Casting method for heavy combustion engine II-stage diverter blade

A casting method and guide technology, applied in the direction of mold, core, mold composition, etc., can solve the problems of low void ratio, affecting the core removal speed, large deformation, etc., to improve wet strength and high temperature strength, reduce Possibility of cracking, effect of solving cracks and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The porosity of the porous quartz glass powder is 10-20%, and it should not be too fine, between 150 mesh and 180 mesh, and the dosage is 30%. At the same time, a mullite mineralizer with a particle size of less than 320 meshes is added, and the dosage is 10%. The usage amount of plasticizer (10% beeswax, 3% polyethylene, and the rest is a mixture of paraffin) is 18%. The particle size of the traditional quartz glass powder is between 180 mesh and 240 mesh.

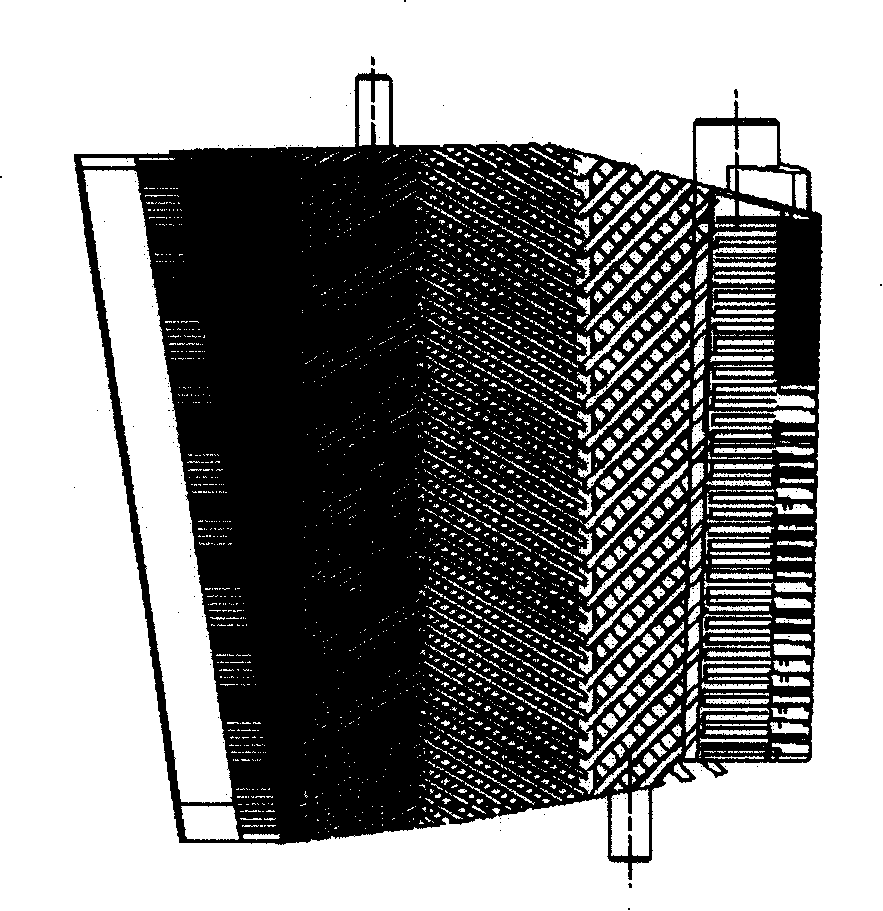

[0046] Mix the above raw materials thoroughly, and press the core press machine according to the figure 1 After the shape shown is pressed and formed, it is fired, and the ceramic core in a wet state should be fully vibrated in the filler before firing. The firing temperature is 200±10°C, 8h+400±10°C, 8h+600±10°C, 1h+900±10°C, 1h+1200±10°C, 10h.

[0047] After being released from the furnace, it is strengthened by ethyl silicate at high temperature and novolak varnish at low temperature. The prepared silicon-bas...

Embodiment 2

[0049] The porosity of the porous quartz glass powder is 10-20%, and it should not be too fine, between 150 mesh and 180 mesh, and the dosage is 35%. At the same time, a mullite mineralizer whose particle size is less than 320 mesh is added, and the consumption is 15%. The usage amount of the plasticizer (12% beeswax, 3% polyethylene, and the rest is a mixture of paraffin) is 20% of the powder proportion. The particle size of the traditional quartz glass powder is between 180 mesh and 240 mesh.

[0050] Mix the above raw materials thoroughly, and press the core press machine according to the figure 1 After the shape shown is pressed and formed, it is fired, and the ceramic core in a wet state should be fully vibrated in the filler before firing. The firing temperature is 200±10°C, 6h+400±10°C, 6h+600±10°C, 1h+900±10°C, 1h+1200±10°C, 8h.

[0051] After being released from the furnace, it is strengthened by ethyl silicate at high temperature and novolak varnish at low tempera...

Embodiment 3

[0053] The porosity of the porous quartz glass powder is 10-20%, and it should not be too fine, between 150 mesh and 180 mesh, and the dosage is 40%. At the same time, a mullite mineralizer with a particle size of less than 320 meshes is added, and the dosage is 10%. The usage amount of the plasticizer (15% beeswax, 4% polyethylene, and the rest is a mixture of paraffin) is 22% of the powder proportion. The particle size of the traditional quartz glass powder is between 180 mesh and 240 mesh.

[0054] Mix the above raw materials thoroughly, and press the core press machine according to the figure 1 After the shape shown is pressed and formed, it is fired, and the ceramic core in a wet state should be fully vibrated in the filler before firing. The firing temperature is 200±10°C, 8h+400±10°C, 8h+600±10°C, 1h+900±10°C, 1h+1200±10°C, 10h.

[0055] After being released from the furnace, it is strengthened by ethyl silicate at high temperature and novolak varnish at low temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com