Low-expansion alloy and preparation method thereof

A technology of low-expansion alloy and alloy ingot casting, which is applied in the field of low-expansion alloy and can solve problems such as strengthening low-expansion alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The present embodiment prepares a low-expansion alloy, which specifically includes the following steps:

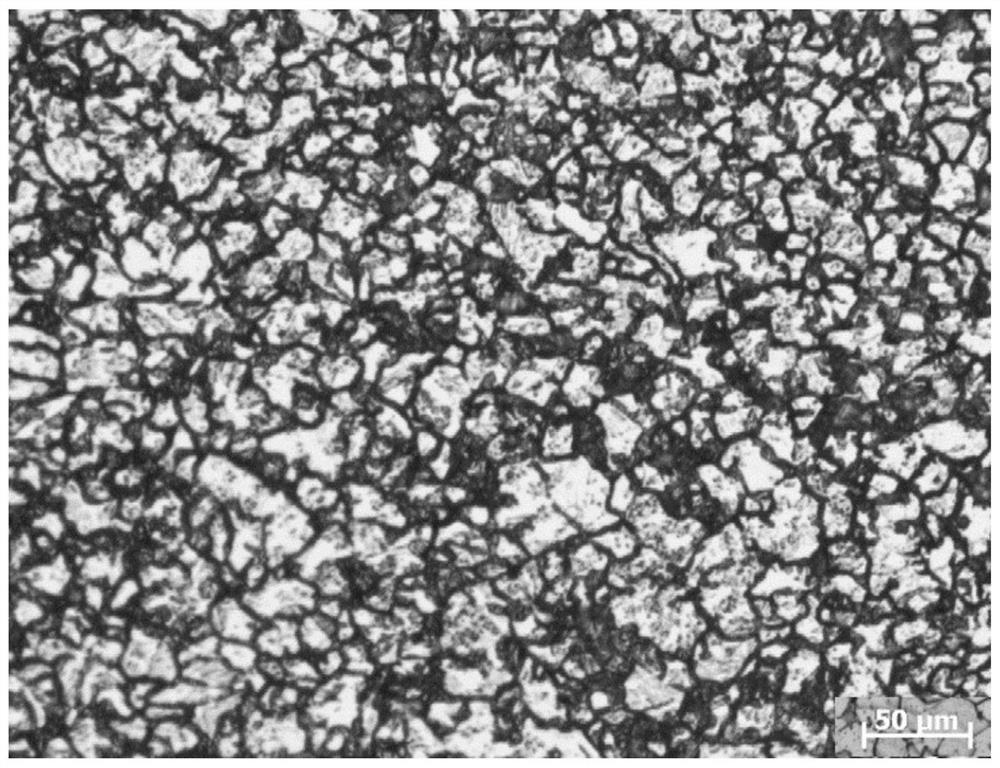

[0056] Preparation of low-expansion alloy body (ie, hot-rolled sheet): put the raw material into a high-frequency vacuum induction melting furnace, heat the temperature to 1450 ° C, and the vacuum degree of the melting furnace is 0.2 × 10 -2 Pa, after all the raw materials are melted, refine at a temperature of 1800° C. for 5 minutes, then introduce inert gas, and cast the crucible into an ingot (alloy ingot). The formulation of the raw materials is as follows: Mo 0.15%, Si 0.18%, Mn 0.32%, Ni 36%, Co 0.25%, and the balance is Fe. After the alloy ingot is cooled, the alloy ingot is heated to 1150° C. and kept at this temperature for 4 hours for homogenization treatment. Subsequently, billeting is carried out on a hot rolling mill, wherein the rolling temperature is 1150° C., the total reduction rate is 95%, and the final rolling temperature is 950° C., and when rol...

Embodiment 2

[0062] The present embodiment prepares a low-expansion alloy, which specifically includes the following steps:

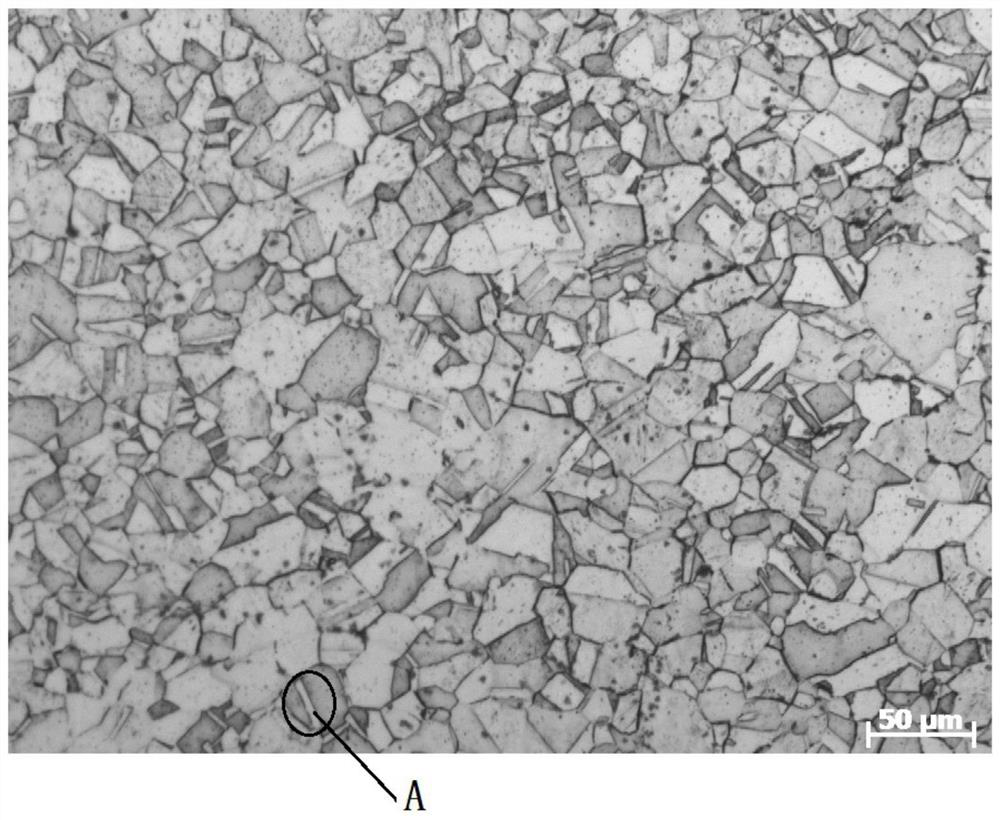

[0063] Preparation of low-expansion alloy body (ie, hot-rolled sheet): put the raw material into a high-frequency vacuum induction melting furnace, heat the temperature to 1500 ° C, and the vacuum degree of the melting furnace is 0.4×10 -2 Pa, after all the raw materials are melted, refine at a temperature of 1600° C. for 6 minutes, then pass in an inert gas, and cast the crucible into an ingot (ie, an alloy ingot). The formula of the raw materials is as follows: Mo 0.15%, Si 0.18%, Mn 0.32%, Ni 36%, Co 0.25%, and the balance is Fe. After the alloy ingot is cooled, the alloy ingot is heated to 1180° C. and kept at this temperature for 3 hours for homogenization treatment. Subsequently, billeting is carried out on a hot rolling mill, wherein the rolling temperature is 1180° C., the total reduction rate is 80%, and the final rolling temperature is 980° C., and when r...

Embodiment 3

[0069] The present embodiment prepares a low-expansion alloy, which specifically includes the following steps:

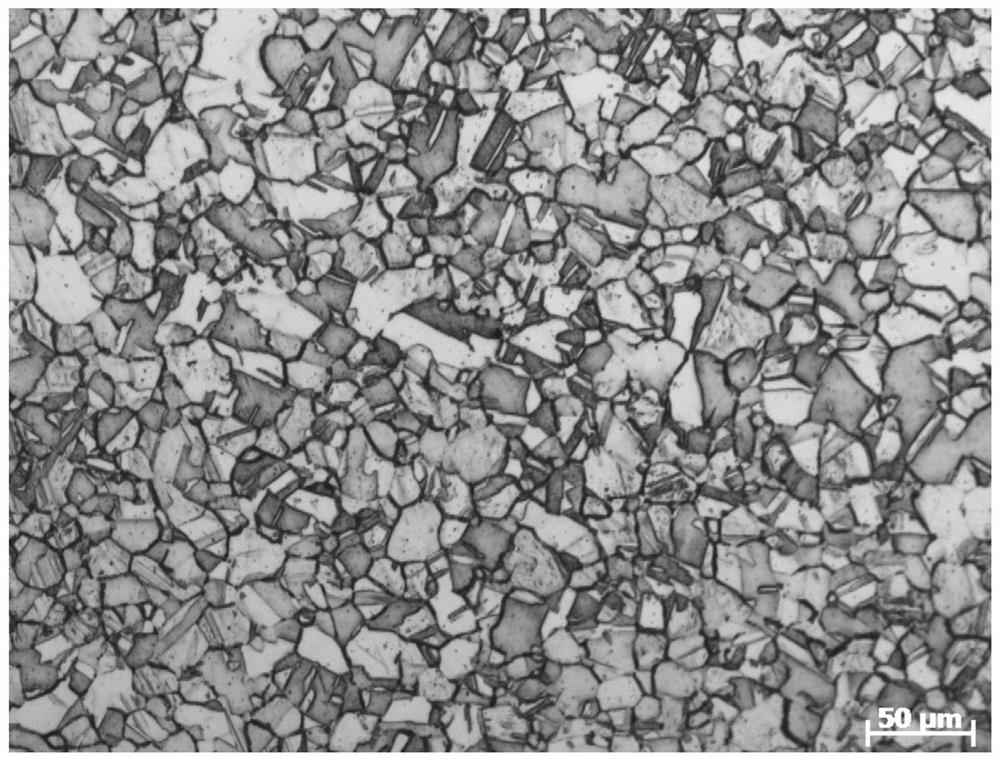

[0070] Preparation of low-expansion alloy body (ie, hot-rolled sheet): put the raw material into a high-frequency vacuum induction melting furnace, heat the temperature to 1550 ° C, and the vacuum degree of the melting furnace is 0.6×10 -2 Pa, after all the raw materials are melted, refine at a temperature of 1550° C. for 8 minutes, then pass in an inert gas, and cast the crucible into an ingot (ie, an alloy ingot). The formula of the raw materials is as follows: Mo 0.15%, Si 0.18%, Mn 0.32%, Ni 36%, Co 0.25%, and the balance is Fe. After the alloy ingot is cooled, the alloy ingot is heated to 1200° C. and kept at this temperature for 2 hours for homogenization treatment. Subsequently, billeting is carried out on a hot rolling mill, wherein the rolling temperature is 1200 °C, the total reduction rate is 60%, and the final rolling temperature is 900 °C, and when rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com