Ca-containing low-ally weathering-resistant steel and preparation method and application thereof

A weathering steel and low-alloy technology, used in buildings, bridges, bridge parts, etc., can solve the problem of high alloy cost, and achieve the effects of improving corrosion resistance, weather resistance, and strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A low-alloy weathering steel containing Ca, its chemical composition and mass percentage content are: C: 0.03%; Si: 0.22%; Mn: 0.75%; Cu: 0.31%; Ni: 0.22%; Nb: 0.06%; Ti: 0.01%; P: 0.02%; S: 0.007%; Ca: 0.001%; the rest is Fe and unavoidable impurities.

[0035] The preparation method of the Ca-containing low-alloy weathering steel comprises the following steps:

[0036] Use a vacuum induction furnace to melt 200kg of molten steel with the chemical composition shown above, cast the melted steel to form a steel ingot, billet the steel ingot and hot forge it into a billet with a section of 80mm×80mm×400mm, heat the billet to 1200°C, and keep it warm 30min;

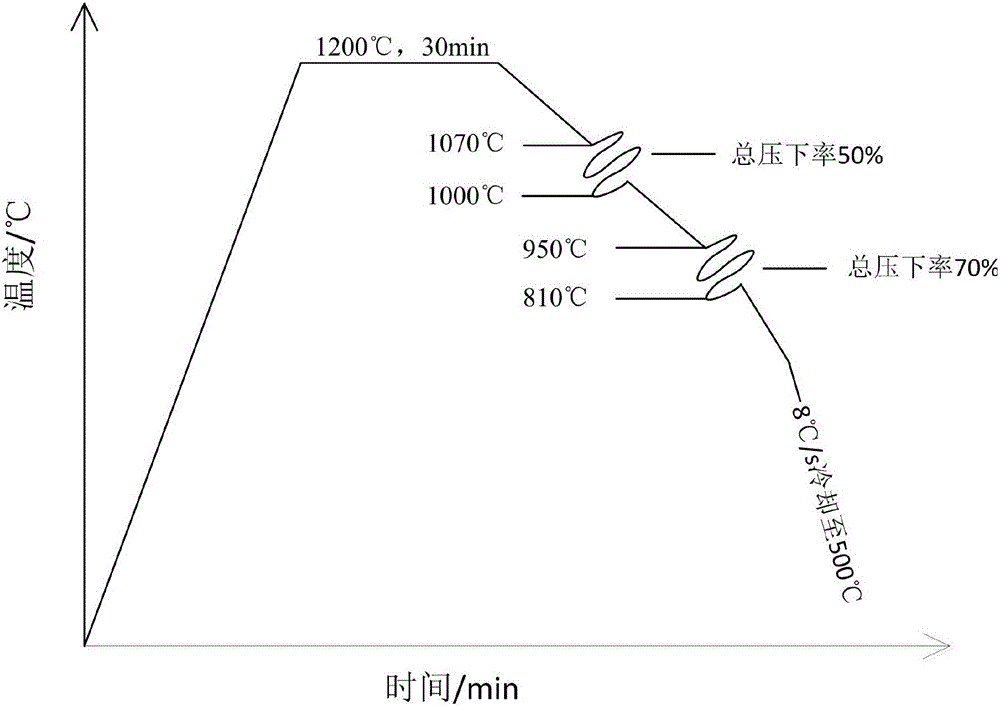

[0037] Two-stage controlled rolling is adopted, and the schematic diagram of the rolling process is as follows: figure 1 As shown, the first stage is rough rolling, the starting temperature is 1070°C, the cumulative reduction rate is 50%, and the final rolling temperature is 1000°C; the second stage is finish roll...

Embodiment 2

[0039] A low-alloy weathering steel containing Ca, its chemical composition and mass percentage content are: C: 0.027%; Si: 0.23%; Mn: 0.63%; Cu: 0.31%; Ni: 0.21%; Nb: 0.07%; Ti: 0.010%; P: 0.015%; S: 0.002%; Ca: 0.0008%; the rest is Fe and unavoidable impurities.

[0040] The preparation method of the Ca-containing low-alloy weathering steel comprises the following steps:

[0041] Use a vacuum induction furnace to melt 200kg of molten steel with the chemical composition shown above, cast the melted steel to form a steel ingot, billet the steel ingot and hot forge it into a billet with a section of 80mm×80mm×400mm, heat the billet to 1200°C, and keep it warm 30min;

[0042] Two-stage controlled rolling is adopted, the first stage is rough rolling, the starting temperature is 1060℃, the cumulative reduction rate is 50%, and the final rolling temperature is 1000℃; the second stage is finish rolling, the starting temperature is 950℃, and the final rolling temperature is 1000℃. ...

Embodiment 3

[0044] A low-alloy weathering steel containing Ca, its chemical composition and mass percentage content are: C: 0.03%; Si: 0.22%; Mn: 0.75%; Cu: 0.35%; Ni: 0.42%; Nb: 0.06%; Ti: 0.01%; P: 0.02%; S: 0.002%; Ca: 0.0013%; the rest is Fe and unavoidable impurities.

[0045] The preparation method of the Ca-containing low-alloy weathering steel comprises the following steps:

[0046] Use a vacuum induction furnace to melt 200kg of molten steel with the chemical composition shown above, cast the melted steel to form a steel ingot, billet the steel ingot and hot forge it into a billet with a section of 80mm×80mm×400mm, heat the billet to 1200°C, and keep it warm 30min;

[0047] Two-stage controlled rolling is adopted, the first stage is rough rolling, the starting temperature is 1060℃, the cumulative reduction rate is 50%, and the final rolling temperature is 1000℃; the second stage is finish rolling, the starting temperature is 950℃, and the final rolling temperature is 1000℃. The...

PUM

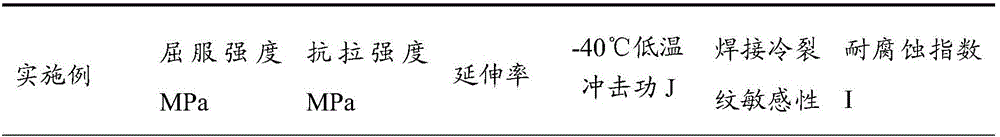

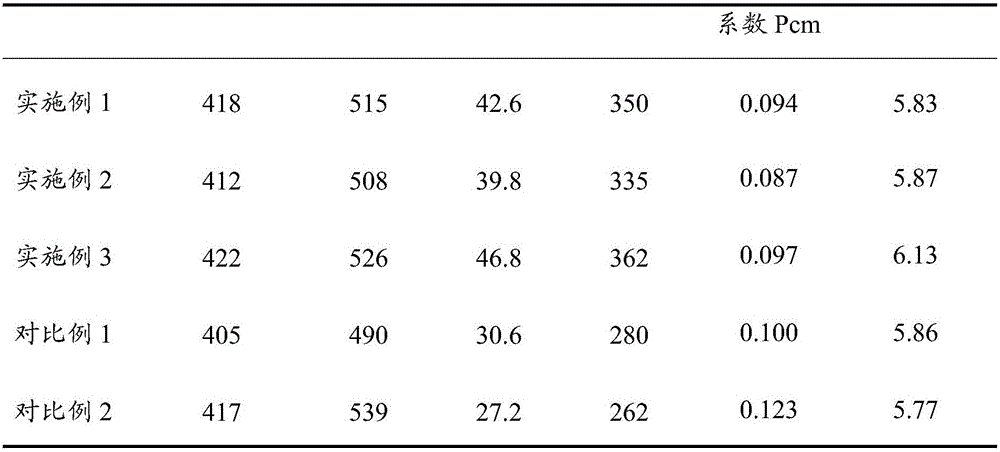

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com