Patents

Literature

85results about How to "Reduce the likelihood of shedding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

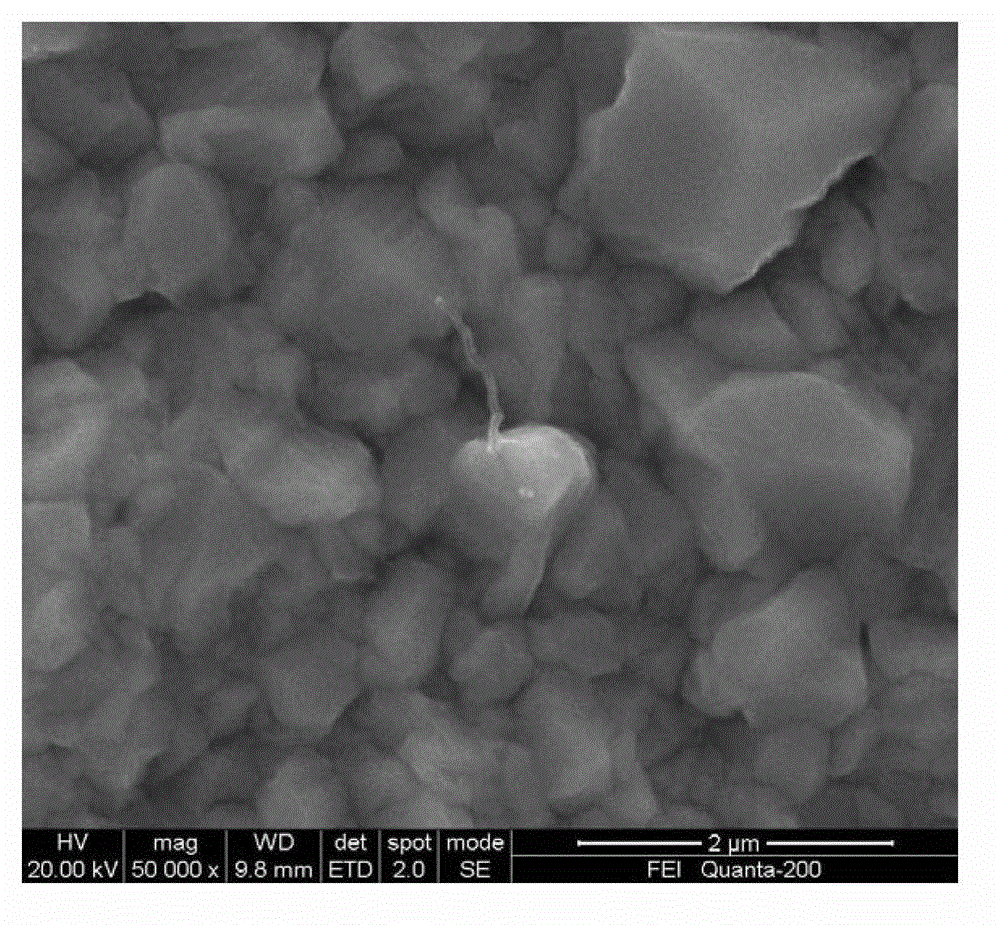

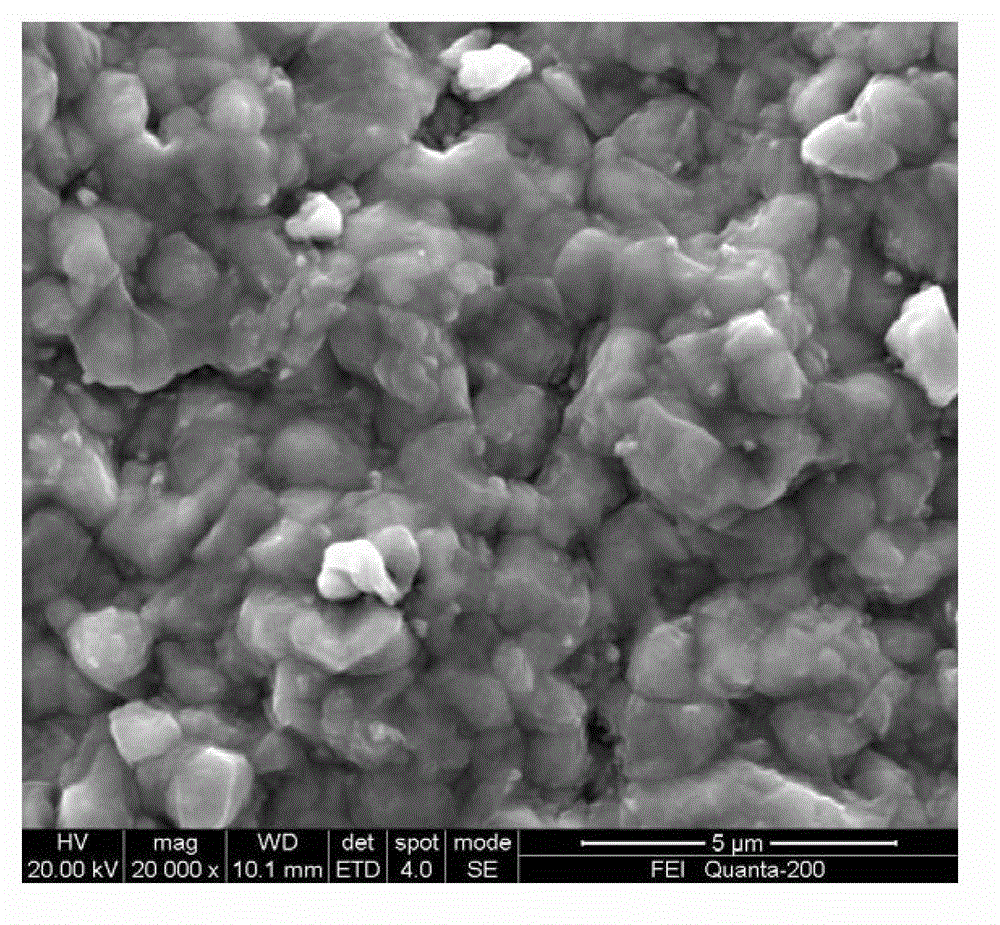

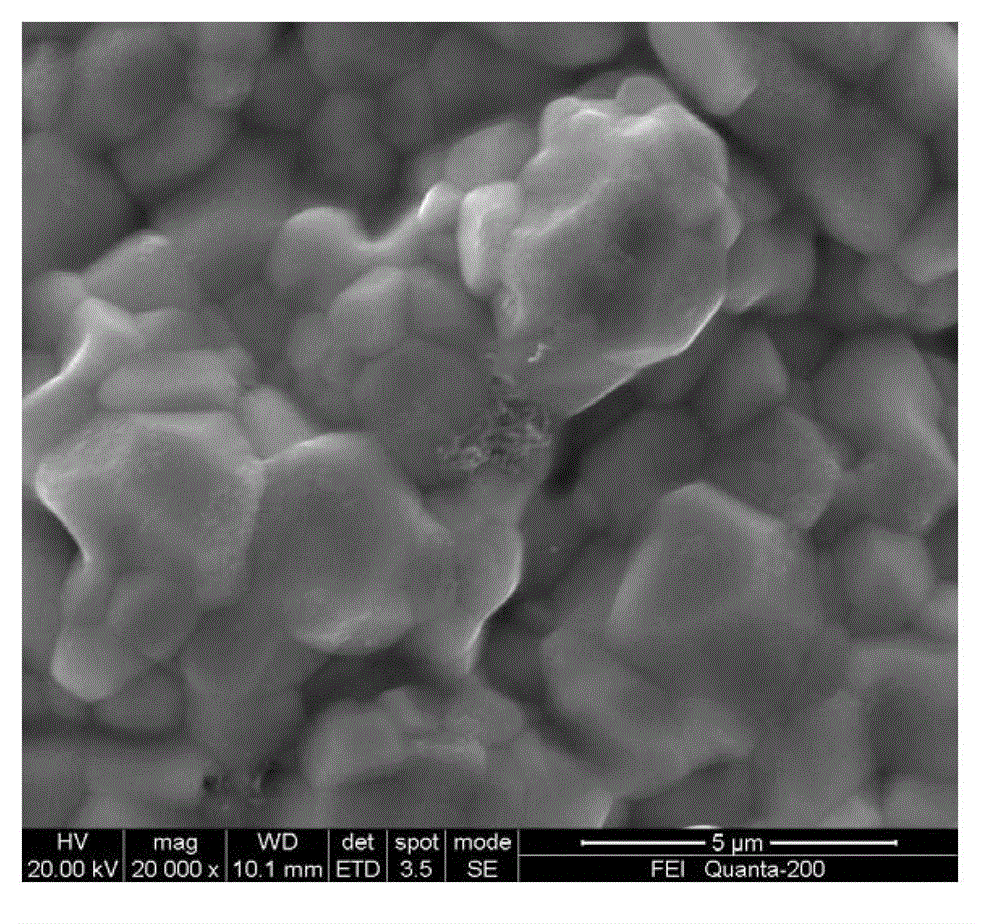

Carbon-Cu6Sn5 alloy negative electrode materials and preparation method thereof

InactiveCN103066252AReduce the likelihood of sheddingIncrease migration rateElectrolytic coatingsCell electrodesCarbon nanotubeAlloy

The invention discloses carbon-Cu6Sn5 alloy negative electrode materials and a preparation method thereof. The carbon-Cu6Sn5 alloy negative electrode materials and the preparation method thereof combine carbon nanometer tubes and graphene into electrodes and add a Cu-CNTs connecting layer between active materials and current collectors. Therefore, cyclic perforce of an alloy negative electrode is improved greatly. The carbon-Cu6Sn5 alloy negative electrode materials and the preparation method thereof use copper foils as the current collectors (electroplating substrates). The copper foils are plated by a Cu-CNTs composite plating and a composite plating of stannum-carbon nanometer tubes or stannum- graphene or stannum-carbon nanometer tubes- graphenes in sequence, wherein the thickness of the Cu-CNTs composite plating is 1-5 micrometers and the thickness of the composite plating of the stannum-carbon nanometer tubes or the stannum- graphene or the stannum-carbon nanometer tubes- graphene is 1-4 micrometers. The carbon-Cu6Sn5 alloy negative electrode materials can be obtained finally through thermal treatments. First specific discharge capacity of lithium ion battery alloy cathodes prepared by the method can achieve 613 m AH / g and specific capacity attenuation of the lithium ion battery alloy cathodes is only 4%-6% after 100 cycles. The carbon-Cu6Sn5 alloy negative electrode materials and the preparation method thereof are simple in technique, good in prepared alloy cathode performance and suitable for large-scale industrial production.

Owner:XIANGTAN UNIV

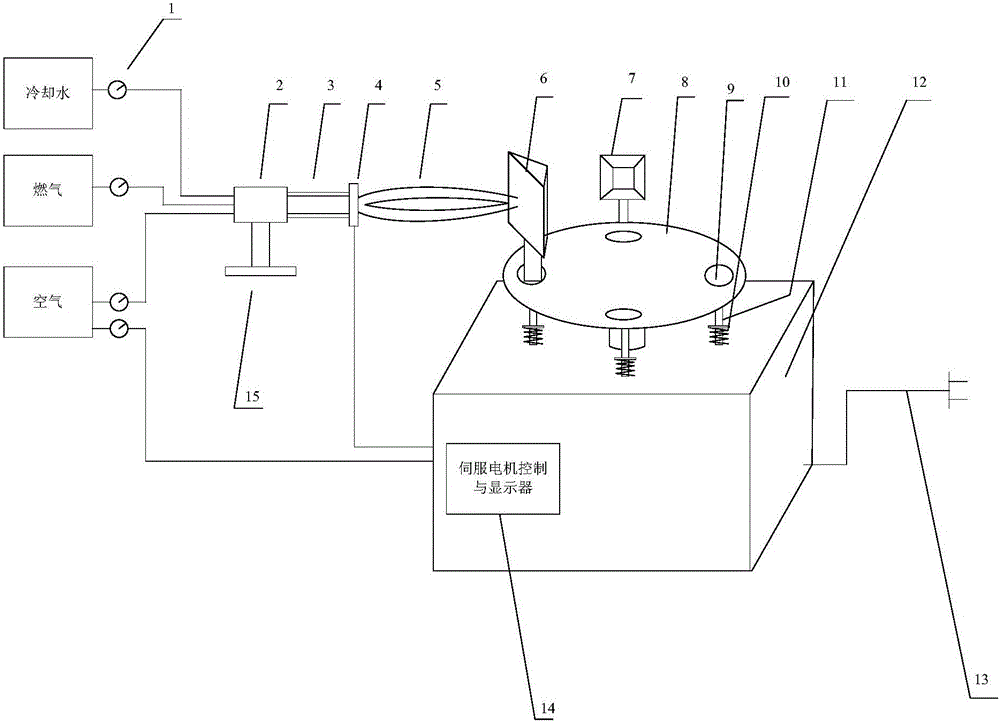

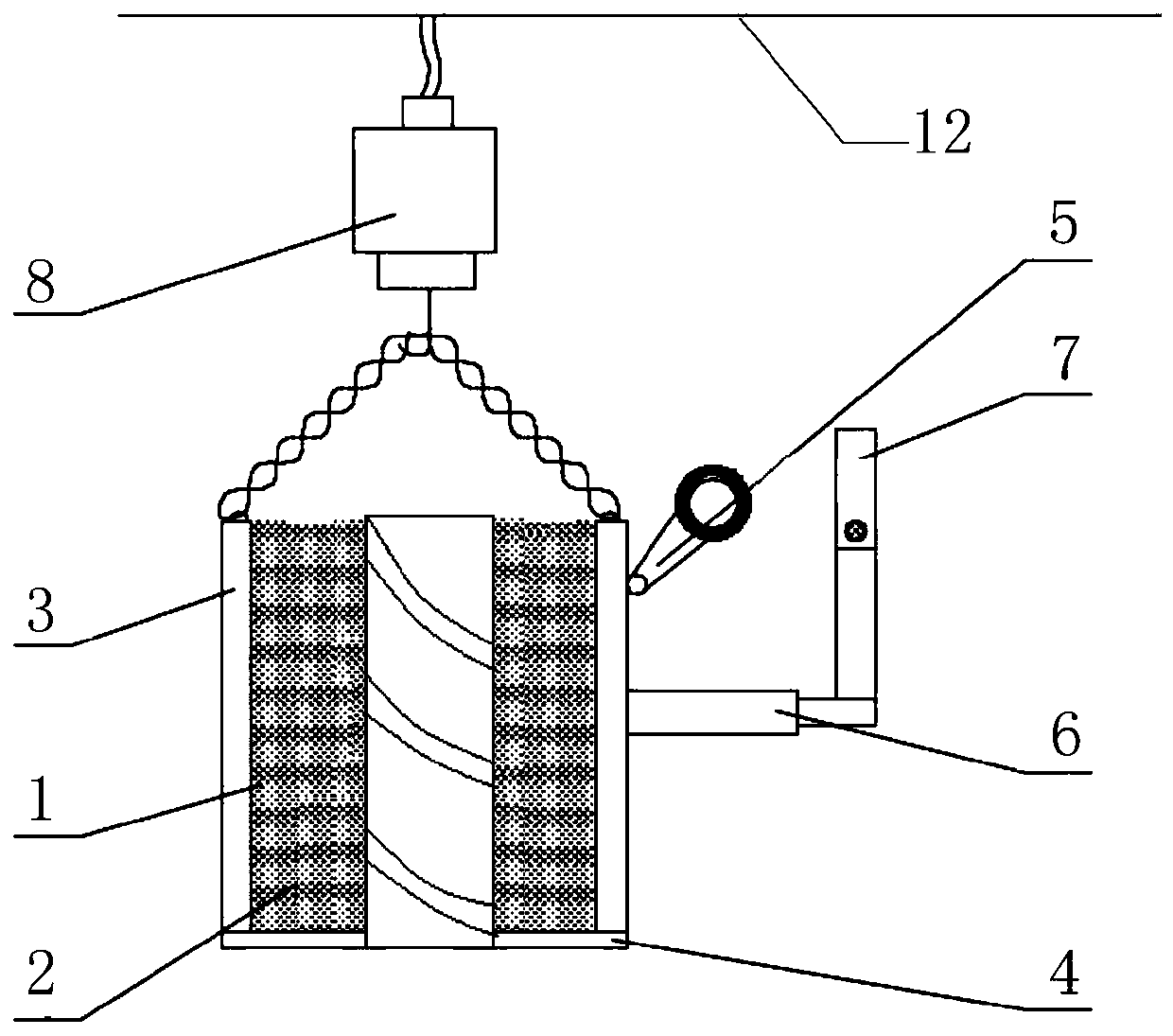

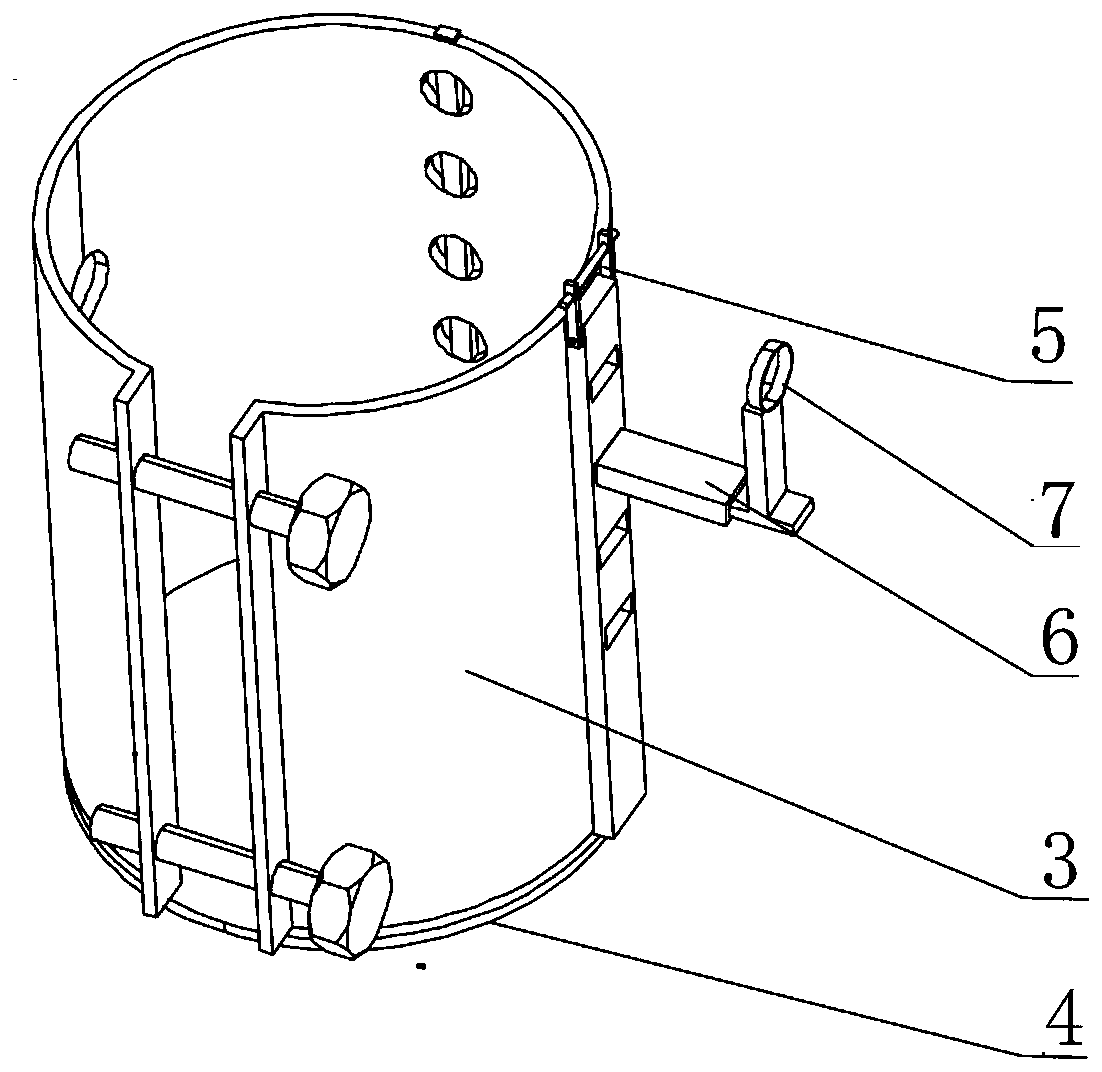

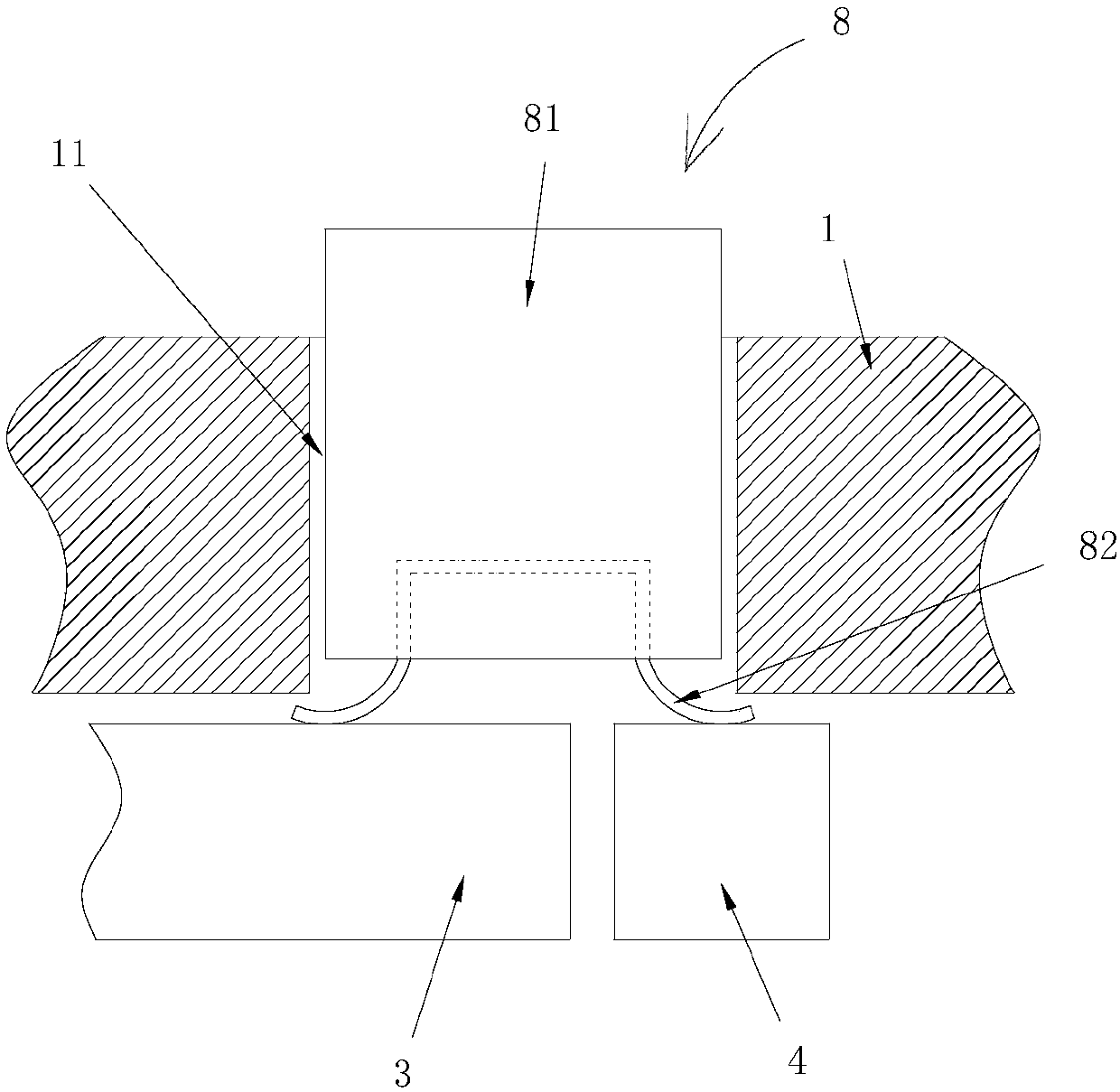

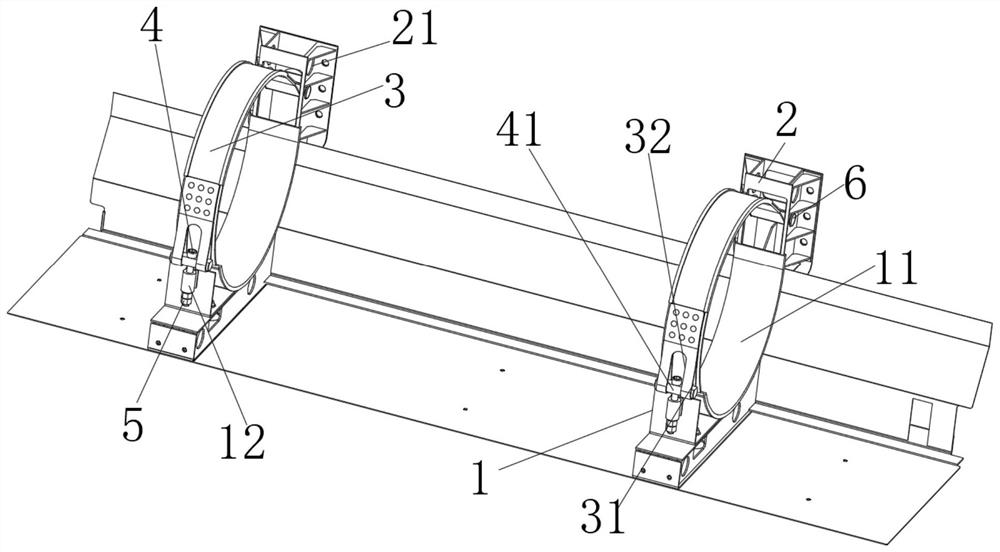

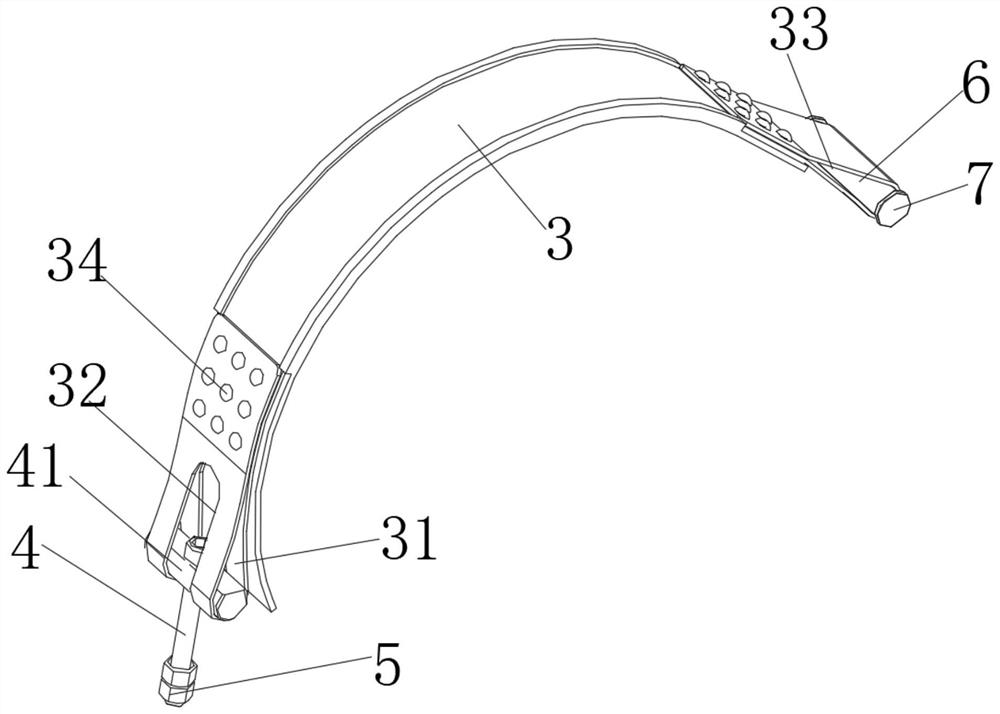

Thermal barrier coating thermal shock simulation testing device and testing method

InactiveCN105823701AImprove accuracyIncrease authenticityMaterial strength using repeated/pulsating forcesInvestigating abrasion/wear resistanceDisplay deviceAlloy substrate

A thermal vibration simulation test device and test method for thermal barrier coatings. The nozzle in the combustion system of the device adopts a contracted and expanded nozzle structure, and the sample adopts a large-sized plate-shaped nickel-based alloy substrate connected to a gas bag of the same size. , forming a hollow cooling structure similar to the blades of a gas turbine. After spraying the coating, connect it to the hollow air supply pipe, insert it into the mounting hole of the turntable and fix it, and the servo motor control unit controls the rotation angle of the sample and the heating and holding time , after turning on the power and cooling water, turn on the air source, then ignite and start thermal vibration. After the heating and holding time is up, rotate to the cooling position to be cooled by the cold air ejected from the cooling outlet of the coating sample, and the sample completes a thermal vibration. , and recorded in the control and display; using the device of the present invention to simulate the thermal shock and high-temperature flame erosion process of the thermal barrier coating in a high-temperature, high-speed flame environment with approximate real working conditions, the accuracy of the test results can be improved, authenticity.

Owner:HUANENG POWER INTERNATIONAL +1

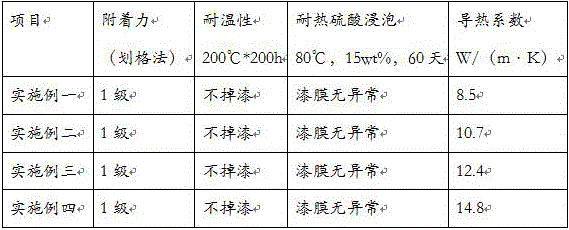

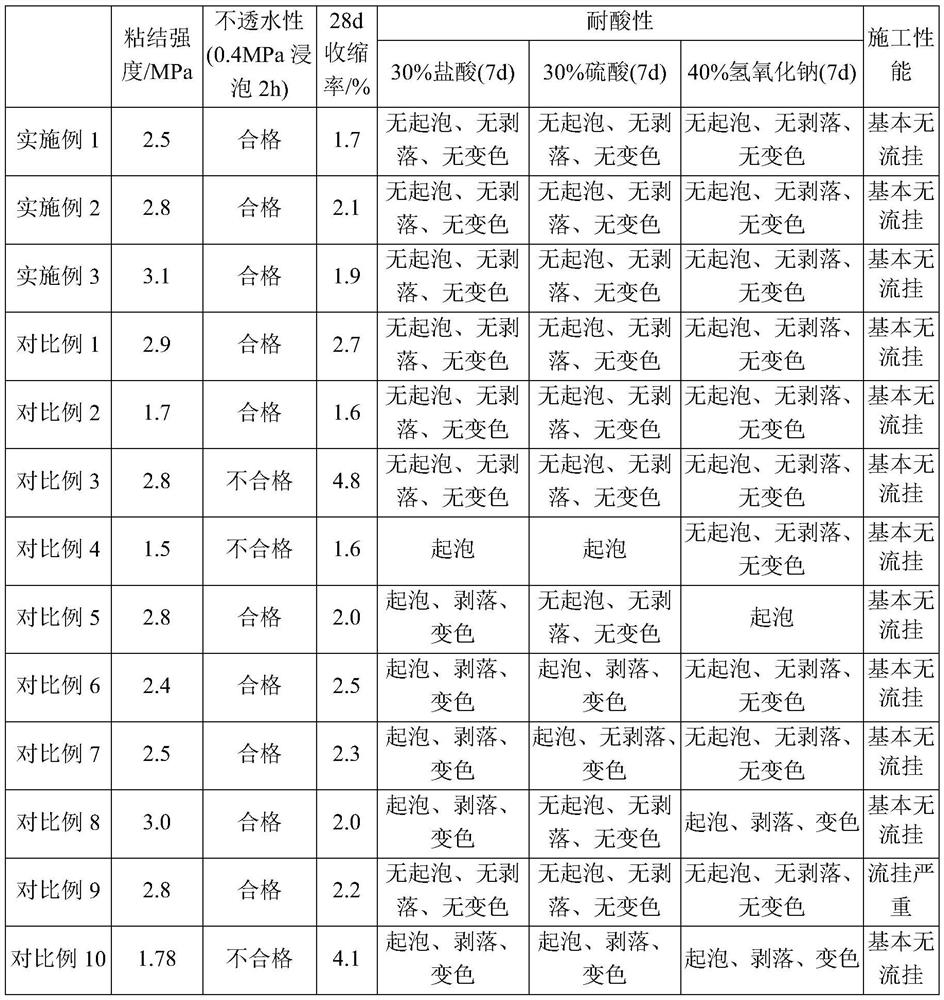

Graphene coating for corrosion prevention of thermal power plant desulfurization chimney, and preparation method of graphene coating

ActiveCN106366928AImprove toughnessImprove thermal stabilityFireproof paintsAnti-corrosive paintsFiberMetallurgy

The invention discloses graphene coating for corrosion prevention of a thermal power plant desulfurization chimney. The graphene coating consists of the following raw materials in parts by weight: 90 to 100 parts of film-forming resin, 0.5 to 3 parts of graphene, 0.5 to 2 parts of reinforced fibers, 10 to 20 parts of fillers, 10 to 20 parts of a curing agent, 15 to 30 parts of a diluents, 1 to 5 parts of polyacrylic acid, 1 to 5 parts of a polyethylenimin crosslinking agent, 1 to 3 parts of stearate and 2 to 6 parts of aids. By the mode of adding the raw materials, such as the reinforced fibers, the fillers, the polyethylenimin crosslinking agent and the polyacrylic acid, the defect that the existing corrosion-resistant coating has low durability and heat stability is overcome, the problem that the corrosion-resistant coating layer is easy to pollute and difficult to clean is solved, the developed graphene corrosion-resistant coating can completely adapt to the high-temperature strong-acid environment, the manufacturing process is simple, the practicability is high and the graphene coating is particularly suitable for thermal power plant desulfurization chimneys and flues.

Owner:CHENGDU LONGZHIQUAN SCI & TECH

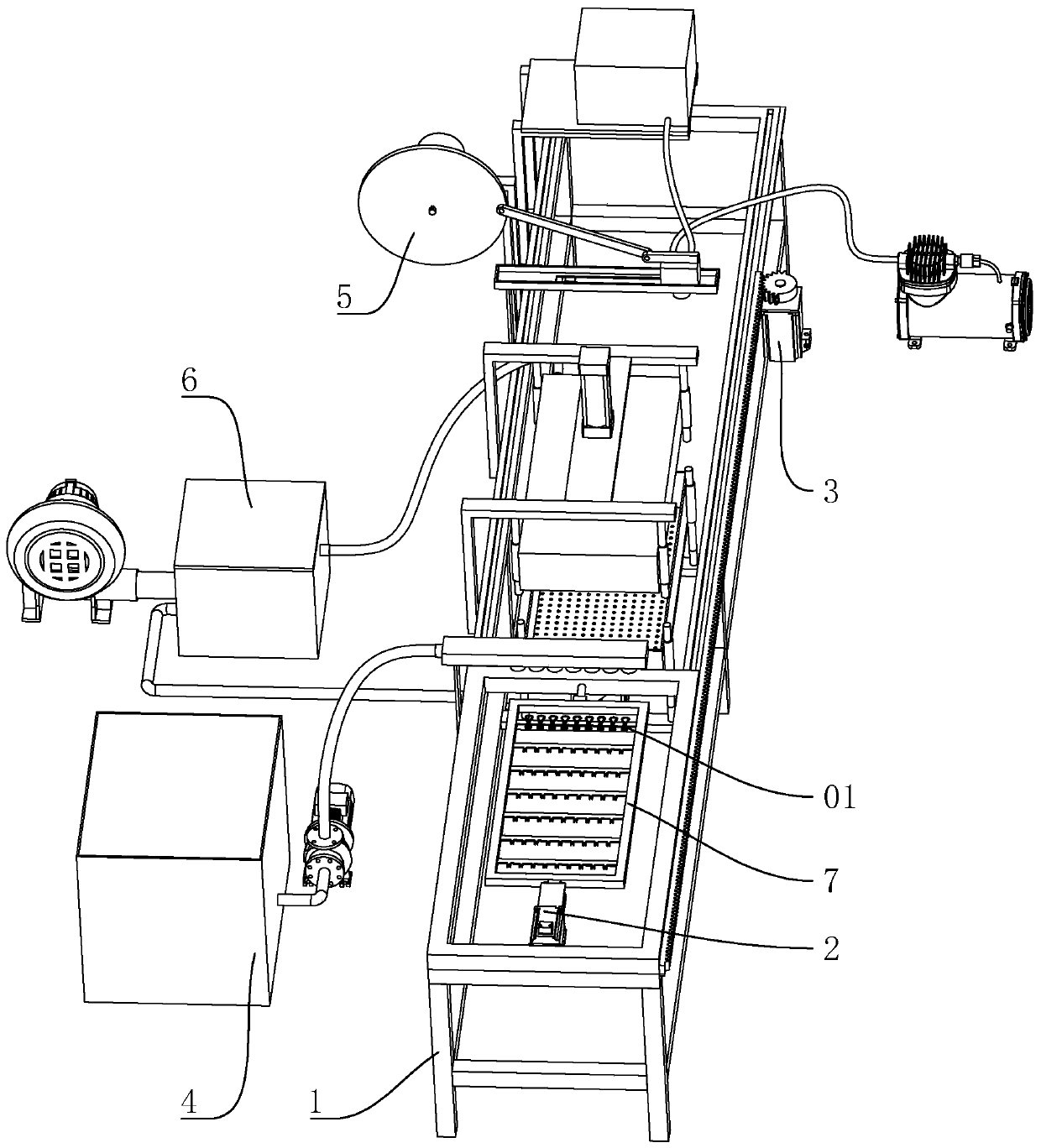

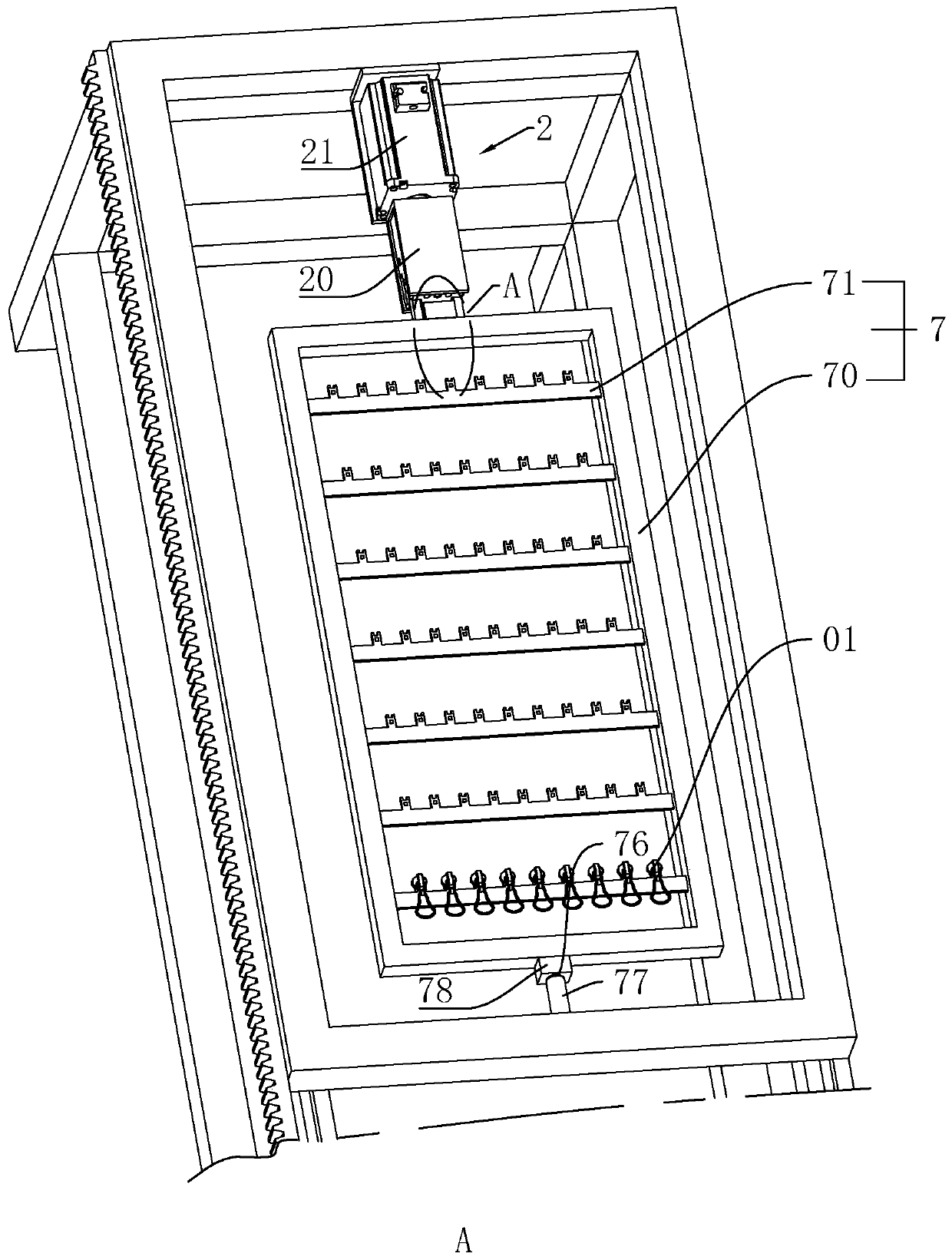

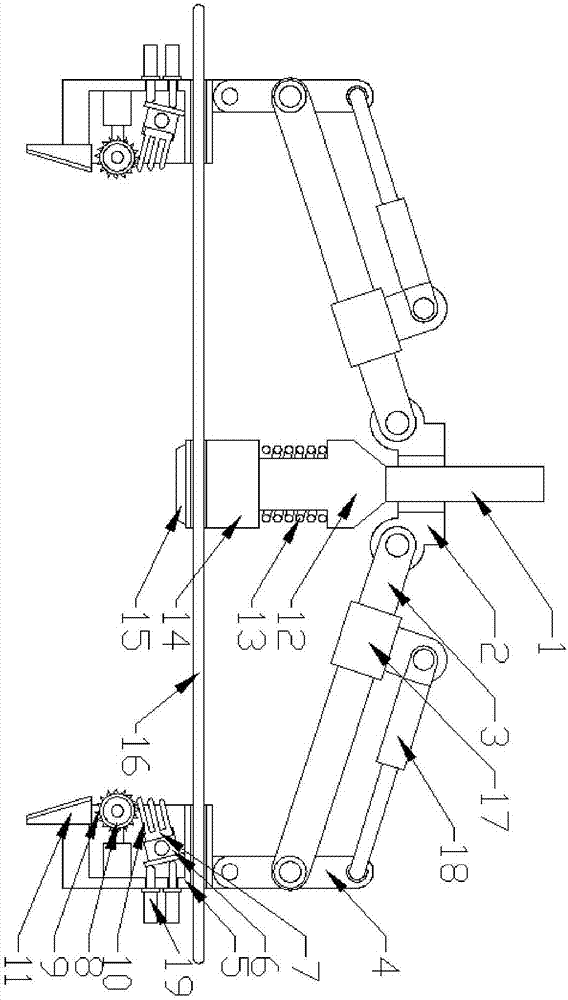

Automatic production device for cleaning, drying and painting zipper head

ActiveCN110064555AReduce the likelihood of sheddingEasy to cleanPretreated surfacesCoatingsEngineeringMechanical engineering

The invention discloses an automatic production device for cleaning, drying and painting a zipper head. According to the technical scheme, the automatic production device comprises a rack, wherein a rotating assembly, a moving assembly, a washing assembly, a painting assembly and a baking assembly are arranged on the rack correspondingly, a hanging frame used for fixing the zipper head is arrangedon the rack, and is fixed on the rotating assembly, and the washing assembly and the painting assembly are located on the two sides of the baking assembly correspondingly; and the zipper head is arranged on the hanging frame, the hanging frame is driven by the moving assembly to move, the cleaning assembly is used for washing the hanging frame, the rotating assembly is used for rotating the hanging frame, the baking assembly is used for drying the zipper head, the painting assembly is used for painting the zipper head, the rotating assembly is used for rotating the hanging frame, the paintingassembly is used for repainting the zipper head, then the moving assembly is used for driving the rotating assembly to return to move to the position blow the baking assembly, the baking assembly isused for drying the zipper head, and finally, the zipper head is output. According to the device, the workload of a worker to carry the zipper head can be reduced, and the working efficiency is improved.

Owner:南京隆宇电子科技有限公司

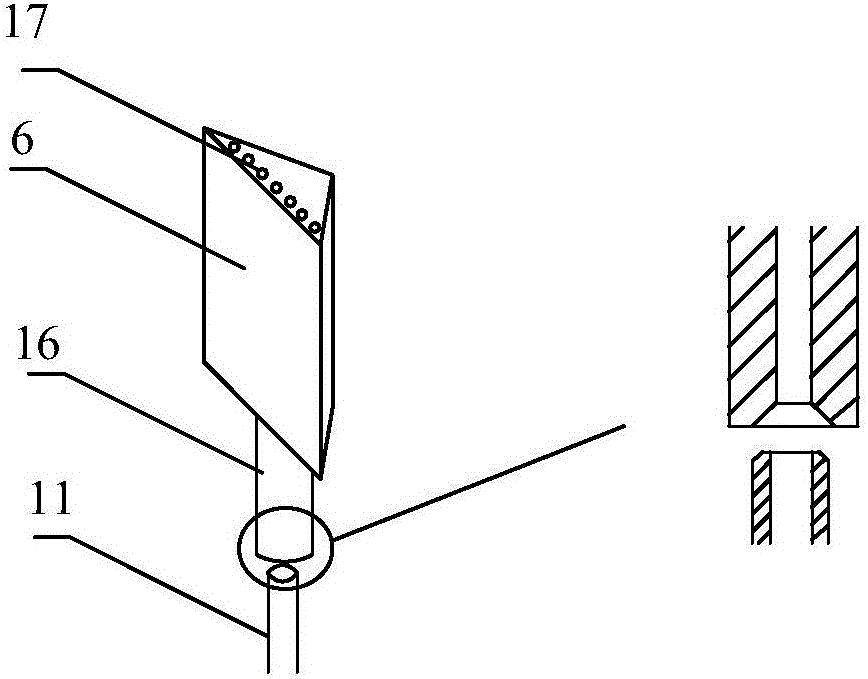

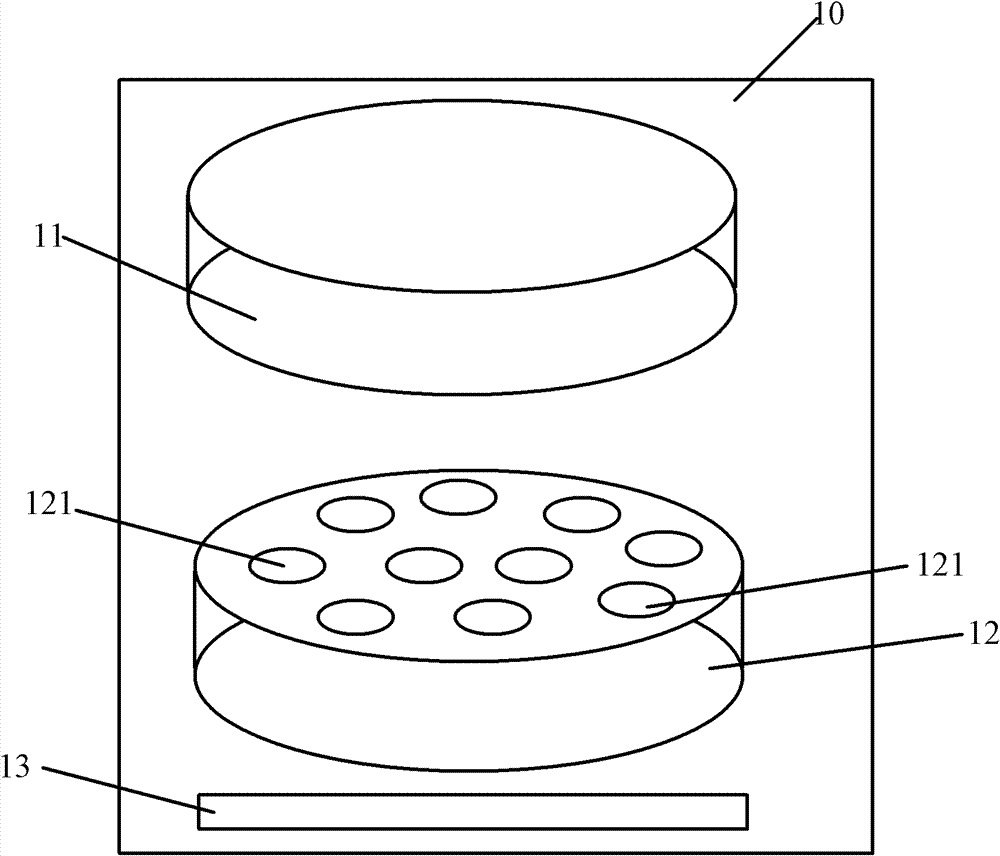

Spray head used in chemical vapor deposition process

InactiveCN103074601AReduce cleaning effectReduce maintenanceChemical vapor deposition coatingSurface layerGas phase

The invention provides a spray head used in a chemical vapor deposition process on a substrate. The spray head comprises a metal main body layer and an outer surface layer. The temperature when the metal main body layer is subjected to the chemical vapor deposition process is lower than 300 DEG C. The outer surface layer is positioned on the surface of one side of the metal main body layer closed to a substrate. When the outer surface layer is subjected to the chemical vapor deposition process, the temperature is higher than that of the metal main body layer. With the spray head provided by the invention, the quality of an epitaxial material layer formed with the chemical vapor deposition process is improved, and production capacity and efficiency of a chemical vapor deposition device are improved.

Owner:BRILLIANT LIGHT TECH

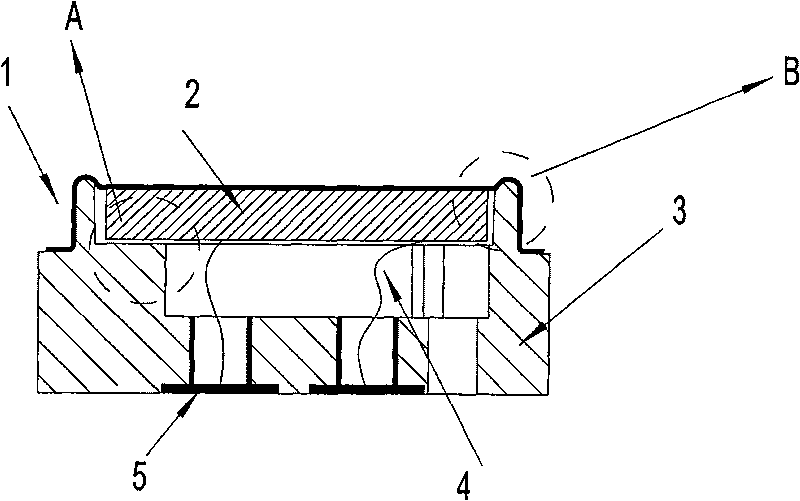

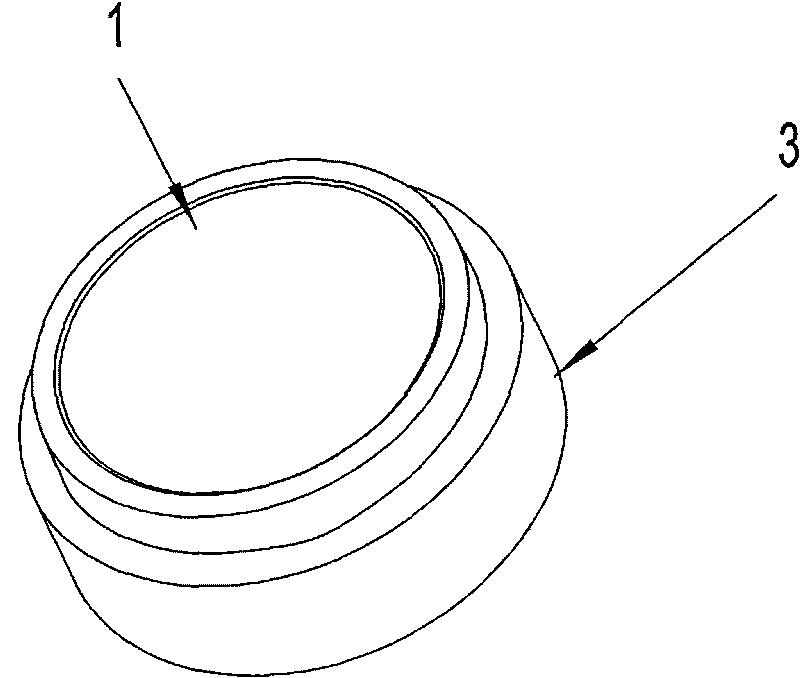

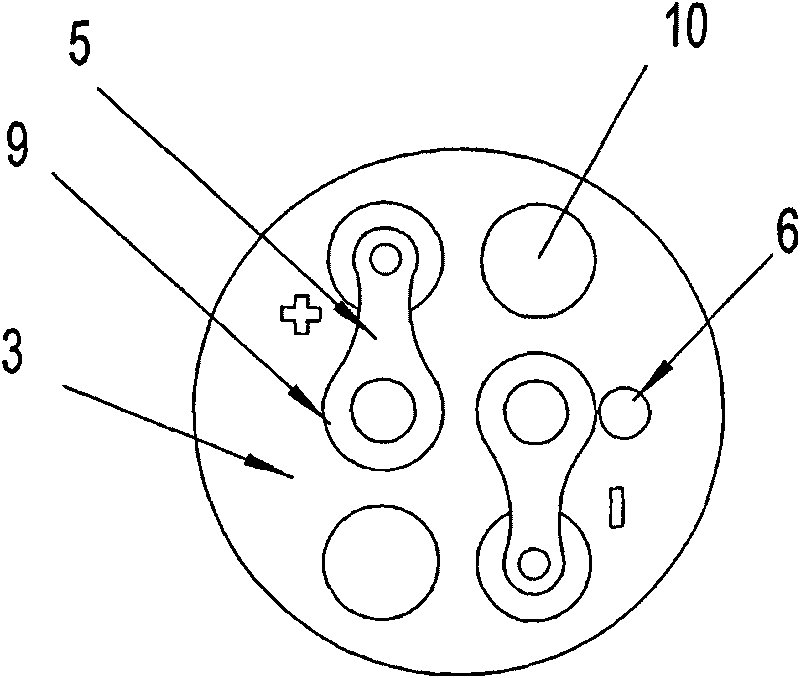

Plesoelectric ultrasonic flow sensor

InactiveCN101709985AImprove deformation stateImprove the vibration stateVolume/mass flow measurementVolume meteringEngineeringMetal

The invention relates to a plesoelectric ultrasonic flow sensor, belonging to the field of the sensor. The plesoelectric ultrasonic flow sensor consists of a metal shell, wafers, a base, connecting leads and welding pieces. The wafers are arranged on the metal shell; the metal shell is arranged on the base; the welding pieces are arranged on the base; the connecting leads are used for connecting the wafers with the welding pieces; and the end surface of the metal shell is provided with an arc-shaped buffering section which can form elasticity to improve the deforming state of the end surface of the metal shell under liquid pressure. The plesoelectric ultrasonic flow sensor has reasonable structural design, and the problem concerning the stability of the performance of the plesoelectric ultrasonic flow sensor under different application condition is effectively solved so that the plesoelectric ultrasonic flow sensor can be applied conveniently to various occasions needing the plesoelectric ultrasonic flow sensor.

Owner:AUDIOWELL ELECTRONICS GUANGDONG

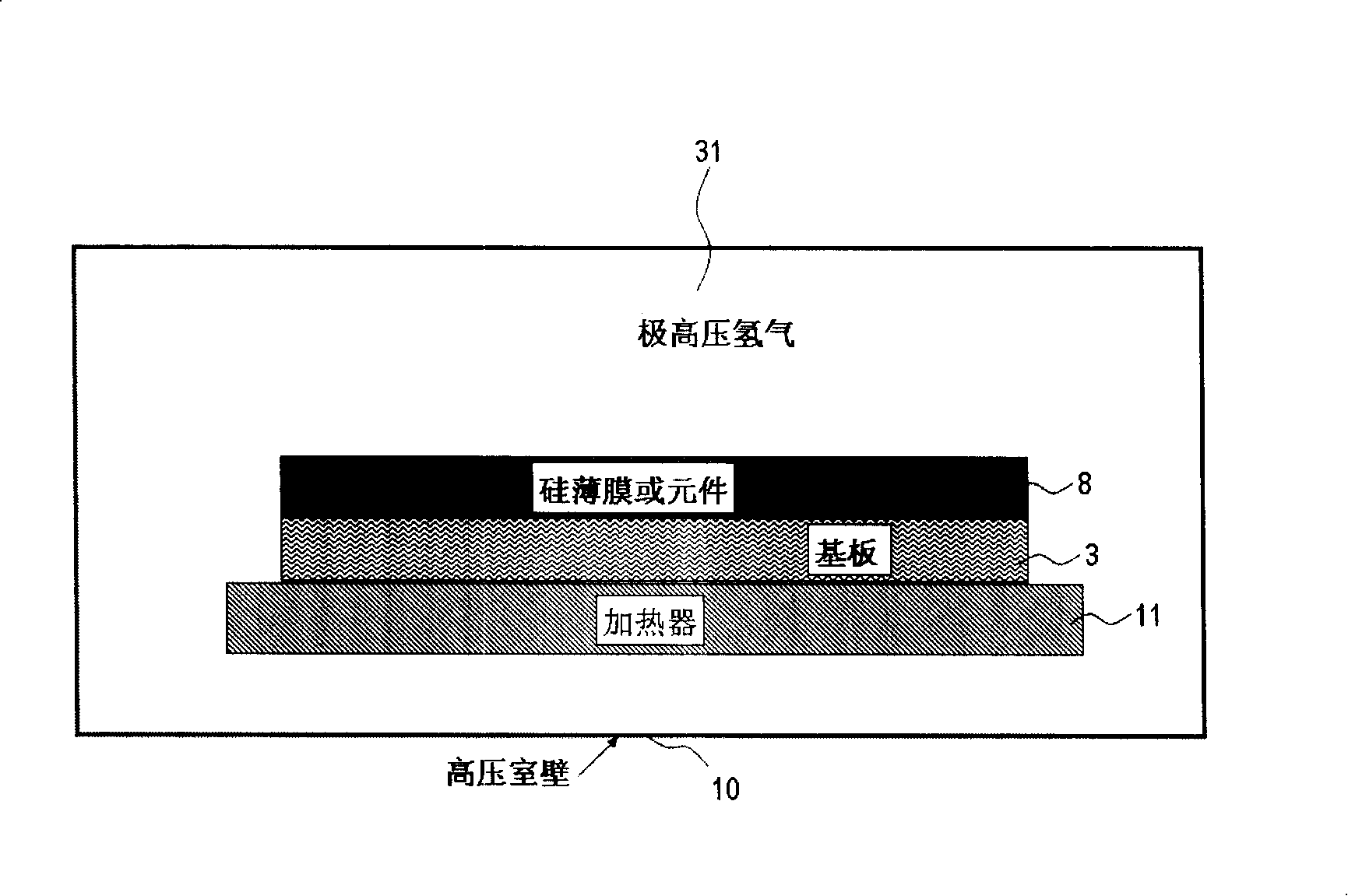

High-pressure solid phase crystallization method

InactiveCN101235534AShorten the timeReduce the likelihood of sheddingPolycrystalline material growthFinal product manufactureHigh pressure hydrogenPolycrystalline silicon

The invention discloses a method for changing an amorphous silicon thin film into a polycrystalline silicon thin film, which comprises the following steps: placing hydrogenated amorphous silicon thin film or a device of the method which are deposited on a base plate into the high pressure hydrogen gas environment with no less than two hundred atmospheric pressure, and maintaining 2-20h under the temperature which is no lower than 600 DGE C, the obtained hydrogen deactivation polycrystalline silicon thin film can be directly used as highly effective photoelectric conversing material.

Owner:BEIJING XINGZHE MULTIMEDIA TECH

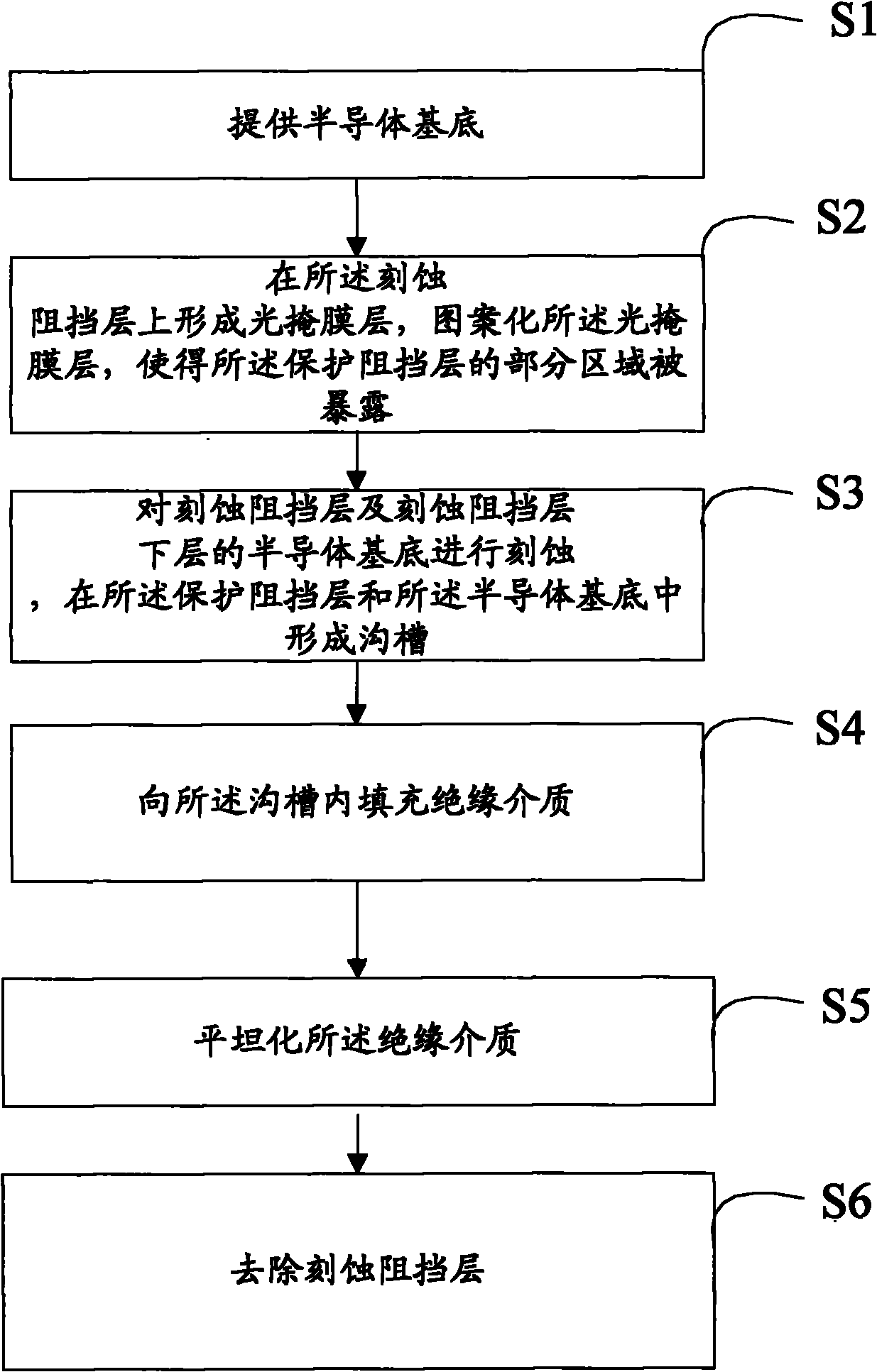

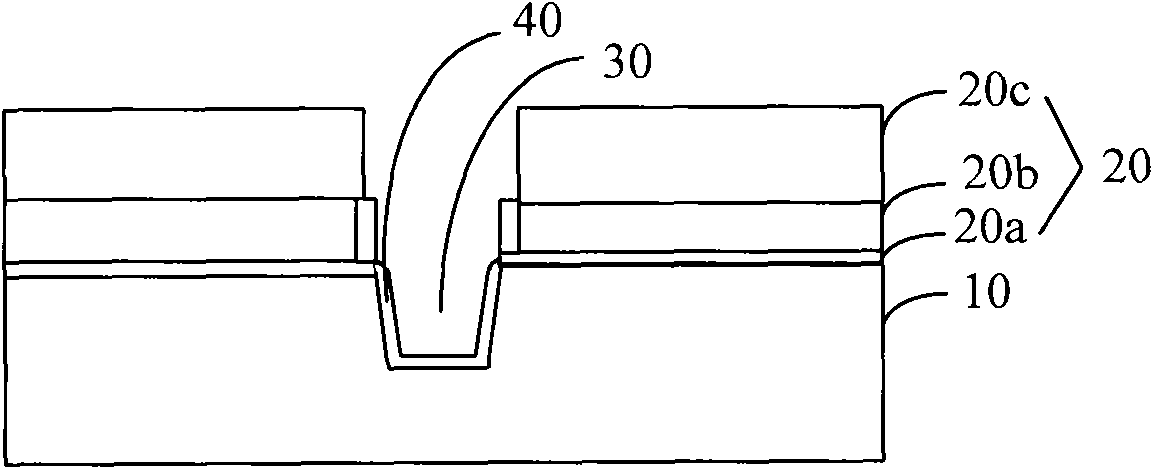

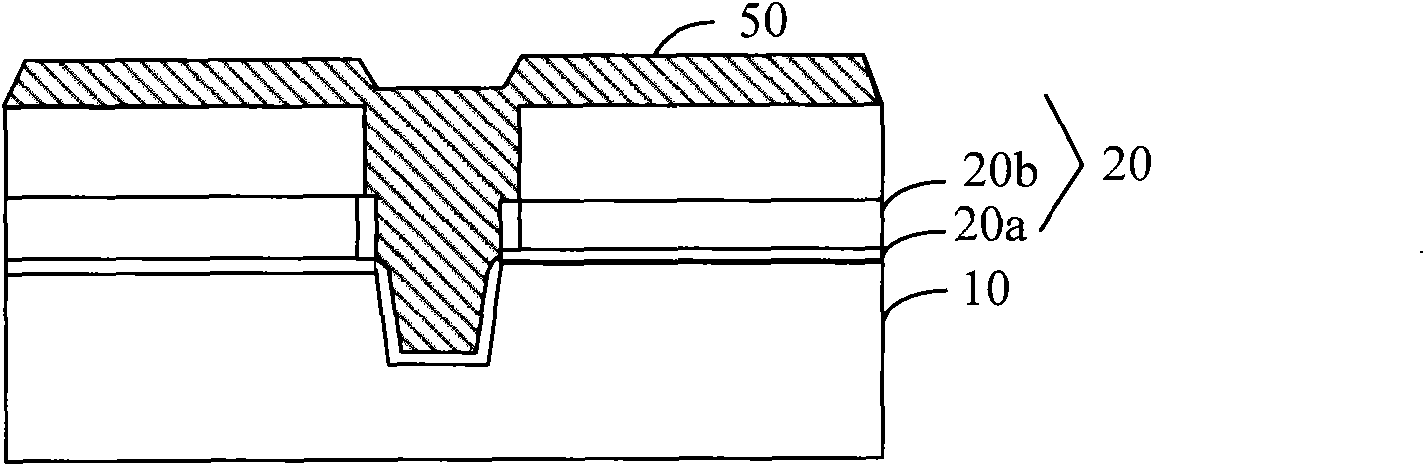

STI forming method

InactiveCN101996921AReduce the likelihood of sheddingImprove planarization efficiencySemiconductor/solid-state device manufacturingSemiconductorMaterials science

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

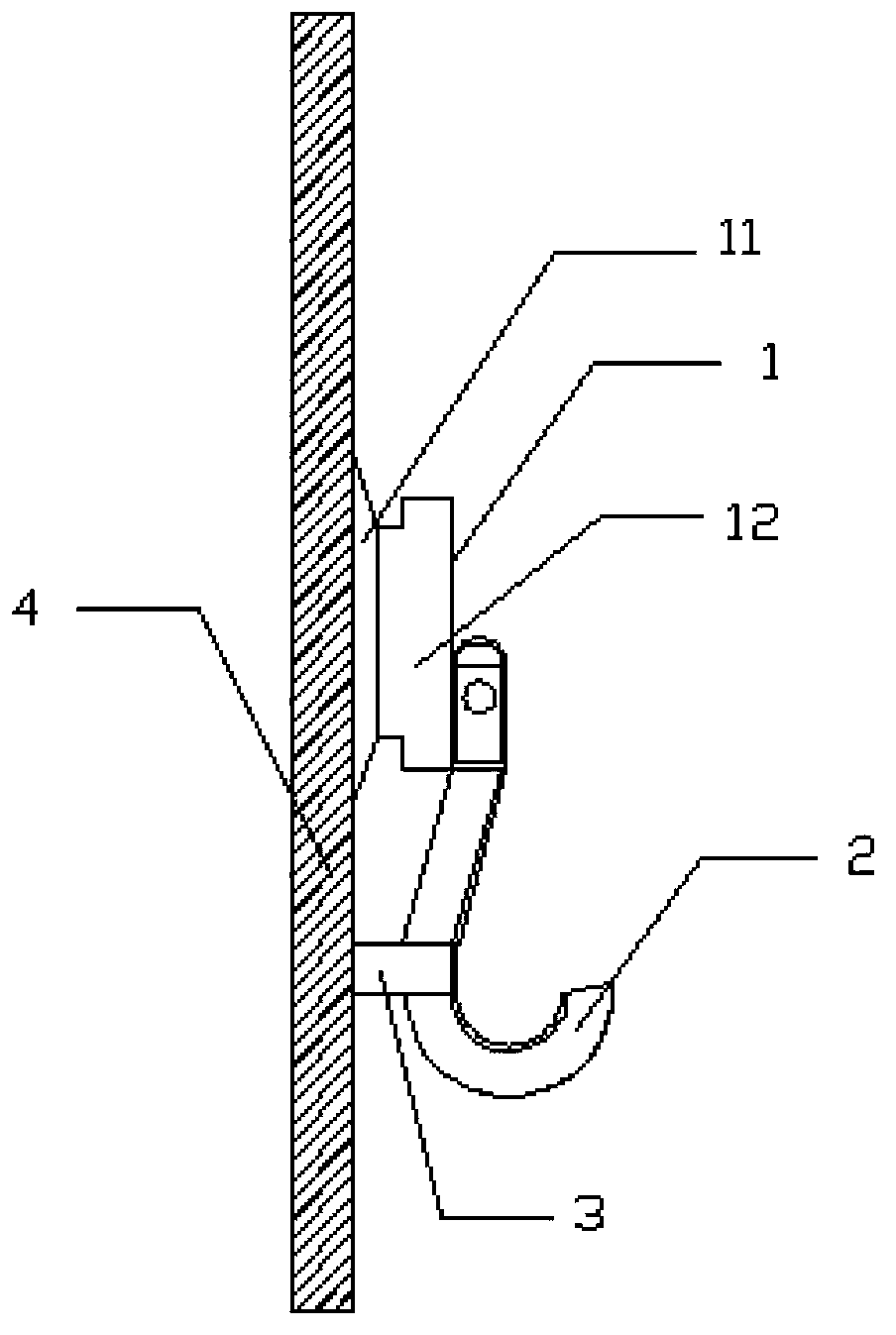

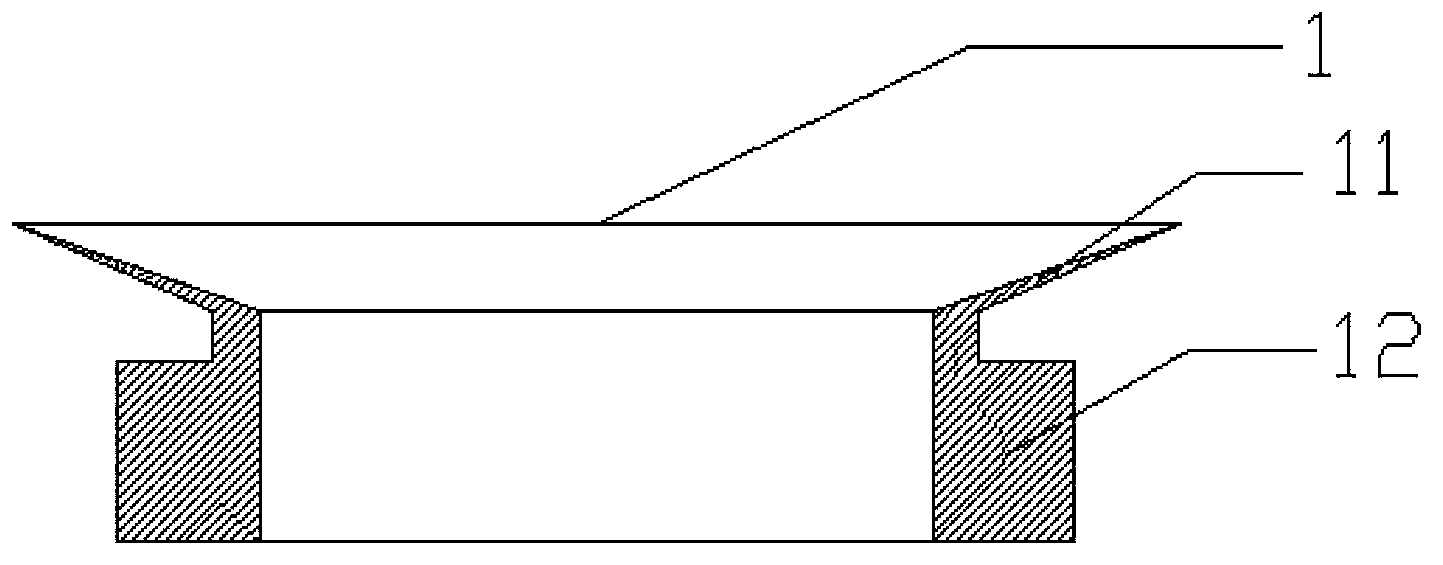

Suction cup type hook with support

The invention provides a suction cup type hook with a support. The suction cup type hook comprises a vacuum suction cup and a hook body connected to the vacuum suction cup, the vacuum suction cup is an annular ring body made of rubber, the annular ring body comprises an upper half portion and a lower half portion, the upper half portion is in a circular truncated cone shape, the wall of the upper half portion is thinner than that of the lower half portion, the inner diameter of the upper half portion of the annular ring body is larger than that of the lower half portion of the annular ring body, the inner diameter of the upper half portion is gradually increased from bottom to top, the hook support is connected to the hook body, and the supporting section of the hook support and the suction end face of the vacuum suction cup are on the same plane. The suction cup type hook has the advantages that the vacuum suction cup of the special structure can generate strong and even suction force, a supporting point is added to the suction cup type hook, force borne by the fixed point of the vacuum suction cup is dispersed, and the probability that the suction cup falls off is effectively lowered.

Owner:TIANJIN HUARONG PNEUMATIC & HYDRAULIC COMPLETE SYST

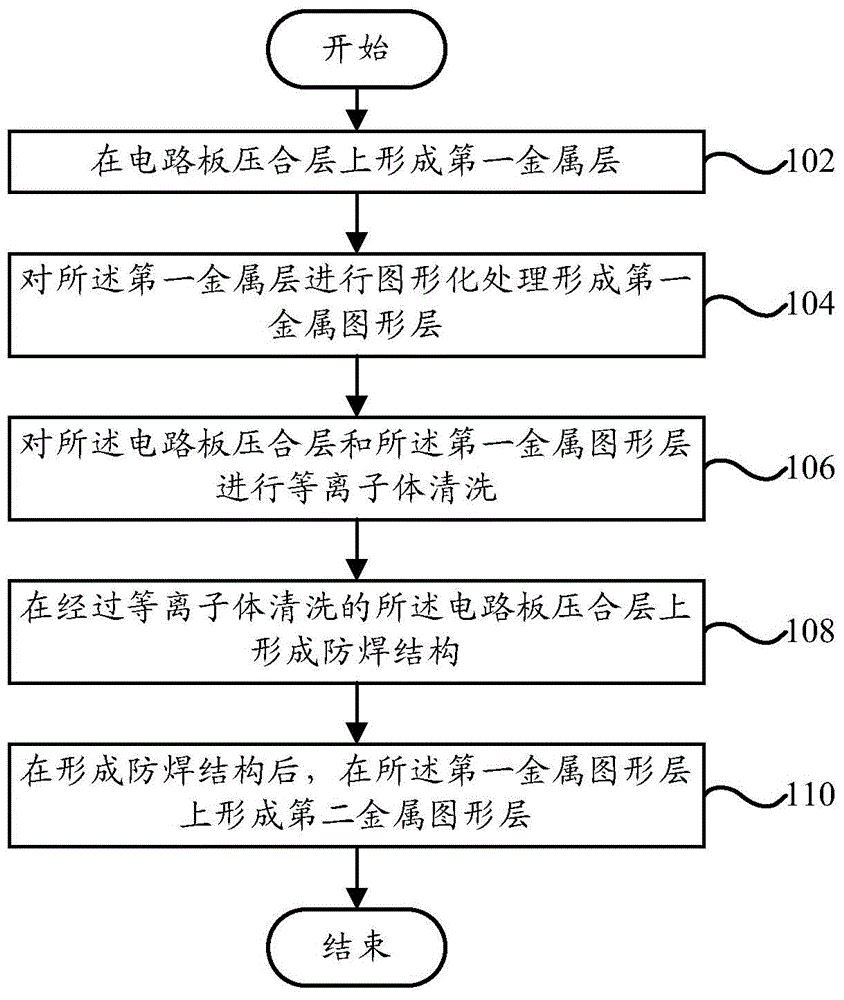

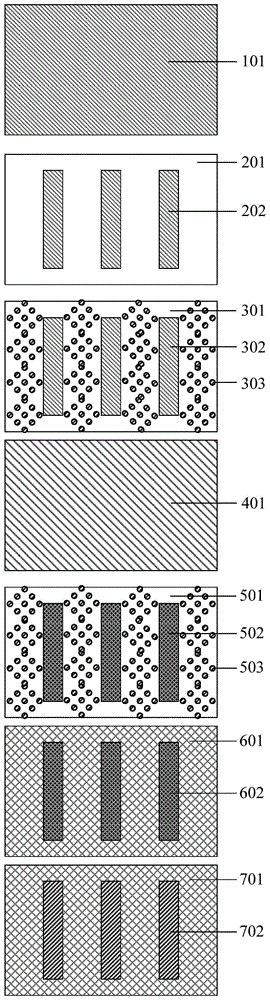

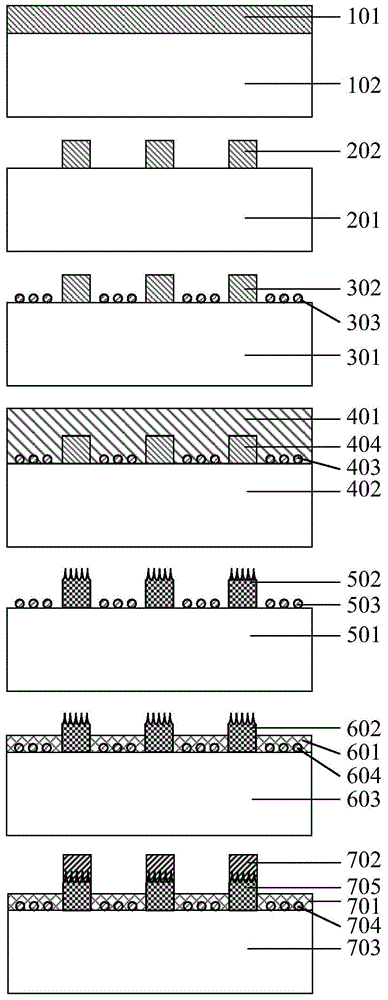

Method for preparing circuit board

InactiveCN105722338AImprove reliabilityImprove protectionInsulating substrate metal adhesion improvementNon-metallic protective coating applicationSolder maskMaterials science

The invention provides a method for preparing a circuit board, comprising: forming a first metal layer on the laminated layer of the circuit board; patterning the first metal layer to form a first metal pattern layer; performing plasma cleaning on the lamination layer and the first metal pattern layer; forming a solder resist structure on the circuit board lamination layer after plasma cleaning; and after forming the solder resist structure, on the first metal pattern A second metal pattern layer is formed on the layer. Through the technical solution of the present invention, the roughness of the laminated layer of the circuit board and the first metal layer is enhanced, the possibility of falling off of the solder resist structure and the risk of gold penetration on the circuit board are reduced. In addition, the solder resist structure enhances the resistance to The protective effect of the first metal pattern layer further improves the quality of the second metal pattern layer, and finally improves the reliability of the circuit board.

Owner:PEKING UNIV FOUNDER GRP CO LTD +1

Solar panel clamper

InactiveCN107275277AAchieve provoking fixationSurface flatness is not requiredSemiconductor/solid-state device manufacturingCells panelLinear actuator

Owner:陈有兵

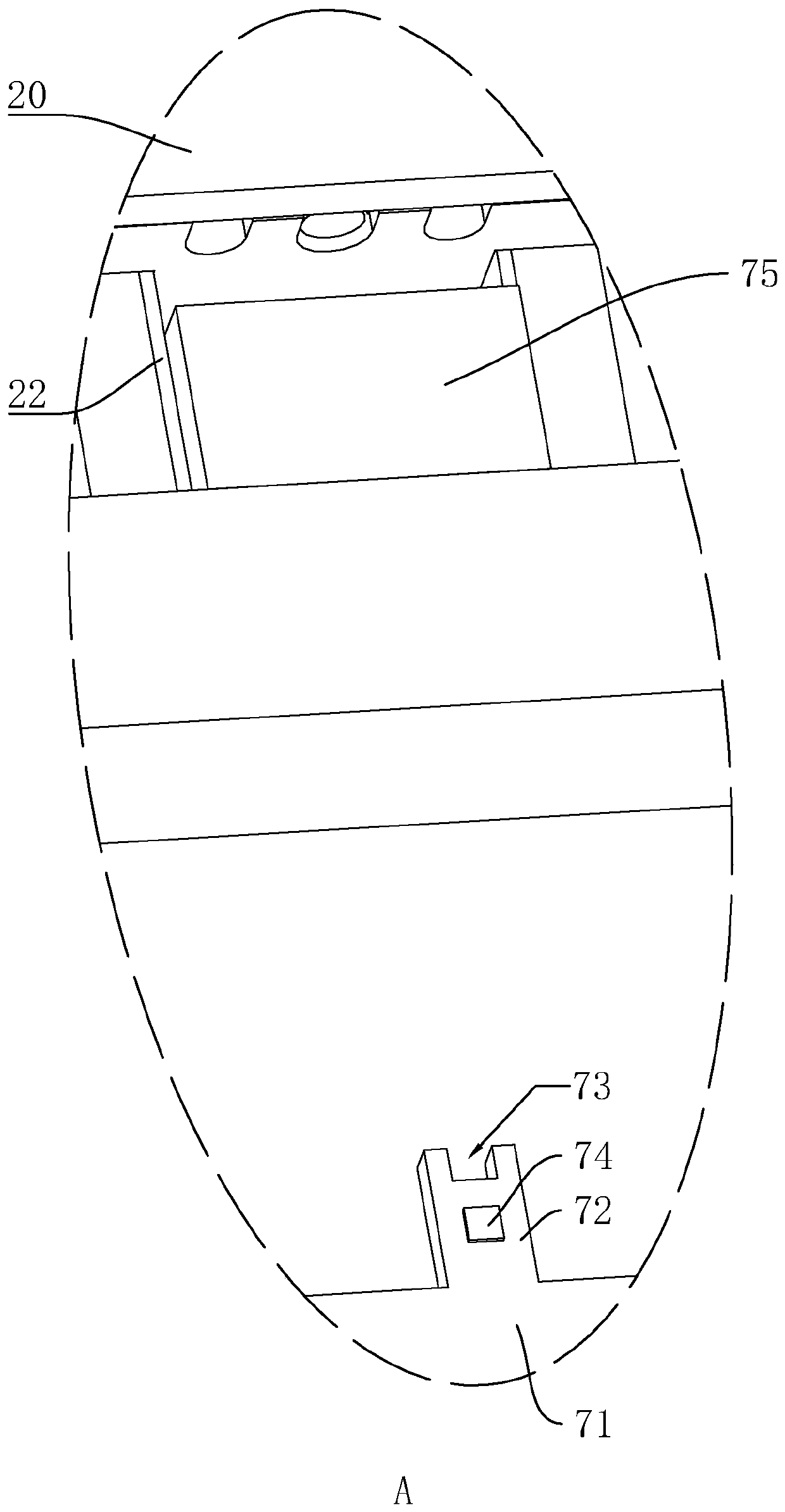

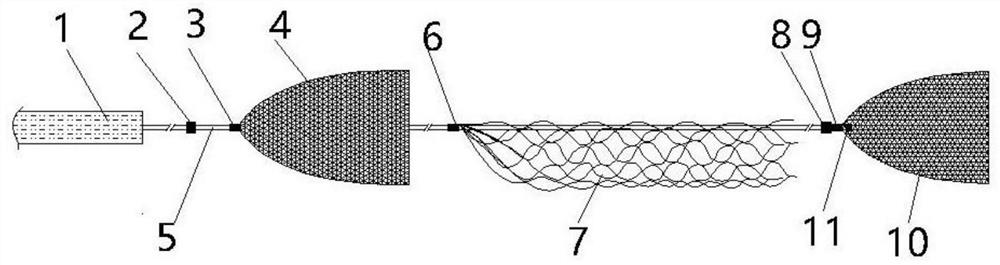

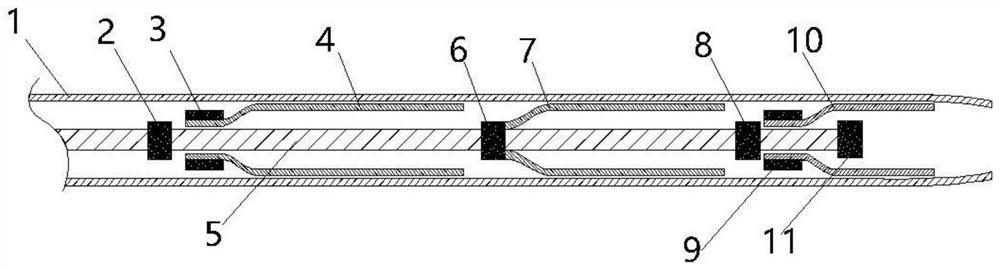

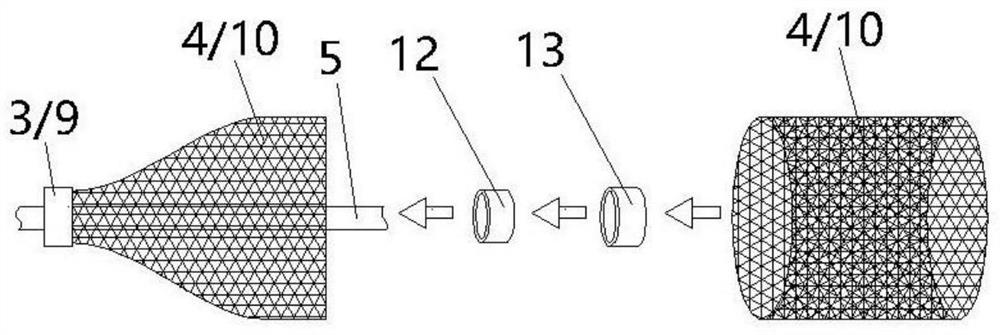

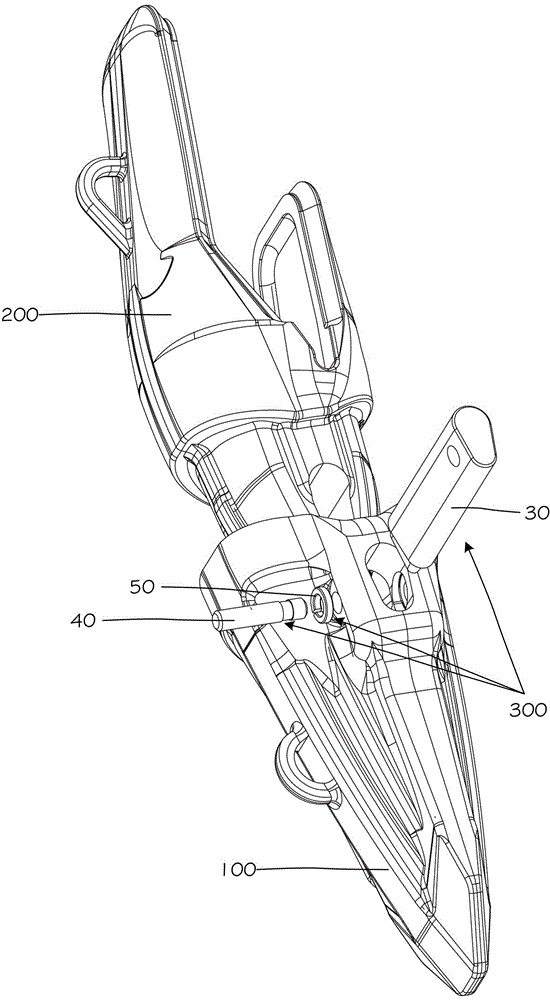

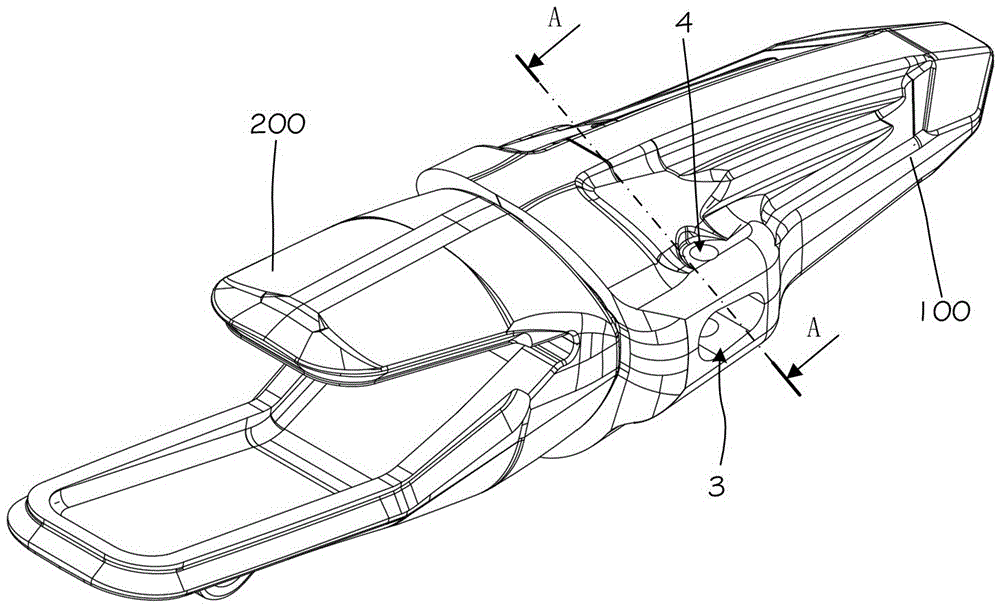

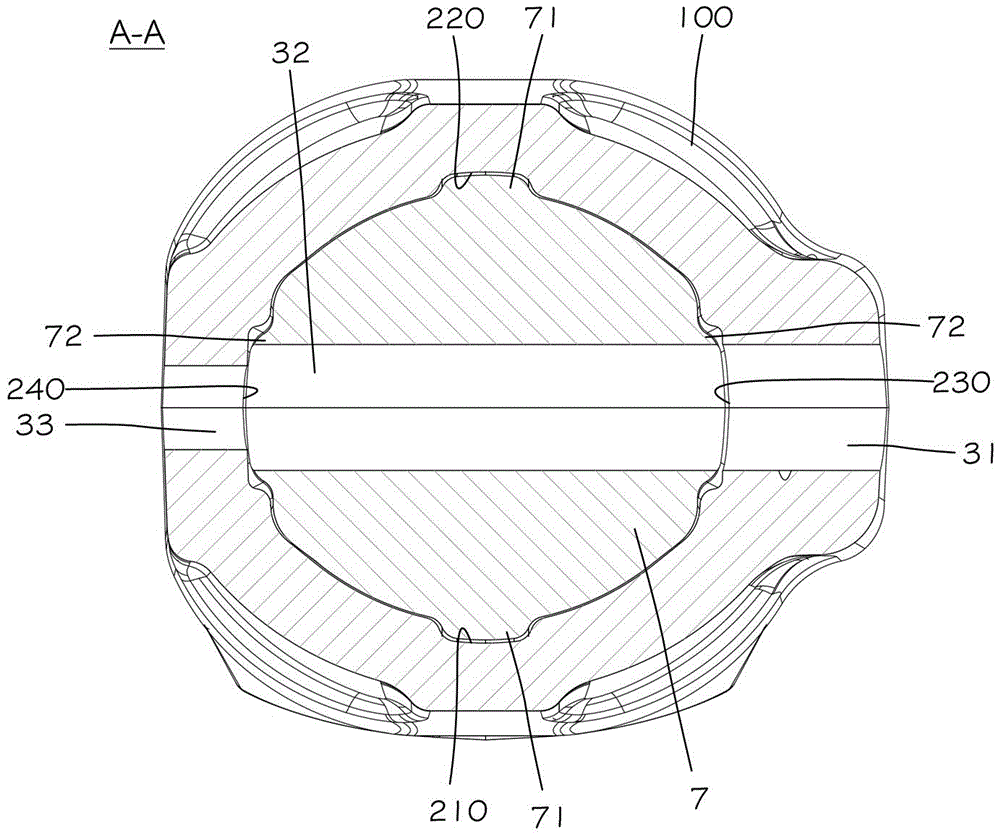

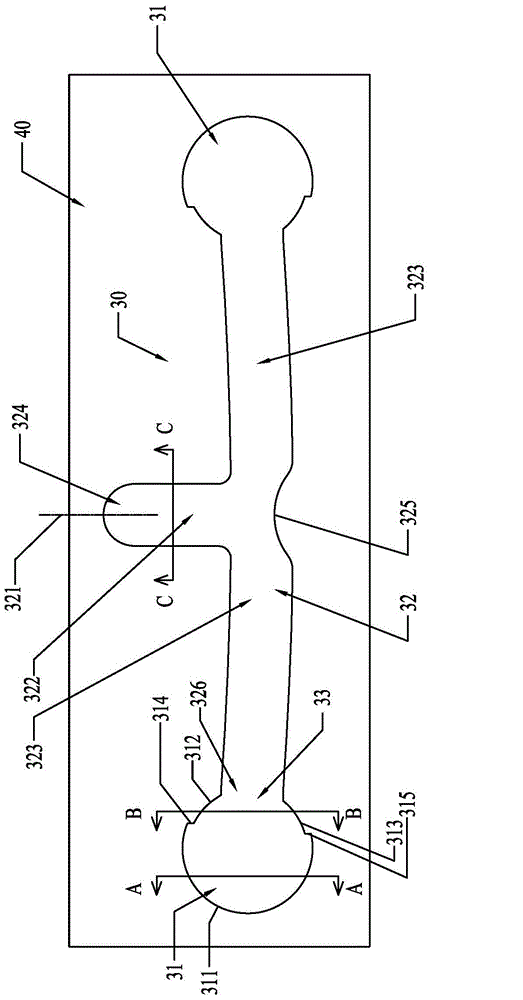

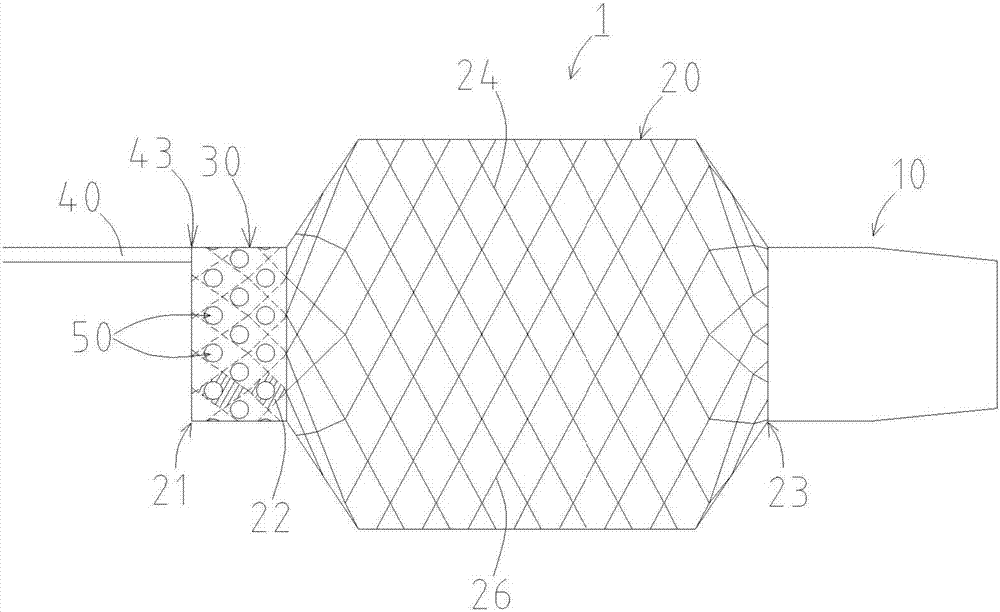

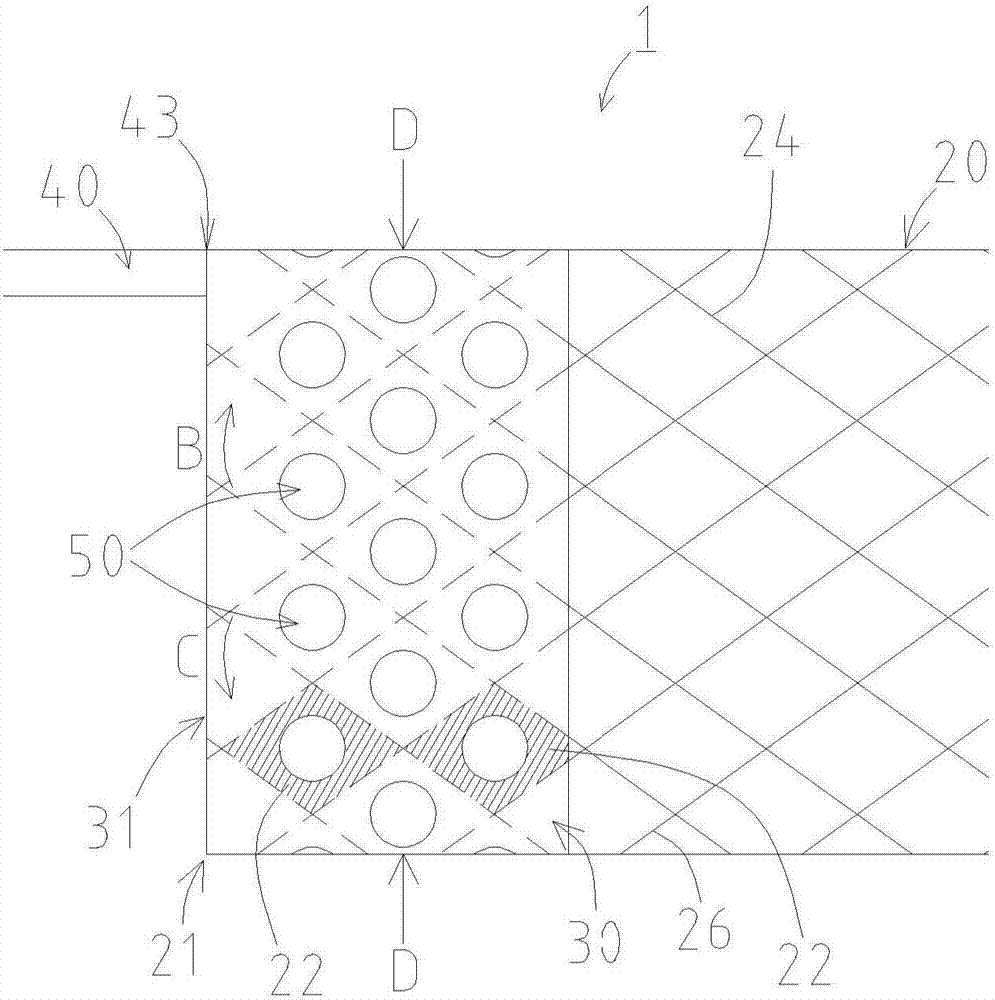

Thrombus taking stent system with near-end protection and far-end protection functions

The invention discloses a thrombus taking stent system with near-end protection and far-end protection functions. The thrombus taking stent system comprises an outer sheath tube, a push rod, a near-end protection device, a thrombus taking stent and a far-end protection device. The thrombus taking stent system has the advantages that in the thrombus taking process, the far-end protection device can filter blood clots or atherosclerotic plaques flowing in the blood flow direction, and small thrombi or plaques are effectively prevented from continuously entering blood vessels. When the thrombus taking stent system is withdrawn after thrombus capture, the near-end protection device can completely store the thrombus taking stent and thrombi captured on the stent, so that the possibility that the thrombi or plaque falls off when the thrombus taking stent is withdrawn into a micro catheter is effectively reduced, and the thrombus capture efficiency can be effectively improved. According to the thrombus taking stent system, before the thrombus taking stent is released, the far-end protection device does not need to be withdrawn to adjust the thrombus taking position, and the positioning accuracy of the thrombus taking stent can be effectively improved.

Owner:JIANGSU NOWYON MEDICAL CO LTD

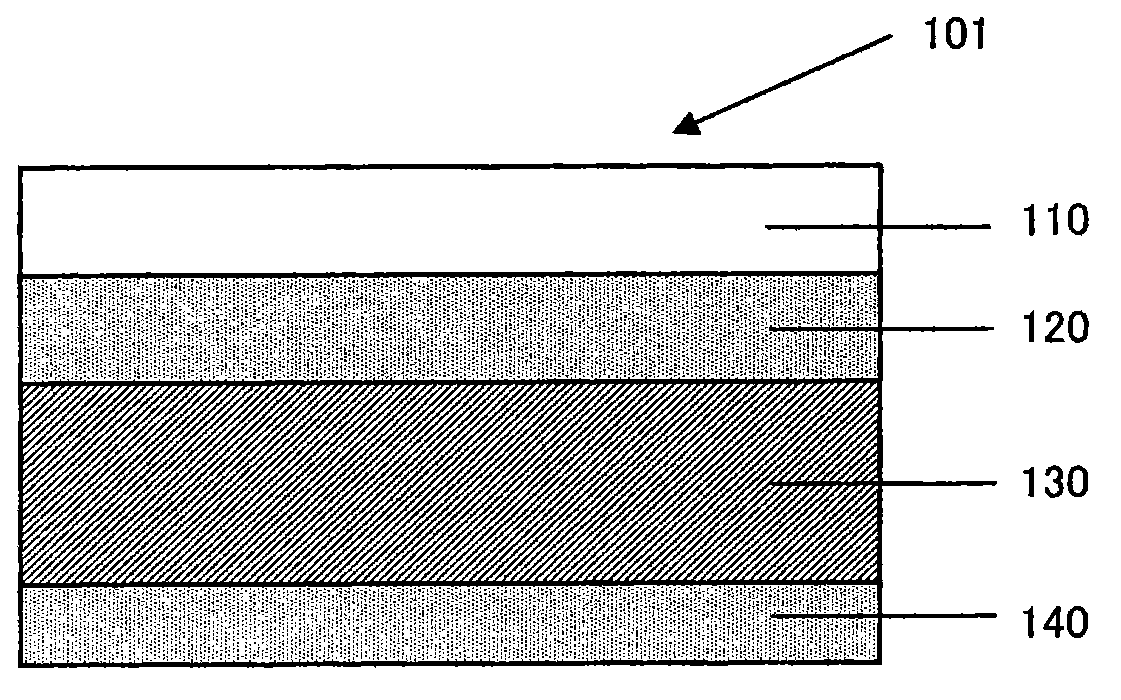

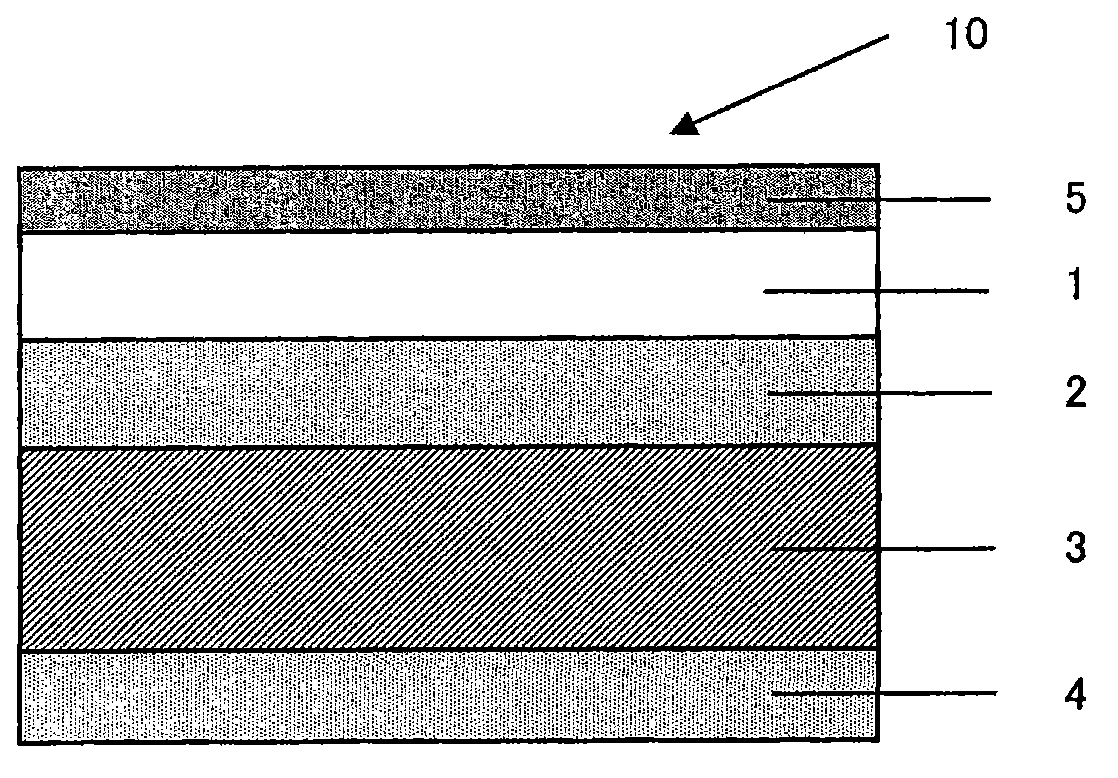

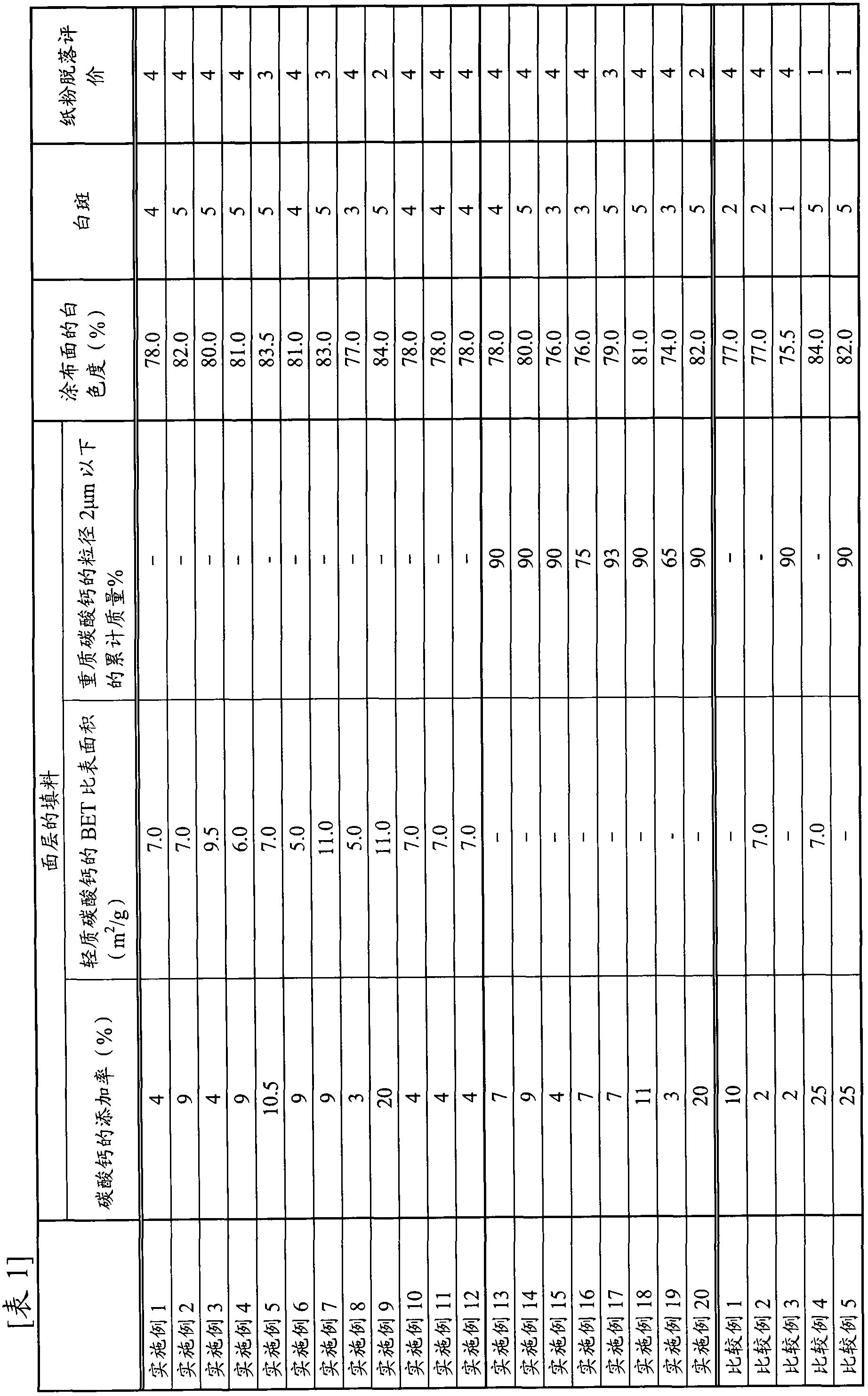

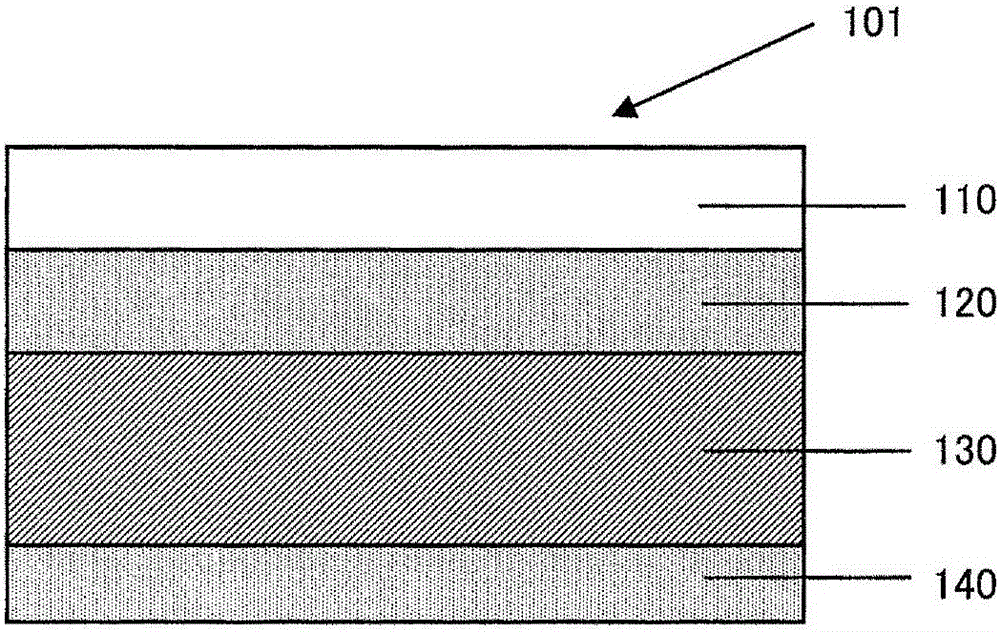

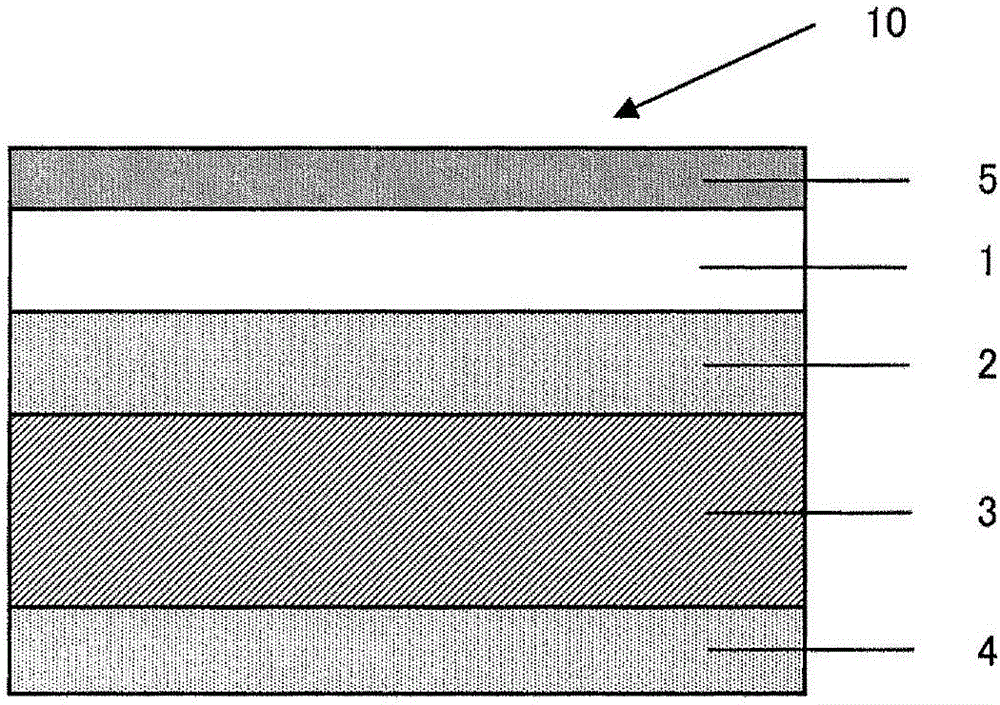

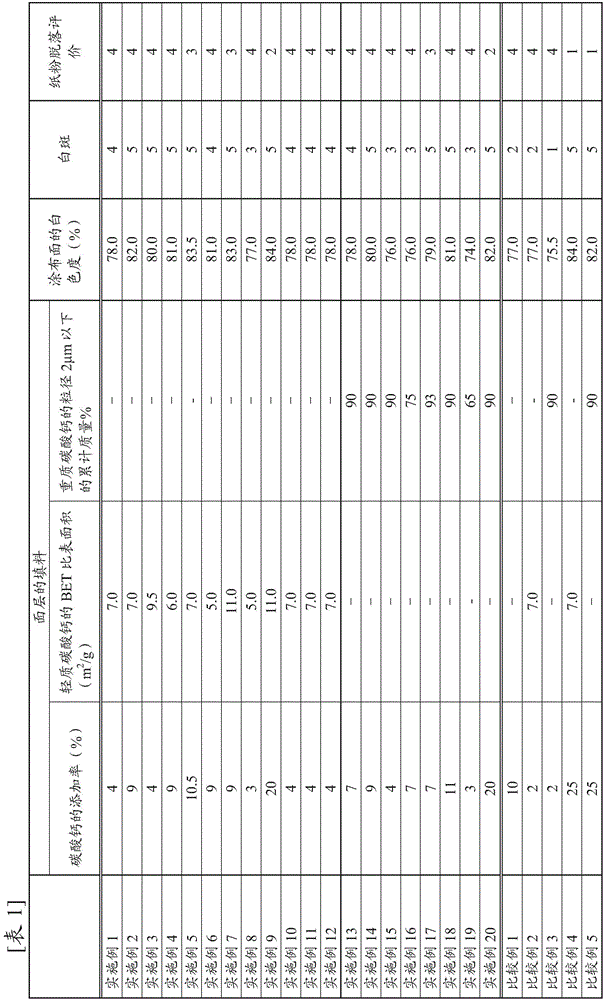

Coated white paperboard

ActiveCN103572666AReduce sheddingReduce the likelihood of sheddingCoatings with pigmentsSpecial paperSurface layerPapermaking

The invention provides a coated white paperboard without obvious hickie. Through use of 3-10wt% of calcium carbonate in a surface layer prepared from surface layer paper pulp, the coated white paperboard which has a multilayer papermaking structure and uniformly hides a dark gray color caused by waste paper closer to the inner side than a lining layer is obtained.

Owner:HOKUETSU KK

Coated white board paper

ActiveCN105951531AReduce sheddingReduce the likelihood of sheddingCoatings with pigmentsSpecial paperGreyish colorWhiteboard

The invention provides white board paper with the white paper appearance free of remarkable hickie. As calcium carbonate with the mass larger than or equal to 3% and smaller than 10% of the surface-layer paper pulp mass is added into a surface layer, the white board paper of the multilayer papermaking structure in which dark gray caused by waste paper closer to the inner side than a lining layer is evenly hidden can be obtained.

Owner:HOKUETSU KK

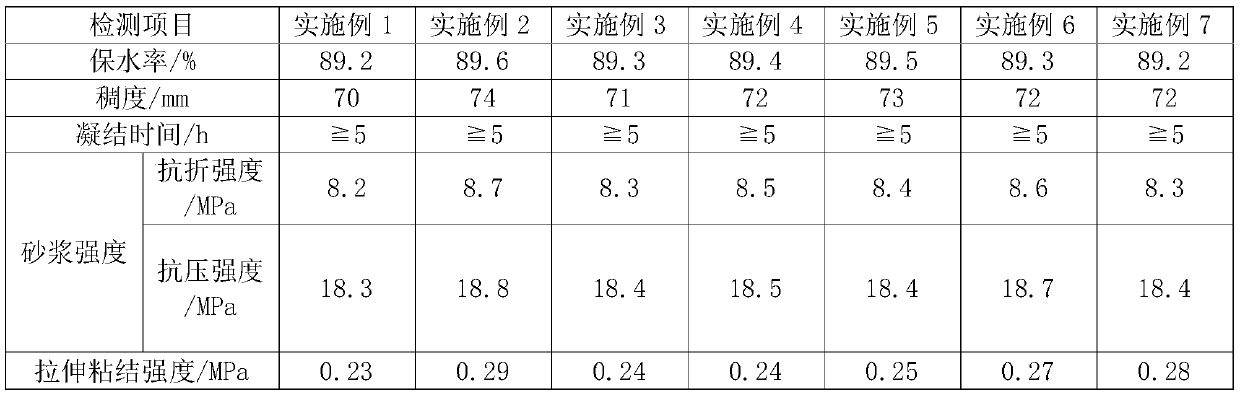

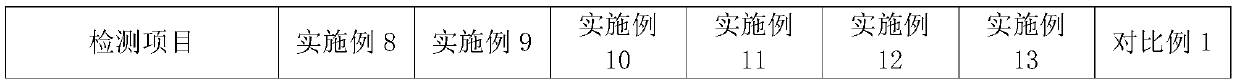

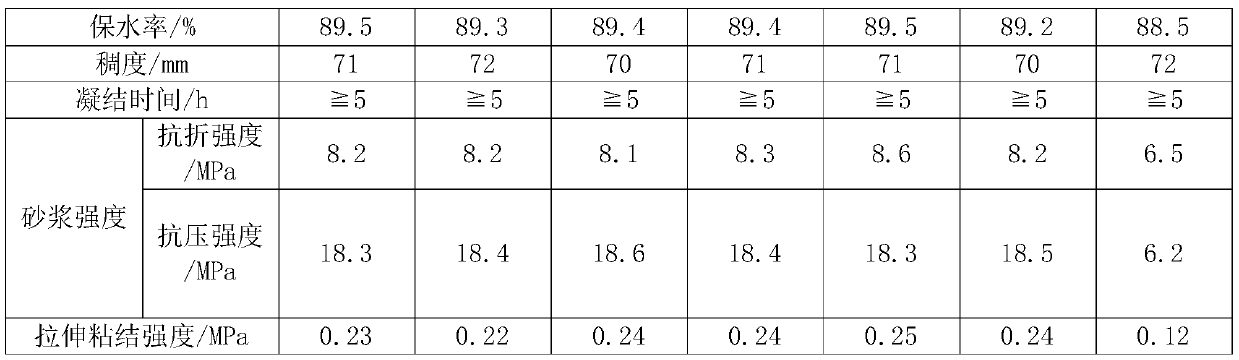

Wet-mixing plastering mortar and preparation method thereof

The invention relates to a wet-mixing plastering mortar, and belongs to the technical field of building materials. The wet-mixing plastering mortar is prepared from, by weight, cement, fine aggregate,water, an additive and a bonding component, wherein the preparation raw materials of the fine aggregate comprise natural siliceous sand, river sand and magnesium slag; the additive comprises hydroxyethyl cellulose ether, wood fibers and glass microbeads; the bonding component comprises epoxy resin, jute fibers, carboxylic butadiene-styrene latex and polyvinyl alcohol. The invention further relates to a preparation method of the wet-mixing plastering mortar. The preparation method comprises the following steps of S1, preparation of the additive; S2, preparation of the bonding component; S3, preparation of the wet-mixing plastering mortar. The prepared mortar has an effect of good bonding strength.

Owner:四川蓝筹建材有限公司

Excavator dipper tooth assembly with improved connecting structure

InactiveCN106638759AReduce sheddingHigh bonding strengthSoil-shifting machines/dredgersEngineeringExcavator

The invention discloses an excavator dipper tooth assembly with the improved connecting structure. The excavator dipper tooth assembly comprises a dipper tooth, a tooth base and a lock pin piece. The dipper tooth is fixedly connected with the tooth base through the lock pin piece, and the lock pin piece comprises a transverse pin, a vertical pin and a clamping spring. A protruding part of the tooth base is inserted into an inserting opening of the dipper tooth, the transverse pin is inserted into a transverse pin hole, the vertical pin is inserted into a vertical pin hole and a through hole, and the clamping spring is clamped in an annular groove in the vertical pin. According to the excavator dipper tooth assembly with the improved connecting structure, the dipper tooth is connected with the tooth base through the transverse pin and the vertical pin, the bonding strength and the bonding compactness between the dipper tooth and the tooth base are enhanced, the falling-off possibility of the dipper tooth is reduced, and trouble and labor are saved during working of an excavator device accordingly.

Owner:熊丽

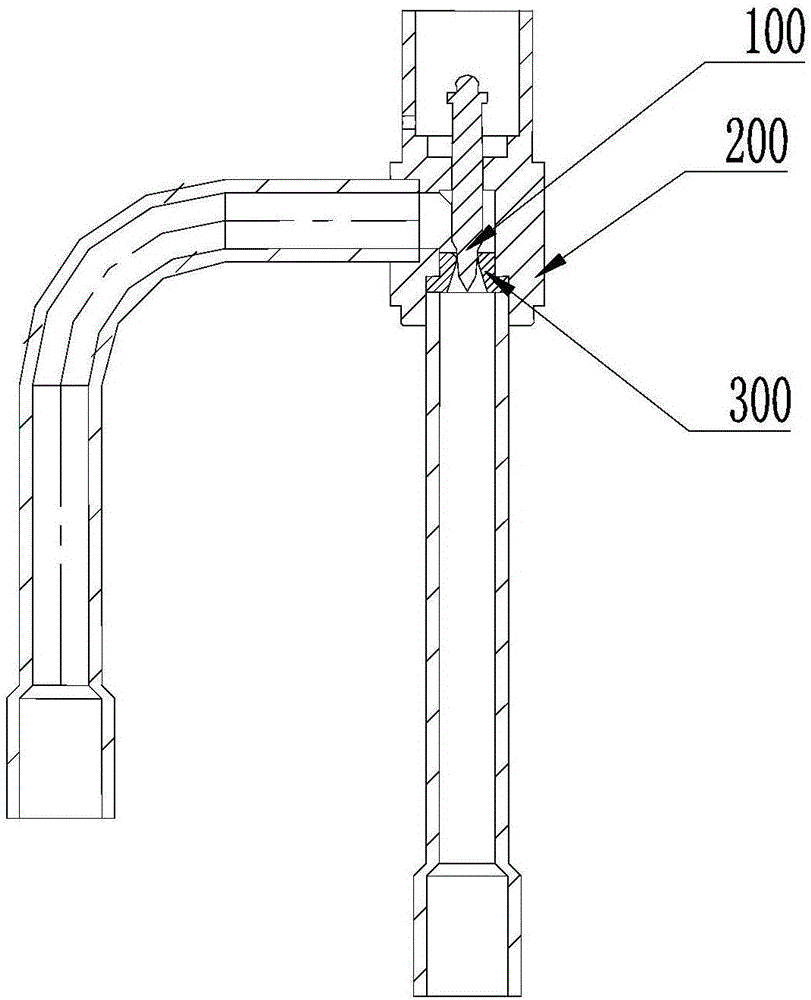

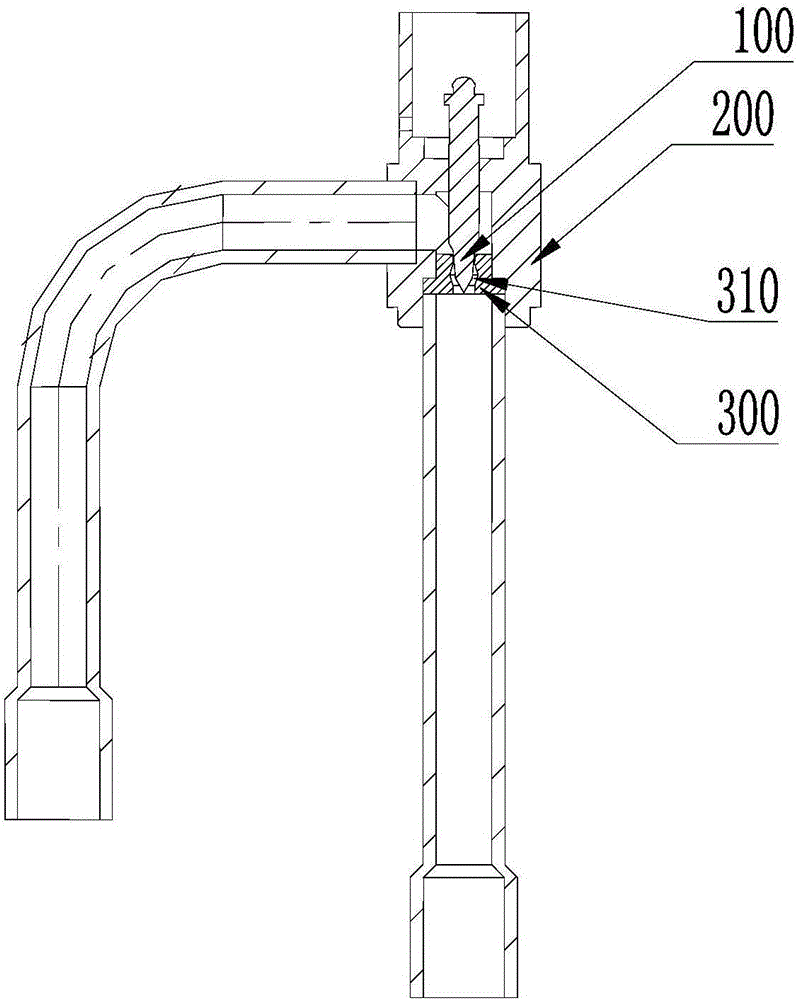

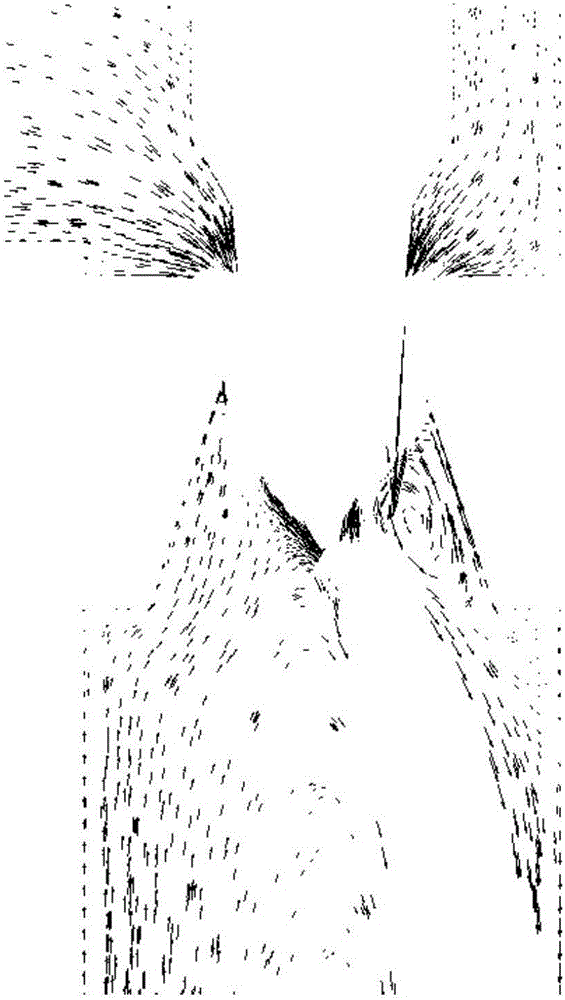

Throttle structure and pressure drop device

ActiveCN104110522BFacilitates a smooth transitionReduce the possibilityValve members for absorbing fluid energyDifferential pressureEngineering

The invention discloses a throttling structure and a pressure drop device. The throttling structure comprises a valve needle, a valve body and a valve seat core, wherein the valve seat core is fixed to the valve body. A through hole in smooth transition is formed in the valve seat core and is matched with the valve needle in shape. The valve needle is inserted into the through hole and forms a throttling round ring with the through hole. The pressure drop device comprises the throttling structure. The throttling structure and the pressure drop device achieve two-stage throttling, and therefore good and smooth transition of the differential pressure change before throttling and after throttling is guaranteed, the possibility of two phase caused when liquid refrigerating fluid flows through a throttling hole is reduced, and the heat exchange efficiency of a system is improved. Meanwhile, the possibility of turbulence vortex forming in the downstream of the throttling hole and dropping is reduced, related noise problems are avoided, and the noise quality of products can be improved.

Owner:GREE ELECTRIC APPLIANCES INC

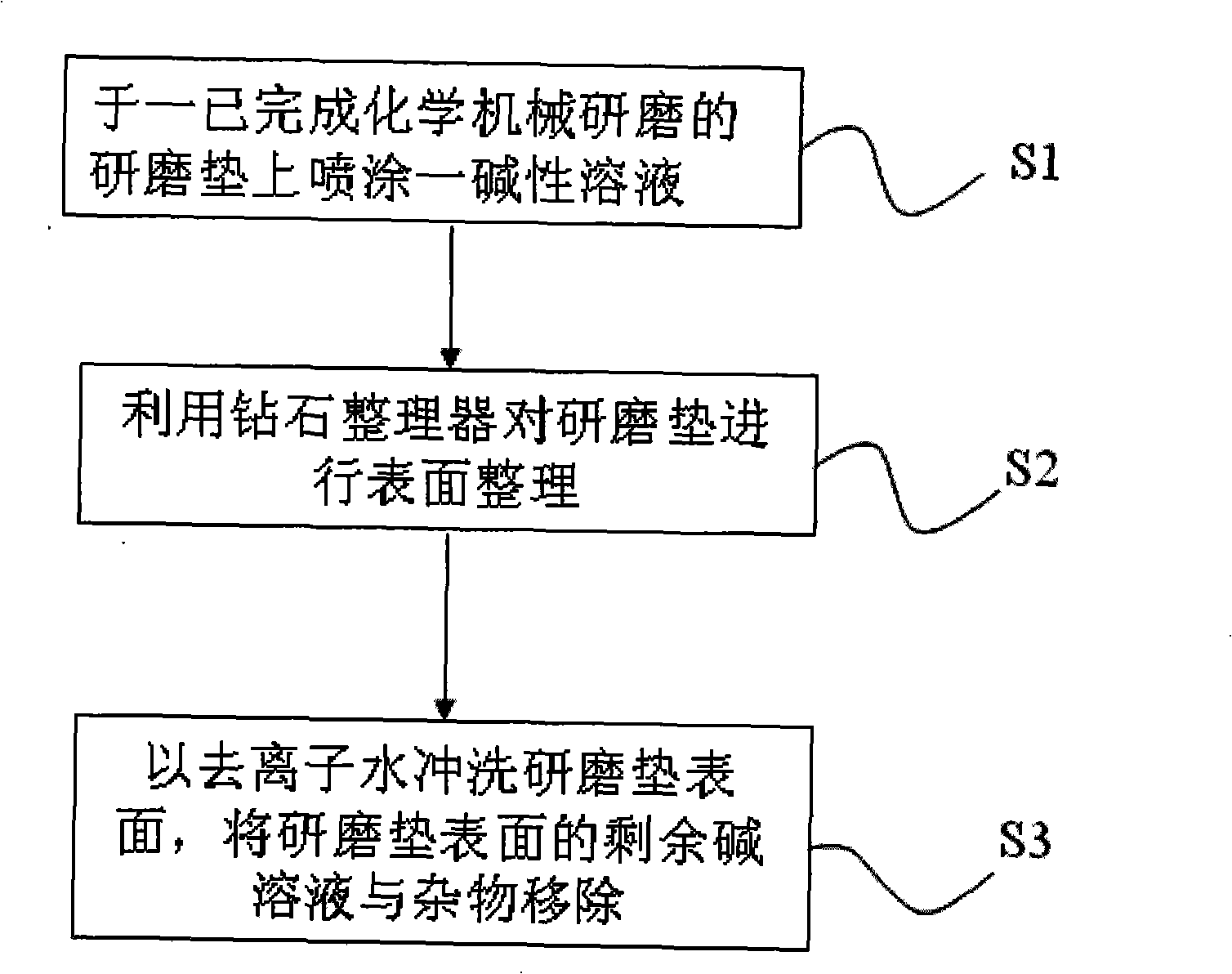

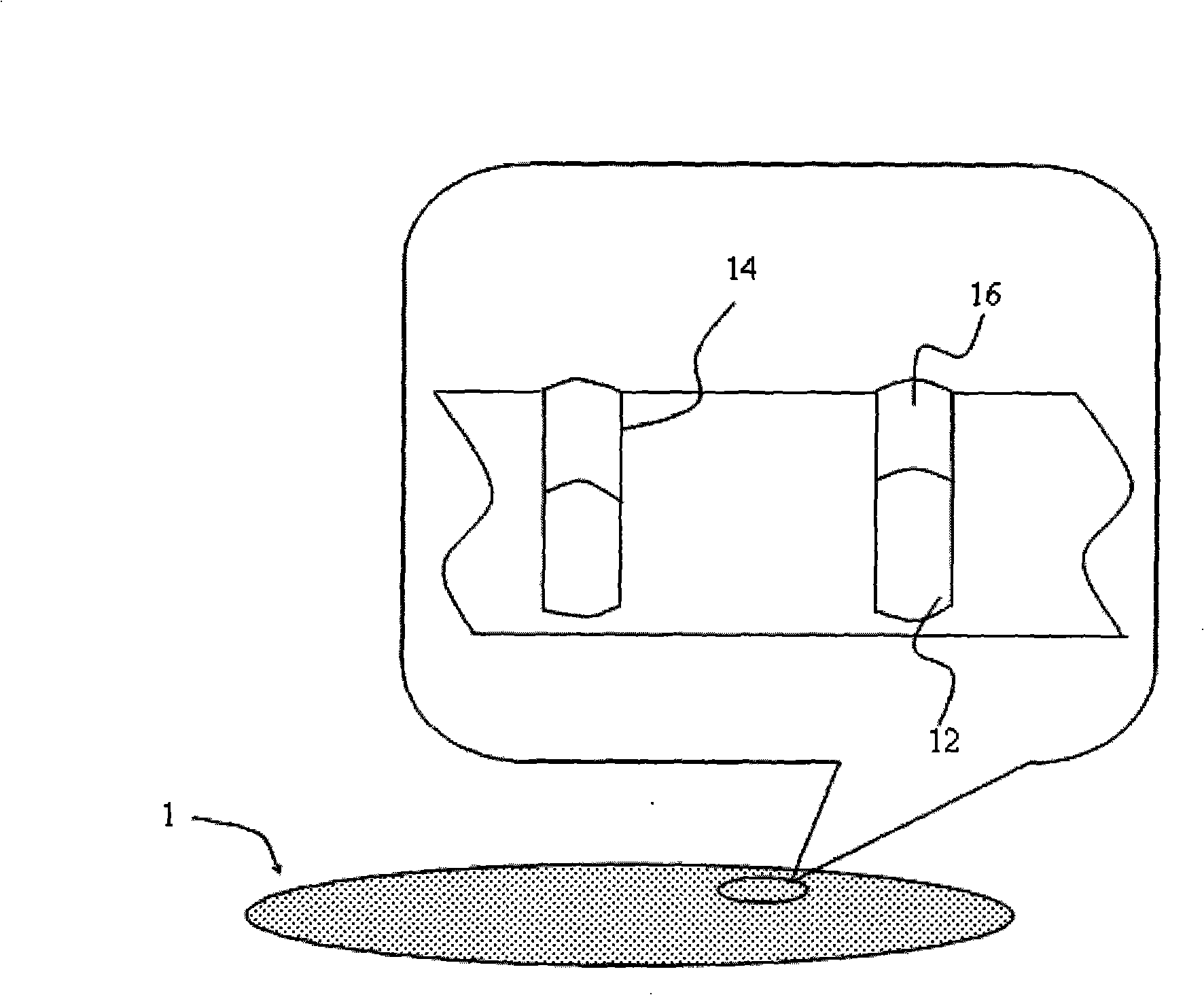

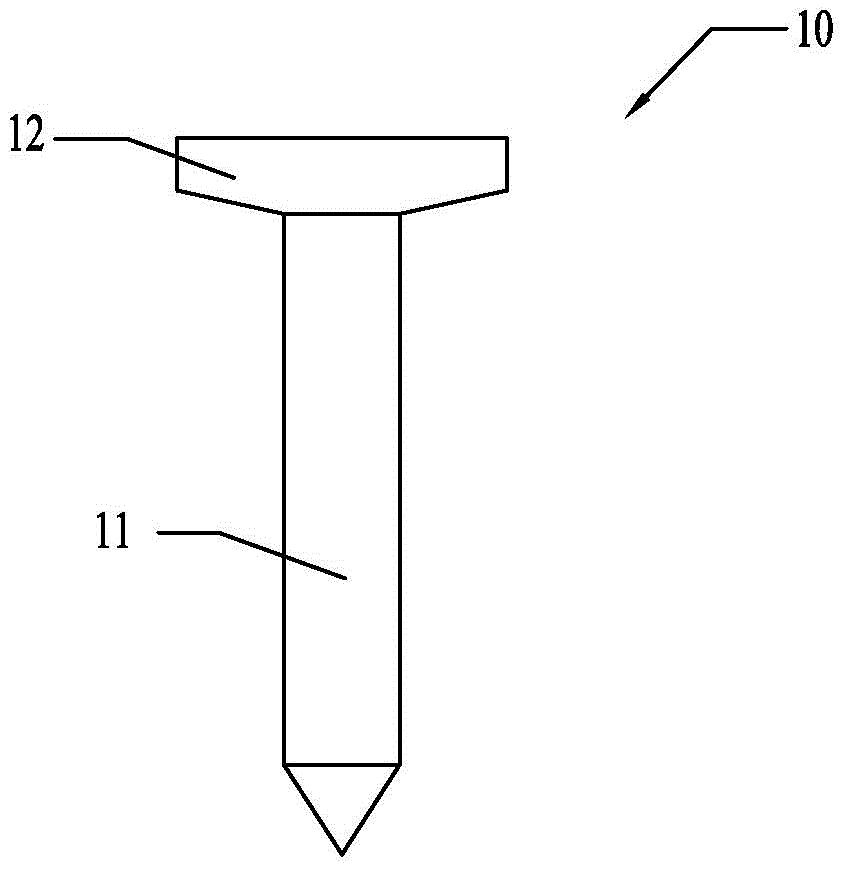

Process for preventing diamond scratch in process of CMP

InactiveCN101285188AAvoid erosionReduce the likelihood of sheddingCleaning using liquidsScratchingErosion

The invention provides a method for preventing diamond scratching during the CMP process. The method is as follows: firstly, alkaline solution with adequate concentration is splashed after the CMP polishing process so as to neutralize acid polishing slurry which is left on a polishing pad after the polishing process; secondly, finishing of the polishing pad is performed by utilization of a diamond finishing device. Therefore, erosion of the acid polishing slurry on the diamond finishing device is effectively avoided and the possibility of falling off of diamond particles of the diamond finishing device is further reduced, so that wafers for performing CMP technique subsequently can avoid generation of diamond scratching.

Owner:GRACE SEMICON MFG CORP

Charging combination and anti-off wall-mounted shell thereof

InactiveCN104619137AEnsure safetyReduce the likelihood of sheddingBatteries circuit arrangementsCasings/cabinets/drawers detailsSpecial designEngineering

The invention discloses a charging combination and an anti-off wall-mounted shell thereof. The charging combination mainly comprises a charger, and a battery pack which can be plugged into and pulled out of the charger along a third direction. The charger comprises an anti-off wall-mounted shell and circuit elements therein. The anti-off wall-mounted shell comprises a shell body which has more than one anti-off nail hanging hole. Each anti-off nail hanging hole at least comprises an inserting hole in which a nail head can be inserted and a limiting hole which can stop the nail head from passing through and only allow a nail body to pass through, a communicating gap is arranged between the inserting hole and the limiting hole, and the limiting hole consists of a linear track and an arc track. The beneficial effect lies in that through special design of the anti-off nail hanging holes, a wall nail can exit to the inserting holes only when the wall nail moves according to a preset exit trajectory, so that the possibility of fall-off is greatly reduced, and the safety of the whole charging combination is ensured.

Owner:NANJING CHERVON IND

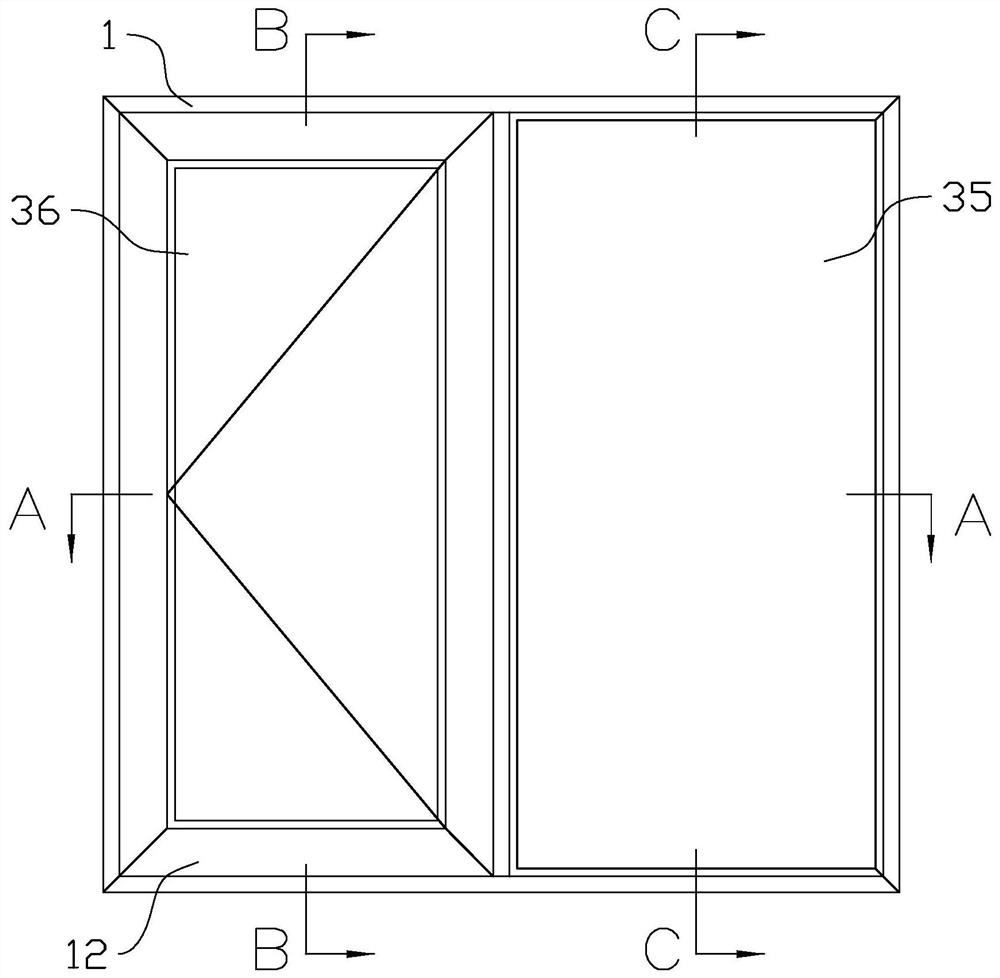

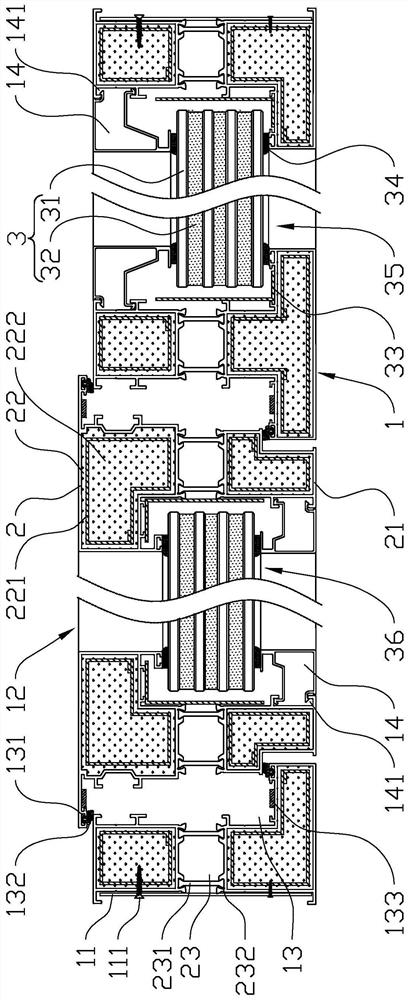

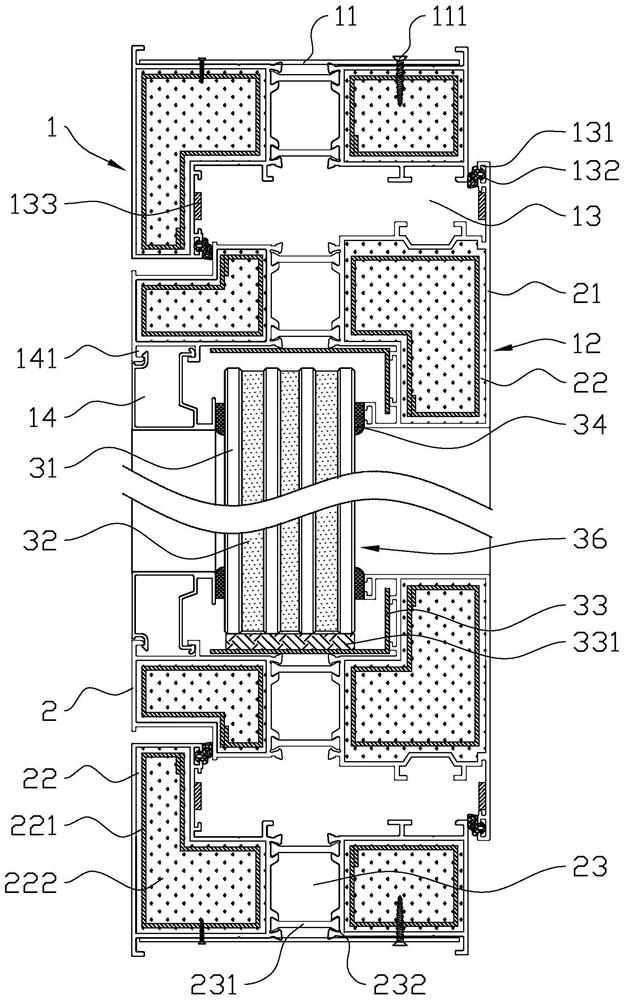

Aluminum alloy heat-insulation fireproof window

InactiveCN112112534AImprove sealingEasy to installFireproof doorsWindow/door framesSash windowSilica gel

The invention relates to an aluminum alloy heat-insulation fireproof window, and relates to the technical field of fireproof windows. The aluminum alloy heat-insulation fireproof window comprises a frame, a window sash and fireproof glass, wherein the frame and the window sash comprise inner profiles and outer profiles; filling cavities are formed in the inner profiles and the outer profiles; steel linings are fixed in the filling cavities; the steel linings are filled with fireproof fillers made of mixtures of perlite particles and polymerized silica gel; and the fireproof glass is arranged between the inner profiles and the outer profiles. The steel linings are fixed in the filling cavities of the inner profiles and the outer profiles, the steel linings are filled with the fireproof fillers made of the mixtures of the perlite particles and the polymerized silica gel, the dried mixtures become hard solids and are firmly adhered in the steel linings, if the inner profiles and the outerprofiles are fused in fire, a structural frame of the fireproof window is kept complete owing to excellent mechanical property and fire resistance of the fireproof fillers and the steel linings, thepossibility that the fireproof glass drops is reduced, and the effect of improving fire resistance and safety of the fireproof window is achieved.

Owner:安徽钟南消防科技有限公司

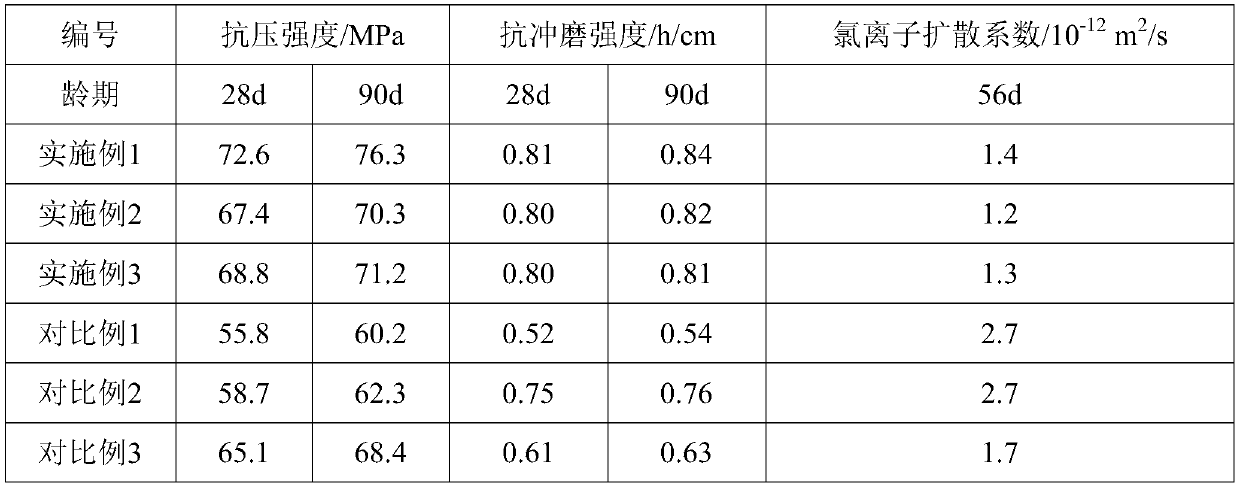

Marine engineering concrete with abrasion resistance and chlorine salt corrosion resistance

The invention discloses a marine engineering concrete with and abrasion resistance and chlorine salt corrosion resistance. The marine engineering concrete is prepared from cement, ceramic powder, superfine mineral powder, gravels, river sand, a polycarboxylate superplasticizer and water in proportion. The gravels such as granite with excellent abrasion resistance are selected, and the aggregate content of the gravels is maximized, so the abrasion resistance of the concrete is effectively improved; the ceramic powder is used as an admixture, so that the abrasion resistance of a cement paste isimproved, chloride ions are adsorbed by using calcium aluminate hydrate generated by a secondary hydration reaction in the later period of the cement paste to prevent the chloride ions from being transmitted inwards, and corrosion of reinforcing steel bars is reduced; and the superfine mineral powder is adopted as an admixture, so that the paste-aggregate interface bonding force is improved, the porosity of the paste is reduced, the abrasion resistance of the concrete is improved, and erosion ions are prevented from being transmitted inwards to reduce corrosion of steel bars. The prepared marine engineering concrete with and abrasion resistance and chlorine salt corrosion resistance has the advantages of high sand-carrying surge erosion resistance, high chloride ion erosion resistance andgreat engineering application values.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD +1

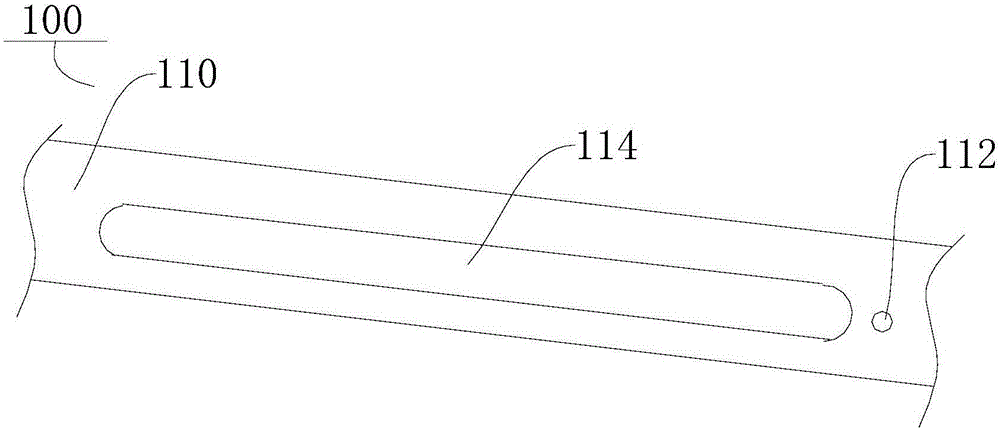

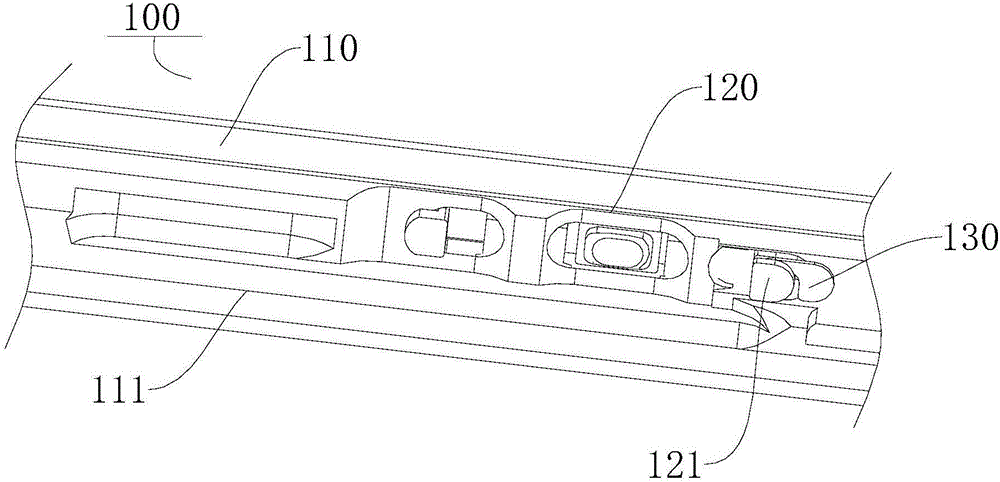

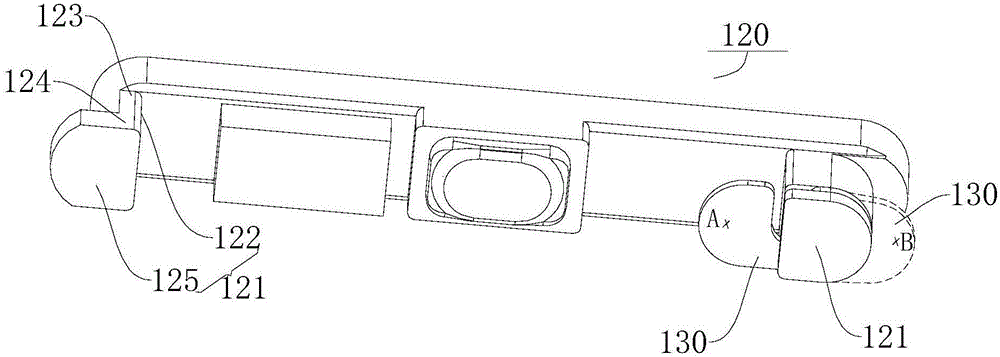

Terminal, shell assembly, and manufacturing method of shell assembly

ActiveCN106790837AShorten the production cycleEasy to useTelephone set constructionsKey pressingProduction cycle

The invention discloses a terminal, a shell assembly and a manufacturing method of the shell assembly. The shell assembly comprises a rear cover, a key assembly and a connecting piece, wherein the rear cover defines a holding cavity; an installing hole communicated with the holding cavity is formed in the rear cover; the key assembly is arranged in the installing hole; the connecting piece is connected with the key assembly and can be switched between a first position and a second position; when the connecting piece is located at the first position, the key assembly is suitable to be assembled in the installing hole; when the connecting piece is located at the second position, the connecting piece is connected with the rear cover in a clamping way so as to limit the key assembly in the installing hole. According to the shell assembly provided by the invention, through designing the connecting piece, the key assembly can be quickly and firmly assembled on the rear cover, and the possibility of falling out of the key assembly and the rear cover is reduced, so that an assembly process of the shell assembly can be simplified, the assembly efficiency of the shell assembly is improved, the production cycle of a terminal can be reduced, the production cost is saved, and meanwhile, the usability of the terminal can be improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

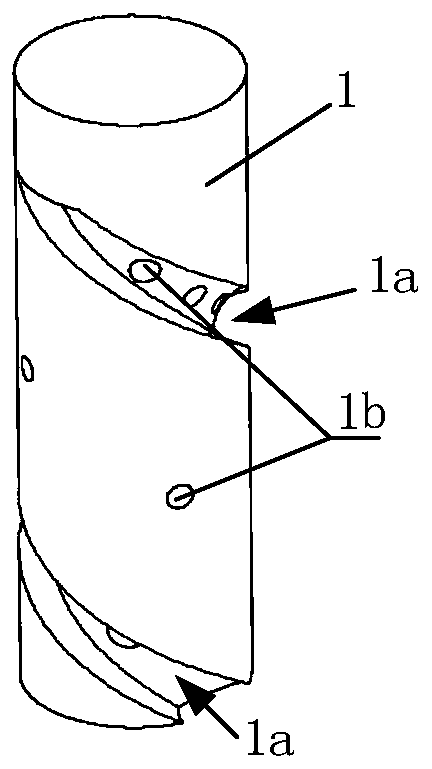

Rat tail suspension device based on weightless state simulation

The invention discloses a rat tail suspension device based on weightless state simulation. The rat tail suspension device comprises a fixing mechanism and a loading mechanism which are arranged in a cage body, the fixing mechanism comprises a tail fixing shaft, a first soft silica gel sleeve and a metal sleeve which are sequentially sleeved from inside to outside, a spiral through groove is formedin the outer side wall face of the tail fixing shaft in the circumferential direction of the tail fixing shaft, and the loading mechanism comprises a swing type connecting rod shaft, a telescopic bearing shaft and a tail end fixing ring. The swing type connecting rod shaft is movably fixed to the top of the metal sleeve, the telescopic bearing shaft is horizontally arranged under the swing type connecting rod shaft, the tail end fixing ring is a ring body fixed to the top of a supporting block of the telescopic bearing shaft, and the axis of the ring body is perpendicular to the side wall ofthe metal sleeve. The device is simple in structure, reasonable in design and high in practicability, and effectively avoids damage or necrosis of the tail of the rat due to mechanical extrusion forceor airtight reasons.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

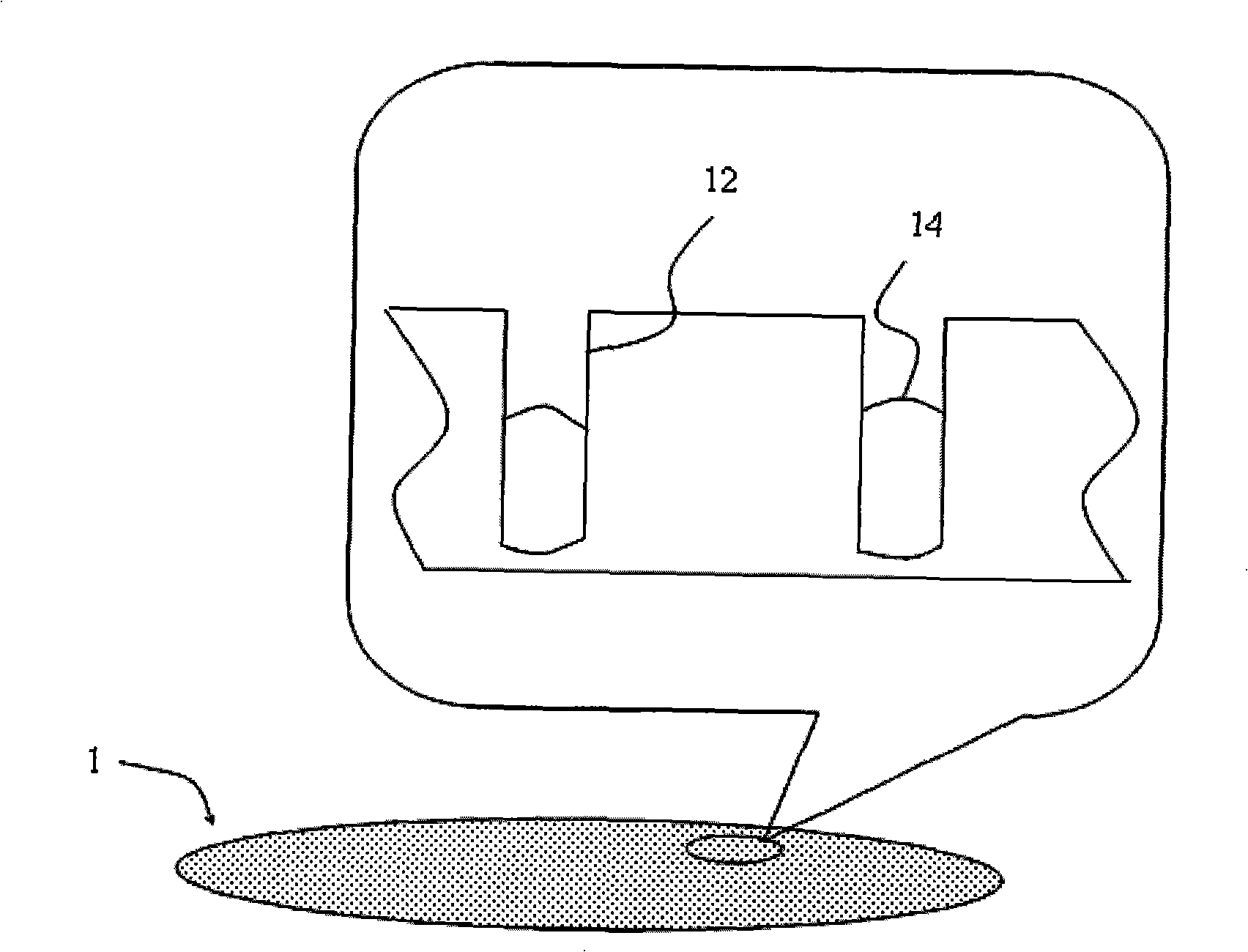

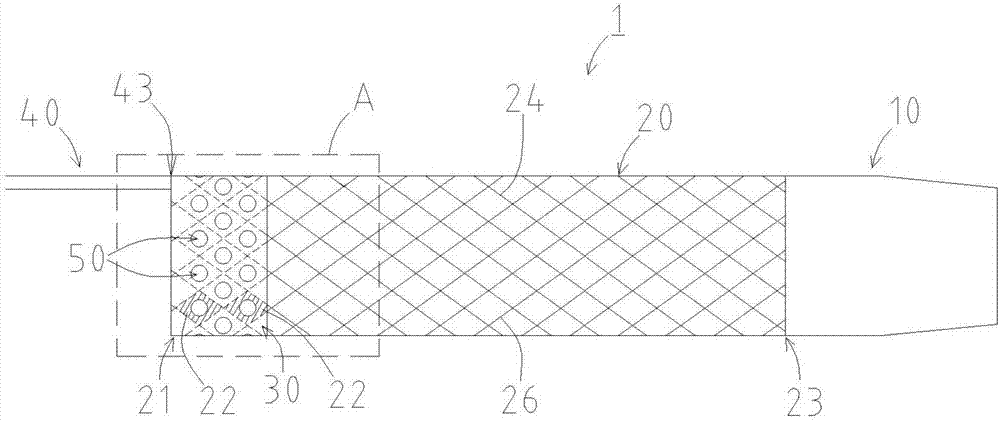

Medical Device

ActiveCN107224656AReduce crackingReliable scalingBalloon catheterDilatorsStress concentrationSurgery

The invention discloses a medical device. The medical device is structured such that a wire which constitutes a mesh member is not restricted to act. When the mesh member is expanded, the structure reduces stress concentration to an end part of the mesh member, so that the wire which constitutes the mesh member is not easily broken. In the medical device (1), a wrapping portion (32) and a lining portion (36) are fixed to each other at fixation portions (50), the fixation portions (50) being within spaces (22) that are defined by the first wire (24) and the second wire (26), wherein neither the wrapping portion (32) nor the lining portion (36) is fixed to any of the first wire (24) or the second wire (26). Therefore, when the mesh member (20) radially expands and radially contracts, the first wire (24) and the second wire (26) are not obstructed by a cylindrical member (30) to act, and the stress concentration at the end part (21) of the mesh member (20) is reduced, which results in the breaking up of the first wire (24) or the second wire (26) which constitutes the mesh member (20).

Owner:ASAHI INTECC CO LTD

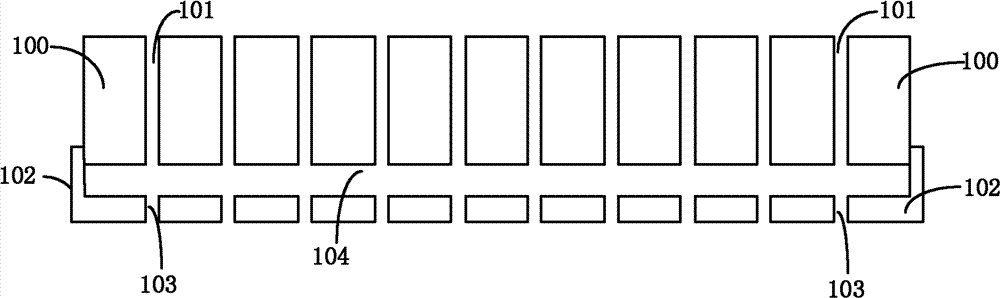

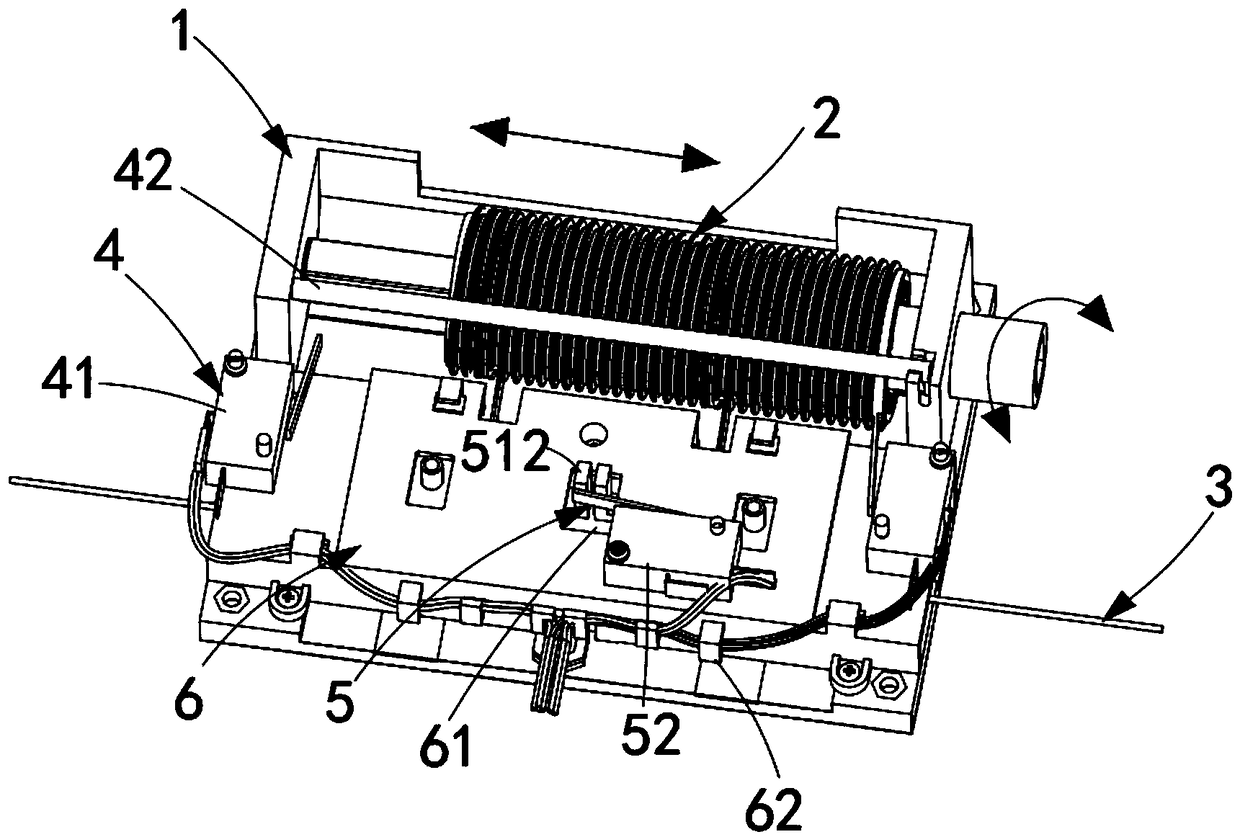

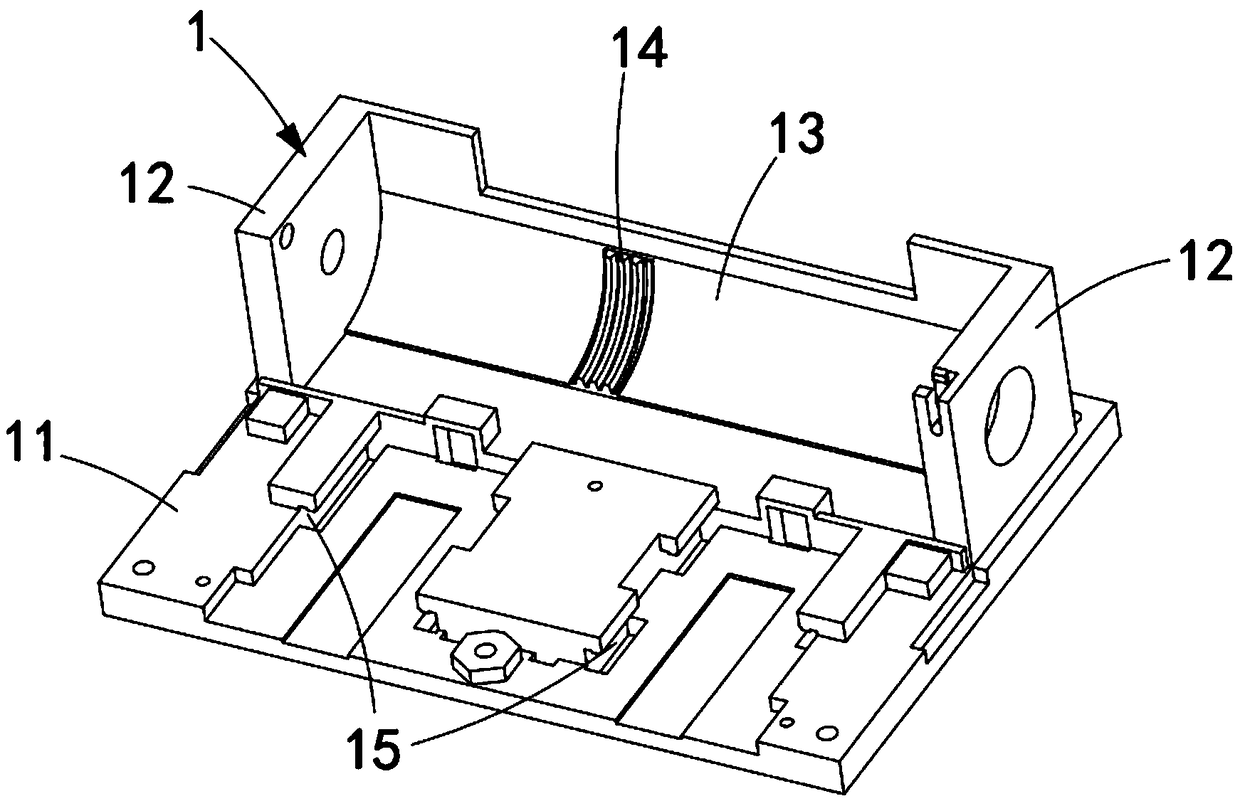

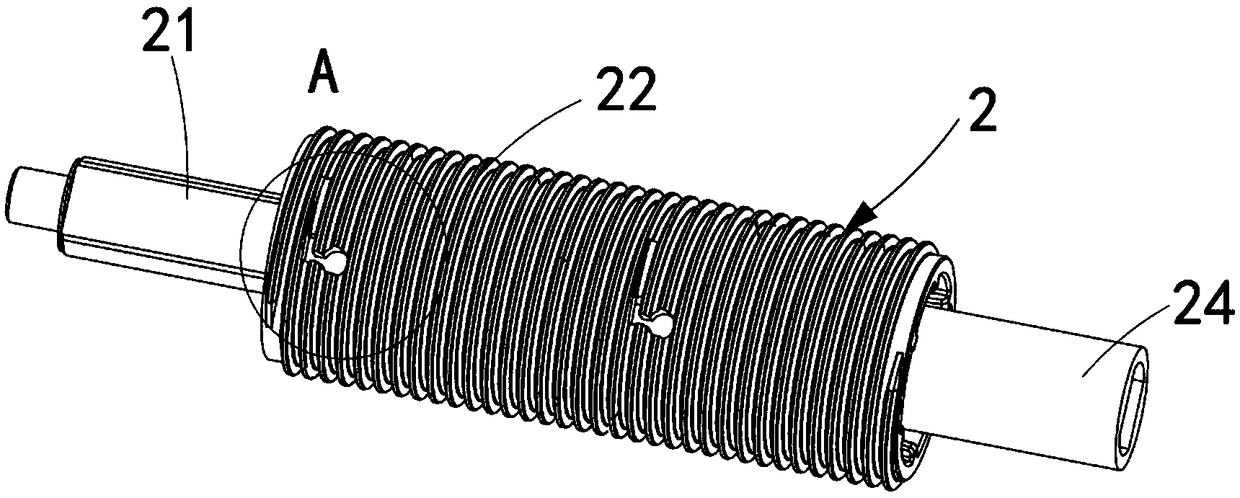

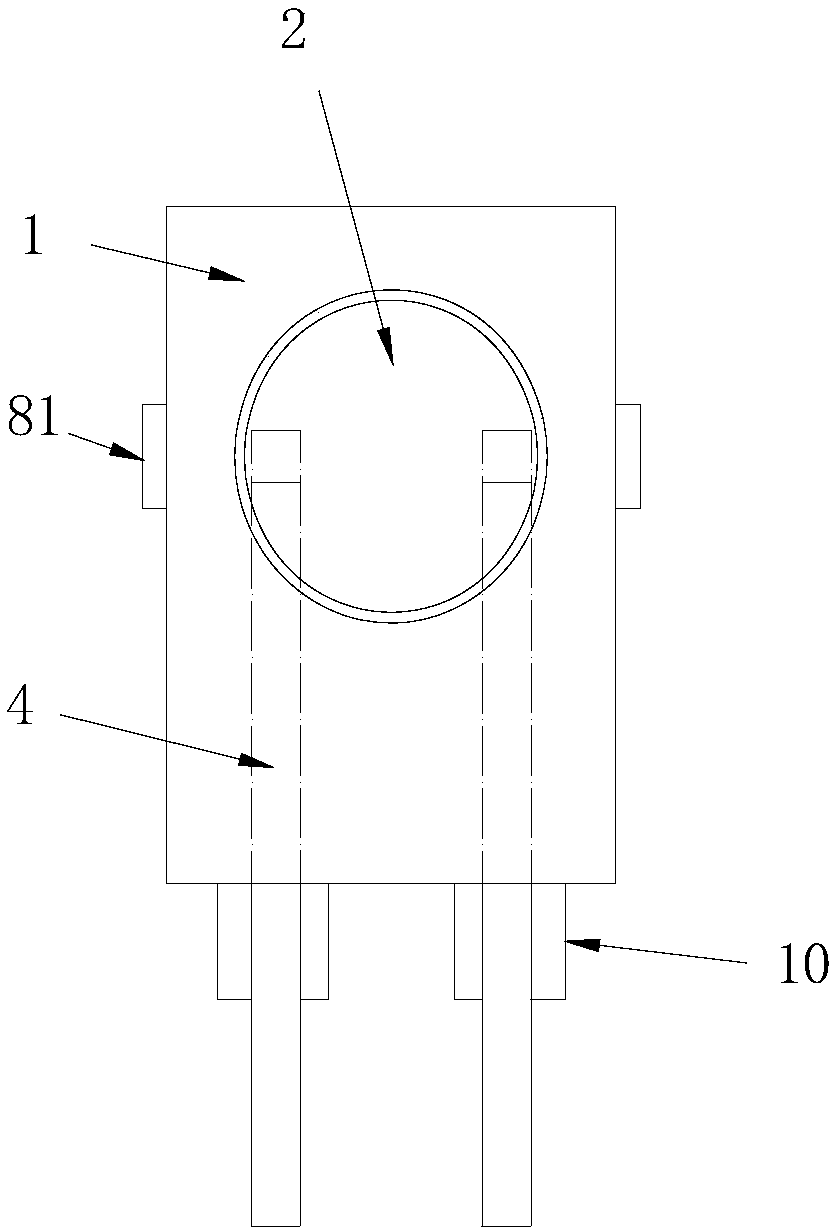

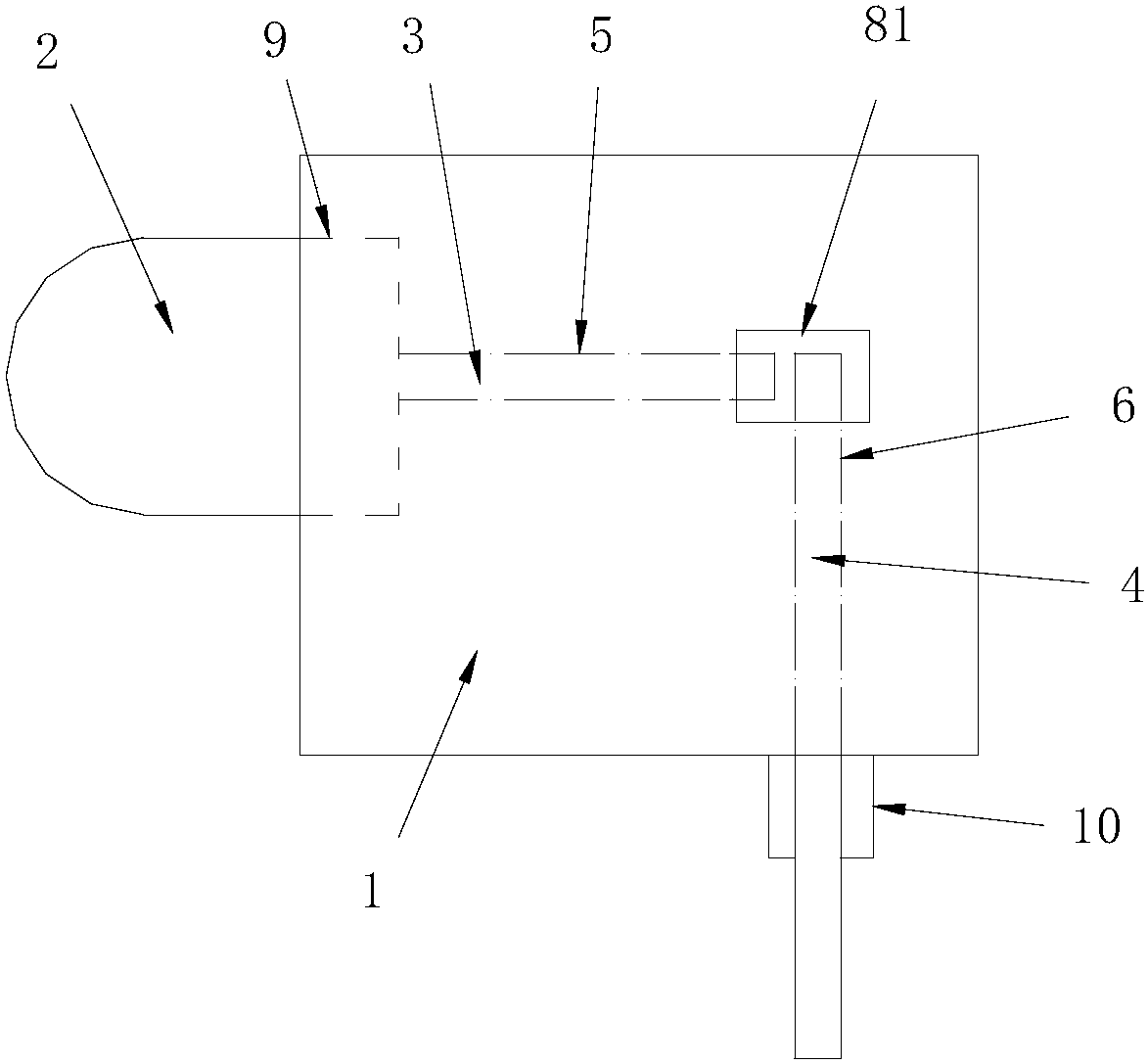

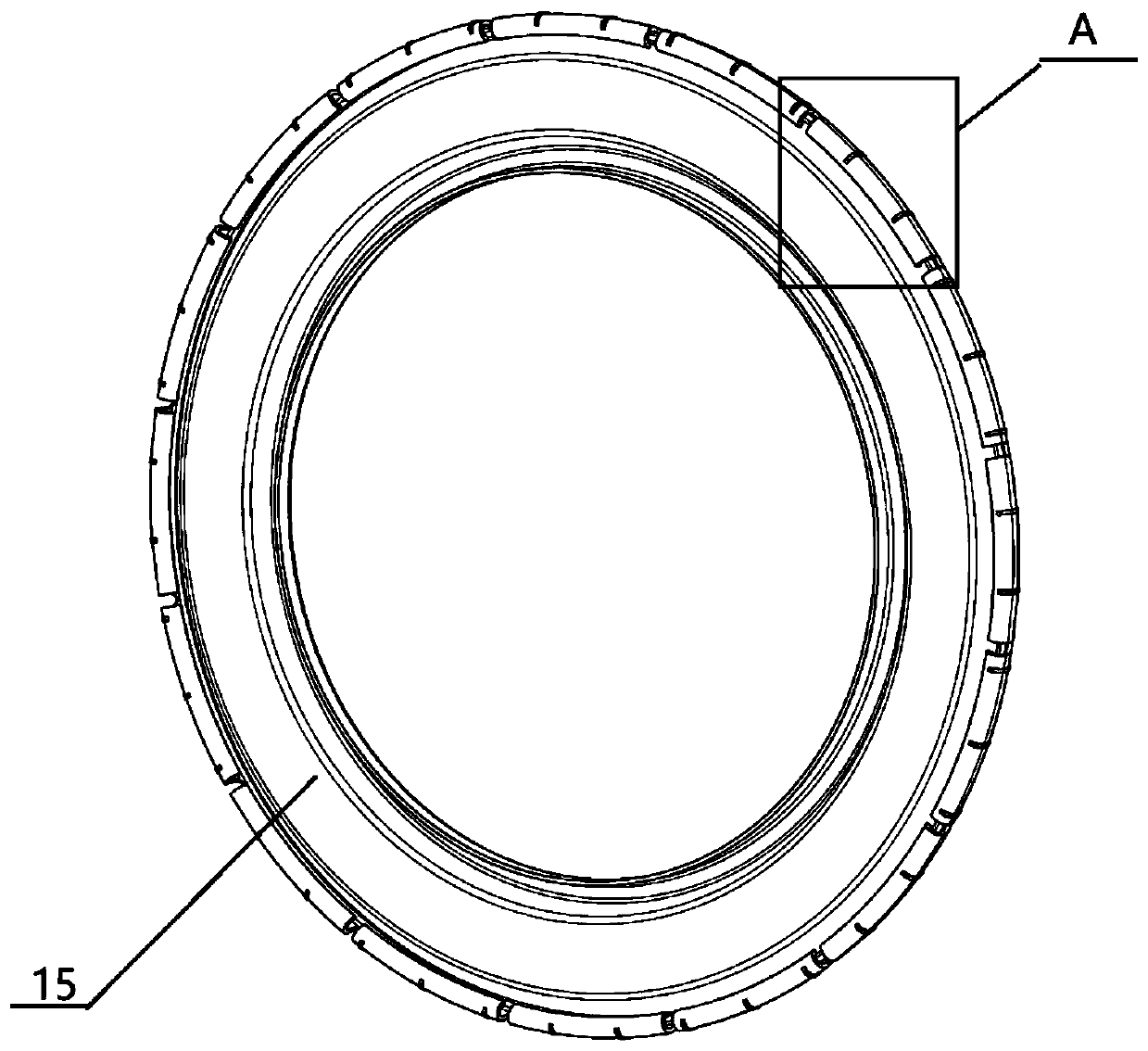

Integrated winding device and electric laundry rack with same

PendingCN108892063APrevent jumpingEasy to wrapOther drying apparatusWinding mechanismsProtection mechanismEngineering

The invention provides an integrated winding device and an electric laundry rack with the same. The integrated winding device and the electric laundry rack have the advantages that a base is integrally machined, a winder is coated and restrained by the base, the base is matched with a thread portion and a restraint rod, accordingly, steel wire ropes on the winder can be restrained at multiple points, and the technical problem that existing steel wire ropes in existing winding devices can easily jump out of the existing winding devices can be solved; a protection mechanism is simplified, the steel wire ropes outputted at two ends of the integrated winding device can be simultaneously synchronously monitored by a protection switch, accordingly, another protection switch can be omitted, and the volume of the integrated winding device can be reduced; the electric laundry rack comprises the integrated winding device, labor saving principles of movable pulleys are utilized, laundry rack mechanisms are provided with pulleys and can be pulled and driven by the steel wire ropes to be lifted in the up-down directions, accordingly, power can be saved, and output power of driving components can be reduced.

Owner:湖州多玛智能科技股份有限公司

Water-based EAU high-barrier thick-film anticorrosive paint

ActiveCN114181556AImprove wear resistanceImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsCelluloseWater reducer

The invention belongs to the technical field of anticorrosive coatings, and particularly relates to a water-based EAU high-barrier thick-film anticorrosive coating which comprises a component A, a component B and a component C in a mass ratio of 1: (1-3): (5-7), the component A comprises the following components in percentage by mass: 30-40% of a curing agent, 0.05-0.1% of a defoaming agent, 0.05-0.1% of a wetting agent and the balance of deionized water; the component B comprises the following components in percentage by mass: 100% of water-based EAU emulsion; the component C is prepared from the following components in percentage by mass: 0.05 to 0.1 percent of lithium carbonate, 0.05 to 0.1 percent of tartaric acid, 1 to 3 percent of basalt sheet, 0.1 to 0.3 percent of water reducing agent, 0.1 to 0.3 percent of hydroxymethyl cellulose ether, 55 to 70 percent of high-alumina cement and the balance of high-alumina clinker. The water-based EAU high-barrier thick-film anticorrosive paint is specially used for providing a protective lining for a structure exposed in an urban sewage environment, is used for resisting abrasion and biological corrosion caused by hydrogen sulfide circulation, can be used for repairing an existing sewage structure, can also be used for a new building, can be matched with anticorrosive mortar for use, can also be independently used, and can be applied to the field of construction. The paint has excellent corrosion resistance.

Owner:苏州大乘环保新材有限公司

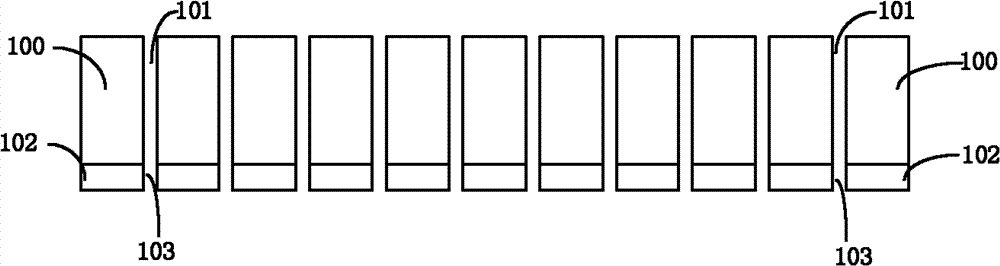

Light emitting diode with two-segment pins

PendingCN107768505AReduce distortionReduce misalignmentSemiconductor devicesLED lampLight-emitting diode

The invention discloses a light emitting diode with two-segment pins. The light emitting diode comprises a lamp housing, an LED lamp and two pins, the two pins are both arranged on the LED lamp, the pins penetrate through the lamp housing, a transverse linear through hole and a vertical linear through hole vertical to each other are arranged in the lamp housing, each pin is formed by two segmentsof branch pins including a first branch pin and a second branch pin, one end of the first branch pin is connected with the LED lamp, the other end of the first branch pin penetrates through the transverse linear through hole, the second branch pin penetrates through the vertical linear through hole, and one ends of the two segments of branch pins located in the lamp housing are connected through conductive spring sheets. According to the light emitting diode, the pins are set as two segments of branch pins which are finally connected through the conductive spring sheets, bending and shearing of the pins by a bending machine and a shearing machine can be avoided, the installation is simple, the deformation and the deviation of the pins are reduced, the side light-emitting effect is guaranteed, the assembling is rapid, and the cost is low.

Owner:苏州市悠文电子有限公司

Tightening device for hydrogen cylinder fixing band of hydrogen fuel automobile

PendingCN113442719AEasy to installEasy to fixUnderstructuresFuel supplyStructural engineeringHydrogen fuel

The invention discloses a hydrogen fuel automobile hydrogen bottle fixing band tightening device. The hydrogen fuel automobile hydrogen bottle fixing band tightening device comprises a support base, a connecting column, a fixing band, an adjusting part and a tightening part. An arc-shaped mounting plate matched with a hydrogen bottle is arranged at the top of the bracket base, a connecting part is arranged at the bottom of one side of the bracket base, and the connecting column is arranged on the other side of the bracket base. The connecting column is sequentially provided with a plurality of connecting holes from top to bottom, and one end of the fixing belt is connected with the connecting holes. A first through hole is transversely formed in the other end of the fixing belt, and the adjusting part can vertically and downwards penetrate out of the connecting part from the first through hole; the tightening part is adjustably connected with one end, extending out of the connecting part, of the adjusting part. The device is connected to the connecting holes with different heights through the fixing belts, so that the fixing belts can be used for fixing hydrogen cylinders with different models; through the cooperation of the adjusting part and the tightening part, the distance of the adjusting part penetrating through the connecting part is adjusted so as to adjust the tightness of the fixing band. The device is easy to install, convenient to adjust and good in fixing effect.

Owner:广东汉合汽车有限公司

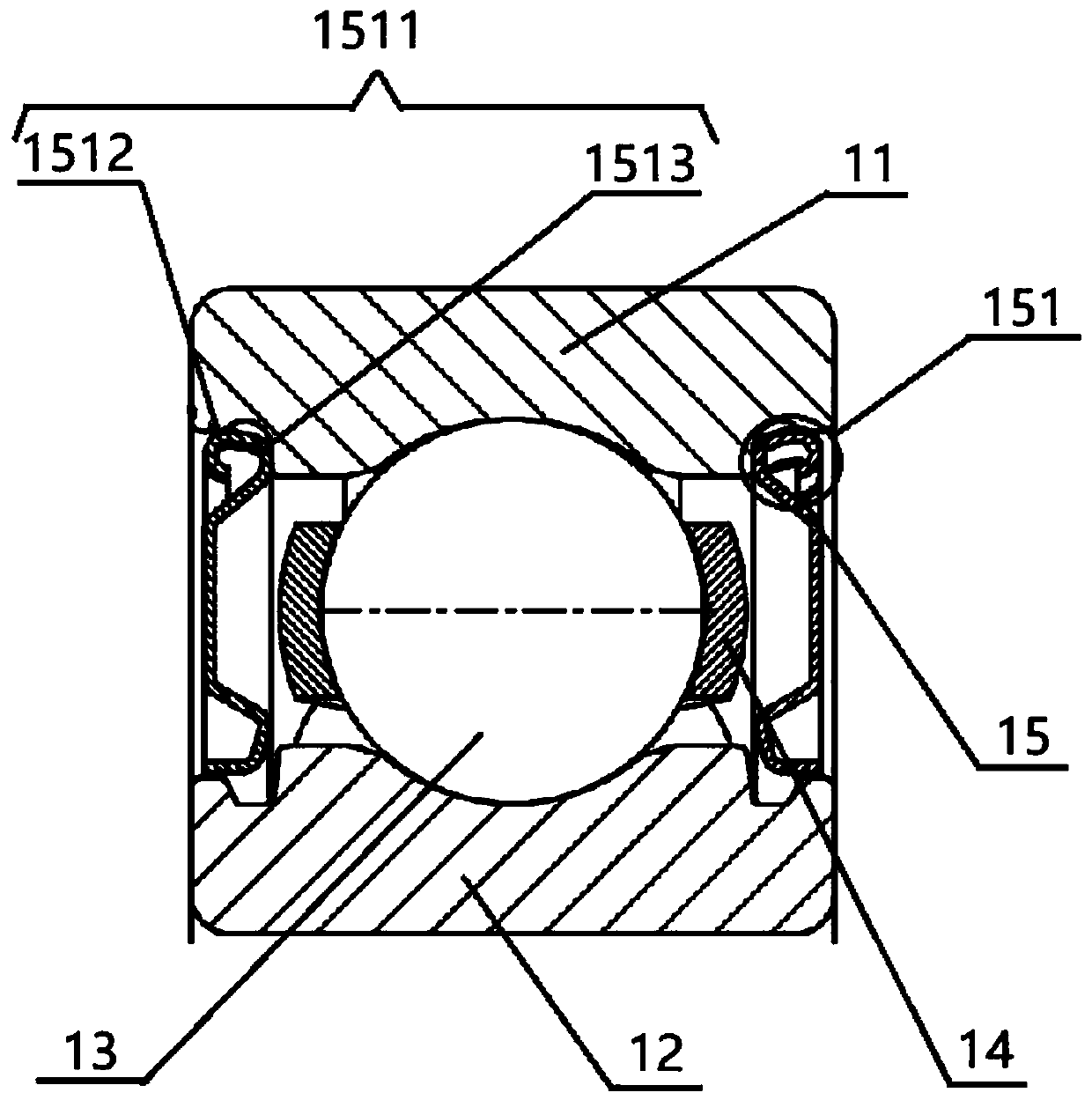

Bearing and bearing dust cover

InactiveCN110307261AReduce sheddingReduce the likelihood of sheddingBearing componentsArchitectural engineering

Owner:SCHAEFFLER TECH AG & CO KG

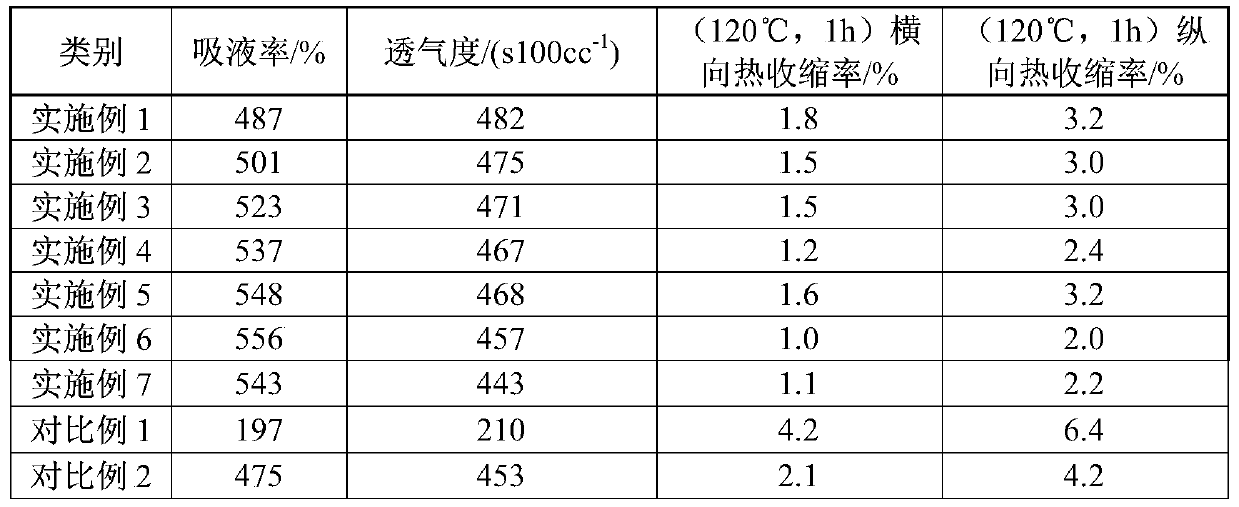

High-infiltration lithium ion battery diaphragm

ActiveCN110783515AGood compatibilityGreat suctionCell component detailsCyclodextrinLithium-ion battery

The present invention relates to the technical field of lithium battery diaphragms, and in particular, to a composite diaphragm for high-infiltration lithium batteries. The invention, in view of the poor electrolyte absorption and liquid holding capacity of a lithium ion battery diaphragm, provides a high-infiltration lithium ion battery diaphragm. The outermost layer of the diaphragm is a polypropylene microporous membrane and the intermediate layer of the diaphragm is a polyethylene composite microporous membrane. Both sides of the polyethylene composite microporous membrane are coated withthe same functional coating. The functional coating is composed of maleic anhydride grafted hydroxypropyl-[beta]-cyclodextrin, nano-silica, an binder and ethyl alcohol. The technical scheme provided by the invention is simple in process and friendly to environment. The prepared composite diaphragm has good electrolyte absorption and electrolyte holding performance, air permeability and thermal stability.

Owner:苏州欧纳克纳米科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com