High-strength weather-proof bridge steel and preparation method thereof

A bridge steel and weather-resistant technology, which is applied in the field of special steel smelting, can solve problems such as insufficient low-temperature toughness, uneven structure, and poor weather resistance, and achieve the effects of improved welding performance, low production cost, and good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be described in more detail below in conjunction with preferred embodiments of the present invention.

[0026] The chemical composition (by weight percentage) of the bridge steel of the present invention is: C: 0.03-0.06%, Si: 0.20-0.50%, Mn: 0.70-1.00%, P≤0.030%, S≤0.003%, Cu: 0.25~ 0.60%, Ni: 0.18-0.45%, Cr: 0.30-0.70%, Nb: 0.030-0.080%, Als≤0.010%, and the balance is Fe and unavoidable impurities.

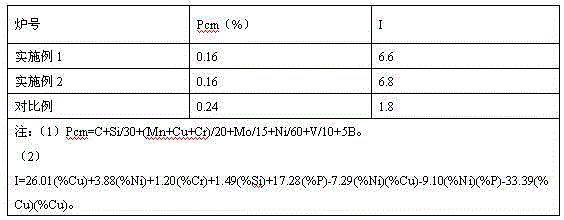

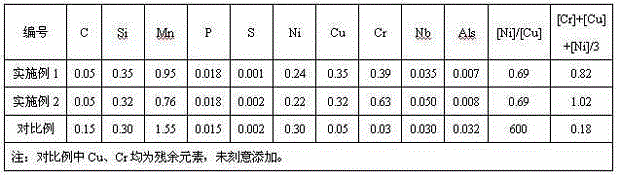

[0027] The specific chemical composition (wt%) of the bridge steel of each embodiment and the selected comparative examples is shown in Table 1.

[0028] Table 1

[0029]

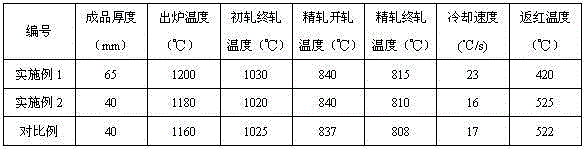

[0030] The specific preparation process of the bridge steel involved in the embodiment is as follows: the smelting raw materials are pretreated by molten iron, steelmaking in a converter, RH vacuum degassing is carried out after LF refining, and a 370mm thick cast slab is formed by protective pouring, and the continuous cast slab is heated to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com