Patents

Literature

209results about How to "Improve liquid retention capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite porous isolating film and electrochemical device

ActiveCN103904276AImprove puncture strengthImprove thermal stabilitySecondary cellsCell component detailsPorous substratePorous coating

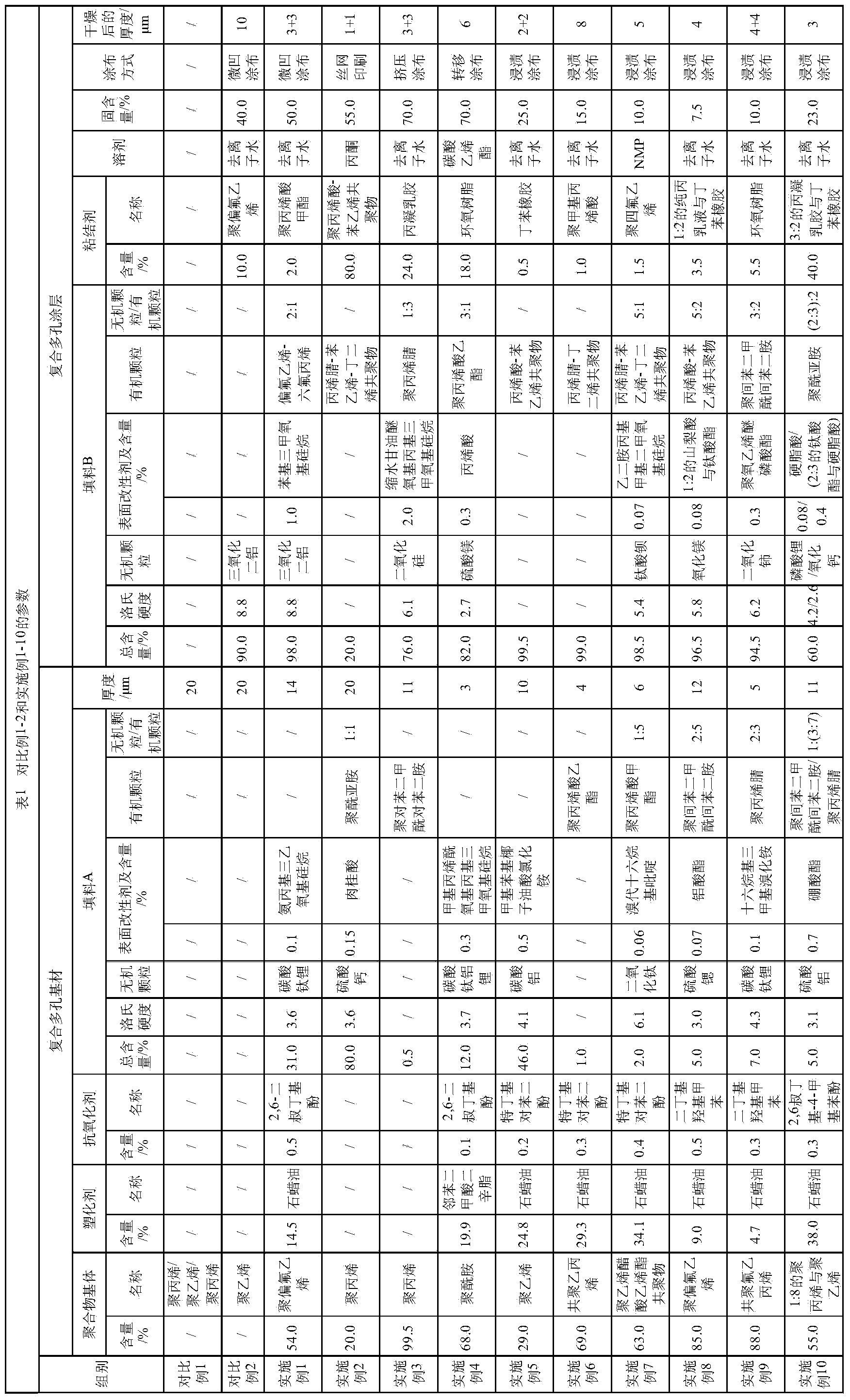

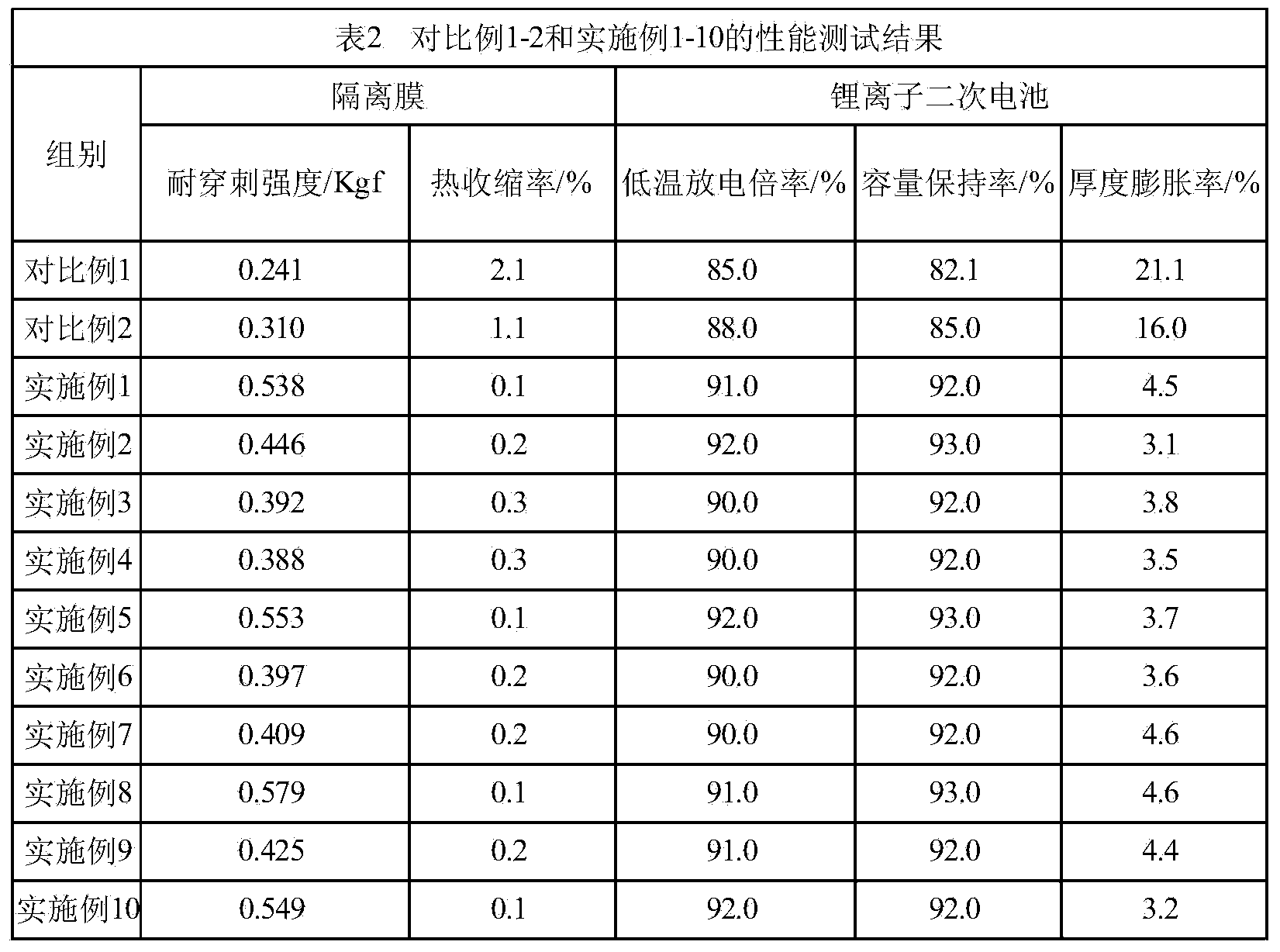

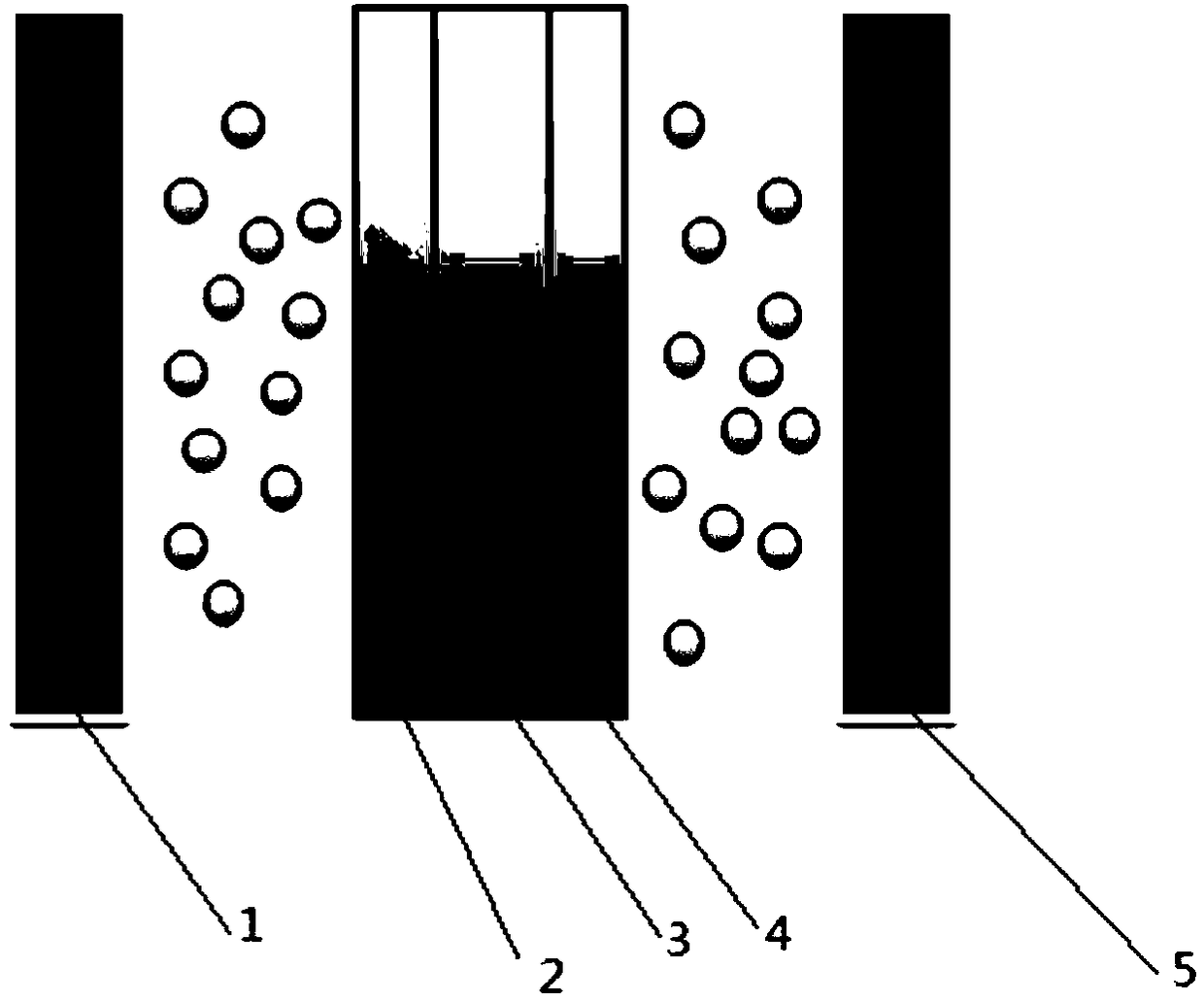

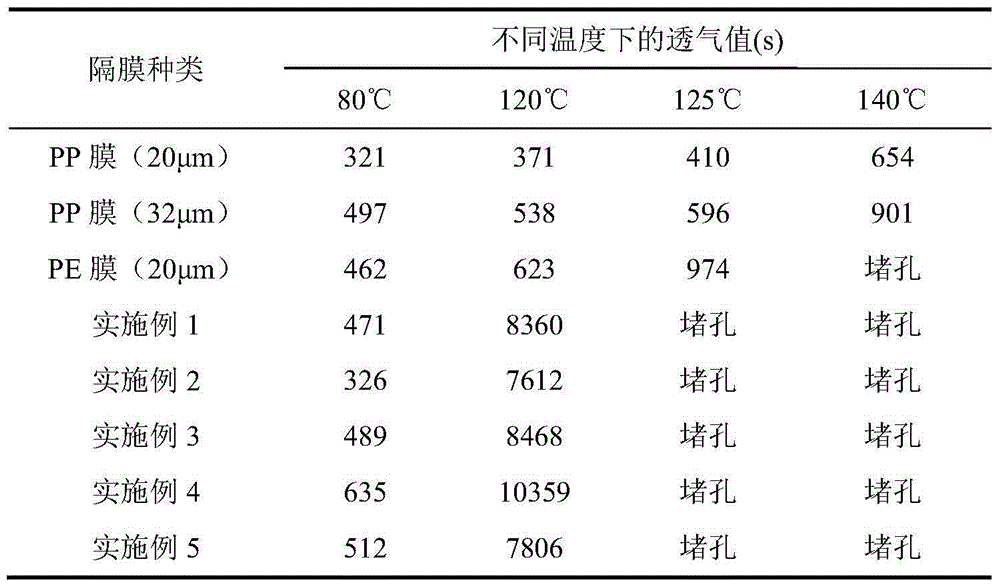

The invention provides a composite porous isolating film and an electrochemical device. The composite porous isolating film comprises a composite porous base material and a composite porous coating which is coated on at least one surface of the composite porous base material. The composite porous base material comprises filler A and a polymer substrate, and the filler A is selected from at least one of inorganic particles and organic particles; the composite porous coating comprises filler B and an adhesive, and the filler B is selected from at least one of inorganic particles and organic particles. The electrochemical device has a composite porous isolating film. By adopting the composite porous isolating film, the heat stability of the composite porous isolating film is improved, the deformation resistance and the capacity maintaining rate of the electrochemical device can be improved, and the cycling performance and low-temperature kinetic performance of the electrochemical device can be improved.

Owner:DONGGUAN AMPEREX TECH

Coated diaphragm for ternary lithium ion battery, and preparation method thereof

PendingCN108550762ANot easy to shrinkImprove thermal safety and stabilitySecondary cellsCell component detailsHigh temperature storagePower battery

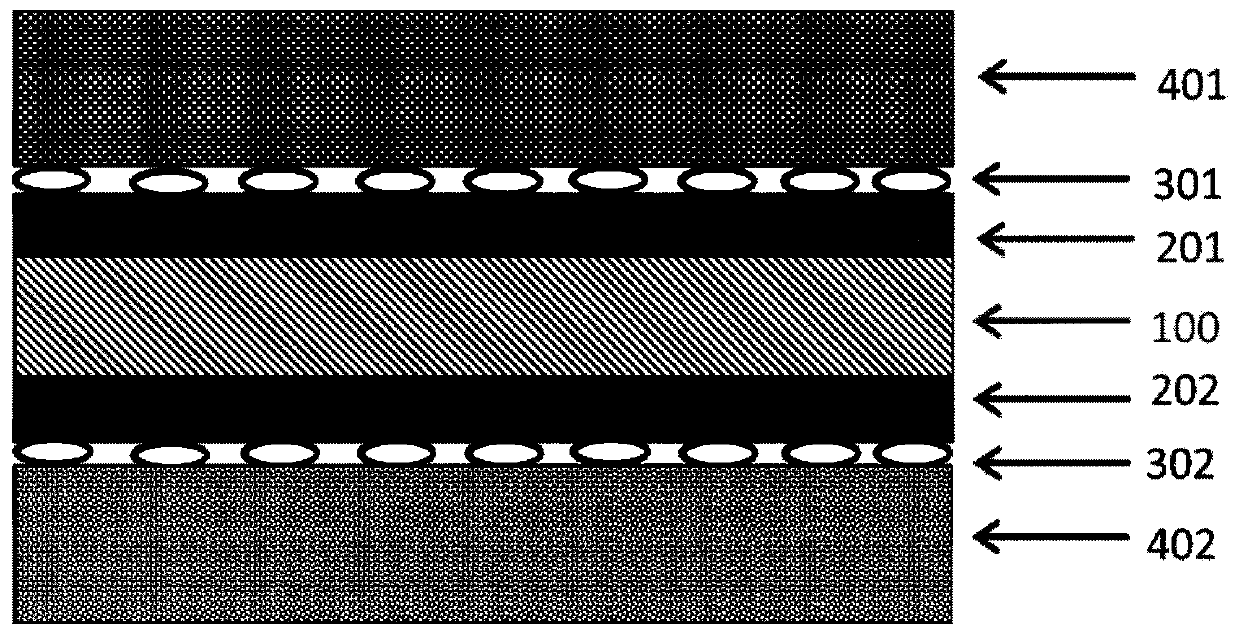

The invention discloses a coated diaphragm for a ternary lithium ion battery, and a preparation method thereof. The coated diaphragm comprises a diaphragm substrate, a ceramic / graphene composite coating and a PVDF coating, two sides of the diaphragm substrate are respectively coated with the ceramic / graphene composite coating and the PVDF coating, the ceramic / graphene composite coating correspondsto a battery positive electrode, and the PVDF coating corresponds to a battery negative electrode. The positive electrode side is the ceramic / graphene composite coating, so no shrinkage of the coateddiaphragm at a high temperature is ensured, and short circuit, explosion and other safety hazards of the coated diaphragm are avoided; the negative electrode side is the PVDF coating, so the internalheat conduction performance of the battery is enhanced to a certain degree, the high-temperature storage performance of the battery is improved, the wettability and the liquid retention property of the coated diaphragm are increased, and the coated diaphragm and an electrode sheet are bonded to inhibit structural collapse of the negative electrode in the charging and discharging process; and thesuperposition of the two coatings greatly improves the safety, the cycle performance and the rate performance of the ternary lithium ion battery material are greatly improved, and the large-scale application of the coated diaphragm on a power battery is promoted.

Owner:余姚市海泰贸易有限公司

Lithium ion battery composite separator, preparation method thereof, and lithium ion battery

InactiveCN105140450APrevent internal short circuitGood high temperature resistanceCell seperators/membranes/diaphragms/spacersFinal product manufactureLithium electrodeElectrochemistry

The invention relates to a lithium ion battery composite separator, a preparation method thereof, and a lithium ion battery, and belongs to the technical field of lithium ion batteries. The lithium ion battery composite separator comprises a base film; one side of the base film is coated with a hot-melting polymer coating; the other side of the base film is coated with a heat-proof coating; the melting temperature of the hot-melting polymer coating is lower than the hot-melting temperature of the base film; the melting temperature of the heat-proof coating is higher than the hot-melting temperature of the base film; the hot-melting polymer coating comprises the following ingredients by weight: 50 to 98 parts of one or more hot-melt polymer materials, and 2 to 50 parts of one or more agglomerants; the heat-proof coating comprises the following ingredients by weight: 50 to 92 parts of one or more heat-proof polymer materials, and 3 to 20 parts of one or more agglomerants. The lithium ion battery composite separator is favorable in liquid sucking and retention properties, low in heat blocking hole temperature, and high in separator breaking temperature, thereby being capable of obviously improving the safety and the electrochemical property of the battery.

Owner:CHINA AVIATION LITHIUM BATTERY LUOYANG

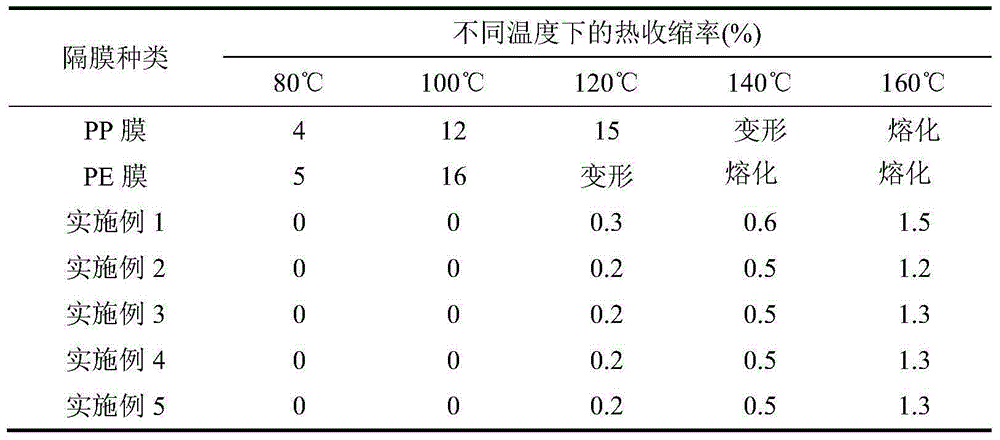

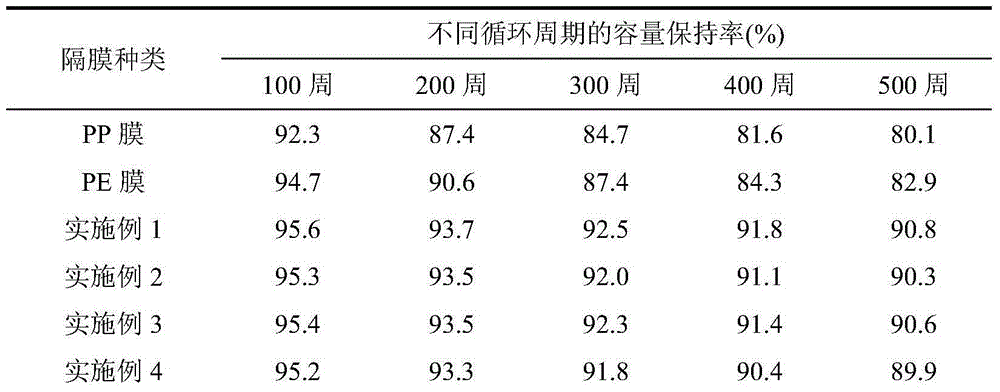

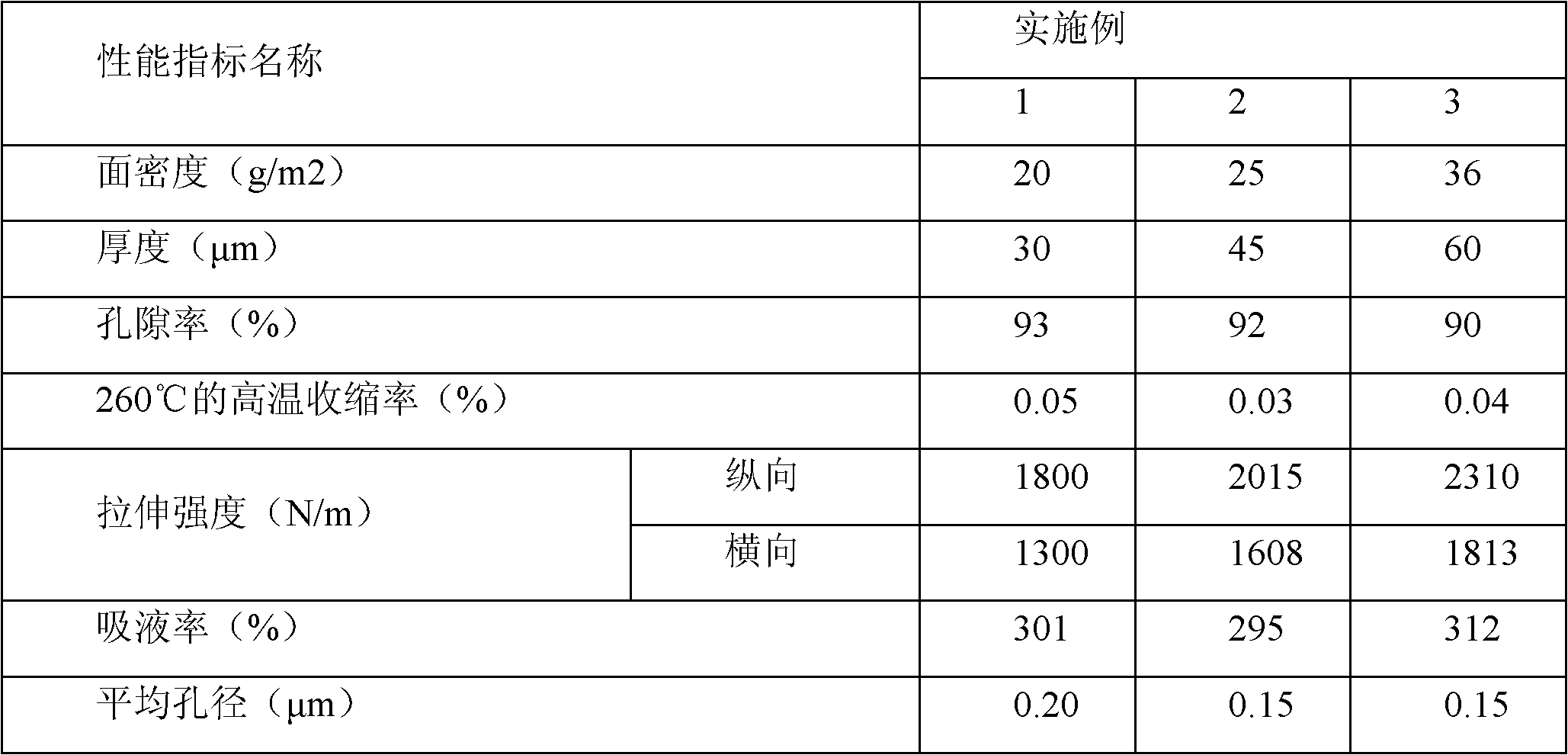

High-temperature resistant micropore thin film material and application thereof

ActiveCN102522514AImprove liquid absorption performanceExcellent liquid retentionCell component detailsPorosityAdhesive

The invention relates to a high-temperature resistant micropore thin film material prepared from inorganic fiber, synthetic fiber, natural organic fiber, nano-grade inorganic powder and an adhesive. The thin film material is a non-woven fabric material prepared through one-step molding with a wet papermaking technology combined with a coating technology. The material has a 3-dimensional network structure and porosity higher than 90%. The high-temperature resistant micropore thin film material has an outstanding high-temperature resistance. Under a temperature of 260 DEG C, excellent dimension and structure stabilities of the material are maintained for a long time. The material has excellent liquid absorbency, excellent liquid retaining capacity, and 3-dimensional stereo pores with good uniformity. An average pore size is 0.02-2.5mum. The high-temperature resistant micropore thin film material can be used as lithium ion power battery separation films, super-capacitor separation films, or filtrating materials.

Owner:莱州联友金浩新型材料有限公司

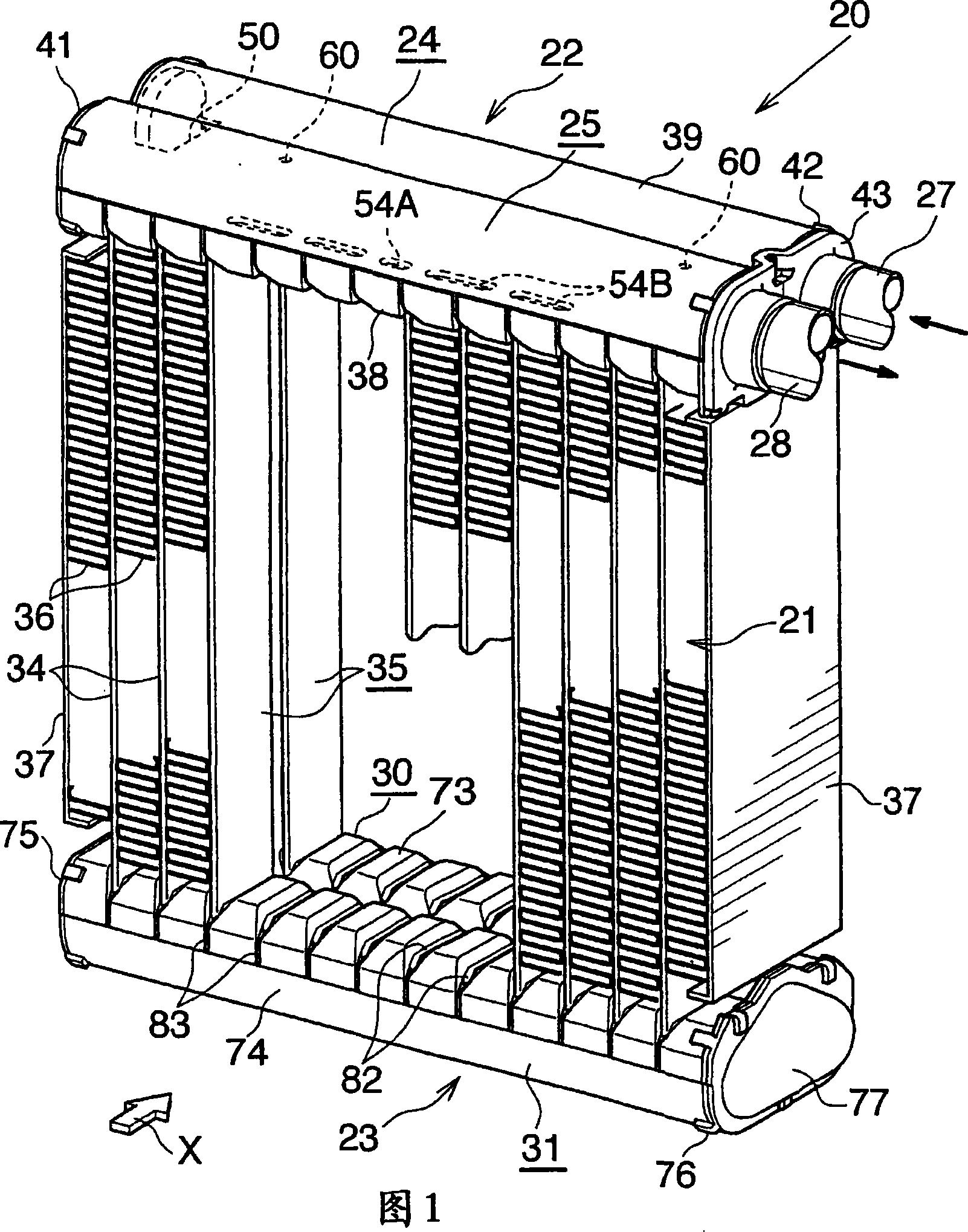

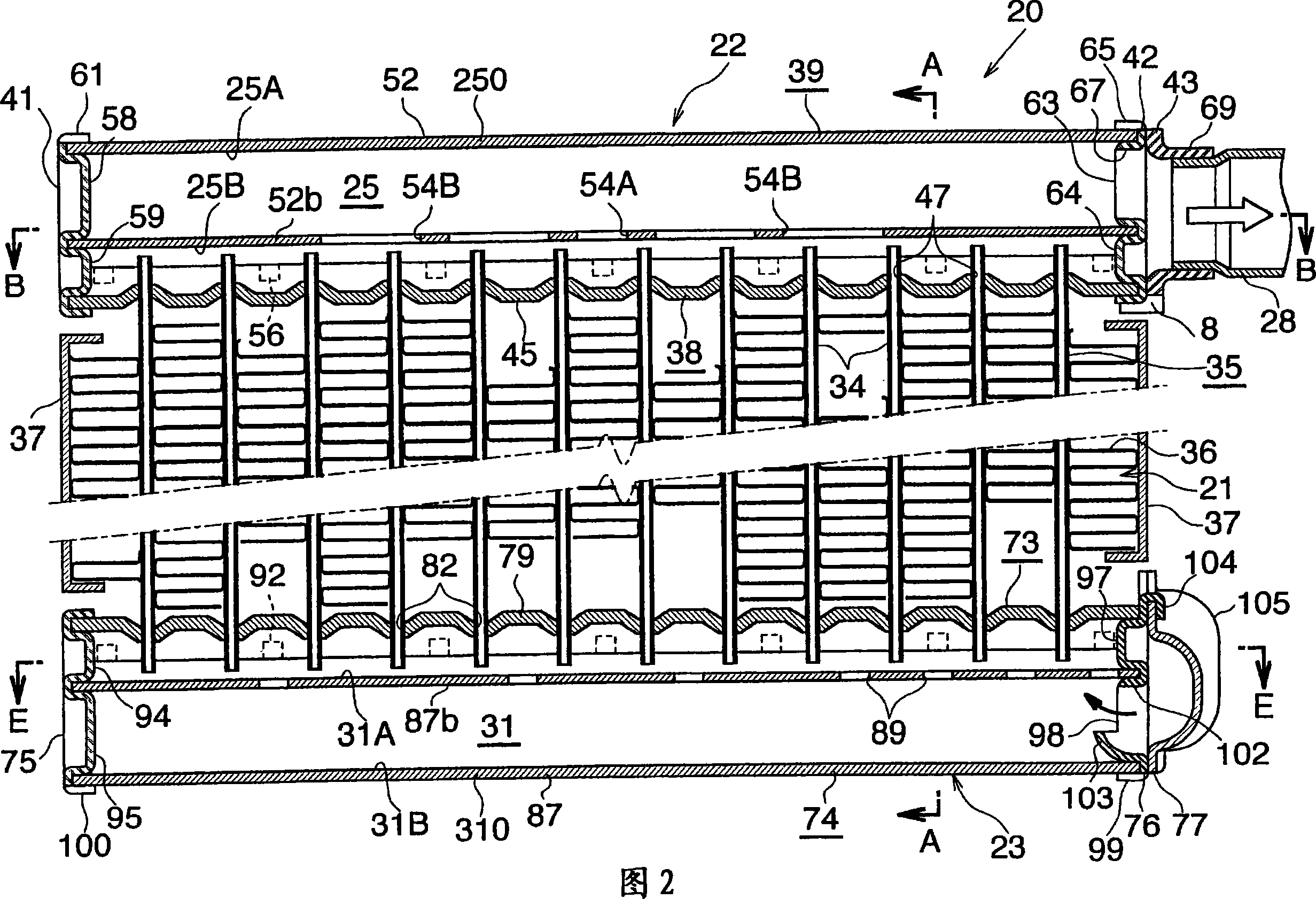

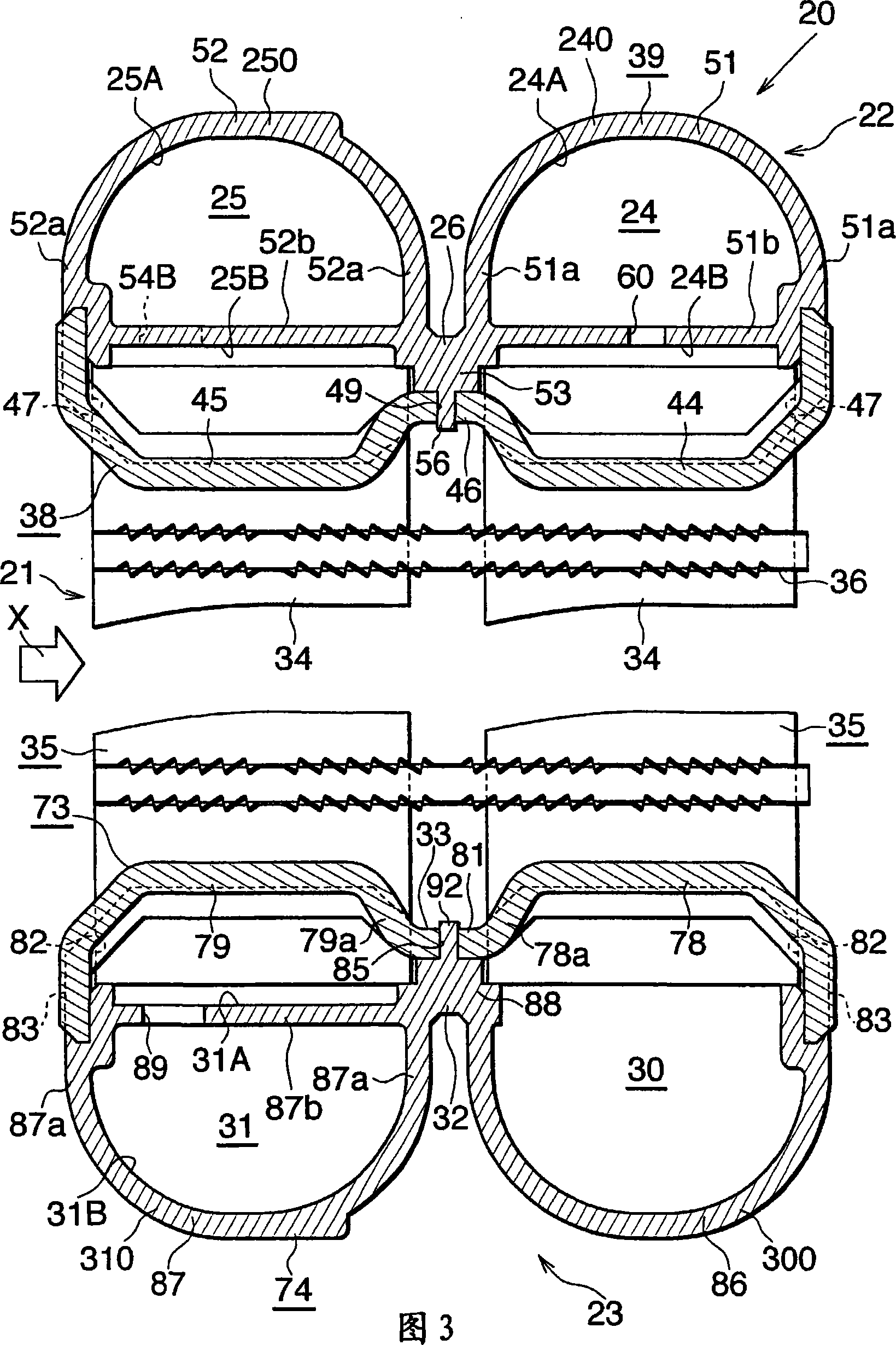

Heat exchange tube and evaporator

InactiveCN101082470AImprove liquid retention capacityImprove comfortEvaporators/condensersClosure meansTemperature differenceEngineering

An evaporator includes a plurality of flat heat exchange tubes extending in a vertical direction and arranged at intervals along a left-right direction with a width direction thereof coinciding with a front-rear direction. The heat exchange tube has a plurality of refrigerant channels arranged along the width direction. The evaporator satisfies a relation 0.558<=A<=1.235, where A is a value in pieces / mm obtained by dividing the number N of the refrigerant channels of the heat exchange tube by a width W of the heat exchange tube as measured in the front-rear direction. Also, the evaporator satisfies a relation 0.35<=Dh<=1.0, where Dh is an equivalent diameter in mm of the heat exchange tube. This evaporator can reduce the temperature difference between air discharged into a compartment when a compressor is turned ON and that when the compressor is turned OFF.

Owner:KEIHIN THERMAL TECH CORP

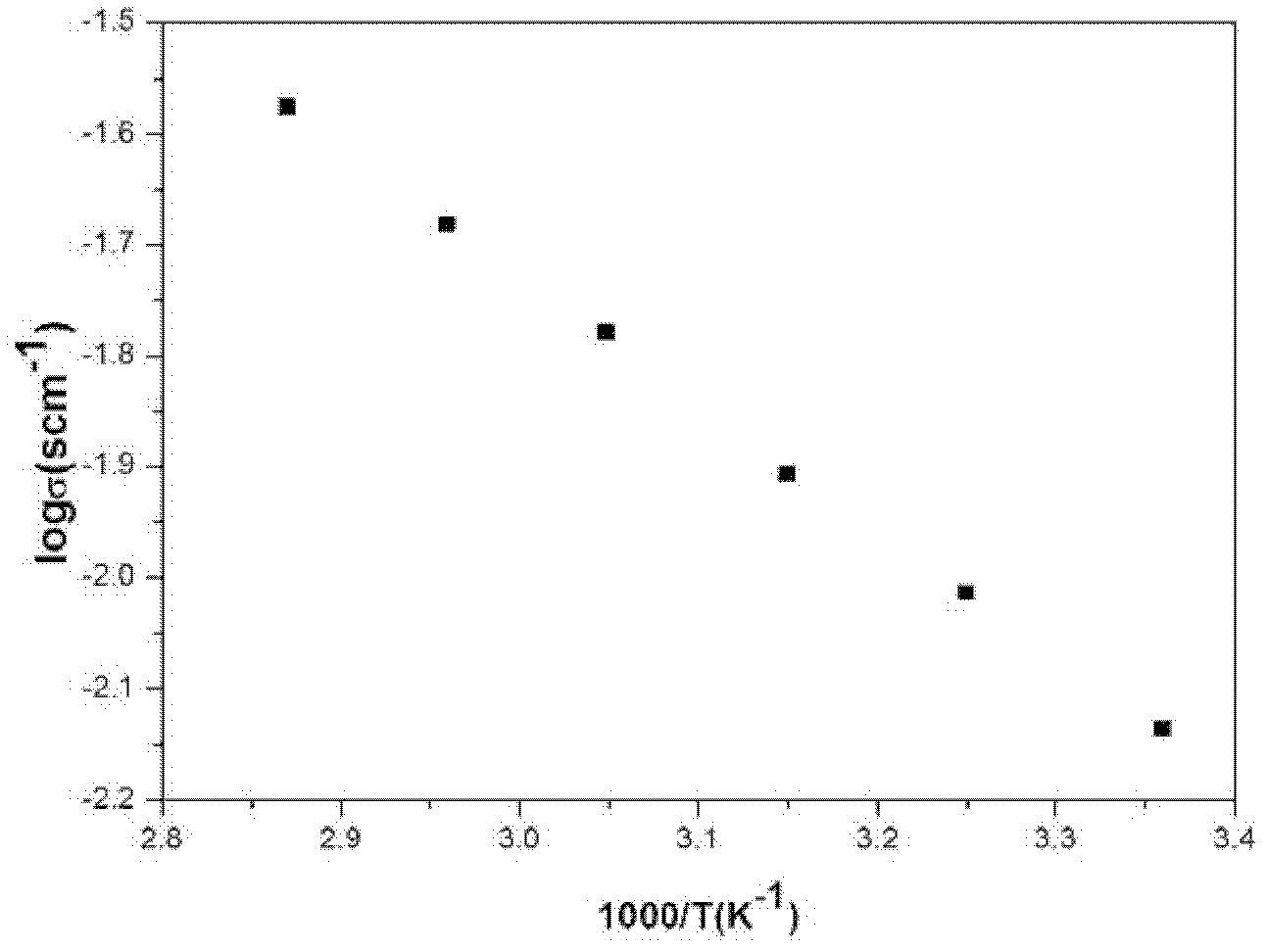

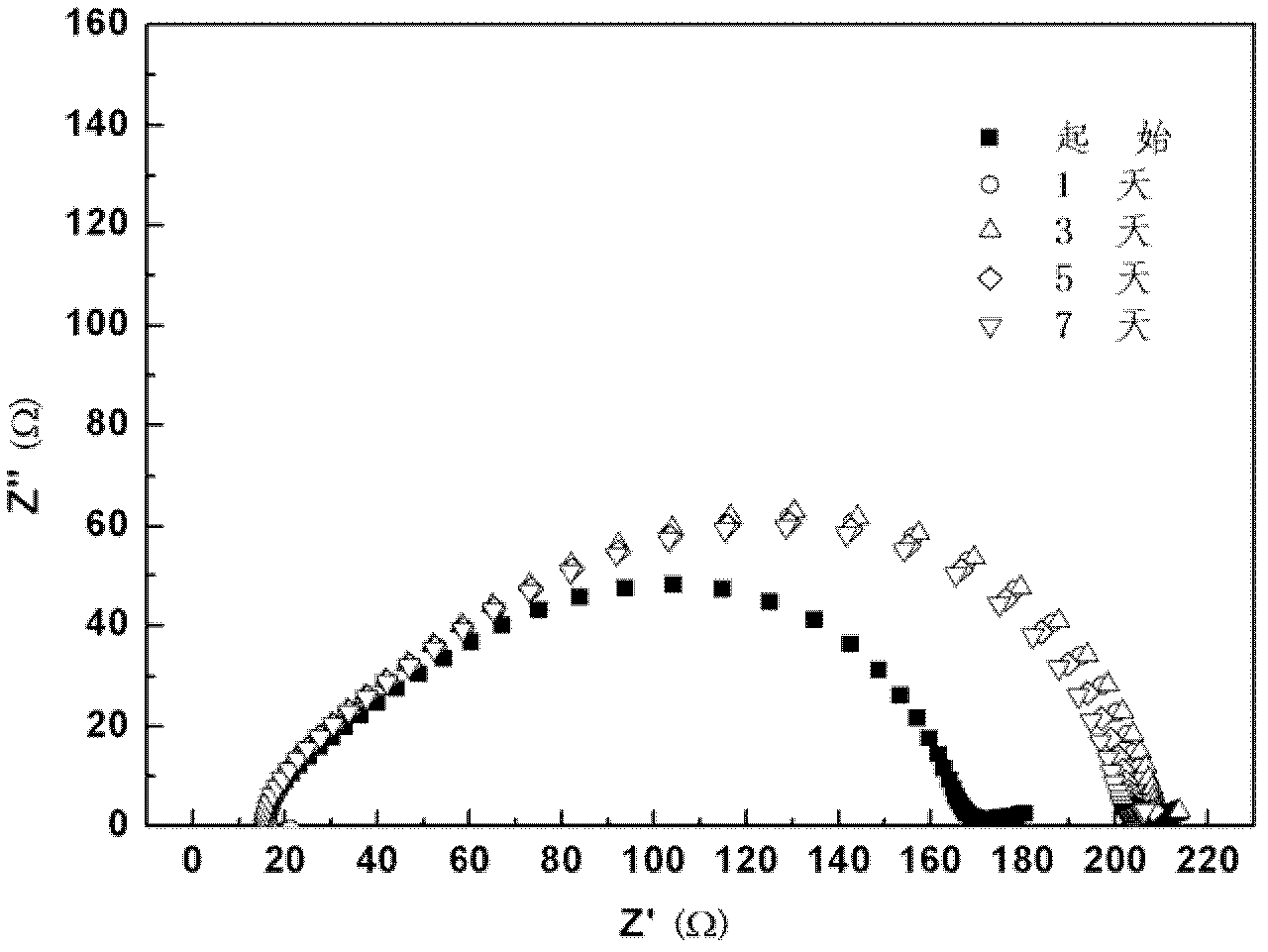

Gel polymer electrolyte preparation method based on 3D printing technology

The invention provides a gel polymer electrolyte preparation method based on a 3D printing technology. The 3D printing technology is used for printing a framework with a network structure inside; theframework is put into a methyl methacrylate monomer mixed solution comprising a cross-linking agent and an initiator to be dipped for a period of time; a vacuum high-temperature condition is adopted for initiation cross linking of methyl methacrylate; and the obtained framework rich in polymethyl methacrylate is immersed in an electrolyte solution for a period of time, so as to obtain a framework-reinforced gel polymer electrolyte. The framework is obtained through 3D printing, so that size of the gaps of the framework can be adjusted and controlled, the three-dimensional net structure, formedby crosslinking polymerization with polymethyl methacrylate, can form a relatively stable structure; and therefore, when the gel polymer electrolyte is formed, the strength of the electrolyte is greatly improved by the framework material, thereby overcoming the defect that an existing gel polymer electrolyte is not high in strength.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

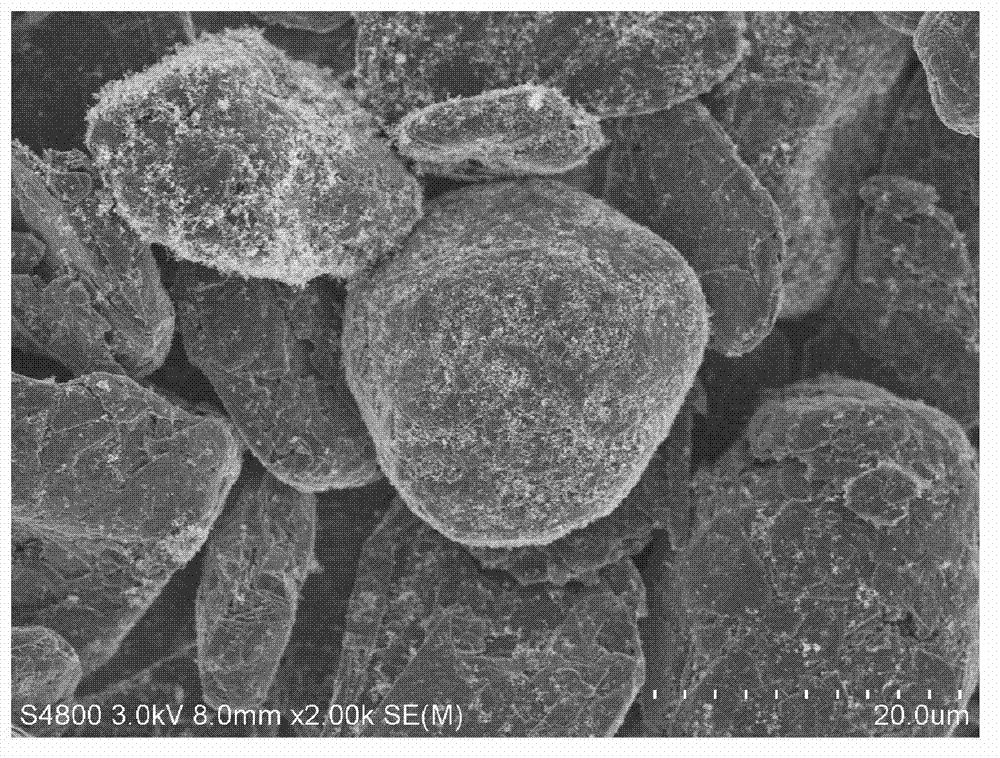

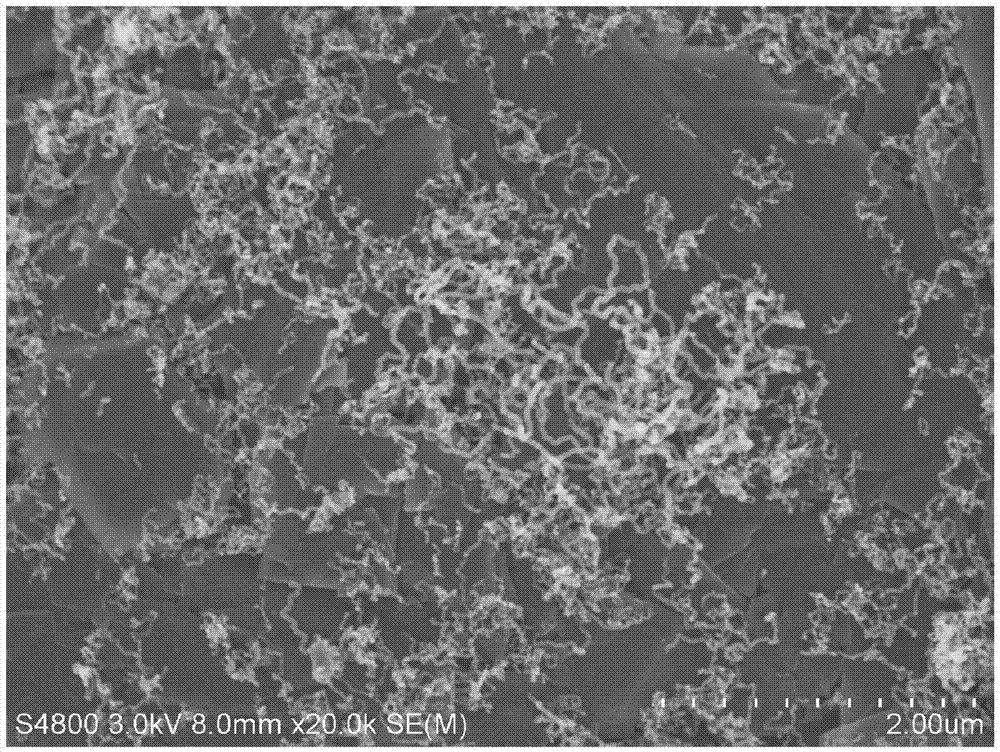

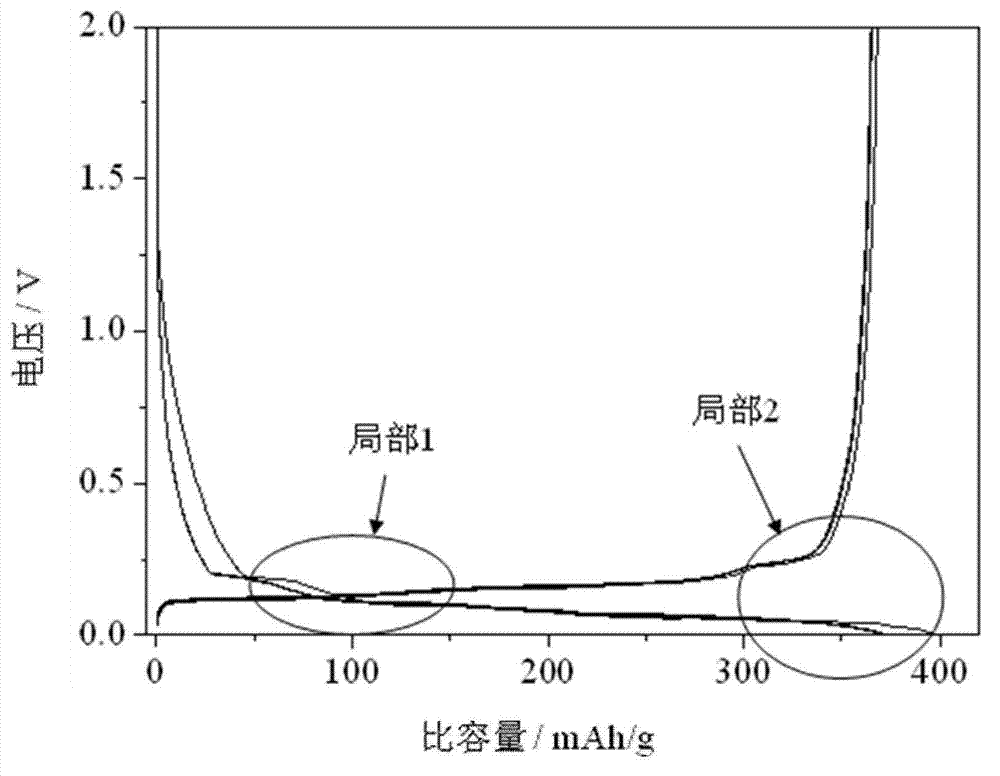

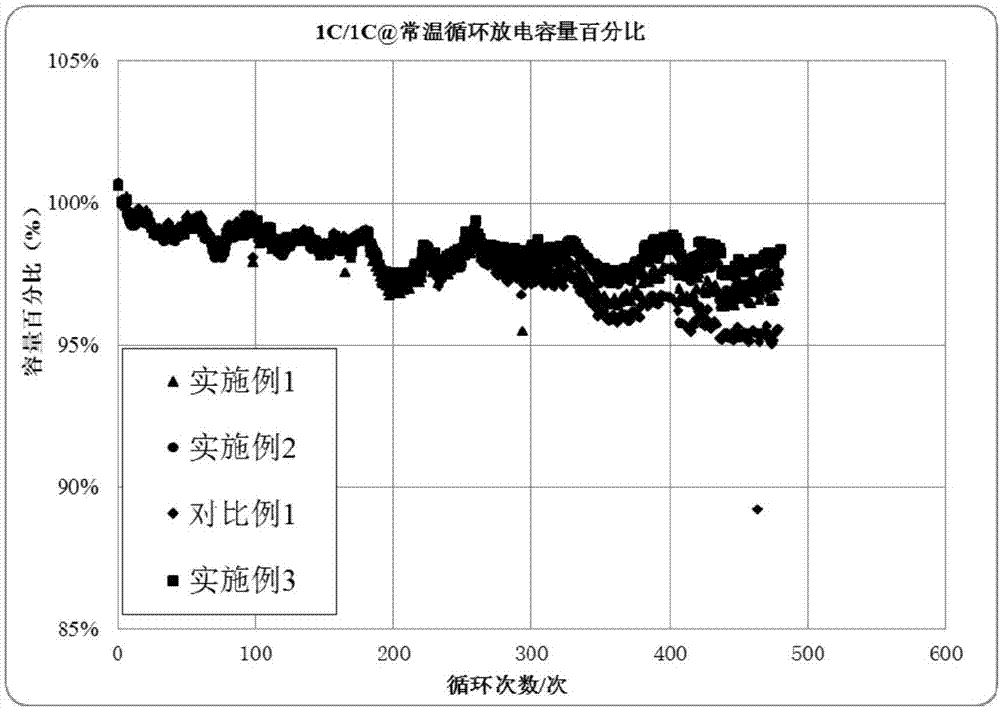

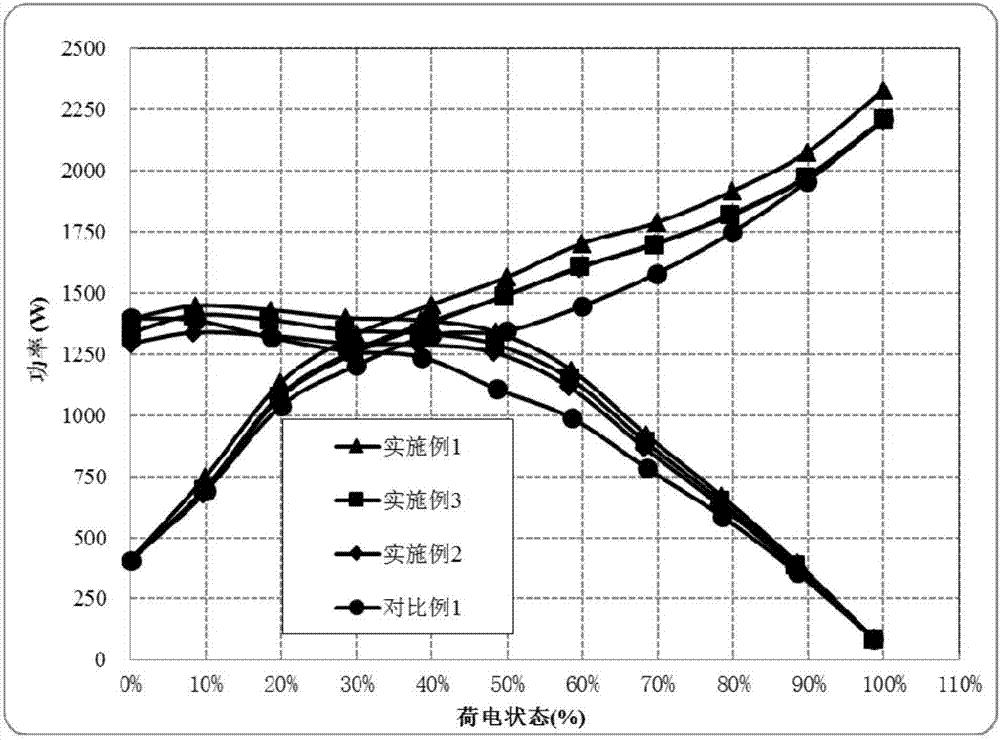

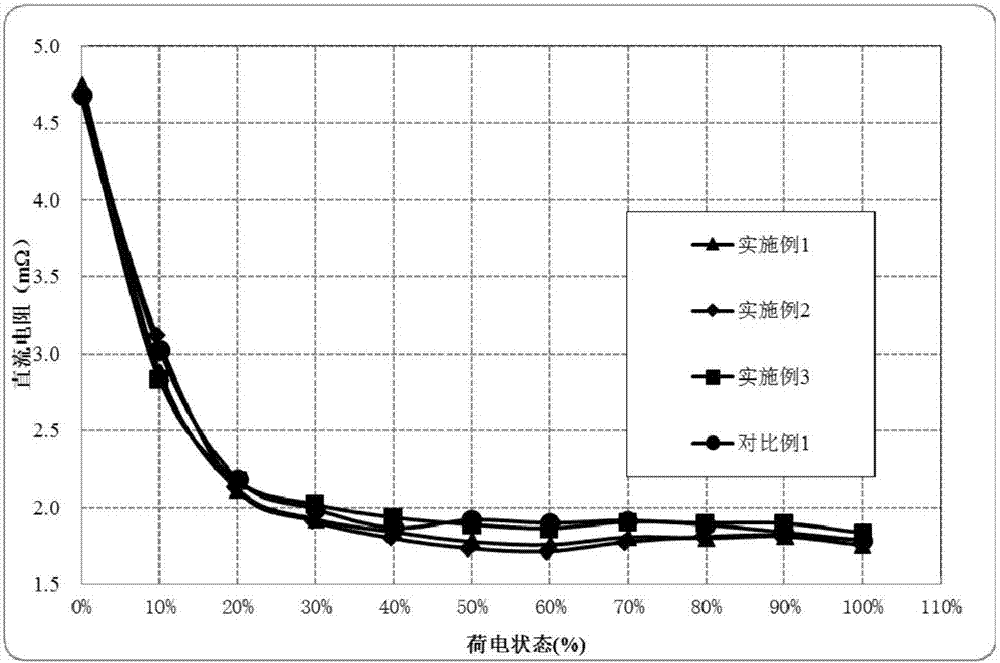

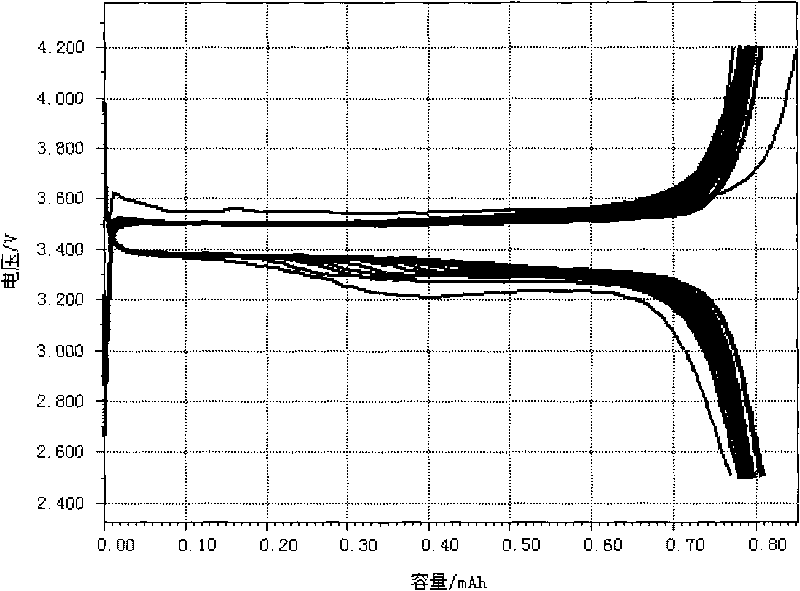

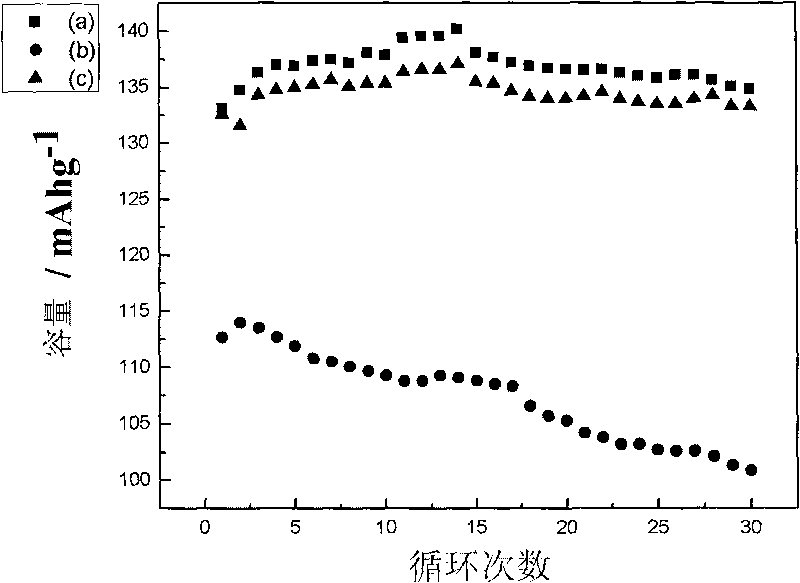

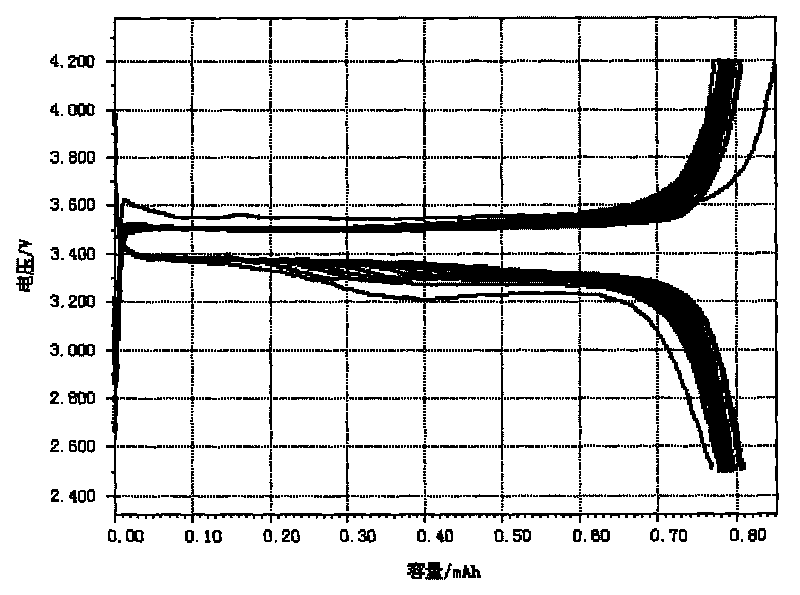

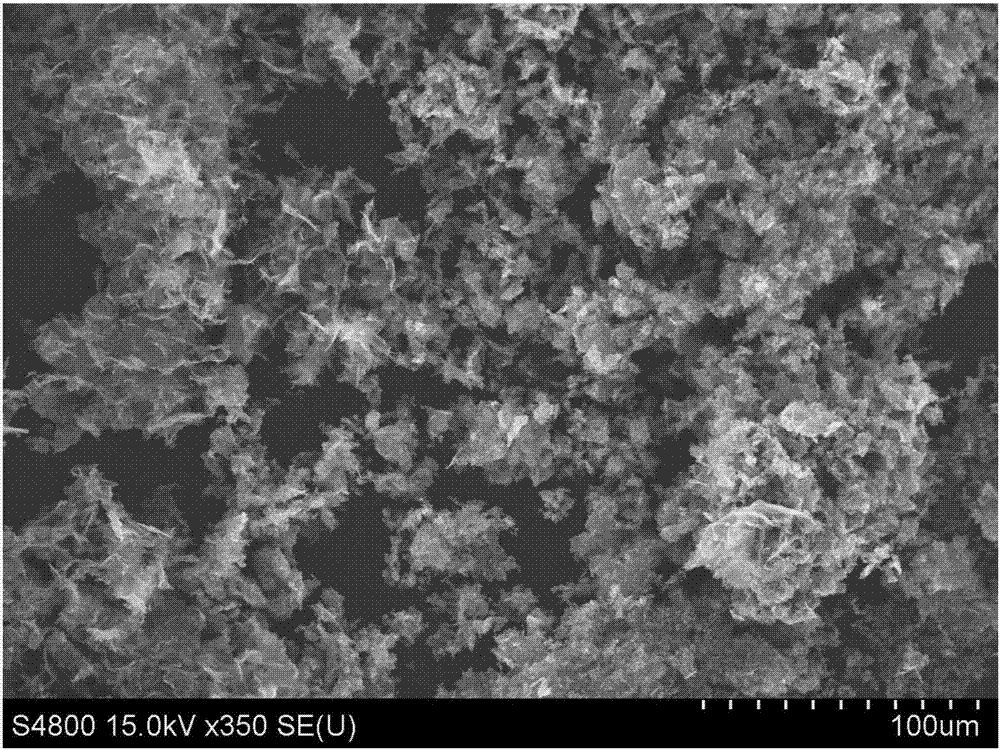

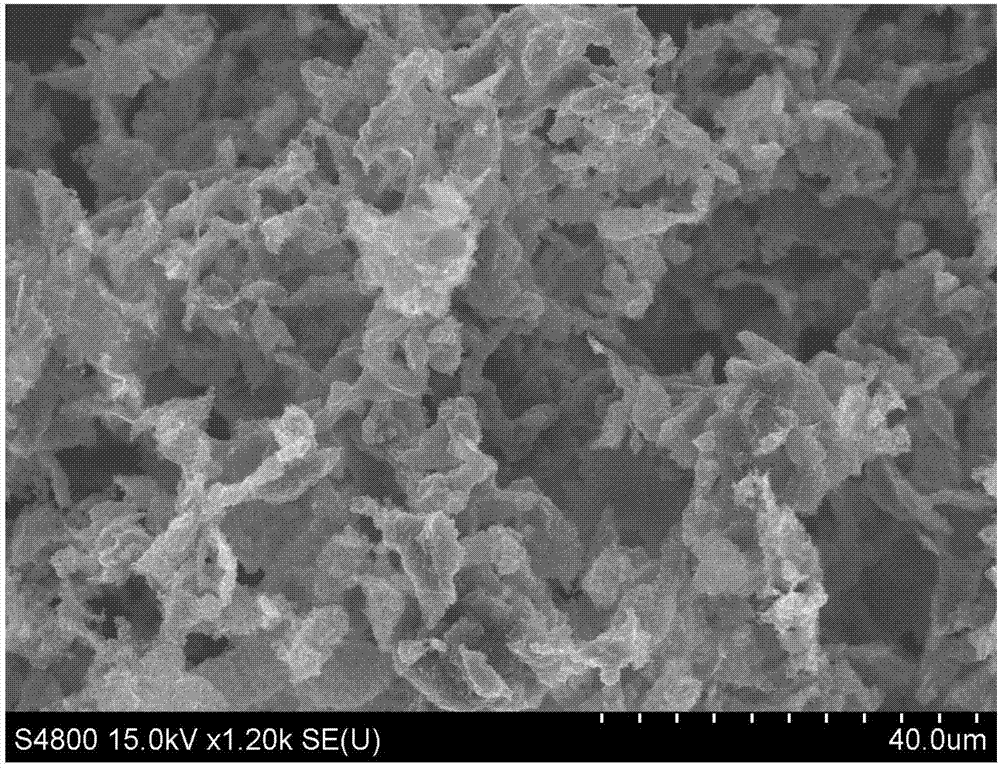

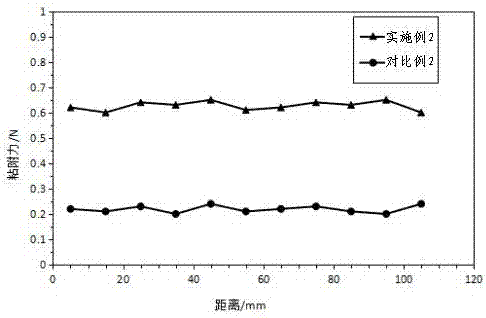

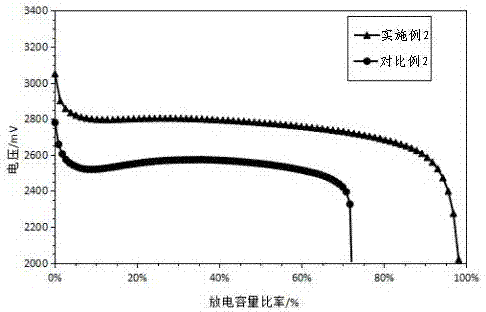

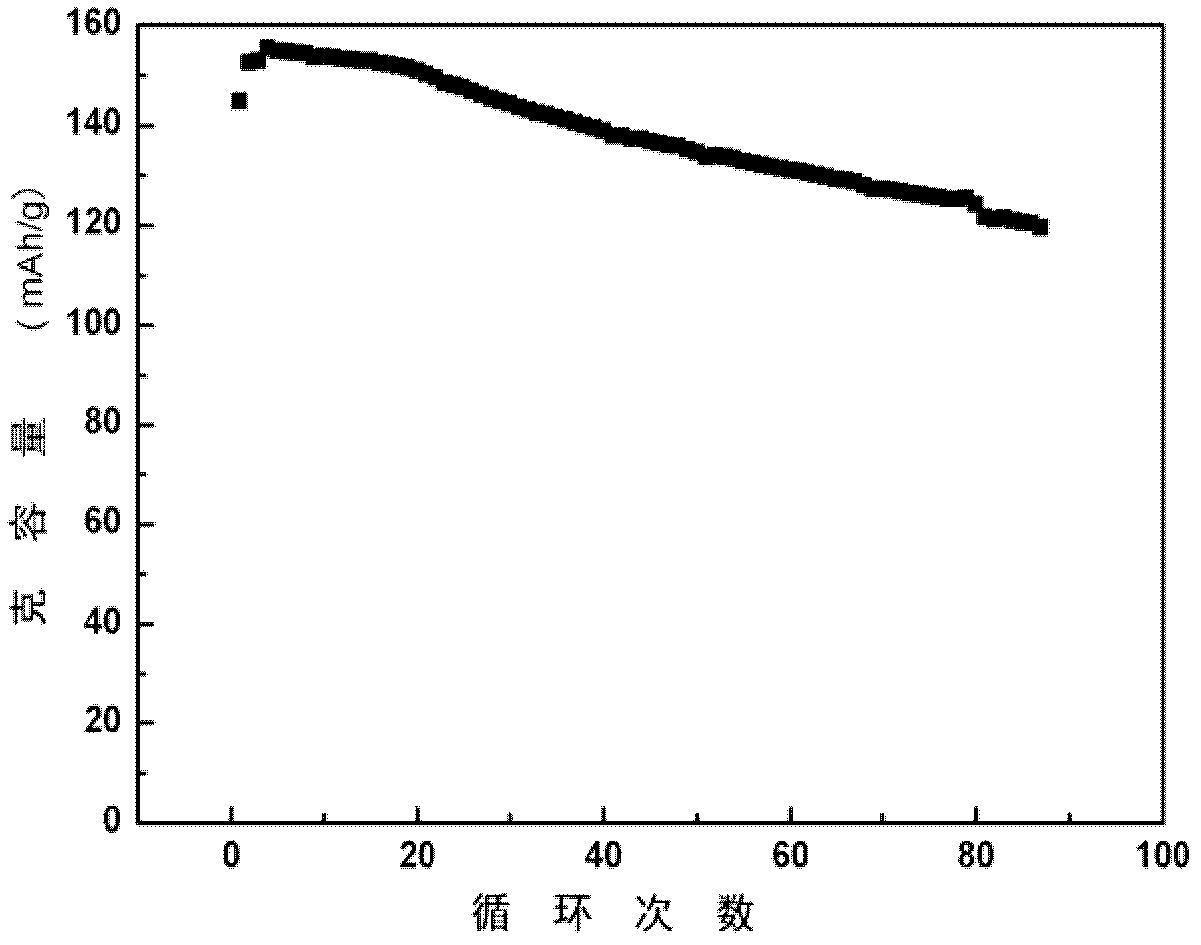

Graphite composite negative electrode material for lithium ion battery, preparation method of material, and lithium ion battery

ActiveCN103247802AImprove conductivityImprove liquid retention capacityCell electrodesSecondary cellsLithium electrodeIn process control

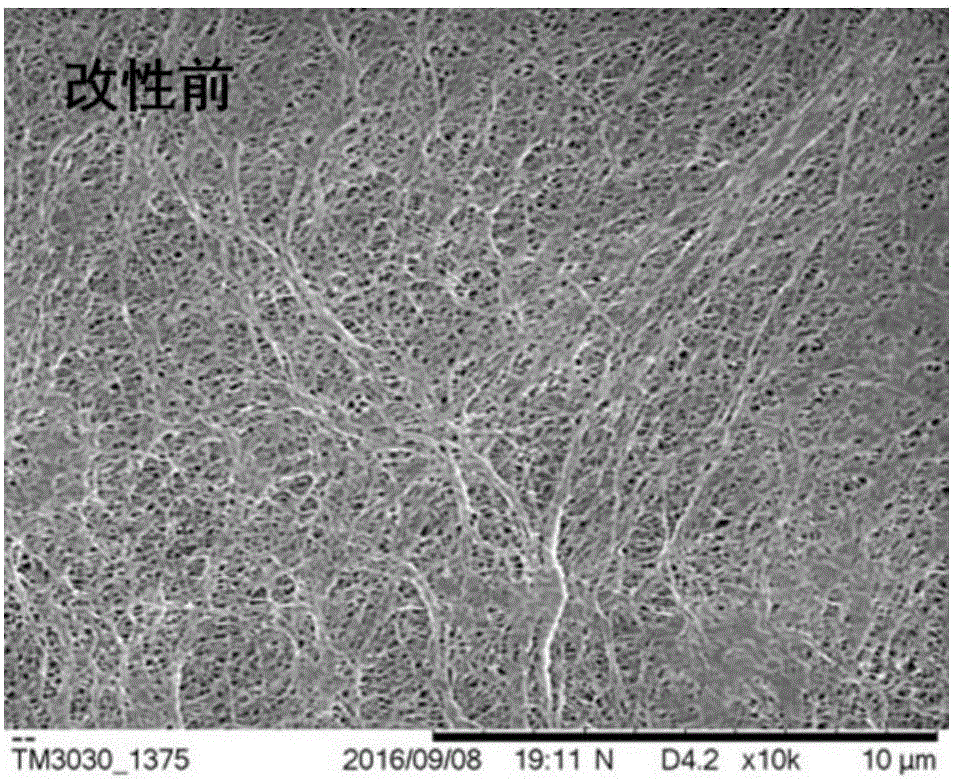

The invention discloses a graphite composite negative electrode material for a lithium ion battery, a preparation method of the material, and the lithium ion battery. The graphite composite negative electrode material for the lithium ion battery has a core-shell structure, wherein graphite is used as an inner core; carbon nano tubes and / or carbon nanofibers which are uniformly distributed on the surface of the graphite and are in in-situ growth are used as the shell; the growth root points of the carbon nano tubes and / or the carbon nanofibers are in tight contact with the surface of the graphite; and the other ends of the carbon nano tubes and / or the carbon nanofibers are distributed on the surface of the graphite randomly. The preparation method comprises the following steps of: fully soaking the graphite as a raw material by a catalyst-containing solution, and drying to obtain a graphite composite material precursor; performing chemical vapor deposition to generate the carbon nano tubes and / or the carbon nanofibers; and finally performing the purification and annealing treatment. The graphite composite negative electrode material has high height ratio, conductivity, and rate capability, and excellent solution absorption performance and cycle performance; and the method is simple in production flow, accurate in process control, low in cost, free from severe conditions, and easy to realize the industrialization.

Owner:BTR NEW MATERIAL GRP CO LTD

Surface coating for improving security performance of power lithium ion battery, surface coating application and power lithium ion battery

InactiveCN107394113AImprove cycle lifeImprove securityCell electrodesSecondary cells servicing/maintenancePower batteryElectrical battery

The invention discloses surface coating for improving the security performance of a power lithium ion battery, a surface coating application and the power lithium ion battery. The component of the surface coating slurry of the surface coating is alpha-Al<2>O<3> or AlOOH. The solid content of the surface coating slurry is 5%-50%. The surface coating is coated on the surface of a cathode plate, an anode plate or diaphragm of the battery. The thickness of the surface coating is about 1-15[mu]m. After a surface coating modification technology is applied to the power battery, the direct contact with the cathode plate and anode plate of the battery is avoided; the internal resistance of the battery in a thermal runaway state is clearly increased through adoption of an insulation characteristic of the surface coating; and the heat stability of the cathode plate and anode plate in the thermal runaway state of the battery is improved. Moreover, through application of the surface coating technology, the liquid preserving capability of the battery can be improved, the oxidation of electrolyte is inhibited, and the stability of SEI film is improved, so the service life of the battery is clearly improved. According to the application of the surface coating technology, the security performance of the power battery can be clearly improved, and the circulation capability of the power battery can be properly improved.

Owner:天津中科先进技术产业有限公司

Method for preparing lithium ion battery membrane via radiation grafting modification by using polypropylene film

InactiveCN101735470AFlexible change of grafting rateAdjust the amount of introductionCell component detailsWater bathsN dimethylformamide

The invention relates to a method for preparing lithium ion battery membrane via radiation grafting modification by using a polypropylene film, belonging to the technical field of high polymer material modification. The method comprises the main processes of: (1) preparing a grafting reaction reagent system and using methacrylic acid shrinkage glyceride with the volume ratio of 15 percent, solvent N,N-dimethylformamide with the volume ratio of 85 percent and a proper amount of inhibitor ammonium ferrous sulfate to form the reagent system; (2) placing a polypropylene film to be processed in a polyethylene bag, filling with nitrogen and placing in an electron irradiation room after being sealed for irradiation, wherein the electron beam intensity is 2mA and the irradiation dose is 100kGy; and (3) placing the irradiated polypropylene film in the mixed solution of the reaction reagent system, performing grafting reaction for 2 hours under the condition of constant-temperature water bath at 50 DEG C, washing and drying to obtain the polypropylene battery membrane via grafting modification. The membrane has favorable electrochemistry property via constant-current charging and discharging test in the lithium ion battery.

Owner:JINYOUNG XIAMEN ADVANCED MATERIALS TECH CO LTD

Composite membrane for lithium ion battery and lithium ion battery using same

InactiveCN101913862AHigh melting pointImprove wettabilityFinal product manufactureCell component detailsElectrolysisCeramic composite

The invention discloses a composite membrane for a lithium ion battery and the lithium ion battery using the same. The composite membrane comprises a membrane matrix and a polyelectrolyte composite layer, wherein the membrane is a ceramic composite membrane consisting of yttrium oxide-stabilized zirconium oxide and polyelectrolyte; in the yttrium oxide-stabilized zirconium oxide, the yttrium oxide accounts for 8 to 13 weight percent and the zirconium oxide accounts for 87 to 92 weight percent; and the polyelectrolyte of the ceramic composite membrane accounts for 0.1 to 2.0 percent of the total weight of the membrane. The lithium ion battery using the composite membrane comprises an electrode assembly and nonaqueous electrolyte which are sealed in a battery shell, and the composite membrane is the ceramic composite membrane. By compounding ceramic and the polyelectrolyte, the composite membrane can effectively improve the wetting property of organic electrolyte to the ceramic membrane, the solution holding capacity of ceramic pores, and the work safety of the battery.

Owner:海悉新能源科技(上海)股份有限公司

Graphene composite conductive powder and preparation method thereof

InactiveCN107394207ASimple processEasy to operateCell electrodesSecondary cellsPolypyrroleIn situ polymerization

The invention relates to graphene composite conductive powder. The graphene composite conductive powder comprises a graphene material and a macromolecule composite material, wherein the macromolecule composite material is a conductive macromolecule compound formed and obtained on the surface of conductive carbon material in an in situ polymerization manner through monomers; the graphene material is tightly combined with the macromolecule composite material through pi-pi conjugate action between the graphene material and the conductive macromolecule compound in the macromolecule composite material; and the conductive macromolecule compound is at least one of polyaniline, polypyrrole and polythiophene. The invention also provides a preparation method of the graphene composite conductive powder.

Owner:NINGBO MORSH TECH

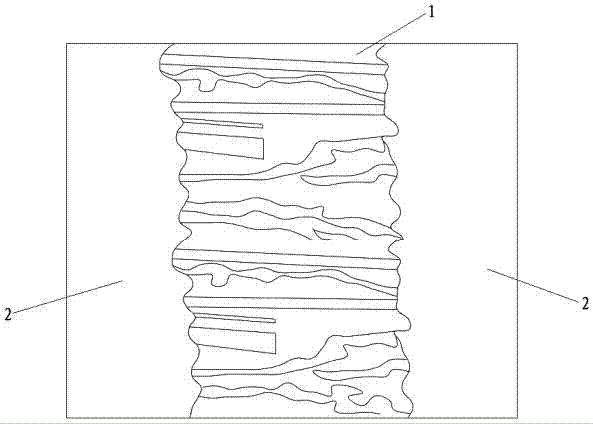

Lithium ion battery positive electrode plate and manufacturing method thereof

PendingCN107394209AImprove conductivityIncrease contact areaElectrode carriers/collectorsSecondary cellsElectrical resistance and conductanceMicrometer

The invention provides a lithium ion battery positive electrode plate and a manufacturing method thereof. The lithium ion battery positive electrode plate comprises porous current collector aluminum foil and positive electrode material layers, through holes and non-through holes are distributed on the porous current collector aluminum foil, and the two sides of the porous current collector aluminum foil are coated with the positive electrode material layers. The manufacturing method of the lithium ion battery positive electrode plate comprises the following steps that 1, current collector aluminum foil with the thickness of 10-50 micrometers is taken, and the surface of the current collector aluminum foil is subjected to a direct-current etching process; 2, the current collector aluminum foil processed through the step 1 is subjected to a chemical etching process with oxidative acid, and then the porous current collector aluminum foil can be obtained; 3, the two side faces of the porous current collector aluminum foil are coated with the positive electrode material layers, and then drying is conducted; and 4, rolling compaction is conducted to obtain the positive electrode plate of a lithium ion battery. According to the lithium ion battery positive electrode plate, by adopting the porous current collector aluminum foil, the adhesive power between a current collector and active material particles is effectively improved, the contact resistance is reduced, the active material coating amount is increased, the space ratio of the current collector is decreased, and the usability of the lithium ion battery is improved.

Owner:ZHENGZHOU BAK BATTERY CO LTD

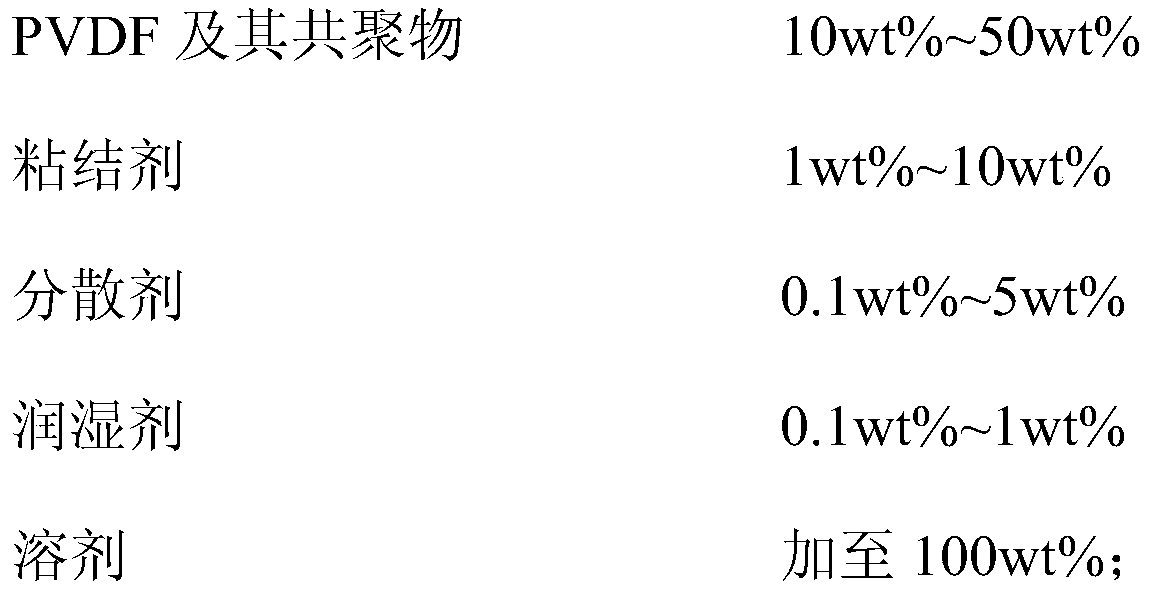

Porous ceramic diaphragm slurry and preparation method thereof, battery diaphragm and battery

PendingCN109742298AGuaranteed heat resistanceGreat suctionCell component detailsHydrofluoric acidOrganic solvent

The invention relates to porous ceramic diaphragm slurry and a preparation method and application thereof. The preparation method comprises the following steps: corroding ceramic powder by using hydrofluoric acid to obtain porous ceramic powder, wherein the ceramic powder is made of at least two ceramic materials; mixing the porous ceramic powder and hydrochloric acid or nitric acid to perform activation so as to obtain activated porous ceramic powder; cladding a surface of the activated porous ceramic powder by using silane coupling agent to obtain sensitive porous ceramic powder; mixing thesensitive porous ceramic powder with adhesive and organic solvent, uniformly stirring to obtain the porous ceramic diaphragm slurry. The ceramic powder prepared from a plurality of ceramic materials is corroded through the hydrofluoric acid, the porous ceramic powder which is the porous structure is manufactured by utilizing the corrosion speed difference on different types of ceramic materials byutilizing the hydrofluoric acid, the porous ceramic powder obtains the porous ceramic diaphragm slurry through activation, sensitization and like treatment; the porous ceramic diaphragm slurry can obviously improve the electric performance of the battery.

Owner:SOUNDON NEW ENERGY TECH CO LTD

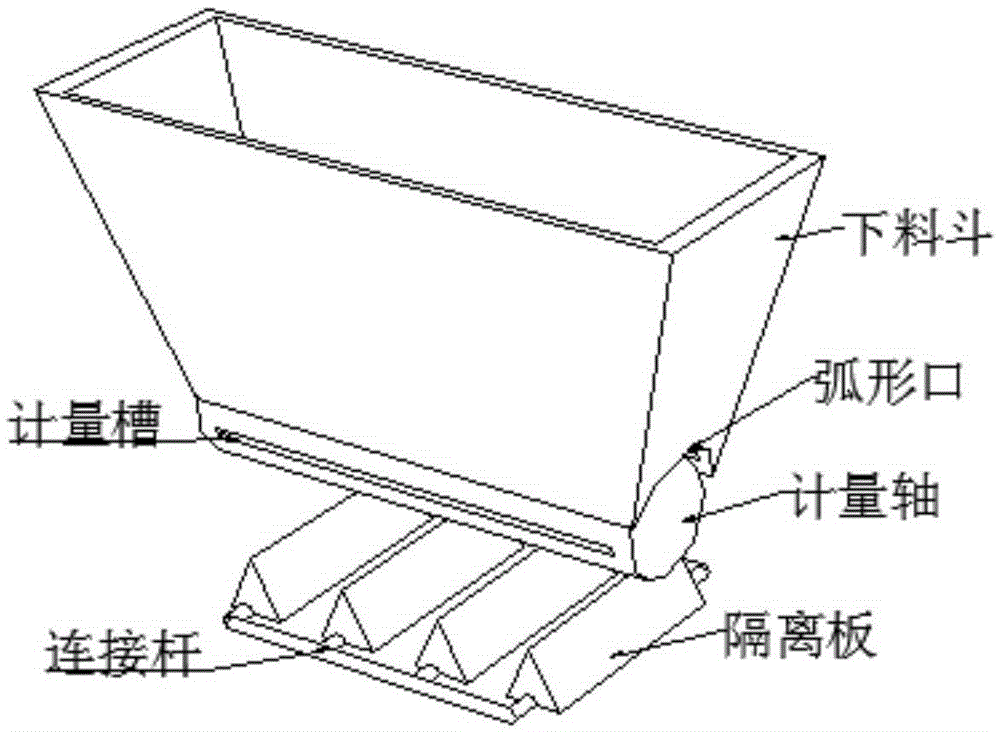

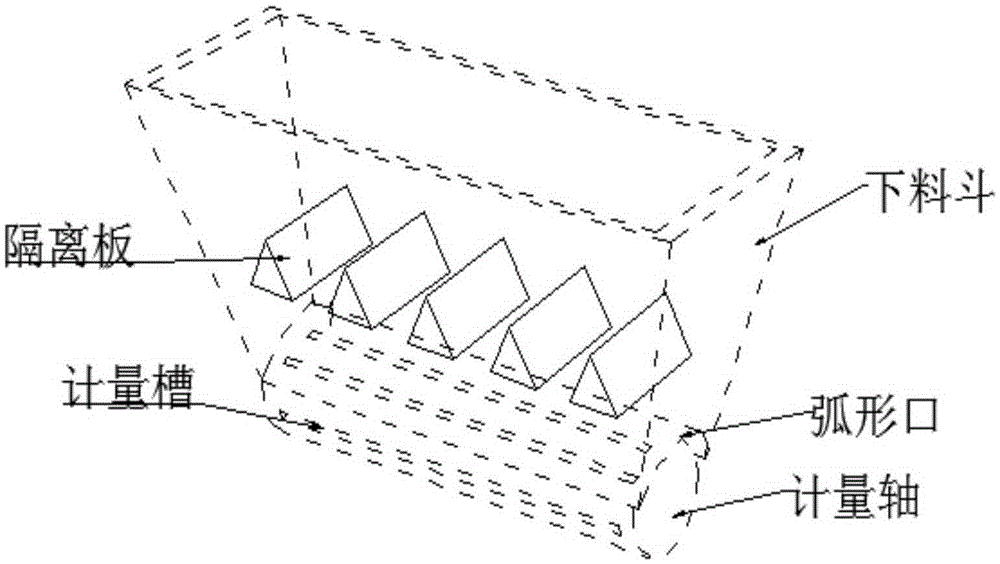

Composite absorbent health product absorbent paper manufacturing method

ActiveCN105266975ASimple processSimple and fast operationAbsorbent padsBandagesPaper manufacturingEngineering

The invention provides a composite absorbent health product absorbent paper manufacturing method .The composite absorbent health product absorbent paper manufacturing method comprises steps that, (1), upper high-molecular absorbent resin layers are distributed at a surface on which high-fluffy non-woven fabric is combined with an upper separating layer with a gap, and an upper diversion trench is formed at the gap portion; (2), the high-fluffy non-woven fabric distributed with the upper high-molecular absorbent resin layers is glued with the upper separating layer of which the surface is coated with hot melt adhesive, and the two parts are stitched and rolled; (3), lower high-molecular absorbent resin layers are distributed at a surface on which high-fluffy non-woven fabric is combined with a lower separating layer, and a lower diversion trench is formed at the gap portion; and (4), the high-fluffy non-woven fabric distributed with the lower high-molecular absorbent resin layer is glued with the lower separating layer of which the surface is coated with hot melt adhesive, and the two parts are stitched and rolled. According to the method, the structure of needed equipment is simple, operation is convenient, products manufactured by utilizing the method have properties of small dimensions, simple technology and relatively low cost, moreover, the absorption characteristic is obviously improved, and the core body utilization rate is improved.

Owner:TIANJIN SINOSH NEW MATERIAL TECH

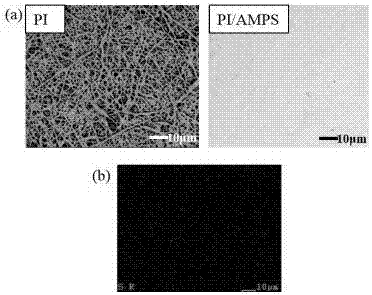

Battery diaphragm and preparation method thereof, lithium ion battery and communication equipment

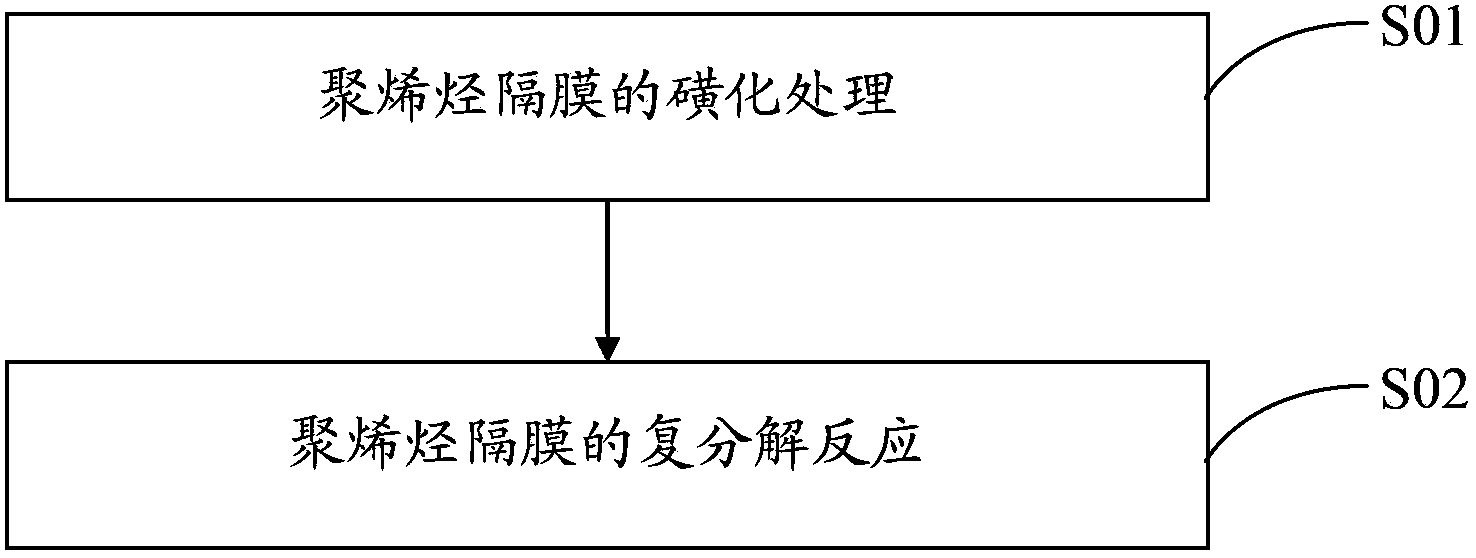

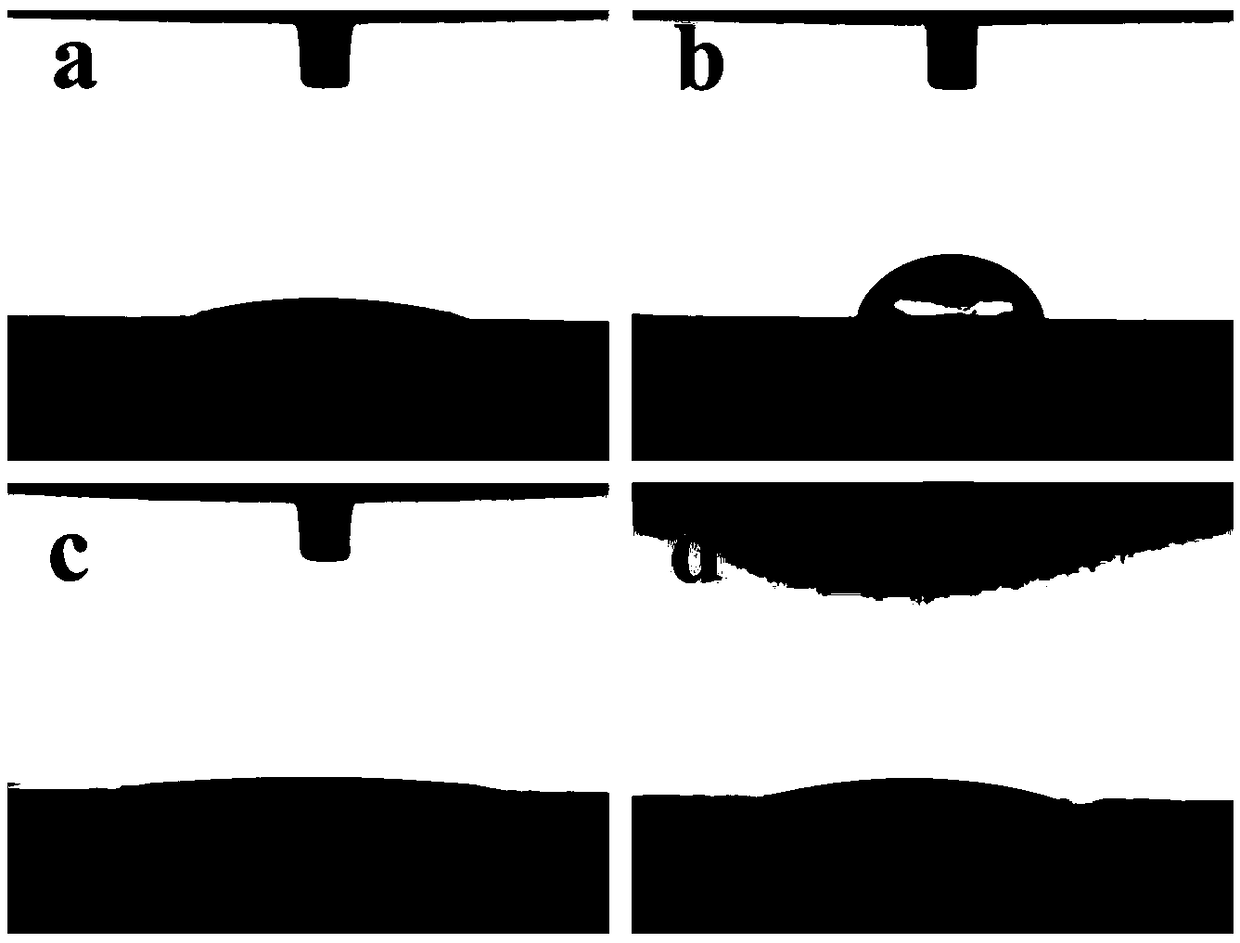

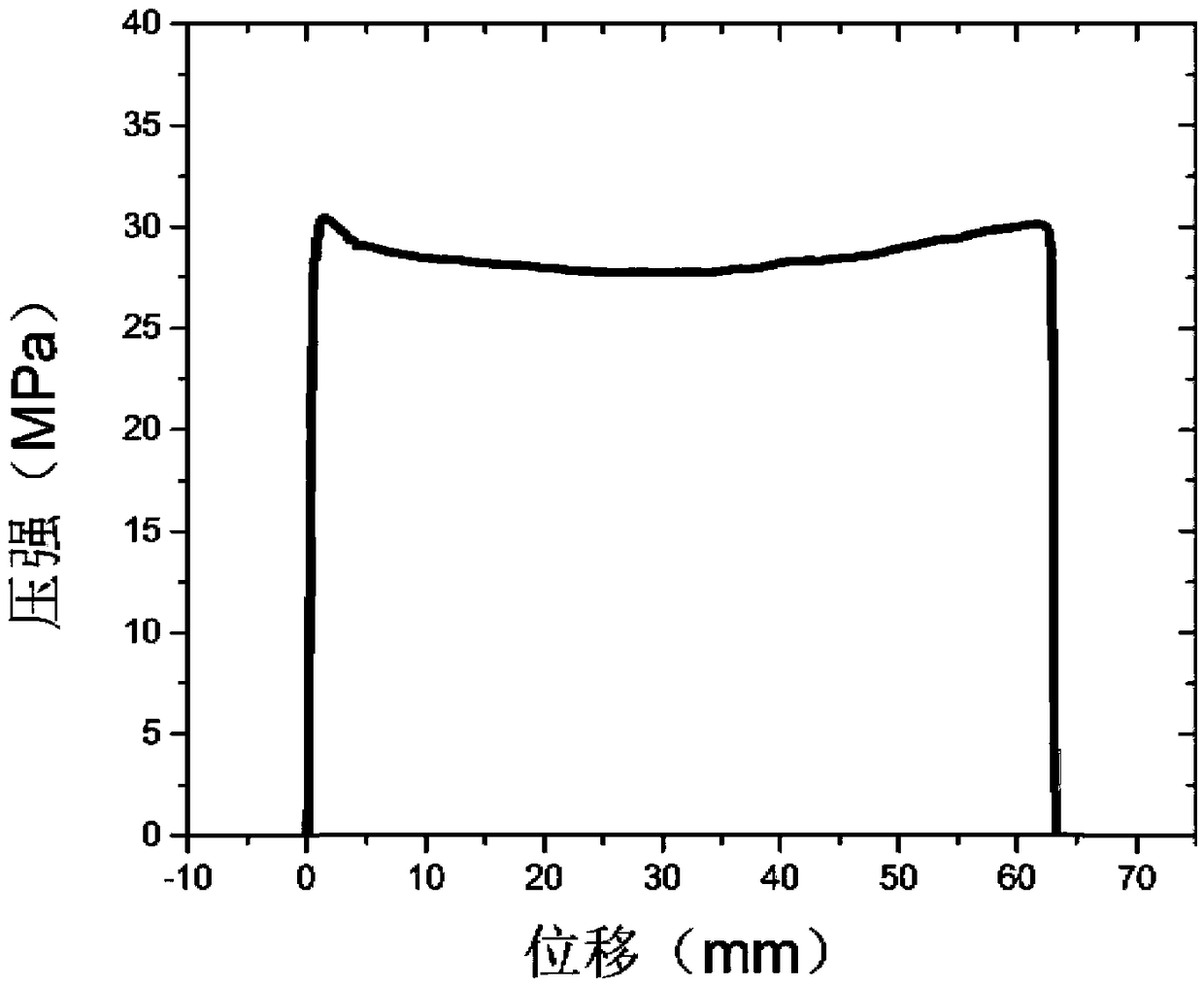

ActiveCN103579560AImprove electrolyte affinityStable chemical propertiesCell seperators/membranes/diaphragms/spacersWound/folded electrode electrodesPolyolefinIon transfer

The invention provides a battery diaphragm and a preparation method thereof, a lithium ion battery and communication equipment. The battery diaphragm comprises a polyolefin diaphragm, and polyolefin molecules of the polyolefin diaphragm contain -SO3Li and -COOLi groups. The preparation method of the battery diaphragm comprises the following steps of a sulfonation step of the polyolefin diaphragm and a replacement reaction step of the polyolefin diaphragm. The lithium ion battery contains the battery diaphragm prepared by the method. The communication equipment contains the lithium ion battery. The battery diaphragm has good electrolyte affinity and increases the capacity for electrolyte retention and ionic conductivity. Lithium ions form a clear lithium ion transfer channel in the polyolefin diaphragm, so that the lithium ion battery has the large-current charging and discharging capacity. The preparation method has the advantages that the process is simple, conditions are easily controlled, the production efficiency is high and the production cost is reduced.

Owner:江苏三正新能源有限公司

High-temperature-resistant polymer modified ceramic diaphragm and application thereof

ActiveCN108666511AImprove thermal stabilityImproved thermal dimensional stabilityCell component detailsSecondary cells servicing/maintenancePolymer modifiedMetallurgy

The invention discloses a high-temperature-resistant polymer modified ceramic diaphragm and an application thereof. The high-temperature-resistant polymer modified ceramic diaphragm comprises a porousbase membrane, and at least one surface of the porous base membrane is coated with a ceramic layer; and a high-temperature-resistant polymer layer is arranged on the surface and in the interior of pores of the ceramic layer, in the interior of pores of the porous base membrane, and on the surface not coated with the ceramic layer in an in-situ polymerization manner. The high-temperature-resistantpolymer modified ceramic diaphragm has relatively high thermal stability. Through the in-situ polymerization method of pyrrole, the thiophene and the aniline monomer, a high-temperature-resistant polymer protection layer is formed on the surface and in the interior of pores of the ceramic layer, on the surface of the porous base membrane, and in the pores in an in-situ coating manner, so that theceramic layer, the polymer layer and the base membrane form an organic integrated body; therefore, the thermal size stability of the modified ceramic diaphragm is improved, and the modified ceramic diaphragm does not contract at a high temperature of 200 DEG C; and in addition, relatively high mechanical performance is still kept, positive and negative electrode contact can be effectively obstructed, and the safety performance of the battery can be guaranteed.

Owner:XIAMEN UNIV

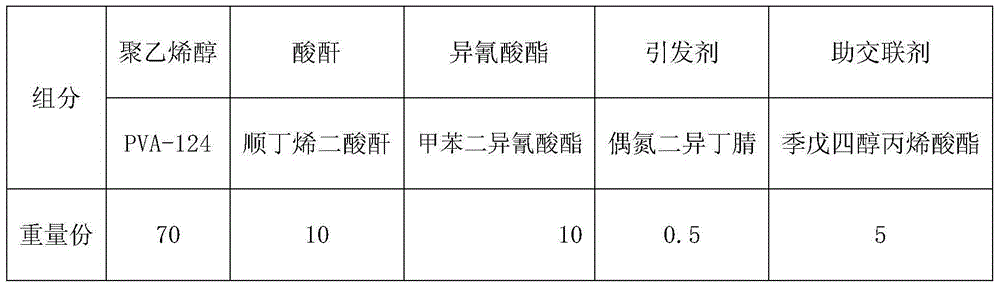

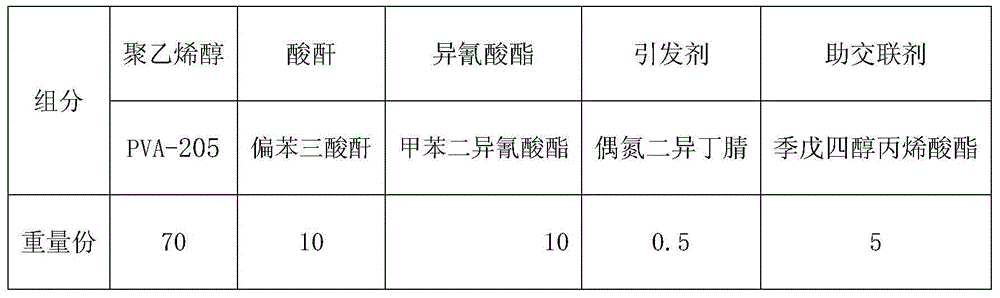

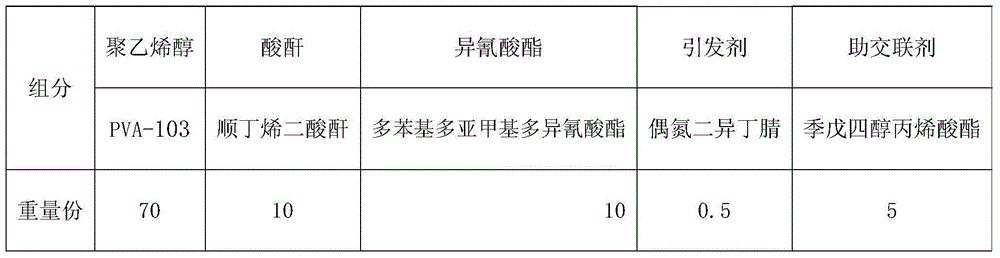

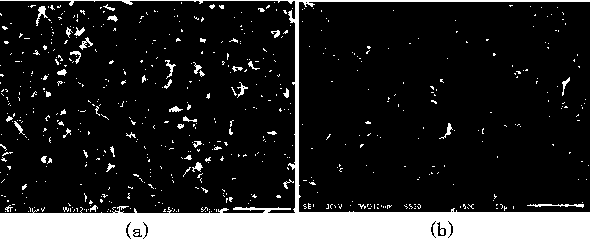

Polymer for lithium ion battery, preparation method of polymer, lithium ion battery gel electrolyte and preparation method thereof

InactiveCN104966848AImprove liquid retention capacityImprove securityFinal product manufactureElectrolyte accumulators manufacturePolyvinyl alcoholPhysical chemistry

The invention discloses a polymer for a lithium ion battery, a preparation method of the polymer, a lithium ion battery gel electrolyte and a preparation method thereof. The polymer is characterized by being prepared by crosslinking of raw materials including polyvinyl alcohol, anhydride and isocyanate under action of auxiliaries, and the auxiliaries include initiator and assistant auxiliary. Compared with conventional lithium ion batteries, the lithium ion battery has the advantages that liquid retaining capability is improved greatly, liquid leakage can be prevented effectively, dangers such as explosion and burning caused by liquid leakage are avoided, and safety coefficient is high.

Owner:储盈新能源科技(上海)有限公司

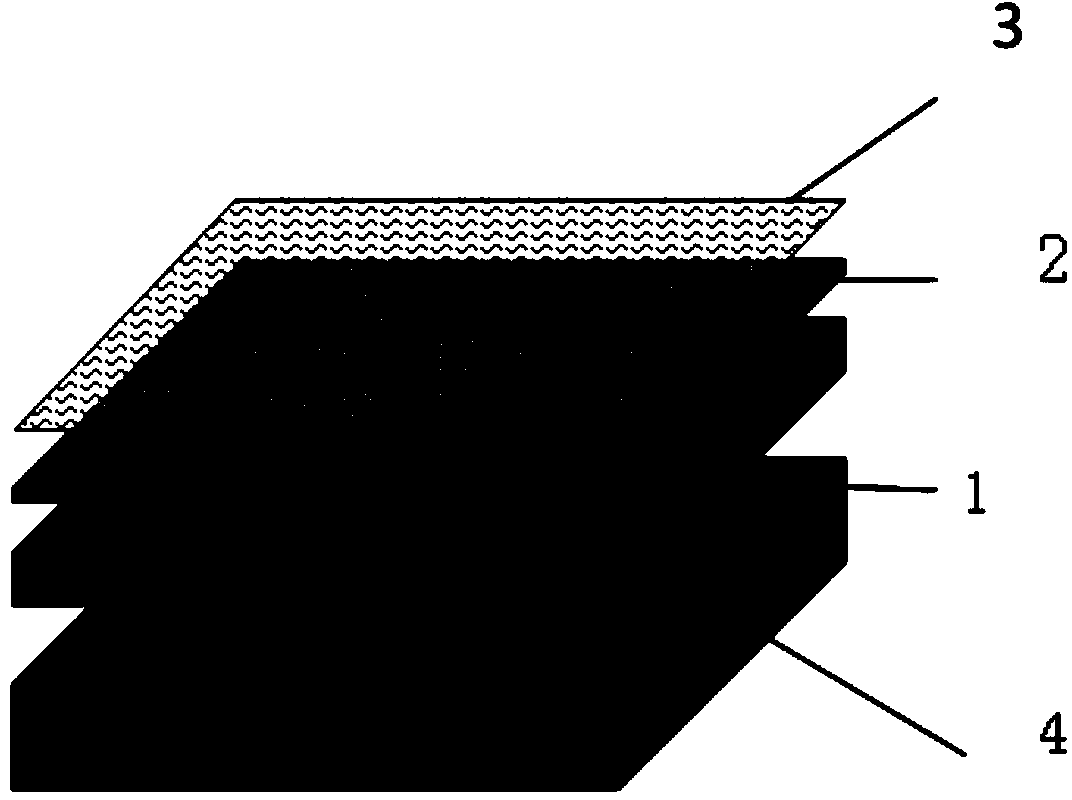

Flexible whole-solid-state battery and preparation method of same

InactiveCN107749491AReduce capacityIncrease capacitySecondary cellsCell component detailsCelluloseSolid state electrolyte

The invention provides a flexible whole-solid-state battery and a preparation method of same. The flexible whole-solid-state battery includes, in a successively stacked manner, a flexible positive plate, a solid state electrolyte membrane, and a flexible negative plate. Each of the flexible positive plate and the flexible negative plate includes a first cellulose substrate, an active substance, aconductive agent and a first solid electrolyte, the active substance and the conductive agent being dispersed in the first cellulose substrate. The solid state electrolyte membrane includes a second solid electrolyte and a second cellulose substrate. Metal compounds are deposited onto the surfaces of the flexible positive plate, the flexible negative plate and the solid state electrolyte membrane.By adding the cellulose substrates to the flexible positive plate, the flexible negative plate and the solid state electrolyte membrane, network total supporting effect is achieved. By adding the solid state electrolyte to the flexible positive plate and the flexible negative plate, ion conduction effect is enhanced; by depositing the metal compound, the battery is improved in rate capability andhigh-temperature performance.

Owner:柔电(武汉)科技有限公司

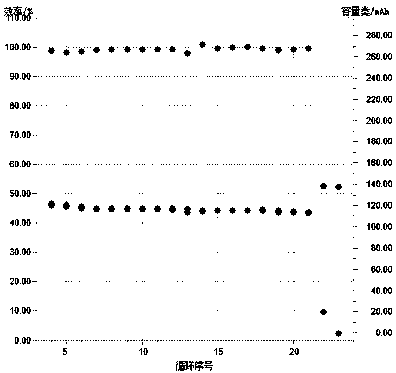

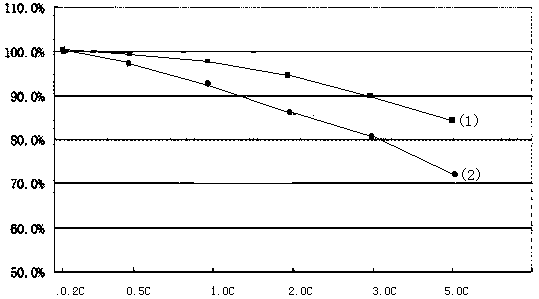

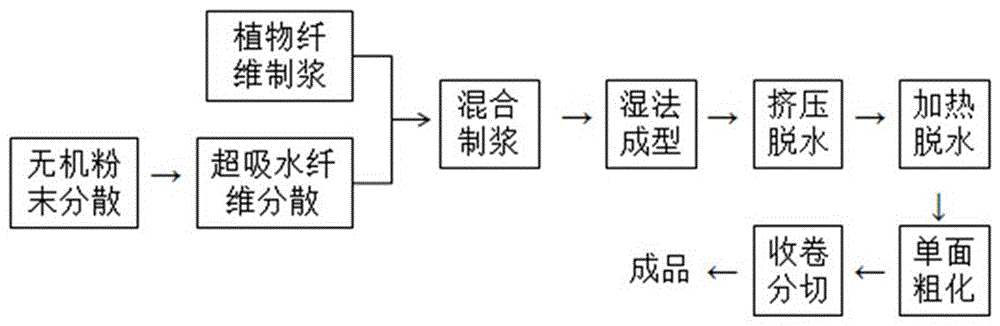

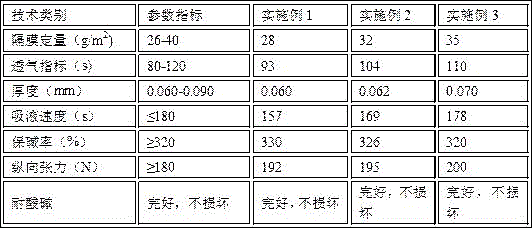

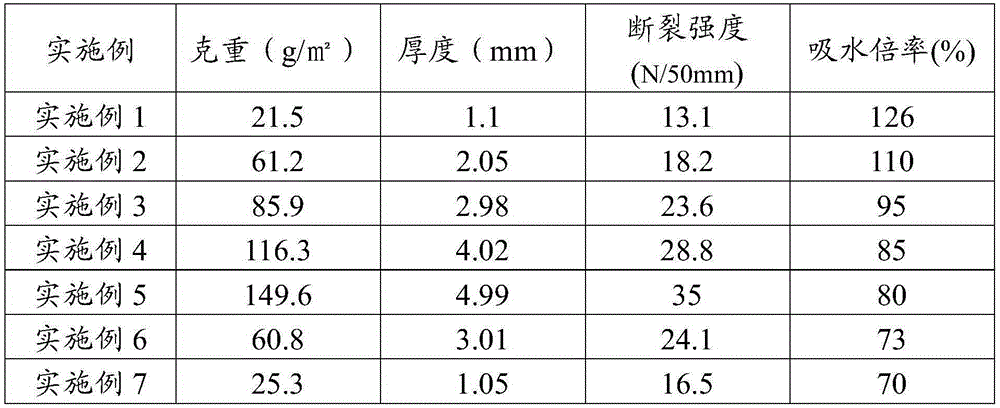

Battery, capacitor diaphragm and preparation method of battery and capacitor diaphragm

InactiveCN105870383ASoft natureImprove toughnessHybrid capacitor separatorsCell component detailsCapacitancePorosity

The invention relates to a battery, a capacitor diaphragm and a preparation method of the battery and the capacitor diaphragm. The diaphragm is prepared from, by weight, 65% to 75% of sulfite wood pulp, 10% to 20% of superabsorbent fibers (SAF), 5% to 30% of attapulgite mineral powder, 0.3% to 0.8% of chitosan, 3% of synthetic fibers and 1.2% to 1.7% of hydrogen storage material ZnO2. The preparation method of the battery and the capacitor diaphragm comprises the step that the finished product is prepared through the steps of plant fiber pulping, inorganic powder dispersing, superabsorbent fiber dispersing, mixed pulping, wet forming, extruding dehydration, heating dehydration, single-face coarsening, rolling and splitting and the like. The defects that in the existing process and technology, the aperture and porosity of a super capacitor diaphragm of a battery are hard to control, the electrolyte retention rate is low, proton passing resistance is large, the gluing process is hard to control, and single-face coarsening of the diaphragm cannot be achieved are overcome, and according to the battery, the capacitor diaphragm and the preparation method of the battery and the capacitor diaphragm, the liquid retention rate is high, gas permeability is good, the physical property is high, internal resistance is low, and the process and technology are more advanced.

Owner:王温珏

Lithium ion battery gel electrolyte with multi-stage structure and preparation method thereof

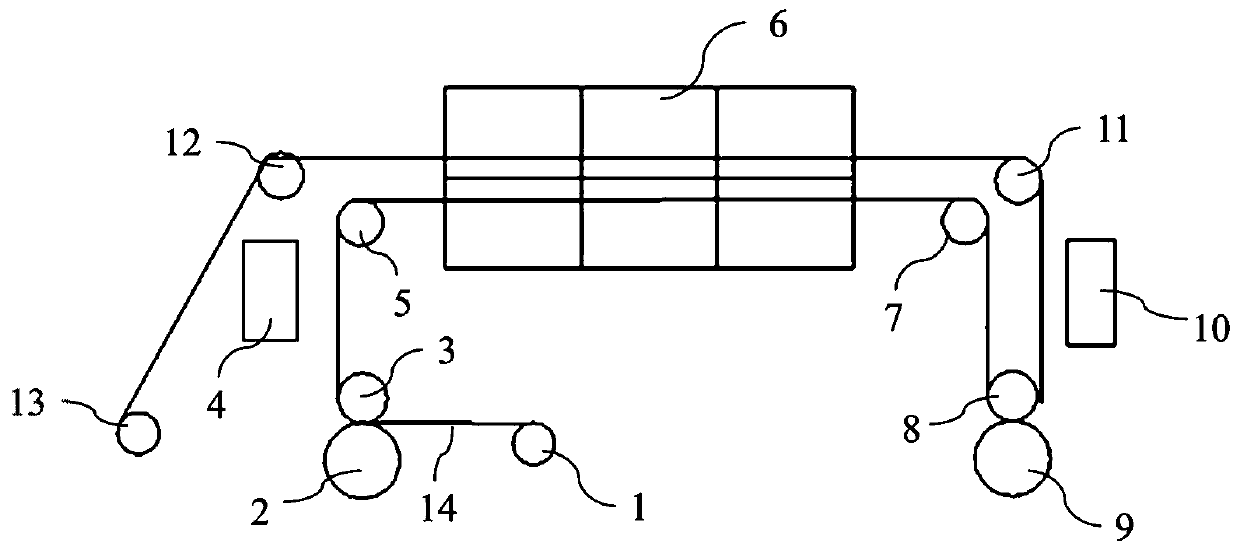

ActiveCN104393337AHigh mechanical strengthImprove liquid retention capacityFinal product manufactureElectrolyte accumulators manufactureThree levelFiber

The invention discloses lithium ion battery gel electrolyte with a multi-stage structure and a preparation method thereof. The lithium ion battery gel electrolyte with the multi-stage structure comprises a polymer network cross-linking framework and a liquid electrolyte in the network framework, wherein the polymer network physical cross-linking framework is composed of nano fibers of PVDF (Polyvinylidene Fluoride) electrostatic spinning, and the cross-linking framework is adsorbed to two sides of a base PE (Poly Ethylene) film. The preparation method comprises the following steps: 1) preparing an electrostatic spinning solution; 2) preparing a first-level framework structure by electrostatic spinning; 3) coating a polymer so as to prepare a second-level framework structure; and 4) carrying out high-temperature in-situ polymerization so as to prepare a PMMA (Polymethyl Methacrylate) gel polymer three-level framework structure. The gel frameworks are distributed in a level-by-level structure, and compared with a conventional gel system, the macromolecule cross-linking system of the multi-level structure has the advantages of high mechanical intensity, high fluid protection capability, high porosity of the network structure, high conductivity and the like, and paves the way for the research of a new generation of gel electrolytes.

Owner:TIANJIN JUYUAN NEW ENERGY TECH CO LTD

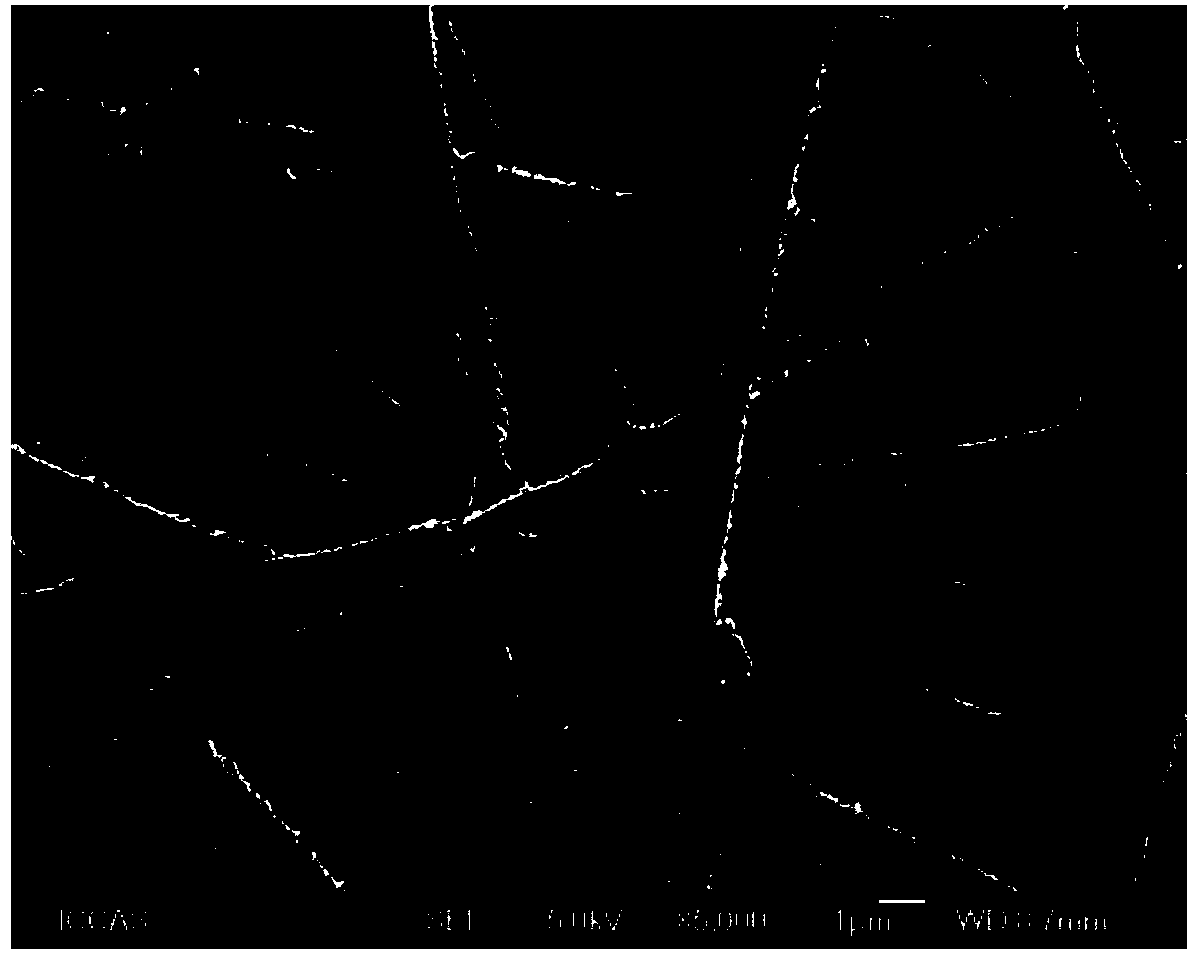

Composite lithium-sulfur battery diaphragm, preparation method thereof and application

InactiveCN107978717AInhibition of the shuttle effectImproved Coulombic efficiency and cycle stabilityCell seperators/membranes/diaphragms/spacersElectro conductivitySolvent

The invention discloses composite lithium-sulfur battery diaphragm, a preparation method thereof and application. The method comprises the steps of impregnating porous substrate membrane into reactionprecursor solution composed of reaction monomers, cross-linking agent, initiator and solvent; and carrying out in situ polymerization and cross-linking reaction under certain condition, thereby acquiring gel electrolyte filled composite lithium-sulfur battery diaphragm with nanoscale pore diameters. According to the lithium-sulfur battery diaphragm, the porous substrate membrane is taken as a framework material, so the good mechanical property and excellent thermal dimension stability are endowed to the diaphragm; the filled gel electrolyte has a great number of lithium conduction functionalgroups, so channels for lithium ions to shuttle are provided, and the problem that the ionic conductivity is relatively low due to reduction of the pore diameters of the diaphragm is avoided; and according to the prepared nanoscale pore diameter composite diaphragm, migration of polysulfide can be inhibited through physical range limitation and chemical absorption effect, so the coulombic efficiency and cycling stability of the lithium-sulfur battery are improved. The composite lithium-sulfur battery diaphragm, the preparation method thereof and the application are simple in technology and high in practicability, are easy to popularize and are beneficial for accelerating industrial application of a lithium-sulfur battery.

Owner:SUN YAT SEN UNIV

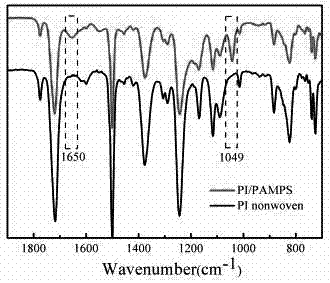

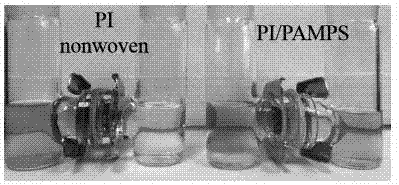

Functional modified diaphragm as well as preparation method and application thereof

ActiveCN106803561AExcellent overall performanceStrong liquid absorption and liquid retention capacitySecondary cellsCell component detailsChemistryPolyolefin

The invention relates to a functional modified diaphragm which comprises an organic diaphragm base material, wherein composite monomer copolymerization polymer layers are arranged on the surface and internal pores of the organic diaphragm base material; each composite monomer copolymerization polymer layer is formed by a monomer A with polyphenol functional groups and a monomer B with amino functional groups in a copolymerization manner. The invention further relates to a preparation method of the functional modified diaphragm, and the application of the functional modified diaphragm in a secondary battery. As the diaphragm is modified in a mode that the composite monomer copolymerization polymer layers are formed on the surface and internal pores of the organic diaphragm base material in situ, the functional modified diaphragm is excellent in comprehensive property, strong in liquid absorption and retention property, high in ionic conductivity, excellent in rate capability and high in security when being compared with a polyolefin diaphragm. The functional modified diaphragm is simple to operate, low in environment requirement and small in pollution, and has good industrial application prospect since substances used in the production process are low in price and green and environmental-friendly.

Owner:厦门益舟新能源科技有限公司

Battery-used separator and preparation method thereof

InactiveCN109860486AImprove breathabilityLow heat shrinkageSecondary cellsCell component detailsCooking & bakingCeramic coating

The invention relates to a battery-used separator and a preparation method thereof. The separator comprises a base film; one side of the base film is sequentially provided with a first ceramic coatinglayer and a first polymer coating layer; the other side of the base film is sequentially provided with a second ceramic coating layer and a second polymer coating layer; or, the other side of the base film is only provided with a second polymer coating layer; and the coverage area of the first polymer coating layer and the second polymer coating layer is 10% to 50% of the total area of the base film. A non-full coverage coating polymer coating layer is adopted, and in comparison with a full coverage coating polymer coating layer in the prior art, the risk of separator hole blocking can be reduced by adopting the non-full coverage coating, and the cycle stability of the material is improved. Besides, baking is carried out after coating of a waterborne ceramic coating and a polymer coatingis completed sequentially, and through using the same type of binder, the coating interface between the waterborne ceramic coating and the polymer coating is eliminated, and a product with stronger binding between the coatings can be obtained.

Owner:HUBEI JINQUAN NEW MATERIALS CO LTD

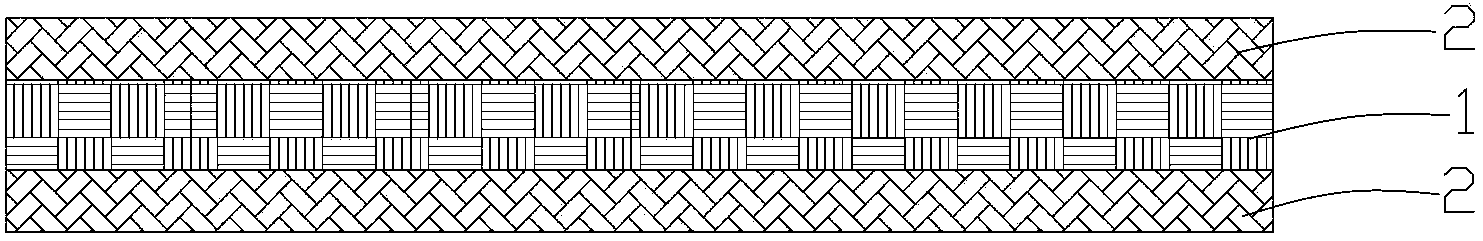

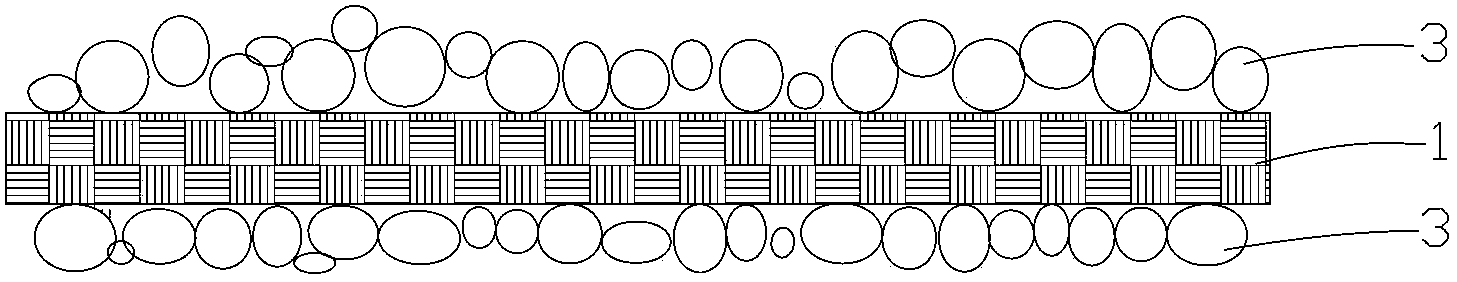

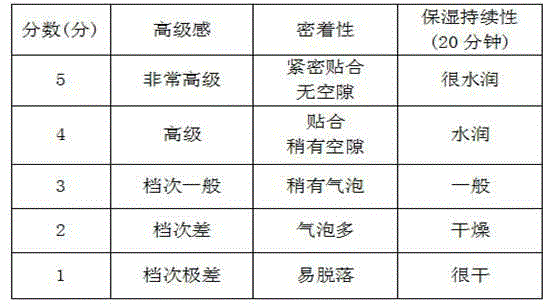

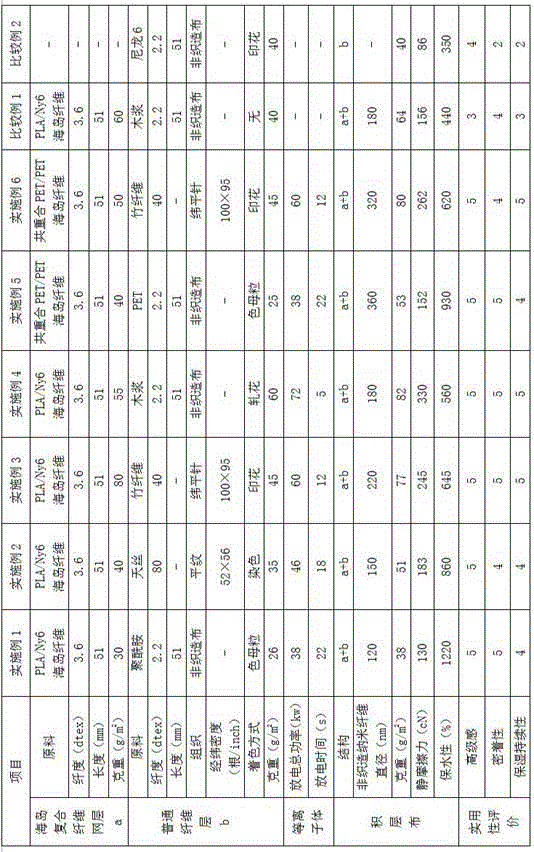

Cosmetic mask cloth and processing method thereof

ActiveCN106283391ALong-lasting liquid retentionEasy to distinguishCosmetic preparationsToilet preparationsFiber layerWoven fabric

The invention discloses a cosmetic mask cloth and a processing method thereof. The cosmetic mask cloth is a two-layer laminated cloth which is formed by a non-woven nanometer fiber layer and a common fiber layer, wherein the common fiber layer is a woven fabric, a knitted fabric layer or a non-woven fabric layer with color or patterns. The cosmetic mask cloth provided by the invention can solve the problems of easiness in tearing and poor water-retaining property of the traditional mask cloth; the cosmetic mask cloth provided by the invention can absorb much more essence; when the mask cloth is adhered to the skin, the liquid can be maintained for a long time; the common fiber layer in the cosmetic mask cloth is designed with color or patterns, so that the cosmetic mask cloth can be easily distinguished; the cosmetic mask cloth can be applied to face masks, eye masks, lip masks, neck masks, foot masks, and the like.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Lithium ion battery alumina hydrate coating membrane and preparation method thereof

InactiveCN105932210AImprove securityImprove heat resistanceCell component detailsAlumina hydrateAdhesive

The invention belongs to the field of lithium ion battery materials, and discloses a lithium ion battery alumina hydrate coating membrane and preparation method thereof. The alumina hydrate slurry is coated on the surface of the lithium ion battery membrane. The preparation method comprises the following steps: mixing nano-level alumina hydrate, surfactant, thickening agent, adhesive, dispersing agent, defoaming agent and solvent, stirring, using a coating device to uniformly coat the slurry on the frontage and the back surface of the lithium ion battery membrane so as to form the coating layer, drying the coating layer to obtain the lithium ion battery alumina hydrate coating membrane, winding and sealing to store. Besides the high security of the coating membrane, the heat resistance, puncture strength, and the electrolyte retention of the lithium ion battery membrane are improved, the electrochemical property of the lithium ion battery can be obviously improved, and the production operability is strong.

Owner:湖南锂顺能源科技有限公司

Gel polymer electrolyte membrane for lithium ion secondary battery and preparation method of gel polymer electrolyte membrane

InactiveCN102306831AImprove ionic conductivityImprove Interface StabilitySecondary cellsPolymer electrolytesLithium

The invention discloses a gel polymer electrolyte membrane for a lithium ion secondary battery and a preparation method of the gel polymer electrolyte membrane. The gel polymer electrolyte membrane comprises 30 to 70 mass percent of polymer electrolyte membrane. The preparation method comprises the following steps of: preparing the polymer electrolyte membrane by using fluorine-containing polymer solution by a solution casting film formation method; performing lithiation and vacuum drying on the polymer electrolyte membrane respectively; and then soaking the polymer electrolyte membrane in electrolyte solution, and thus obtaining the gel polymer electrolyte membrane. The gel polymer electrolyte membrane provided by the invention has extremely high liquid absorbing capacity and liquid keeping capacity; and lithium ions exist on a branched chain of the polymer electrolyte membrane, so that electric conductivity equivalent to liquid electrolyte can be reached only by adding a small quantity of lithium salt into the battery, and the manufacturing cost of the battery is reduced.

Owner:SHANGHAI JIAO TONG UNIV

High-imbibition hot-air non-woven fabric

InactiveCN105401338AFluffy and softImprove liquid absorption capacityAbsorbent padsNon-woven fabricsPolymer scienceNonwoven fabric

The invention discloses a high-imbibition hot-air non-woven fabric, containing low-melting-point complex fibers and superabsorbent fibers SAF. The weight ratio of the low-melting-point complex fibers is 25-95%, and the weight ratio of the superabsorbent fibers SAF is 5-75%. Through using a superabsorbent hot-air non-woven fabric layer made of mixing the low-melting-point complex fibers and the superabsorbent fibers SAF as an absorption core of an imbibitions hygienic material, the superabsorbent performance of the superabsorbent fibers SAF makes manufactured non-woven fabric soft and fluffy in hand feel and have super-strong imbibition capability and liquid retention capability, and a product is not easy to deform. The fabric can be used as an imbibitions core layer material of a diaper or a sanitary napkin.

Owner:FOSHAN GOOD FEELING EISAI TECH CO LTD

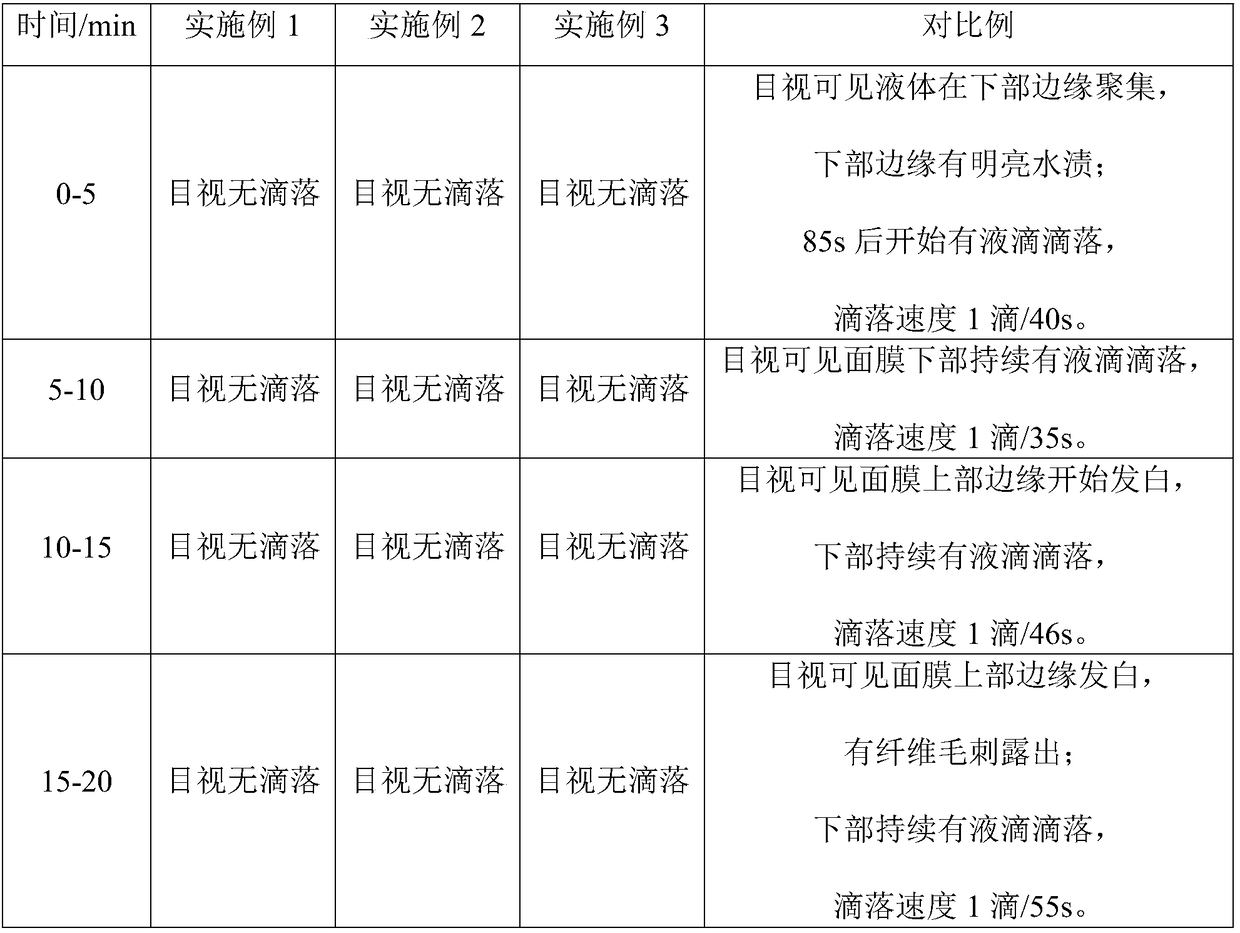

Bamboo charcoal viscose facial mask base cloth and high moisture retention and moisturizing facial mask

ActiveCN108403446AMeet physiological requirementsEliminates allergy riskCosmetic preparationsToilet preparationsCardingSlurry

The invention relates to a bamboo charcoal viscose facial mask base cloth and a high moisture retention and moisturizing facial mask. The bamboo charcoal viscose facial mask base cloth is prepared with the following method: 1) adding nanometer bamboo charcoal powder and sodium alga acid into dispersion solution to be dispersed evenly in bamboo charcoal serous fluid; 2) adding the bamboo charcoal serous fluid into viscose spinning solution to be dispersed evenly, and filtering and deforming to obtain mixed spinning solution; 3) carrying out wet method spinning on the mixed spinning solution toobtain the bamboo charcoal viscose, and carrying out opening, mixing, carding and lapping to obtain a bamboo charcoal viscose felt; 4) dissolving chitosan in acetic acid aqueous solution, adding gelatin to be dissolved to obtain finishing liquor, and dipping the bamboo charcoal viscose felt into the finishing liquor to carry out impregnation modification to obtain a compound fiber felt; 5) carrying out spunlace reinforcement on the compound fiber felt. The bamboo charcoal viscose facial mask base cloth has high constraint ability on serum and good water retention and moisture liberation performance; after the facial mask serum is loaded through a liquid hanging step, the high moisture retention and moisturizing facial mask is obtained, situation that serum loss due to dripping and droppingcan be avoided, and waste is avoided.

Owner:魏科峰

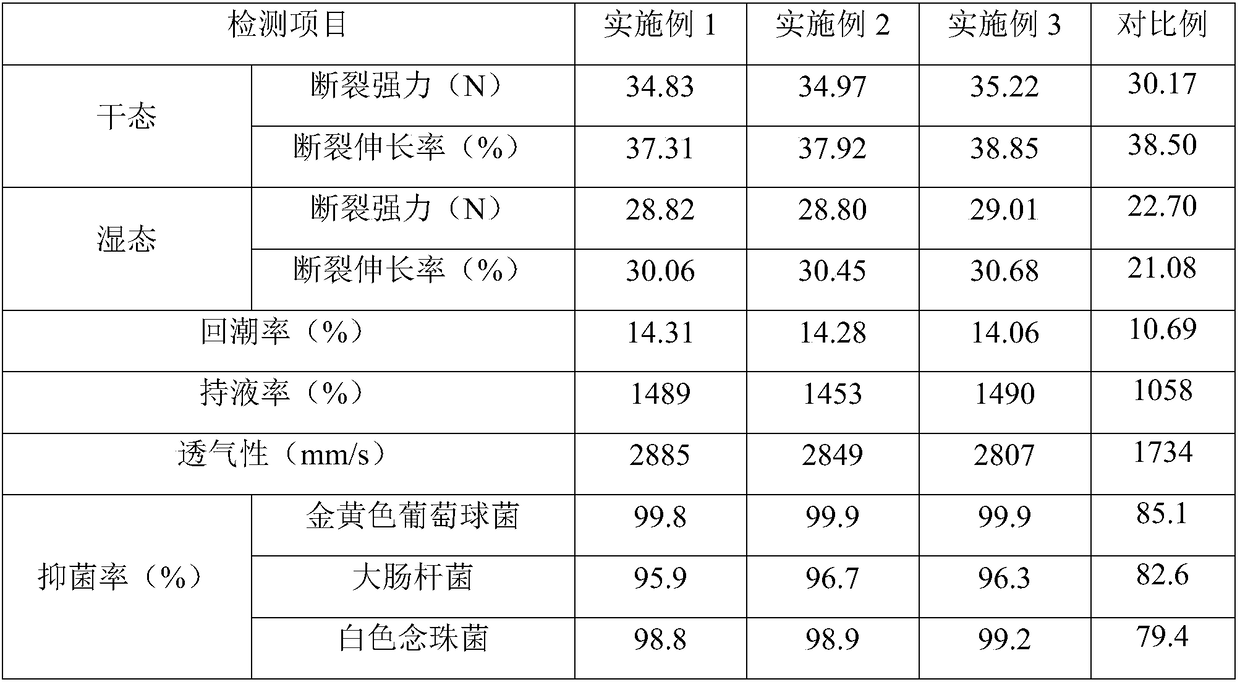

Bacterial cellulose/fabric laminated composite material and preparation method thereof

ActiveCN103938447AEasy to operateEasy to usePhysical treatmentFibre typesOxygen plasmaUltraviolet lights

The invention discloses a bacterial cellulose / fabric laminated composite material and a preparation method thereof. The preparation method comprises the following steps: (1) inoculating acetobacter xylinum into a fluid medium for enlarged cultivation; (2) appropriately cutting a fabric and treating with low-temperature oxygen plasmas or aqueous alkali, or through ultraviolet light surface grafting; and sterilizing and then drying the fabric; (3) arranging the medium containing floccules into a culture dish, spreading the treated fabric on bacterium solution, adding the medium containing floccules into the fabric, and arranging in a biochemical incubator until the laminated composite material is formed; and (4) soaking the composite material with deionized water at normal temperature, soaking the composite material with sodium hydroxide solution for two days, and soaking the composite material with deionized water until the composite material is neutral. The composite material is formed at a time, the appetency of the single fabric and the texture is improved, and the water retainability and the transdermal absorption ratio of the fabric are improved; meanwhile, the operation is convenient and simple and the using efficacy is greatly improved.

Owner:SOUTH CHINA UNIV OF TECH

Nanometer composite antibacterial agent with cerium loaded on porous graphene and method for preparing nanometer composite antibacterial agent

InactiveCN107416802ALarge specific surface areaLow boiling pointGrapheneProsthesisPorous grapheneCerium nitrate

The invention discloses a nanometer composite antibacterial agent with cerium loaded on porous graphene and a method for preparing the nanometer composite antibacterial agent. The nanometer composite antibacterial agent with the cerium loaded on the porous graphene comprises the three-dimensional porous graphene, the nanometer cerium and nanometer titanium dioxide. The nanometer cerium and the nanometer titanium dioxide are deposited on three-dimensional porous graphene sheet layers, and the specific surface area of the nanometer composite antibacterial agent with the cerium loaded on the porous graphene is 1200-1470 m<2> / g. The nanometer composite antibacterial agent and the method have the advantages that graphene oxide is etched by potassium hydroxide, then composition is carried out on the graphene oxide and cerium nitrate, three-dimensional graphene composite nanometer cerium materials are prepared by means of reduction by the aid of hydrothermal processes, tert-butyl alcohol and the nanometer titanium dioxide are mixed with each other to replace water in the three-dimensional porous graphene, then freeze-drying is carried out, and the nanometer composite antibacterial agent with the cerium loaded on the porous graphene is ultimately obtained by means of calcining; the nanometer composite antibacterial agent prepared by the aid of the method has the large specific surface area, and good loading effects can be realized by the nanometer composite antibacterial agent.

Owner:长沙小新新能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com