Lithium ion battery composite separator, preparation method thereof, and lithium ion battery

A technology of lithium-ion batteries and composite diaphragms, which is applied in the manufacture of electrolyte batteries, battery pack parts, non-aqueous electrolyte batteries, etc., can solve the problems of poor wettability with electrolytes, improve liquid retention performance, prevent internal short circuits, and improve The effect of cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

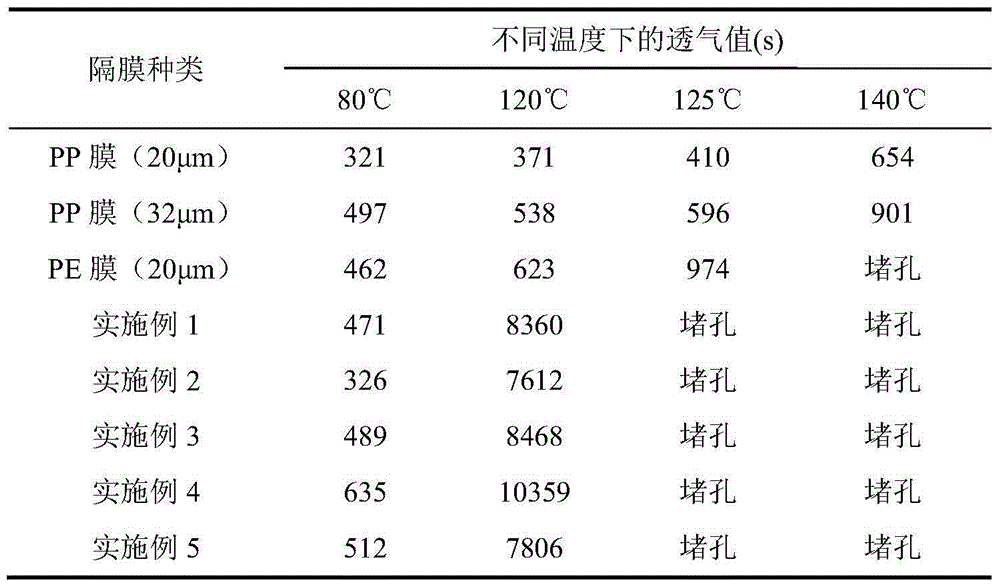

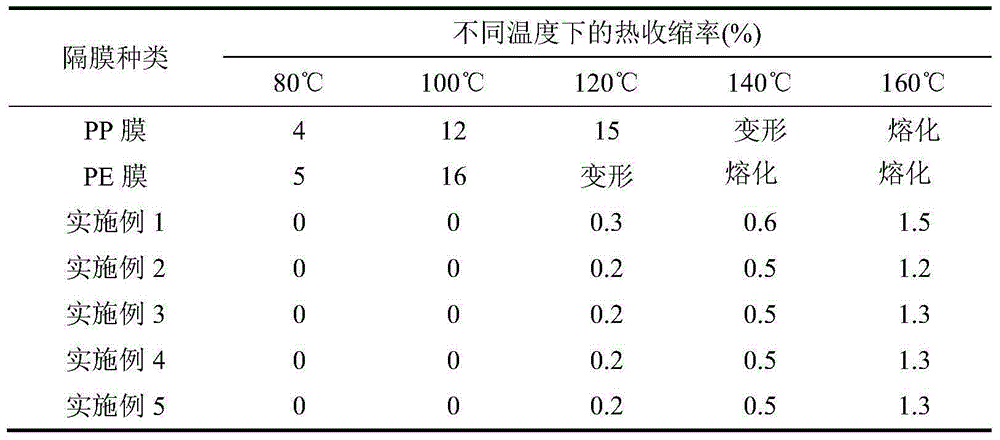

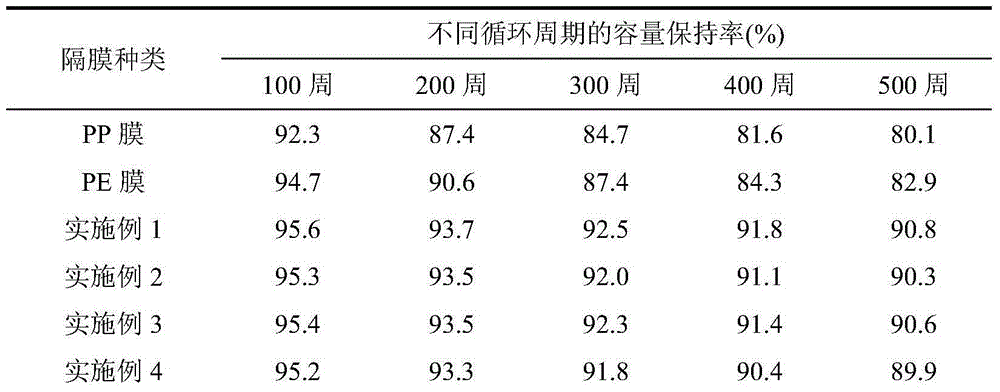

Embodiment 1

[0040] The lithium-ion battery composite diaphragm of the present embodiment comprises a base film, the base film is a polyethylene microporous film, one side of the polyethylene microporous film is coated with a hot-melt polymer coating, and the other side is coated with a Heat-resistant coating, the melting temperature of the hot-melt polymer coating is lower than the thermal melting temperature of the base film, and the melting temperature of the heat-resistant coating is higher than the thermal melting temperature of the base film; The molecular coating includes 90 parts of hot-melt polymer material styrene-diethylene copolymer (PS-based copolymer), 10 parts of binder PVA, and the particle size of styrene-divinyl copolymer is 0.7 μm; heat-resistant coating Including 95 parts of heat-resistant polymer material polyimide, 5 parts of binder PVDF, the particle size of polyimide is 1.1 μm; the thickness of the above composite diaphragm is 28 μm, of which the thickness of polyeth...

Embodiment 2

[0058] The lithium-ion battery composite diaphragm of the present embodiment includes a base film, which is a polypropylene microporous membrane, one side of the polypropylene microporous membrane is coated with a hot-melt polymer coating, and the other side is coated with a Heat-resistant coating, the melting temperature of the hot-melt polymer coating is lower than the thermal melting temperature of the base film, and the melting temperature of the heat-resistant coating is higher than the thermal melting temperature of the base film; Molecular coating includes 93 parts of hot-melt polymer material acrylonitrile-acrylate copolymer, 7 parts of binder LA132 (polyacrylic copolymer), the particle size of acrylonitrile-acrylate copolymer is 1.2 μm; heat-resistant The coating includes 85 parts of heat-resistant polymer material polyimide, 5 parts of binder PVDF, inorganic filler Al 2 o 3 10 parts, the particle size of polyimide is 2.0μm, inorganic filler Al 2 o 3 The particle s...

Embodiment 3

[0068] The lithium-ion battery composite diaphragm of the present embodiment includes a base film, which is a polypropylene microporous membrane, one side of the polypropylene microporous membrane is coated with a hot-melt polymer coating, and the other side is coated with a Heat-resistant coating, the melting temperature of the hot-melt polymer coating is lower than the thermal melting temperature of the base film, and the melting temperature of the heat-resistant coating is higher than the thermal melting temperature of the base film; The molecular coating includes 90 parts of hot-melt polymer material ethylene-vinyl acetate copolymer (EVA, wherein the VA content is 9%), 10 parts of binder LA132 (polyacrylic acid copolymer), ethylene-vinyl acetate copolymer The particle size is 0.7μm; the heat-resistant coating includes 90 parts of heat-resistant polymer material polytetrafluoroethylene, 7 parts of binder PVDF, and inorganic filler SiO 2 3 parts, the particle size of polytet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting temperature | aaaaa | aaaaa |

| Melting temperature | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com