High-infiltration lithium ion battery diaphragm

A lithium-ion battery, wettability technology, applied in the direction of battery pack components, circuits, electrical components, etc., can solve the problems of poor liquid retention performance, liquid absorption, and poor liquid retention performance, achieve good compatibility, improve absorption liquid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

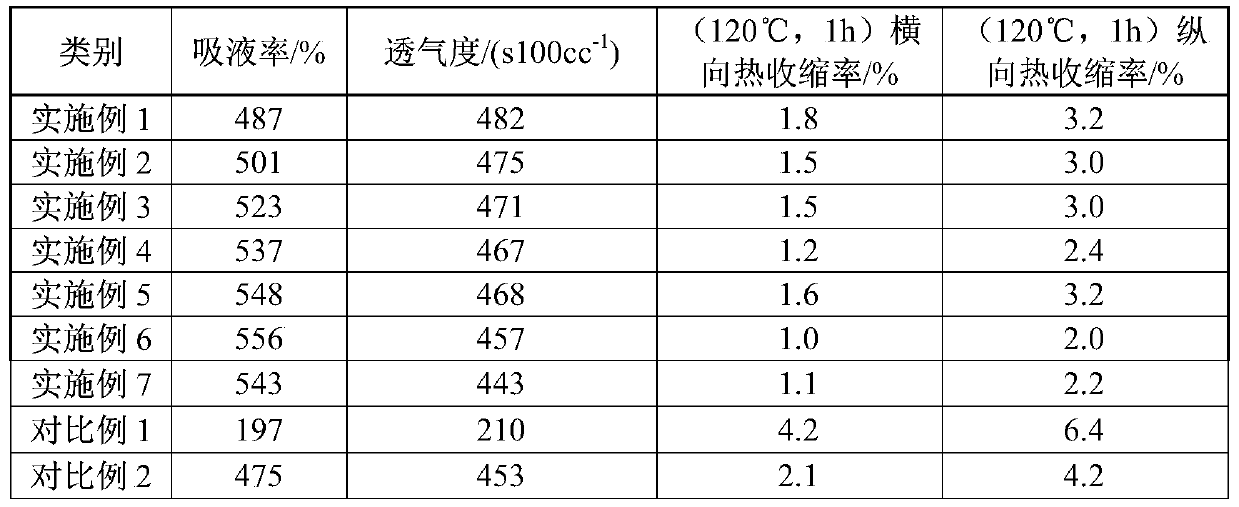

Examples

Embodiment 1

[0036] (a) First prepare maleic anhydride grafted hydroxypropyl-β-cyclodextrin, the preparation method is: completely dissolve 10g maleic anhydride with 15mL glacial acetic acid to form a mixed solution of maleic anhydride / glacial acetic acid, and weigh the pre-dried Add hydroxypropyl-β-cyclodextrin with a degree of substitution of 2.8 to 85 mL of glacial acetic acid solution to prepare a saturated solution. Under mechanical stirring, pass the obtained saturated solution of hydroxypropyl-β-cyclodextrin / glacial acetic acid through Add a constant pressure dropping funnel dropwise into the mixed solution of maleic anhydride / glacial acetic acid at a rate of 4-5d / s, add a certain amount of sodium acetate, stir and dissolve at 90°C for 6 hours, and wait for infrared detection at 1700cm -1 The asymmetric absorption peak of the anhydride on the maleic anhydride disappears, that is, the reaction is stopped, cooled to room temperature, the reactant is poured into 200mL distilled water, l...

Embodiment 2

[0045] Others are the same as in Example 1, except that the mass percentages of maleic anhydride grafted hydroxypropyl-β-cyclodextrin, zirconia, and PVA in ethanol solution in step (c) during the preparation process are: 30%, 10%, 1%;

[0046] In step (d), the total thickness of the functional coating on both sides of the polyethylene composite microporous membrane is 3 μm, and the others are the same as in Example 1.

Embodiment 3

[0048] Others are the same as in Example 1, except that the mass percentages of maleic anhydride grafted hydroxypropyl-β-cyclodextrin, zirconia, and PVA in ethanol solution in step (c) during the preparation process are: 30%, 10%, 1%;

[0049] In step (d), the total thickness of the functional coating on both sides of the polyethylene composite microporous membrane is 5 μm, and the others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com