Patents

Literature

81results about How to "Fully recrystallized" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation technology for recrystallizing carborundum product

The invention discloses a making technique of recrystallizing carborundum product, which comprises the following steps: blending carborundum powder with certain grain grade with purity over 96% and silicon powder and carbon powder evenly; adding a little of adhesive; moulding according to normal technique; placing green compact in the sintering stove; connecting graphite electrode on two ends; filling the composite powder of carborundum powder and carbon powder around two ends; supplying power for graphite electrode; utilizing the conductivity of mould to realize itself heating sintering; insulating 1-4h after the temperature reaches to 1400-1700 deg. c; heating continuously to 2500 deg. c; insulating 3-10h; cooling the stove to indoor temperature naturally; obtaining the high-purity recrystallizing carborundum product.

Owner:HUNAN UNIV

Economical low-yield-ratio steel for pipe fittings for oil and gas transmission and method for producing economical low-yield-ratio steel

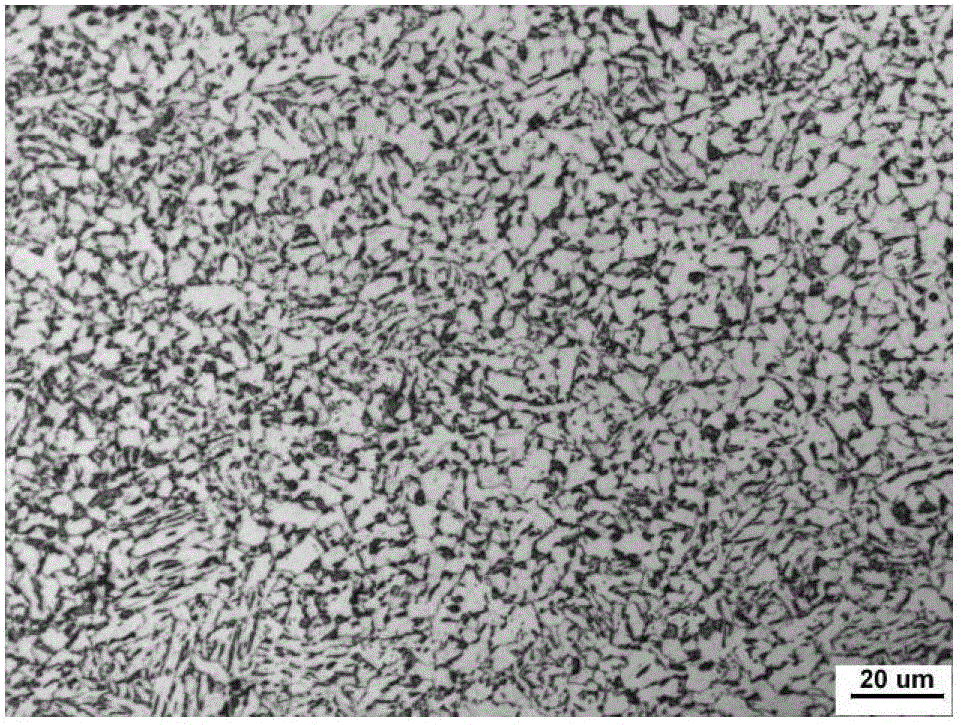

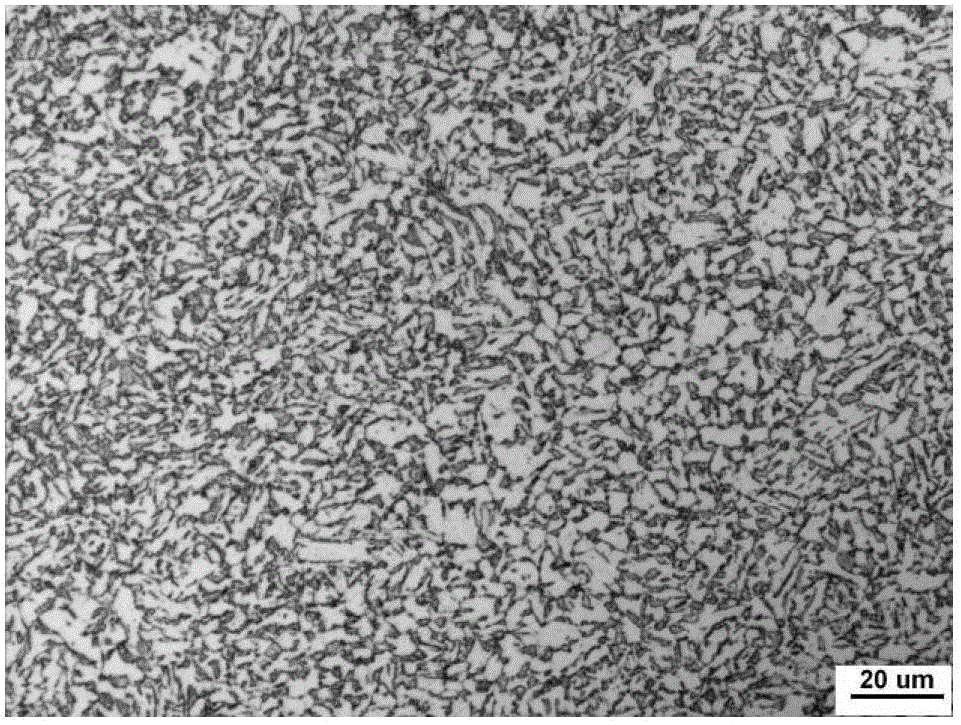

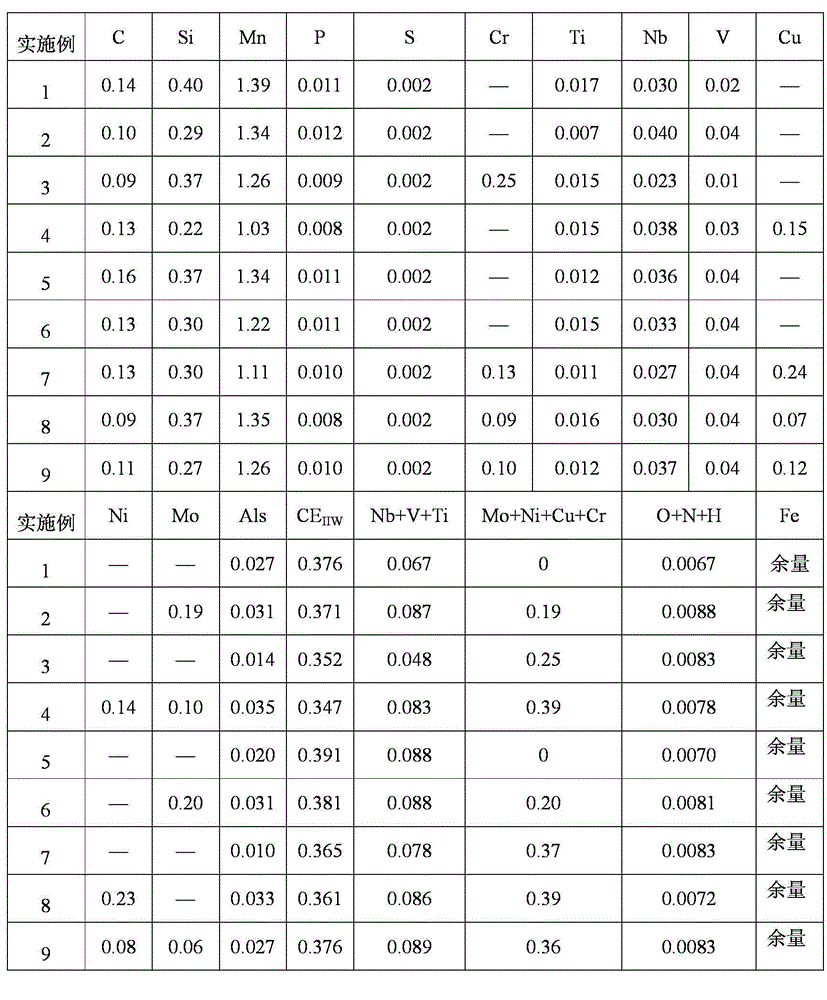

The invention discloses economical low-yield-ratio steel for pipe fittings for oil and gas transmission and a method for producing the economical low-yield-ratio steel. The economical low-yield-ratio steel comprises from 0.09% to 0.16% of C, from 0.20% to 0.40% of Si, from 1.00% to 1.39% of Mn, from 0.01% to 0.04% of Nb, from 0.005% to 0.018% of Ti, from 0.01% to 0.04% of V, from 0.008% to 0.035% of Als, from 0% to 0.20% of Mo, from 0% to 0.30% of Ni, from 0% to 0.30% of Cu, from 0% to 0.25% of Cr, the balance iron and inevitable impurities, wherein the total content of the Nb, the V and the Ti is lower than or equal to 0.09%, and the total content of the Mo, the Ni, the Cu and the Cr is lower than or equal to 0.40%. After the economical low-yield-ratio steel is subjected to heat treatment, the yield strength of the economical low-yield-ratio steel for the pipe fittings can be higher than 490MPa or 560MPa, the tensile strength of the economical low-yield-ratio steel can be higher than 670MPa or 720MPa, the yield ratio of the economical low-yield-ratio steel is lower than 0.80, the impact toughness of the economical low-yield-ratio steel at the temperature of minus 46 Celsius degrees is not lower than 80J, and technical requirements of X70-grade steel for pipe fittings and X80-grade steel for pipe fittings are met completely.

Owner:ANGANG STEEL CO LTD

Thin-gauge, ultra-low iron loss, low-noise and high-magnetic induction oriented silicon steel sheet and production method thereof

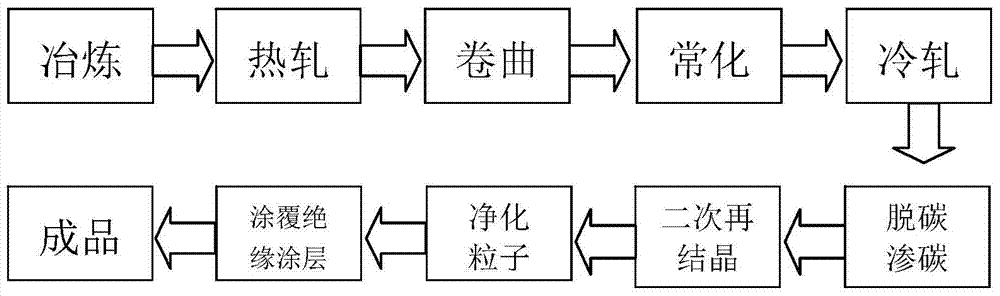

The invention discloses a production technology of a thin-gauge, ultra-low iron loss, low-noise and high-magnetic induction oriented silicon steel sheet. The oriented silicon steel sheet comprises the following components in percentage by weight: 0.003-0.05 percent of C, 4.1-9 percent of Si, 0.05-0.5 percent of Mn, 0.02-0.06 percent of Al, 0.01-1 percent of Sn, 0.05-0.1 percent of Mo, 0.2-1 percent of Cu, 0.003-0.02 percent of N, 0.002-0.06 percent of P, 0.001-0.008 percent of S and the balance of iron and other inevitable impurities. The high-magnetic induction oriented silicon steel sheet which is produced through hot rolling, cold rolling and annealing processes and the like has the superior performances such as ultra-low iron loss, high flux density, low magnetostriction coefficient and small thickness, has the advantages of simple process, stable texture and capabilities of greatly saving the materials and saving the resources while guaranteeing that the capacity of a transformer is unchanged, and is the best candidate material for manufacturing high-grade power transmission and distribution transformer cores at present.

Owner:STATE GRID CORP OF CHINA +2

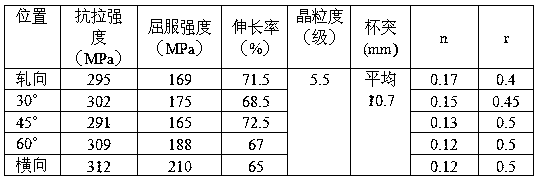

Preparation method of titanium plate for deep drawing

Disclosed is a preparation method of a titanium plate for deep drawing. Titanium sponge which is not lower than the 0A level and meets the conditions that the O content is smaller than or equal to 0.05%, the N content is smaller than or equal to 0.006% and the Fe content is smaller than or equal to 0.05% is used as a raw material and subjected to smelting casting and forging, and two or more timesof drawing-out and / or upsetting are carried out in the forging process, so that a plate blank with a good structure and tiny texture is prepared; and then the plate blank is subjected to hot rolling,cold rolling and rolling in changed directions in combination with the steps of annealing and subsequent processing, so that the pure titanium plate with proper crystalline grains, qualified performance and a high Erichsen value is obtained. Through the method, the pure titanium plate can be made to be short in production procedure, high in efficiency and good in deep drawing performance.

Owner:LUOYANG SUNRUI TI PRECISION CASTING

Cogging method for Ti2AlNb-based alloy ingot

ActiveCN104148562ALow Steady State Deformation ResistanceGood process plasticityMetal-working apparatusFiberWire cutting

The invention discloses a cogging method for a Ti2AlNb-based alloy ingot. The cogging method comprises the steps that the Ti2AlNb-based alloy ingot is loaded on a wire cutting machine and manufactured into a Phi290*280mm bar; the Ti2AlNb-based alloy ingot is sleeved with alumina silicate fibers, placed into a high-temperature heating furnace to be heated to 1150 DEG C and then placed on a press after the temperature is kept for 80 minutes, and repeated upsetting and drawing are performed at the strain rate of 0.01S-1; the ingot is drawn out to 350mm after first fire, upset to 350mm after second fire, drawn out to 350mm after third fire, upset to 270mm after fourth fire and drawn out to 350mm after fifth fire, and air cooling is performed. The ingot is returned to the furnace to be heated to 1150 DEG C and the temperature is kept for 40 minutes for each fire, and the final forging temperature of each fire is guaranteed to be equal to or larger than 1050 DEG C. According to the method, the steady state deformation resistance of the Ti2AlNb-based alloy ingot is reduced in a fully dynamic recrystallization state, the technological plasticity is improved, cracking is prevented, a cast structure is smashed completely, and a uniform and dense forge structure is obtained.

Owner:GUIZHOU ANDA AVIATION FORGING +1

Annealing process of martensitic stainless steel cold-rolled strip steel for tool

InactiveCN107674946ASmall footprintEasy to operateProcess efficiency improvementRough surfaceProduction line

The invention discloses an annealing process of martensitic stainless steel cold-rolled strip steel for a tool, and belongs to the technical field of stainless steel machining. The problems that according to existing processes, strip breaking and oxidization are prone to occurring, oxide skins are uneven, the phenomena of oxidized residues, poor pickling, color difference and rough surfaces are prone to occurring, annealing raw materials pollute the environment and are high in cost, moreover, equipment is complex, the production line is long, and scratching is prone to occurring are solved. The annealing process comprises the following steps of raw material hot rolling, hot rolling annealing, hot line pickling, rolling, bell type annealing, and cutting and packaging. According to the annealing process, compared with common 2D production equipment, a bell type annealing furnace is simple in equipment, small in occupied area, low in equipment cost and easy to operate, a production methodis simple and easy to implement, manufactured strip steel is bright in surface, high in plasticity, toughness and quenching hardness, slitting machining, forming machining, surface machining and surface grinding are facilitated, and the tool with a small specification can be rolled and produced conveniently.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

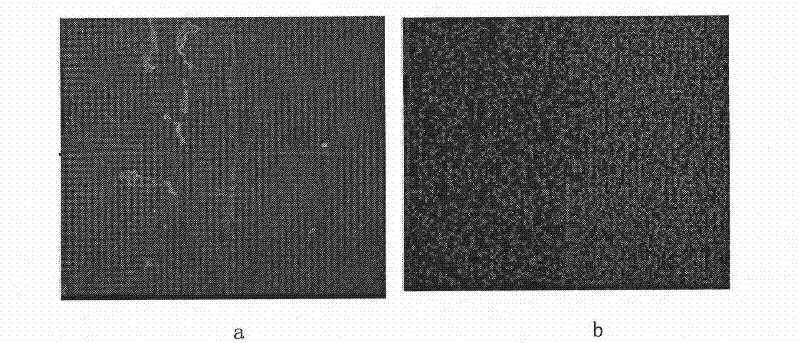

Six-series aluminum alloy sheet for outer plate of automotive body and preparation method thereof

The invention belongs to the field of aluminum alloy sheets for automotive bodies, and relates to a six-series aluminum alloy sheet for an outer plate of an automotive body and a preparation method thereof. The six-series aluminum alloy sheet is prepared from the following elemental constituents according to weight percentages: 0.55 to 0.65 % of Si, 0.10 to 0.20% of Fe, 0.10 to 0.20% of Cu, 0.05 to 0.15% of Mn, 0.65 to 0.75% of Mg, 0. 01 to 0.03% of Ti, less than or equal to 0.03% of single impurity, less than or equal to 0.10% of impurities in total, and the balance being Al. According to thepreparation method of the six-series aluminum alloy sheet, the rolling pass and working procedure time of hot rough rolling are strictly limited, and annealing is performed two times in the cold rolling process. Compared with a traditional 6016 alloy, the finished product has the advantages that the edge covering performance is significantly improved, the finished product has a smooth and fine surface without macroscopic Roping line defects after stamping, and the surface quality is significantly improved.

Owner:TIANJIN ZHONGWANG ALUMINUM IND CO LTD

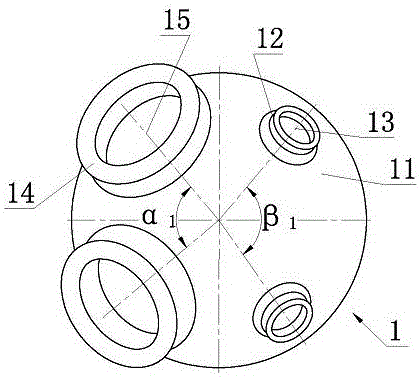

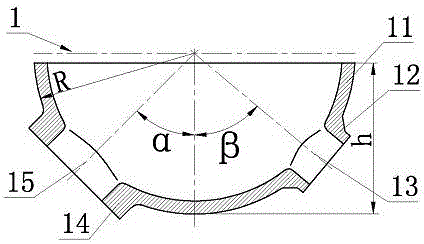

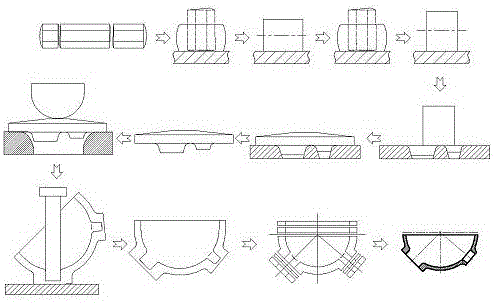

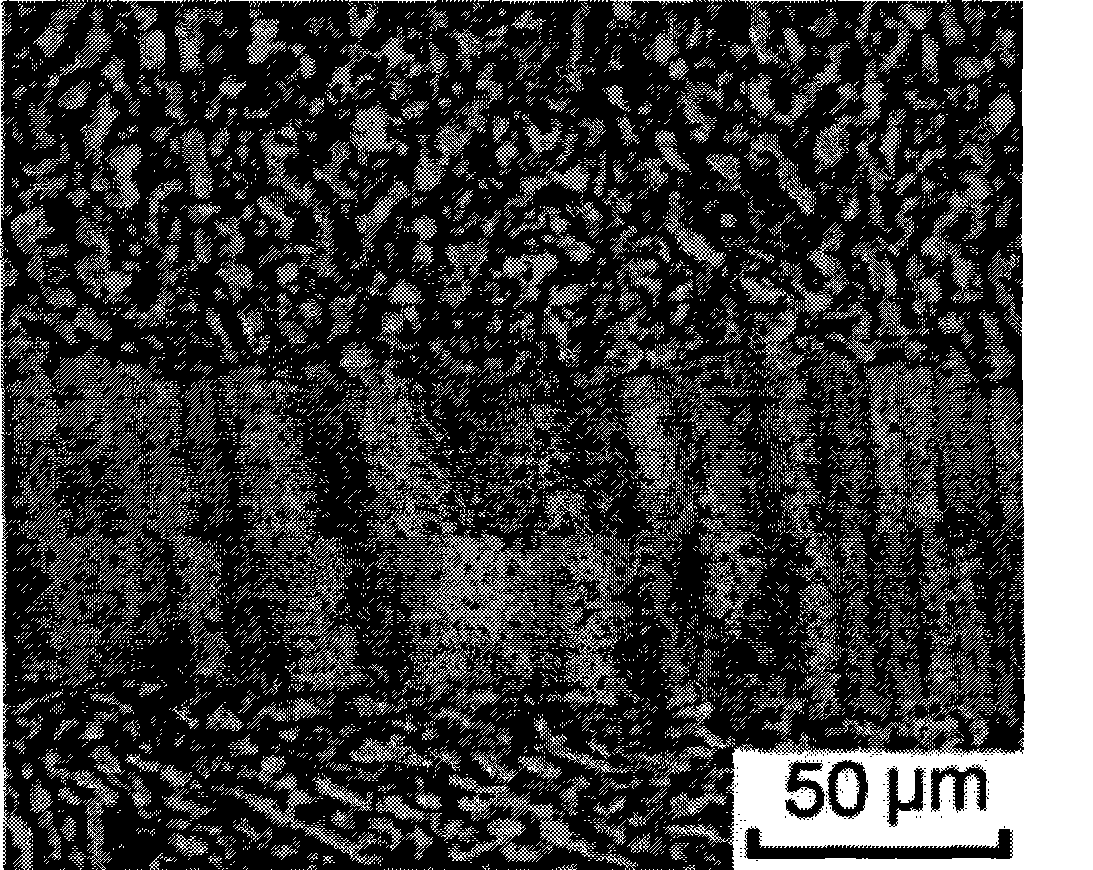

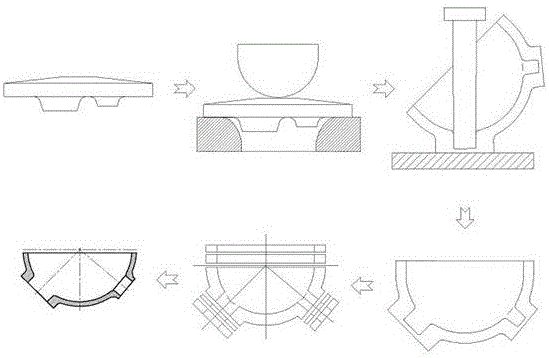

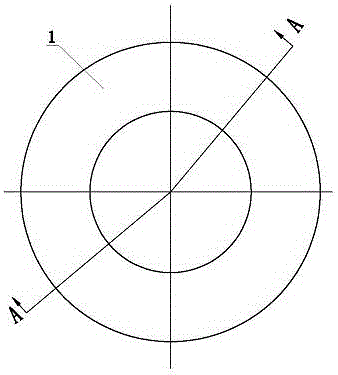

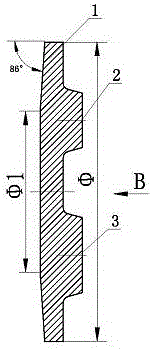

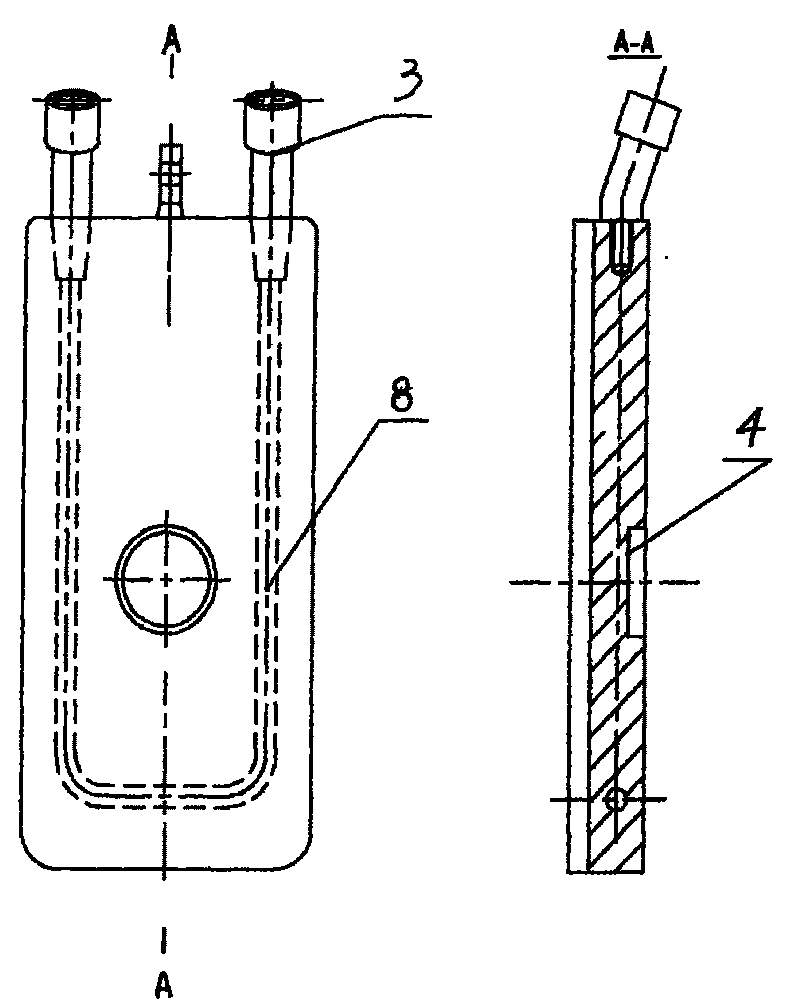

Pressure vessel integrated end socket for nuclear power, end socket plate blank of pressure vessel integrated end socket and forging method of pressure vessel integrated end socket

ActiveCN106051721AImprove mechanical propertiesImprove operational safetyMetal-working apparatusSteam boilersFiberPunching

The invention discloses a pressure vessel integrated end socket for nuclear power, an end socket plate blank of the pressure vessel integrated end socket and a forging method of the pressure vessel integrated end socket. According to the pressure vessel integrated end socket for nuclear power, a manhole base and a pipe hole base are arranged on an end socket body which is of a spherical crown structure; the manhole base and the pipe hole base are integrated with the end socket body in a forged mode; and the intersection point of the hole center line of a manhole and the hole center line of a pipe hole is located in the center of the sphere where the end socket body is located. A plate blank body of the end socket plate blank is of a circular plate structure, one surface of the plate blank body is provided with two manhole circular truncated cones and two pipe hole circular truncated cones, and the other surface of the plate blank body is a large-cone-angle circular truncated cone surface. The forging method comprises the following steps of steel ingot heating, forged blank blanking, forged blank upsetting and drawing, die forging formation, plate blank heat treatment, plate blank rough machining, end socket formation, end socket punching, forge piece heat treatment, machining of a forge piece, performance heat treatment and finished product machining. The integrated formation of the end socket of a vapor generator is achieved, the forge piece is uniform and compact in texture, the metal flow line is complete, and the fiber texture and the appearance of the forge piece tend to be more coincident.

Owner:SHANGHAI XINMIN DONGTAI HEAVY FORGING

Linear friction welding method

InactiveCN101367156AReduce vibrationExtended service lifeNon-electric welding apparatusPhysicsConstant frequency

The invention discloses a linear friction welding method, which is characterized in that the method comprises the following steps: the amplitude of two weldments is preset as a constant amplitude, and the vibration frequency is increased to higher frequency from lower frequency at the early stage of friction; then a constant-frequency constant-amplitude friction stage is performed, and the vibration frequency and the amplitude are constant at this time; at the final stage of the friction, the amplitude is gradually reduced, and the welding is finished by applying upsetting pressure when the amplitude is gradually reduced to zero to lead the two weldments to return and align; and the friction pressure is constant during the whole welding process. The larger amplitude and the lower frequency at the early stage of the friction can perform effective mechanical cleaning and preheating to the friction interface; at the middle and late stage of the friction, the amplitude is gradually reduced to ensure that a high temperature interval of a joint is wider and evener, deformed metal can be fully restored and recrystallized, thereby eliminating the residual stress of the welding joint and improving the quality of the joint.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

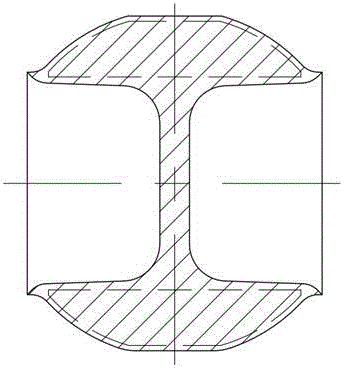

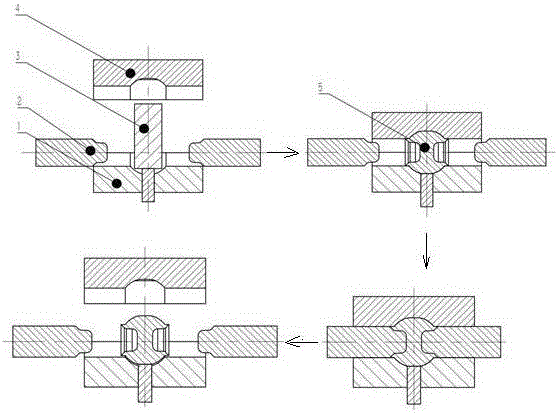

Extrusion molding method of nickel based alloy sphere for valve

InactiveCN105964850AImprove mechanical propertiesAvoid crackingValve arrangementsMetal-working apparatusMachiningWorking hours

The invention relates to an extrusion molding method of a nickel based alloy sphere for a valve. The extrusion molding method comprises the steps that technological parameters are determined through computer numerical simulation; a blank is firstly preheated and then continues to be heated to the forging temperature; a program is set through extrusion equipment; running is carried out for extrusion; pressure maintaining is carried out after mold combining of molds is completed, and a puncher pin carries out extrusion to a set position; the molds and the puncher pin reset, and the sphere blank is demolded; and blank air cooling, heat treatment and machining are carried out. The extrusion molding method has the beneficial effects that one-time heating extrusion molding is achieved, and a nickel based alloy is prevented from cracking and alloy element impoverishment in the forging process; metal flow line continuity is guaranteed, and corrosion resisting performance is improved; in the extrusion molding process, deformation of materials is large, extremely sufficient recrystallization is carried out in the deformation process, grains are refined, and the phenomena of coarse grains and mixed grains happening in the free forging process and the mold forging process are avoided; and the material utilization rate is high, machining work hours are few, and the production efficiency can be effectively improved.

Owner:22MCC GRP PRECISION FORGING

Method for manufacturing extra-thick plate blank by accumulative roller welding process

InactiveCN101590596BGuaranteed bonding strengthFully recrystallizedOther manufacturing equipments/toolsThick plateDirectional solidification

The invention relates to a method for manufacturing an extra-thick plate blank by an accumulative roller welding process, which comprises the following steps: taking continuous casting billets which have the same size and are made of the same material, carrying out surface treatment for superposed surfaces of the continuous casting billets, then superposing the superposed surfaces of the continuous casting billets together, and welding and sealing surrounding seams under vacuum; and heating the welded continuous casting billets to between 1,150 and 1,250 DEG C of an austenitic area, and forging or / and rolling the heated continuous casting billets, wherein the one-time pressing rate is 30 to 35 percent, and the total pressing rate is 50 to 70 percent. The method adopts the accumulative roller welding process to produce extra-thick plates, and the tissues of the superposed surfaces are the same as the tissues of a matrix. Because the continuous casting billets are applied to producing the blank, the yield of the blank is higher than that of an ingot casting, and the processing cost of the blank is lower than that of the blank produced by a directional solidification method.

Owner:LAIWU IRON & STEEL GRP

Valve core

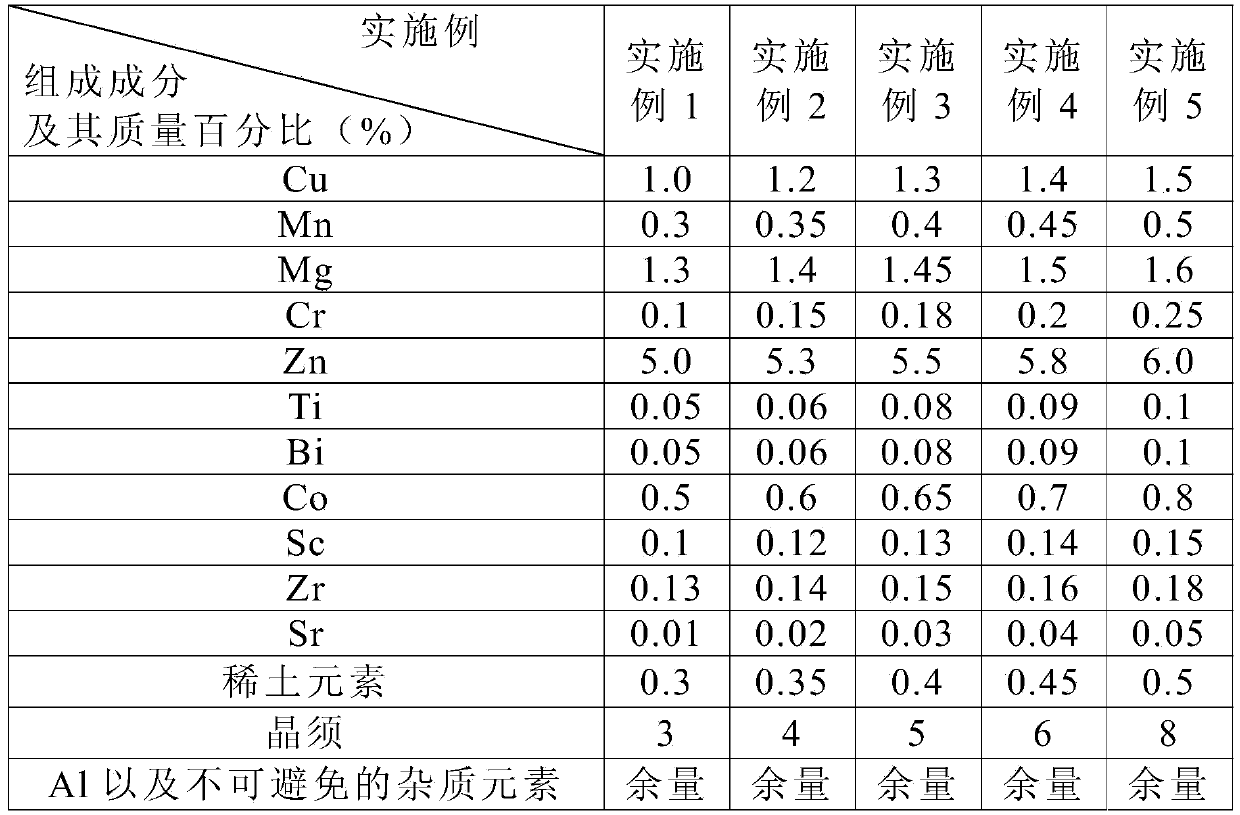

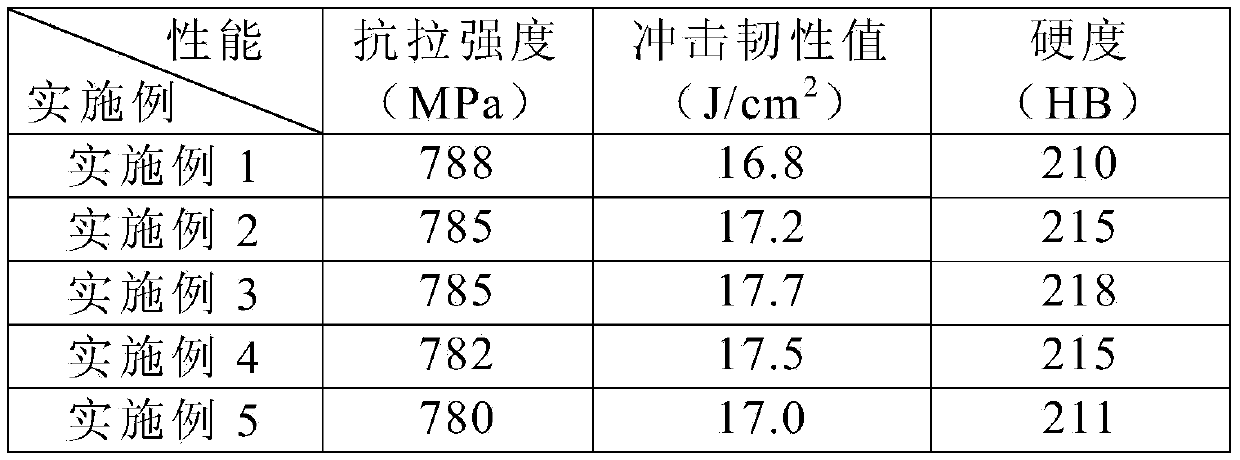

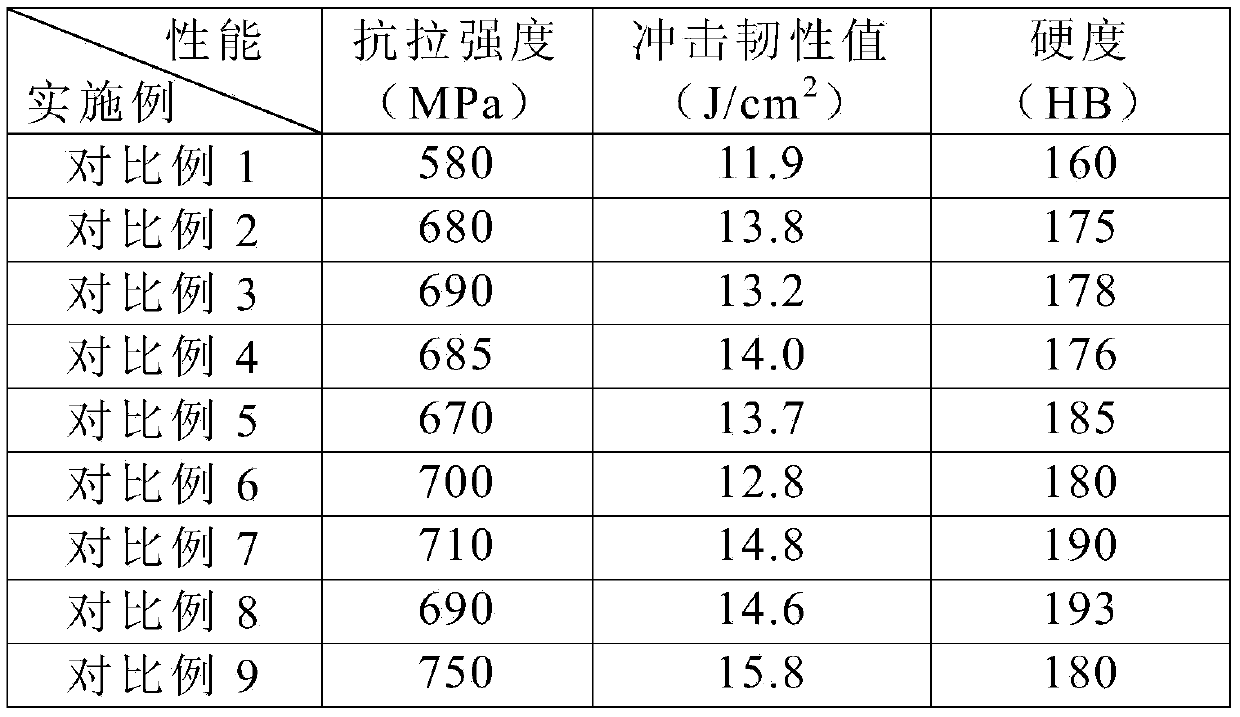

The invention relates to a valve core. The valve core comprises a valve core body made of aluminum alloy. The aluminum alloy is composed of, by mass, 1.0%-1.5% of Cu, 0.3%-0.5% of Mn, 1.3%-1.6% of Mg, 0.10%-0.25% of Cr, 5.0%-6.0% of Zn, 0.05%-0.1% of Ti, 0.05%-0.1% of Bi, 0.5%-0.8% of Co, 0.1%-0.15% of Sc, 0.13%-0.18% of Zr, 0.01%-0.05% of Sr, 0.3%-0.5% of rare earth elements, 3%-8% of crystal whiskers, and the balance Al and inevitable impurity elements. The valve core is made of the aluminum alloy and has the advantages of being light, high in strength, resistant to corrosion and the like. Besides, a cold heading process is added to a manufacturing method of the valve core, so that the material utilization rate is increased.

Owner:NINGBO YINZHOU YINXIN ALUMINUM CO LTD

Integral seal punch molding method of nuclear power pressure container

The invention discloses an integral seal punch molding method of a nuclear power pressure container. The punch molding method comprises the following steps: roughening of a plate blank: the heated seal plate blank is machined; heating of the plate blank: the roughened seal plate blank is sent in a heating furnace for heating; molding of a seal: the seal plate blank is shifted to an annular mold with a center hole for punching to mold a semi-spherical seal blank; punching of the seal: a seal punching part with two man holes and two pipe holes is punched; heat treatment of the punched part: the punched part is discharged from a furnace for air cooling when being cooled to 180 DEG C along with the furnace after autoclaving; machining of the punched part: the heated seal punched part is machined as a seal rough finished product; performance heat treatment: the quenching treatment is performed firstly; and then, the thermal refining is performed; and the finished product is machined to a qualified seal finished product. The method realizes integral molding of a steam generator seal, and is uniform and compact in metal structure and complete in streamline.

Owner:SHANGHAI XINMIN DONGTAI HEAVY FORGING

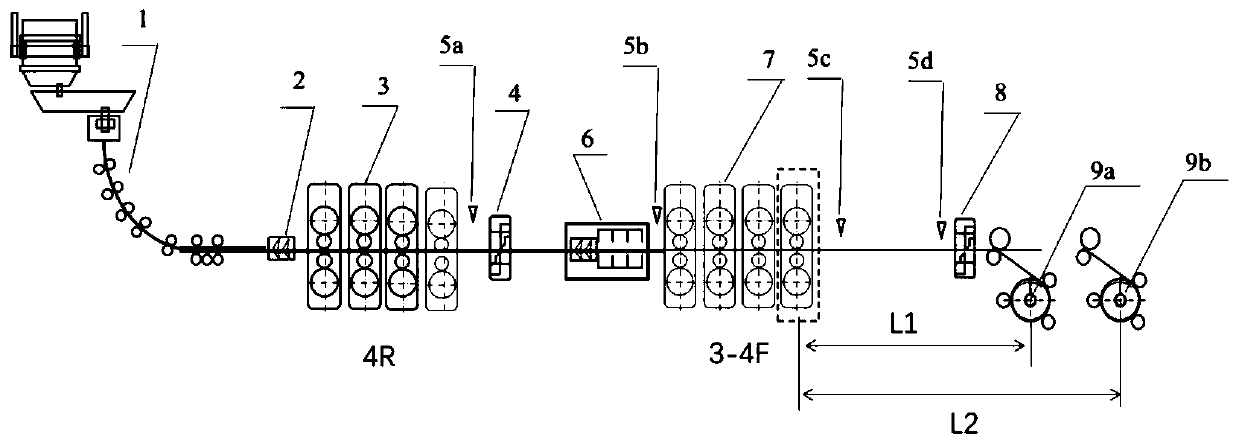

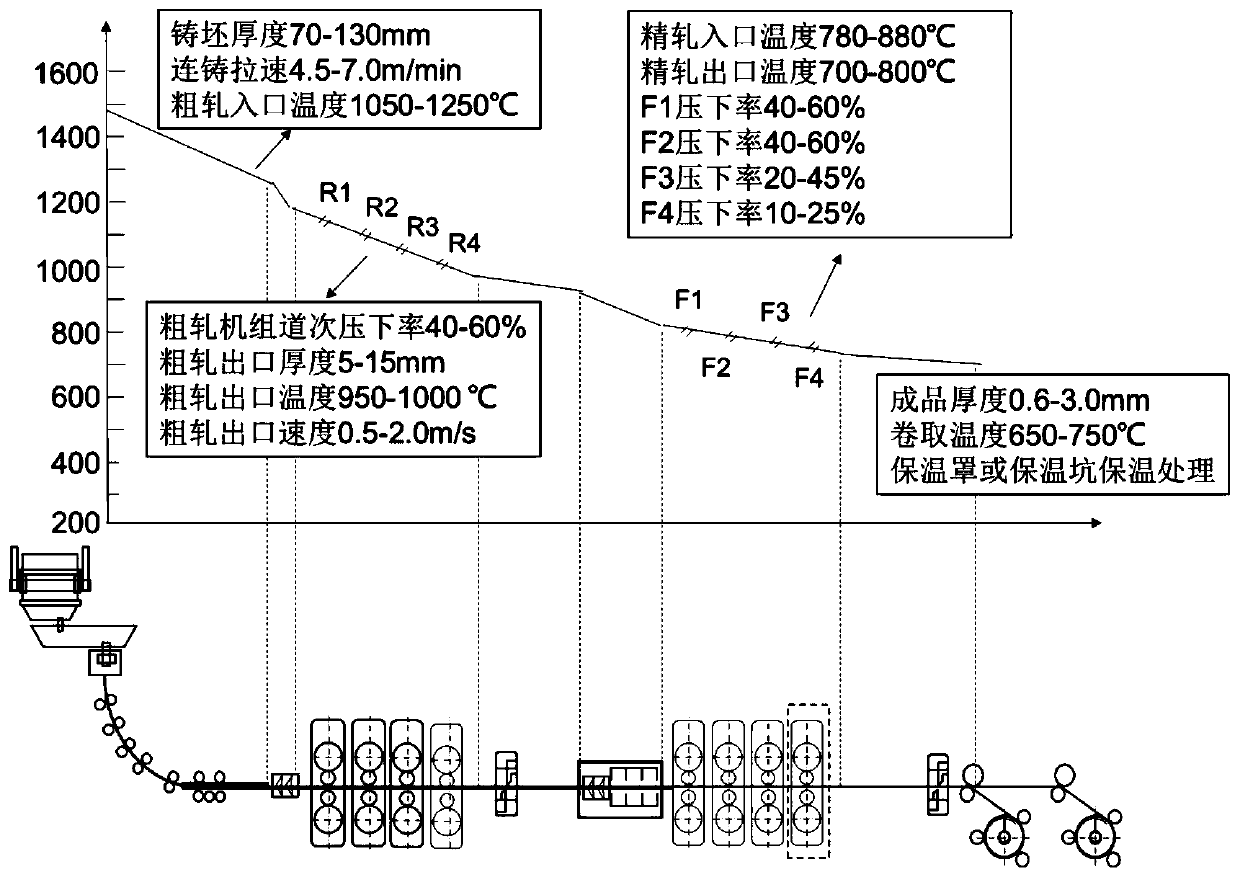

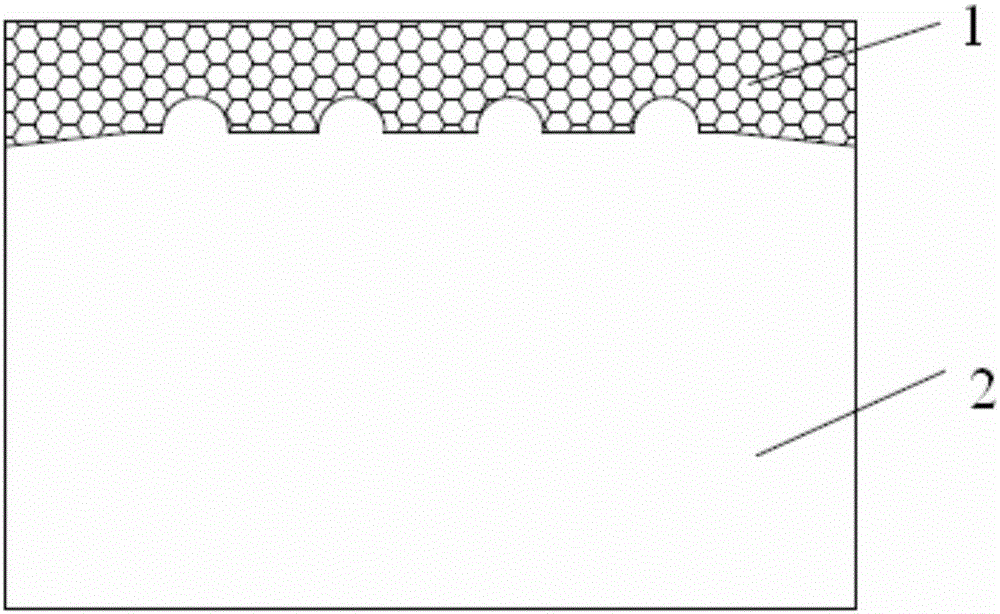

Hot-rolled strip steel full-continuous production device and method for ferrite rolling

ActiveCN110479762AReasonable configurationShort line lengthTemperature control deviceMeasuring devicesHigh pressure waterHigh pressure

The invention discloses a hot-rolled strip steel full-continuous production device and method for ferrite rolling. The hot-rolled strip steel full-continuous production device is characterized in thatthe production line of the device is short, and components are reasonably configured; a multifunctional cooling control device is adopted, and high-pressure water descaling and intermediate blank cooling functions are integrated so as to achieve simplicity and high efficiency; and 4R+(3-4) rolling mills, four temperature detectors and close-range underground coilers are arranged, so that the cooling load of an intermediate billet is reduced, accurate temperature control of the process is achieved, and the product quality is conveniently improved. The method comprises the steps of continuouslycasting to manufacture the billet; dephosphorizing by high-pressure water rotary; carrying out rough rolling by using a four-frame large screw-down rough rolling unit; shearing by using a rotary drum; carrying out cooling in a multifunctional cooling control device after dephosphorization through the high pressure water; performing fine rolling by using a three-frame or four-frame fine rolling unit; carrying out air cooling; shearing and dividing rollers by using a high-speed flying shear; and reeling by using a underground coiler, wherein the temperature monitoring is respectively carried out before roughing rolling, before and after fine rolling, and before reeling by the underground coiler. The method has the advantages of energy consumption and low cost, good product quality and thinthickness, and is capable of better meeting the performance requirement of replacing cold with heat.

Owner:武汉钢铁有限公司

Austenitic stainless steel, preparation method thereof and application of austenitic stainless steel in hydrogen storage pressure vessel

ActiveCN114351051AReasonable design of ingredientsReduced ferrite contentFixed capacity gas holdersMetal rolling arrangementsMetallurgySS - Stainless steel

The invention belongs to the technical field of steel smelting, and relates to austenitic stainless steel, a preparation method thereof and application of the austenitic stainless steel in a hydrogen storage pressure container. The austenitic stainless steel provided by the invention comprises the following components in percentage by weight: 0.010%-0.030% of C, 0.40%-0.75% of Si, 1.3%-2.0% of Mn, 17.5%-18.0% of Cr, 13.05%-14.00% of Ni, 2.5%-3.0% of Mo, less than or equal to 0.030% of P, less than or equal to 0.002% of S, less than or equal to 0.06% of N, less than or equal to 0.5% of Cu, 0.002%-0.005% of B, 28.5%-35% of Nieq, and the balance of Fe and inevitable impurities. The austenitic stainless steel is stable in structure performance, low in ferrite content and good in hydrogen embrittlement resistance, the development requirement of a hydrogen storage pressure container of a hydrogen refueling station is met, and the austenitic stainless steel has important practical significance on safe and efficient development of the hydrogen energy storage technology.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

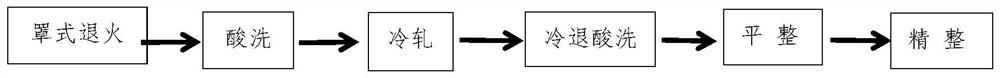

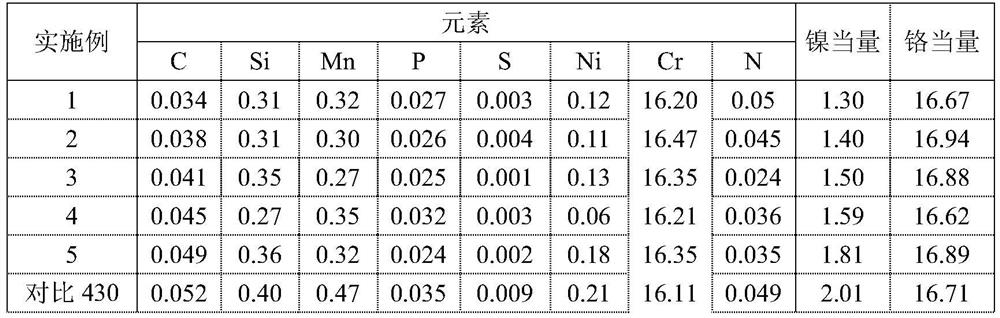

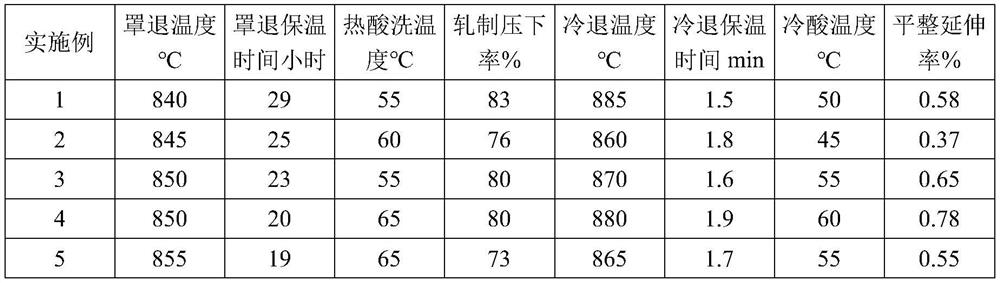

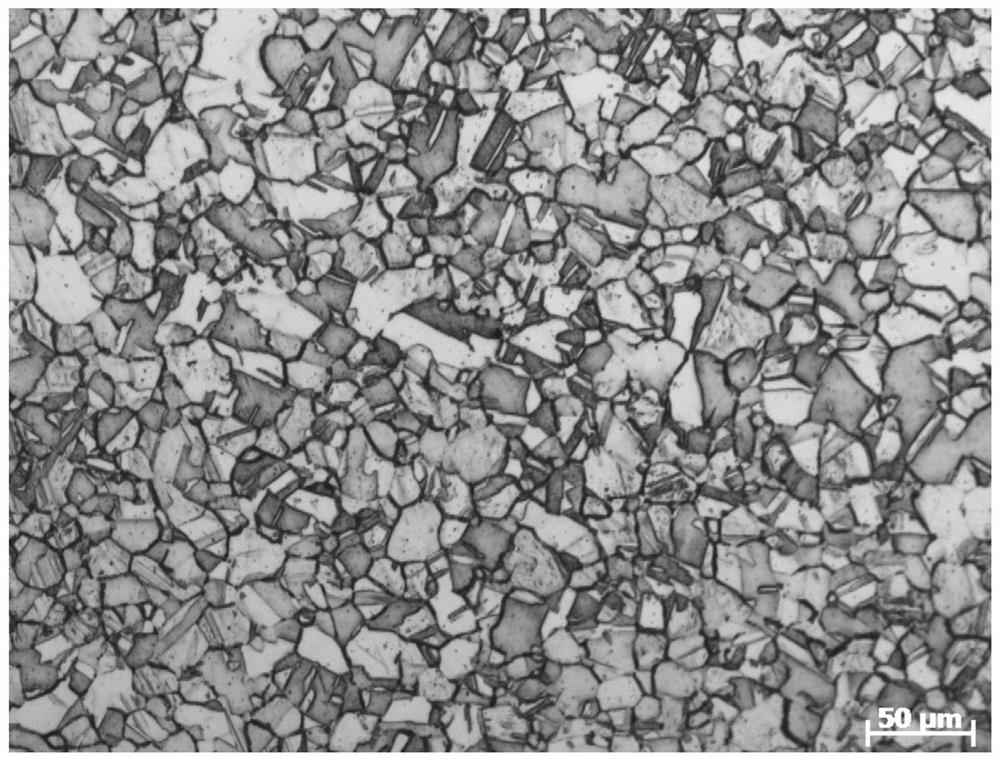

430 ferritic stainless steel for kitchen ware panels and preparation method thereof

InactiveCN113388780AHigh ferrite stabilityReduce work hardeningSS - Stainless steelUltimate tensile strength

The invention discloses 430 ferritic stainless steel for kitchen ware panels and a preparation method thereof. The 430 ferritic stainless steel comprises the following components in percentage by mass: 0.030-0.05% of C, 0.02-0.05% of N, 0.20-0.40% of Si, less than or equal to 0.20% of Ni, less than or equal to 0.35% of Mn, 16.00-16.50% of Cr, less than or equal to 0.035% of P, less than or equal to 0.010% of S, and the balance of Fe and inevitable impurity elements. The equivalent value of nickel is not greater than 2.00, and the equivalent value of chromium is not less than 16.50. During preparation, a hot-rolled black skin roll is subjected to cover annealing, acid pickling, cold rolling, cold annealing and acid pickling, leveling and other procedures to be prepared into a finished product with the required target thickness. The formula and the preparation process of the 430 ferritic stainless steel are scientific and reasonable, and the prepared stainless steel has higher ferritic stability and lower hardness and yield strength, so that the material is more suitable for stamping, can meet the requirement of cost control in the kitchen ware industry, and is suitable for production and processing of high-end kitchen ware.

Owner:NINGBO BAOXIN STAINLESS STEEL

Isothermal die forging technology for large-size high-strength aluminum alloy parts

InactiveCN105964849AImprove plasticityImprove malleabilityMetal-working apparatusLarge deformationLarge size

The invention relates to an isothermal die forging technology for large-size high-strength aluminum alloy parts, and belongs to the technical field of aluminum alloy machining. According to the isothermal die forging technology, large-size aluminum alloy forging cake blanks undergo isothermal die forging formation in one step after being heated and thermally insulated for obtaining forge pieces, the forge pieces are taken out and cooled, and finally finished products are obtained; in the isothermal die forging process, the descending speed of upper dies is 0.1-0.2 mm / s. By selecting raw materials and strictly controlling forging parameters, continuous large deformation is realized on the condition that alloy crystal grains do not grow, and the large-size and high-performance aluminum alloy parts can be prepared with high efficiency and low cost. The isothermal die forging technology has the advantages that the operation is easy, the production efficiency is high, the product quality is high and the practicability is high, thereby being suitable for industrialized use and popularization.

Owner:SHANDONG NANSHAN ALUMINUM

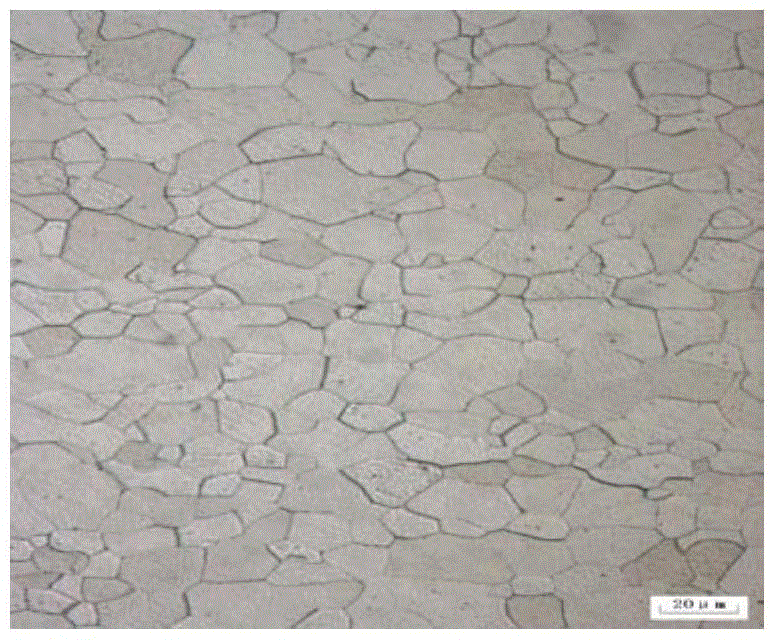

Low-expansion alloy and preparation method thereof

ActiveCN111809120AImprove the strengthening effectDoes not affect linear expansion coefficientFurnace typesHeat treatment furnacesSolution treatmentMetallurgy

The invention relates to a low-expansion alloy and a preparation method thereof, and relates to the technical field of low-expansion alloys. According to the mainly adopted technical scheme, the volume fraction of annealing twin crystals in the low-expansion alloy is larger than or equal to 20%, and the linear expansion coefficient of the low-expansion alloy within the temperature range of -160 DEG C to 25 DEG C is 0.8*10<-6> / DEG C to 1.5*10<-6> / DEG C. The preparation method of the low-expansion alloy comprises the step of sequentially carrying out solution treatment, cold rolling deformationtreatment and annealing treatment on a low-expansion alloy body so as to obtain the low-expansion alloy, wherein in the cold rolling deformation treatment step, the total deformation of the alloy is 65-99%, and in the annealing step, the annealing temperature ranges from 800 DEG C to 900 DEG C, and the annealing time ranges from 5 min to 30 min. According to the low-expansion alloy, annealing twincrystals can be effectively introduced into the low-expansion alloy, so that the low-expansion alloy is strengthened on the premise that the linear expansion coefficient of the alloy is hardly influenced. The contradictory relation between the expansion performance and the strength of the alloy is fundamentally solved, and application of the low-expansion alloy in precise structural parts is facilitated.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Anti-corrosion aluminum alloy pipe and preparation method thereof

The invention provides an anti-corrosion aluminum alloy pipe and belongs to the technical field of aluminum alloy materials. The composition elements of the aluminum alloy pipe comprise, by mass, 0.05-0.1% of Si, 0.15% of Fe or the less, 0.01% of Cu or the less, 0.8-1.0% of Mn, 0.2-0.4% of Mg, 0.01% of Zn or the less, 0.01-0.05% of Ti, 0.05% of the other elements or the less and the balance Al. According to the anti-corrosion aluminum alloy pipe, through adjustment of components and change of the technique, the anti-corrosion performance of the aluminum pipe can be effectively improved while the 3003 aluminum pipe strength is met, and the service life of a product is prolonged.

Owner:JIANGSU ASIA PACIFIC LIGHT ALLOY TECH CO LTD

Easy-to-cut titanium alloy

The invention discloses easy-to-cut titanium alloy, which comprises the following components in percentage by weight: 3 percent to 6.1 percent of chromium, 1 percent to 4 percent of manganese, 5.1 percent to 8 percent of aluminum, 0.4 percent to 1.3 percent of silicon, 3.7 percent to 7 percent of magnesium, 1.3 percent to 2.7 percent of lead, and the balance titanium. According to the easy-to-cut titanium alloy provided by the invention, the manganese, the aluminum, a small amount of lead and other metals are added, a vacuum consumable-electrode arc melting technology is adopted for melting for three times repeatedly, and degassing, deoxidizing and impurity removing processes are better realized for the metal materials, so that a pure metal material billet is acquired; due to high melting rate and the accurate control of an electric arc heating area, the consistency of a melting metal solidification direction is ensured, a metal performance of the material is greatly improved, and the titanium alloy can be easily cut; and later, double annealing is carried out, so that recrystallization is fully carried out without increasing crystal particles in the titanium alloy, the plasticity and the structure stability of the titanium alloy are improved, the machinability of the titanium alloy is improved, and meanwhile, the high strength and the stability of the titanium alloy are further maintained.

Owner:ANHUI YINLONG PUMP VALVE

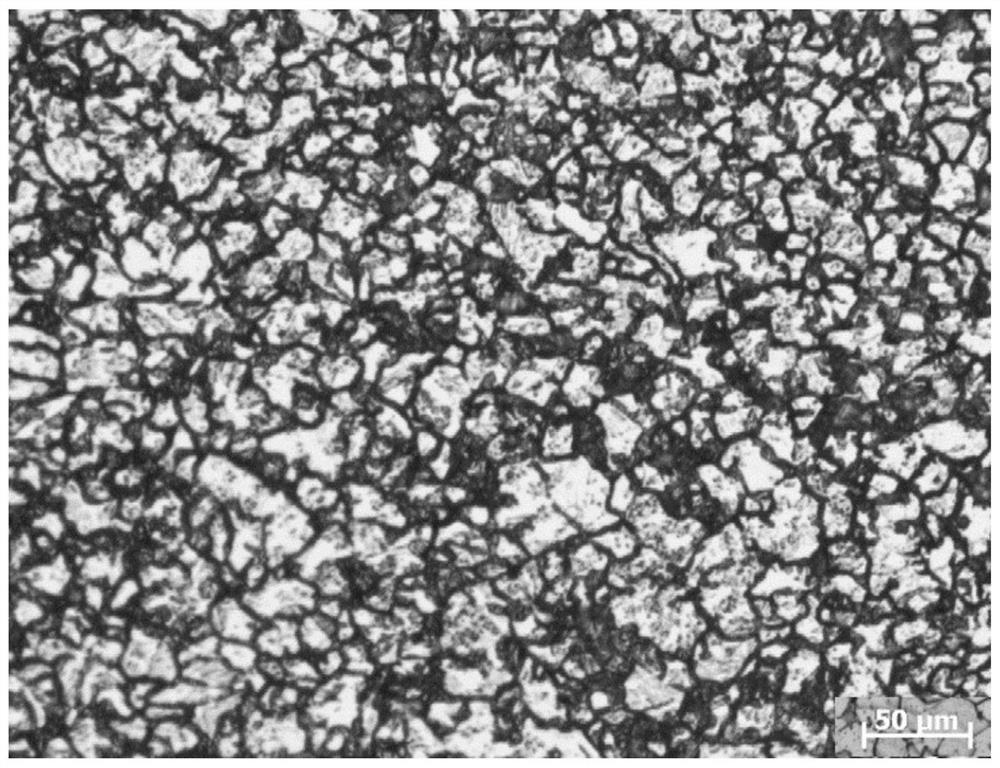

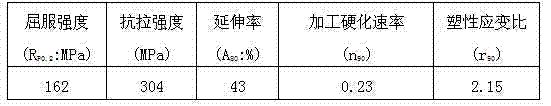

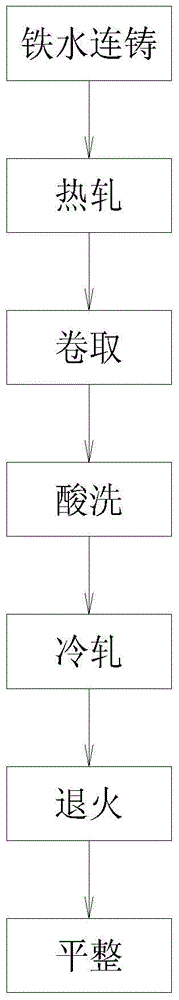

Low-carbon aluminium killed steel with excellent stamping properties and production method of low-carbon aluminium killed steel

The invention discloses a low-carbon aluminium killed steel with excellent stamping properties and a production method of the low-carbon aluminium killed steel. The production method comprises the steps of hot rolling, cold rolling and batch annealing, and a casting blank adopted in the method comprises the following components in percentage by weight: less than or equal to 0.010% of C, 0.05-0.20% of Mn, less than or equal to 0.015% of S, less than or equal to 0.020% of P, greater than or equal to 0.05% and less than or equal to 0.25% of Si, 300-600 ppm of Als, less than or equal to 30 ppm of N, less than or equal to 20 ppm of Ca, and the balance of Fe and unavoidable impurities. The method adopts a bran-new composition design, by controlling the processing parameters of heat rolling, the rolling reduction of cold rolling and the process parameters and the like of batch annealing, a good recrystallization annealing structure and texture is obtained, and then a low-carbon Al killed steel with excellent stamping properties is obtained so as to meet the requirements of automobile parts on stamping properties.

Owner:HEBEI IRON AND STEEL

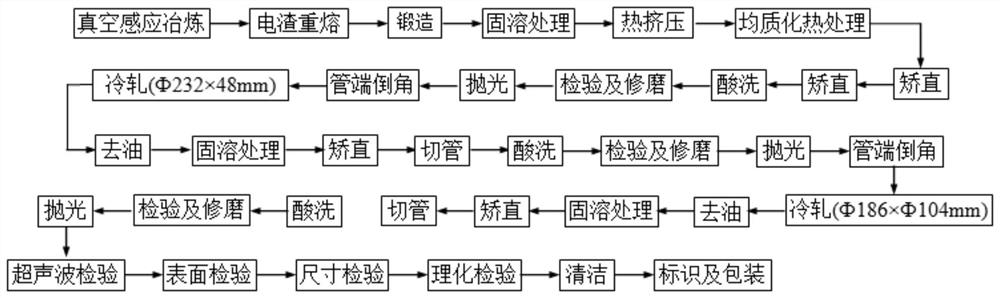

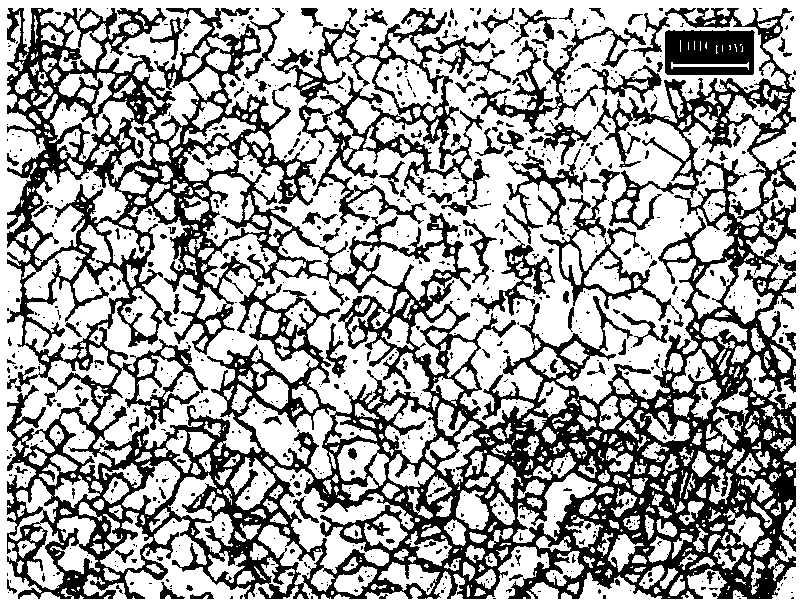

Alloy movable conduit for sodium-cooled fast reactor control rod driving mechanism and manufacturing method

ActiveCN111876690AHigh strengthImprove corrosion resistanceNuclear energy generationNuclear reaction controlChemical compositionNichrome

The invention discloses an alloy movable conduit for sodium-cooled fast reactor control rod driving mechanism and a manufacturing method, and relates to iron-nickel-chromium alloy seamless tubes. Thealloy movable conduit comprises the following chemical components including, by mass, 0.04%-0.09% of C, 1.2%-1.8% of Mn, not more than 0.015% of P, not more than 0.010% of S, not more than 0.20% of Si, 15.0%-17.0% of Cr, 35.0%-37.0% of Ni, 3.0%-3.5% of Mo, not more than 0.05% of Cu, not more than 0.05% of Y, not more than 0.002% of B, not more than 0.05% of Zr, not more than 0.1% of Al, not more than 0.2% of W, not more than 0.03% of N, not more than 0.025% of Co, not more than 0.006% of As, not more than 0.005% of Sb, not more than 0.005% of Bi, not more than 0.006% of Sn, not more than 0.006% of Pb, not more than 0.015% of the sum of As, Sb, Bi, Sn and Pb and the balance Fe and trace elements. The alloy movable conduit has the good structure and mechanical properties, corrosion resistance, dimensional precision and surface quality, and the use requirements of a sodium-cooled fast reactor are met.

Owner:JIANGSU YINHUAN PRECISION STEEL TUBE CO LTD

Production method of large-specification nickel-base high-temperature alloy forged piece

ActiveCN111235502AStable production processEfficient production processMetal-working apparatusTemperature controlUltimate tensile strength

The invention discloses a production method of a large-specification nickel-base high-temperature alloy forged piece. By means of the steps of blank preparation, grinding feeding operation, heating and heat preservation, isothermal forging operation and machining operation, the isothermal forging technology is adopted to control the technological parameters such as the blank height-diameter ratio,the forging temperature and the deformation rate, the mold temperature is controlled within a certain range, the blank temperature drop is effectively reduced, then delta-phase excessive precipitation is avoided, and the grain organization can be effectively refined under the condition of the high deformation. The GH4169 alloy (In718 in foreign countries) forged piece which meets the requirementsof airspace engines and vessel steam turbines is produced, and has the excellent strength, the endurance property and the high toughness.

Owner:宝武特种冶金有限公司

Red copper brass new technique used by ore-smelting electric furnace

ActiveCN101704176AImprove high temperature resistanceImprove corrosion resistanceElectric discharge heatingTemperature resistanceMechanical property

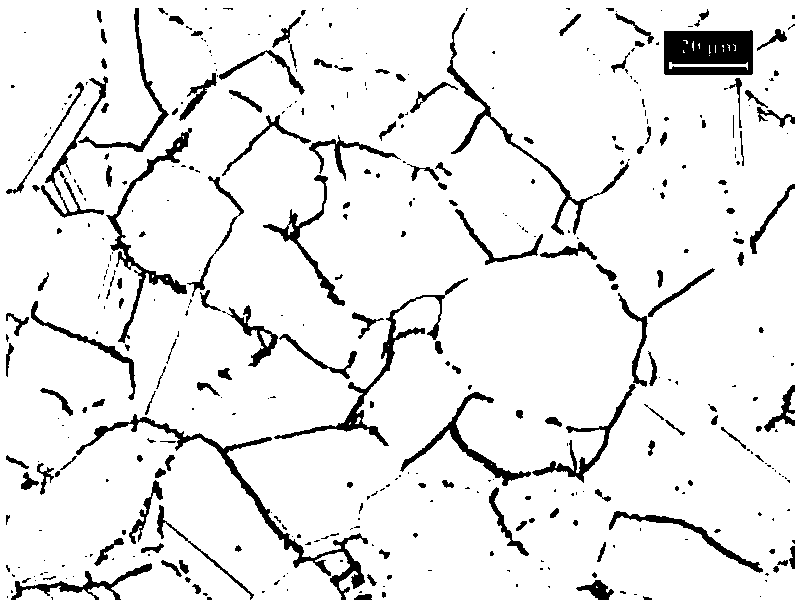

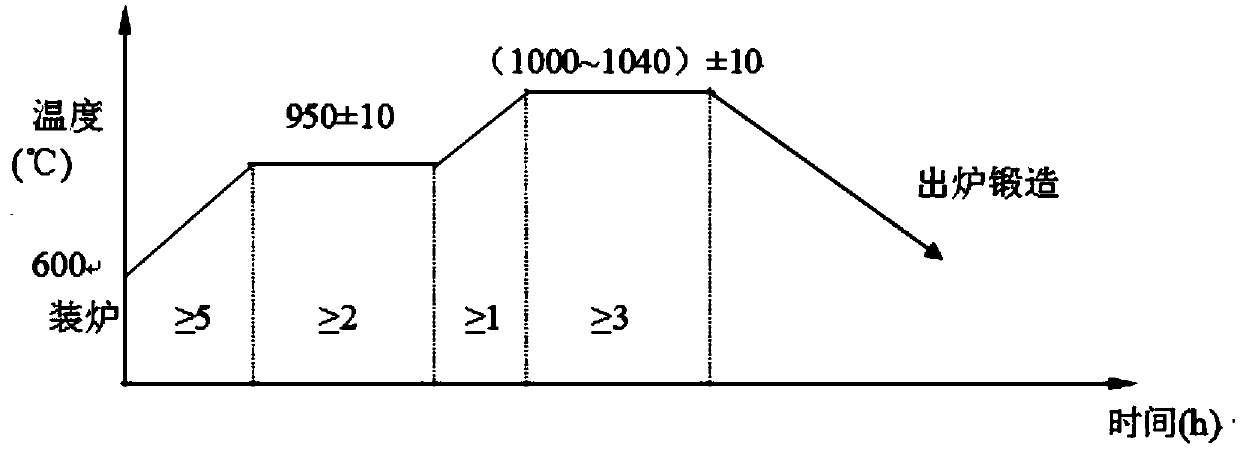

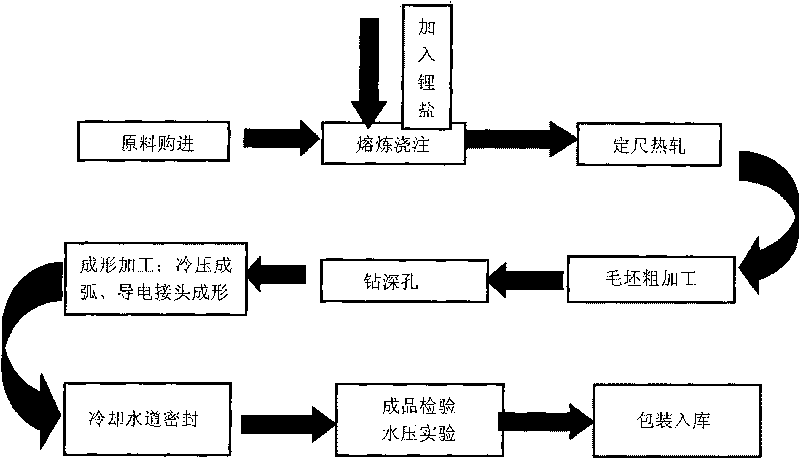

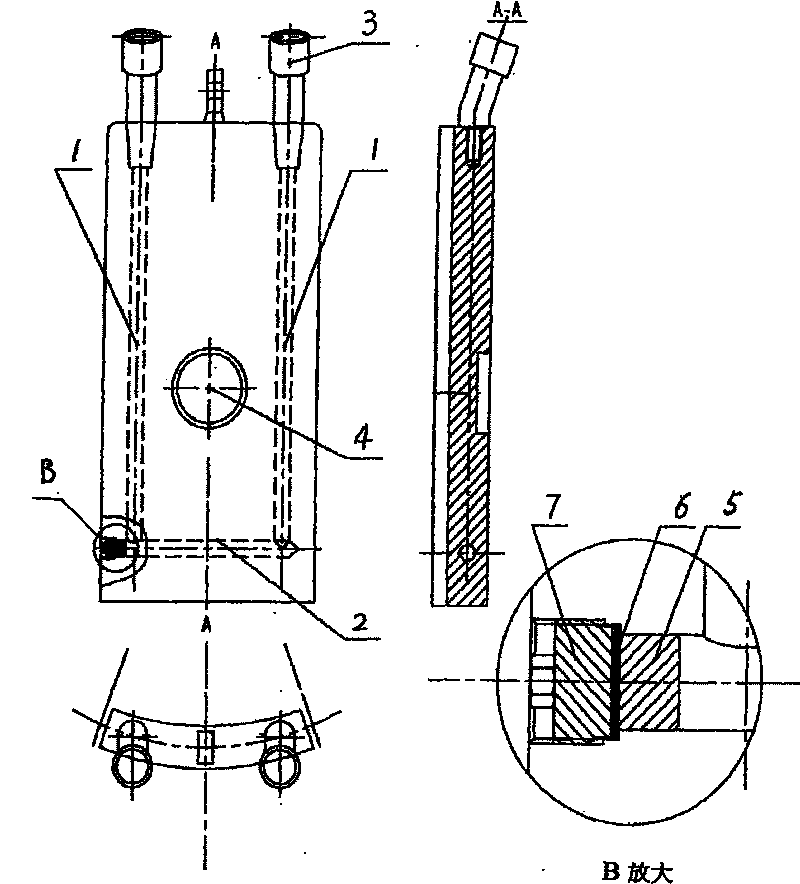

The invention relates to a method for manufacturing brass widely used as conductive element in ore-smelting electric furnace equipment in enterprises producing metallic silicon, ferrosilicon, calcium carbide and the like. The whole production technique mainly comprises the steps of adding trace lithium salt in red copper in melting and casting semicontinuously, hot rolling in set dimension, rough processing the blanks, drilling cooling deep holes, cold pressing and shaping, assembling into a whole, testing the finished product, etc. Cathode pure copper is selected as raw material compulsorily; deoxidation is carried out in melting to ensure the casting blank to be anaerobic copper ingot, and trace lithium salt is added, after casting and crystallizing, the compactness, corrosion resistance, high temperature resistance, abrasion resistance, impact resistance, hardness, electrical conductivity and thermal conductivity of the copper product are improved; the hot rolling process smashes bulky arborization crystal to cause crystalline grains to be thin, the fiber structure is continuous with being cut off the mechanical property, electrical conductivity and thermal conductivity are vastly enhanced; water holes are cooled by deep hole drilling machine processing; a press is used for performing cold pressing to roll the blank into arc shape; a boring machine and other equipments are used for boring out required cambered surface radius, electrical conduction joint parts and brass propping parts; and finally the parts are assembled into a whole, and the product is warehoused after passing the test.

Owner:GANSU MINGWANG ALUMINUM MATERIAL

Method for manufacturing boron-containing diamond compact

ActiveCN106735252AGood controllabilityFully recrystallizedTurbinesOther manufacturing equipments/toolsCemented carbideWear resistance

The invention discloses a method for manufacturing a boron-containing diamond compact. The method comprises the steps as follows: (1) diamond powder is soaked in a boric acid aqueous solution; (2) soaked diamond micro-powder is dried; (3) dried diamond micro-powder is evenly mixed with a binding agent; (4) the diamond micro-powder mixed with the binding agent is combined with a hard alloy matrix to form a synthetic block; (5) the synthetic block is placed in a special press for diamond for high-temperature and high-pressure treatment at the high temperature of 1,400-1,650 DEG C and under the high pressure of 5-7.5 MPa. With the method, the phenomenon of uneven boron containing or local accumulation in mixtures due to other methods is avoided, and more sufficient crystallization is realized through pretreatment, so that the strength, the wear resistance, the impact resistance, the heat resistance and the oxidation resistance of a diamond layer are further improved.

Owner:CR GEMS SUPERABRASIVES

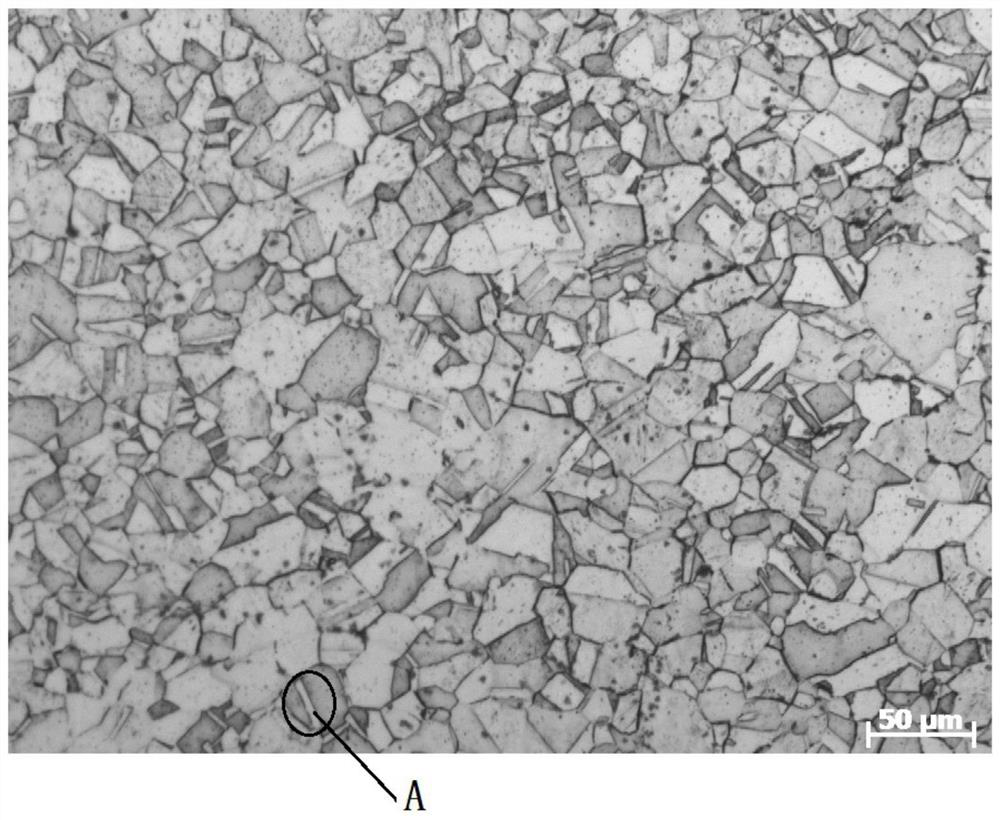

A kind of steel with high r value and thick specification IF automobile and its production method

The invention relates to a high-r-value thick IF automotive steel and a production method thereof. The method comprises: desulfurizing molten iron, converter blowing, RH vacuum refining, and continuous casting to obtain continuous casting slabs; heating the continuous casting slabs rolling to obtain hot-rolled slabs; coiling hot-rolled slabs to obtain hot-rolled steel coils; uncoiling pickling of hot-rolled steel coils; cold-rolling hot-rolled steel coils after pickling to obtain cold-rolled steel sheets ; Anneal the cold-rolled steel plate in the continuous annealing furnace; smooth the cold-rolled steel plate after annealing; the high r-value thick specification IF automotive steel produced by this method has good formability and mechanical properties, and can meet the requirements of medium and high grades. Stamping performance requirements for automotive sheets.

Owner:SHOUGANG CORPORATION

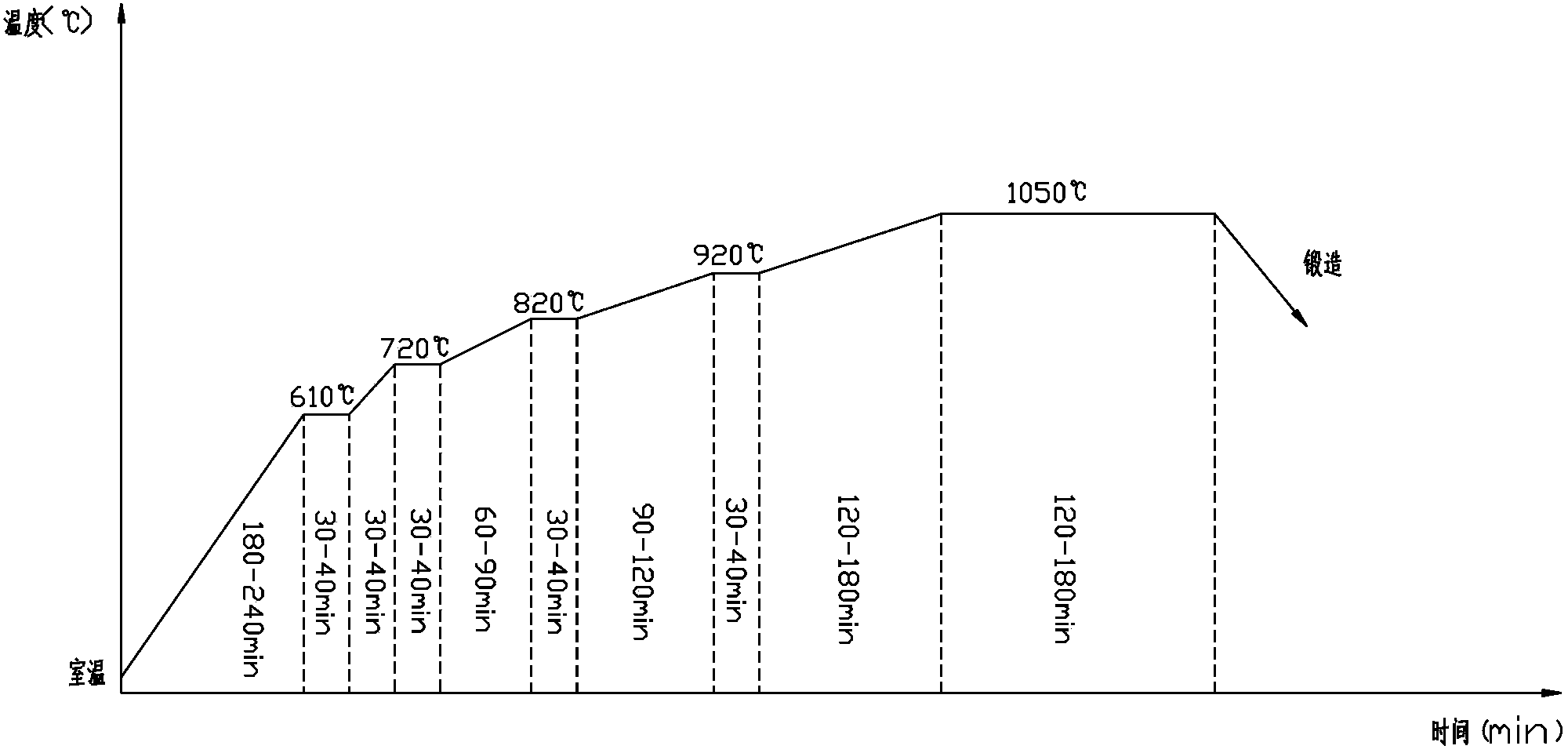

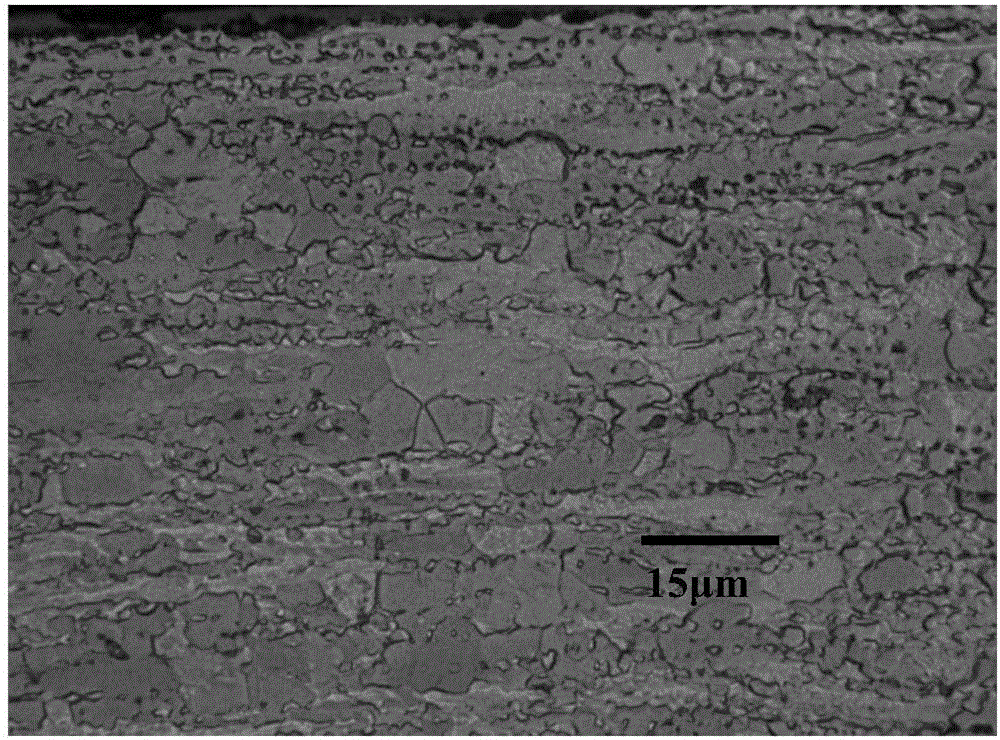

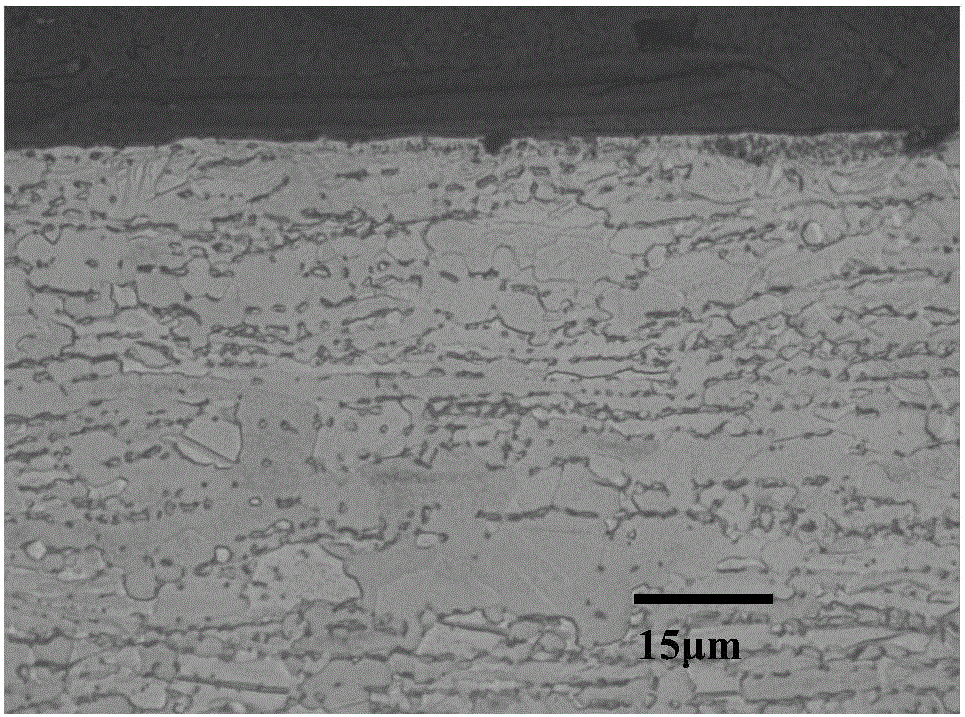

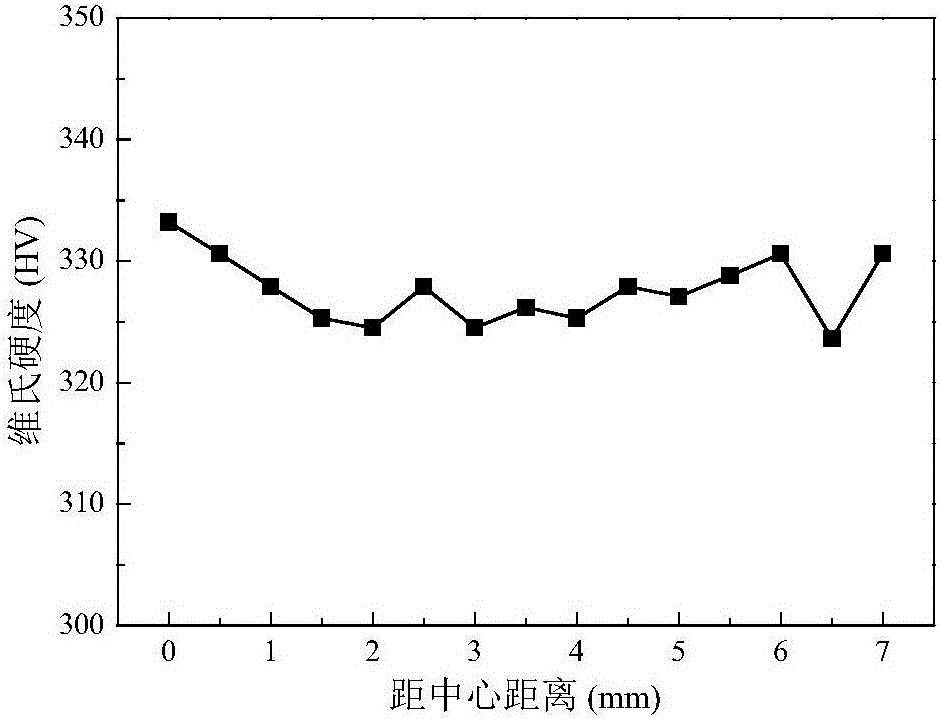

Forging processing technique for Fe-Si-B magnetic material

ActiveCN103409603AAvoid breakingFixed issue where Fractures could not be produced by forgingRoom temperaturePre treatment

The invention relates to a forging processing technique for a Fe-Si-B magnetic material. Fe-Si-B magnetic material blank is fed into a furnace at room temperature, slowly heated to 610 DEG C, kept warm, heated to 720 DEG again, subjected to warm keeping, then heated to 820 DGC C, kept warm, heated to 920 again, subjected to warm keeping, heated to the peak temperature of 1080 DEG C, subjected to warm keeping and forged. According to the invention, through heating pre-processing and reasonable heating processing parameters, the Fe-Si-B magnetic material can be prevented from fracturing when being heated before forging, so that the Fe-Si-B magnetic material can be processed and produced through a forging technology, and the problem that the conventional Fe-Si-B magnetic material fractures when being forged and heated directly and can not be produced through forging is solved.

Owner:度测(上海)科技服务中心

Method for improving stability of contracting sizes of TC4 medical U-shaped nails

ActiveCN106825102AFully recrystallizedFull mechanical propertiesPinsFurnace typesRe crystallizationMedicine

The invention discloses a method for improving the stability of the contracting sizes of TC4 medical U-shaped nails. The method for improving the stability of the contracting sizes of the TC4 medical U-shaped nails comprises the following steps of high-temperature heat treatment, hyperbolic curve straightening, low-temperature heat treatment, and detection of the contracting sizes of the U-shaped nails. According to the method for improving the stability of the contracting sizes of the TC4 medical U-shaped nails, a rod which is provided with an equiaxed structured and sufficient in re-crystallization is obtained through adjustment of the high-temperature heat treatment temperature; then, a rod meeting the GB / T 13810-2007 requirements is obtained through adjustment of the low-temperature heat treatment temperature; and finally, the rods obtained after different heat treatment technologies are conducted are each machined into 15 U-shaped nails, and the contracting size of each U-shaped nail is detected. Because the high-temperature heat treatment technology and the low-temperature heat treatment technology of the TC4 rods are adjusted, and detection is additionally conducted in each step, the contracting size of each U-shaped nail is guaranteed to be smaller than 0.10 mm, and the contracting sizes are kept stable. When the method for improving the stability of the contracting sizes of the TC4 medical U-shaped nails, it is only needed to conduct high-temperature and low-temperature heat treatment on the TC4 rods within a certain temperature range, other technological parameters do not need to be adjusted, and temperature adjustment is convenient, reliable and easy to operate.

Owner:DALIAN SUNNY TITANIUM IND

Hot rolling method for non-oriented electrical steel thin strip

InactiveCN105779728AReduce iron loss of finished productGood electromagnetic performanceSteel platesElectrical steel

The invention provides a hot rolling method for a non-oriented electrical steel thin strip. The electrical steel thin strip comprises, by weight, C<=0.003%, 3.5%-7.0% of Si, Al<=3.0%, 0.10%-1.50% of Mn, P<=0.03%, S<=0. 01%, N<=0.05%, and the balance Fe and unavoidable impurities. Before finish rolling, a plurality of slabs are stacked together to be rolled, the slabs are the same in thickness and component, and the thickness of each slab is 30-40 mm. The rolling starting temperature is controlled to be 950 DEG C or below. In the rolling process, cooling water in a rack is stopped. The final rolling temperature is controlled to be 800 DEG C or above. The coiling temperature is controlled to be 700 DEG C or below. Each roll of steel plate is rolled to be 0.2-0.7 mm. Slow cooling is conducted after coiling. After slow cooling, edge cutting and roll division are conducted. According to the hot rolling method, hot stacking continuous rolling is adopted, and the final rolling temperature is raised, so that a hot rolled plate is fully recrystallized, and the finished product iron loss is further reduced. The electromagnetic property is excellent, the production efficiency is improved, the steel plate is even in thickness, and the hot rolling method is suitable for high-speed stamping and automatic lamination.

Owner:ANGANG STEEL CO LTD

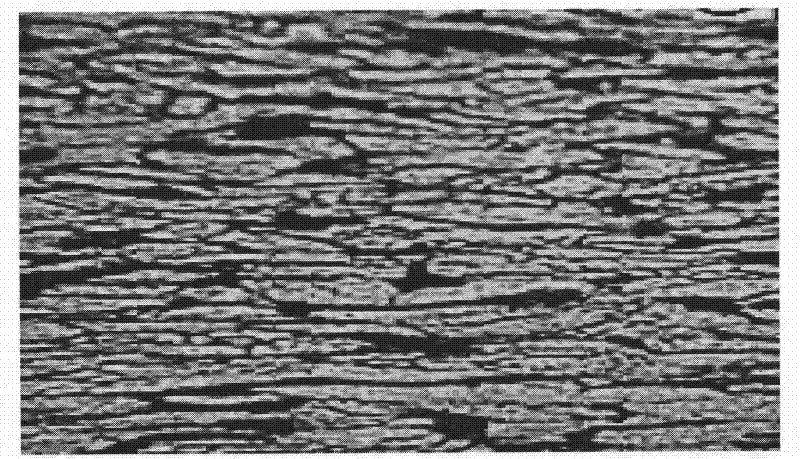

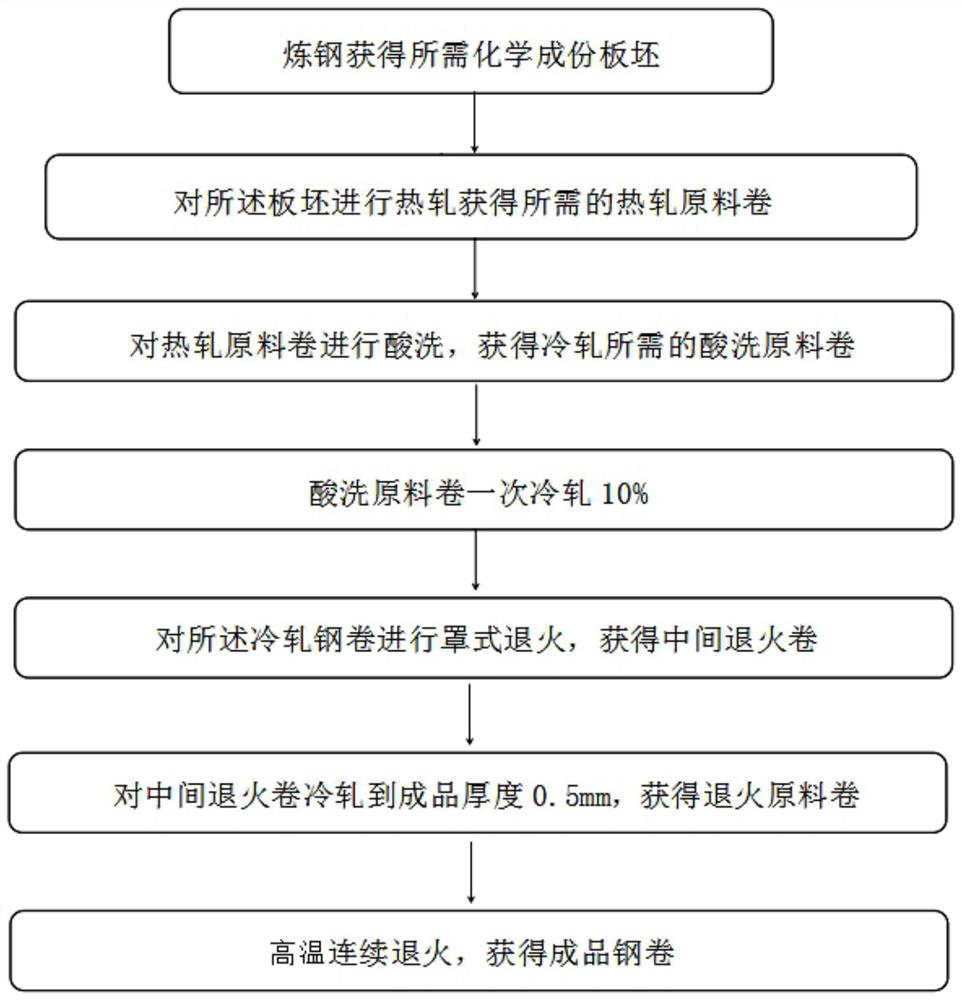

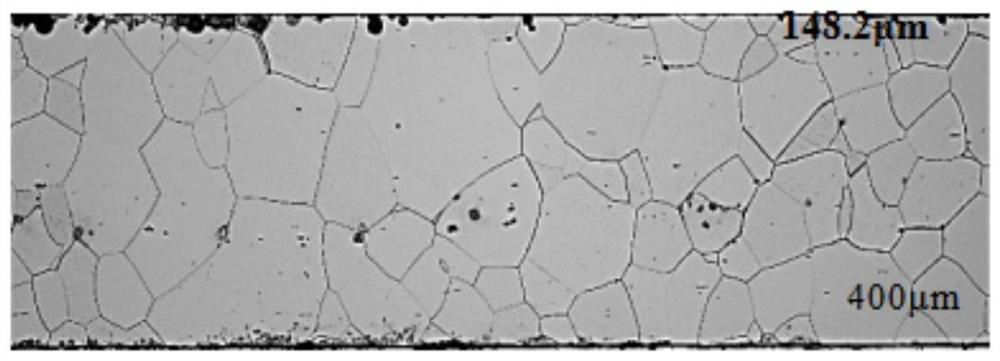

Production method of cover type intermediate annealing high-grade non-oriented silicon steel 50BW350

The invention relates to a production method of cover type intermediate annealing high-grade non-oriented silicon steel 50BW350. The production method comprises the steps of molten steel chemical component design, a hot rolling process, a cold rolling process, an annealing process and the like. The molten steel comprises the following chemical components: less than or equal to 0.004% of C, 1.80-2.1% of Si, 0.70-0.90% of Mn, 0.30-0.45% of Als, less than or equal to 0.015% of P, less than or equal to 0.0030% of S, less than or equal to 0.0020% of O, less than or equal to 0.0025% of N, 0.06-0.12% of Sb and the balance of Fe. The high-grade non-oriented silicon steel product without surface corrugation defects is obtained through special chemical design, Sb element addition, improvement of electromagnetic performance by optimizing the structure of the product, proper reduction of Si content, improvement of Mn element content and elimination of the influence of hot-rolled thick fiber tissues by a secondary cold rolling method. And compared with a traditional high-grade production method, the cost is low, and the produced silicon steel is excellent in electromagnetic performance.

Owner:BENGANG STEEL PLATES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com