Preparation method of graphene-reinforced copper-based composite

A copper-based composite material and graphene technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of poor dispersion and poor metal wettability, and achieve the effect of fast temperature rise, uniform heating, and good tissue performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

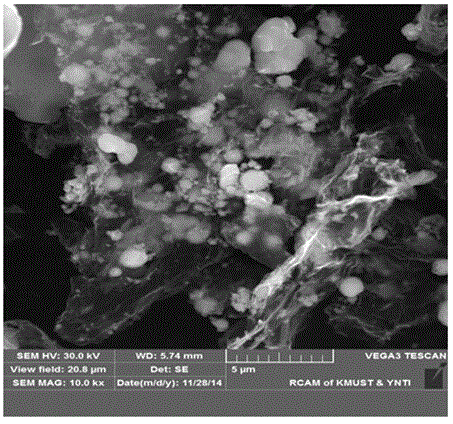

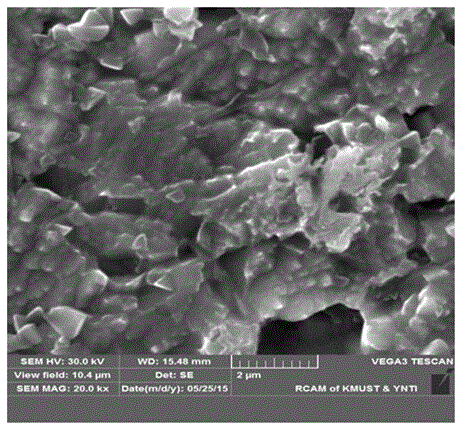

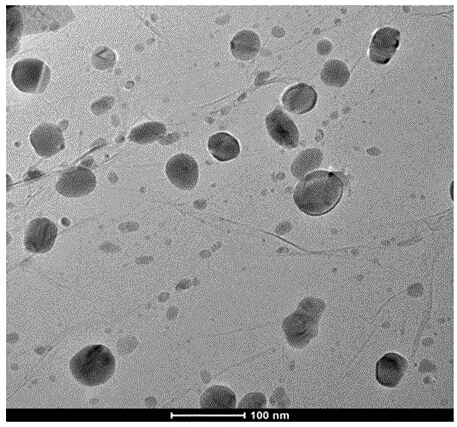

Image

Examples

Embodiment 1

[0031] The preparation method of the graphene-reinforced copper-based composite material described in this embodiment specifically comprises the following steps:

[0032] (1) Mix graphene (thickness 0.8~1.2nm), nano-copper powder (R200~500nm), nano-cobalt powder (R30~100nm) to obtain a mixed material, and the volume ratio of ethanol to mixed powder is 2:1 Proportion Put the mixed material in absolute ethanol (mass percentage concentration of absolute ethanol ≥ 99.7%), vibrate on an electromagnetic oscillator (power 150w) for 1 hour to physically disperse the mixed slurry, and graphene in the mixed material The mass percentage is 0.1%, the mass percentage of the nano-cobalt powder is 5%, and the mass percentage of the nano-copper powder is 94.9%.

[0033] (2) Put the mixed slurry in a ball mill for 2 hours to obtain a composite powder, wherein the rotational speed during the ball milling process is 100r / min, the ball-to-material ratio is 5:1, and the composite powder is dried i...

Embodiment 2

[0039] The preparation method of the graphene-reinforced copper-based composite material described in this embodiment specifically comprises the following steps:

[0040](1) Mix graphene (thickness 0.8~1.2nm), nano-copper powder (R200~500nm), nano-cobalt powder (R30~100nm) to obtain a mixed material, according to the volume ratio of ethanol and mixed powder is 3:1 Proportion Put the mixed material in absolute ethanol (mass percentage concentration of absolute ethanol ≥ 99.7%), vibrate on an electromagnetic oscillator (power 100w) for 2 hours to physically disperse the mixed slurry, and graphene in the mixed material The mass percentage is 0.6%, the mass percentage of the nano-cobalt powder is 1%, and the mass percentage of the nano-copper powder is 98.4%.

[0041] (2) Put the mixed slurry in a ball mill for ball milling for 6 hours to obtain a composite powder, wherein the rotational speed during the ball milling process is 300r / min, the ball-to-material ratio is 20:1, and the...

Embodiment 3

[0047] The preparation method of the graphene-reinforced copper-based composite material described in this embodiment specifically comprises the following steps:

[0048] (1) Mix graphene (thickness 0.8~1.2nm), nano-copper powder (R200~500nm), nano-cobalt powder (R30~100nm) to obtain a mixed material, and the volume ratio of ethanol to mixed powder is 5:1 Proportion Put the mixed material in absolute ethanol (mass percentage concentration of absolute ethanol ≥ 99.7%), vibrate on an electromagnetic oscillator (power 80w) for 4 hours to physically disperse the mixed slurry, and the graphene in the mixed material The mass percentage is 1%, the mass percentage of the nano-cobalt powder is 2%, and the mass percentage of the nano-copper powder is 96%.

[0049] (2) Put the mixed slurry in a ball mill for ball milling for 10 hours to obtain a composite powder, wherein the rotational speed during the ball milling process is 400r / min, the ball-to-material ratio is 10:1, and the composit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| carrier mobility | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com