Economical low-yield-ratio steel for pipe fittings for oil and gas transmission and method for producing economical low-yield-ratio steel

A low-yield-strength-ratio, economical technology, applied in the field of economical low-yield-strength ratio pipe fittings for oil and gas transportation and its production field, can solve problems such as deficiencies, increase nucleation sites, improve surface quality, and refine grains. grain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

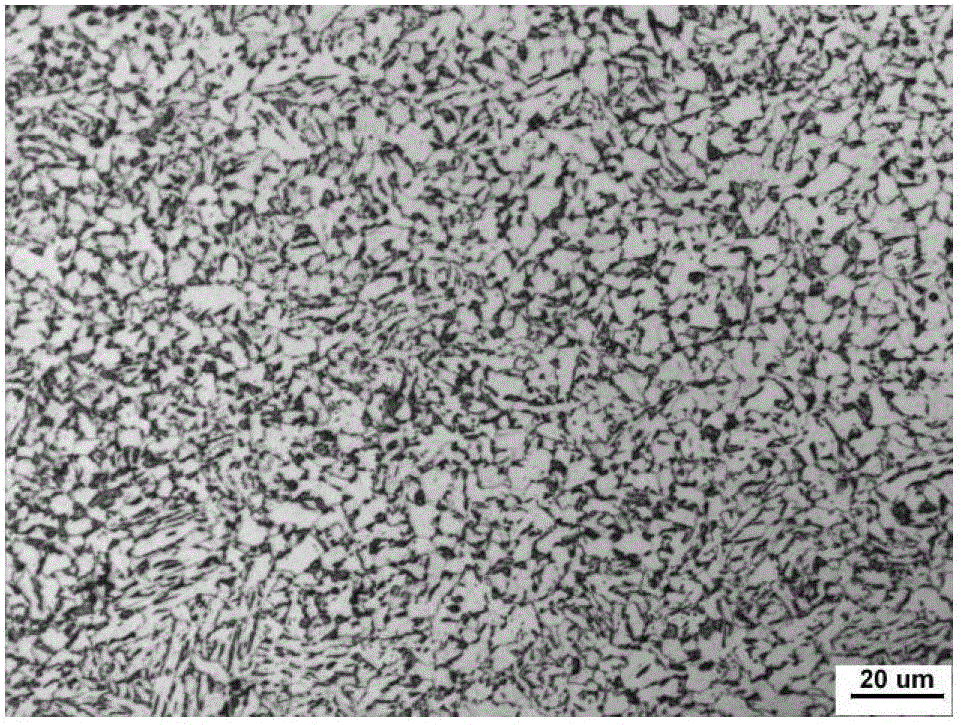

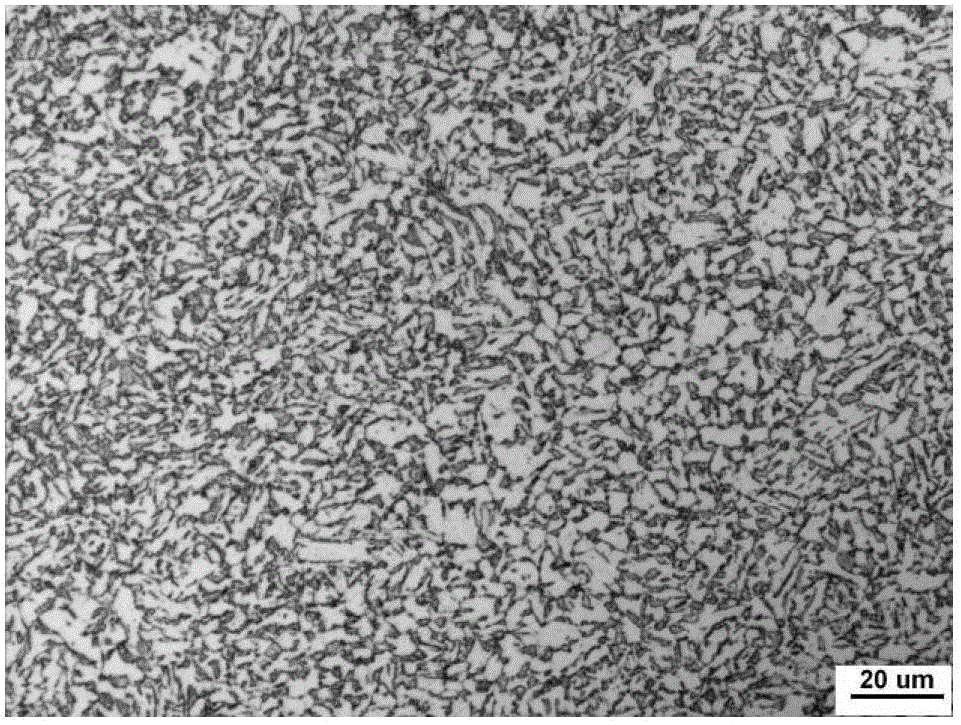

[0026] The present invention will be further described below in conjunction with accompanying drawing:

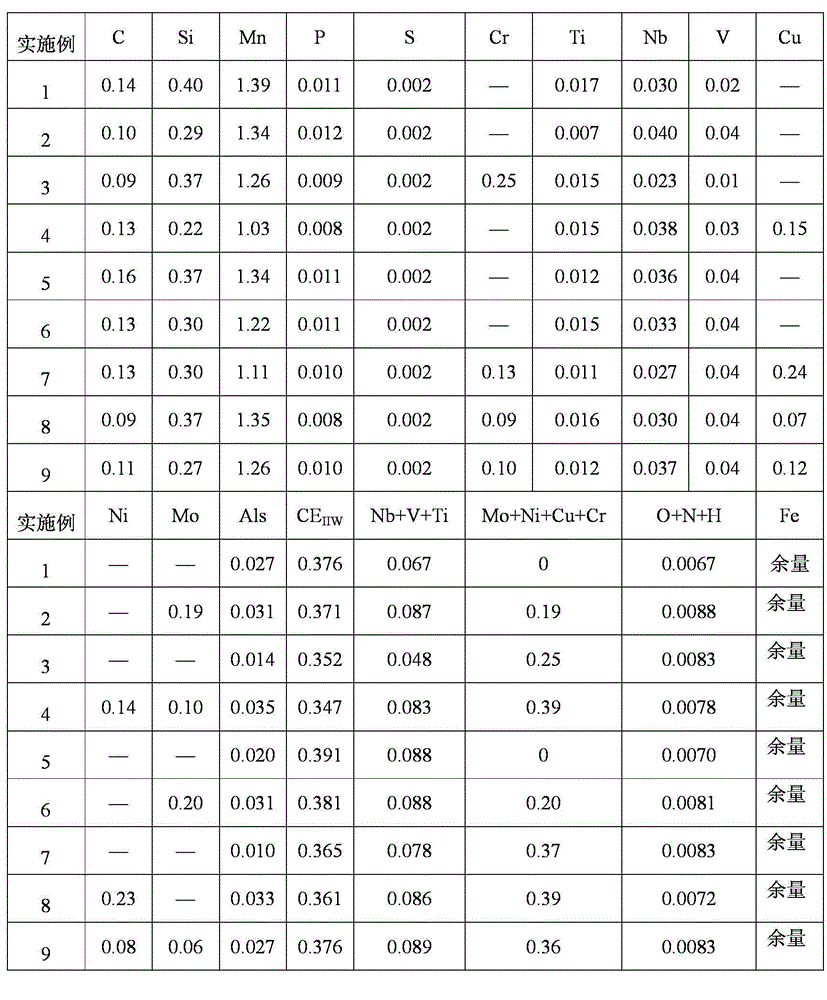

[0027] The chemical composition of the embodiments of the present invention is shown in Table 1; the rolling process of the corresponding embodiments is shown in Table 2; the quenching and tempering heat treatment process is shown in Table 3; the performance after quenching and tempering heat treatment is shown in Table 4.

[0028] Table 1 The chemical composition wt% of steel for economical low yield ratio pipe fittings in the embodiment of the present invention

[0029]

[0030] Table 2 The rolling process of the economical low yield ratio pipe fitting steel of the embodiment of the present invention

[0031]

[0032] Table 3 Quenching and tempering process of economical low yield ratio pipe fitting steel in the embodiment of the present invention

[0033]

[0034] Table 4 Properties of economical low-yield-strength-ratio pipe fitting steels of the examples of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com