Technology for improving wavy shapes of lithium ion battery positive plate edge

A lithium-ion battery and positive electrode technology, which is applied in battery electrodes, electrode manufacturing, electrode heat treatment, etc., can solve the problem of inconsistent tension and tightness on both sides of the electrode, and achieve the effect of ensuring the orderly winding and tension, and avoiding internal short circuits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] A process for improving the wavy shape of the edge of the positive electrode sheet of a lithium ion battery, and the specific steps are as follows:

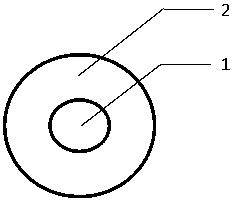

[0015] Step 1: The rolled lithium-ion battery positive sheet is wound using a hot-pressed silica gel roll with an inner diameter of 5mm;

[0016] Step 2: After the winding is completed, put the positive electrode sheet in the oven without vacuuming and bake it for 2 hours at a temperature of 100°C;

[0017] Step 3: After the baking time is over, the pole piece rolls are cooled to room temperature and then slit to make positive pole pieces.

Embodiment 2

[0019] A process for improving the wavy shape of the edge of the positive electrode sheet of a lithium ion battery, and the specific steps are as follows:

[0020] Step 1: The rolled lithium-ion battery positive sheet is wound using a hot-pressed silicone rubber roll with an inner diameter of 7.5mm;

[0021] Step 2: After the winding is completed, put the positive electrode sheet in the oven without vacuuming and bake for 3 hours at 110°C;

[0022] Step 3: After the baking time is over, the pole piece rolls are cooled to room temperature and then slit to make positive pole pieces.

Embodiment 3

[0024] A process for improving the wavy shape of the edge of the positive electrode sheet of a lithium ion battery, and the specific steps are as follows:

[0025] Step 1: The rolled lithium-ion battery positive sheet is wound with a hot-pressed silica gel roll with an inner diameter of 10mm;

[0026] Step 2: After the winding is completed, put the positive electrode sheet in the oven without vacuuming and bake it for 4 hours at a temperature of 120°C;

[0027] Step 3: After the baking time is over, the pole piece rolls are cooled to room temperature and then slit to make positive pole pieces.

[0028] The positive plates of the lithium-ion batteries prepared in the above examples 1-3 have no edge wave shape, so that when the lithium-ion battery cell is wound, there will be no misalignment or misalignment of the pole pieces, thereby avoiding the use of the lithium-ion battery The internal short circuit during the process reduces potential safety hazards such as fire and explosion of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com