Process for preventing diamond scratch in process of CMP

A diamond and chemical-mechanical technology, applied in the field of using alkaline solution to prevent diamond scratches in the CMP process, can solve problems such as the loss of diamond grains in polishing finishers, scratches on the surface of wafers, etc., so as to reduce the possibility of falling off and avoid The effect of erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

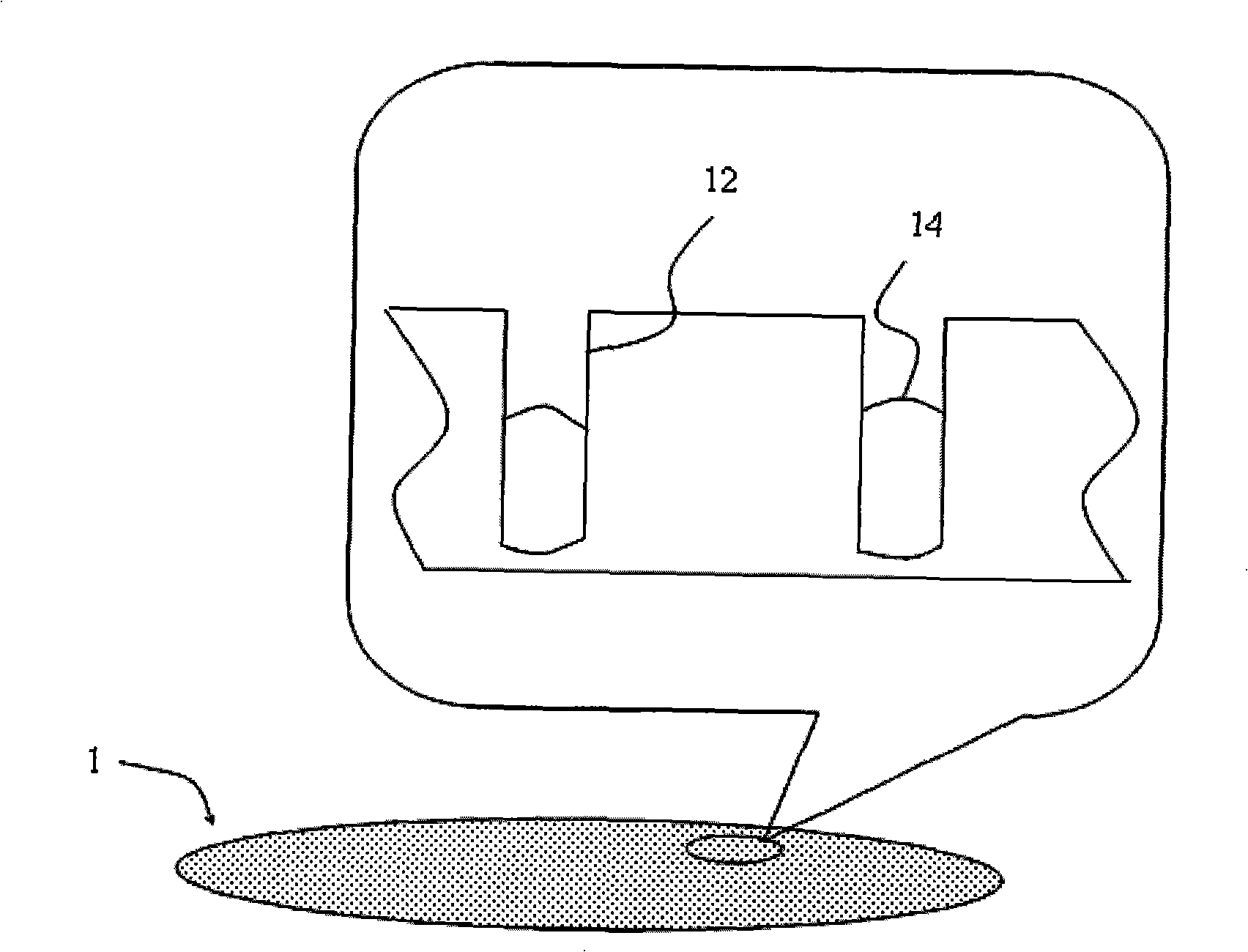

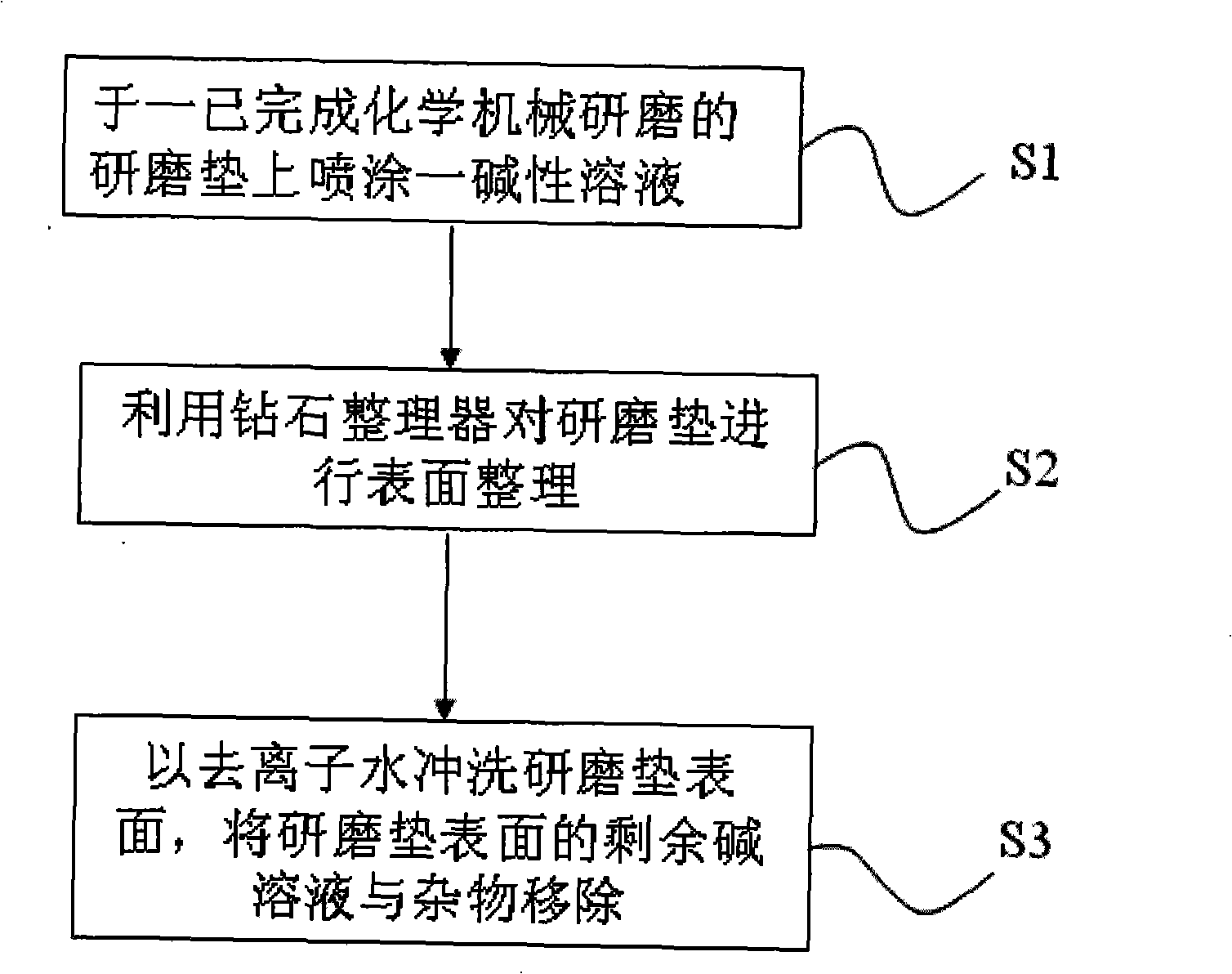

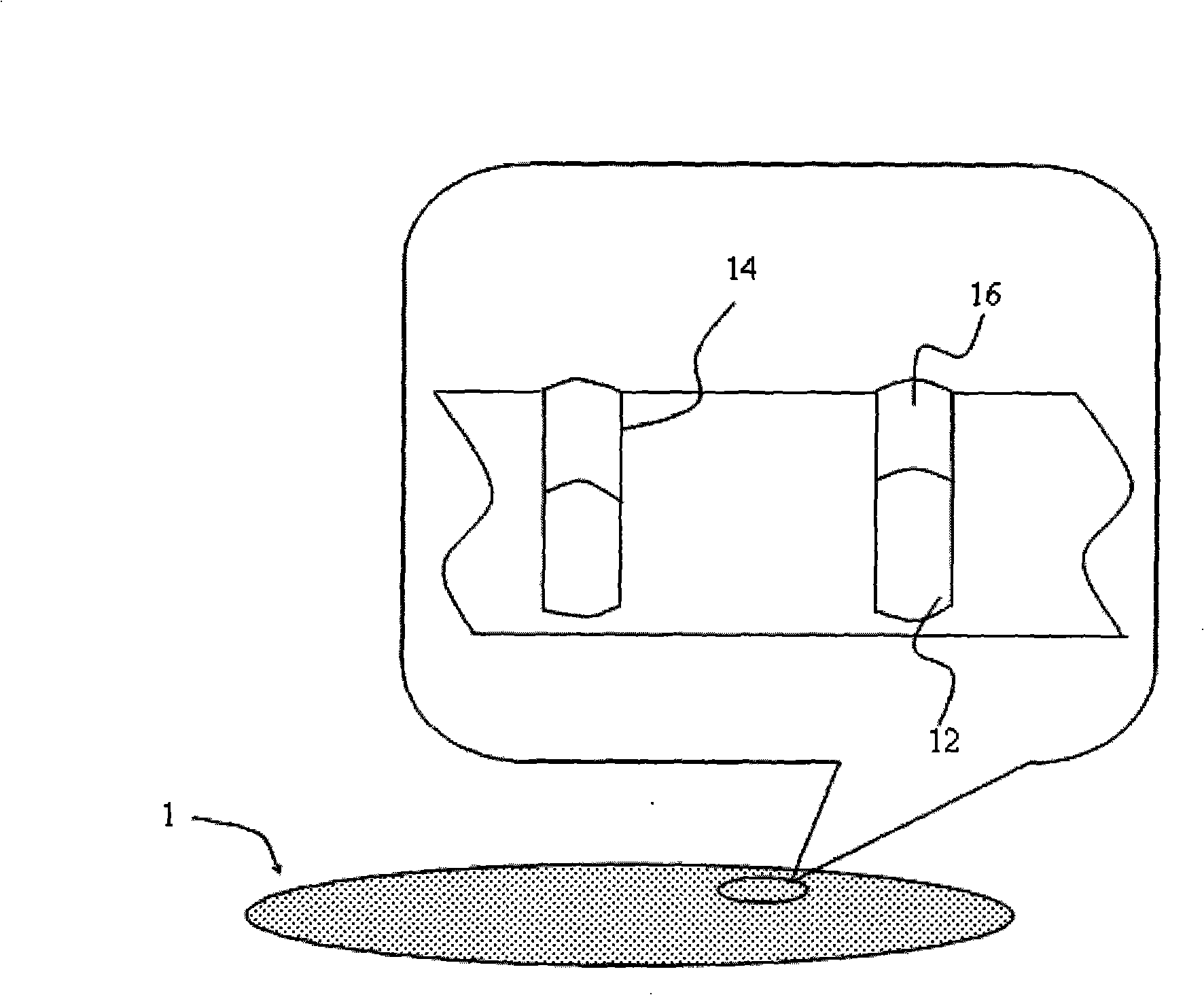

[0019] The present invention relates to a method for preventing diamond scratches during CMP, which can be widely applied to polishing pad finishing after CMP (chemical mechanical polish) process of various materials in semiconductor technology. In a preferred embodiment, the CMP process is performed on the tungsten metal layer as an example to illustrate the present invention, and those skilled in the art should know that many technical features in this example can be changed, such as the chemical composition of the polishing slurry, The shape design and material of the polishing plate, etc., but these equivalent changes will undoubtedly not depart from the spirit and scope of the present invention.

[0020] The CMP process of the tungsten metal layer mainly uses the polishing pad and the acidic polishing slurry composed of potassium ferricyanide, ferric nitrate, potassium iodate and hydrogen peroxide to perform chemical reaction and mechanical polishing on the tungsten metal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com