Aluminum alloy heat-insulation fireproof window

A fire-resistant window and aluminum alloy technology, applied in the field of fire-resistant windows, can solve the problems of poor fire resistance and safety, glass falling off, limited heat absorption ability, etc., achieve excellent weather aging resistance, high and low temperature resistance, and improve airtightness , Excellent adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

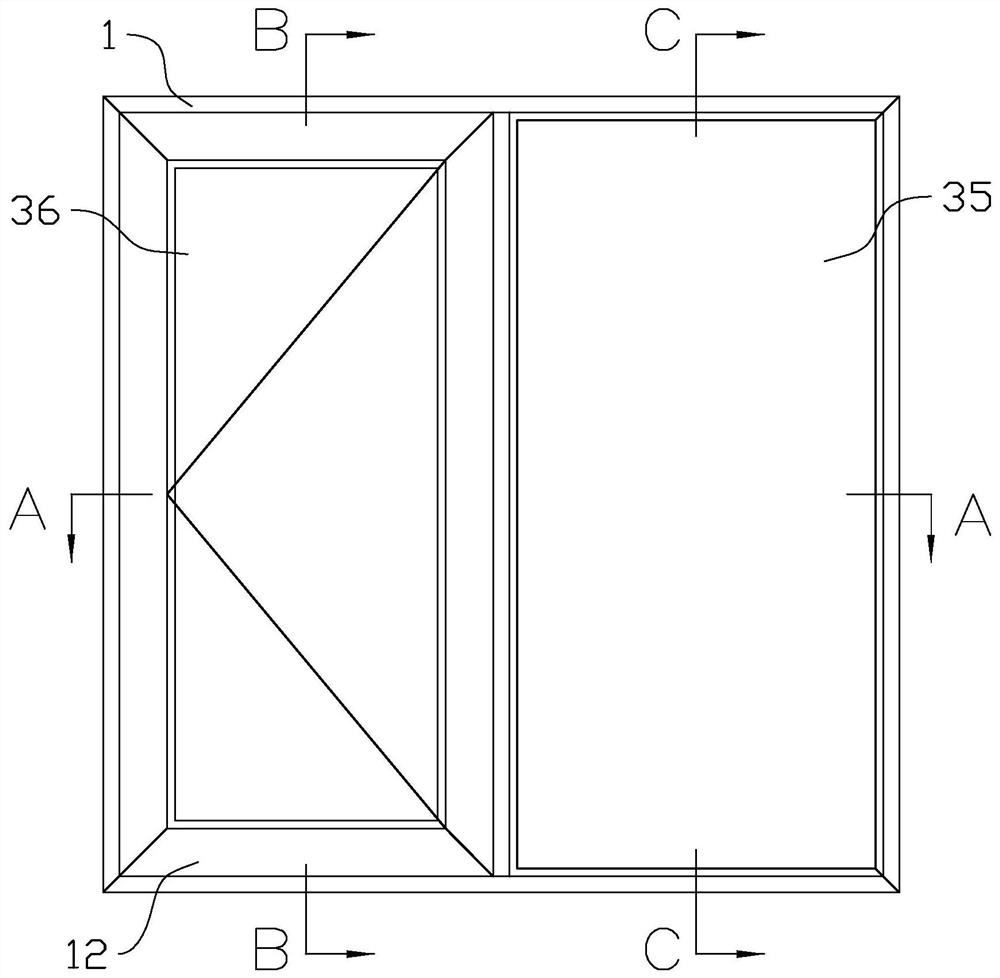

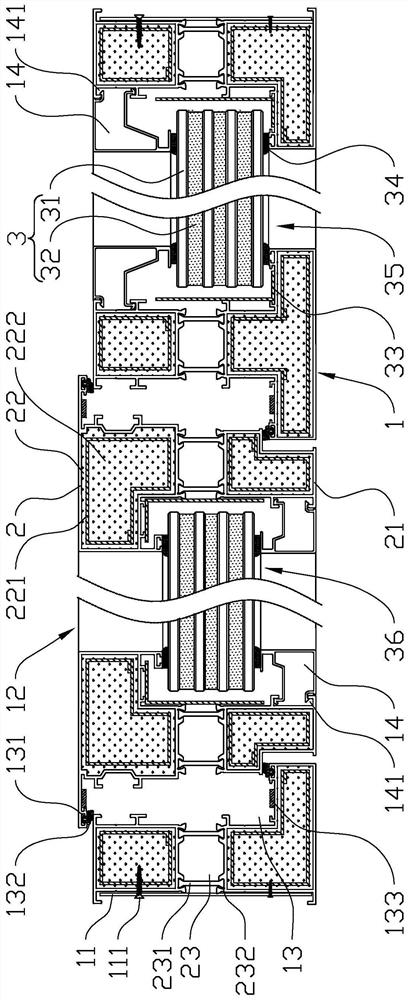

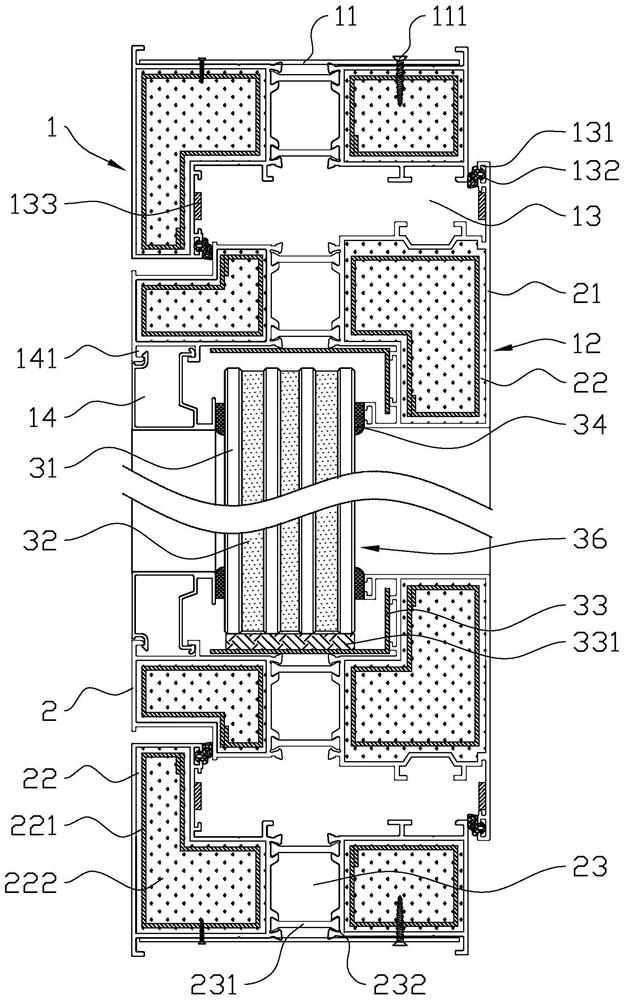

[0035] The following is attached Figure 1-4 The application is described in further detail.

[0036] The embodiment of the present application discloses an aluminum alloy heat-insulating fireproof window. refer to figure 1 , figure 2 , The aluminum alloy heat-insulating fireproof window includes a frame 1 , a window sash 12 and a fireproof glass 3 . The frame 1 is fixedly installed in the wall, and the window sash 12 is hinged on the side of the frame 1 close to the outdoor. The frame 1 and the window sash 12 both include an outer profile 2 and an inner profile 21. The outer profile 2 and the inner profile 21 are respectively located near the outdoor and indoor. The outer profile 2 and the inner profile 21 are both made of aluminum alloy. The fireproof glass 3 is fixedly arranged between the outer profile 2 and the inner profile 21 , wherein the fireproof glass 3 inside the frame 1 is a fixed glass leaf 35 , and the fireproof glass 3 inside the window sash 12 is a movabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com