Water-based EAU high-barrier thick-film anticorrosive paint

An anti-corrosion coating and high-barrier technology, applied in anti-corrosion coatings, cement coatings, epoxy resin coatings, etc., to achieve the effects of improving bonding force, improving anti-corrosion performance, increasing impermeability and anti-cracking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

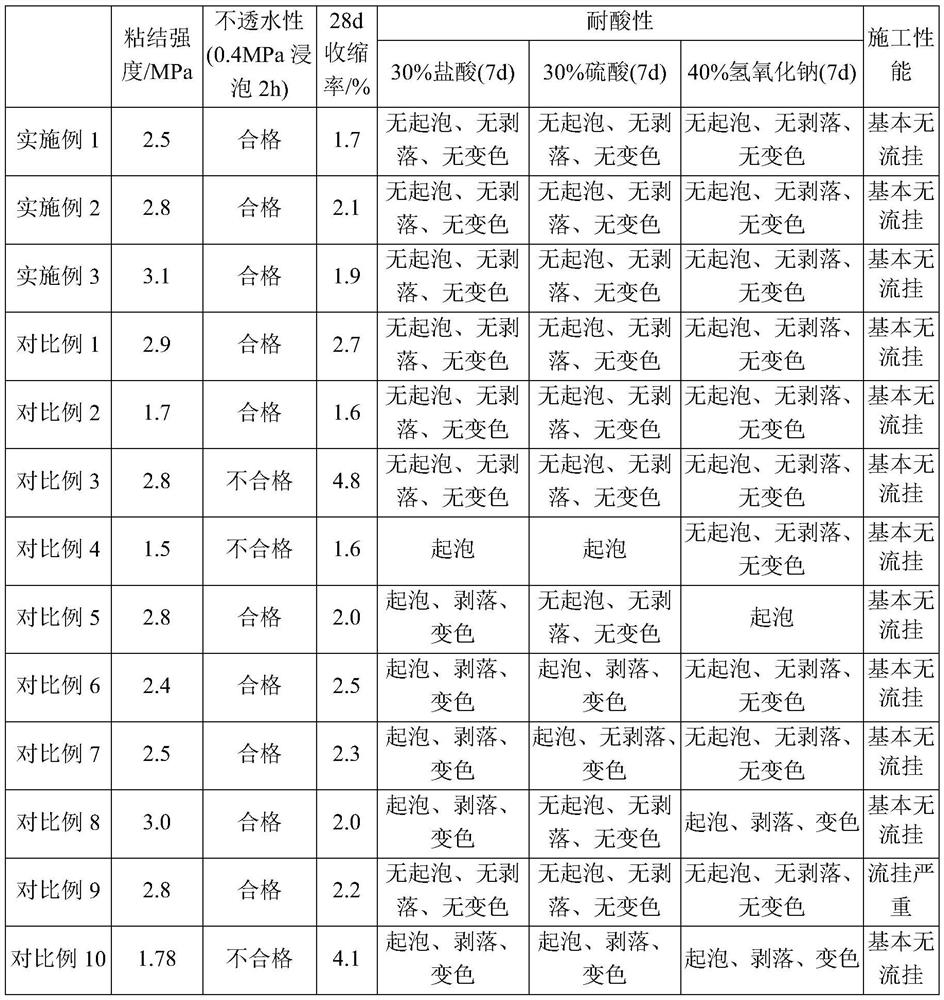

Examples

Embodiment 1

[0032] Component A: 30kg curing agent (diethylenetriamine), 0.05kg defoamer (TEGO Foame 10), 0.05kg wetting agent (TEGO Wet 505), 69.9kg deionized water.

[0033] B component: 100kg epoxy modified acrylic emulsion.

[0034] Component C: 0.05kg lithium carbonate, 0.05kg L+ tartaric acid, 3kg basalt flakes, 0.3kg melamine superplasticizer, 0.3kg hydroxymethyl cellulose ether, 55kg high alumina cement, 41.3kg high alumina clinker.

[0035] Preparation of component A: Add curing agent into the stirring tank, add wetting agent and defoamer in sequence at a stirring speed of 400r / min and stir evenly, then add deionized water, stir evenly, and pack to obtain component A.

[0036] Preparation of component C: add high alumina cement, high alumina clinker, lithium carbonate, L+ tartaric acid, melamine water reducer, hydroxymethyl cellulose ether and basalt flakes into a gravity-free mixing tank and mix evenly, and pack to obtain C components.

[0037] Mix component A, component B and ...

Embodiment 2

[0039] Component A: 40kg curing agent (diethylenetriamine), 0.1kg defoamer (TEGO Foame 10), 0.1kg wetting agent (TEGO Wet 505), 59.8kg deionized water.

[0040] B component: 100kg epoxy modified acrylic emulsion.

[0041] Component C: 0.1kg lithium carbonate, 0.1kg L+ tartaric acid, 1kg basalt flakes, 0.1kg melamine water reducer, 0.1kg hydroxymethyl cellulose ether, 70kg high alumina cement, 28.6kg high alumina clinker.

[0042] Preparation of component A: Add curing agent into the stirring tank, add wetting agent and defoamer in sequence at a stirring speed of 400r / min and stir evenly, then add deionized water, stir evenly, and pack to obtain component A.

[0043] Preparation of component C: add high alumina cement, high alumina clinker, lithium carbonate, L+ tartaric acid, melamine water reducer, hydroxymethyl cellulose ether and basalt flakes into a gravity-free mixing tank and mix evenly, and pack to obtain C components.

[0044] Mix components A, B and C at a mass rati...

Embodiment 3

[0046] Component A: 35kg curing agent (diethylenetriamine), 0.08kg defoamer (TEGO Foame 10), 0.08kg wetting agent (TEGO Wet 505), 64.84kg deionized water.

[0047] B component: 100kg epoxy modified acrylic emulsion.

[0048]Component C: 0.08kg lithium carbonate, 0.08kg L+ tartaric acid, 2kg basalt flakes, 0.2kg melamine superplasticizer, 0.2kg hydroxymethyl cellulose ether, 62kg high alumina cement, 35.44kg high alumina clinker.

[0049] Preparation of component A: Add curing agent into the stirring tank, add wetting agent and defoamer in sequence at a stirring speed of 400r / min and stir evenly, then add deionized water, stir evenly, and pack to obtain component A.

[0050] Preparation of component C: add high alumina cement, high alumina clinker, lithium carbonate, L+ tartaric acid, melamine water reducer, hydroxymethyl cellulose ether and basalt flakes into a gravity-free mixing tank and mix evenly, and pack to obtain C components.

[0051] Mix components A, B and C at a m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com