Vacuum carburizing heat treatment process for low-carbon high-alloy steel

A technology of vacuum carburizing and high-alloy steel, which is applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., to achieve the effects of improving diffusion efficiency, accelerating carburizing speed, and reducing internal and external temperature differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

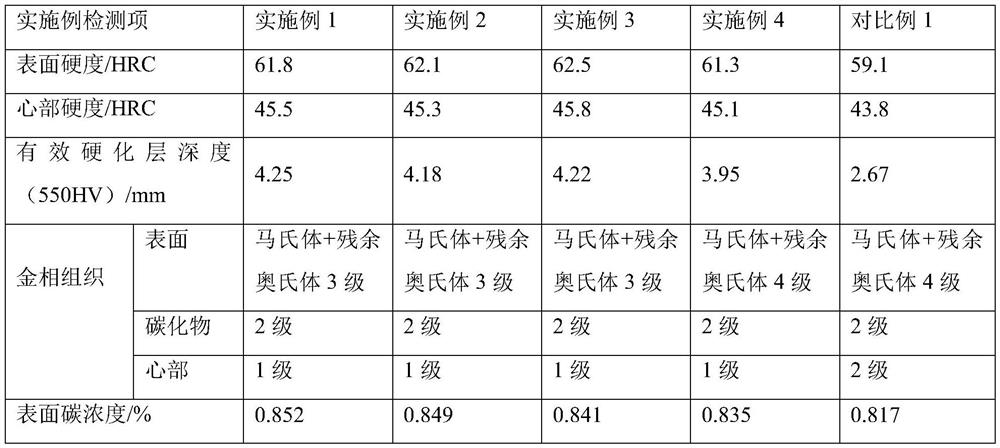

Examples

Embodiment 1

[0050] A low-carbon high-alloy steel vacuum carburizing heat treatment process, comprising the following steps:

[0051] S1. Pre-cleaning stage: Put the workpiece into the vacuum immersion cleaning machine, and clean it with a degreasing hydrocarbon cleaning agent. The cleaning temperature is 110°C. After cleaning the oil stains on the surface of the workpiece, take it out;

[0052] S2. The first stage of uniform temperature: put the workpiece into the heating chamber of the vacuum carburizing oil quenching furnace, heat it to 845 ° C, and keep it for 90 minutes;

[0053]S3, the second stage of uniform temperature: heat the vacuum carburizing oil quenching furnace to 985°C and keep it for 100min;

[0054] S4. Carburizing stage: keep the temperature of the vacuum carburizing oil quenching furnace at 985°C, continuously feed acetylene into the vacuum carburizing oil quenching furnace, and the flow rate of acetylene is 14L / min. Vacuum the carbon oil quenching furnace and keep it...

Embodiment 2

[0062] A low-carbon high-alloy steel vacuum carburizing heat treatment process, comprising the following steps:

[0063] S1. Pre-cleaning stage: Put the workpiece into a vacuum immersion cleaning machine, and clean it with a degreasing hydrocarbon cleaning agent. The cleaning temperature is 120 ° C. After cleaning the oil stains on the surface of the workpiece, take it out;

[0064] S2. The first stage of uniform temperature: put the workpiece into the heating chamber of the vacuum carburizing oil quenching furnace, heat it to 855°C, and keep it for 110min;

[0065] S3, the second stage of uniform temperature: heat the vacuum carburizing oil quenching furnace to 980°C and keep it for 90min;

[0066] S4. Carburizing stage: keep the temperature of the vacuum carburizing oil quenching furnace at 980°C, continuously feed acetylene into the vacuum carburizing oil quenching furnace, and the flow rate of acetylene is 13L / min. Vacuum the carbon oil quenching furnace and keep it for 2...

Embodiment 3

[0074] A low-carbon high-alloy steel vacuum carburizing heat treatment process, comprising the following steps:

[0075] S1. Pre-cleaning stage: Put the workpiece into a vacuum immersion cleaning machine, and clean it with a degreasing hydrocarbon cleaning agent. The cleaning temperature is 130°C. Clean the oil stains on the surface of the workpiece and take it out;

[0076] S2. The first stage of uniform temperature: put the workpiece into the heating chamber of the vacuum carburizing oil quenching furnace, heat it to 850°C, and keep it for 100min;

[0077] S3, the second stage of uniform temperature: heat the vacuum carburizing oil quenching furnace to 975°C and keep it for 110min;

[0078] S4. Carburizing stage: keep the temperature of the vacuum carburizing oil quenching furnace at 975°C, and continuously feed acetylene into the vacuum carburizing oil quenching furnace. The flow rate of acetylene is 15L / min. Vacuum the carbon oil quenching furnace and keep it for 205 minu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com