Patents

Literature

60results about How to "Improve planarization efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

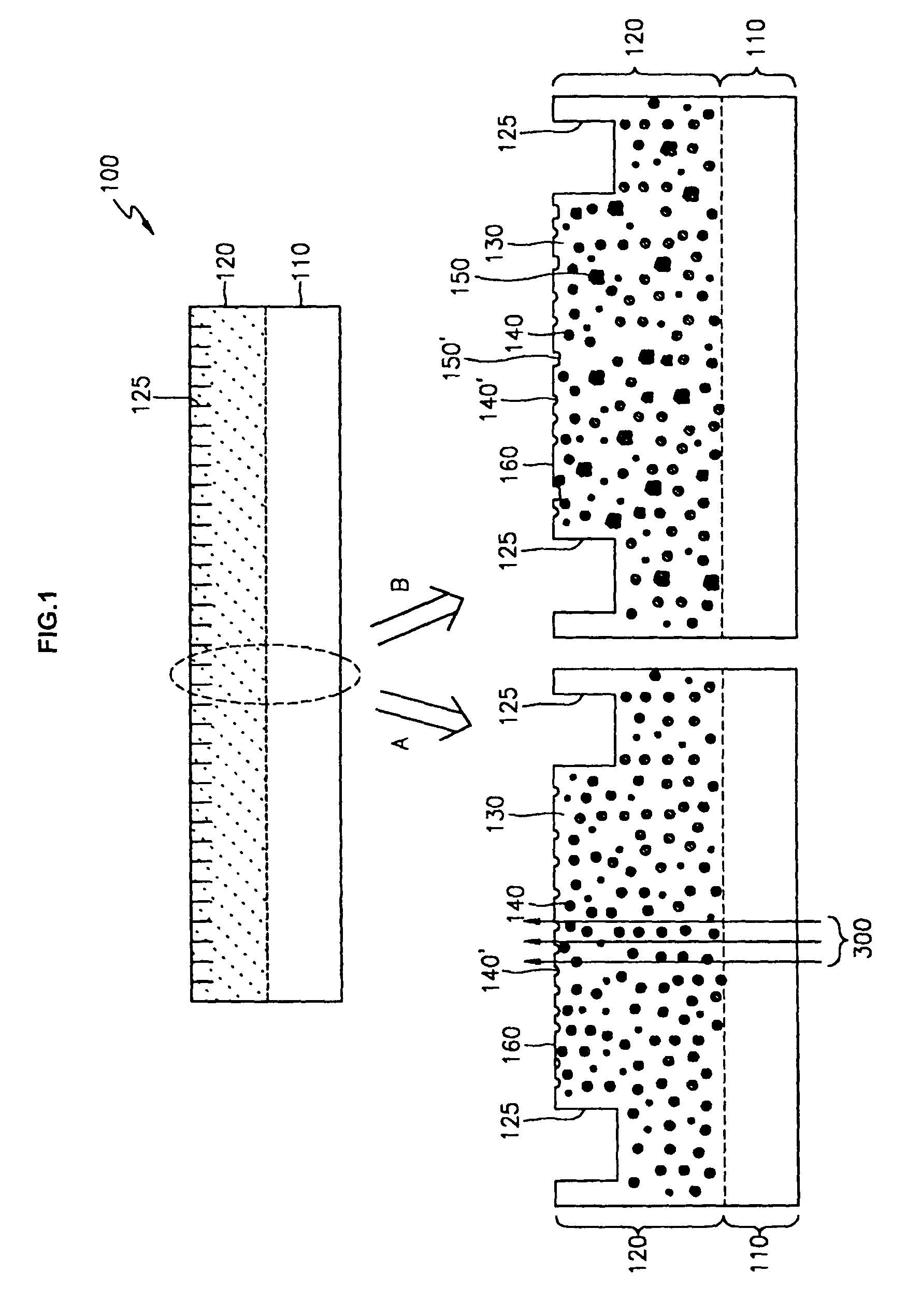

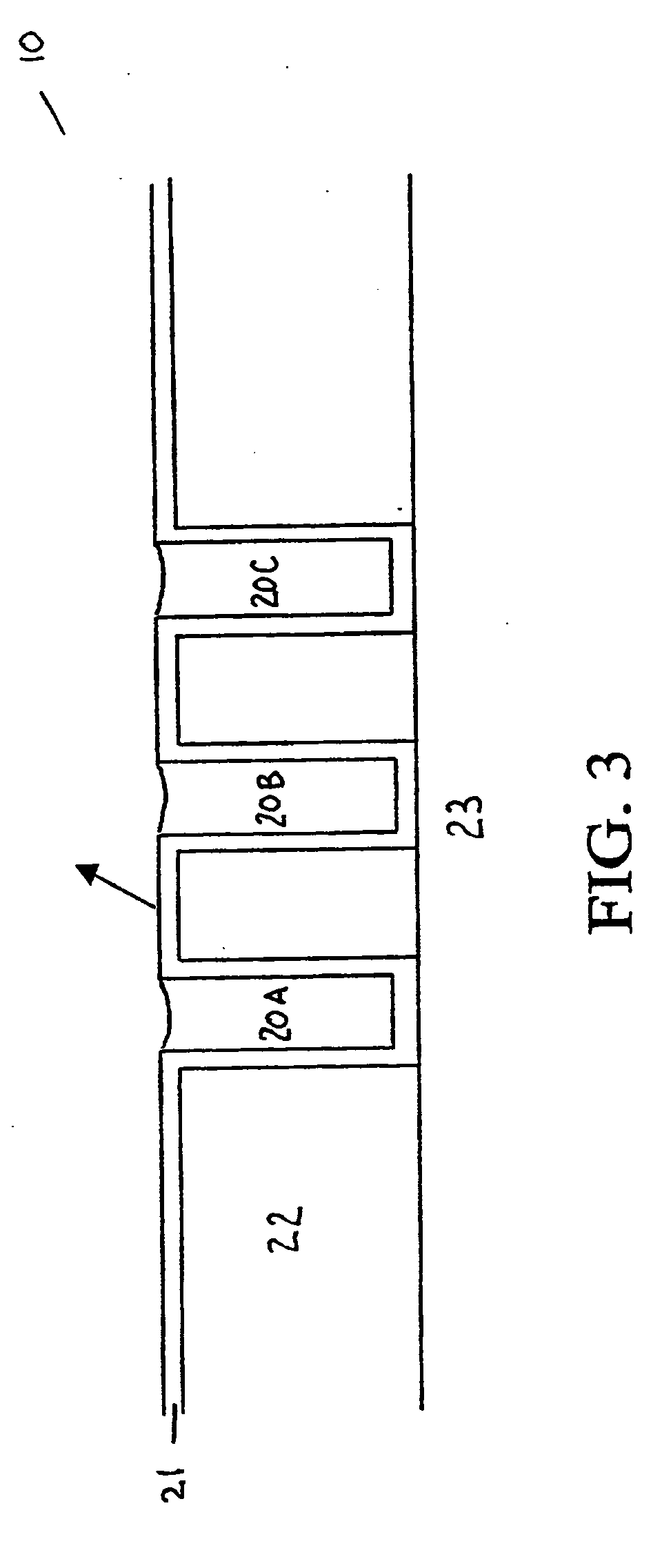

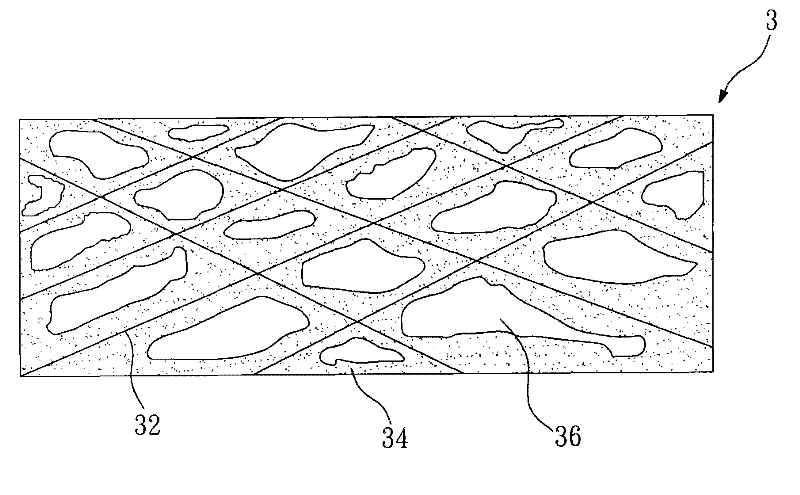

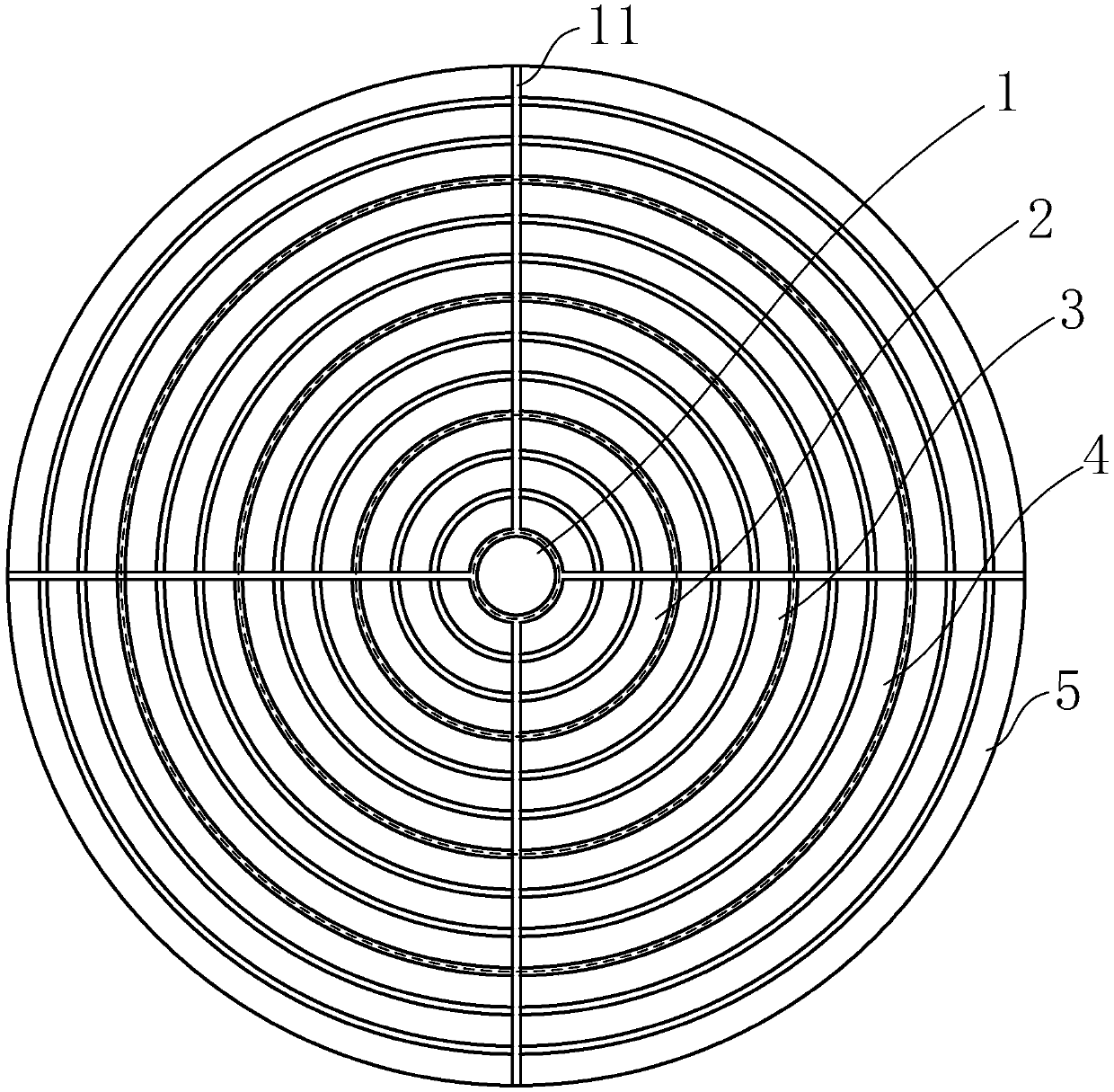

Integral polishing pad and manufacturing method thereof

InactiveUS7029747B2Improve planarization efficiencyEasy to manufactureSemiconductor/solid-state device manufacturingTraffic signalsAdhesiveHardness

Owner:KPX CHEM

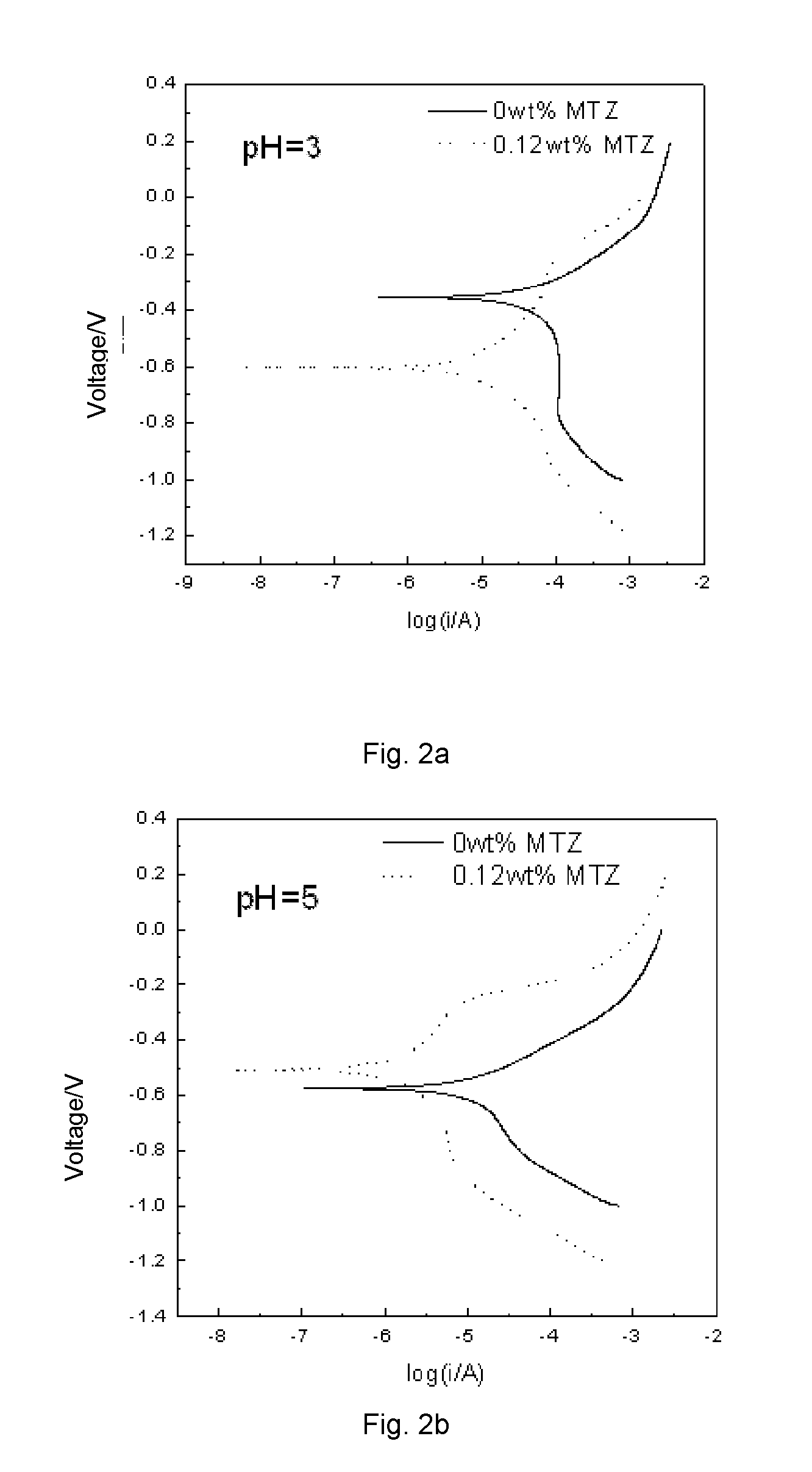

Slurry for chemical mechanical polishing of cobalt

InactiveUS20130140273A1Inhibition of corrosion rateLow corrosion rateOther chemical processesDecorative surface effectsSlurryCobalt

A slurry for chemical mechanical polishing of Co. The slurry comprises components by weight as follows, Inhibitor 0.01-2%, Oxidant 0-5%, Abrasive 0.1-10%, Complexing agent 0.001-10%, and the rest of water. The pH value of the slurries is adjusted to 3-5 by a pH value adjustor. The inhibitor is chosen from one or more kinds of five-membered heterocycle compound containing S and N atoms or containing S or N atom. The oxidant is one or more chosen from H2O2, (NH4)2S2O8, KIO4, and KClO5. The abrasive is one or more chosen from SiO2, CeO2, and Al2O3. The complexing agent is one or more chosen from amino acid and citric acid. The slurry can effectively prevent Co over corrosion and reduce the polishing rate of Co in the polishing process.

Owner:FUDAN UNIV

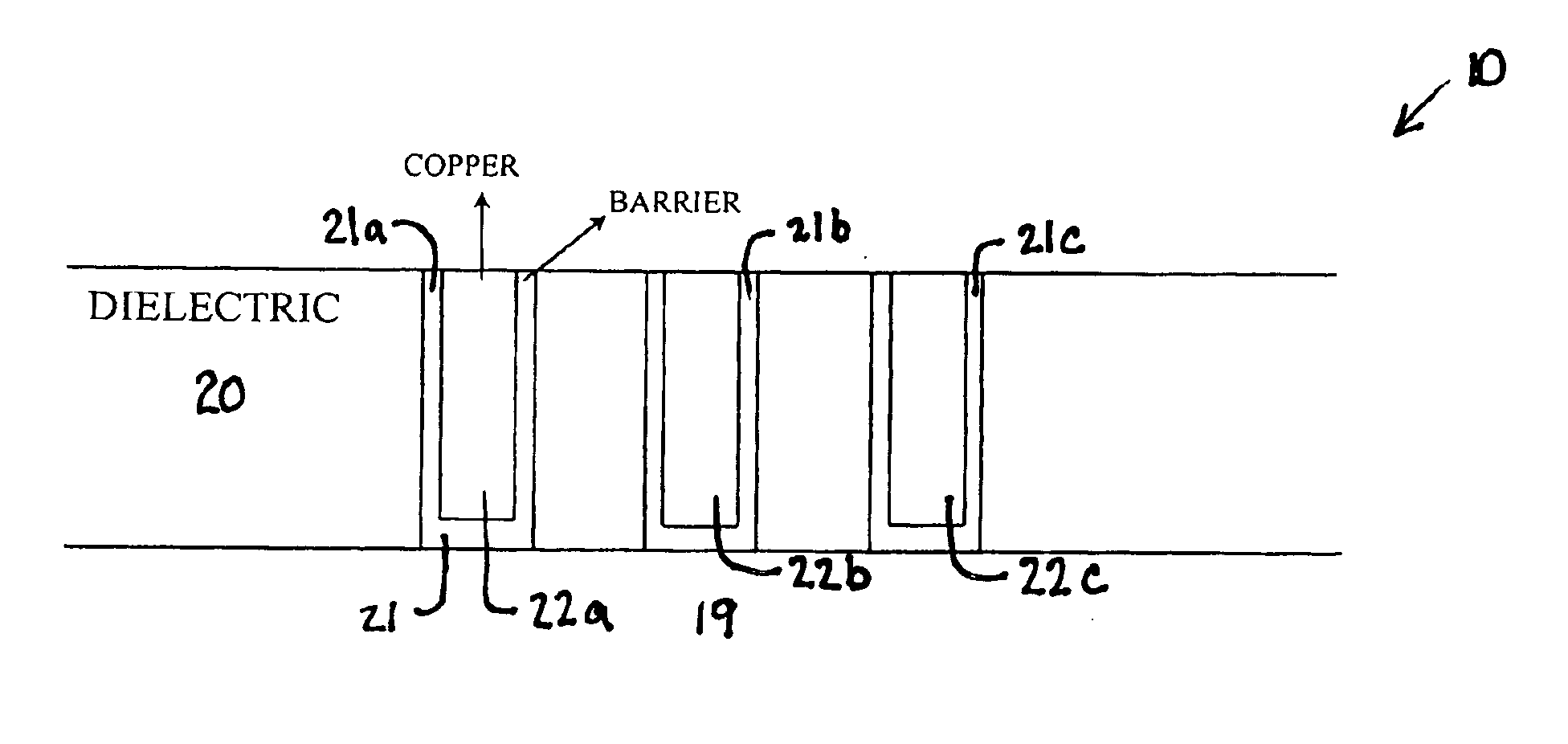

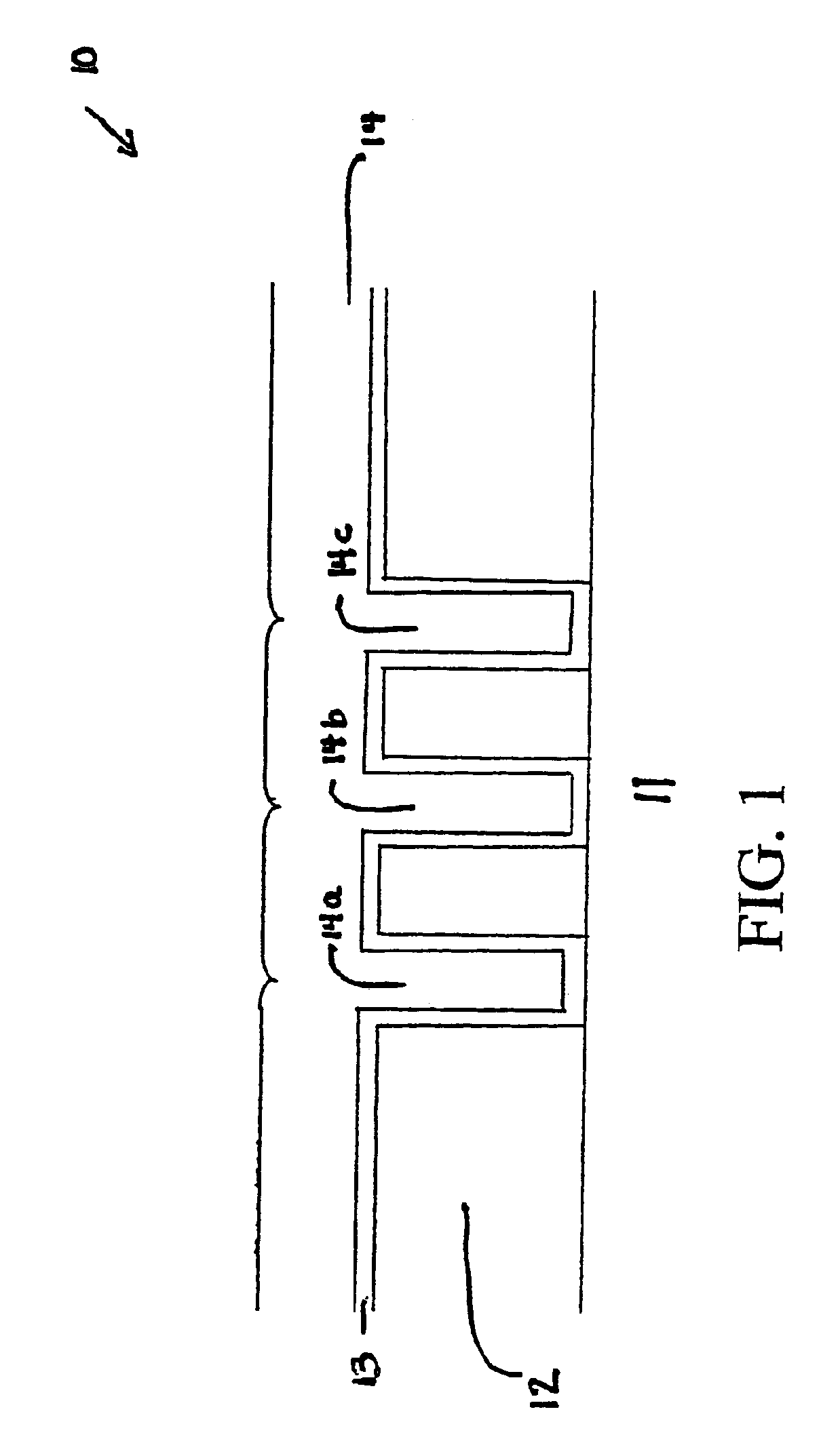

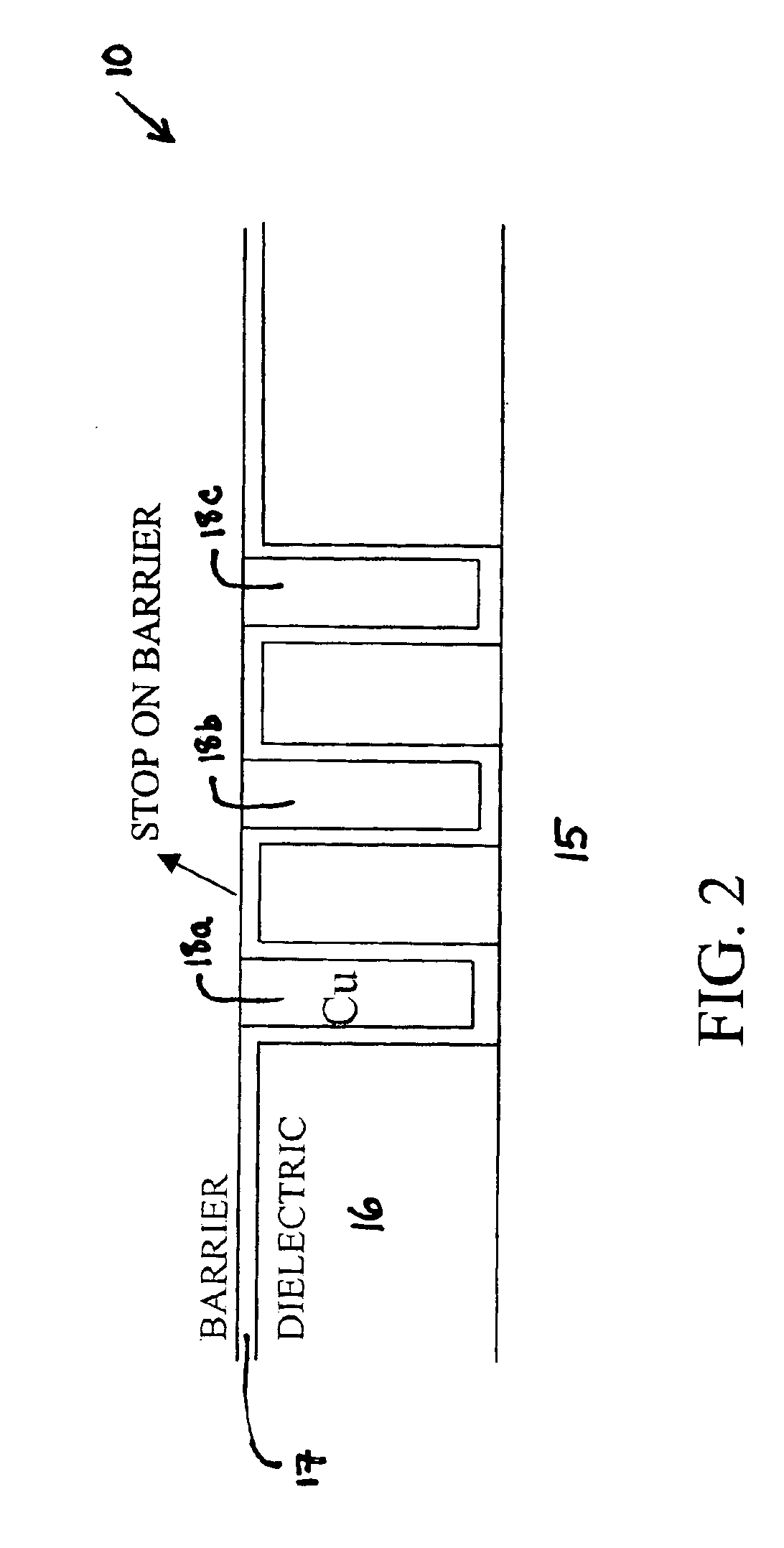

Chemical mechanical polishing compositions for metal and associated materials and method of using same

InactiveUS7029373B2High removal rateLow removal ratePigmenting treatmentOther chemical processesCompound (substance)Copper

A chemical mechanical polishing slurry composition and method for using the slurry composition for polishing copper, barrier material and dielectric material that comprises first and second-step slurries. The first-step slurry has a high removal rate on copper and a low removal rate on barrier material. The second-step slurry has a high removal rate on barrier material and a low removal rate on copper and dielectric material. The first slurry comprises at least an organic polymeric abrasive.

Owner:ADVANCED TECH MATERIALS INC

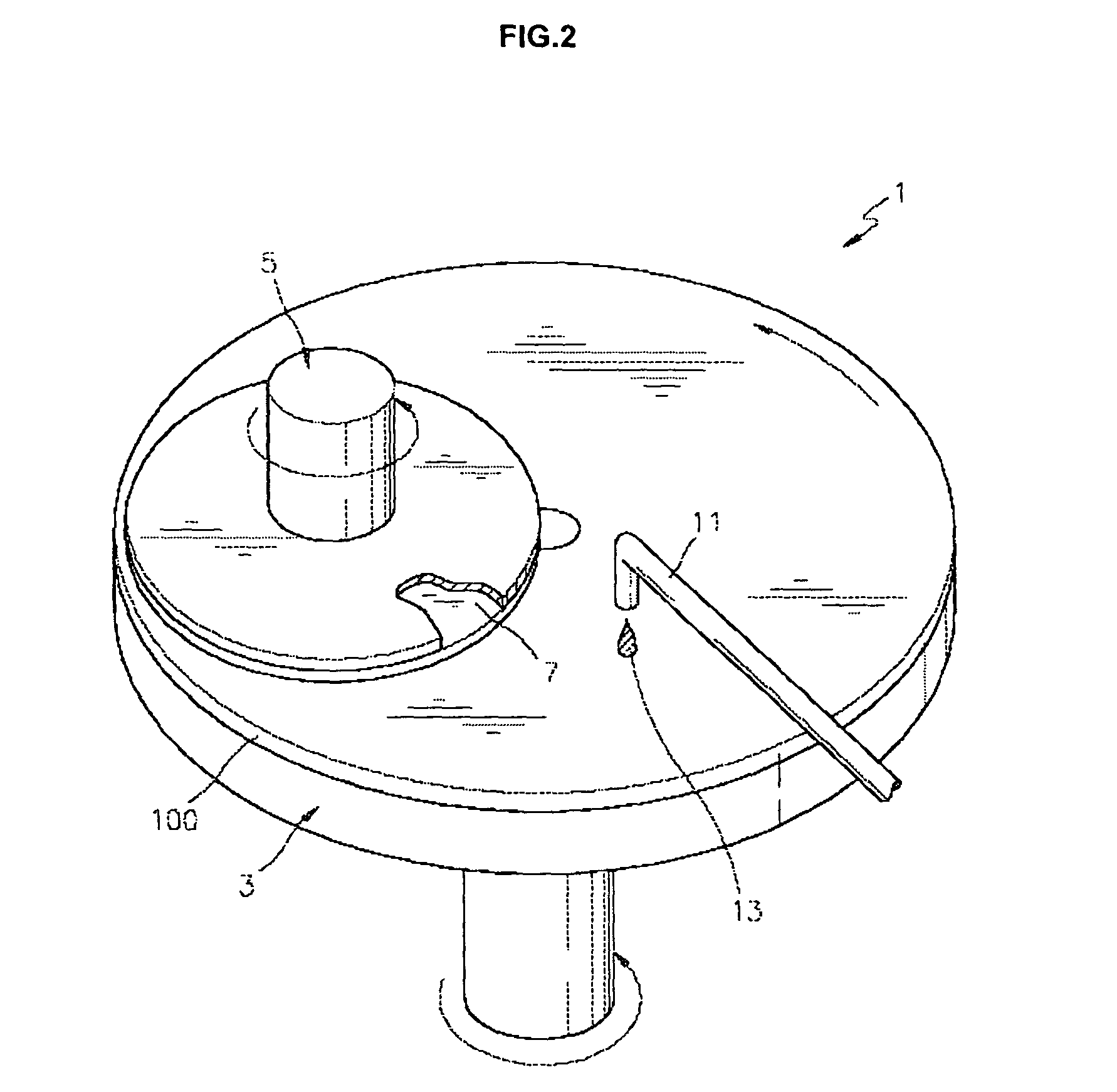

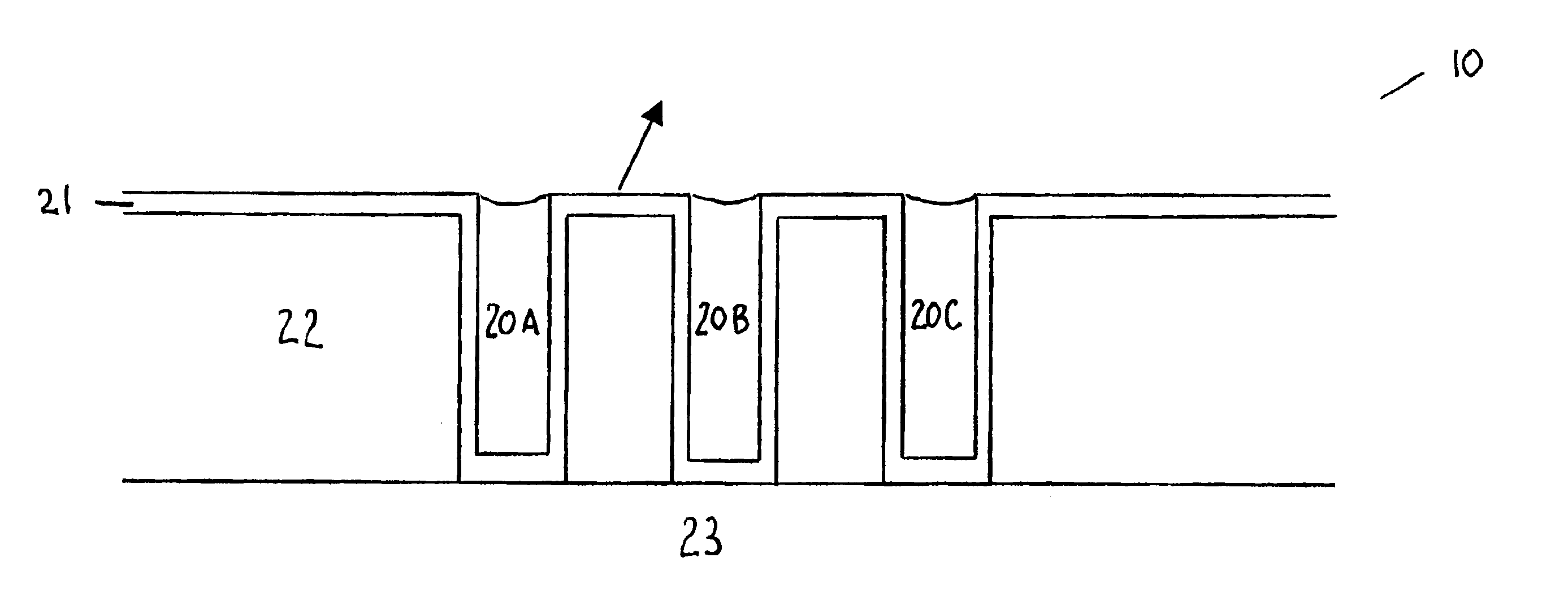

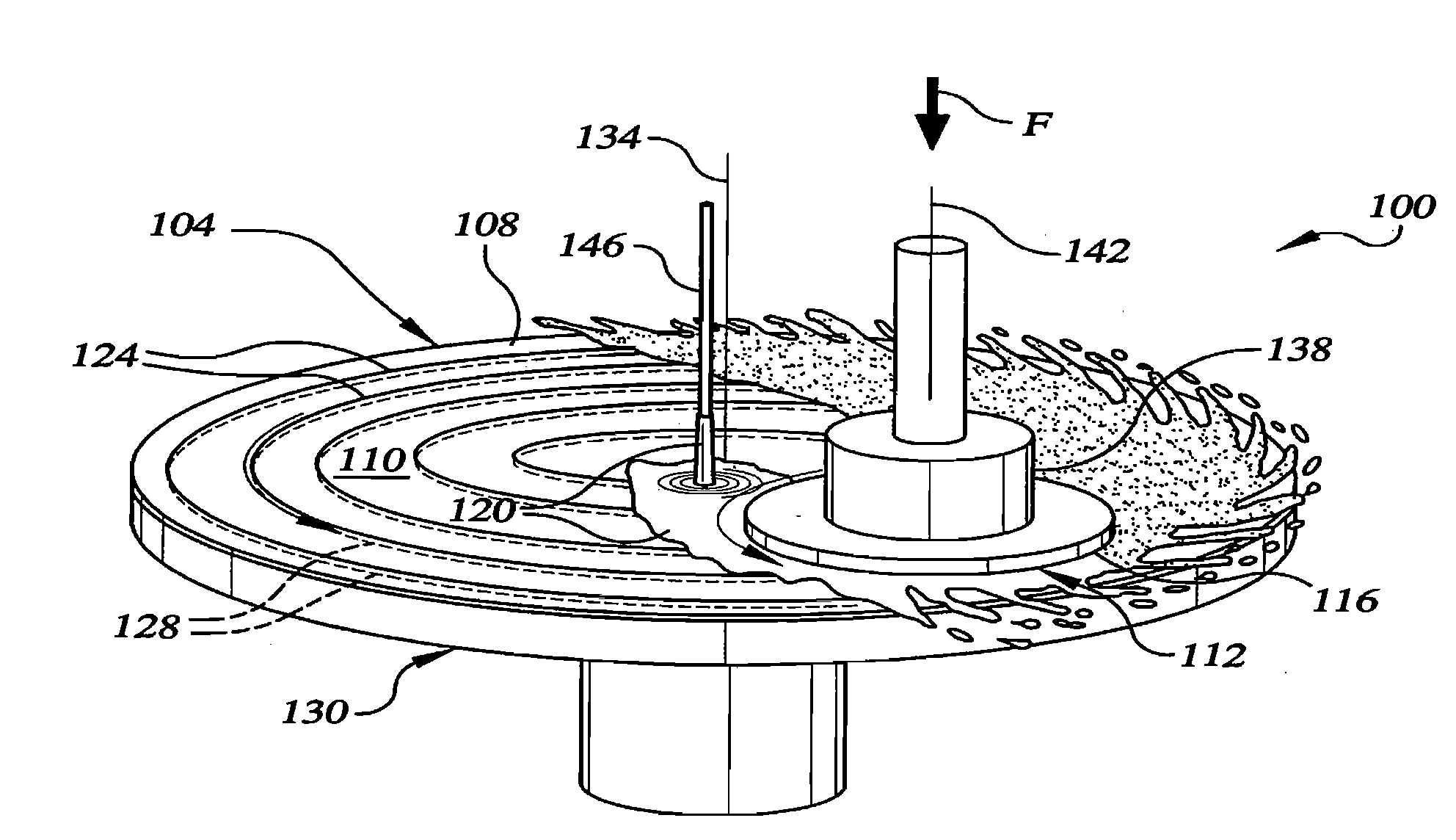

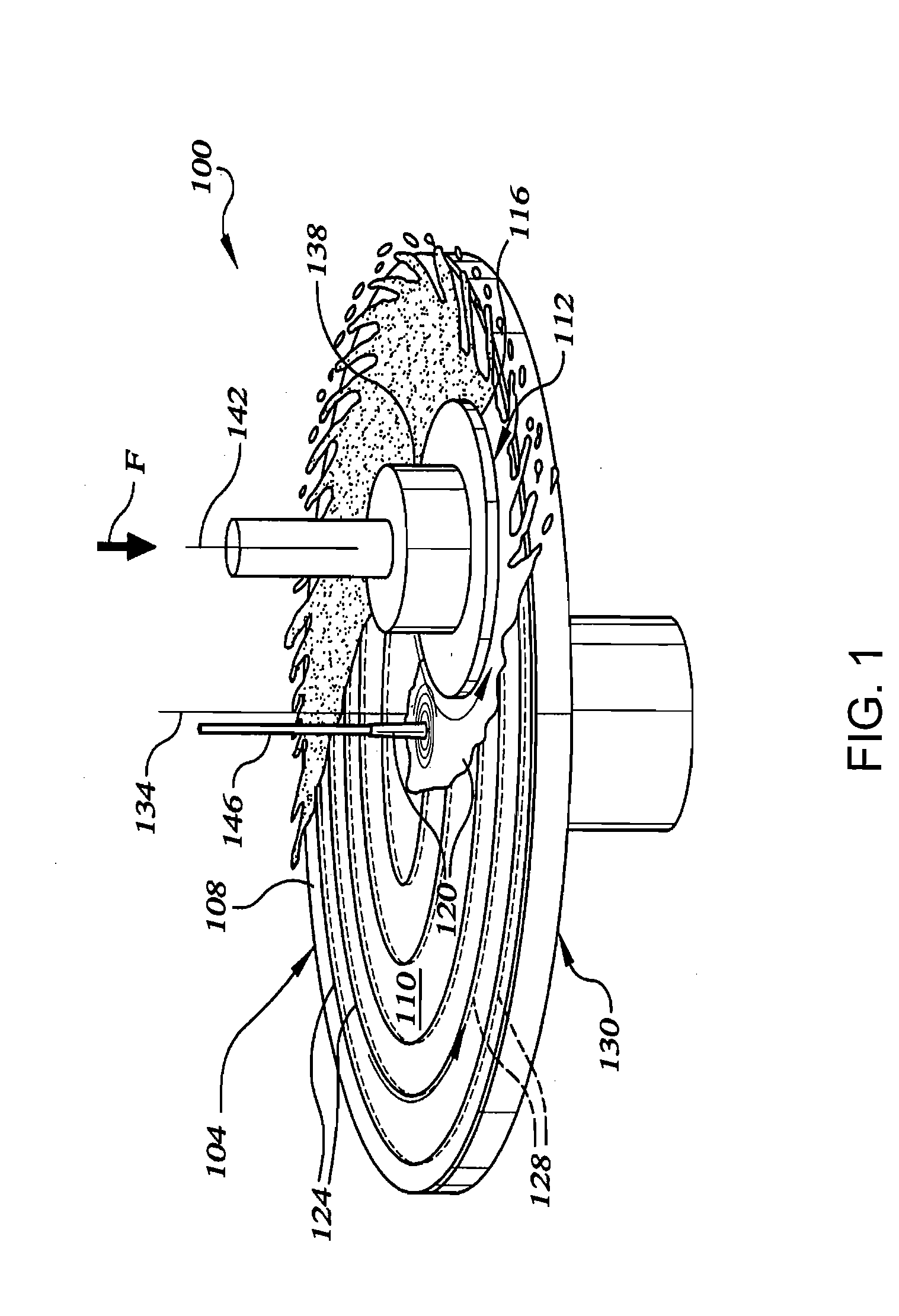

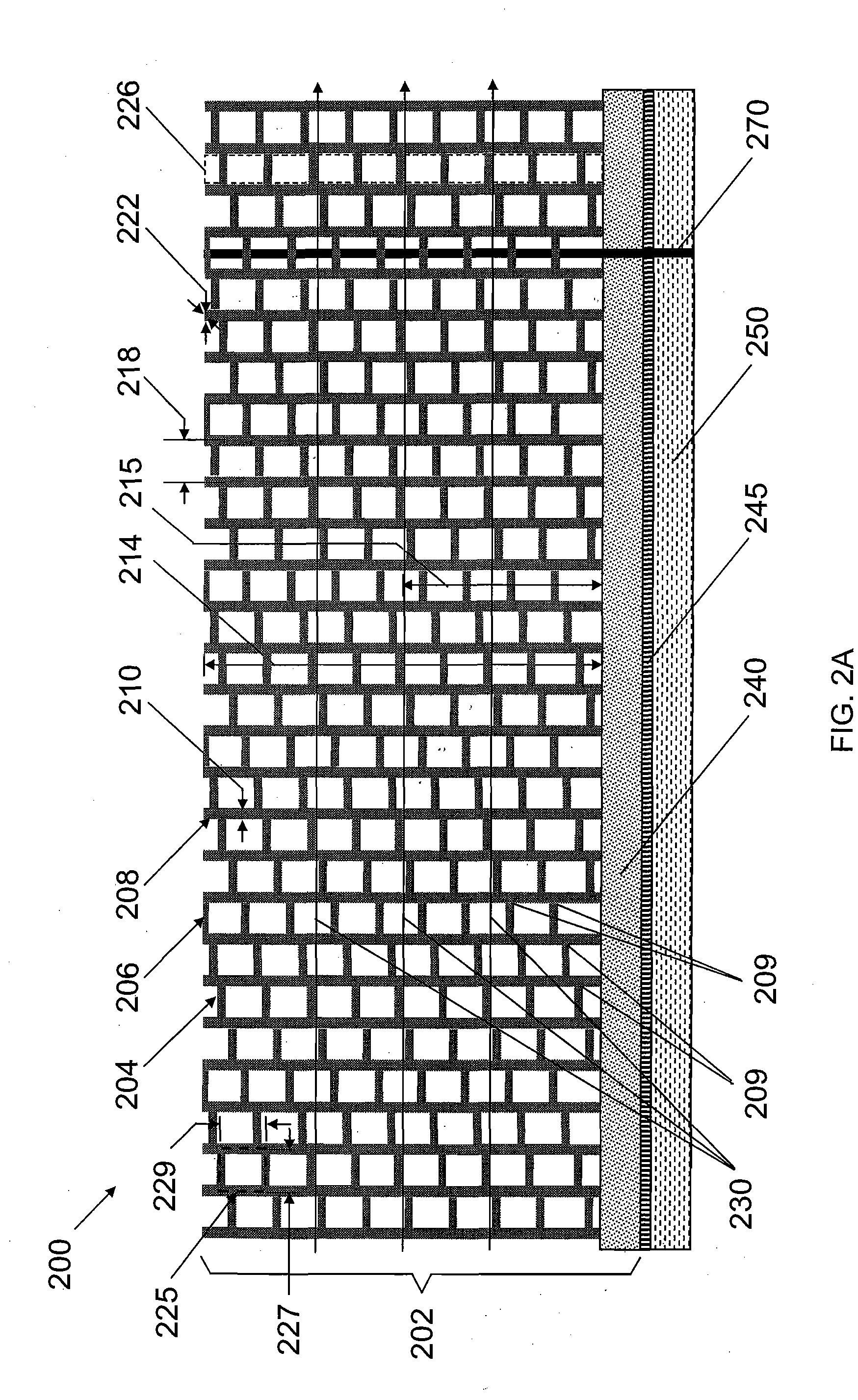

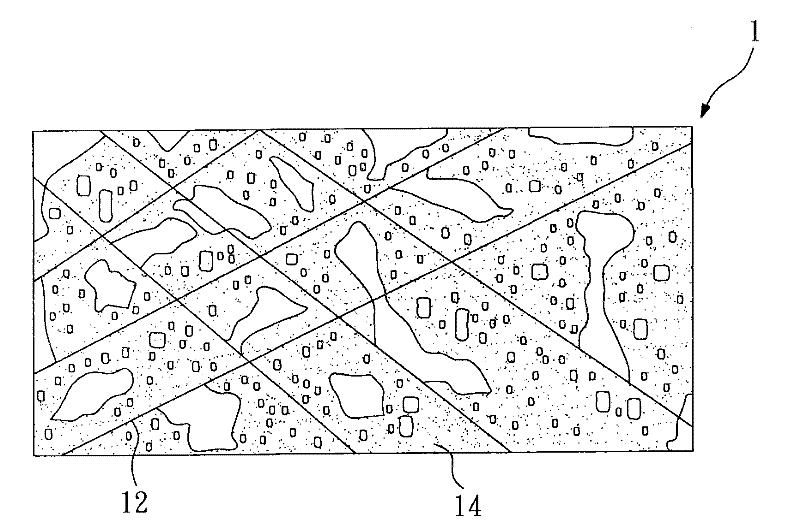

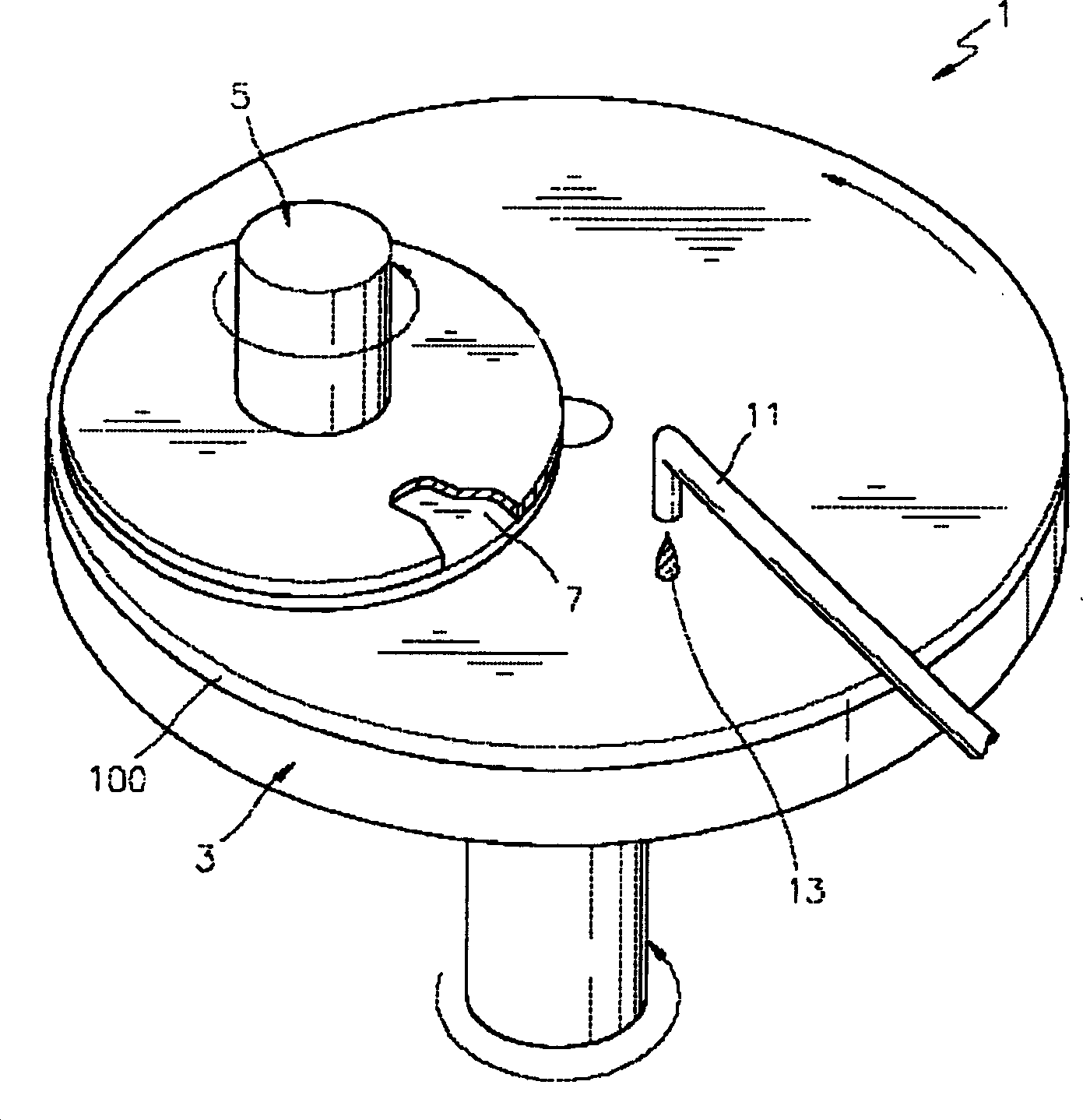

Three-dimensional network for chemical mechanical polishing

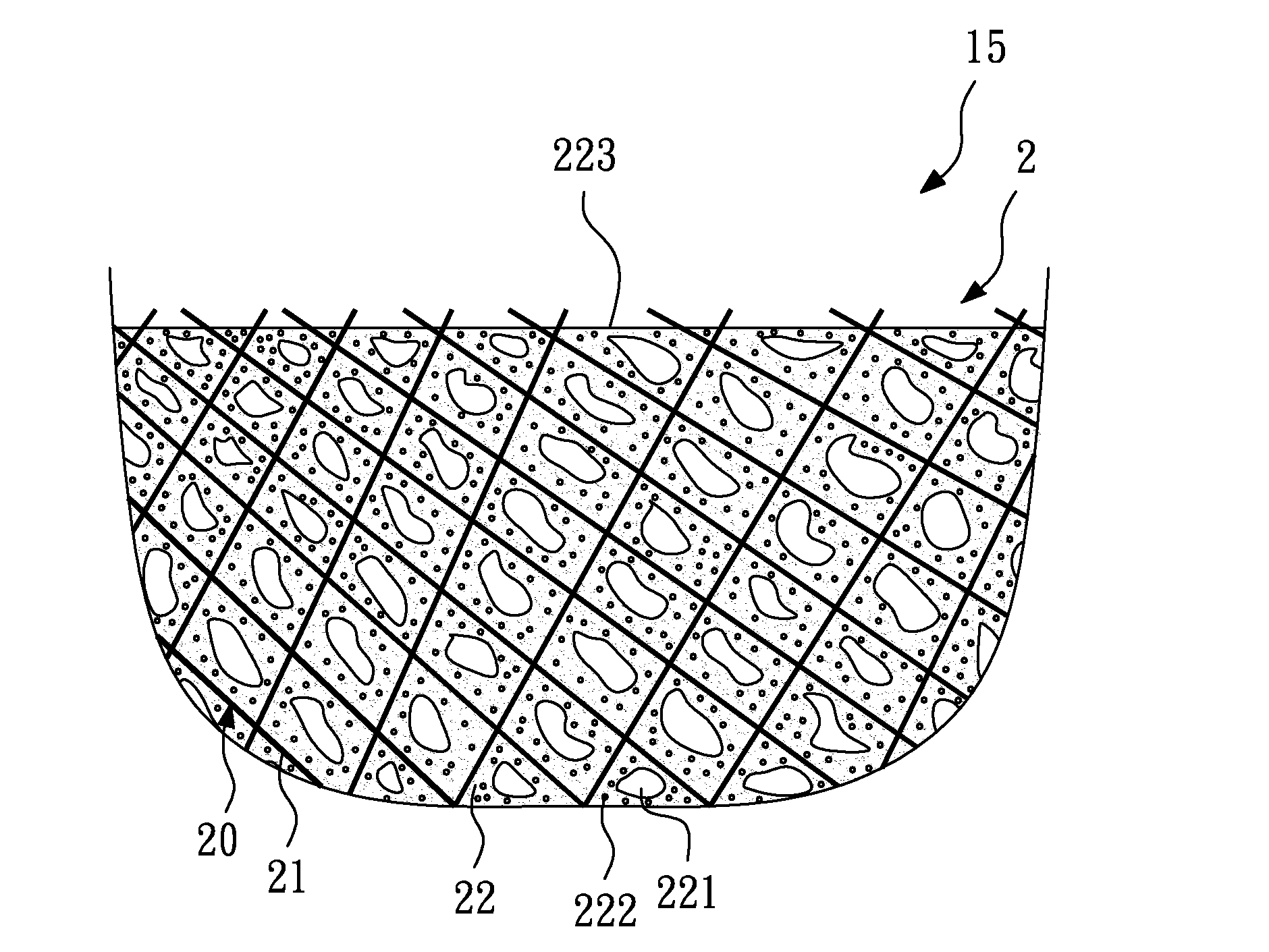

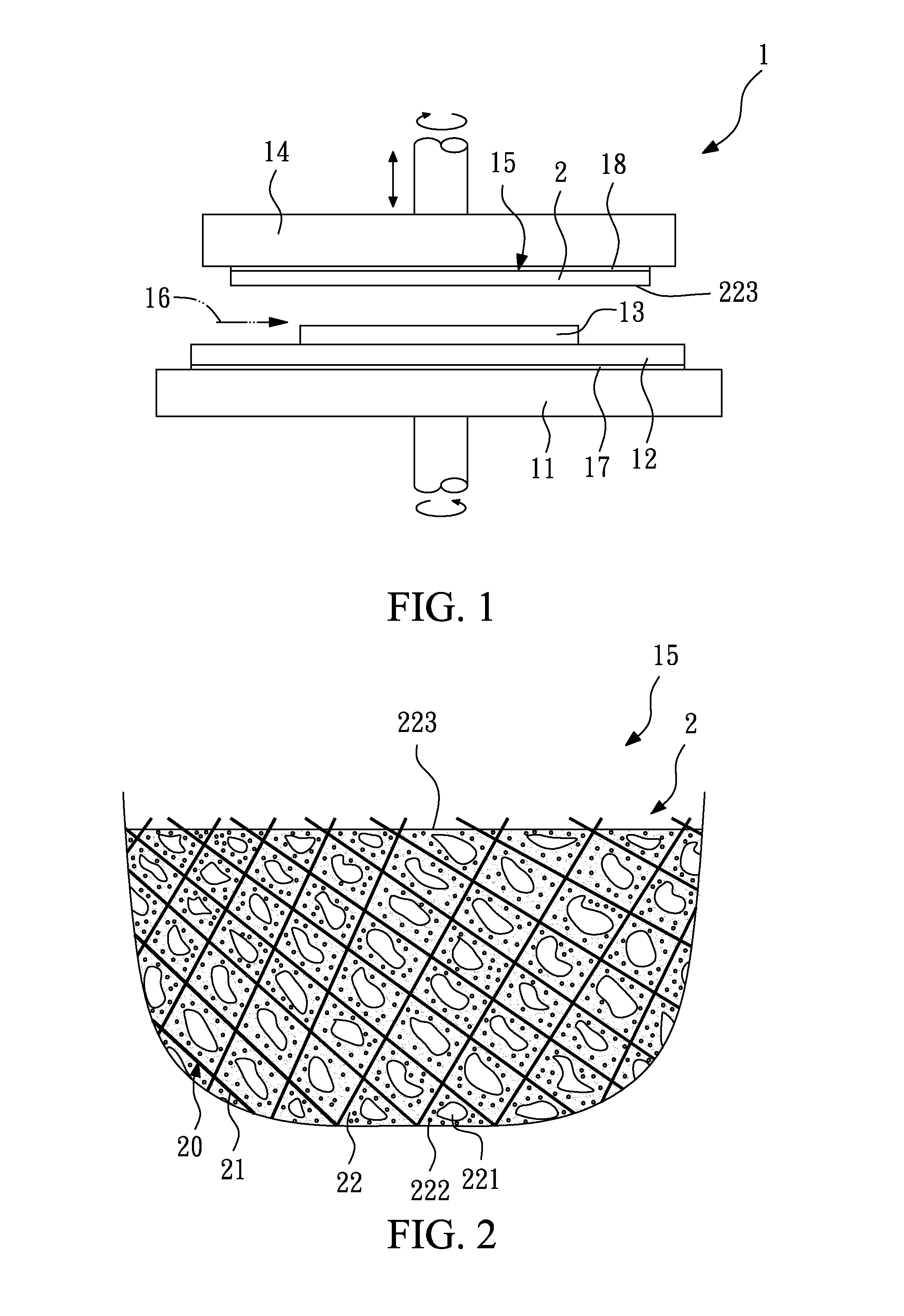

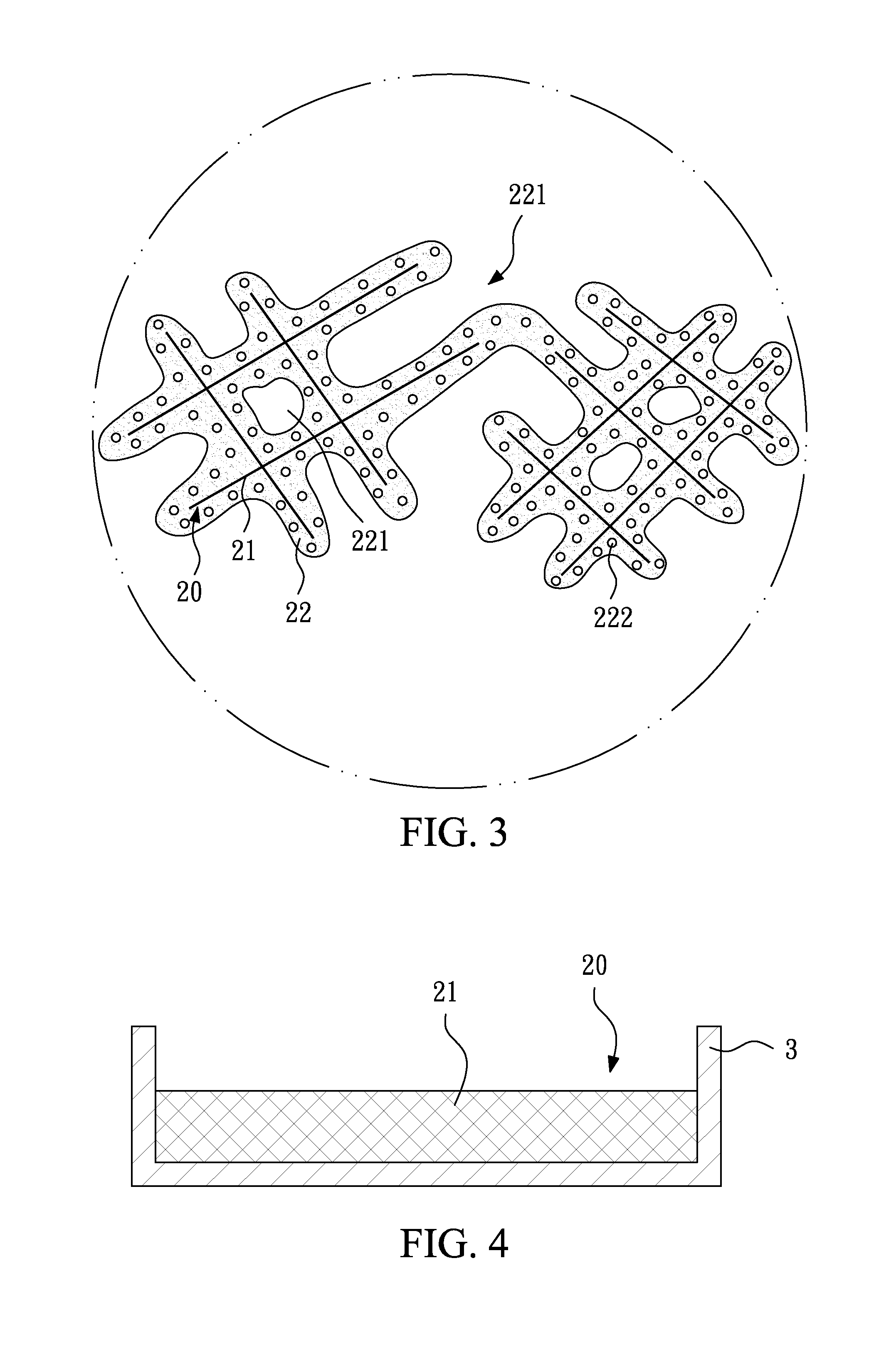

ActiveUS20070190909A1Increase contact areaReducing and eliminating needPolishing machinesRevolution surface grinding machinesEngineeringSemiconductor

The polishing pad (104) is useful for polishing at least one of magnetic, optical and semiconductor substrates (112) in the presence of a polishing medium (120). The polishing pad (104) includes a three-dimensional network of interconnected unit cells (225). The interconnected unit cells (225) are reticulated for allowing fluid flow and removal of polishing debris. A plurality of polishing elements (208, 308 and 408) form the three-dimensional network of interconnected unit cells (225). The polishing elements (208, 308 and 408) have a first end connected to a first adjacent polishing element at a first junction (209, 309 and 409) and a second end connected to a second adjacent polishing element at a second junction (209, 309 and 409) and having a cross-sectional area (222, 322 and 422) that remains within 30% between the first and the second junctions (209, 309 and 409). The polishing surface (200, 300 and 400) formed from the plurality of polishing elements (208, 308 and 408) remains consistent for multiple polishing operations.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

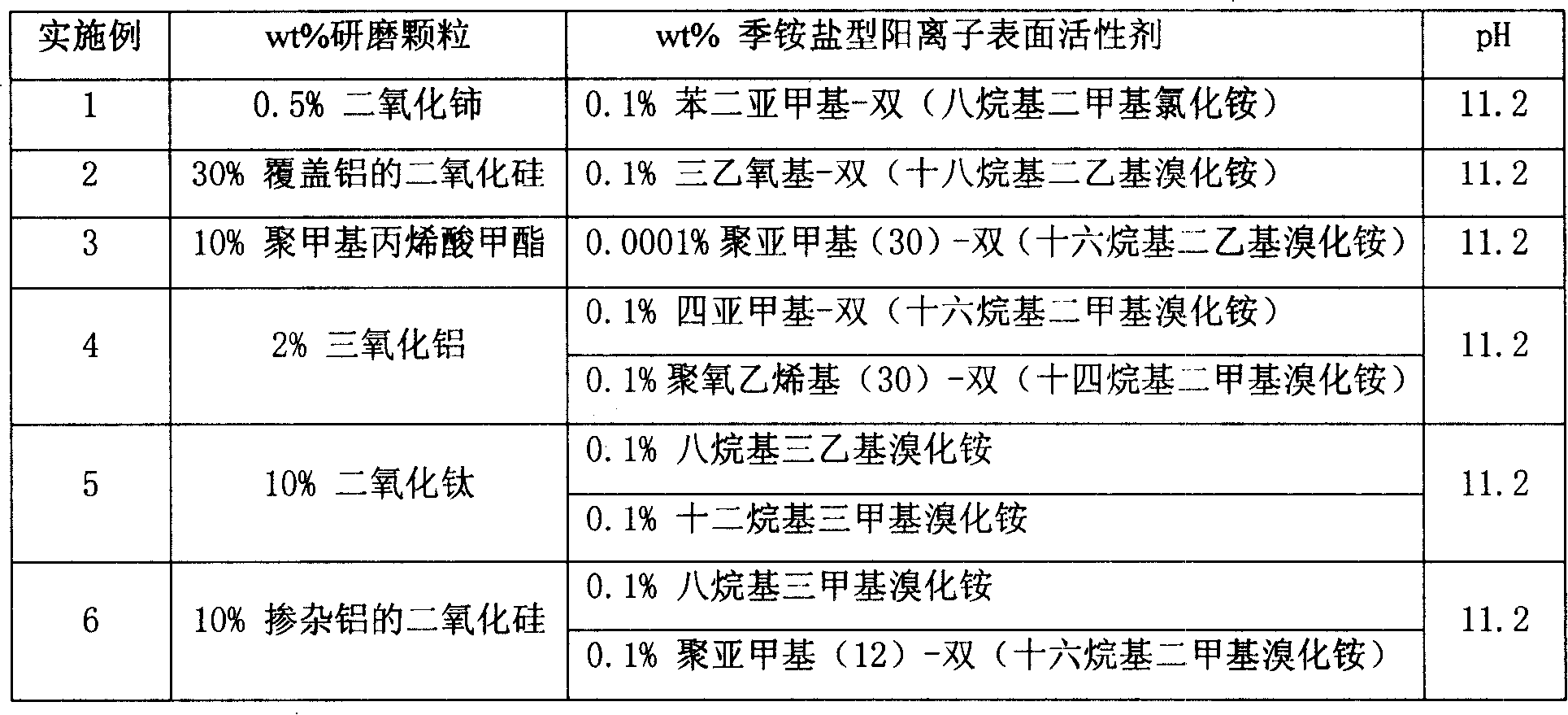

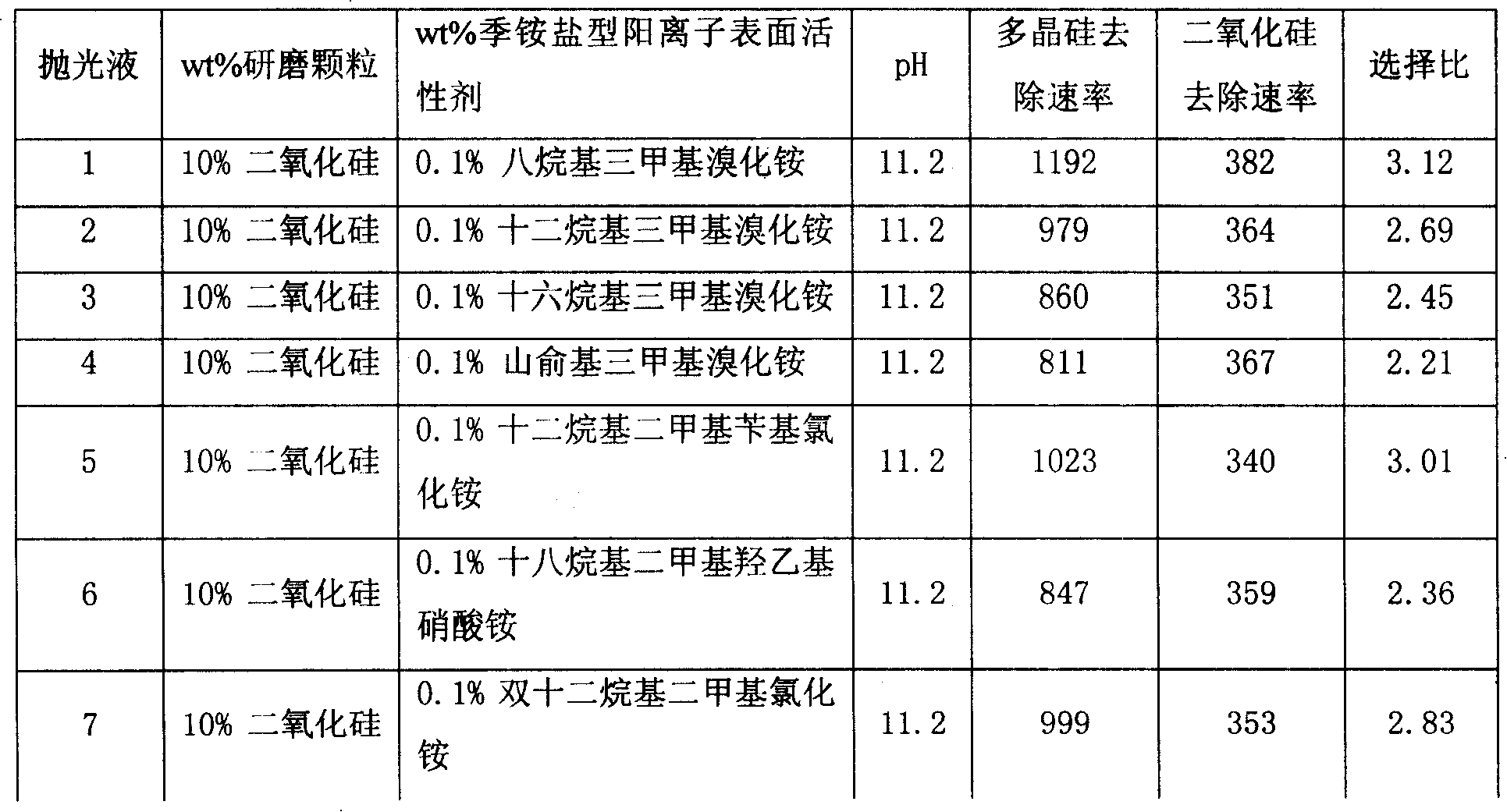

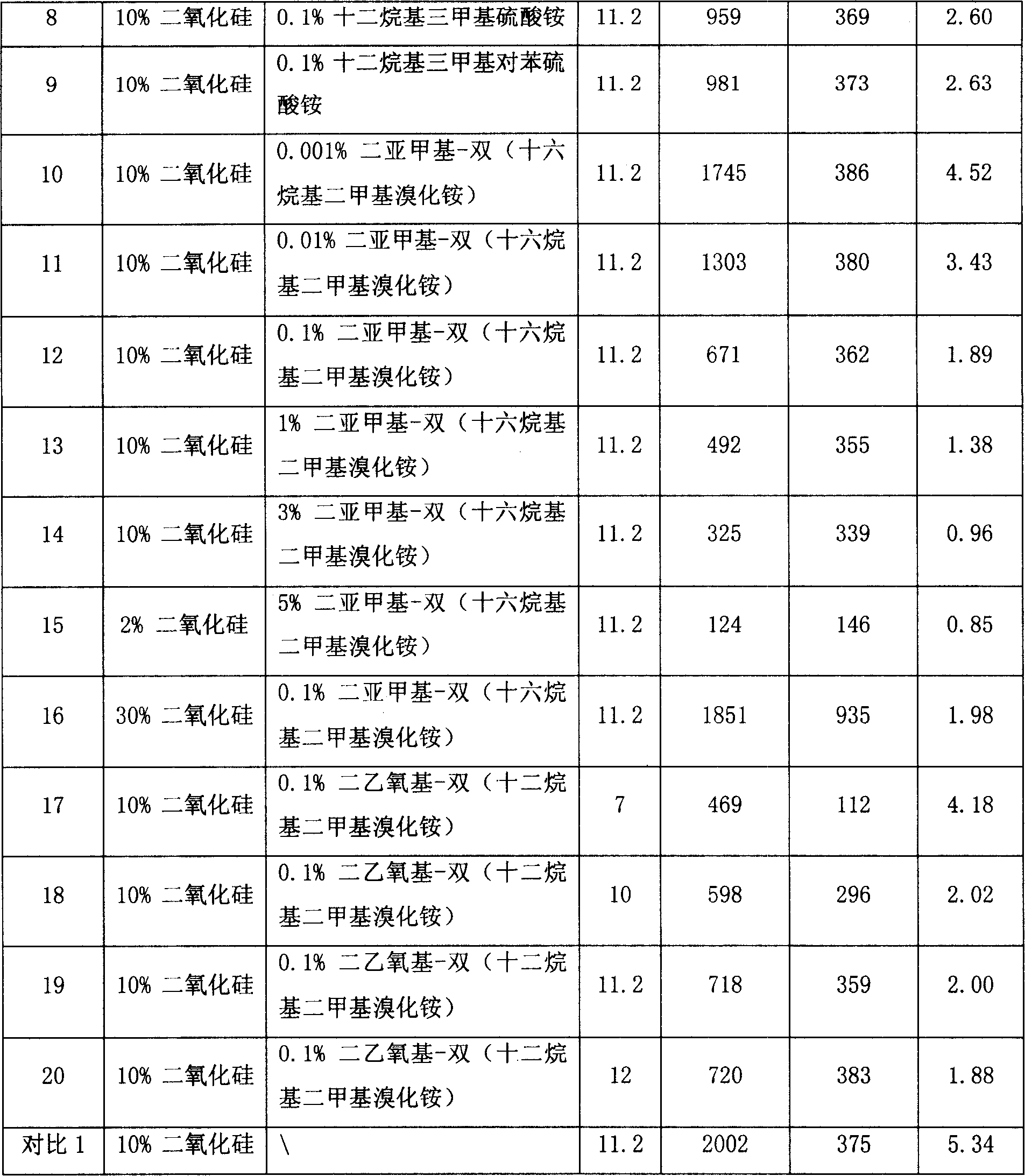

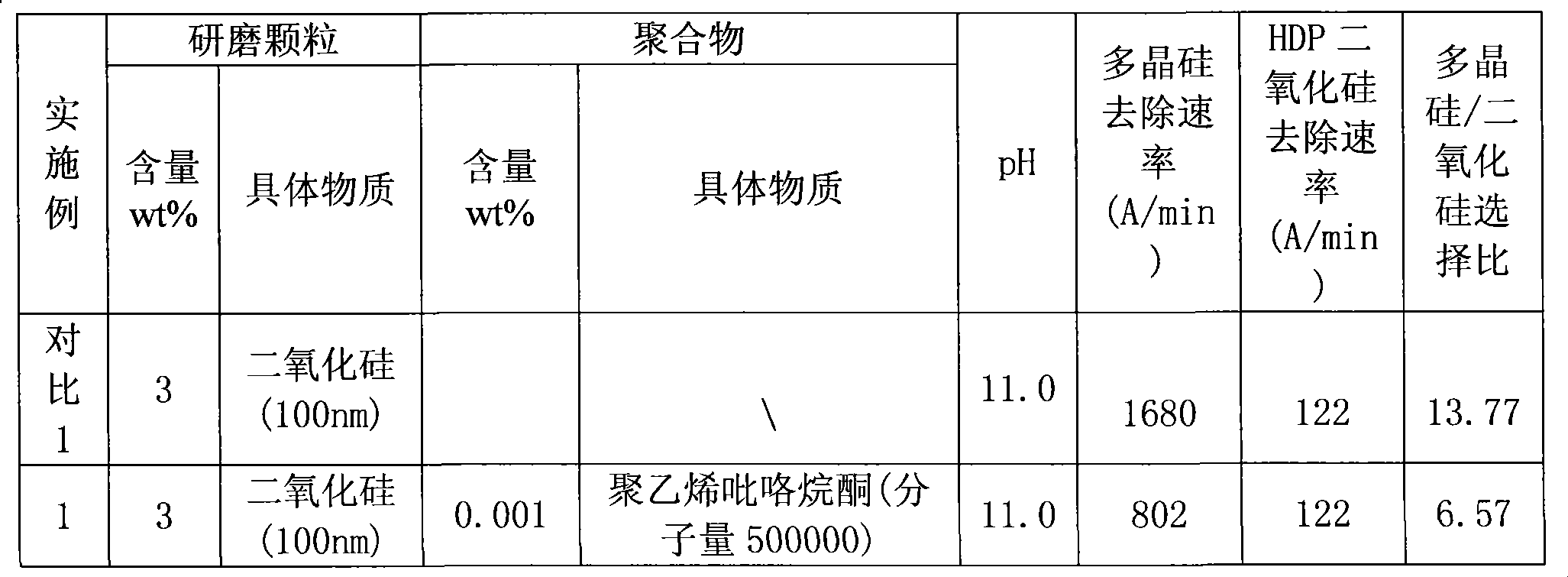

Chemical mechanical polishing fluid for polishing polycrystalline silicon

InactiveCN101168647AReduced removal rateImprove planarization efficiencySemiconductor/solid-state device manufacturingPolishing compositions with abrasivesSilicon dioxidePolycrystalline silicon

The invention discloses chemically machinery polishing solution used for polishing polysilicon. The polishing solution which comprises grinding grains and water is characterized in that a kind of or a plurality of kinds of quaternary ammonium salt type positive ion surface activating agent (s) is provided. The polishing solution of the invention can polish the polysilicon under the alkality condition, and also can obviously reduce the removing speed rate of the polysilicon and the selection ratio of the polysilicon and silicon dioxide, and obviously improve the even efficiency of the polysilicon.

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

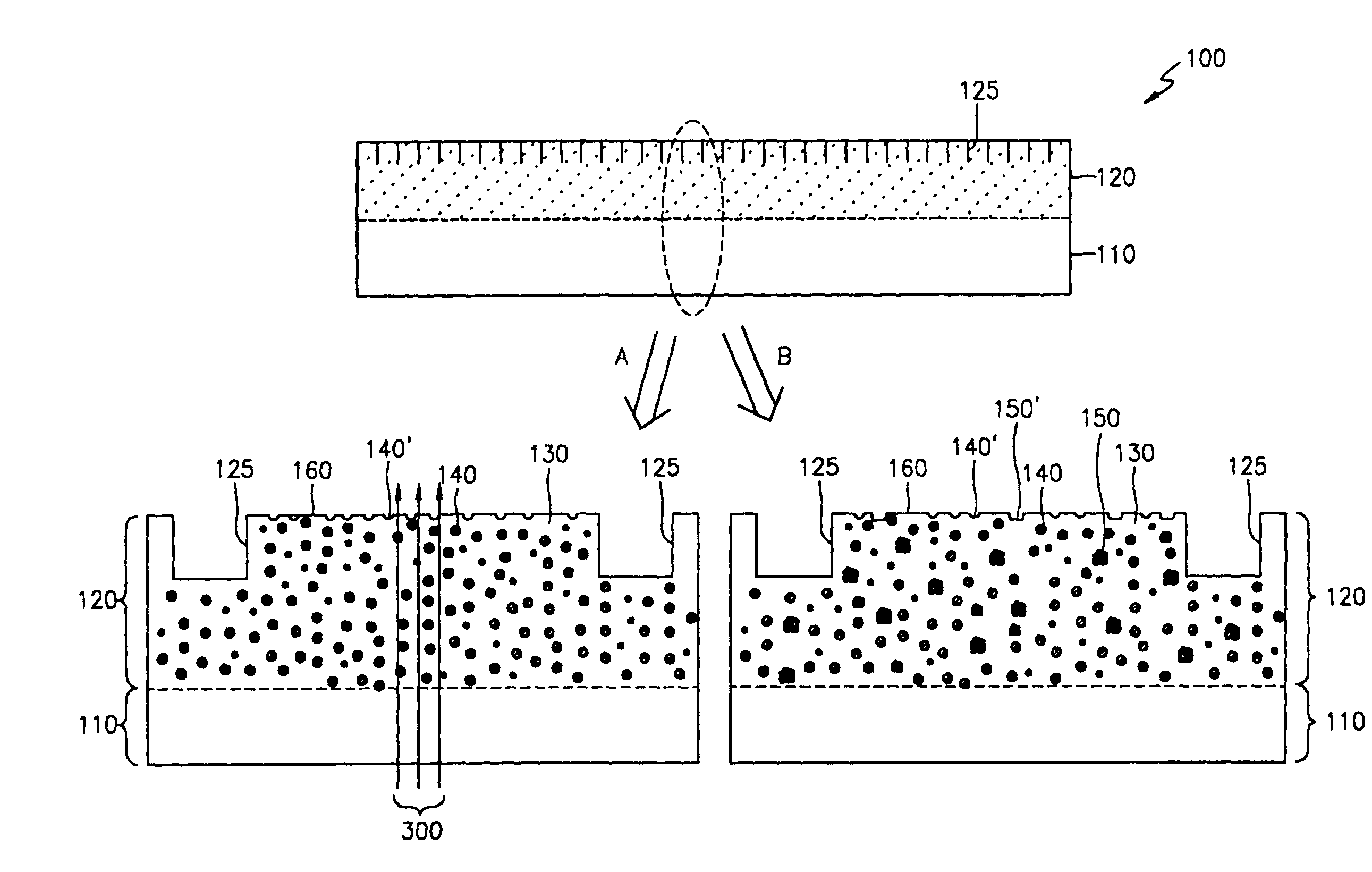

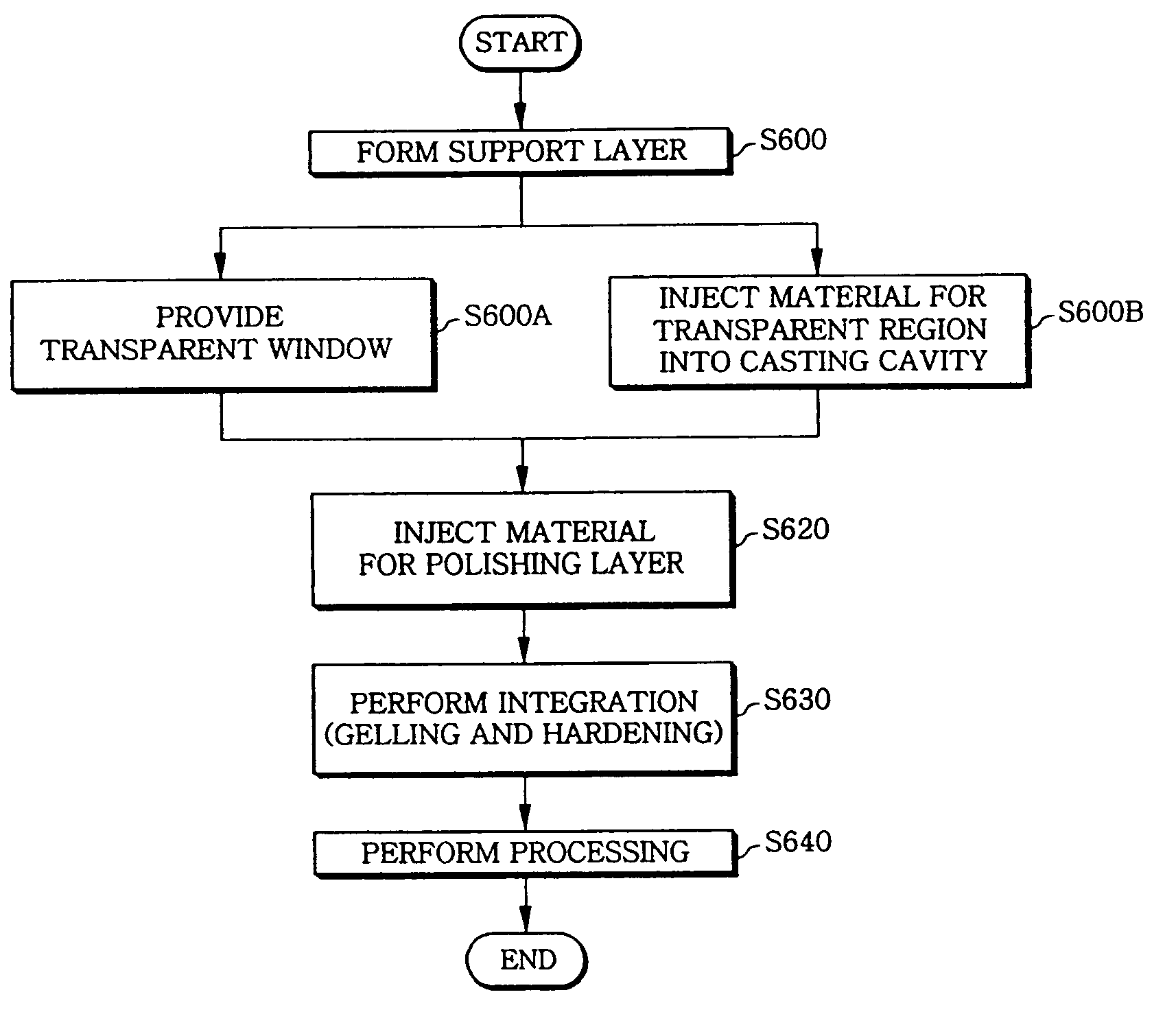

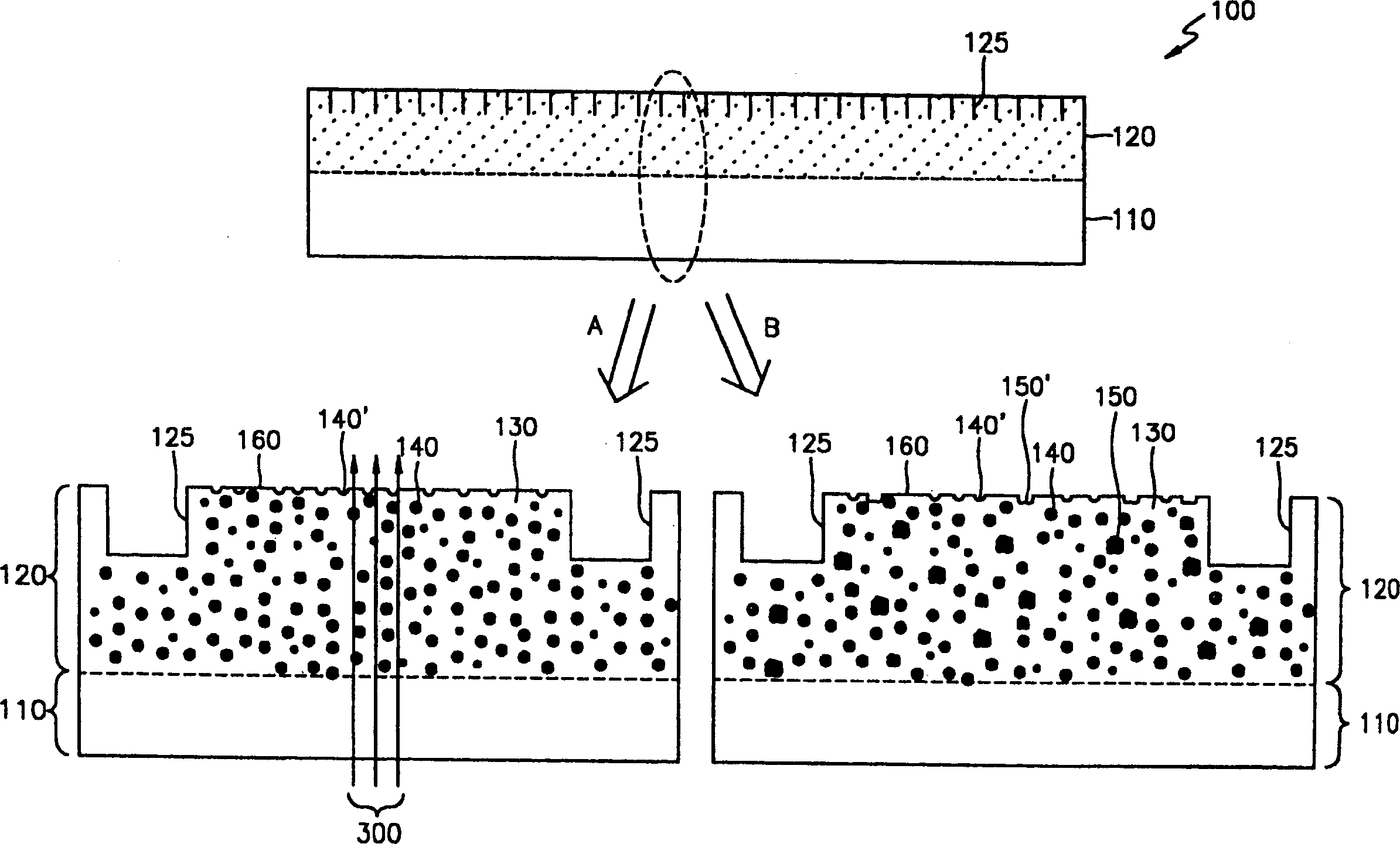

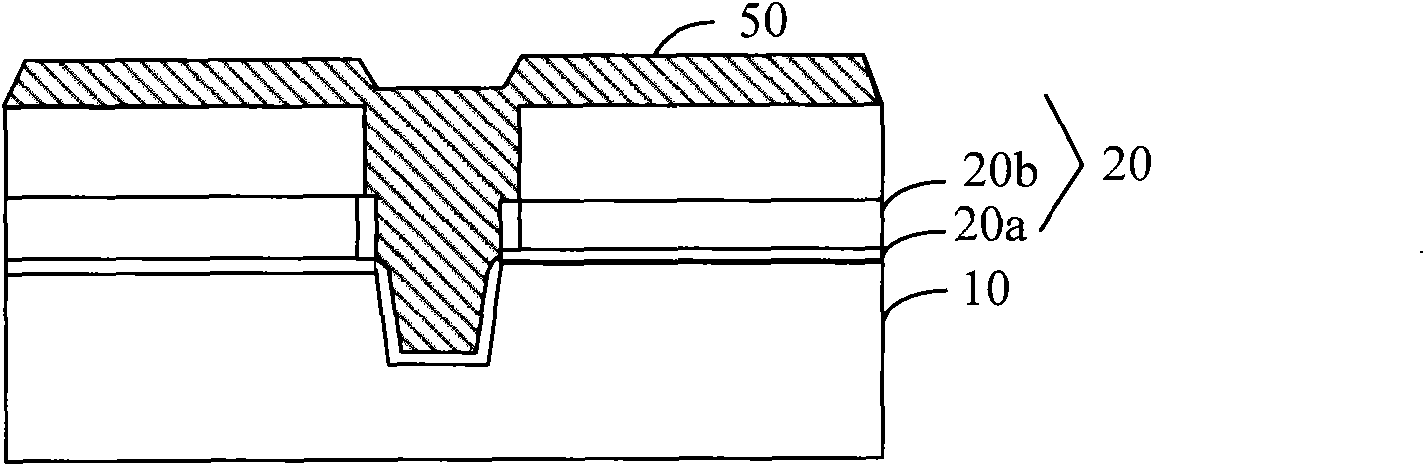

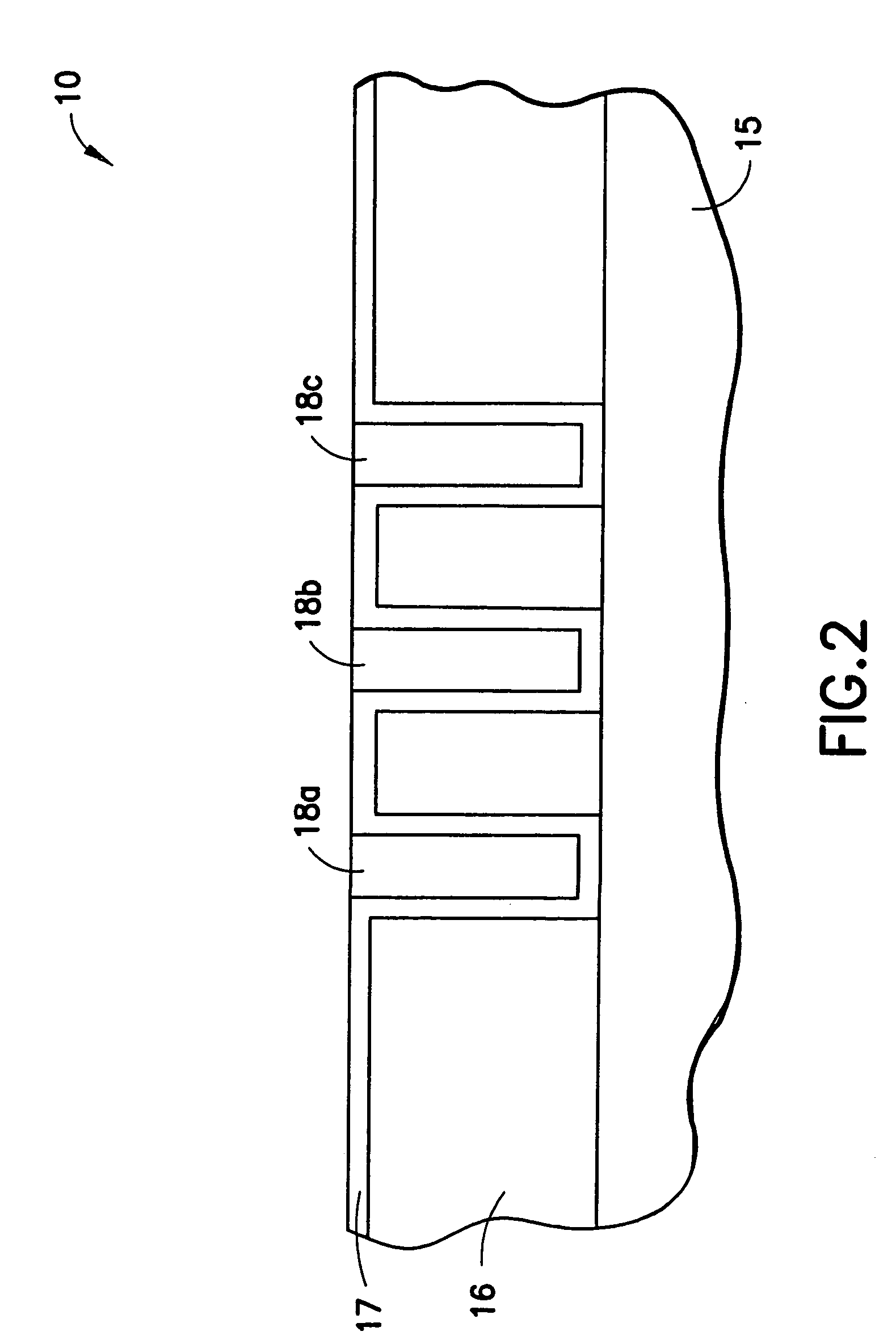

Integral polishing pad and manufacturing method thereof

InactiveUS20050260928A1Improve planarization efficiencyEasy to manufactureSemiconductor/solid-state device manufacturingTraffic signalsManufacturing technologyAdhesive

An integral polishing pad includes an elastic support layer and a polishing layer, which is formed on the elastic support layer and has a higher hardness than the elastic support layer. The elastic support layer and the polishing layer are made from materials chemically compatible with each other so that a structural border between the elastic support layer and the polishing layer does not exist. In addition, the integral polishing pad also includes a transparent region, which is transparent to a light source used to detect the surface state of an object being polished and integrated with the other elements of the integral polishing pad. The integral polishing pad has high planarization efficiency and uniform properties, and thus can be reliably used for polishing. In addition, the integral polishing pad prevents a congestion of a polishing slurry and facilitates delivery of the polishing slurry. The integral polishing pad does not need an adhesive for connecting elements or a process for bonding the elements, thereby simplifying manufacturing processes.

Owner:KPX CHEM

Silicon dioxide-based CMP (Chemical Mechanical Polishing) solution and preparation method thereof

ActiveCN102796460AReduce surface activityLower free energyPolishing compositions with abrasivesElectrical conductorUltrasonic dispersion

The invention provides silicon dioxide-based CMP (Chemical Mechanical Polishing) solution which is applied to global planarization of a very large scale integrated circuit silicon substrate and an interlayer medium and a preparation method of the silicon dioxide-based CMP solution. The polishing solution contains the following components in percentage by weight: 10-50 percent of nano silicon dioxide grinding material, 0.1-10 percent of dispersant, 0.1-10 percent of wetting agent, 0.1-10 percent of chelating agent, 0.01-1 percent of pH (Potential of Hydrogen) regulator and the balance of de-ionized water. The polishing solution is prepared through the means of: modifying with a surfactant, strongly and mechanically stirring, performing high-shear grinding, performing ultrasonic dispersion and the like, and the problem of extreme easiness in flocculation and agglomeration of nano-scale grinding material particles is solved. Since the particle size distribution of the grinding material is narrow, the range is selectable, the polishing rate is easy to adjust and control and the polishing solution is alkaline, equipment is not corroded, less damage is caused, cleaning is easy and the environment is not polluted. The silicon dioxide-based CMP solution can be used for chemical mechanical polishing of the very large scale integrated circuit silicon substrate, the interlayer medium, a shallow trench isolation isolator, conductor and damascene metal.

Owner:ANTEDI TIANJIN TECH

Chemical mechanical polishing compositions for metal and associated materials and method of using same

InactiveUS20060160475A1Low to moderate removal rateHigh removal rateSemiconductor/solid-state device manufacturingLapping machinesCompound (substance)Slurry

A chemical mechanical polishing slurry composition and method for using the slurry composition for polishing copper, barrier material and dielectric material that comprises first and second-step slurries. The first-step slurry has a high removal rate on copper and a low removal rate on barrier material. The second-step slurry has a high removal rate on barrier material and a low removal rate on copper and dielectric material. The first slurry comprises at least an organic polymeric abrasive.

Owner:MA YING +5

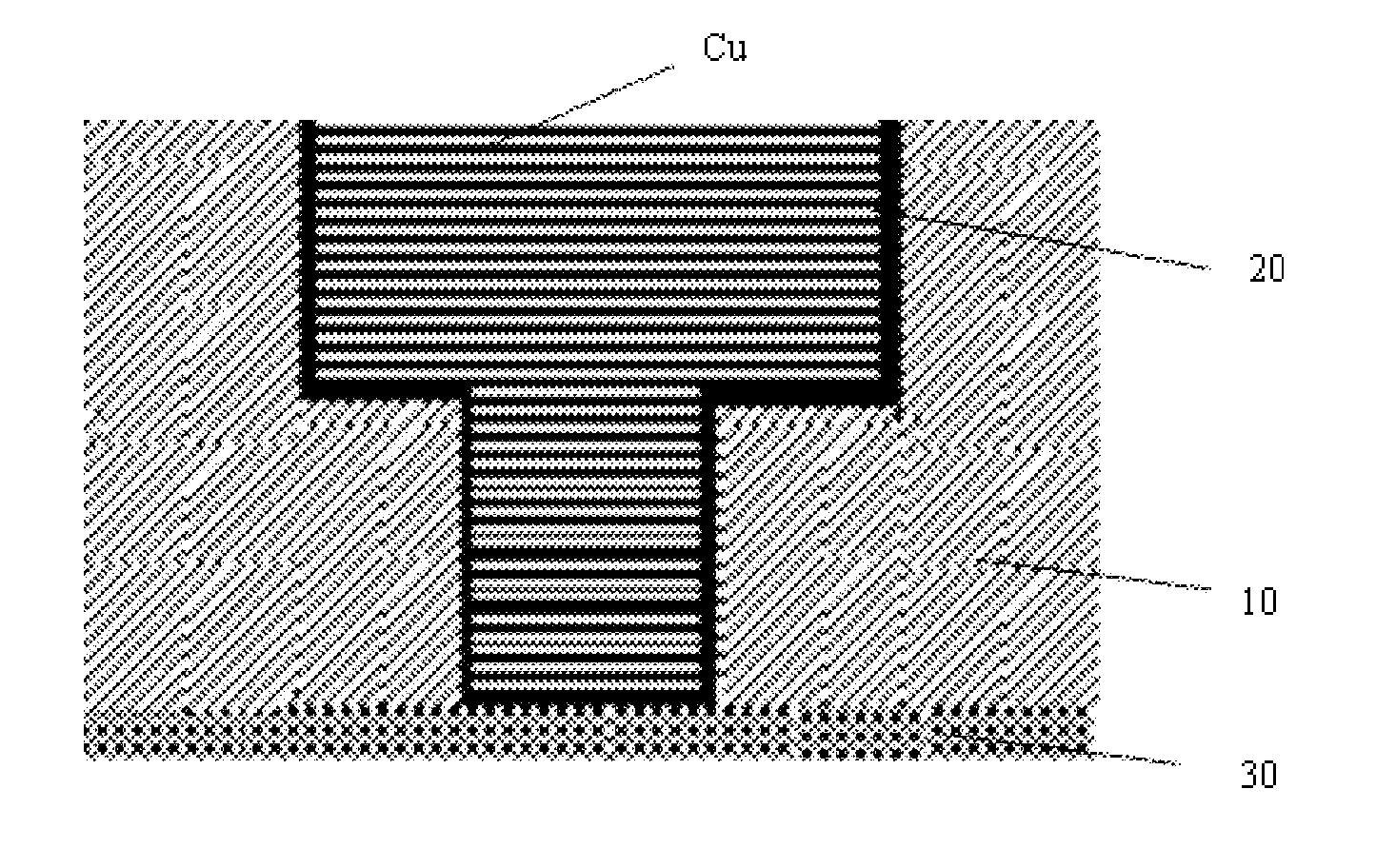

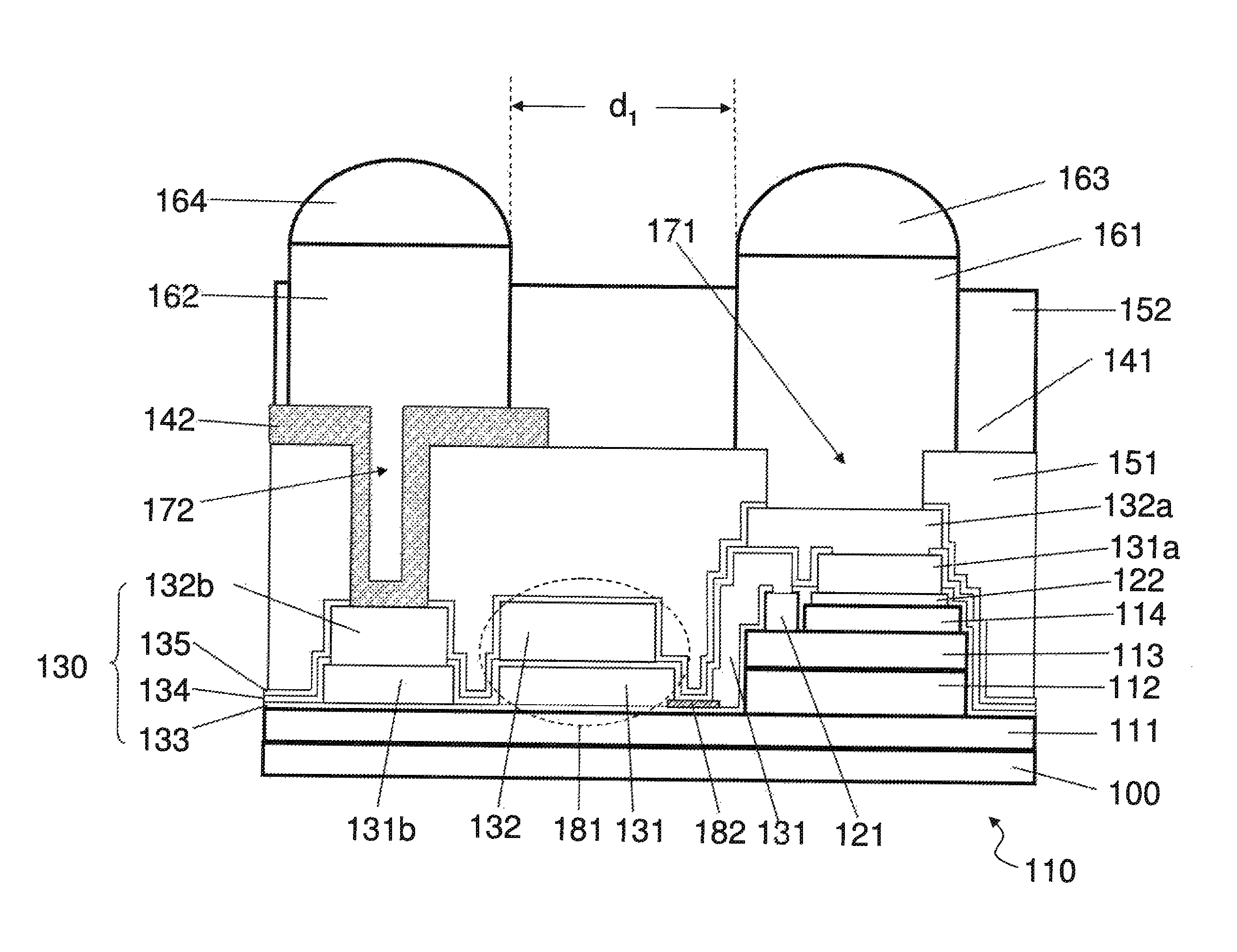

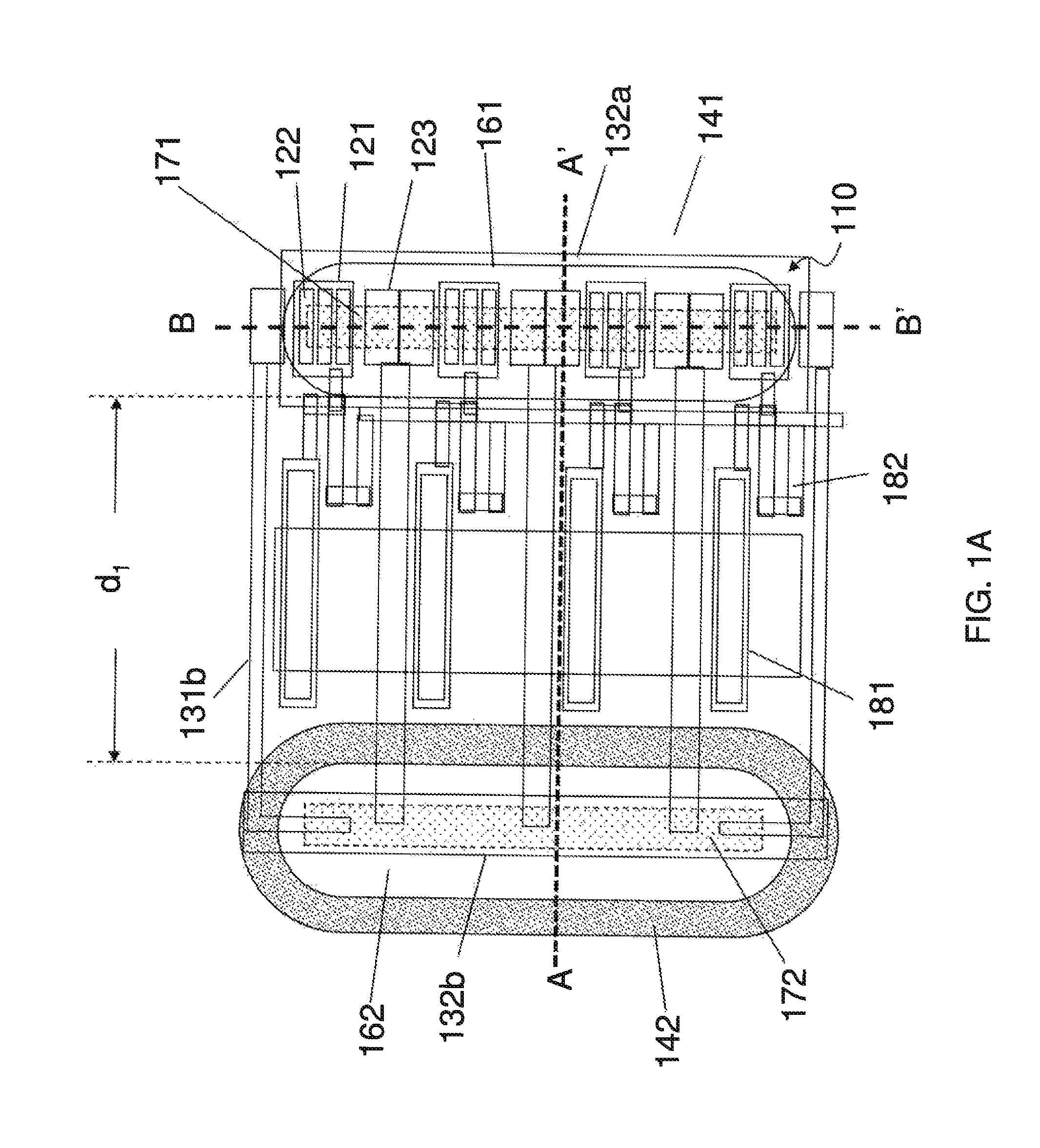

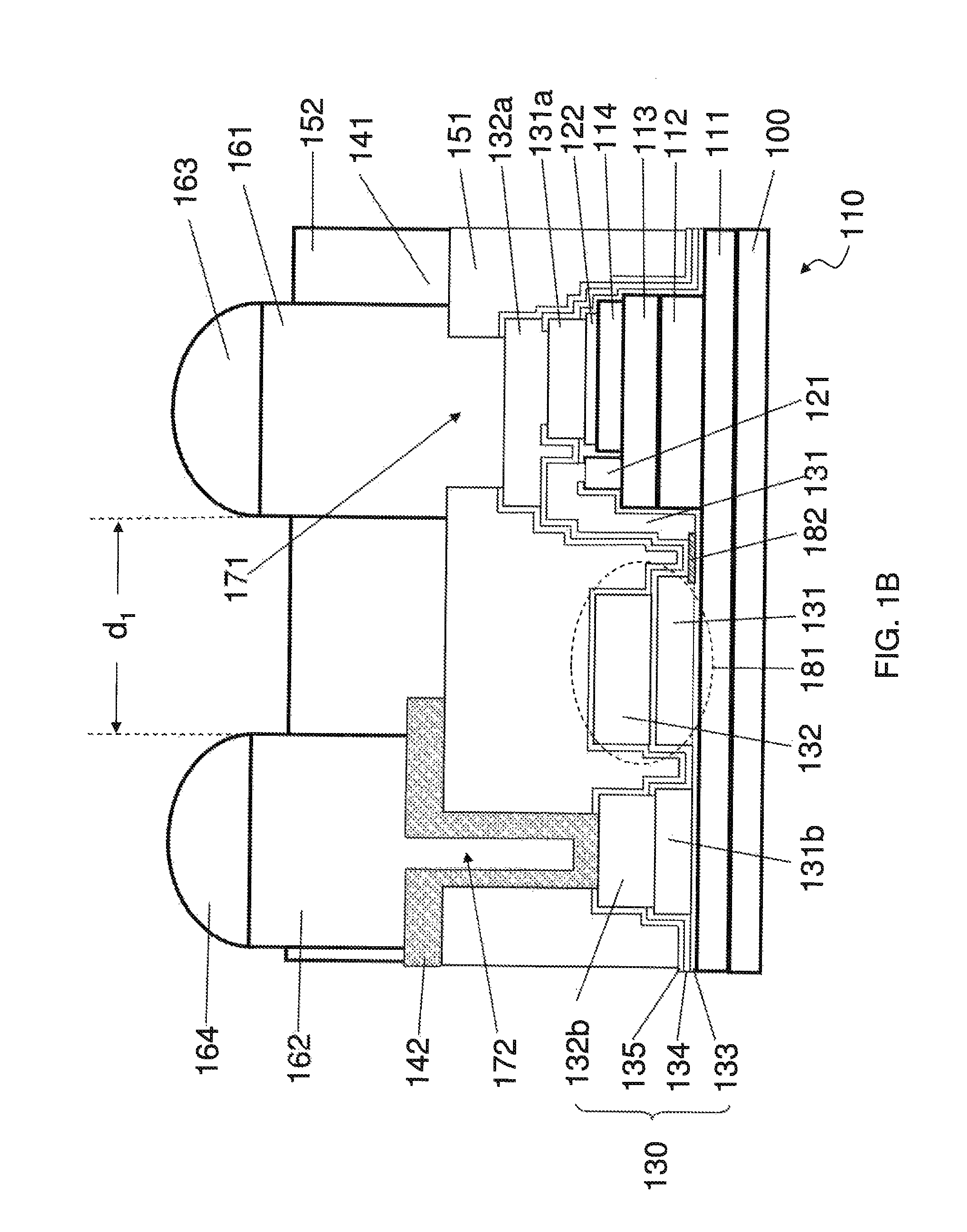

Layout structure of heterojunction bipolar transistors

ActiveUS9356127B2Improve cooling efficiencyLayout design of the emitter and collector copper pillars becomes more flexibleTransistorSemiconductor/solid-state device detailsHeterojunctionRedistribution layer

A layout structure of HBTs comprising one or more HBTs, each of which comprises a base electrode, an emitter electrode, and a collector electrode. A passive layer, a first dielectric layer, a collector redistribution layers, one or more emitter copper pillars, and one or more collector copper pillars are formed above the one or more HBTs. The passive layer comprises a collector and an emitter pads. The first dielectric layer has one or more emitter and collector via holes. The emitter copper pillar is disposed on the emitter via hole and forms an electrical connection to the emitter electrode. The collector copper pillar is disposed on the collector redistribution layer and forms electrical connection to the collector electrode. The layout design of the emitter and collector copper pillars is therefore flexible, and the heat dissipation efficiency is improved.

Owner:WIN SEMICON

Method for preparing infrared cut-off filter

ActiveCN104977638ANot suitable for chippingIncrease productivityOptical filtersRejection rateInfrared cut-off filter

The invention relates to a method for preparing an infrared cut-off filter, specifically comprising the steps of cutting, shaping, slicing, chamfering, grinding, double-sided chemical polishing, coating, and the like. An infrared cut-off filter prepared by the method has high quality. The rejection rate is low. The production efficiency is high.

Owner:中山市飞科光学科技有限公司

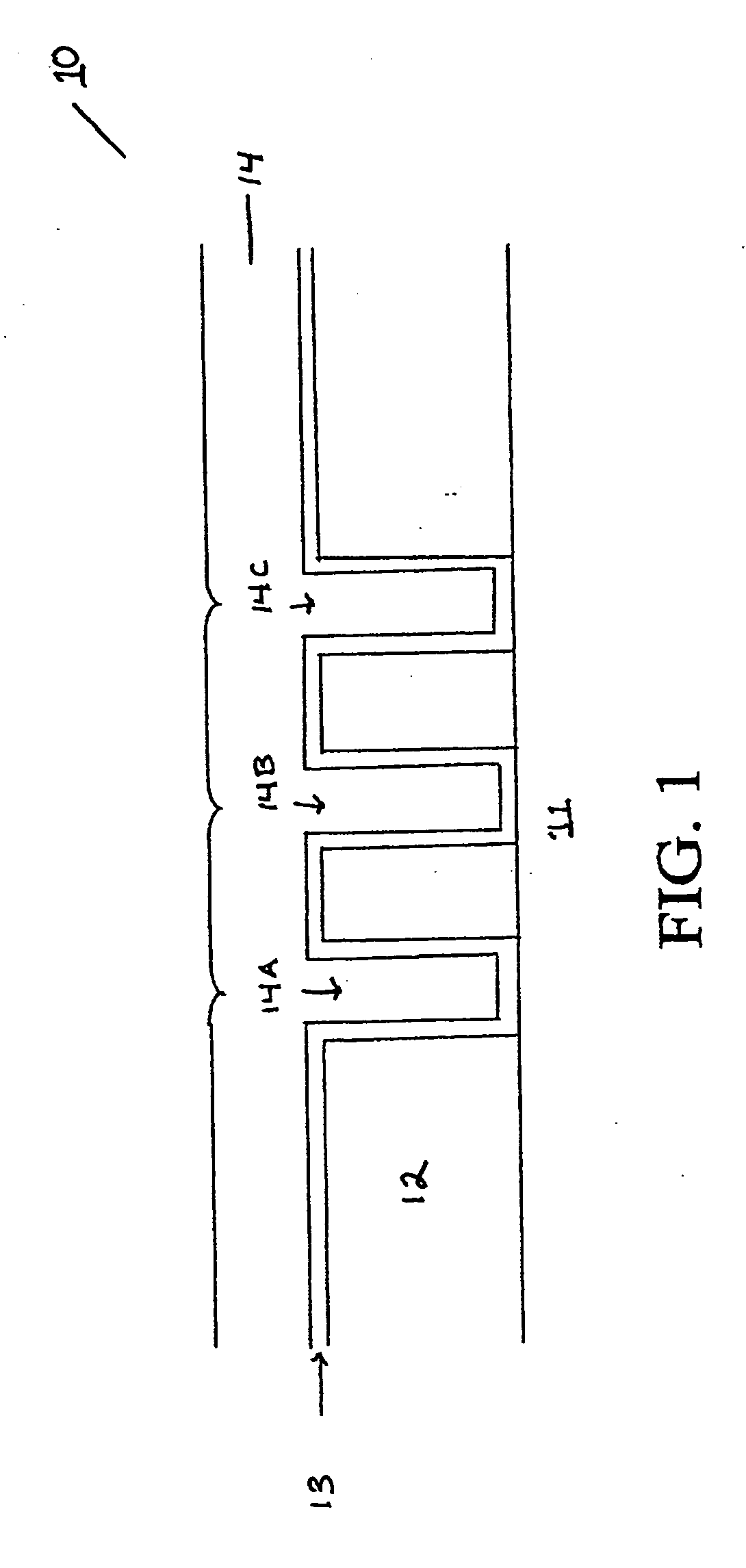

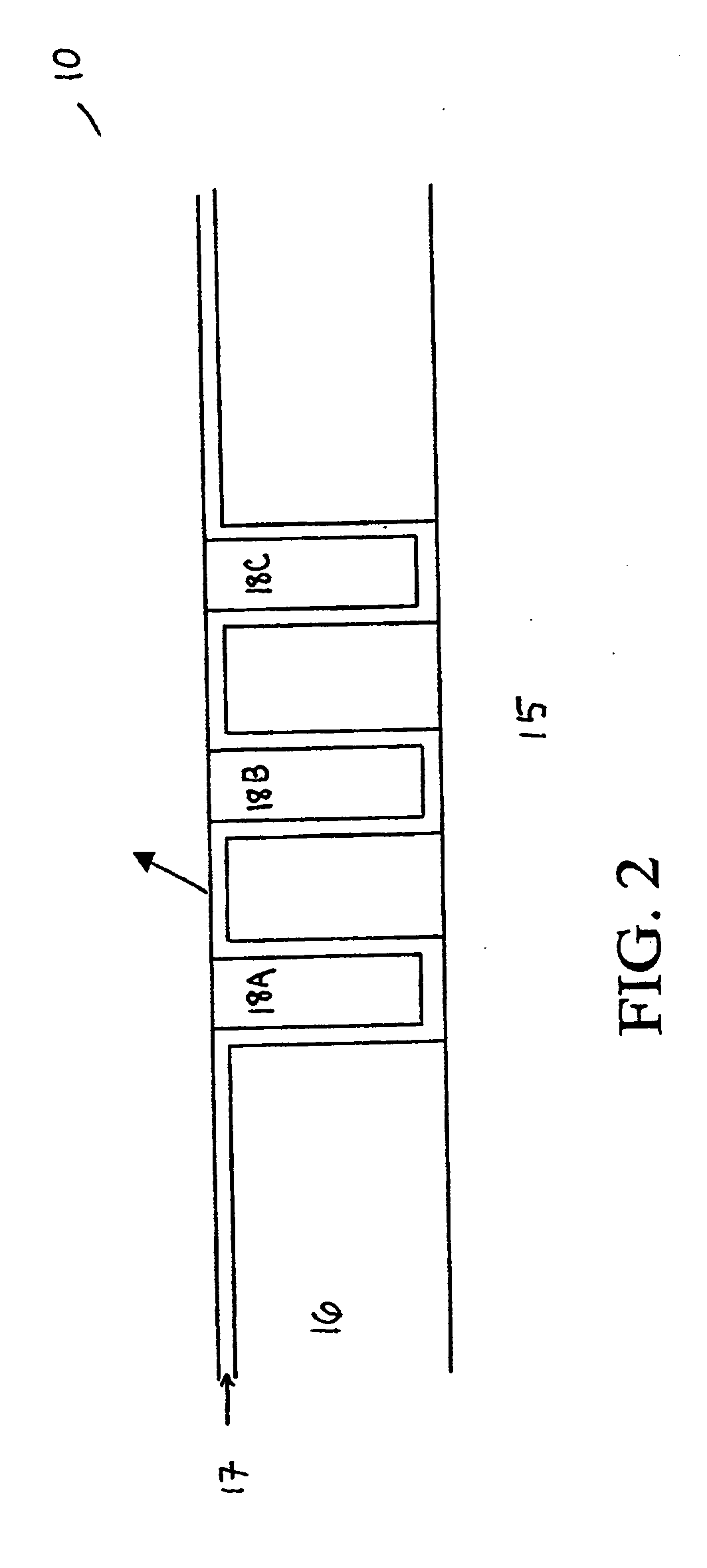

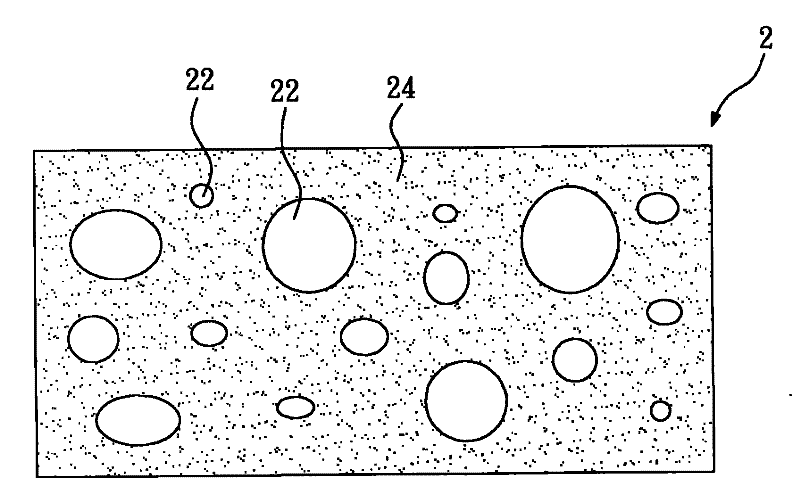

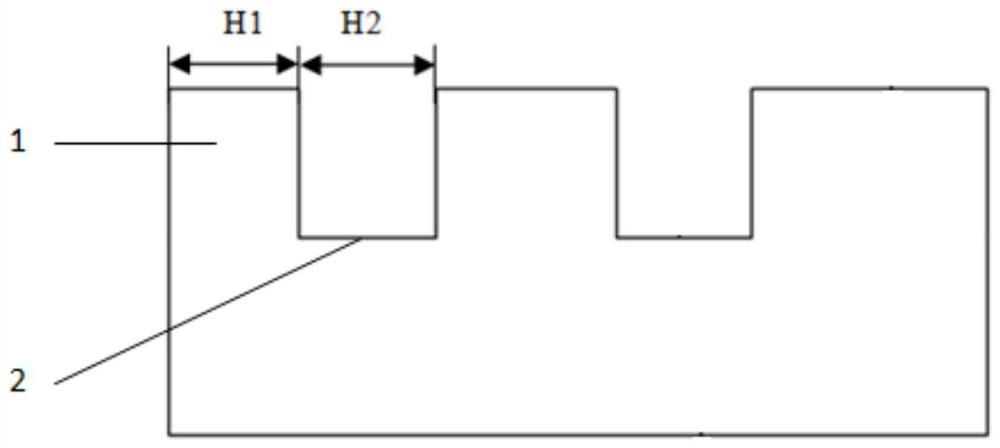

Polishing pad and method for making the same

ActiveUS20150099439A1Improve rigidityImprove planarization efficiencyAbrasion apparatusLapping toolsHardnessPolymer chemistry

The present invention relates to a polishing pad and a method for making the same. The polishing pad has a grinding layer. The grinding layer includes a plurality of fibers and a main body. The fineness of the fibers is 0.001 den to 6 den. The main body is a foam and encloses the fibers. The main body has a plurality of first pores and a plurality of second pores, wherein the first pores are communicated with each other, and the second pores are independent from each other. The size of the first pores is at least 5 times greater than the size of the second pores. The hardness of the grinding layer is 30 to 90 shore D, and the compression ratio thereof is 1% to 10%.

Owner:SAN FANG CHEM IND

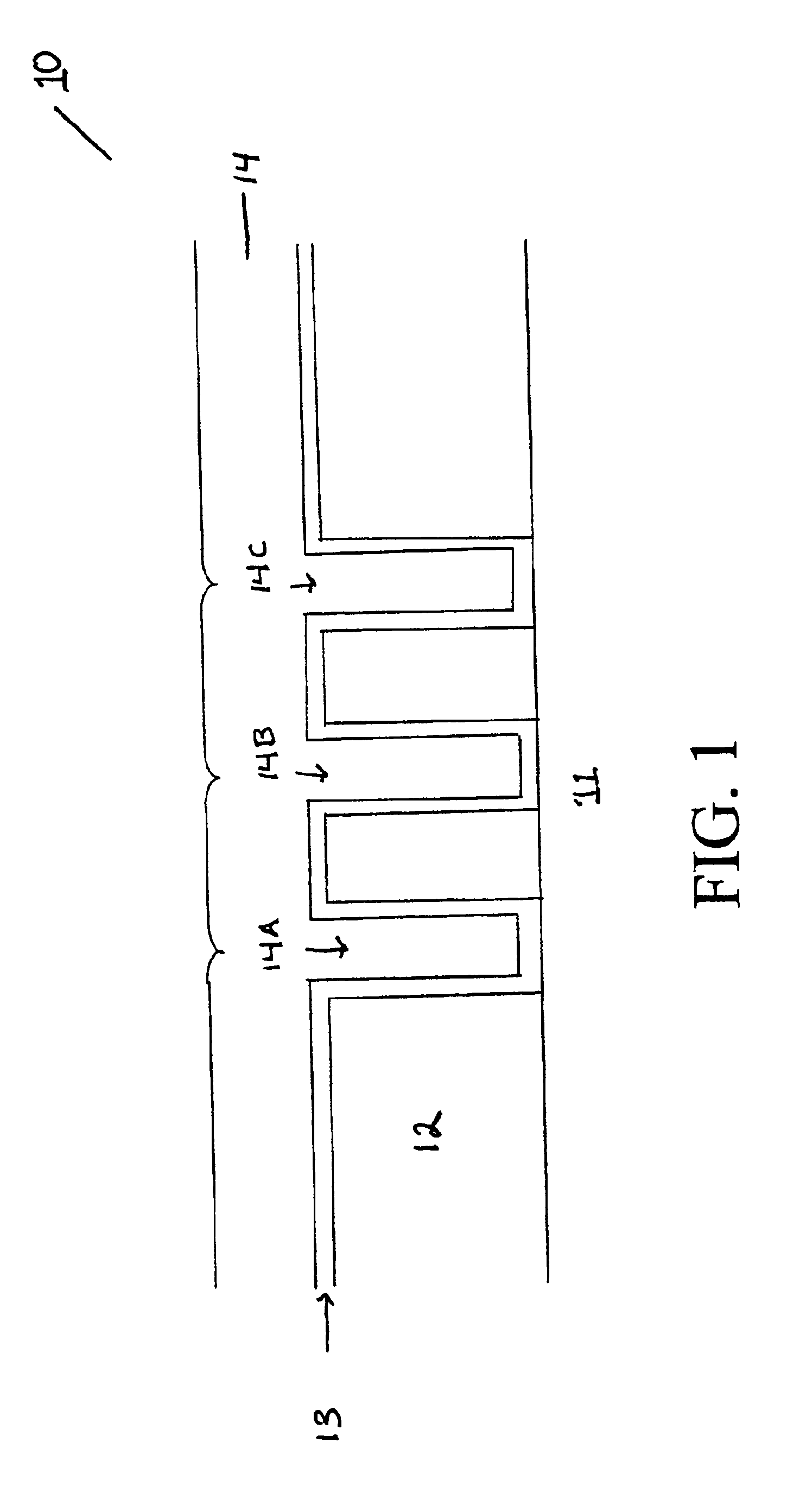

Polishing slurries for copper and associated materials

InactiveUS6936542B2High removal rateLow removal ratePigmenting treatmentOther chemical processesCorrosion inhibitorOxidizing agent

A chemical mechanical polishing slurry and method for using the slurry for polishing copper, barrier material and dielectric material that comprises a first and second slurry. The first slurry has a high removal rate on copper and a low removal rate on barrier material. The second slurry has a high removal rate on barrier material and a low removal rate on copper and dielectric material. The first and second slurries at least comprise silica particles, an oxidizing agent, a corrosion inhibitor, and a cleaning agent.

Owner:CABOT MICROELECTRONICS CORP

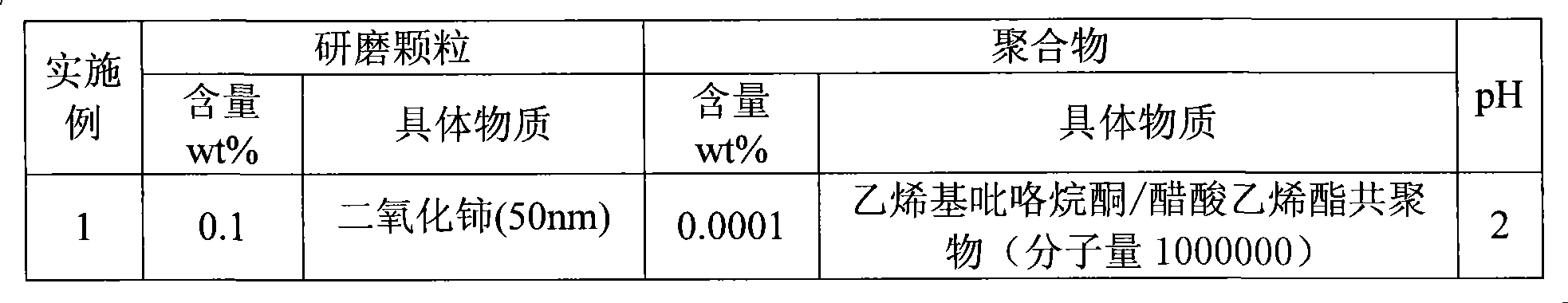

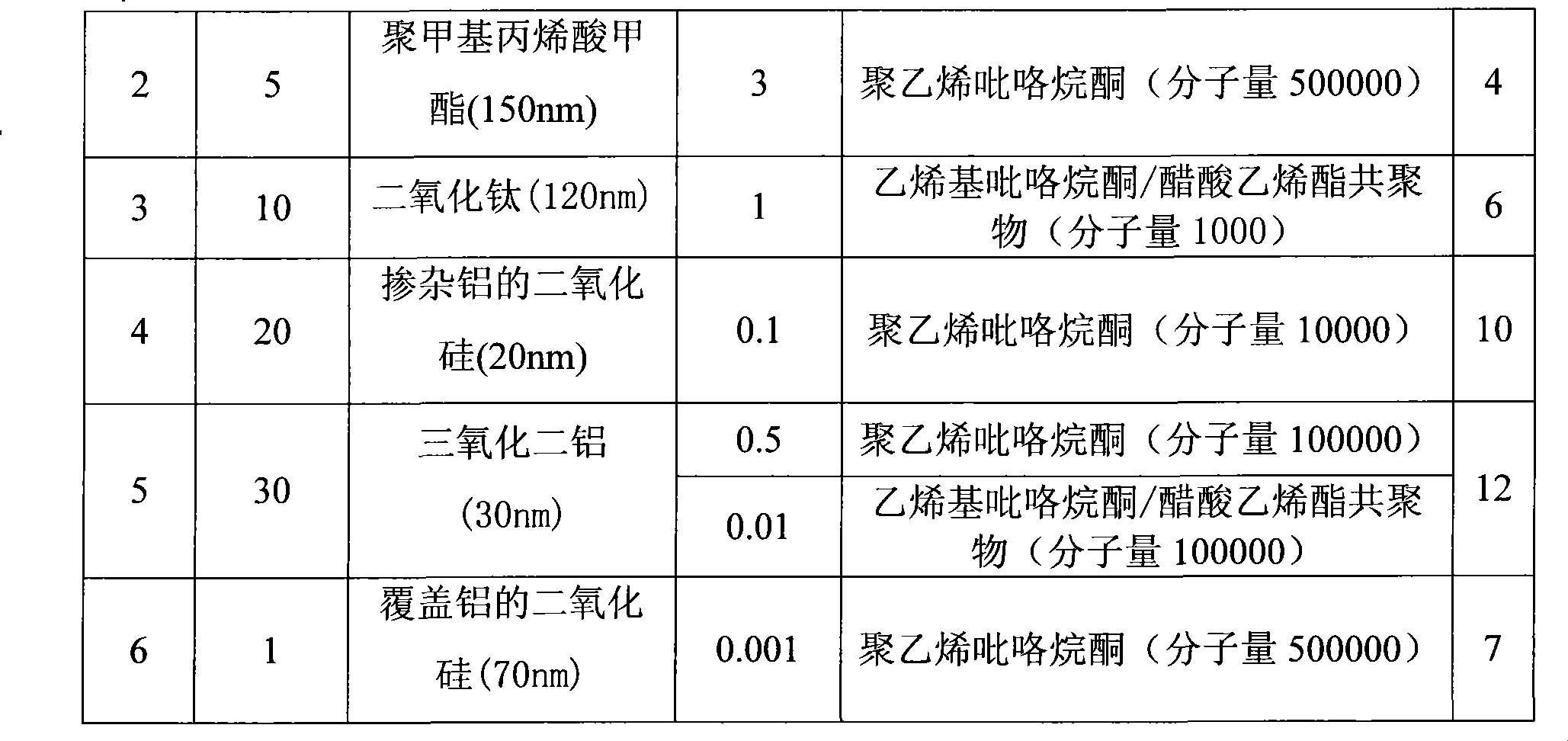

Chemico-mechanical polishing liquid

ActiveCN101457126AReduced removal rateImprove planarization efficiencyPolishing compositions with abrasives2-PyrrolidoneSilicon dioxide

The present invention discloses a chemical machinery polishing solution which contains seat grinding granule and water, and n-vinyl-2-pyrrolidone polymeric compound. The polishing solution provided in the invention has low polycrystalline silicon removal rate, and removal rate selection ratio between polycrystalline silicon and silicon dioxide, which can reduce depression and improve plainness efficiency of polycrystalline silicon significantly.

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

Polishing pad and method of manufacturing the same

InactiveCN102275143AImprove rigidityImprove planarization efficiencyFlexible-parts wheelsFiberPolyester

The present invention relates to a polishing pad and its manufacturing method. The polishing pad includes a plurality of fibers and a polymer elastomer compound. These fibers are interlaced to form a fibrous matrix. The polymer elastomer compound is composed of a first polymer elastomer resin and a second polymer elastomer resin, wherein the weight average molecular weight of the first polymer elastomer resin is 100,000-300,000, and the second polymer elastomer resin is elastic The body resin is a two-component polymer elastomer resin, which includes a first component and a second component. The first component is a polyester polyol with a molecular weight of 1500 to 2500, and its weight percentage is 1% to 15% %, the second component is a polyester polyol with a molecular weight of 3500 to 4500, and its weight percentage is 85% to 99%. Therefore, the polishing pad not only has better rigidity and high planarization efficiency, but also has interconnected holes and active fibers, so that the workpiece to be polished / grinded has excellent surface quality.

Owner:SAN FANG CHEM IND

Method for preparing infrared cut-off filter

InactiveCN104977639ANot suitable for chippingIncrease productivityOptical filtersInfrared cut-off filterRejection rate

The invention relates to a method for preparing an infrared cut-off filter, specifically comprising the steps of cutting, shaping, slicing, chamfering, grinding, double-sided chemical polishing, coating, and the like. An infrared cut-off filter prepared by the method has high quality. The rejection rate is low. The production efficiency is high.

Owner:江苏苏创光学器材有限公司

Integrated grinding pad and its mfg. method

InactiveCN1494986AImprove planarization efficiencyUniform physical propertiesLapping machinesAbrasion apparatusAdhesiveHardness

An integral polishing pad includes an elastic support layer and a polishing layer, which is formed on the elastic support layer and has a higher hardness than the elastic support layer. The elastic support layer and the polishing layer are made from materials chemically compatible with each other so that a structural border between the elastic support layer and the polishing layer does not exist. In addition, the integral polishing pad also includes a transparent region, which is transparent to a light source used to detect the surface state of an object being polished and integrated with the other elements of the integral polishing pad. The integral polishing pad has high planarization efficiency and uniform properties, and thus can be reliably used for polishing. In addition, the integral polishing pad prevents a congestion of a polishing slurry and facilitates delivery of the polishing slurry. The integral polishing pad does not need an adhesive for connecting elements or a process for bonding the elements, thereby simplifying manufacturing processes.

Owner:KPX CHEM

Polishing solution for TSV barrier layer

ActiveCN103146306AImprove removal rateImprove protectionOther chemical processesSemiconductor/solid-state device manufacturingCopperHigh silica

The invention discloses a chemical-mechanical polishing solution for a through silicon via (TSV) barrier layer. The polishing solution comprises at least one grinding material, a compound metal copper corrosion inhibitor, a complexing agent and a silicon nitride regulator. The polishing solution has relatively high silica removal rate and relatively low silicon nitride removal rate, can planarize the barrier layer efficiently and stop the silicon nitride layer to form the through silicon via (TSV), does not produce metal corrosion, and has relatively high defect correction capability and relatively low surface contamination index.

Owner:ANJI MICROELECTRONICS TECH (SHANGHAI) CO LTD

Manufacturing method for sapphire fingerprint recognition panel

ActiveCN105128157ANot suitable for chippingIncrease productivityPolycrystalline material growthAfter-treatment detailsAgricultural engineeringRejection rate

The invention relates to a manufacturing method for a sapphire fingerprint recognition panel. The manufacturing method comprises the specific steps of crystal growth, crystal bar drawing, crystal cutting, laser wafer taking, grinding, chamfering, annealing, double-face polishing, film plating, ink smearing, hot drying and the like. According to the manufacturing method for the sapphire fingerprint recognition panel, the quality of finished wafers is high, the rejection rate is low, and the production efficiency is high.

Owner:清远惠晶科技有限公司

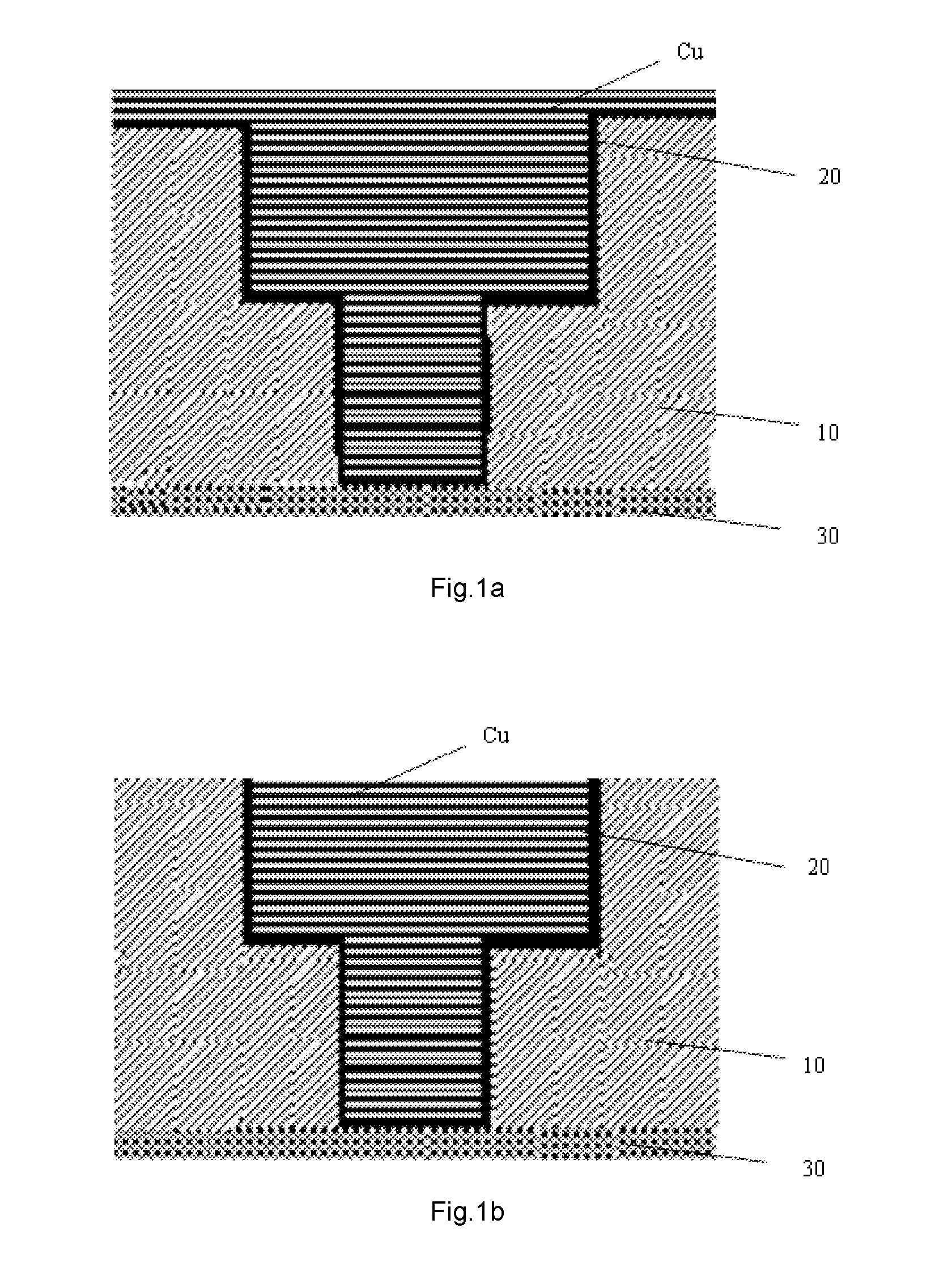

STI forming method

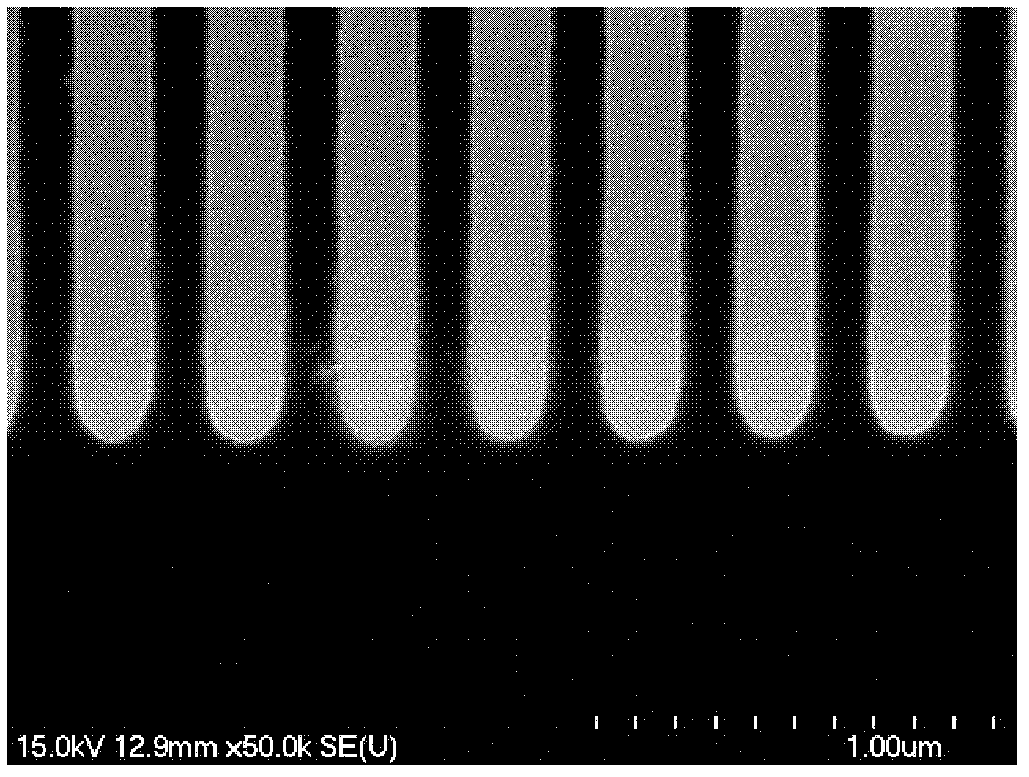

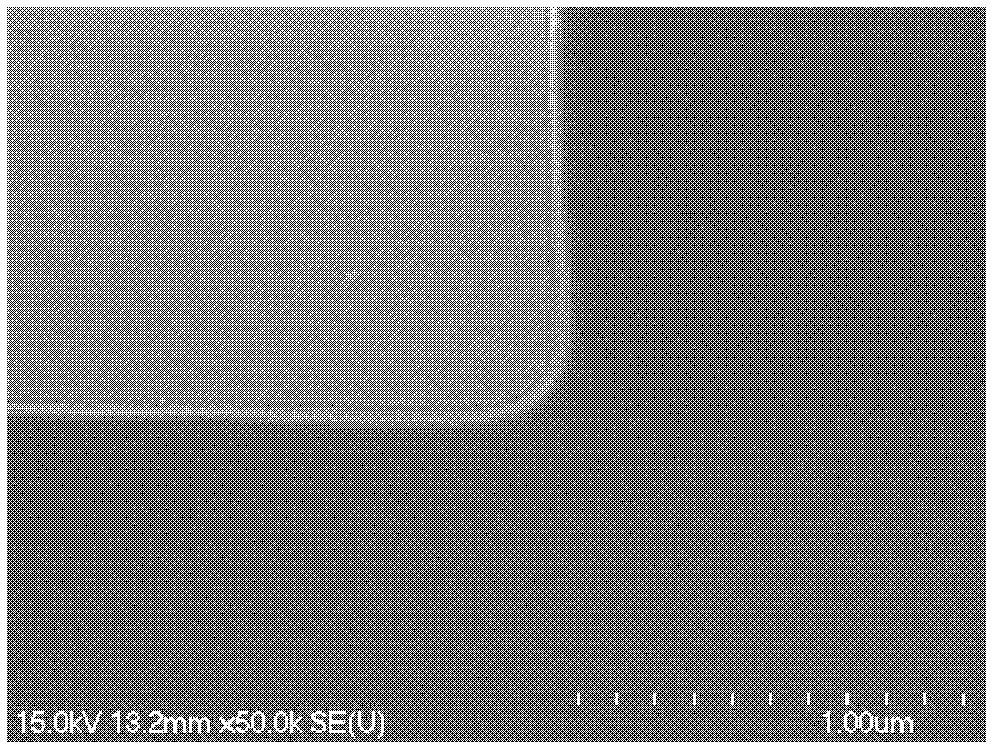

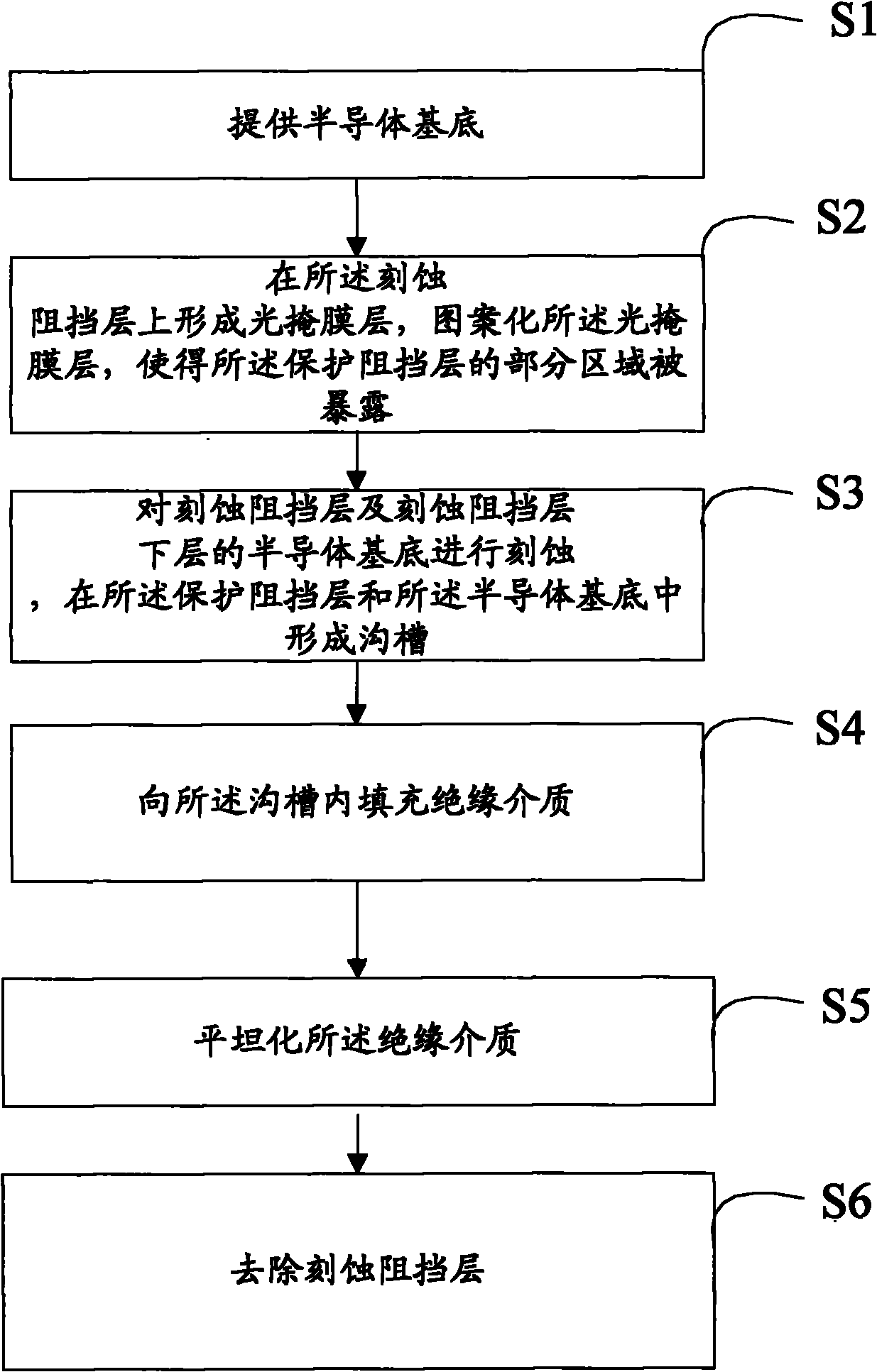

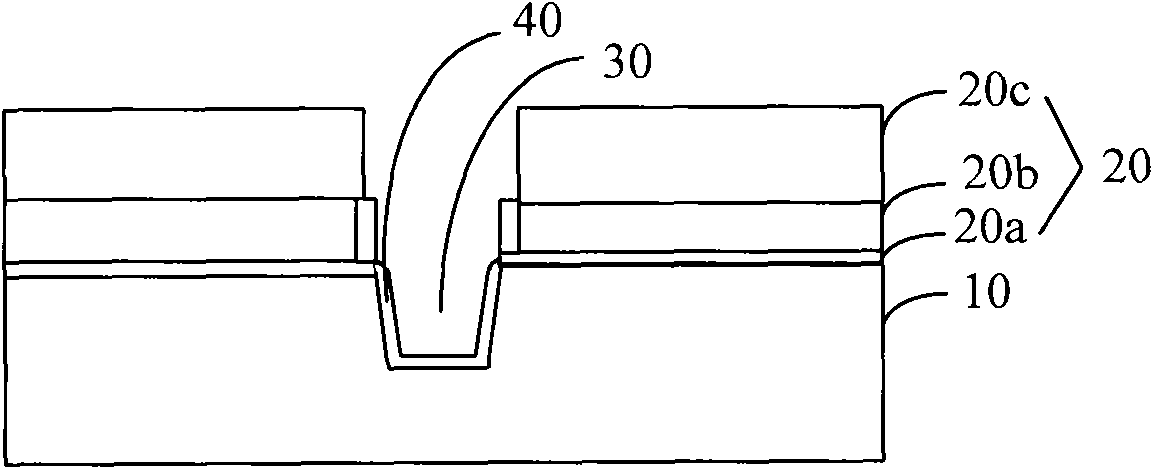

InactiveCN101996921AReduce the likelihood of sheddingImprove planarization efficiencySemiconductor/solid-state device manufacturingSemiconductorMaterials science

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

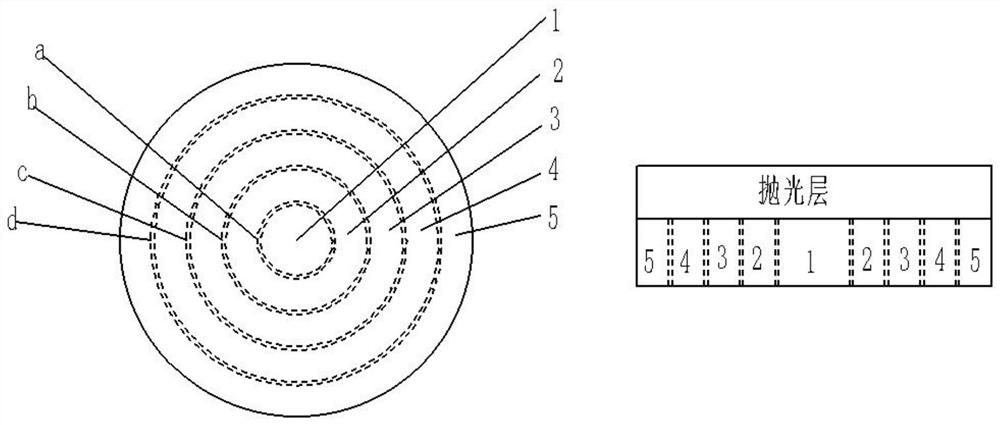

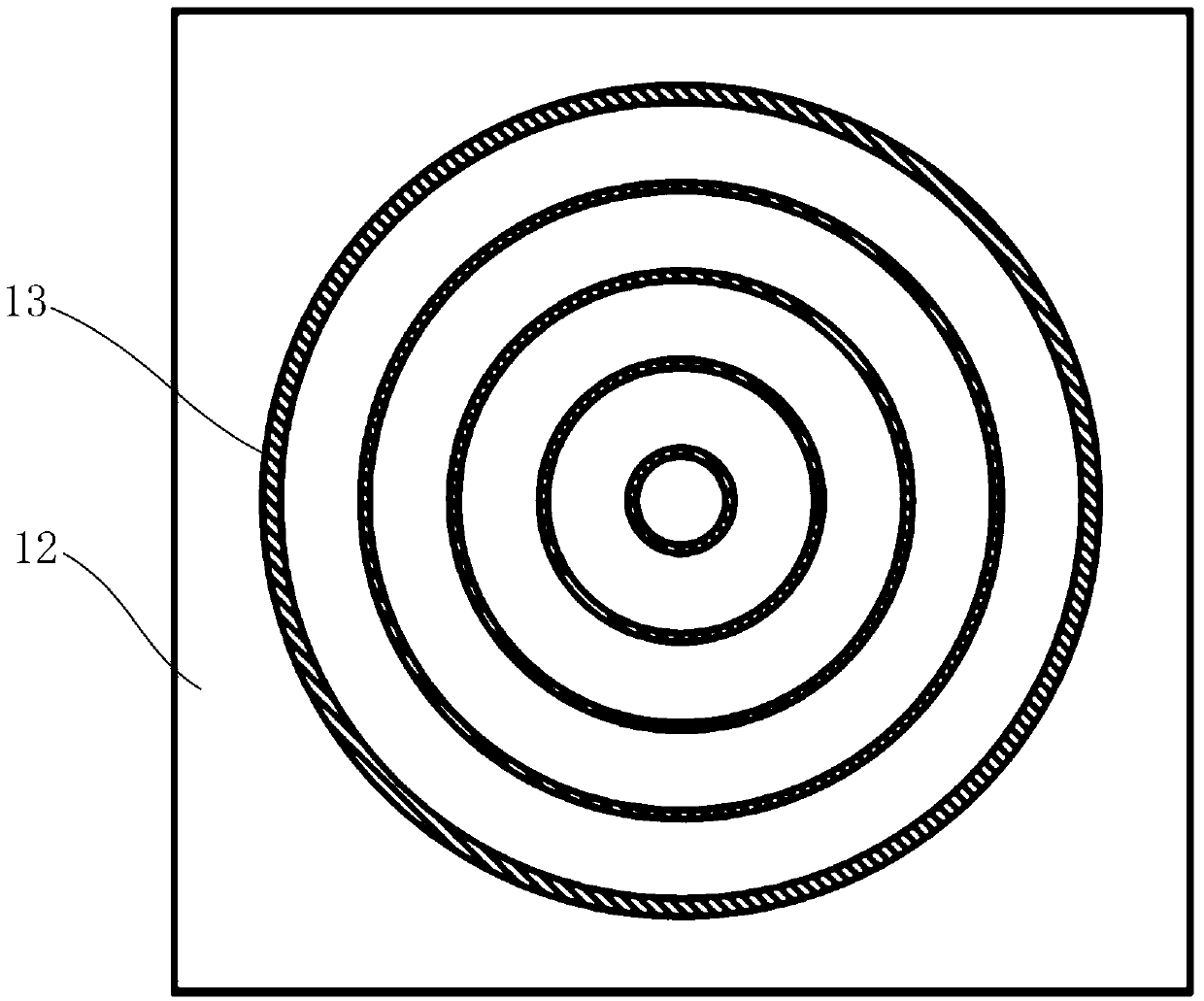

Polishing pad and preparation method and application thereof

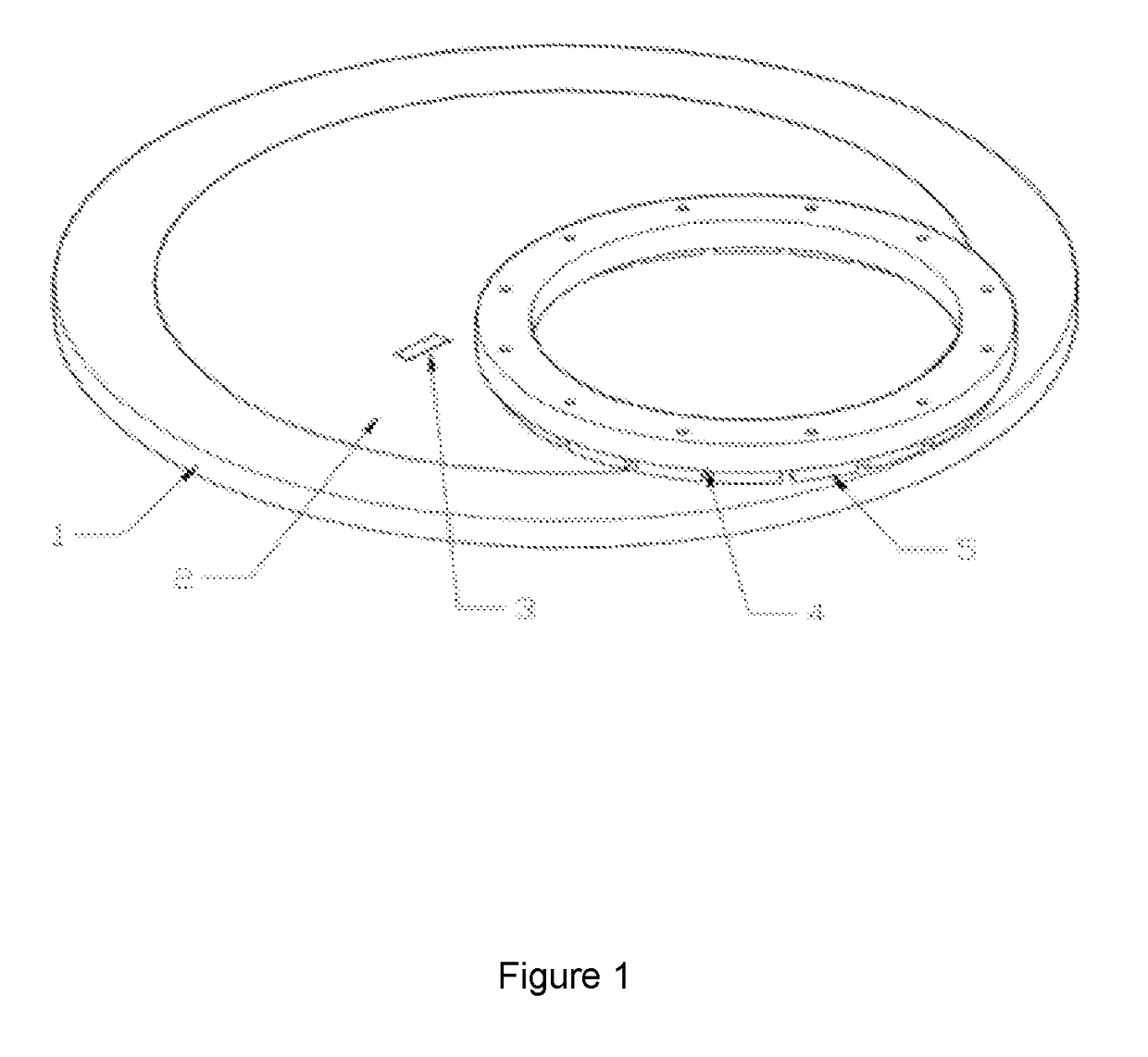

ActiveCN112338820AImprove planarization efficiencyConsistent grinding removal rateAbrasion apparatusGrinding devicesWaferingPolishing

The invention discloses a polishing pad and a preparation method and application thereof. The polishing pad is provided with a buffer layer and a polishing layer, wherein the buffer layer is formed bycombined pieces with different compression ratios and resilience rates, and the polishing layer is overlapped on the buffer layer; and a center circle center buffer area, one or more middle annular buffer areas sequentially arranged around the center buffer area and an outer edge annular buffer area arranged around the middle buffer areas are formed by the different combined pieces. The compression ratios and the resilience rates of the combined pieces of the buffer layer are different in the direction from the center of the polishing pad to the outer edge of the polishing pad, in the mechanical polishing process, the wear rate of the combined pieces is basically kept consistent, and therefore the surface of a wafer to be polished can become flat, and the flattening efficiency is high.

Owner:HUBEI DINGHUI MICROELECTRONICS MATERIALS CO LTD +1

Chemical mechanical polishing solution for polishing polycrystalline silicon

InactiveCN112608685AChange the removal rateGood removal effectPolishing compositions with abrasivesActive agentSurface roughness

The invention discloses a chemical mechanical polishing solution for polishing polycrystalline silicon. The chemical mechanical polishing solution comprises grinding particles, water, one or more oxidants and a nonionic surfactant for reducing the surface roughness of a silicon wafer, the polishing solution comprises the following components in percentage by weight: 0.1-30% of grinding particles, 0.1-20% of an oxidant and 0.001-5% of a nonionic surfactant. According to the method, the removal rate of polycrystalline silicon can be remarkably changed under the alkaline condition, the silicon surface roughness is low, the selection ratio of the polycrystalline silicon to silicon dioxide is adjusted, the planarization efficiency of the polycrystalline silicon is remarkably improved, and polishing residues are removed.

Owner:芯越微电子材料(嘉兴)有限公司

Chemical mechanical polishing solution for polishing polycrystalline silicon

ActiveCN103045099AChange the removal rateGood removal effectPolishing compositions with abrasivesSilicon dioxideOxidizing agent

The invention discloses chemical mechanical polishing solution for polishing polycrystalline silicon. The polishing solution comprises ground particles, water and one or a plurality of oxidants. Under the alkaline condition, the polishing solution disclosed by the invention can obviously change removal rate of the polycrystalline silicon, regulates selection ratio of the polycrystalline silicon to silicon dioxide and obviously improves planarization efficiency of the polycrystalline silicon and removal of polishing residues.

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

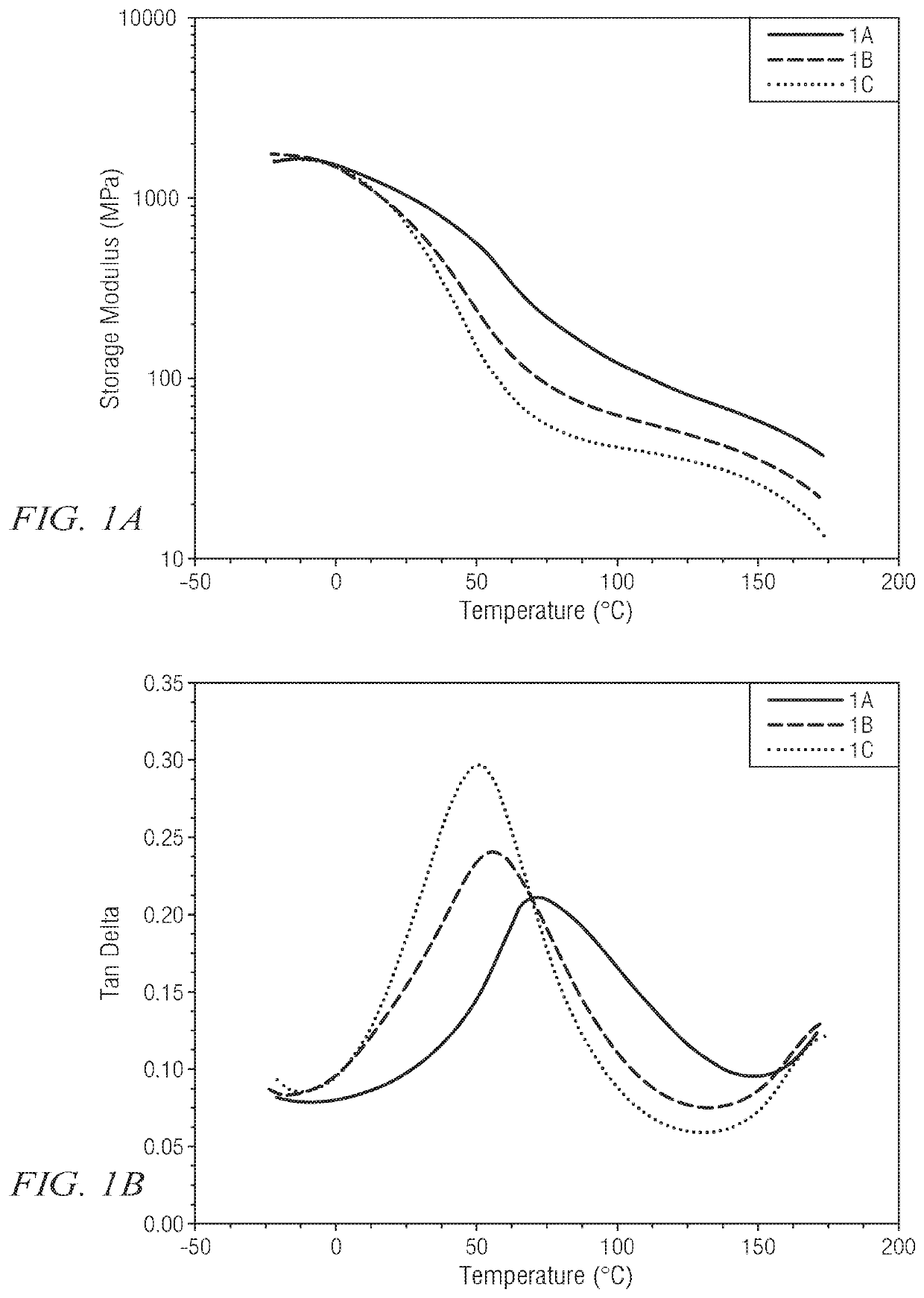

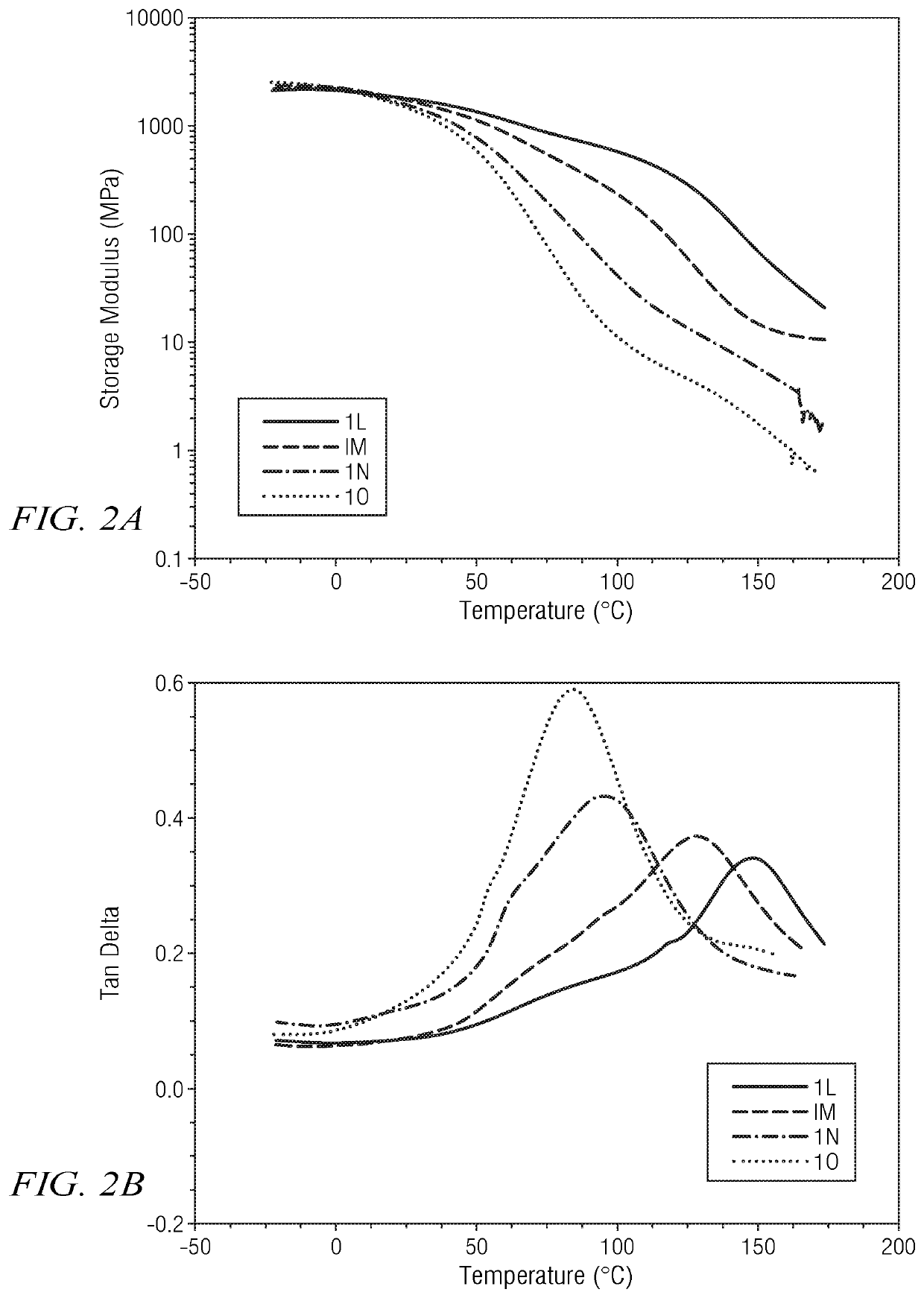

Polishing pad employing polyamine and cyclohexanedimethanol curatives

PendingUS20210008687A1Improve planarization efficiencyReduce defective rateSynthetic resin layered productsFlexible-parts wheelsCyclohexanedimethanolPolymer science

A chemical-mechanical polishing pad comprising a thermosetting polyurethane polishing layer includes an isocyanate-terminated urethane prepolymer, a polyamine curative, and a cyclohexanedimethanol curative. The polyamine curative and the cyclohexanedimethanol curative are in a molar ratio of polyamine curative to cyclohexanedimethanol curative in a range from about 20:1 to about 1:1.

Owner:CMC MATERIALS INC

Preparing method for sapphire touch screen panel

InactiveCN105171583ANot suitable for chippingIncrease productivityPolishing machinesLapping machinesPrinting inkIngot

The invention relates to a preparing method for a sapphire touch screen panel. The preparing method comprises the specific steps of crystal growing, crystal ingot drawing, crystal cutting, laser sheet taking, grinding, chamfering, annealing, double-sided polishing, printing ink coating, heat baking and other procedures. According to the preparing method for the sapphire touch screen panel, the sheet forming quality is high, the rejection rate is low, and the production efficiency is high.

Owner:江苏苏创光学器材有限公司

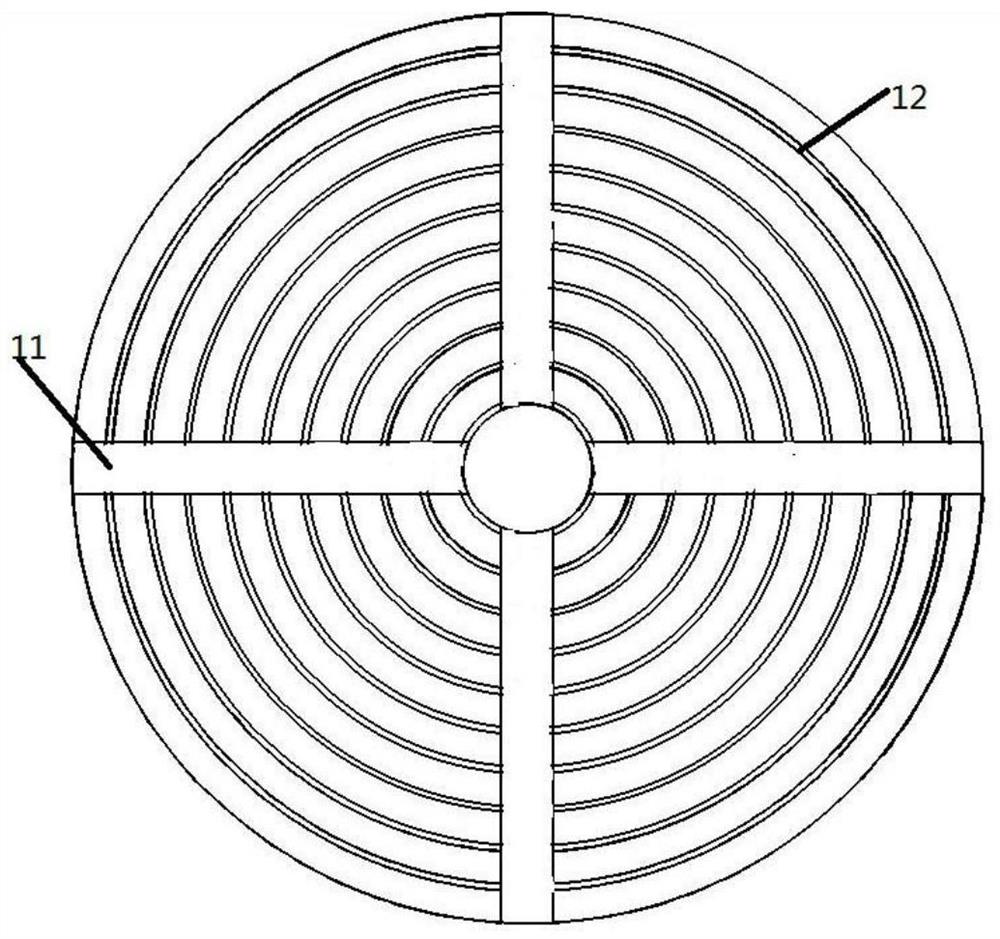

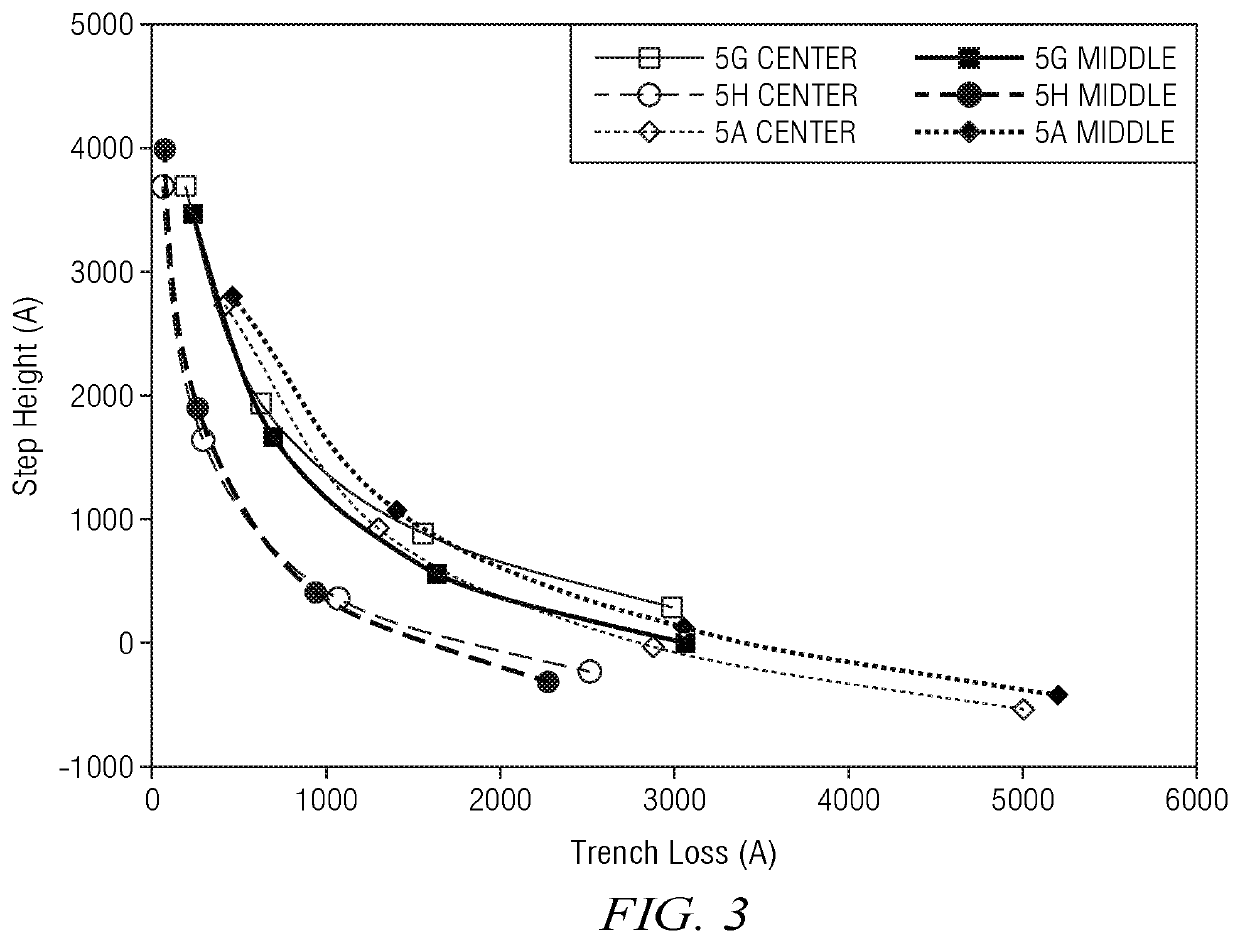

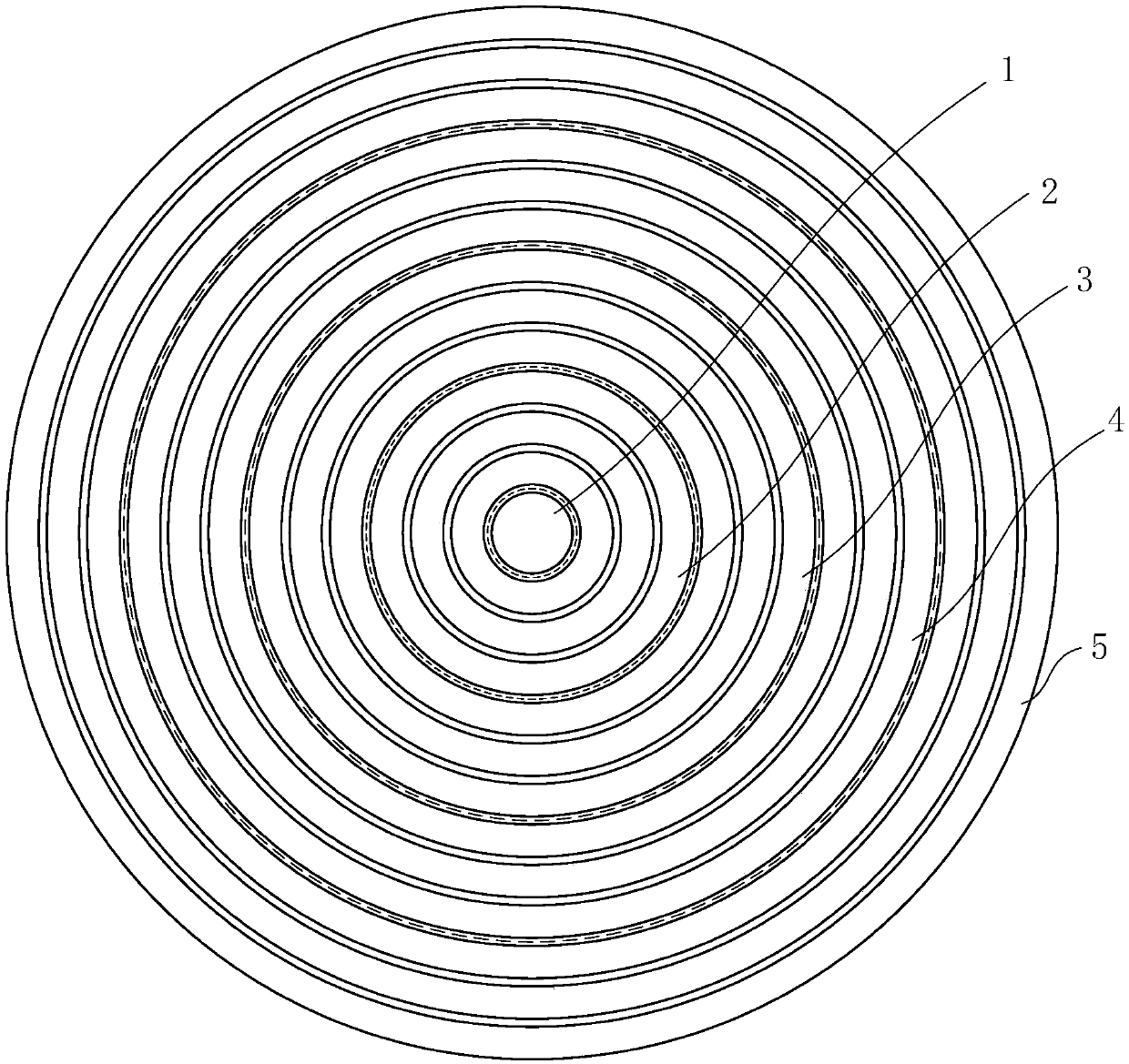

Polishing pad and preparation method and application thereof

ActiveCN110815038ACompensate for differences in linear velocityImproved polishing planarization efficiencyAbrasion apparatusLapping toolsWaferingPolishing

The invention discloses a polishing pad and a preparation method and application thereof. The polishing pad is provided with combination pieces and a bottom lining, the combination pieces are fixed tothe bottom lining, the combination pieces form a polishing layer together, the polishing layer is provided with a central polishing area, one or more intermediate polishing areas which are sequentially arranged around the central polishing area and outer edge polishing areas which are arranged around the intermediate polishing areas, the central polishing area is circular, the intermediate polishing areas are annular, and the outer edge polishing areas are annular; annular gaps are correspondingly formed between adjacent two polishing areas, and are used for receiving polishing fluid in the polishing process; the shore hardness of the polishing layer is sequentially decreased in the direction from the central polishing area to the outer edge polishing areas; and the shore hardness gradient of the two adjacent polishing areas is 0.5-5 D. The hardness of the polishing pad is decreased gradually in the diameter direction, in the process of mechanical polishing, the wear rate of the polishing pad is basically kept to be same, thus the surface of a to-be-polished crystal plate can be flat, and the flattening efficiency is high.

Owner:HUBEI DINGLONG CO LTD +1

Preparation method of sapphire fingerprint identification panel

InactiveCN105160286ANot suitable for chippingIncrease productivityPrint image acquisitionRejection rateCrystal growth

The invention relates to a preparation method of a sapphire fingerprint identification panel, which specifically comprises the working procedures of crystal growth, crystal extracting, crystal cutting, laser slice taking, grinding, chamfering, annealing, double-sided polishing, film coating, ink printing, baking and the like. The preparation method of the sapphire fingerprint identification panel is high in slice forming quality, low in rejection rate and high in production efficiency.

Owner:江苏苏创光学器材有限公司

Polishing slurries for copper and associated materials

InactiveUS20060084272A1High removal rateLow removal ratePigmenting treatmentSemiconductor/solid-state device manufacturingSilica particleCompound (substance)

A chemical mechanical polishing slurry and method for using the slurry for polishing copper, barrier material and dielectric material that includes a first and second slurry. The first slurry has a high removal rate on copper and a low removal rate on barrier material. The second slurry has a high removal rate on barrier material and a low removal rate on copper and dielectric material. The first and second slurries can include silica particles, an oxidizing agent, a corrosion inhibitor, and a cleaning agent.

Owner:CABOT MICROELECTRONICS CORP

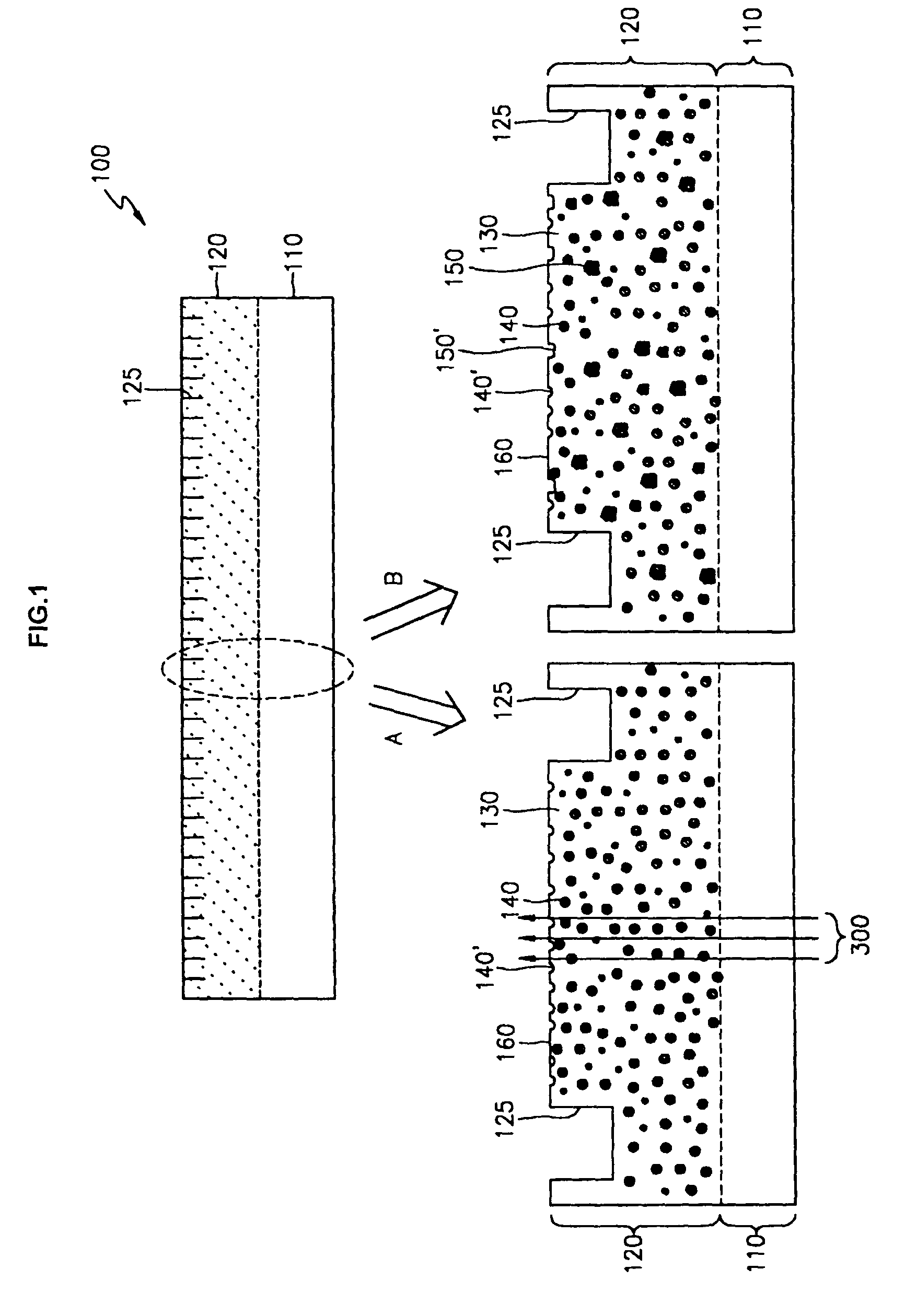

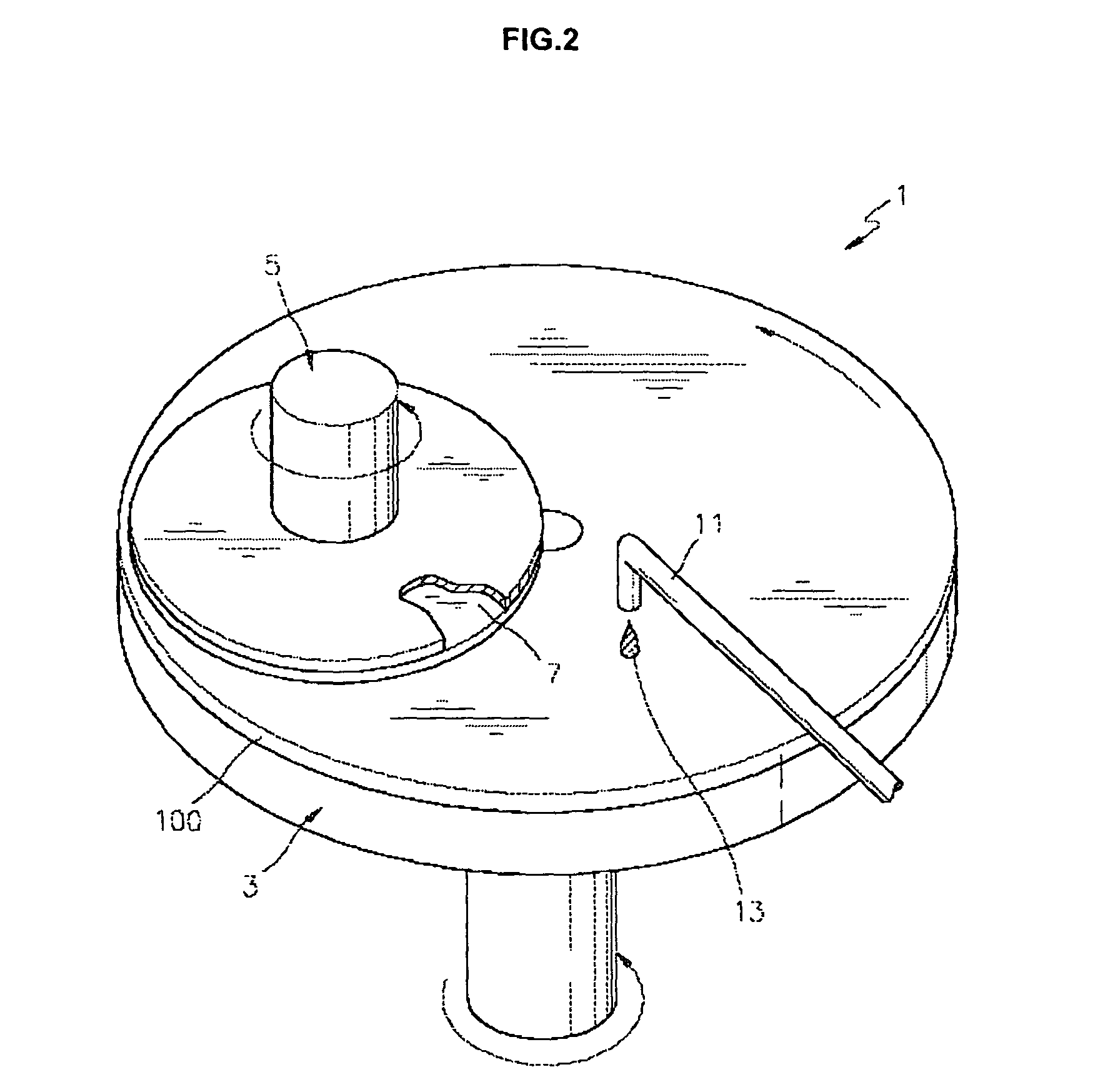

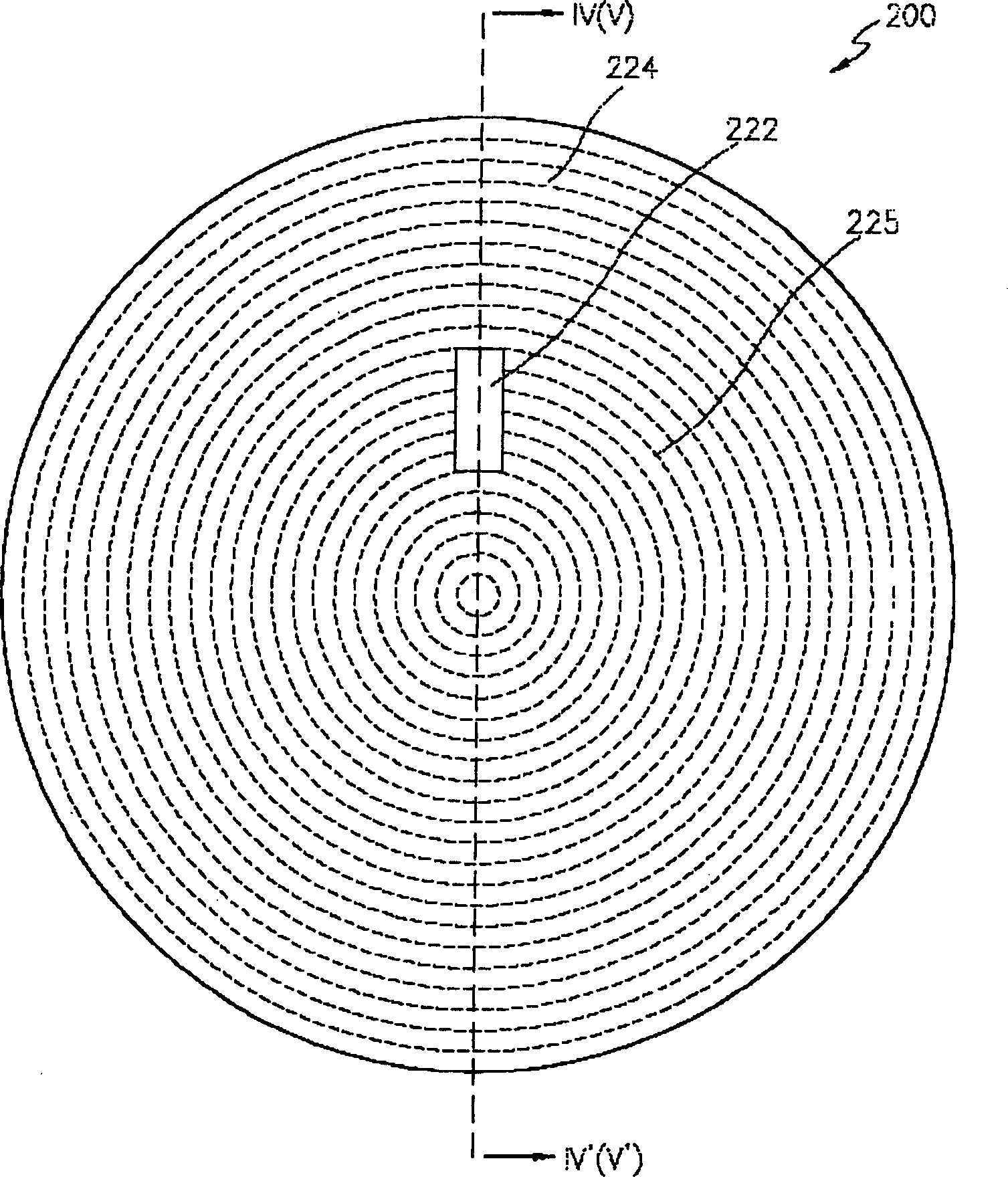

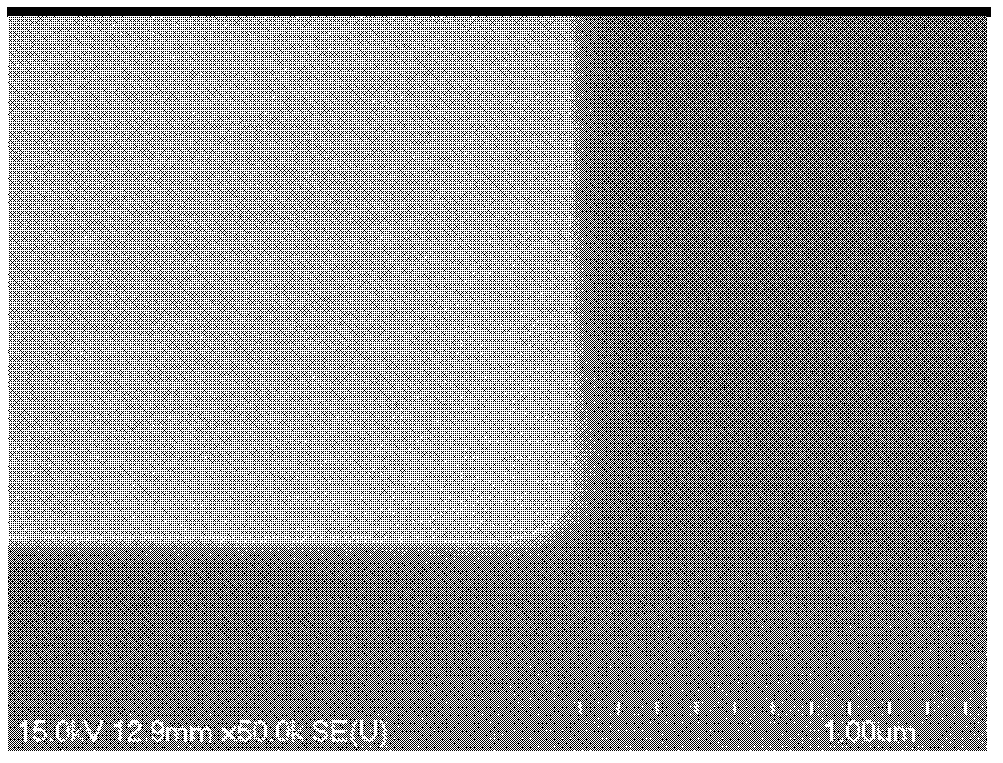

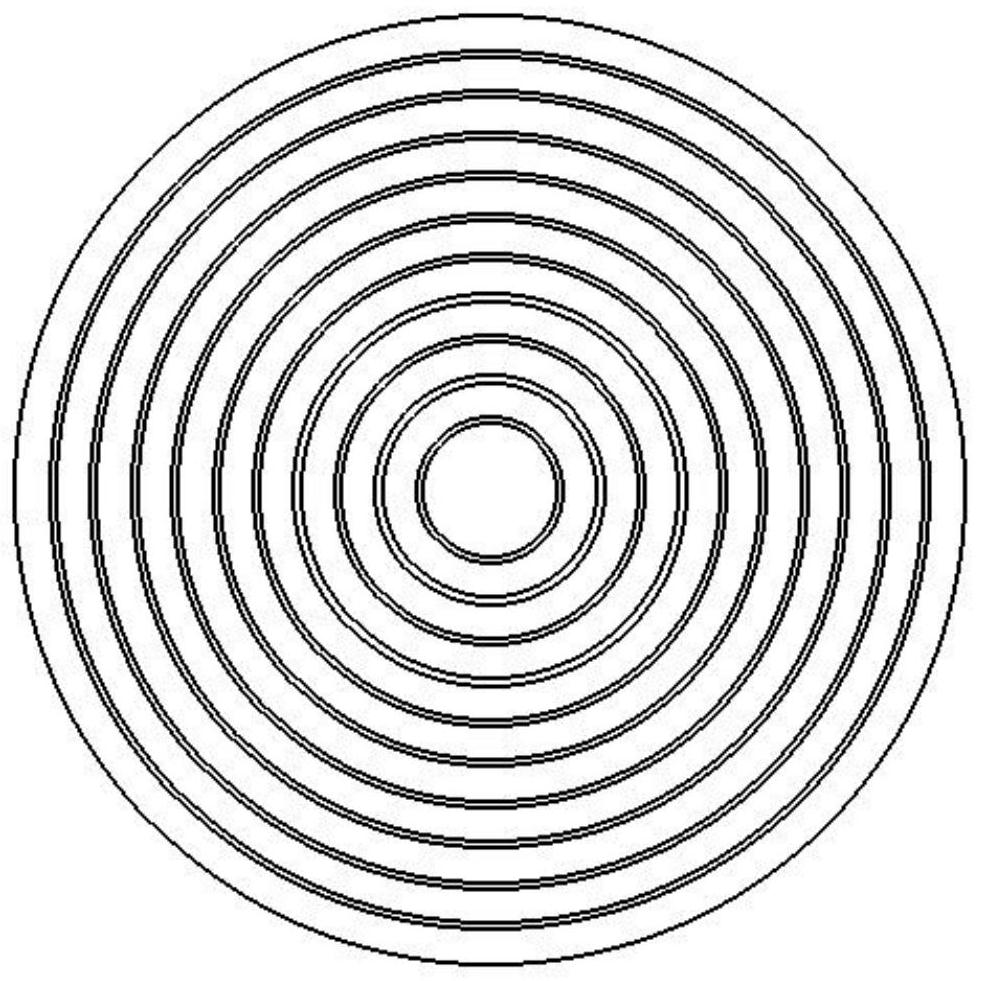

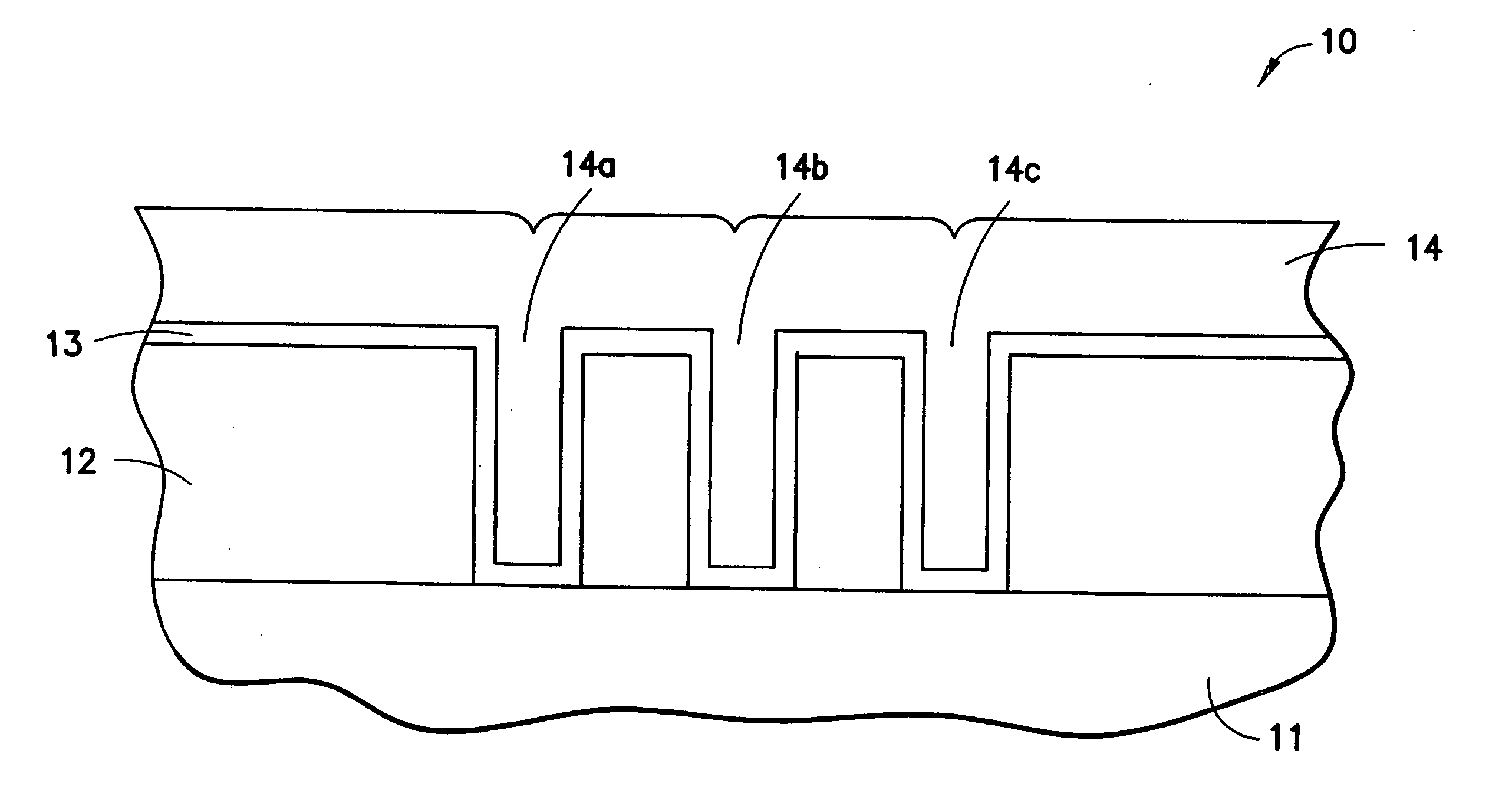

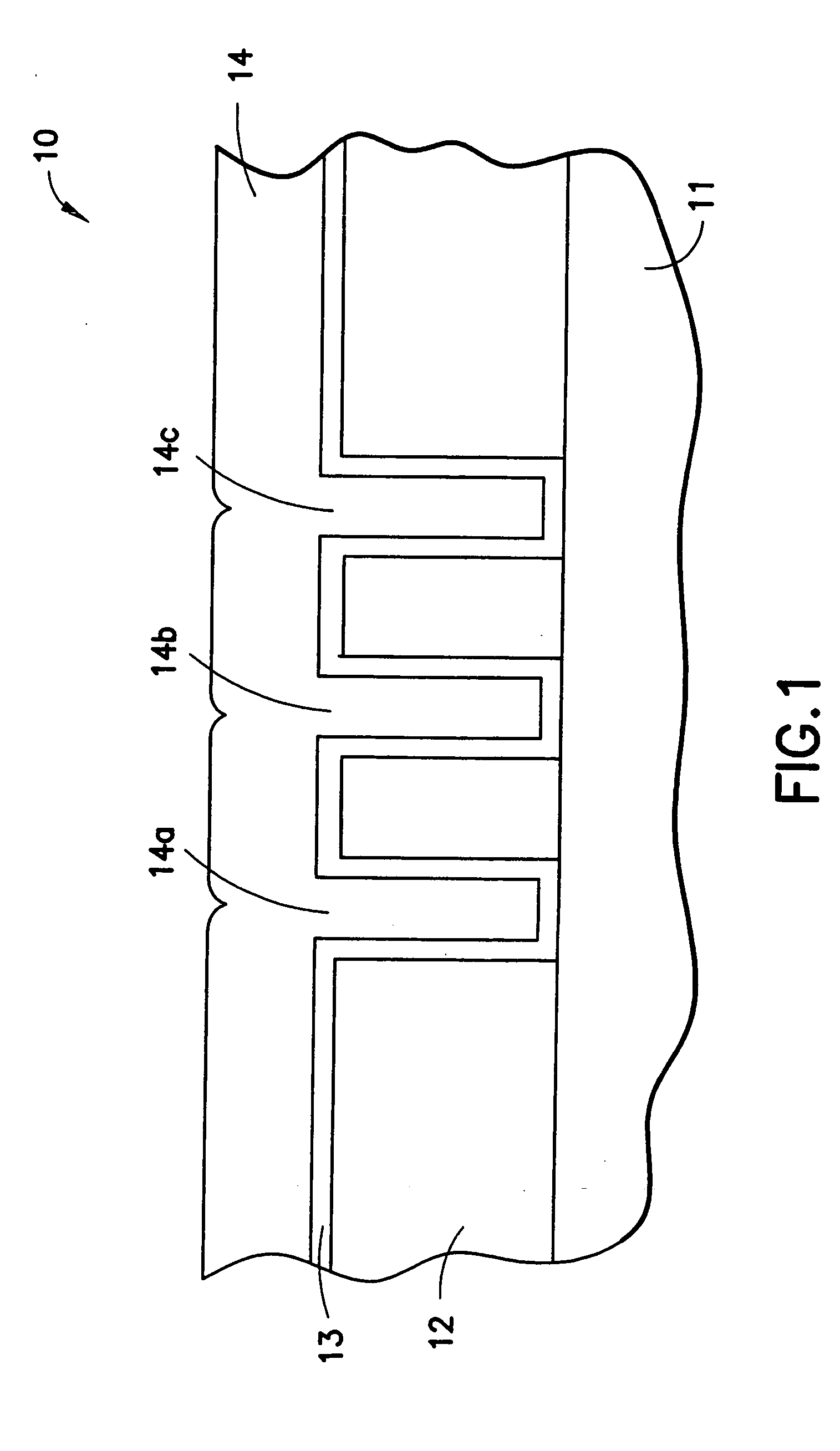

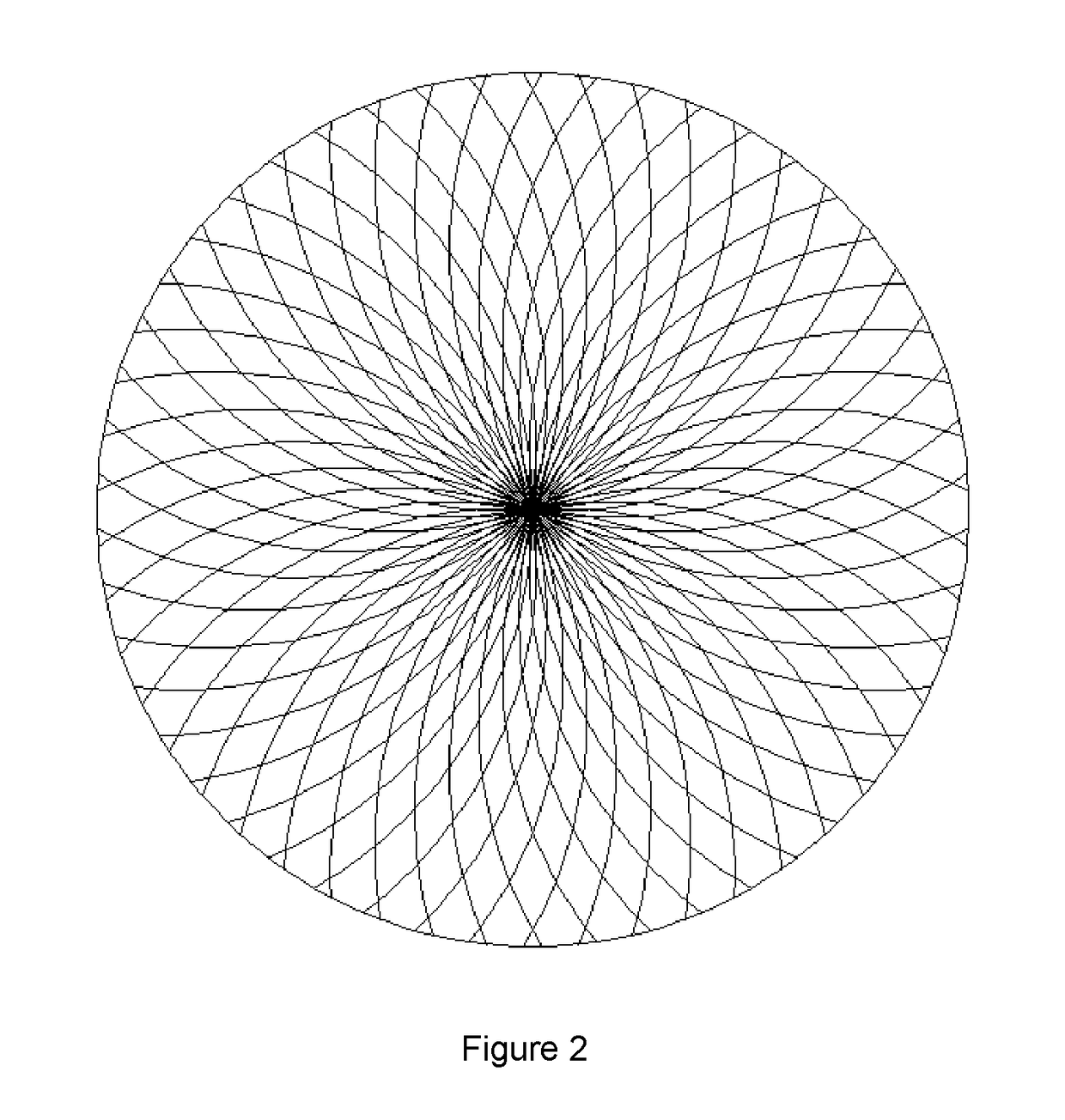

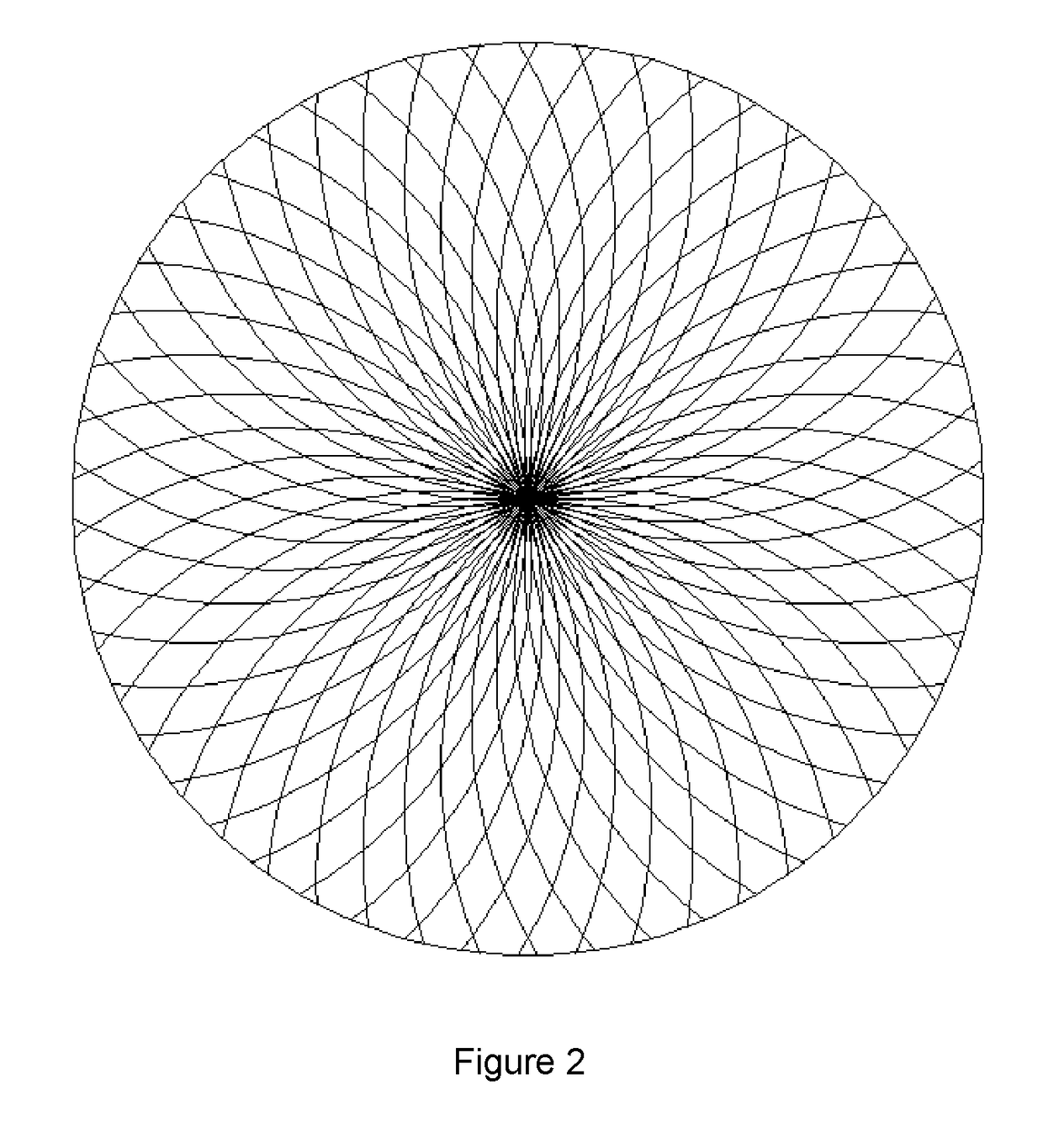

Method to shape the surface of chemical mechanical polishing pads

ActiveUS9802293B1Efficient polishingImprove planarization efficiencyGrinding devicesAbrasive surface conditioning devicesPre-conditionSurface roughness

The present invention provides methods for making a pre-conditioned chemical mechanical (CMP) polishing pad having a pad surface microtexture effective for polishing comprising grinding the surface of the CMP polishing pad having a radius with a rotary grinder while it is held in place on a flat bed platen surface, the rotary grinder having a grinding surface disposed parallel to or substantially parallel to the surface of the flat bed platen and made of a porous abrasive material, wherein the resulting CMP polishing pad has a surface roughness of from 0.01 μm to 25 μm, Sq. The present invention also provides a CMP polishing pad having a series of visibly intersecting arcs on the polishing layer surface, the intersecting arcs having a radius of curvature equal to or greater than half of the radius of curvature of the pad and extending all the way around the surface of the pad in radial symmetry around the center point of the pad.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

Chemical mechanical polishing pads having a consistent pad surface microtexture

InactiveUS20180085888A1Efficient polishingImprove planarization efficiencyAbrasion apparatusAbrasive surface conditioning devicesPre-conditionPre conditioning

The present invention provides pre-conditioned chemical mechanical (CMP) polishing pads comprising a polymer, preferably, a porous polymer having a pad surface microtexture effective for polishing having a series of visibly intersecting arcs on the polishing layer surface, the intersecting arcs having a radius of curvature equal to or greater than half of the radius of curvature of the pad and extending all the way around the surface of the pad in radial symmetry around the center point of the pad wherein the resulting CMP polishing pad has a surface roughness of from 0.01 μm to 25 μm, Sq. The CMP polishing pads may be made by methods comprising grinding the surface of a CMP polishing pad with a rotary grinder to form the surface microtexture.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

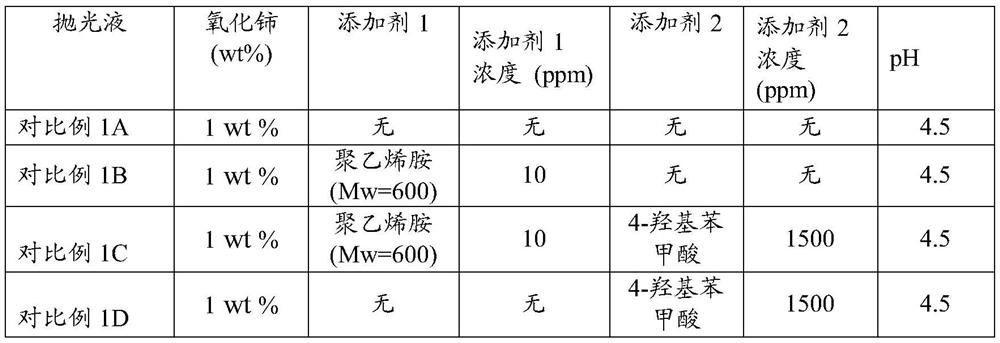

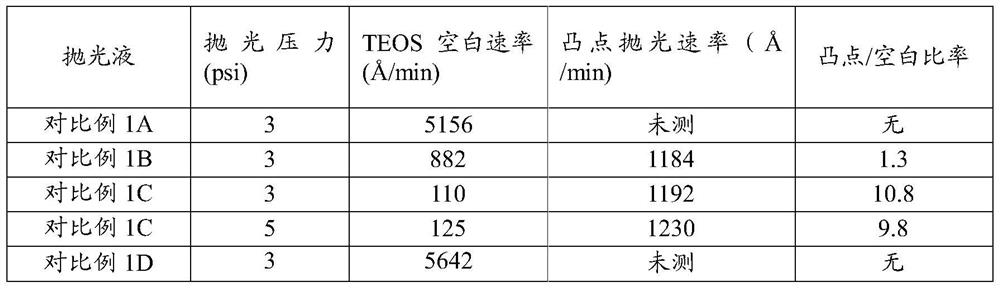

Chemical mechanical polishing solution

PendingCN113004797AImprove polishing rateReduce polishing rateOther chemical processesSemiconductor/solid-state device manufacturingPhysical chemistryCerium

The invention provides a chemical mechanical polishing solution. The chemical mechanical polishing solution comprises water, cerium oxide, polyquaternium salt, carboxylic acid containing a benzene ring and polyvinylamine. Only when the polyquaternium salt, the carboxylic acid containing the benzene ring and the polyvinylamine are used together, the real automatic stopping function can be achieved, a blank wafer has the low polishing rate, the high polishing rate is kept when the step height of the patterned silicon wafer is high, the lower the step height is, the better the polishing speed is restrained, and the better the polishing effect is achieved. Therefore, the automatic stop function is realized.

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com