Lithium ion secondary cell

A secondary battery, lithium ion technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problem of low probability of internal short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

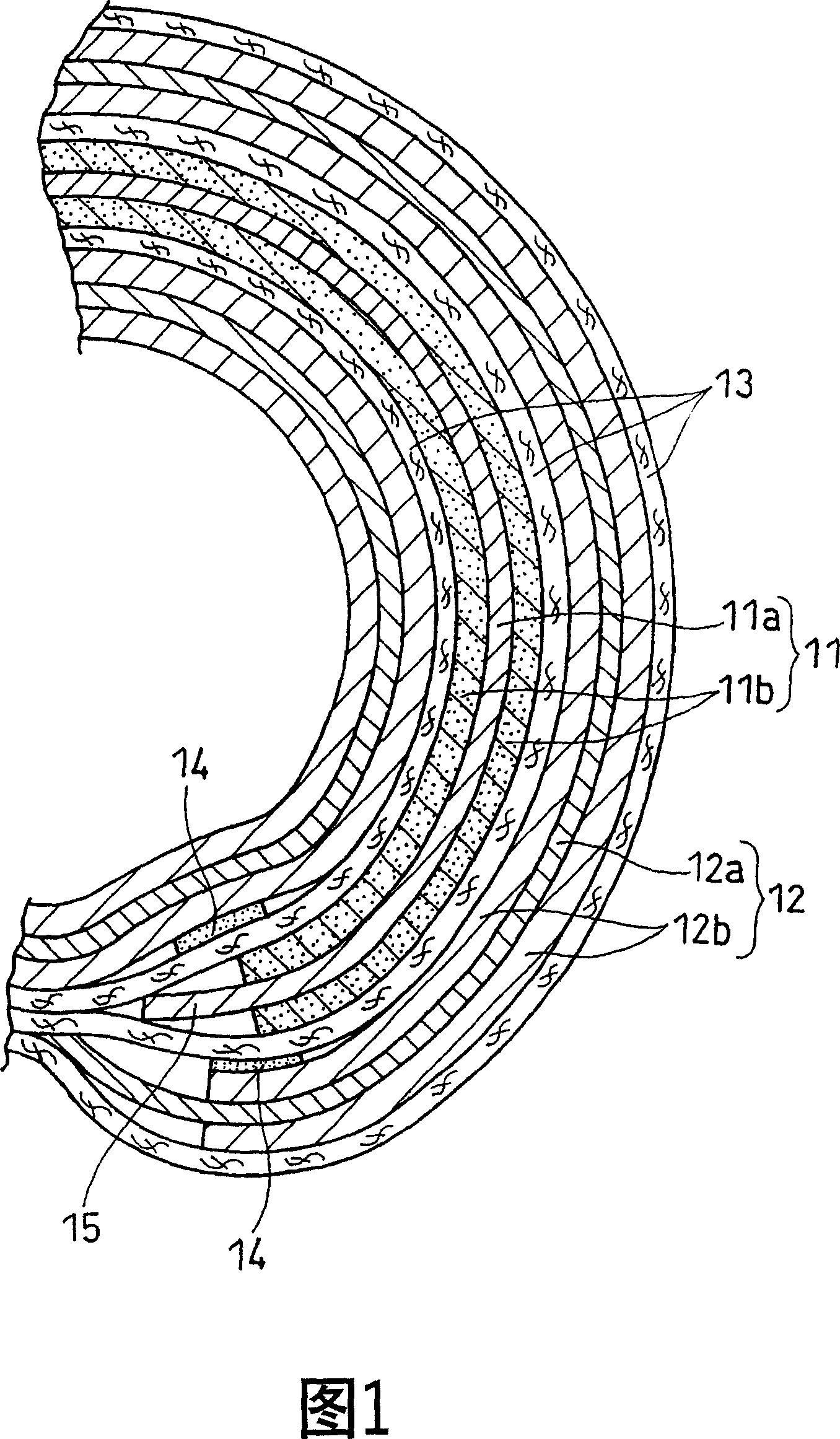

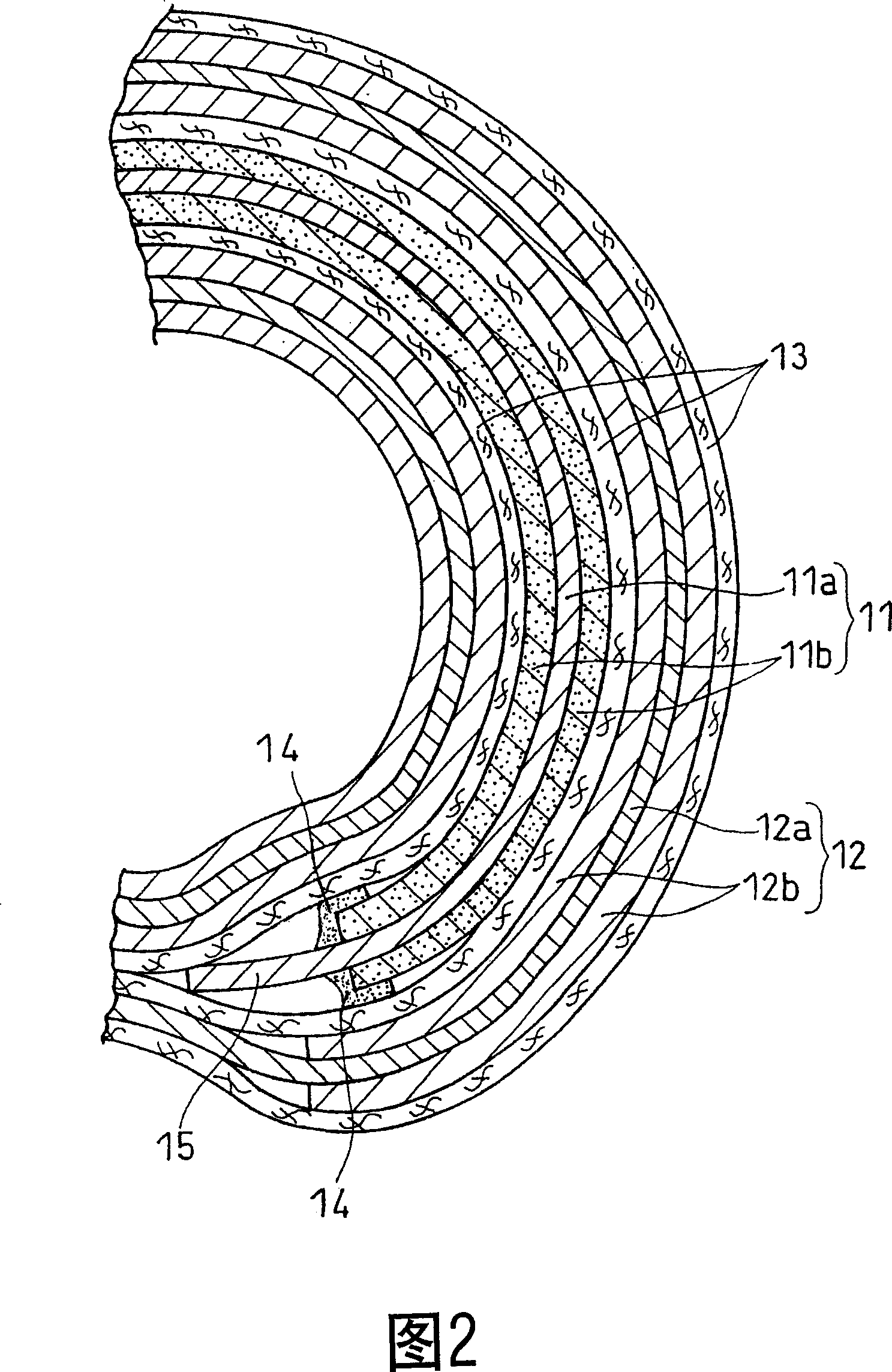

[0040] FIG. 1 shows a part of the winding end side of an electrode group used in a lithium ion secondary battery according to an embodiment of the present invention.

[0041] The electrode group in FIG. 1 has a strip-shaped positive electrode 11 , a strip-shaped negative electrode 12 , and a separator 13 arranged between the positive electrode and the negative electrode. In the electrode group of FIG. 1 , the positive electrode 11 is composed of a positive electrode current collector 11 a and positive electrode mixture layers 11 b carried on both surfaces thereof. The negative electrode 12 is composed of a negative electrode current collector 12a and negative electrode mixture layers 12b carried on both surfaces thereof. In addition, the positive electrode 11 and the negative electrode 12 are wound together by being separated by a separator. In addition, the exposed portion 15 of the positive electrode current collector in which the positive electrode mixture layer does not e...

Embodiment approach 2

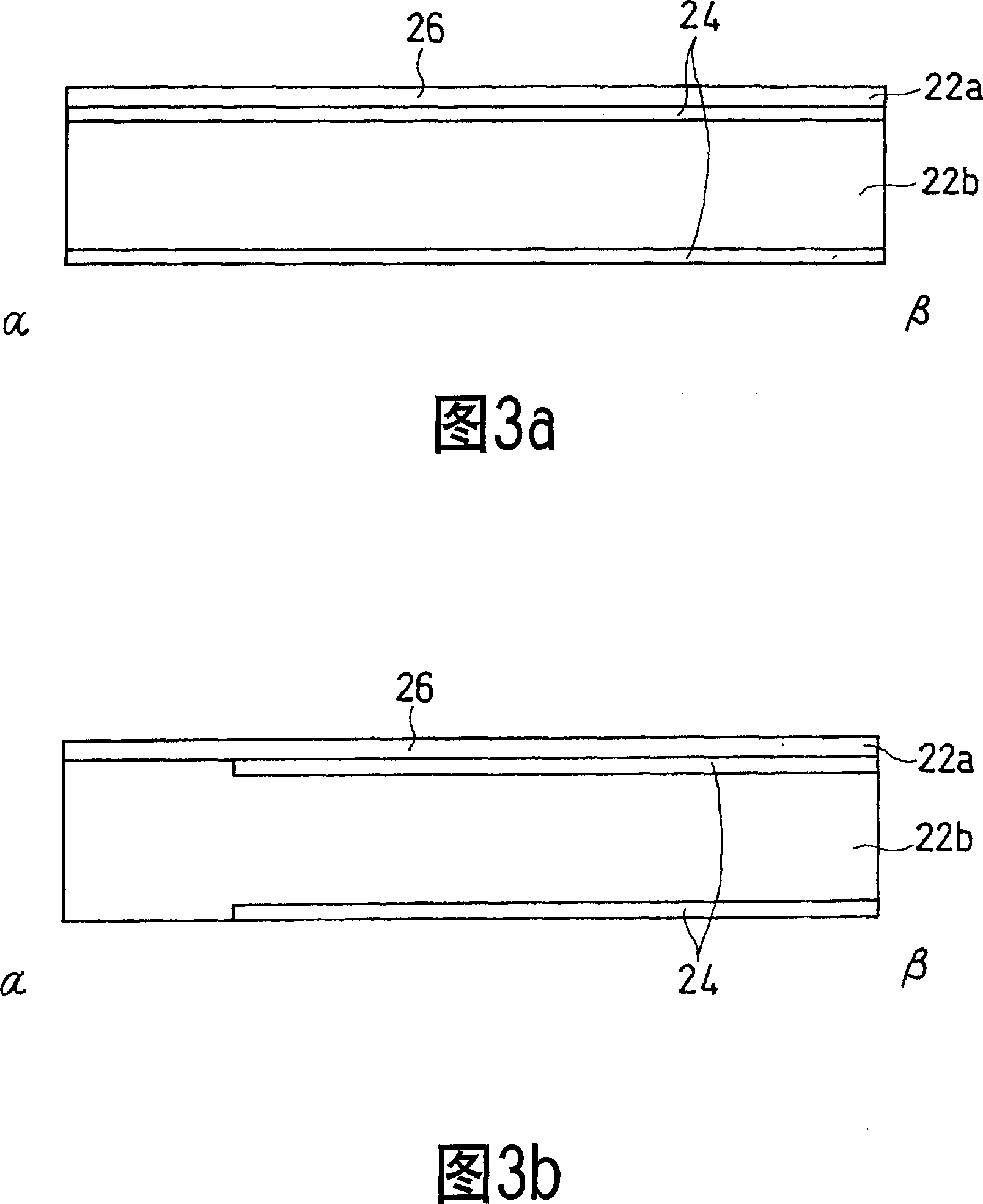

[0071] 3a and 3b show a first side view and a second side view of a negative electrode used in a lithium ion secondary battery according to another embodiment of the present invention. In addition, FIG. 4 shows a vertical cross-sectional view of an electrode group fabricated using the negative electrodes shown in FIGS. 3a and 3b. Also in the present embodiment, the porous heat-resistant layer and the like are used as those in the first embodiment described above.

[0072] In the present embodiment, the belt-shaped positive electrode 21 is composed of a positive electrode current collector 21a and positive electrode mixture layers 21b carried on both surfaces thereof. The strip-shaped negative electrode 22 is composed of a negative electrode current collector 22a and negative electrode mixture layers 22b attached to both surfaces thereof. Here, along one long side of the positive electrode, the exposed portion 25 of the positive electrode current collector without the positive...

Embodiment approach 3

[0086] Fig. 5a shows a cross-sectional view of a positive electrode, a separator, and a negative electrode used in a lithium ion secondary battery according to another embodiment of the present invention. In addition, also in this embodiment, a porous heat-resistant layer etc. are the same as that of said Embodiment 1.

[0087] As shown in FIG. 5 a , the positive electrode 31 includes a positive electrode current collector 31 a and positive electrode mixture layers 31 b carried on both sides thereof. The negative electrode 32 includes a negative electrode current collector 32 a and negative electrode mixture layers 32 b carried on both surfaces thereof. Furthermore, a porous insulating layer 34 is provided on the upper surfaces of the mixture layers of the positive electrode 31 and the negative electrode 32 from the end on the winding start side to a predetermined position. As an example, FIG. 5b is a schematic view showing one side of the negative electrode, which is located...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com