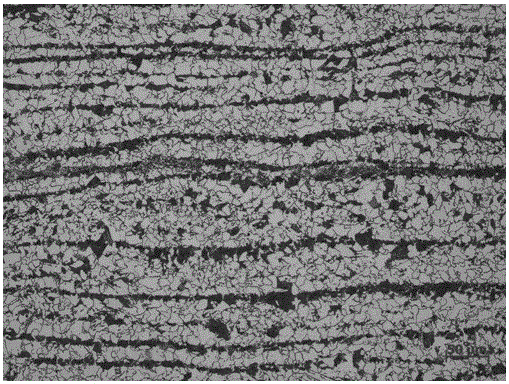

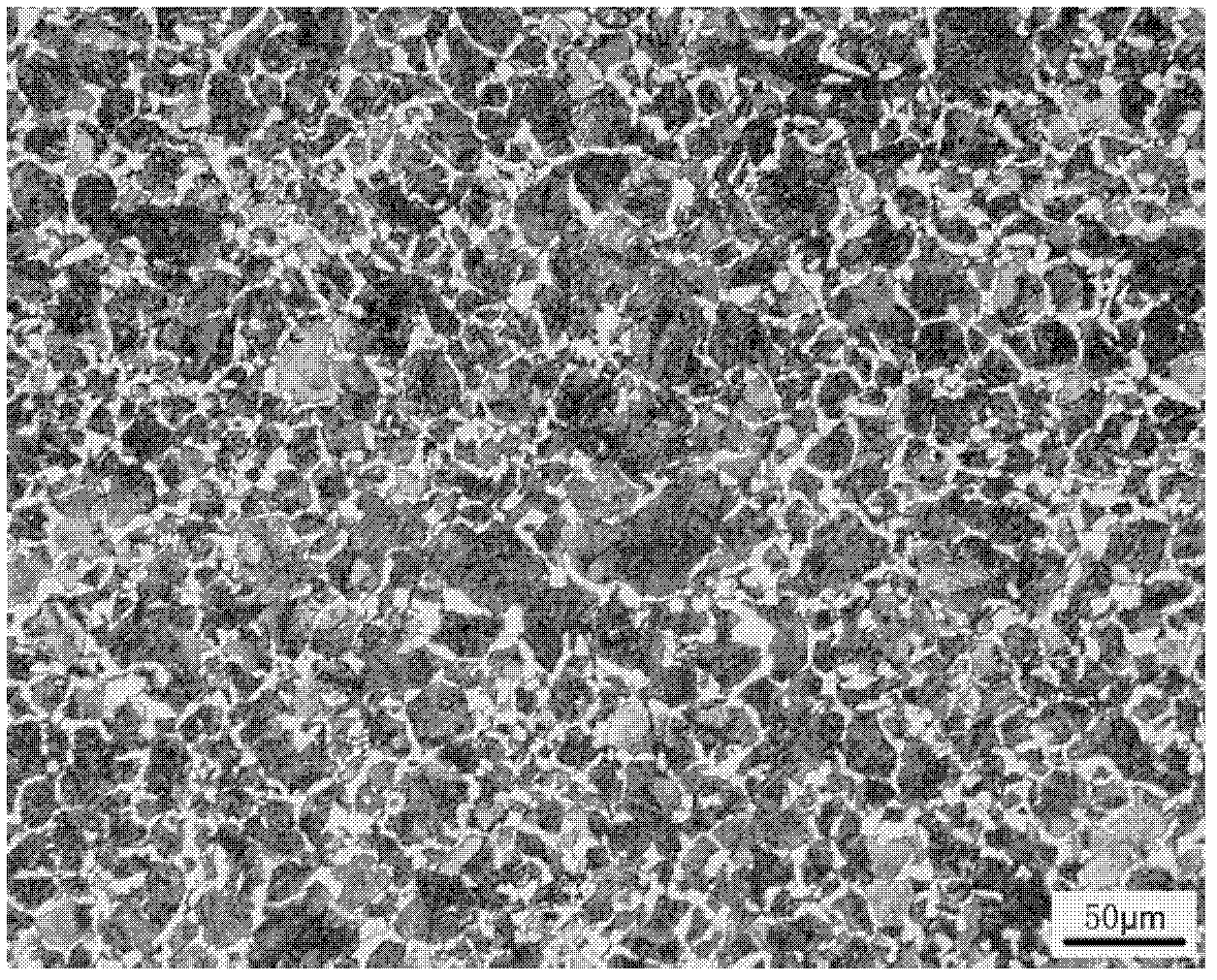

The invention relates to a high strength hot rolled plate and a production process thereof, in particular to a heavy gauge hot rolled steel plate for a roll bending forming high strength steel plate pile and a production process thereof. The invention mainly solves the technical problems of inadequate thickness, and lowcold bending performance and absorbed-in-fracture energy in the prior high strength heavy gauge steel plate. The technical proposal comprises: the heavy gauge hot rolled steel plate for the roll bending forming high strength steel plate pile comprises the following chemical components by weight percentage: 0.08 to 0.15 percent of C, 0.10 to 0.40 percent of Si, 0.30 to 0.90 percent of Mn, 0.020 to 0.040 percent of Nb, 0.010 to 0.030 percent of Ti, less than or equal to 0.025 percent of P, less than or equal to 0.015 percent of S, and the balance being Fe. The microscopic structures can be fine grain ferrites, and pearlitic structures plus a small amount of bainite structures which are dispersed; the grain size level is 11 to 14; and the banded structure level is less than 0.5. The high strength hot rolled plate is mainly used for producing the steel plate pile.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

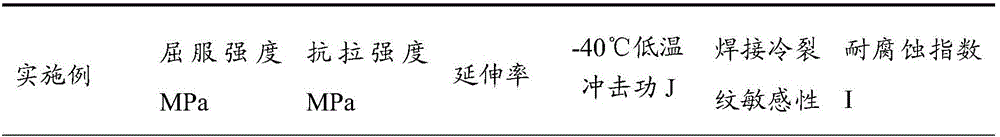

High-strength and low-yield ratio easy-to-weld movable pressure vessel steel plate and manufacturing method thereof

The invention relates to a high-strength, low-yield-ratio, easy-to-weld mobile pressure vessel steel plate. The chemical composition of the steel plate is calculated by mass percentage, C: 0.14-0.20%, Si: 0.20-0.60%, Mn: 1.10-1.70%, P≤ 0.020%, S≤0.010%, Ni: 0.20~0.80%, Nb: 0.010~0.050%, V: 0.010~0.20%, 40ppm≤N≤80ppm, H≤2ppm, Pcm≤0.30, the balance is Fe and unavoidable of impurities. Manufacturing process: converter smelting→ladle furnace refining→vacuum treatment→continuous casting→slab heating→controlled rolling→controlled cooling→slow cooling→flaw detection→normalizing→performance inspection. The present invention adopts design concepts such as solid solution strengthening, fine grain strengthening and toughening, and the steel plate is delivered in a normalized state, integrating high strength, high toughness, low yield ratio, and excellent welding performance. It has excellent performance and short production cycle. Features such as low cost.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

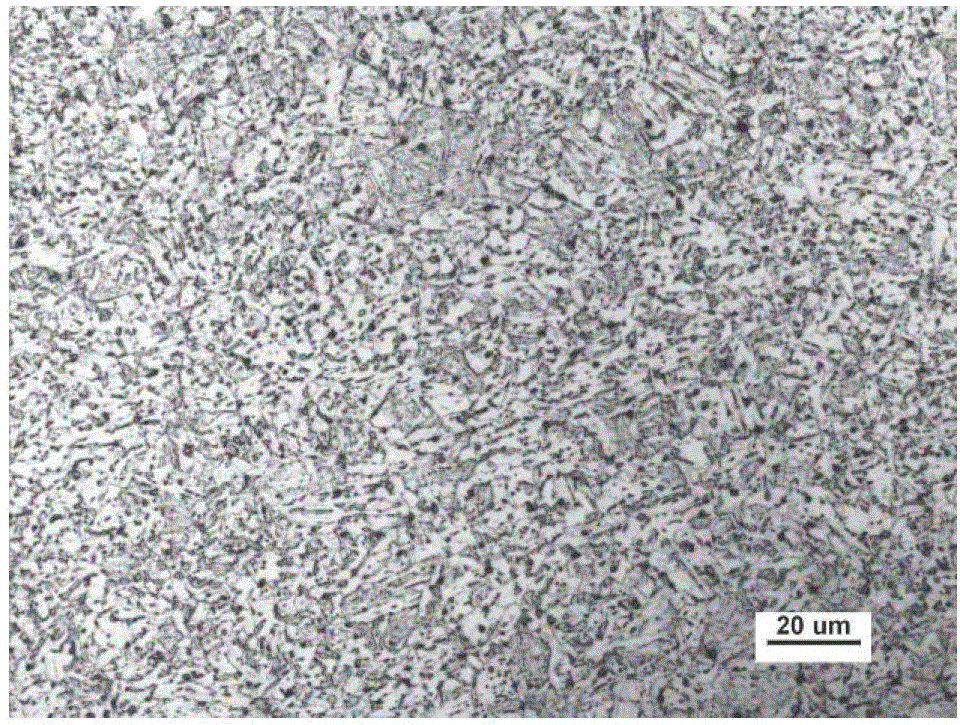

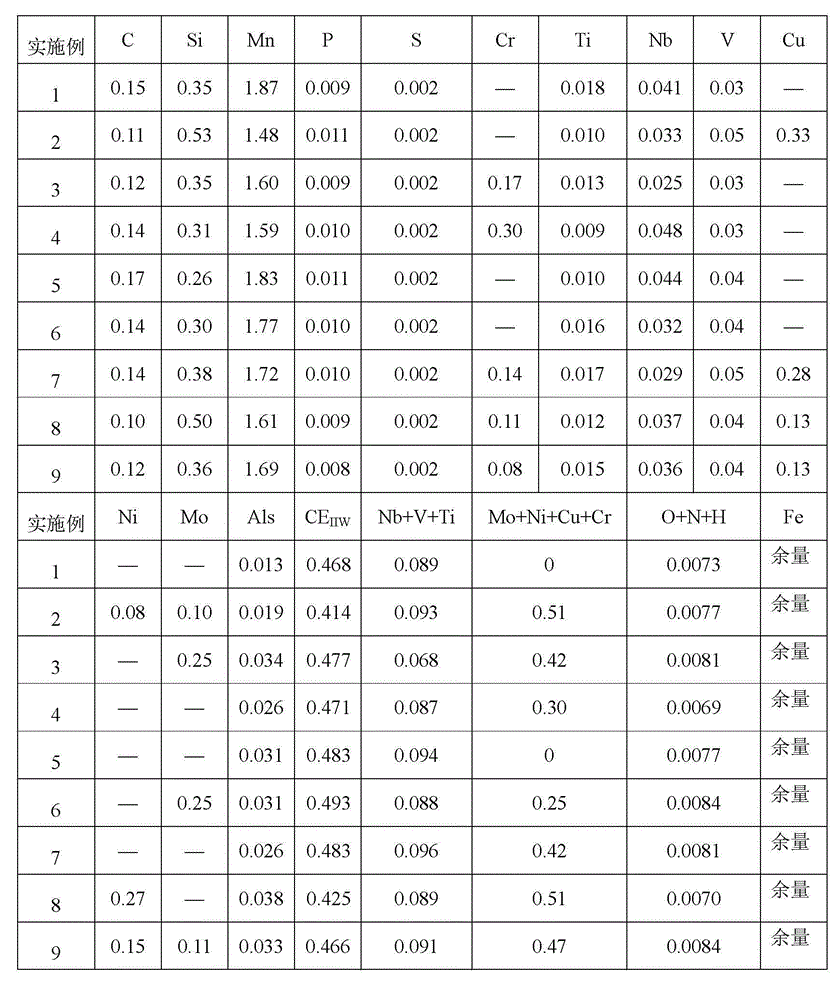

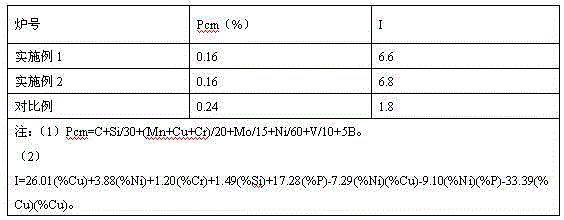

Economical low-yield-ratio steel for pipe fittings for oil and gas transmission and method for producing economical low-yield-ratio steel

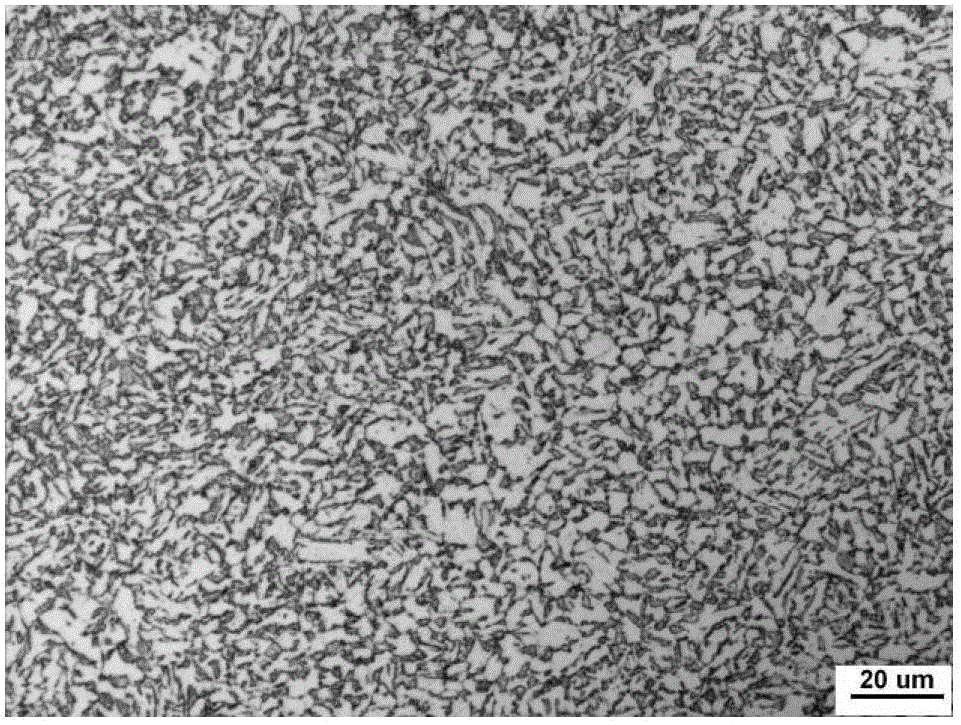

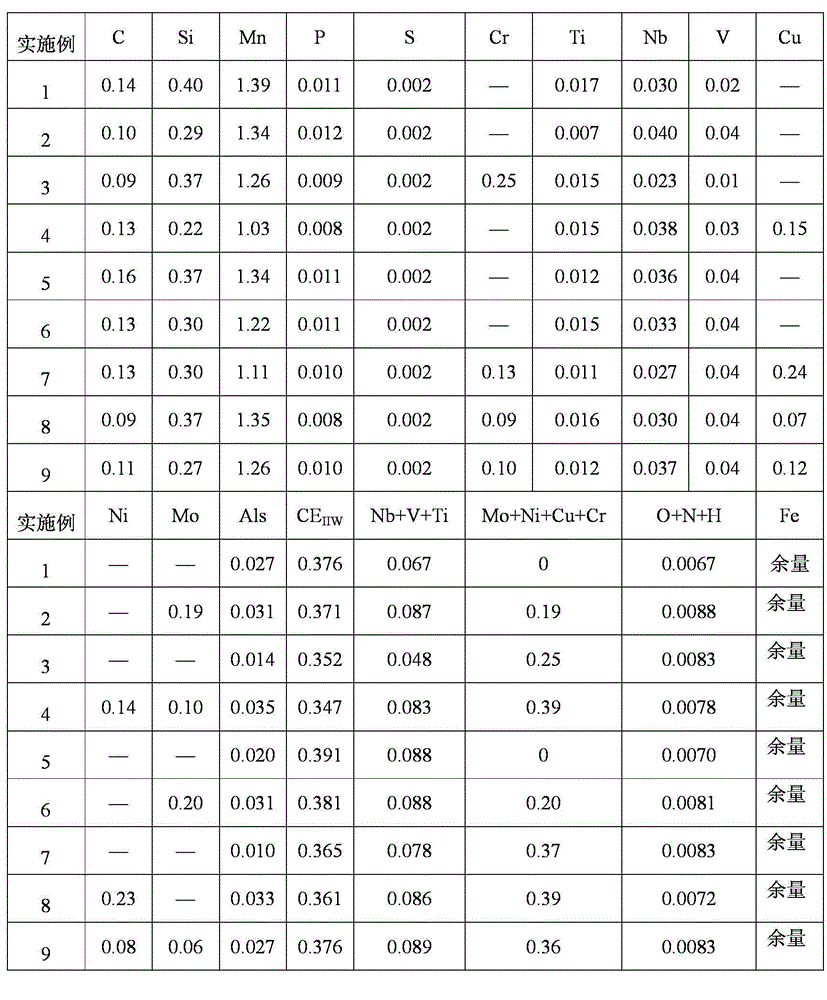

The invention discloses economical low-yield-ratio steel for pipe fittings for oil and gas transmission and a method for producing the economical low-yield-ratio steel. The economical low-yield-ratio steel comprises from 0.09% to 0.16% of C, from 0.20% to 0.40% of Si, from 1.00% to 1.39% of Mn, from 0.01% to 0.04% of Nb, from 0.005% to 0.018% of Ti, from 0.01% to 0.04% of V, from 0.008% to 0.035% of Als, from 0% to 0.20% of Mo, from 0% to 0.30% of Ni, from 0% to 0.30% of Cu, from 0% to 0.25% of Cr, the balance iron and inevitable impurities, wherein the total content of the Nb, the V and the Ti is lower than or equal to 0.09%, and the total content of the Mo, the Ni, the Cu and the Cr is lower than or equal to 0.40%. After the economical low-yield-ratio steel is subjected to heat treatment, the yield strength of the economical low-yield-ratio steel for the pipe fittings can be higher than 490MPa or 560MPa, the tensile strength of the economical low-yield-ratio steel can be higher than 670MPa or 720MPa, the yield ratio of the economical low-yield-ratio steel is lower than 0.80, the impact toughness of the economical low-yield-ratio steel at the temperature of minus 46 Celsius degrees is not lower than 80J, and technical requirements of X70-grade steel for pipe fittings and X80-grade steel for pipe fittings are met completely.

Owner:ANGANG STEEL CO LTD

Ultra-low carbon oriented silicon steel and preparation method thereof

ActiveCN104294155AGood molding effectImprove secondary recrystallization orientation degreeHydrogenLaminar cooling

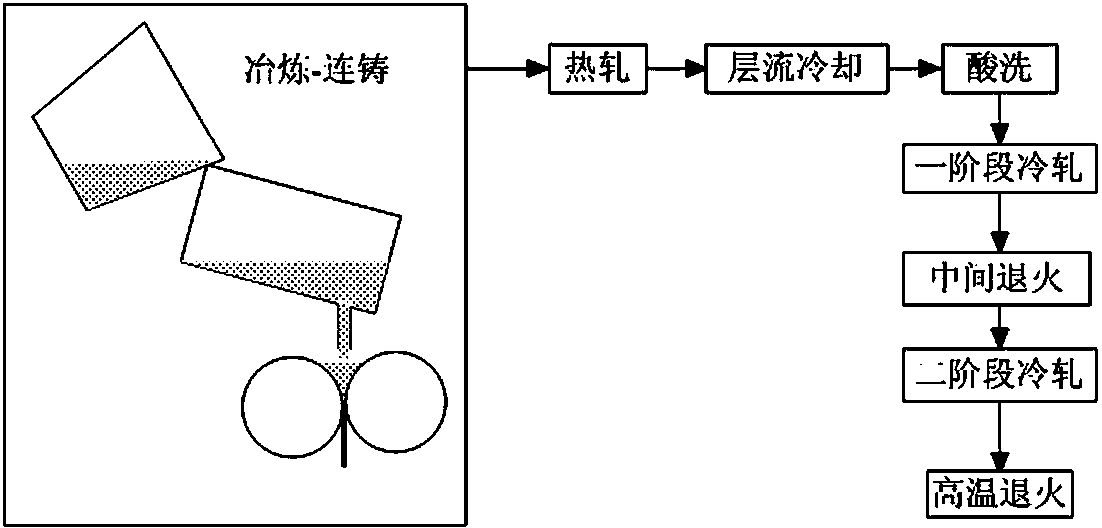

The invention discloses ultra-low carbon oriented silicon steel and a preparation method thereof. The ultra-low carbon oriented silicon steel comprises the following components in percentage by mass: 0.002%-0.005% of C, 2.8%-4.0% of Si, 0.07%-0.3% of Mn, 0.02%-0.1% of Al, no more than 0.5% of Cu, 0.01%-0.03% of S, 0.004%-0.02% of N, no more than 0.005% of O, and the balance of Fe and inevitable impurities, wherein the magnetic property P17 / 50 is 0.8-1.1W / kg, and the magnetic induction B8 is 1.85-1.94T. The preparation method comprises the following steps: (1) smelting molten steel, introducing the molten steel into a tundish and carrying out roll-casting to form a casting strip; (2) carrying out hot rolling; (3) carrying out laminar cooling, pickling, and carrying out two-stage cold rolling; and (4) heating to 1200+ / -10 DEG C under the protective condition of nitrogen, then carrying out heat preservation under the condition of pure dry nitrogen, carrying out high-temperature annealing, and cooling to 400+ / -10 DEG C along with the furnace, and carrying out air cooling. According to the method disclosed by the invention, the content of C is controlled to be lower than 50ppm; the entire process is controlled to be single-phase ferrite matrix; the molding property of the casting strip is improved; fine and uniform primary recrystallization tissues are obtained; and the product has good property.

Owner:NORTHEASTERN UNIV

TiAl alloy crystal grain refinement method

The invention provides a TiAl alloy crystal grain refinement method. Through cyclic treatment in a solid-liquid two-phase region, a bulky columnar crystal undergoes remelting, a fused dendritic crystal can be used as a new nucleation particle which undergoes nucleation and growth, so a crystal grain is refined. According to the invention, treatment is carried out on a peritectic solidification path with a Ti48Al2Cr2Nb alloy as a representative, an alpha solidification path with a Ti50Al alloy as a representative and a beta solidification path with a Ti45Al8Nb0.2W0.2B alloy as a representative, and a substantial refinement effect is obtained; the method has the characteristics of a wide application scope and suitability for crystal grain refinement of a plurality of TiAl alloys.

Owner:重庆两航金属材料有限公司

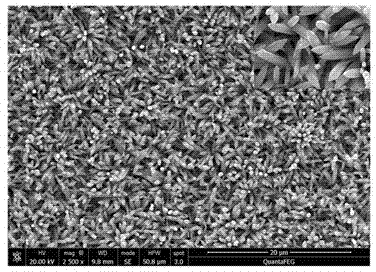

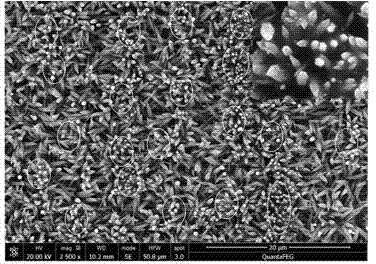

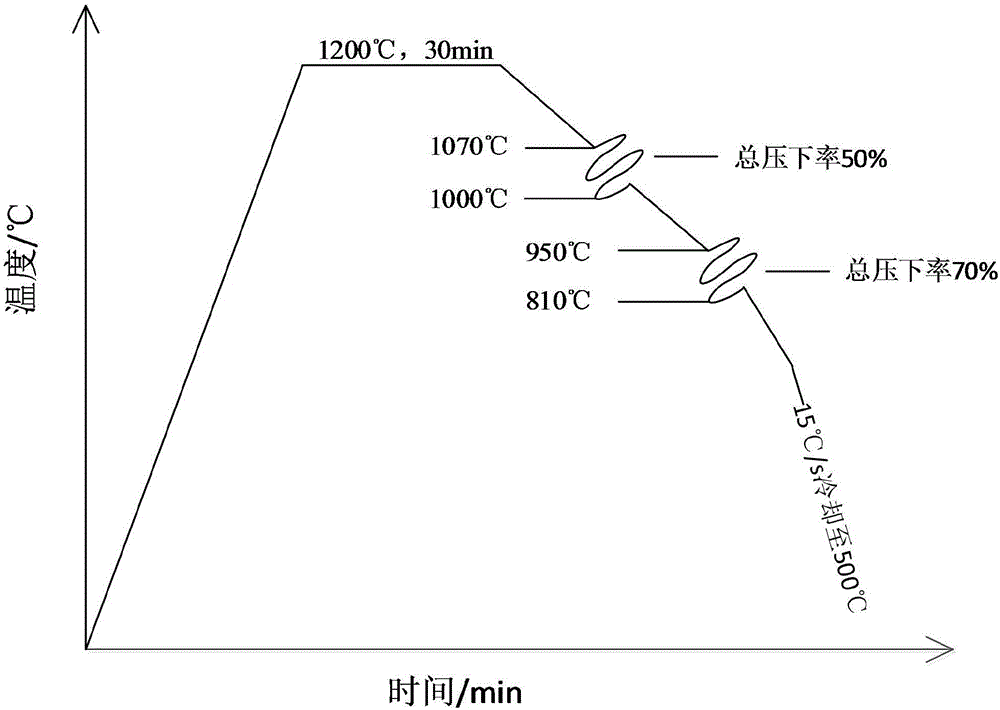

Rolling technology for high-carbon steel in thin slab casting and rolling

ActiveCN104438326AIncrease nucleation sitesUniform nucleationTemperature control deviceTension/compression control deviceThree stageSlow cooling

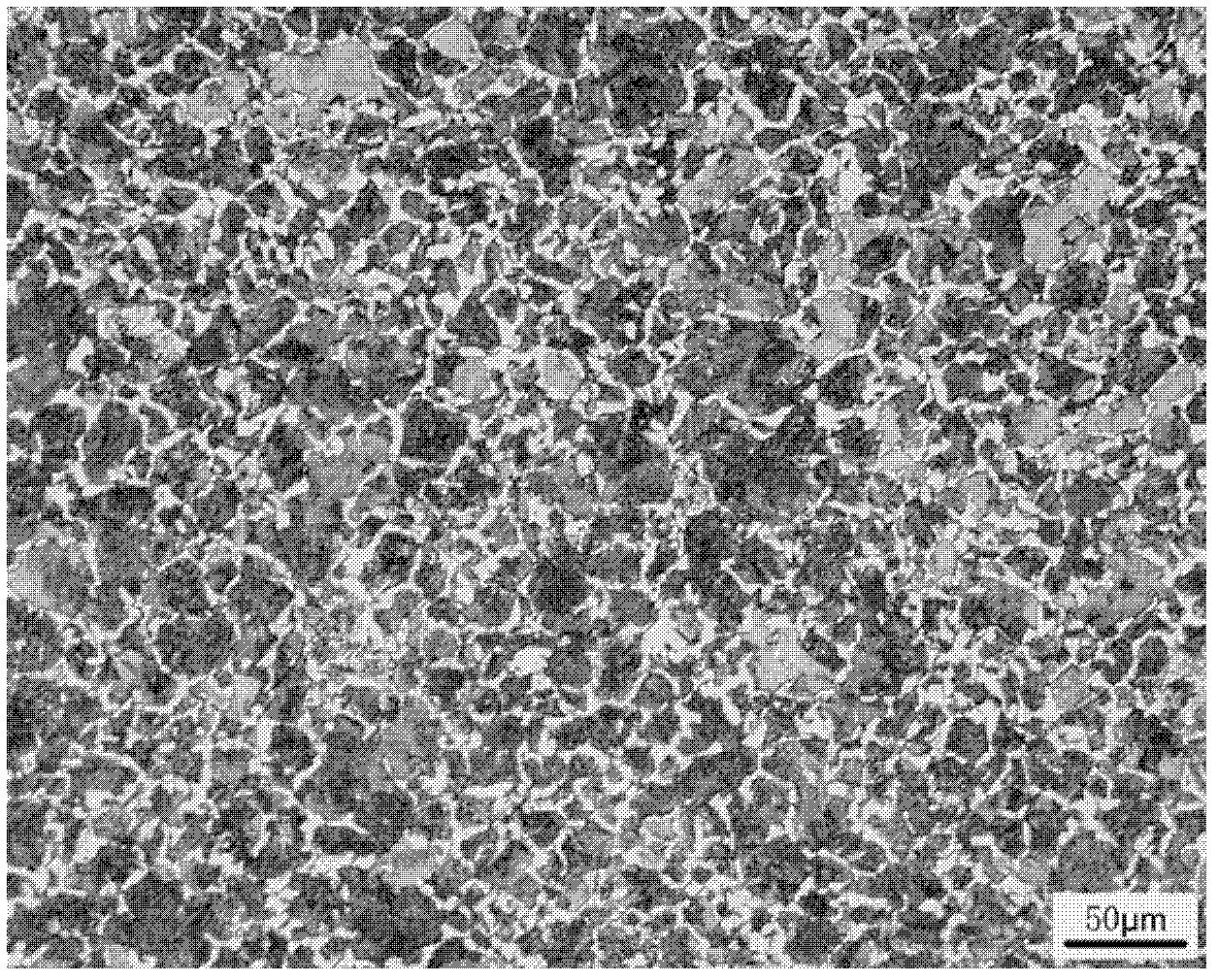

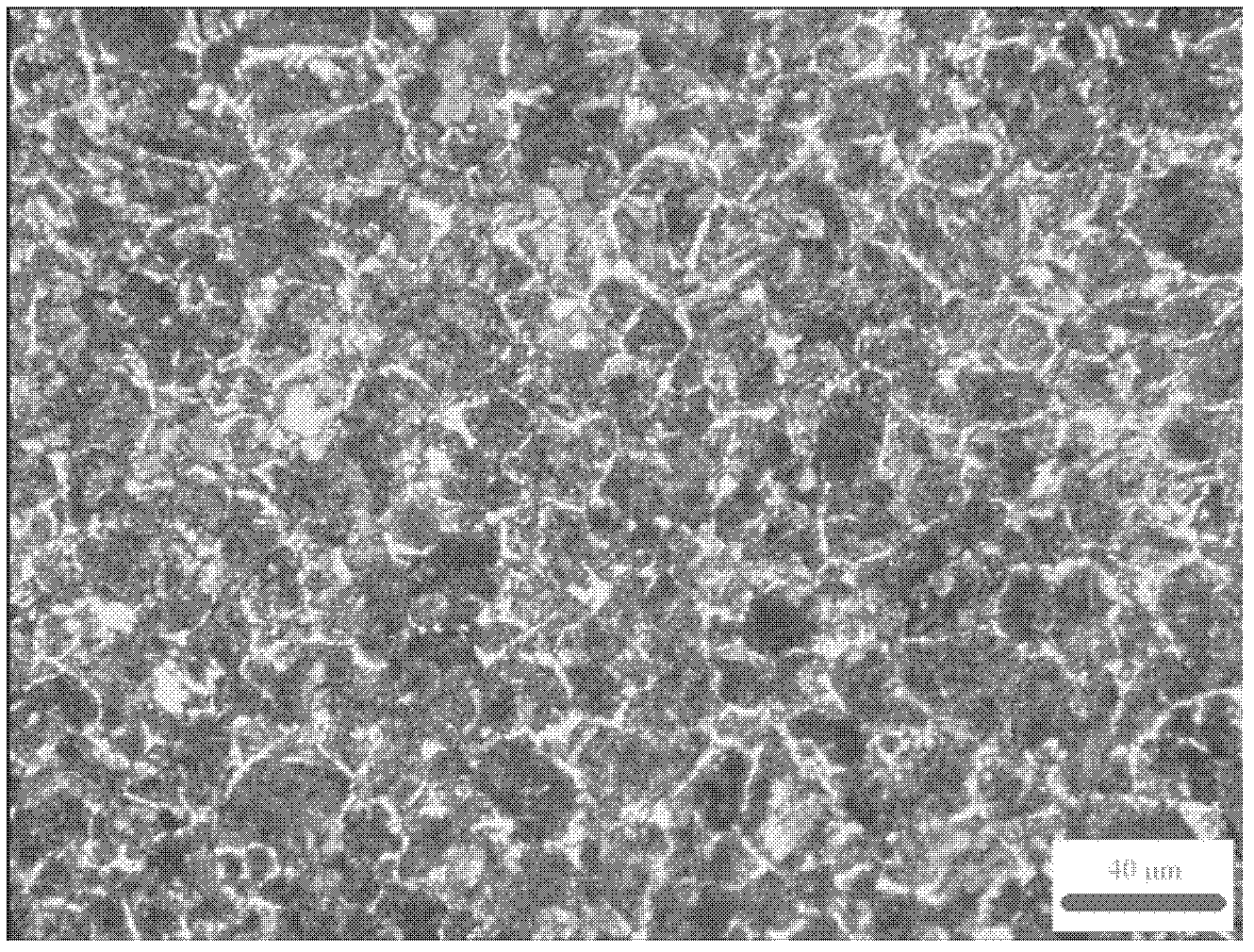

The invention provides a rolling technology for high-carbon steel in thin slab casting and rolling. The rolling technology includes the processes of continuous casting, heat evening, scale removing, rolling, inter-stand cooling, laminar cooling, reeling and insulation cover slow cooling. The rolling technology is characterized in that the rolling process includes three stages of Austenite perfect recrystallization rolling, non-recrystallization area Austenite rolling and two-phase area rolling. Medium-and-high-carbon steel structures rolled through the rolling technology are even and fine ferrite and particular pearlite, banded structures can be improved, the mechanical property is good, the annealing process does not need to be conducted before forming, cost is reduced, and quite high practicability is achieved.

Owner:武汉钢铁有限公司

Method for preparing super-hydrophilic and hydrophobic composite nano array interface material

ActiveCN104846369AEfficient condensation nucleation is goodGood fast growth effectPretreated surfacesNanotechnologyPolyvinyl alcoholUltrasonic atomization

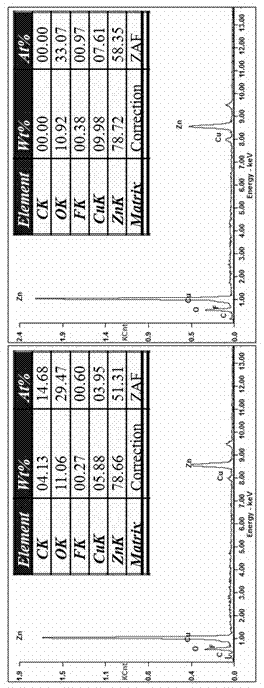

The invention relates to a method for preparing a super-hydrophilic and hydrophobic composite nano array interface material, which comprises the following steps: 1)taking a copper sheet as a base material, preparing a zinc oxide nano conical fascia by a chemical bath sedimentation method in hot bath; 2)using seventeen perfluorinated silane for modifying the oxidative nano conical fascia at 120 DEG C by a vapour deposition method; 3)preparing a polyvinyl alcohol low-solid content aqueous solution; 4)establishing an ultrasonic atomization and condensation platform, atomizing the polyvinyl alcohol aqueous solution with concentration being 0.1-0.2%, reducing the temperature of the surface of the copper-based zinc oxide nano conical fascia to 1-5 DEG C through the condensation platform, uniformly condensing the surface of the super-hydrophobic zinc oxide nano conical fascia by the polyvinyl alcohol dispersion liquid dispersed in air, performing spray deposition under observation of a high power CCD imaging system; and 5)rapidly transferring to a constant temperature heating stage, solidifying at constant temperature, after solvent moisture is completely volatilized, solidifying polyvinyl alcohol and absorbing on the surface of the zinc oxide nano conical fascia to form a hydrophilic and hydrophobic composite nano array interface. The method has the advantages of simple process and low cost, and the material has high anti-condensation frosting performance.

Owner:SHAANXI UNIV OF SCI & TECH

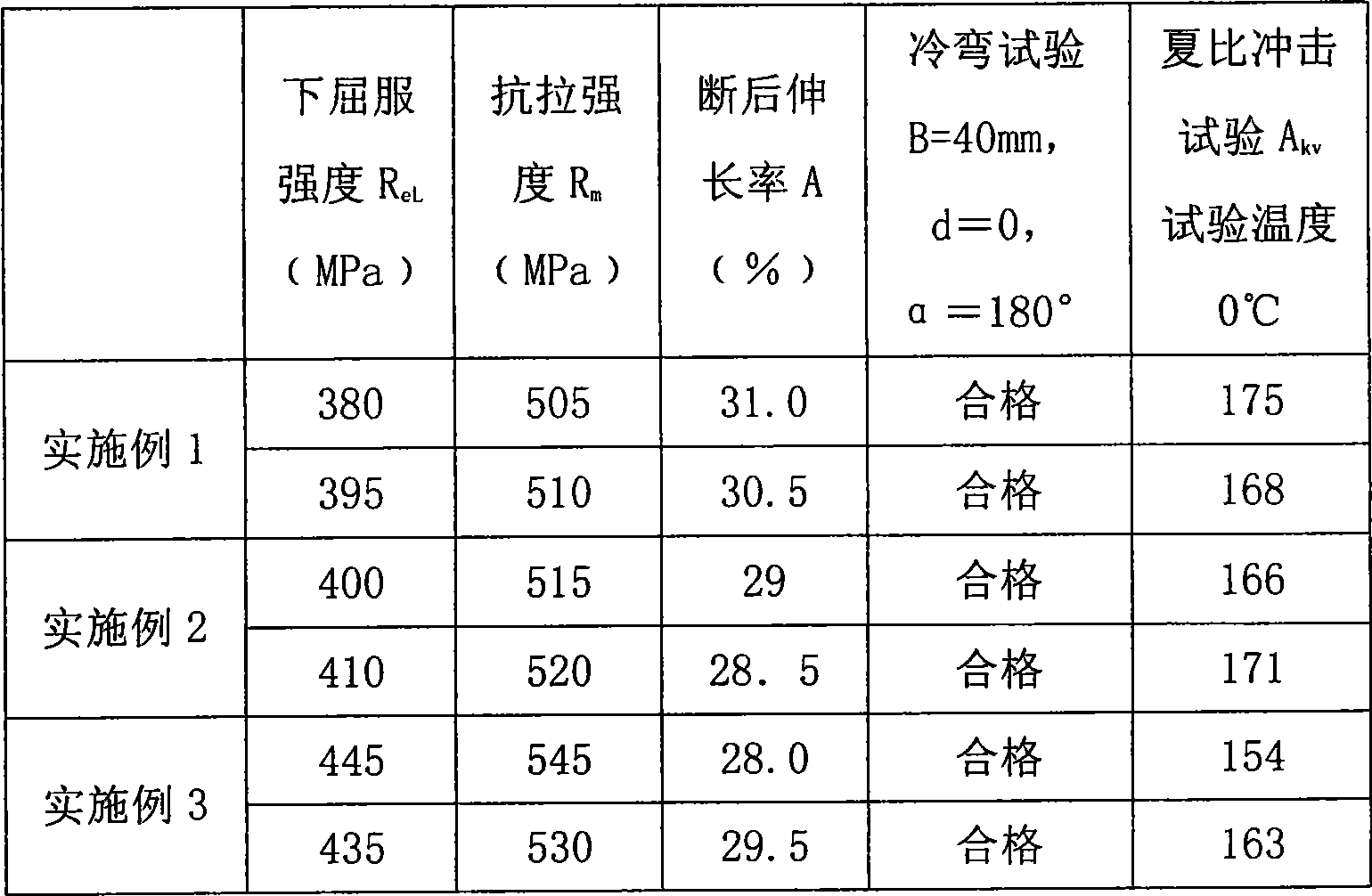

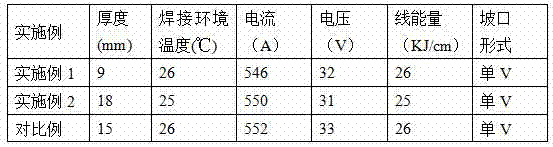

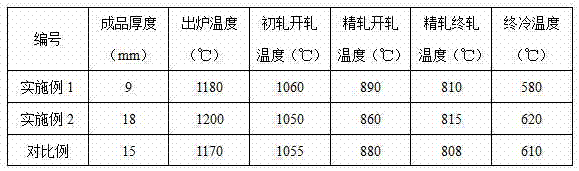

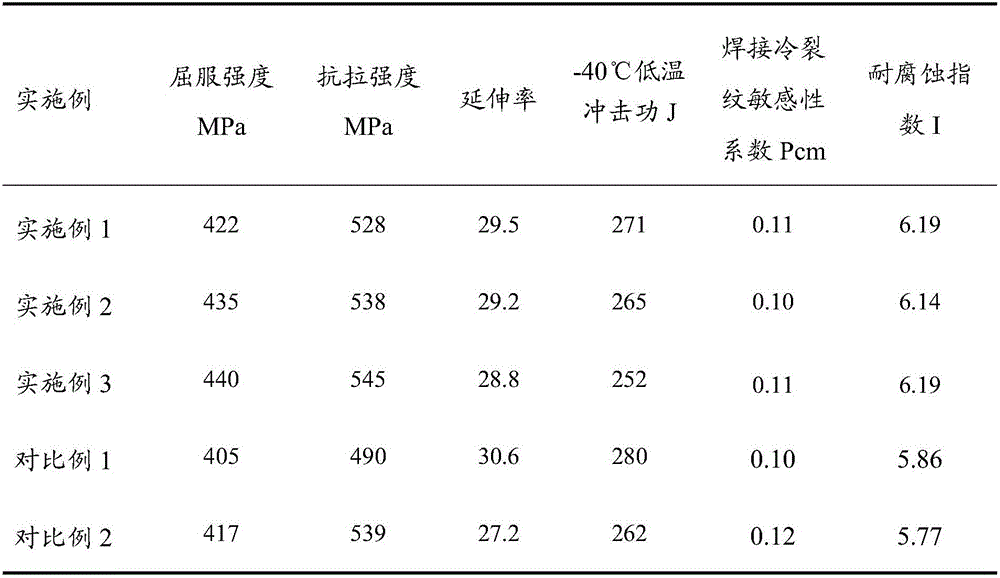

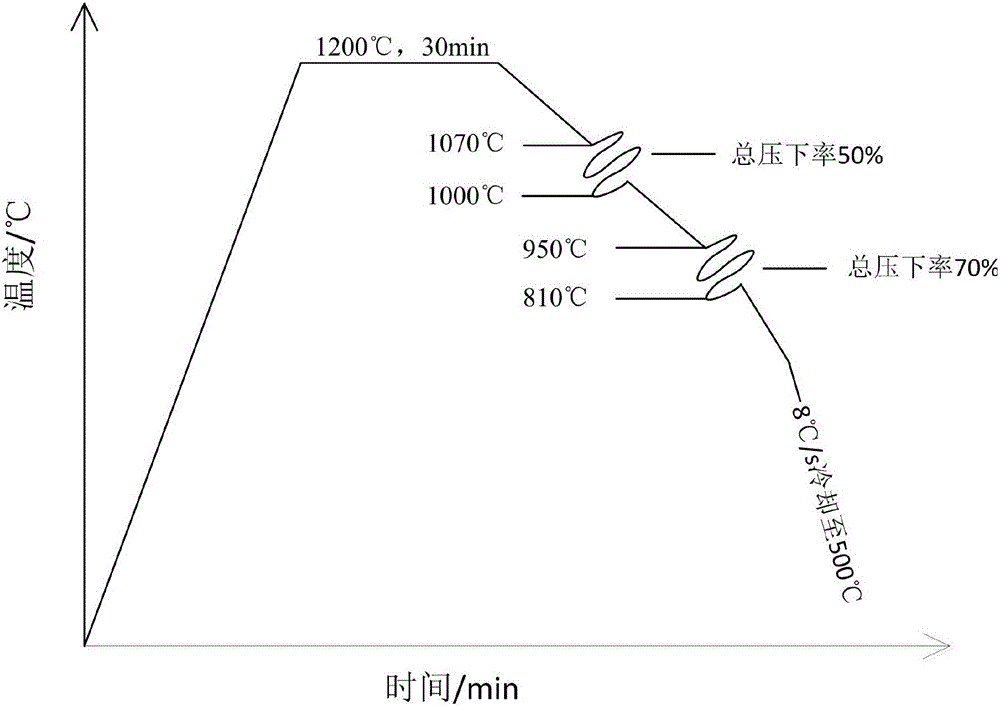

Hydrogen-corrosion-resistant normalized low-alloy steel for mobile tanker and preparation method of hydrogen-corrosion-resistant normalized low-alloy steel

The invention relates to hydrogen-corrosion-resistant normalized low-alloy steel for a mobile tanker. The hydrogen-corrosion-resistant normalized low-alloy steel is prepared from the following chemical components: 0.13 to 0.20 percent of C, 0.20 to 0.50 percent of Si, 1.20 to 1.70 percent of Mn, less than or equal to 0.030 percent of P, less than or equal to 0.01 percent of S, 0.10 to 0.45 percent of Ni, 0.010 to 0.050 percent of Nb, 0.010 to 0.20 percent of V, wherein N is greater than or equal to 30ppm and less than or equal to 50ppm, H is less than or equal to 2ppm, w(V) / w(N) is greater than or equal to 8 and less than or equal to 15, and the balance of Fe and converter, refining in a ladle furnace, vacuum treating, continuous casting, heating a cast blank, controlling and rolling, controlling and cooling, slowly cooling, detecting flaws, normalizing, and inspecting performance. A steel plate is delivered at a normalized state, and integrates high strength, high flexibility, low yield ratio and high hydrogen corrosion resistance, on the premise of maintaining the excellent mechanical performance, the thickness of the steel plate is controlled at 6 to 25 mm, a minimum thickness is 6 mm, the weight of the steel material is reduced, and the capacity of the mobile tanker is increased.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

High-strength and high-conductivity rare earth copper and zirconium alloy and preparation method thereof

High-strength and high-conductivity rare earth copper and zirconium alloy is composed of zirconium, nickel, silicon, copper and rare earth elements and comprises, by weight, 0.1-0.5% of zirconium, 0.1-0.5% of nickel, 0.1-0.15% of silicon, 0.2-0.4% of silver, 0.02-0.1% of a rare earth element and the balance copper. The high-strength and high-conductivity rare earth copper and zirconium alloy has the beneficial effects that the reparation process is simple, the technological process is short, the strength, the conductivity and elasticity are high, the hot-working character is good, and the tensile strength of the high-strength and high-conductivity rare earth copper and zirconium alloy can reach 690 MPa.

Owner:HENAN UNIV OF SCI & TECH

High-strength and high-conductivity copper magnesium alloy contact wire and preparing method thereof

The invention provides a high-strength and high-conductivity copper magnesium alloy contact wire. The contact wire comprises the following components of, by weight, 0.1%-0.8% of magnesium, 0.1%-0.4% of nickel, 0.1%-0.4% of zinc, 0.1%-0.4% of silver, and the balance copper and inevitable impurity elements. The prepared high-strength and high-conductivity copper magnesium alloy contact wire has excellent comprehensive performance, solves the technical problem that in the prior art, consideration cannot be given to electric conductivity and tensile strength of a copper magnesium alloy at the same time, and can meet the requirement for the performance of the copper alloy for railway contact wires.

Owner:HENAN UNIV OF SCI & TECH

Wide-width, high-strength, high-toughness and thick-wall X80M pipeline steel plate and manufacturing method thereof

The invention relates to a wide-width, high-strength, high-toughness and thick-wall X80M pipeline steel plate and a manufacturing method thereof. The steel plate is prepared from the chemical components including, by weight, 0.045%-0.08% of C, 0.20%-0.38% of Si, 1.55%-1.85% of Mn, 0.15%-0.35% of Cu, less than or equal to 0.010% of P, less than or equal to 0.015% of S, 0.04%-0.08% of Nb, 0.015%-0.028% of Ti, 0.015%-0.045% of Al, 0.25%-0.5% of Cr, 0.004%-0.006% of N, 0.032%-0.06% of V, 0.03%-0.05% of Zr, less than or equal to 0.15% of Ni, less than or equal to 0.12% of Mo, 0.0012%-0.0035% of Ca and the balance Fe and inevitable impurities. The produced steel plate has the comprehensive performance of high strength and good low-temperature toughness, and can ensure the safety of oil and gas transmission pipelines.

Owner:ANGANG STEEL CO LTD

Method for producing Nb-containing high-speed train wheel steel

InactiveCN102534396AHigh strengthImproves the toughness of steel under high-strength conditionsMetallic materialsPearlite

The invention relates to a method for producing Nb-containing high-speed train wheel steel, and belongs to the field of metal materials. The wheel steel comprises the following components in percentage by weight: 0.40 to 0.70 percent of C, 0.70 to 0.80 percent of Mn, 0.30 to 0.60 percent of Si, 0.015 to 0.110 percent of Nb, 0.20 to 0.35 percent of Cr, less than or equal to 0.020 percent of P, less than or equal to 0.015 percent of S and the balance of Fe and inevitable elements. The method comprises the following steps of: smelting, forging to obtain a steel billet, performing normalization and heat preservation at the temperature of between 850 and 900 DEG C for 1 hour, performing air cooling or water spray cooling to room temperature, and ensuring that cooling speed is controlled in therange of 1 to 15 DEG C / s and a room temperature structure is ferrite and pearlite. The high-speed train wheel steel produced by the method has the tensile strength of 740 to 900MPa, the yield strength of 450 to 570MPa, the breaking elongation of 15 to 25 percent and the low temperature (-20 DEG C) impact work (Akv) of 15 to 20J, and a uniform structure with 10 to 25 percent of ferrite can be obtained at room temperature. The Nb-containing high-speed train wheel steel has mechanical properties of high strength and toughness, and overcomes the defect of a low toughness value of the conventionalhigh and medium carbon wheel steel.

Owner:UNIV OF SCI & TECH BEIJING

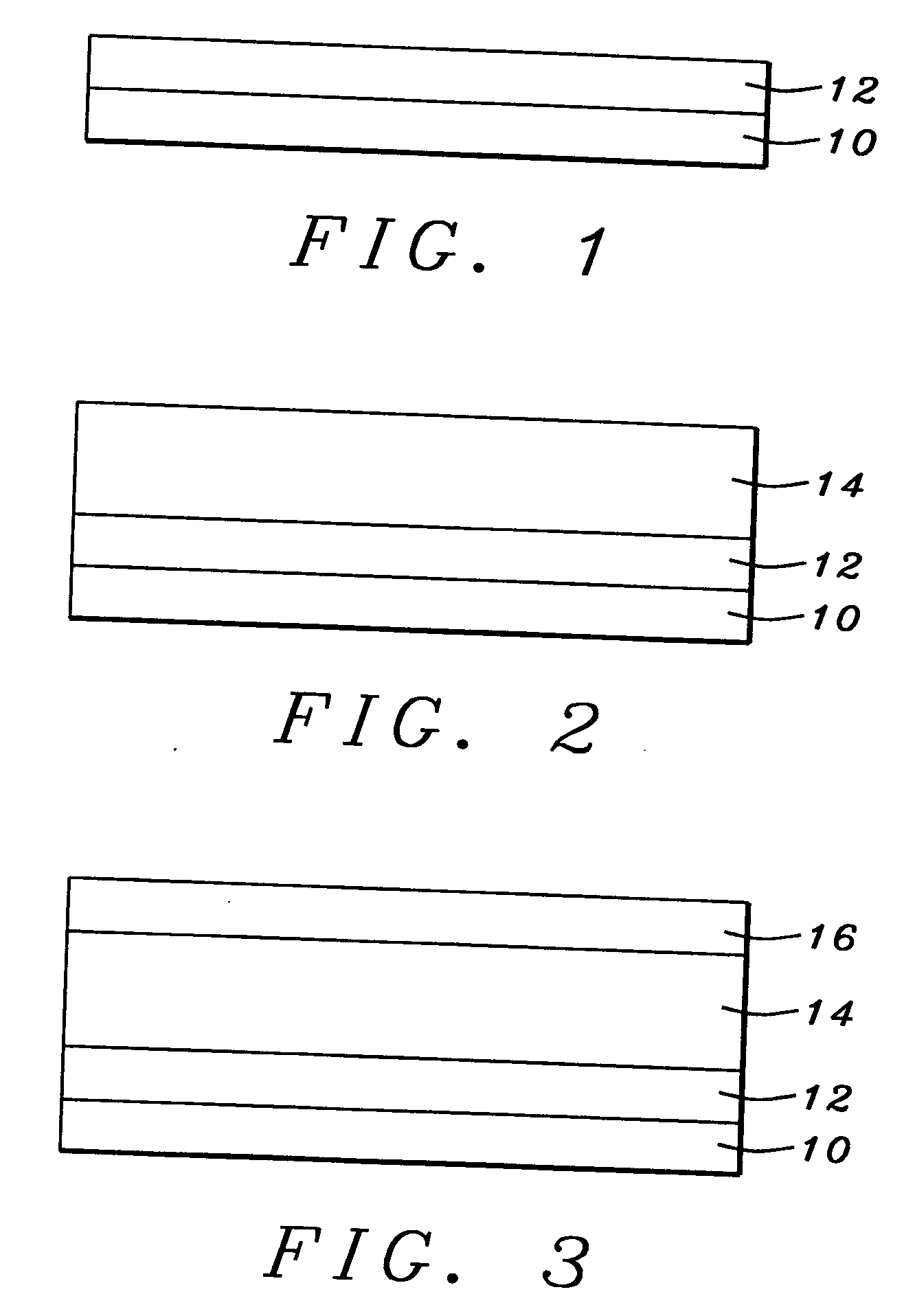

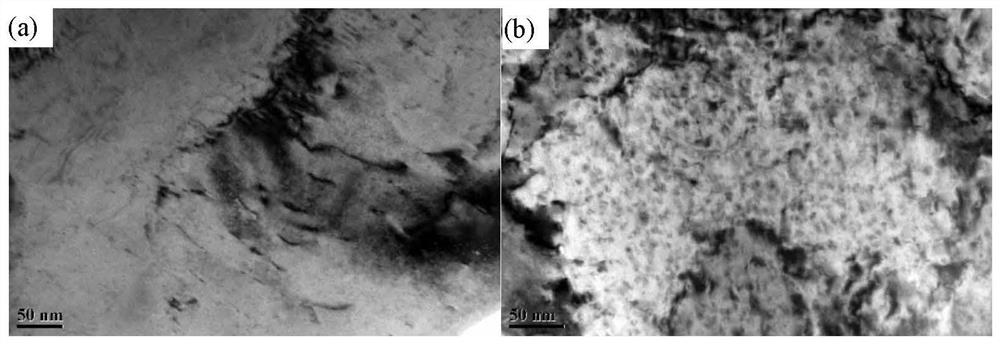

Novel deposition method for si-ge epi layer on different intermediate substrates

ActiveUS20050176229A1Increase nucleation sitesDevoid of discontinuitySemiconductor/solid-state device manufacturingSemiconductor devicesOptoelectronicsNucleation

A method of forming an Si—Ge epitaxial layer comprising the following steps. A structure is provided and a doped Si—Ge seed layer is formed thereover. The doped Si—Ge seed layer having increased nucleation sites. A Si—Ge epitaxial layer upon the doped Si—Ge seed layer whereby the Si—Ge epitaxial layer lacks discontinuity.

Owner:TAIWAN SEMICON MFG CO LTD

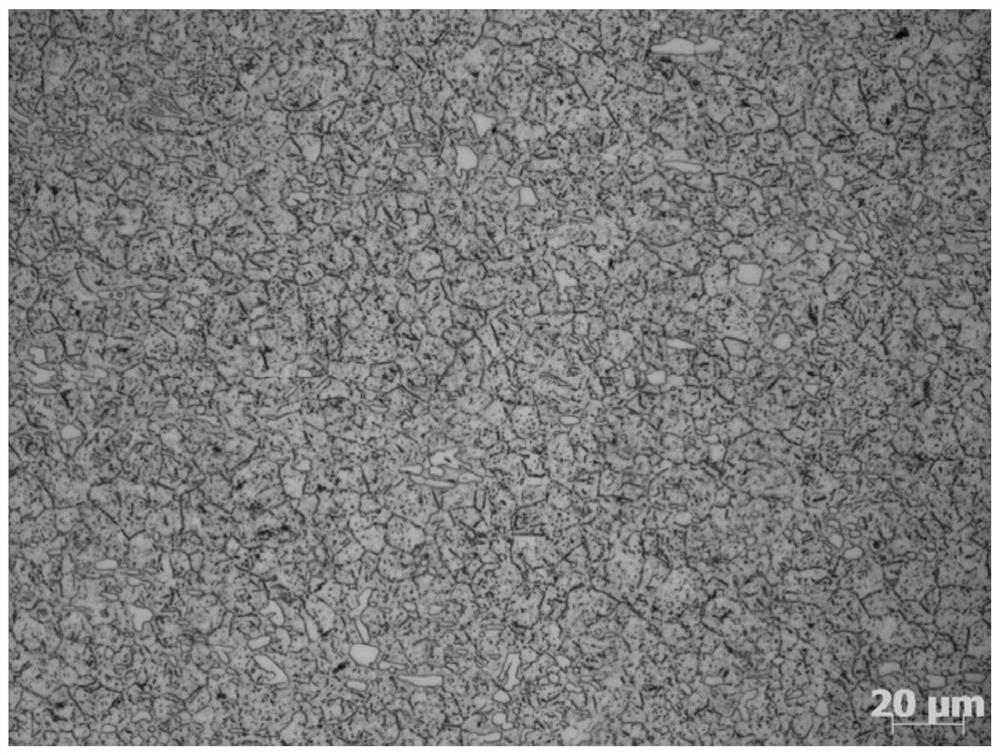

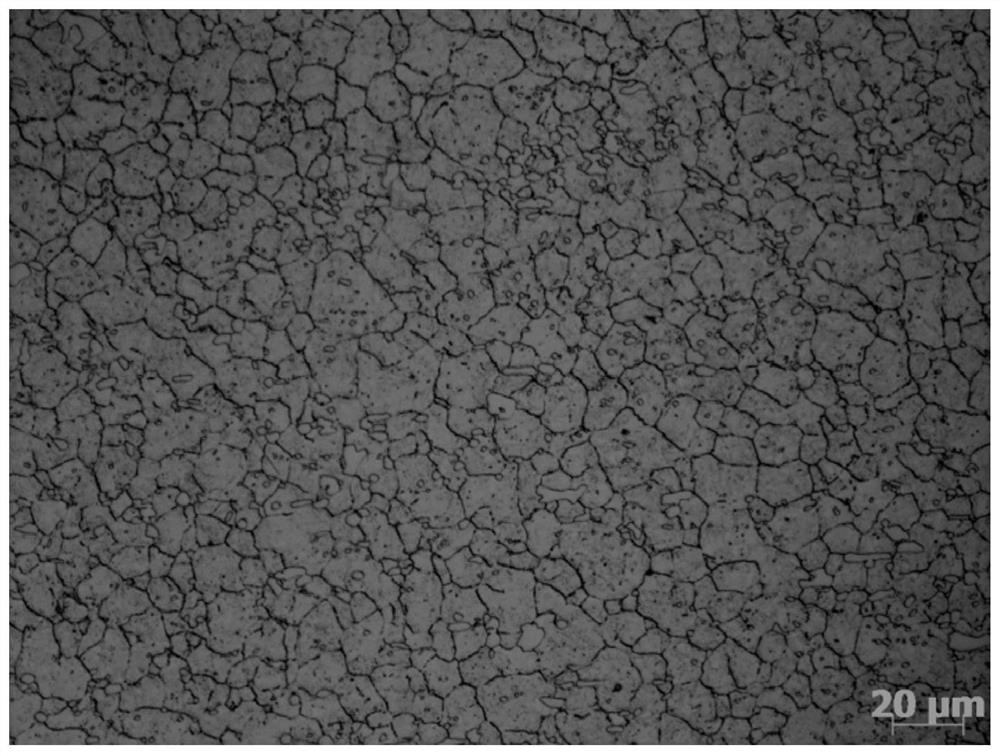

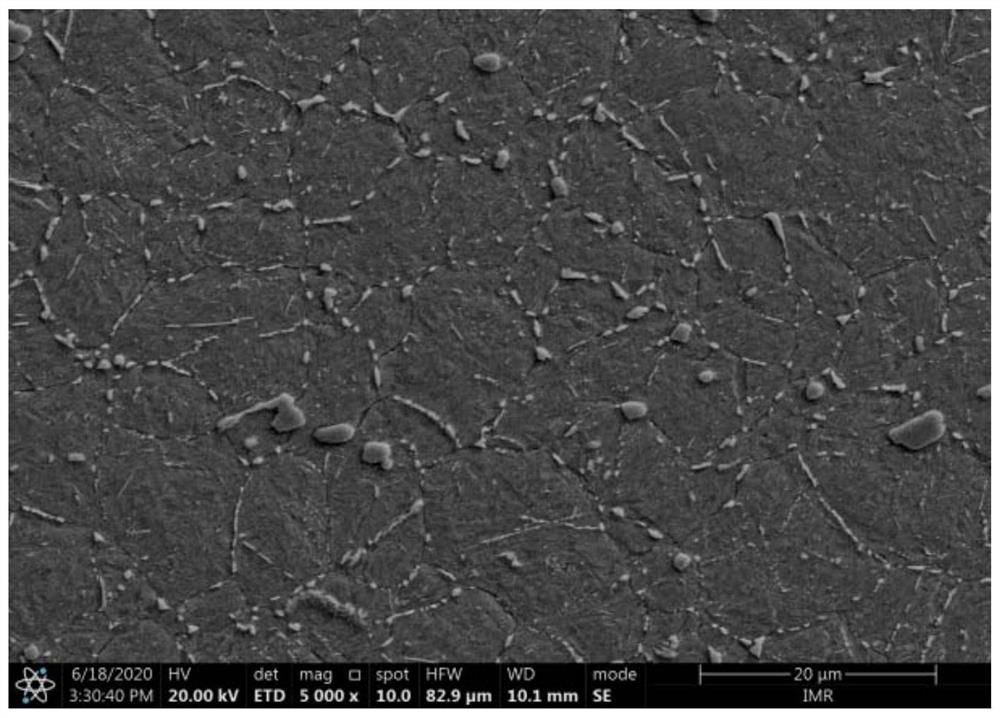

High-carbon high-chromium martensitic stainless steel for cutter and preparation method thereof

ActiveCN112522635APromotes even distributionPurified smelting inclusion contentFurnace typesHeat treatment furnacesMartensitic stainless steelChromium

The invention relates to high-carbon high-chromium martensitic stainless steel for a cutter and a preparation method thereof, and belongs to the technical field of materials. The high-carbon high-chromium martensitic stainless steel comprises the following chemical components of, in percentage by weight, 0.90%-1.20% of C, 14.0%-16.0% of Cr, 1.0%-2.0% of Co, 0.5%-1.5% of Mo, 0.20%-0.40% of V, 0.2%-0.6% of Mn, 0.001%-0.01% of La, less than 0.01% of P, less than 0.01% of S and the balance iron. The preparation method of the high-carbon high-chromium martensitic stainless steel comprises the following steps of burdening, smelting, casting molding, forging and hot working, cold working and heat treatment. According to the high-carbon high-chromium martensitic stainless steel for cutter and thepreparation method thereof, the rare earth element content in the material is optimized, primary carbide coarsening is inhibited, carbide uniform distribution is promoted, the heat treatment process is improved, the martensite content and the austenite content in a matrix are controlled, and the optimal matching of the strength and the toughness of the material is obtained.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

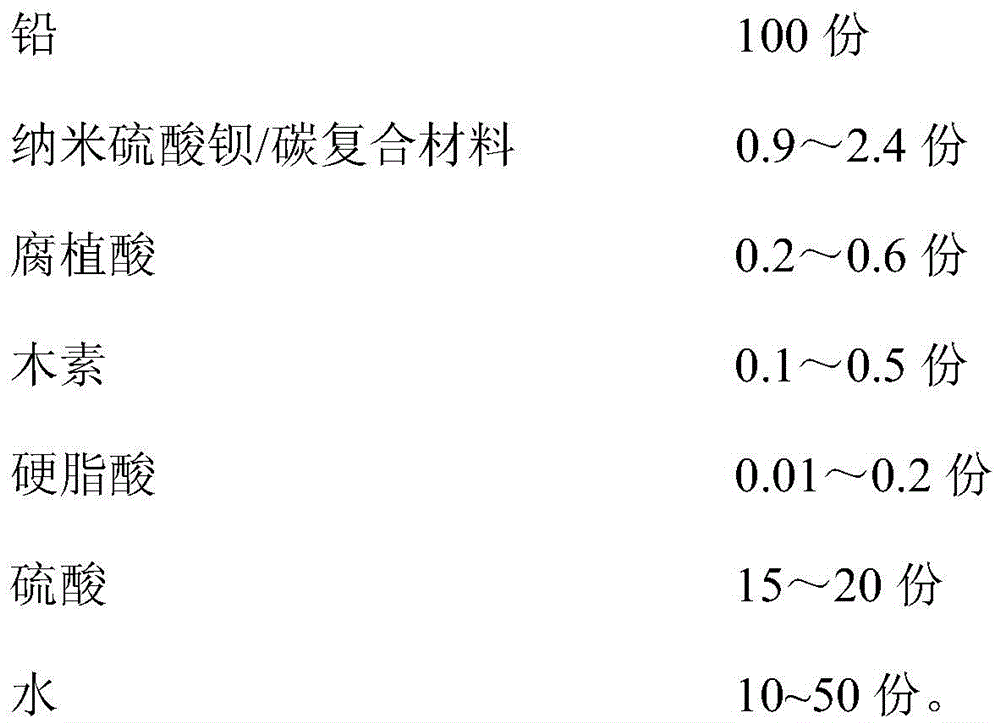

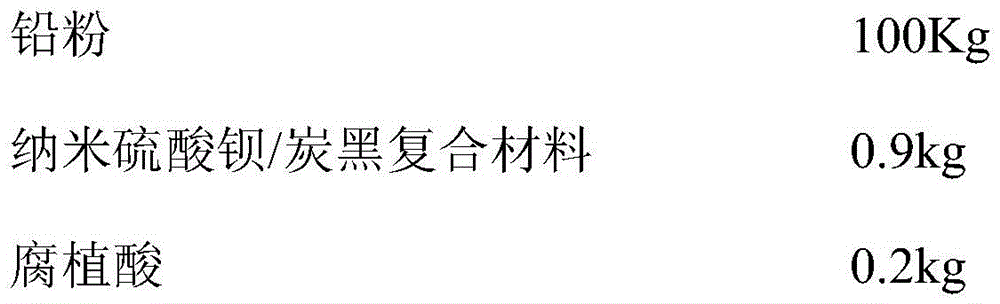

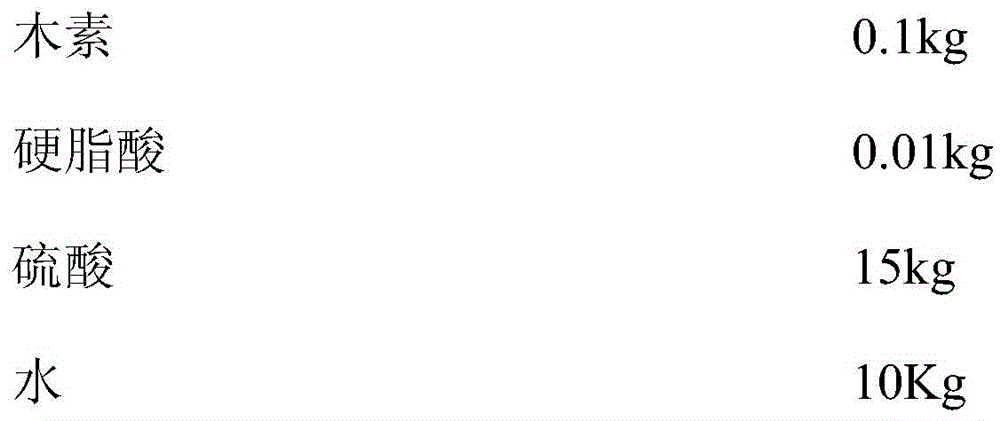

Nano barium sulfate carbon composite material and preparation method and application therefor

ActiveCN105576240ASimple methodShort cycleMaterial nanotechnologyHybrid capacitor electrodesCarbon compositesCharge discharge

The invention belongs to the field of an electrochemical energy storage material, and relates to a nano barium sulfate / carbon composite material and a preparation method and an application therefor. According to the nano barium sulfate / carbon composite material, the nano barium sulfate is distributed on the surface of the carbon material, and is in full contact with the surface of a lead plaster active material for providing a large amount of crystal nucleus for lead sulfate crystalline grain deposition; meanwhile, carbon combined with active locations of barium sulfate can transfer electrons, so that the conductivity in the reaction points is reinforced; and in addition, the preparation method for the nano barium sulfate / carbon composite material is simple in method, short in period, free of pollution, and high in advantages used in industrial production. A negative electrode material prepared by taking the nano barium sulfate / carbon composite material provided by the invention as one of the raw materials is excellent in the charge-discharge performance; the negative electrode sulfation phenomenon can be reduced; and the capacity retention ratio of the negative electrode material is still kept more than 90% after the negative electrode material is subjected to 2,000 charge-discharge circles at current of 1C for charge and at current of 0.3C for discharge, so that the advantage of high cost performance is achieved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

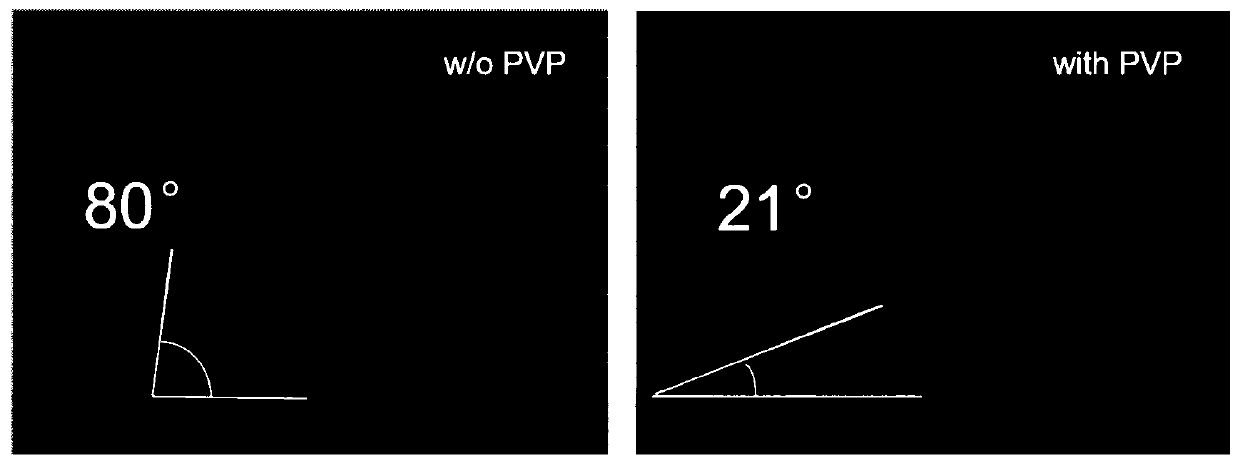

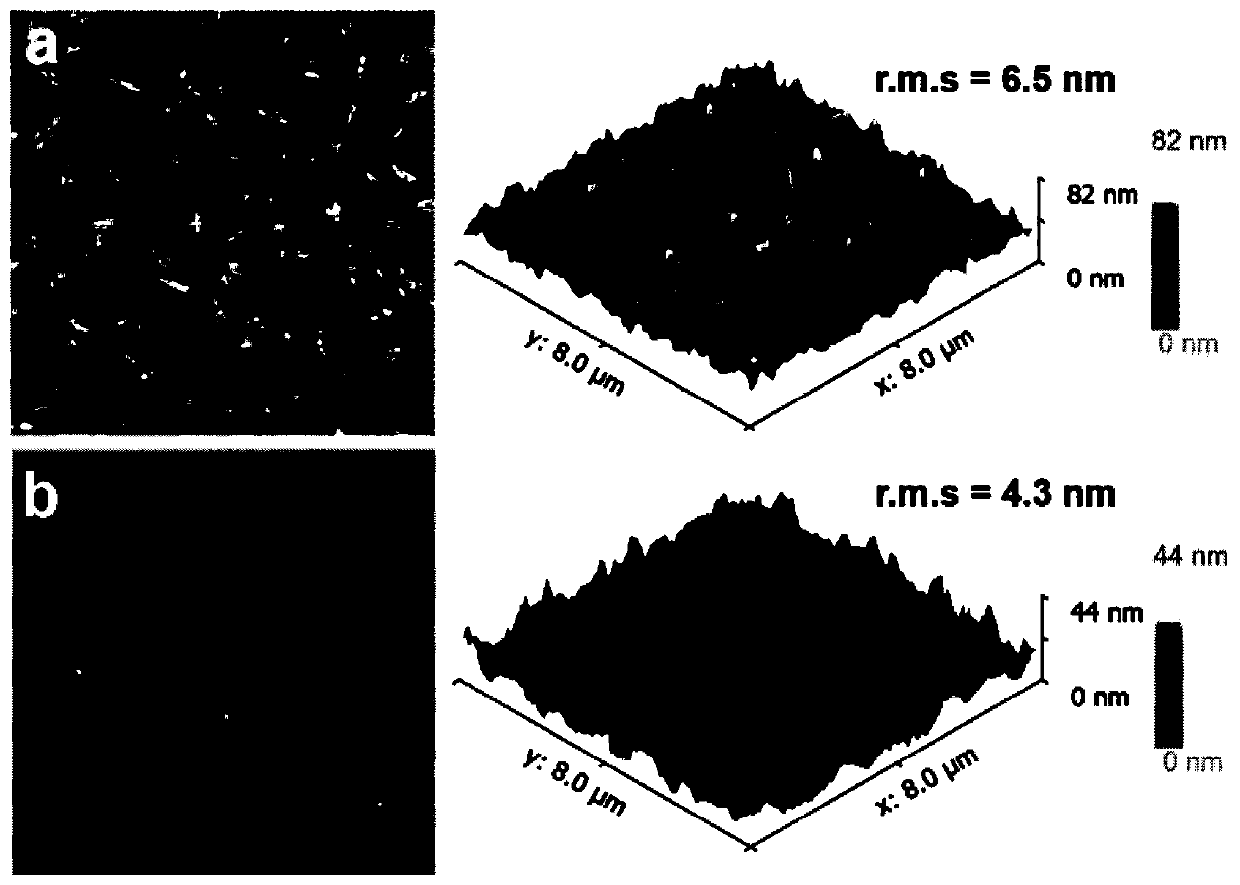

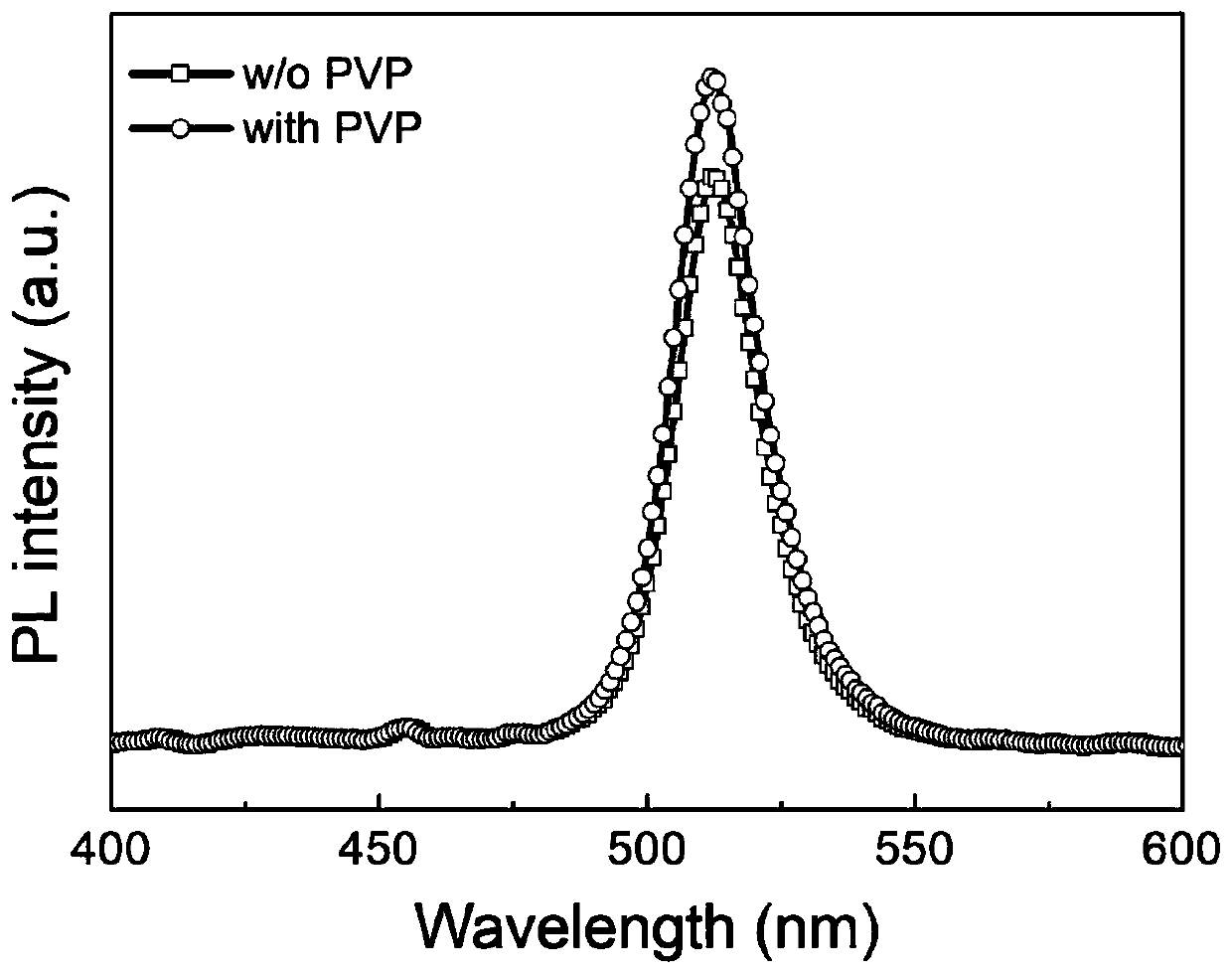

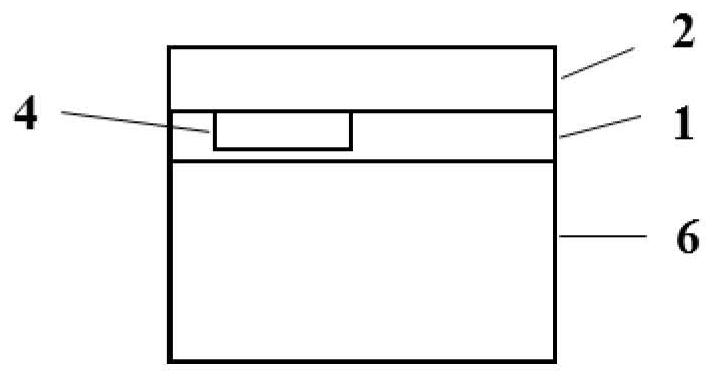

Method for depositing perovskite film on hydrophobic hole transport layer

InactiveCN110752322AImprove wettabilityImprove surface hydrophobic propertiesSolid-state devicesSemiconductor/solid-state device manufacturingFluorescenceThin membrane

The invention discloses a method for depositing a perovskite film on a hydrophobic hole transport layer. A high-quality perovskite film is prepared by using a hole transport layer modified by a polyvinylpyrrolidone (PVP) interface. A PVC interface modification layer can be introduced between the hole transport layer and the perovskite film to prepare the perovskite film with high smoothness and high fluorescence yield. Compared with the perovskite film prepared by the traditional method without PVC modification, the surface roughness of the film modified by the PVC interface is reduced, and the fluorescence yield is enhanced. In the method disclosed by the invention, the interface of HTL is modified by PVP, the pyrrolidone portion in the PVP has good hydrophilicity, so that the wettabilityof a perovskite precursor to the HTL is greatly improved, the nucleation site of the perovskite is improved, and smooth and flat perovskite films can be prepared.

Owner:SHANGHAI UNIV

High heat input welding high-intensity hot-rolled steel bar and production technology thereof

The invention discloses a high heat input welded high-intensity hot-rolled steel bar which comprises 0.27-0.29 percent of C, 0.15-0.17 percent of Si, 1.11-1.13 percent of Mn, 0.007-0.009 percent of P, 0.001-0.003 percent of S, 0.057-0.059 percent of Als, 0.005-0.007 percent of Nb, 0.06-0.08 percent of V, 0.035-0.037 percent of Ti, 0.05-0.07 percent of Ni, 0.07-0.09 percent of Cu, 0.6-0.8 percent of Cr, 0.53-0.55 percent of Mo, 0.007-0.009 percent of B, 0.07-0.09 percent of lanthanum, 0.03-0.05 percent of cerium, 0.01-0.03 percent of praseodymium and the balance of Fe. According to the high heat input welded high-intensity hot-rolled steel bar, the intensity of the steel bar and the toughness of a welding heat affecting region can be effectively improved.

Owner:TIANSHUN GROUP

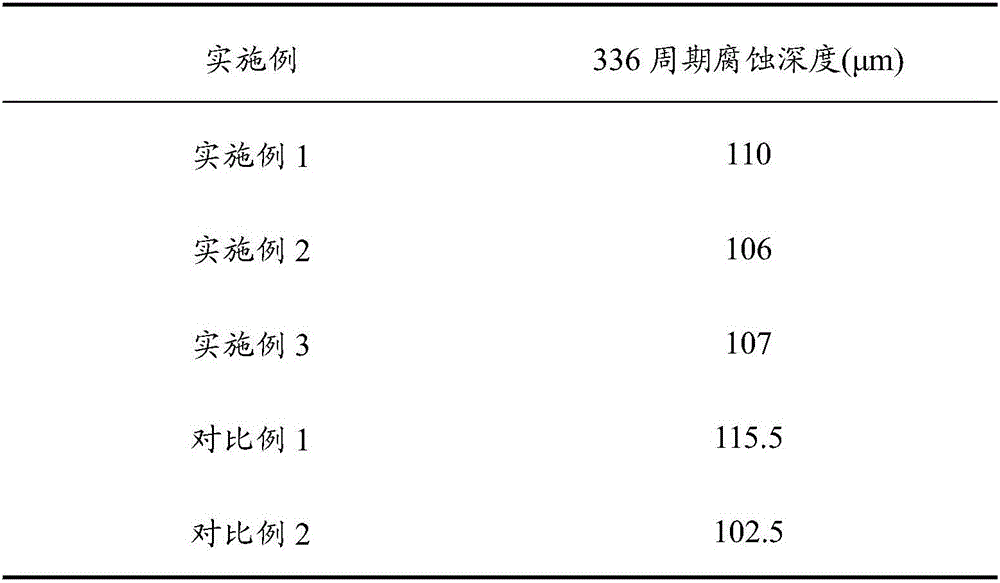

Low alloy weathering steel, and preparation method and application thereof

The invention provides a low alloy weathering steel. The low alloy weathering steel contains chemical components by following weight percentage: 0..02-0.05% of C, 0.6-1% of Mn, 0.2-0.4% of Cu, 15-0.5% of Ni, 0.04-0.07% of Nb, 0.005-0.015% of Ti, 0.3-0.6% of Si, <= 0.02% of Al, <=0.02% of P, <=0.08% of S and the balance of Fe and inevitable impurities. The low alloy weathering steel reduces usage amount of the high cost alloy elements of Cr and Ni by improving content of the low cost alloy element of Si, and adopts synergistic effects among the alloy elements to reduce usage of the high cost alloy elements and achieve maximization of cost effectiveness. Simultaneously, the low alloy weathering steel has good comprehensive mechanical properties, and is suitable for application requirements of bridges and the like under industrial marine atmospheric environment.

Owner:NORTHEASTERN UNIV

Curing liquid applicable to calcium phosphate-based bone cement as well as preparation method and application of curing liquid

ActiveCN109125804AImprove curing effectImprove early strengthTissue regenerationProsthesisCalcium biphosphatePhosphate

The invention provides curing liquid applicable to calcium phosphate-based bone cement as well as a preparation method and application of the curing liquid. The curing liquid applicable to the calciumphosphate-based bone cement comprises the following components by mass percentage: 2-9% of citric acid, 1-6% of PVP, 5-25% of phosphate and 1-5% of PVA. The invention creatively utilizes the abilityof phosphate to promote early hydration products; an acidic environment is provided by citric acid; PVP has a molecular mediated effect on calcium phosphate deposition; PVA has a water-retaining function; through the synergistic effect of citric acid, phosphate, PVP and PVA, the mechanical properties of calcium phosphate bone cement such as curing ability, early strength, late strength and the like are significantly improved, the medical value of calcium phosphate bone cement is expanded, at the same time, calcium phosphate bone cement is closer to clinical use standards, and calcium phosphatebone cement has broad application prospects.

Owner:JINAN UNIVERSITY

Method for improving room-temperature tensile property of Ti-48Al-2Cr-2Nb alloy through adding of nano Y2O3

InactiveCN105821232AImprove plasticityIncreased tensile strength at room temperatureCrucibleRoom temperature

The invention discloses a method for improving the room-temperature tensile property of a Ti-48Al-2Cr-2Nb alloy through adding of nano Y2O3, and belongs to the field of room-temperature mechanical properties of metal materials. The method for improving the room-temperature tensile property of the Ti-48Al-2Cr-2Nb alloy through adding of the nano Y2O3 aims at solving the problem that an existing directly-casted Ti-48Al-2Cr-2Nb alloy is coarse in structure, and serious in segregation. The method comprises the steps that nano Y2O3 particles are added in the Ti-48Al-2Cr-2Nb alloy, a water cooled copper crucible is adopted to induce a solidification shell smelting furnace, and under the high-vacuum / argon environment, through the melt reaction, a full-lamellar structure with the fine Y2O3 particles evenly distributed in a dispersed manner is directly generated. After the nano Y2O3 is added, the room-temperature tensile strength of the alloy is obviously improved, and the room-temperature plasticity of the alloy is greatly improved.

Owner:HARBIN INST OF TECH

A kind of high-strength and high-conductivity rare earth copper-zirconium alloy and its preparation method

A high-strength and high-conductivity rare earth copper-zirconium alloy. The copper-zirconium alloy is composed of zirconium, nickel, silicon, copper and rare earth elements. 0.1~0.5%, silicon 0.1~0.15%, silver 0.2~0.4%, rare earth elements 0.02~0.1%, and the balance is copper. Beneficial effects of the invention: the invention has the characteristics of simple preparation process, short process flow, high strength, high conductivity, high elasticity, excellent thermal processing performance, etc., and its tensile strength can reach 690 MPa.

Owner:HENAN UNIV OF SCI & TECH

Preparation method of high-performance bridge weathering steel containing Mo

The invention belongs to the field of manufacture of low-alloy steel, in particular to high-performance bridge weathering steel containing Mo and a preparation method thereof. The invention provides bridge weathering steel containing Mo with the high performance, which comprises the following chemical components by mass percent: 0.02-0.05 percent of C, 0.20-0.30 percent of Si, 1.0-1.50 percent of Mn, at most 0.02 percent of P, at most 0.010 percent of S, 0.20-0.40 percent of Cu, 0.40-0.60 percent of Cr, 0.20-0.40 percent of Ni, 0.1-0.30 percent of Mo, 0.04-0.07 percent of Nb, 0.005-0.015 percent of Ti, at most 0.02 percent of Al and the balance of Fe and inevitable impurities. The high-performance bridge weathering steel containing Mo adopts two stages of rolling. The rough rolling and bloom rolling temperature of the first stage is 1050-1070 DEG C, the precision rolling and bloom rolling temperature of the second stage is 900-950 DEG C, and the finish rolling temperature is 800-850 DEG C. The high-performance bridge weathering steel containing Mo disclosed by the invention has good mechanical property, welding performance and atmospheric-corrosion resistance performance. The high-performance bridge weathering steel containing Mo adopts an Ultra-low carbon design, and the production cost is low.

Owner:NORTHEASTERN UNIV LIAONING +1

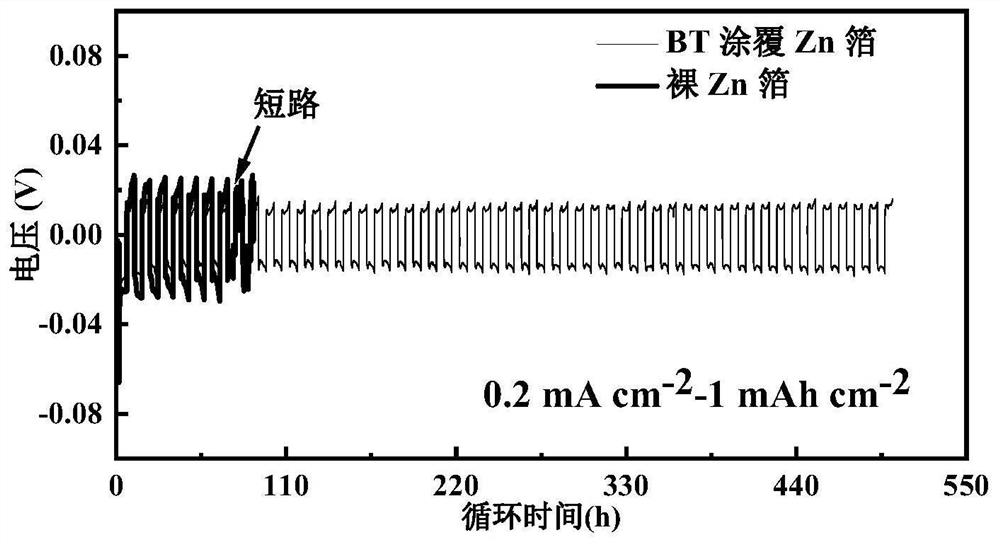

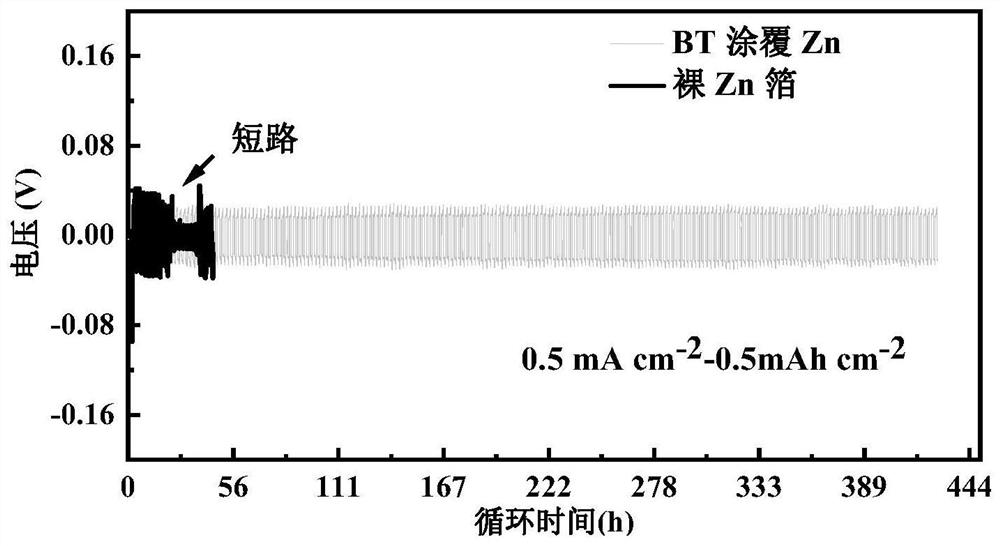

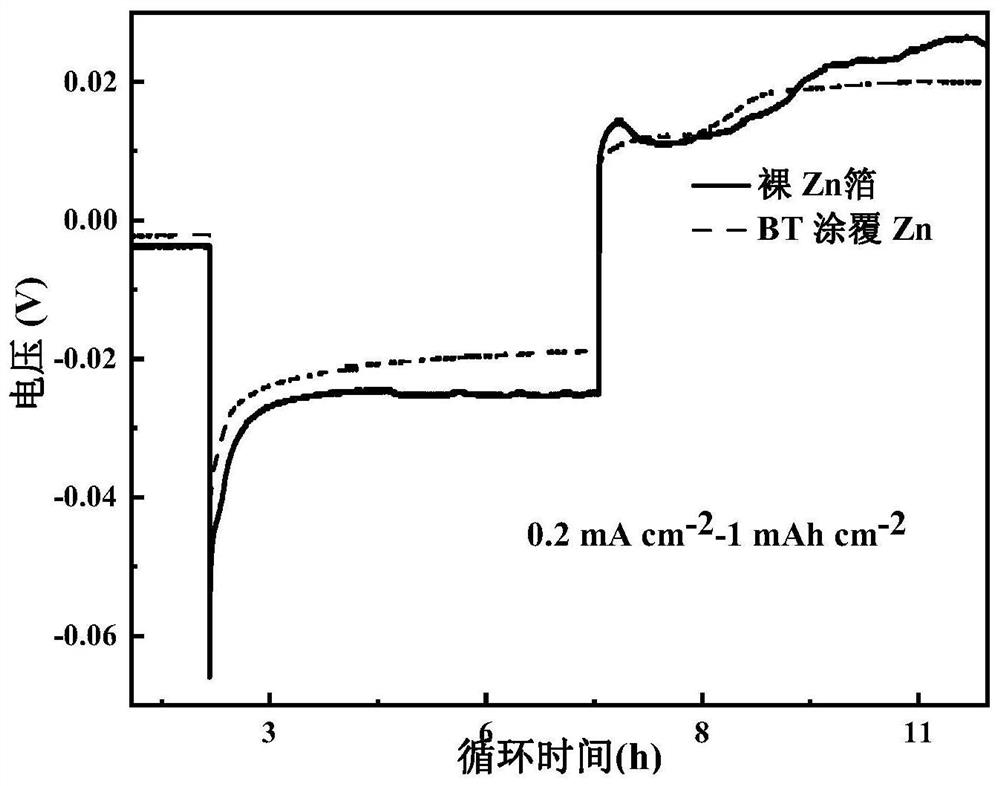

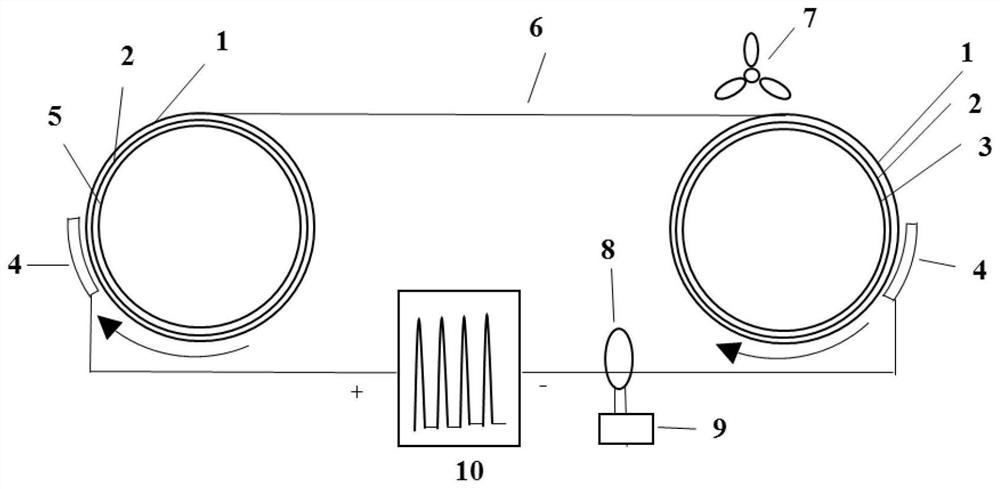

Electrode coating as well as preparation method and application thereof

ActiveCN112072105AAvoid corrosionInhibitory reactivityElectrode carriers/collectorsActive material electrodesDielectricElectrolytic agent

The invention discloses an electrode coating as well as a preparation method and an application thereof. According to a coating formed by the coating, the uniformity of zinc deposition is adjusted byusing a cheap nano dielectric filler, on one hand, transmission of zinc ions can be adjusted by a nano channel formed by nano particles, and on the other hand, nucleation sites of zinc on an electrodecan be increased, so that dendritic-crystal-free zinc deposition is realized. Meanwhile, water molecules in an electrolyte can be effectively isolated under the barrier action of dipoles generated bythe coating containing the high-dielectric-constant nano filler and physics, so that corrosion and hydrogen evolution reaction on the zinc negative electrode are inhibited, and the stability of the zinc negative electrode can be remarkably improved. A coating layer formed by the coating is large in dielectric filler proportion, dipole-dipole effect produced by the dielectric filler can be used, distribution of zinc ions relative to the surface of an electrode can be adjusted through the electrostatic interaction of dipoles and the zinc ions, the tip electric field enhancement effect is weakened, nucleation sites on the surface of the electrode are increased, and therefore dendritic crystals are effectively restrained from being generated.

Owner:HUNAN UNIV OF SCI & TECH

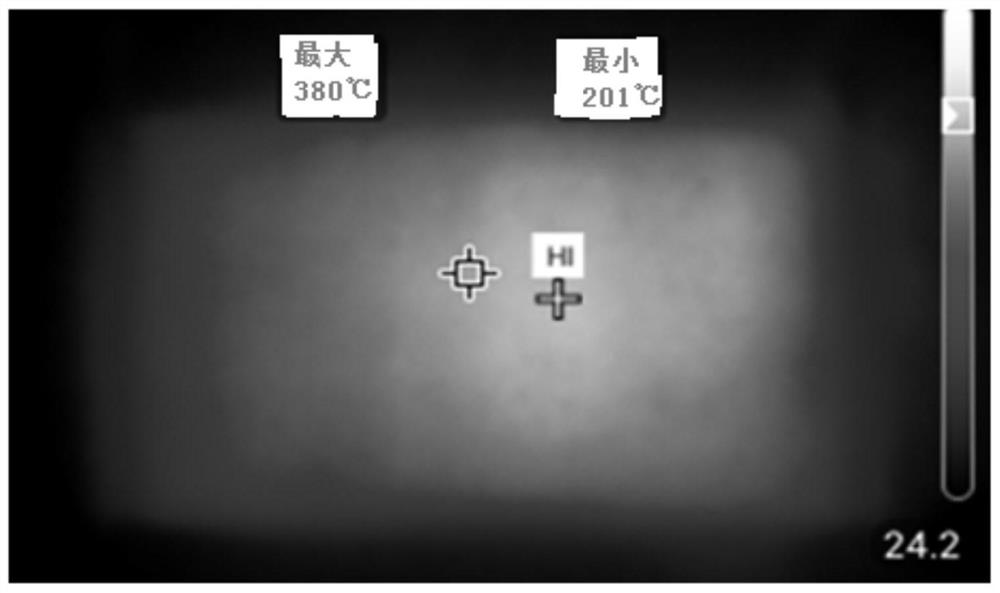

Accelerated aging treatment method for metal plate strip

PendingCN113122697AHigh strengthImprove conductivityFurnace typesHeat treatment furnacesAccelerated agingEngineering

The invention provides an accelerated aging treatment method for a metal plate strip. The method comprises the following steps of: conducting pulse current to the metal plate strip through a roller type positive electrode and a roller type negative electrode, and the like, so as to realize the aging treatment of the pulse current on metal. According to the method, the used current frequency is 50-1000 Hz, the peak current is 1000-500 KA, and the pulse width is smaller than 100 microseconds. According to the pulse current aging treatment provided by the invention, diffusion of solute atoms is accelerated, nucleation and growth of a second phase are accelerated, the aging process is shortened, and the comprehensive performance of the metal plate strip is improved.

Owner:CHINALCO MATERIALS APPL RES INST CO LTD

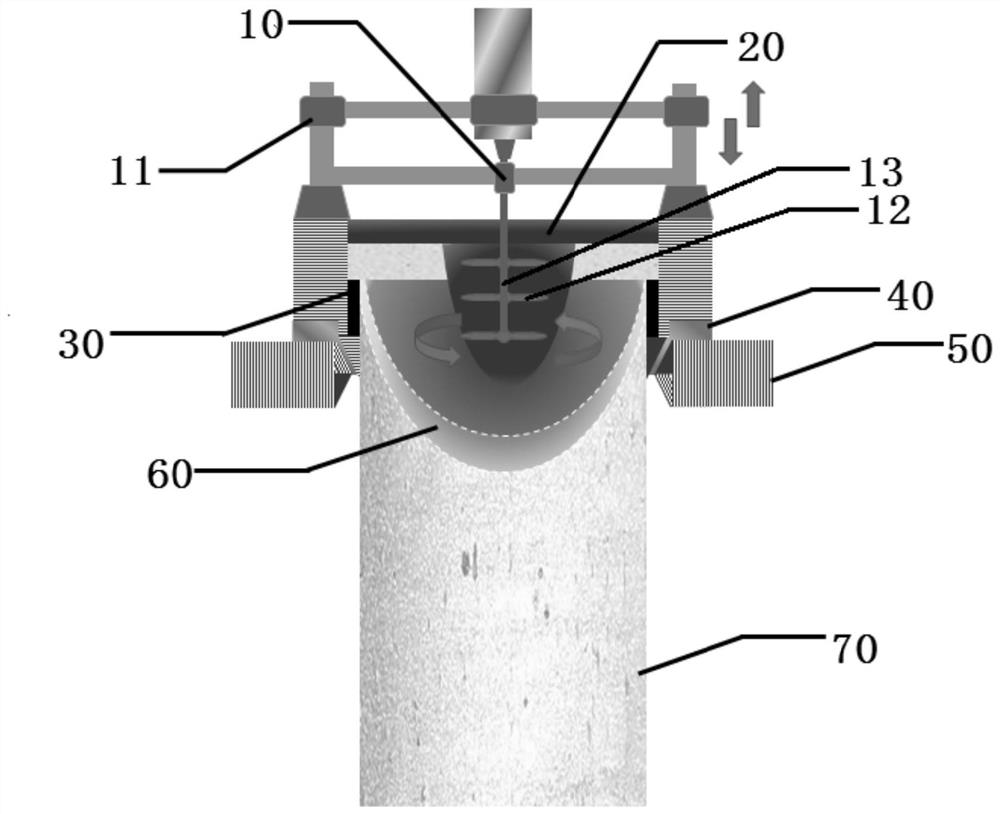

Casting method of aluminum alloy cast rod

The invention provides a casting method of an aluminum alloy cast rod. Chemical composition elements of the aluminum alloy cast rod and the structure of a crystallizer are optimized so that when the aluminum alloy cast rod is cast, a temperature adjusting device, the stirring speed and the stirring time can be more accurately controlled through a controller, formability of aluminum alloy melt is guaranteed, meanwhile, uniformity of the internal temperature of the aluminum alloy melt can be guaranteed, the situation that an aluminum alloy dendritic crystal arm is broken into dendritic crystal fragments is effectively reduced, nucleation positions are added, more non-uniform nucleation occurs, the grain refining effect is remarkably generated, then the tendency that cracks are generated on the cast rod is reduced, the casting smelting quality is improved, and the yield is increased. The problems that when a large-size and large-diameter aluminum alloy cast rod is cast, the temperature of aluminum alloy melt is not uniform due to the high casting temperature, consequently, the cooling speeds and the cooling degrees of all parts of the cast rod are different, the cracking tendency exists, and cracks are generated in the cast rod are effectively solved.

Owner:佛山市三水凤铝铝业有限公司 +1

Ca-containing low-ally weathering-resistant steel and preparation method and application thereof

ActiveCN106591719AUniform tissueHigh strengthBridge structural detailsChemical IngredientsCorrosion resistant

The invention provides Ca-containing low-alloy weathering-resistant steel. Chemical ingredients of the Ca-containing low-alloy weathering-resistant steel include, by mass, 0.02%-0.05% of C, 0.20%-0.30% of Si, 0.6%-1.00% of Mn, 0.005%-0.010% of Ti, 0.0005%-0.0020% of Ca, 0.20%-0.40% of Cu, 0.20%-0.60% of Ni, 0.04%-0.07% of Nb, not larger than 0.02% of P, not larger than 0.08% of S, not larger than 0.02% of Al and the balance Fe and inevitable impurities. The size and distribution of inclusions in the steel can be changed by adding the appropriate amount of Ca, the tiny inclusions in the steel are easily generated and are evenly dispersed and distributed, the structure of the steel can be more uniform, the strength of the steel is improved, the weathering resistance of the steel can be effectively improved by using the Ca and other elements such as Si and Cu in cooperation, the weathering resistance of the steel under the natural condition is improved, and the corrosion-resistant performance of the steel is improved.

Owner:NORTHEASTERN UNIV

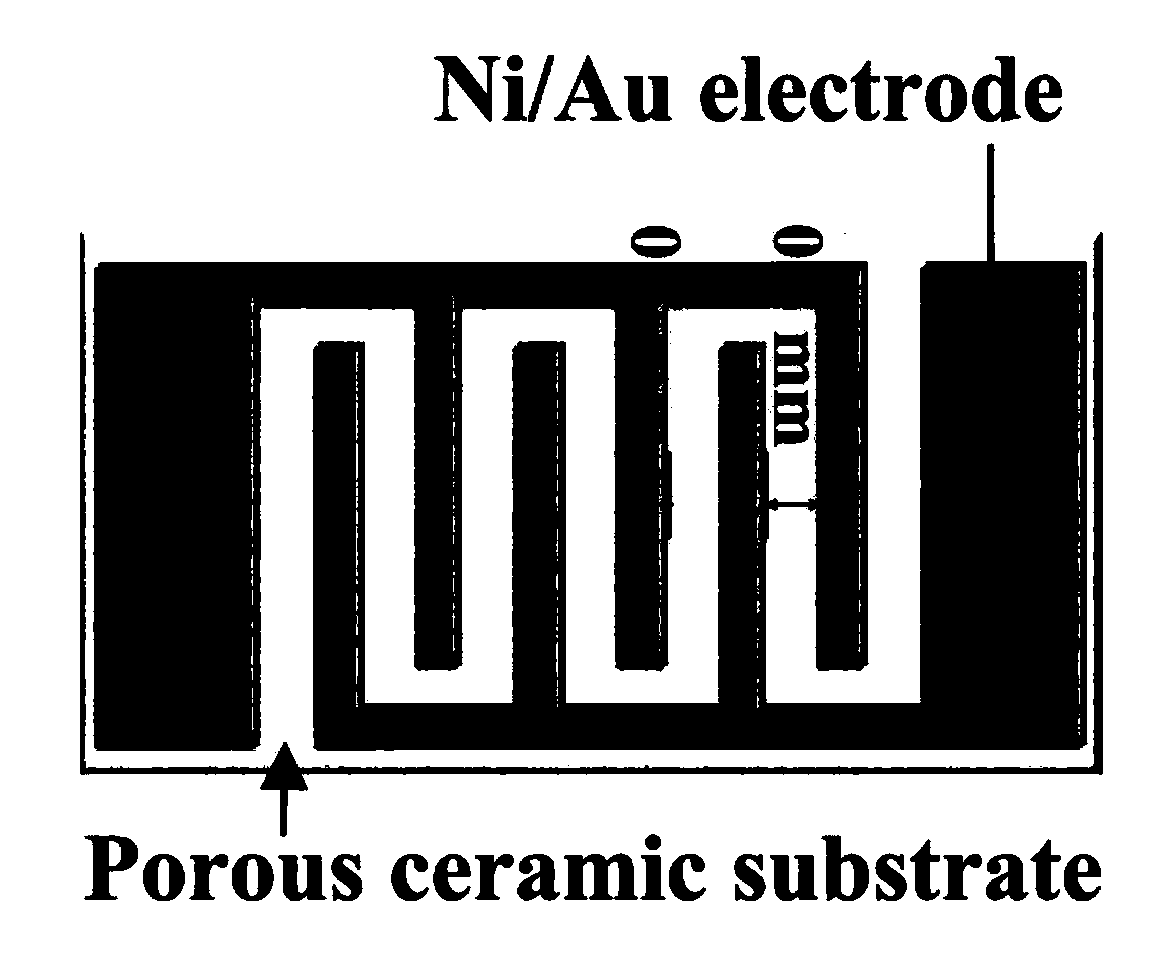

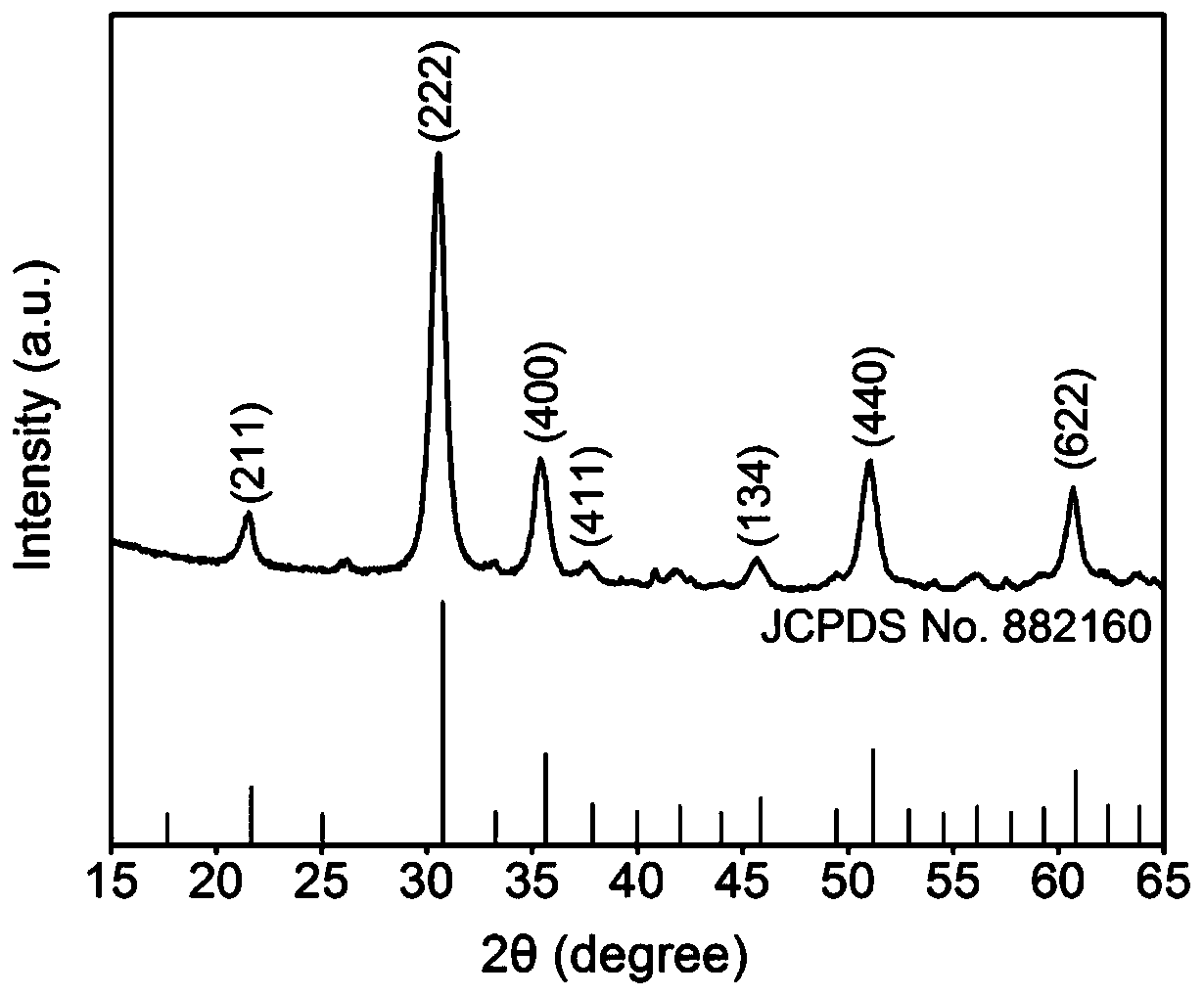

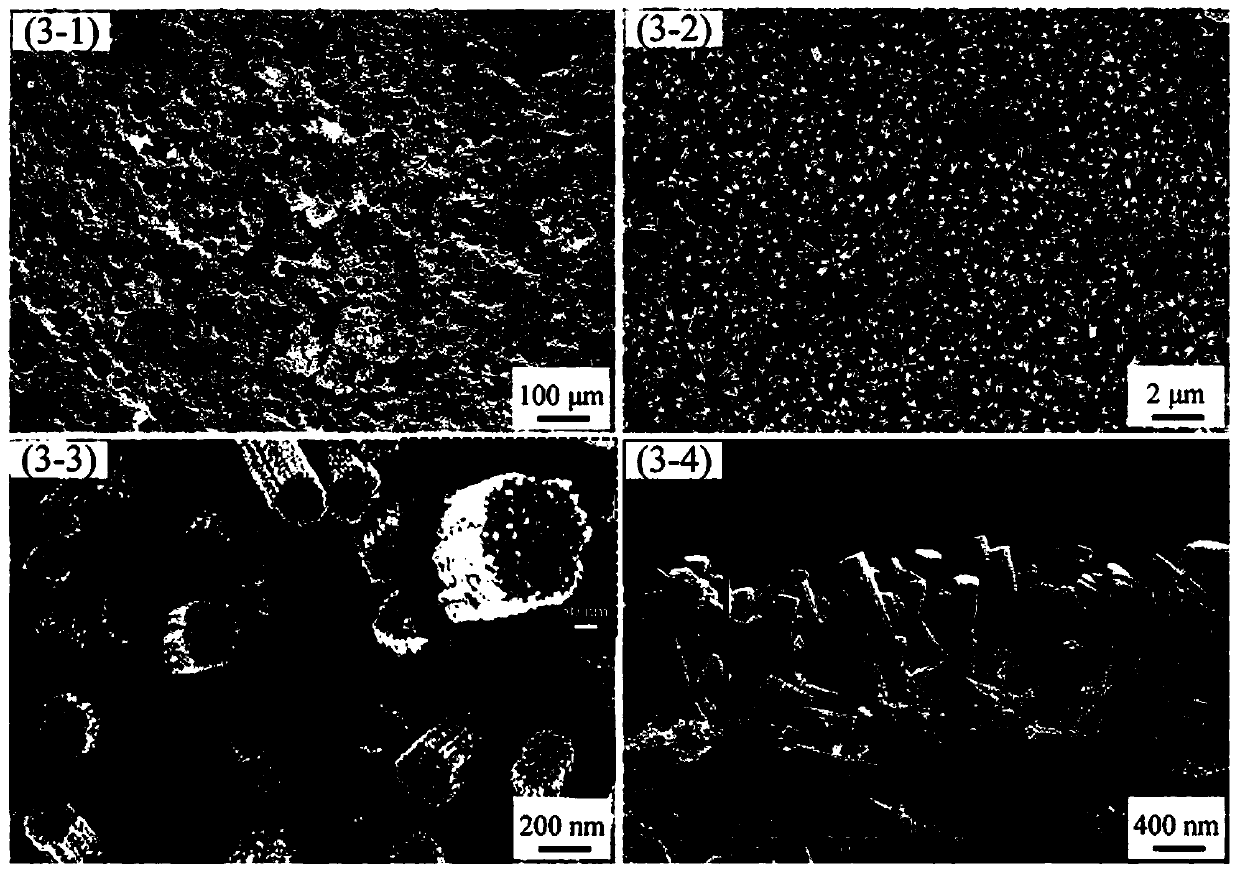

Room temperature NO2 sensor based on in-situ growth nano In2O3 on surface of non-metal mineral electrode substrate and preparation method

ActiveCN110261445AIncrease nucleation sitesHigh densityMaterial nanotechnologyNanosensorsOxide semiconductorOxide

The invention discloses a room temperature NO2 sensor based on in-situ growth nano In2O3 on the surface of a non-metal mineral electrode substrate and a preparation method, which belong to the field of gas sensors of metal oxide semiconductor materials. According to the invention, a non-metal mineral porous ceramic electrode is used as a substrate; a direct current sputtering method is used to sputter an interdigital electrode on the surface of the substrate, and the In2O3 nano material hydrothermally grows in situ on the surface thereof; the In2O3 nano material is in a rod-like structure and uniformly and densely distributed on the surface of the substrate, wherein the diameter thereof is 120 to 200nm and the length thereof 0.5 to 1 micron; the rod-like structure is composed of nanoparticles stacked on each other; the nanoparticles are in the structure of In2O3 cubic phase crystals, and the diameter thereof is 10 to 30 nm. The gas sensor can have a fast response and recovery rate for 0.1 to 1 ppm NO2 under room temperature working conditions and under UV light assisted recovery, and has the advantages of excellent selectivity, long-term stability and good application prospects.

Owner:NORTHEASTERN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com