Method for packaging dye-sensitized solar cell

A technology of solar cells and encapsulation methods, applied in circuits, capacitors, photosensitive equipment, etc., can solve problems such as increased battery difficulty and short circuit of working electrodes, and achieve the effects of shortening encapsulation time, preventing internal short circuit, and good sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The transparent conductive substrate adopts the FTO (F-doped tin oxide) conductive glass of Japan Nippon Sheet Glass Company. The conductive glass is cleaned in an ultrasonic water bath and then dried.

[0031] Preparation of TiO 2 Nanoparticle Slurry: Preparation of Nano-TiO by Sol-Gel Method 2 slurry. Prepare a certain concentration of triethylamine solution 50mL and 0.1mol / L titanium acetate solution 250mL. Under vigorous stirring, the triethylamine solution was added to the titanium acetate solution; in order to make TiO 2 The particles are uniform to prevent rapid agglomeration of the particles, and the triethylamine solution is slowly added to the titanium acetate solution using a dropping funnel. With the addition of triethylamine solution, white flocs were formed. Constantly stirring, after about 15h, it becomes a stable sol. Then filter to remove large particles of TiO 2 .

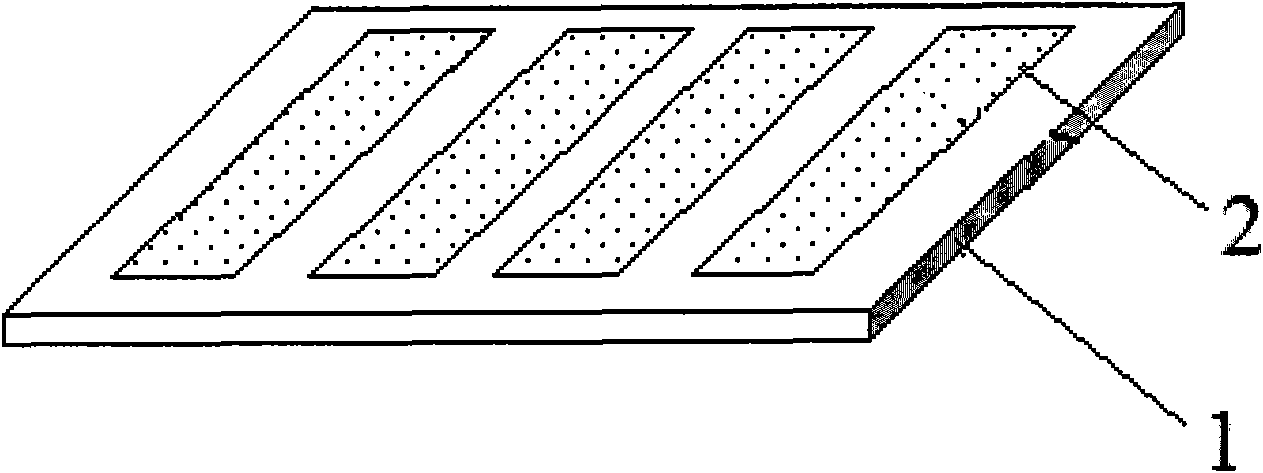

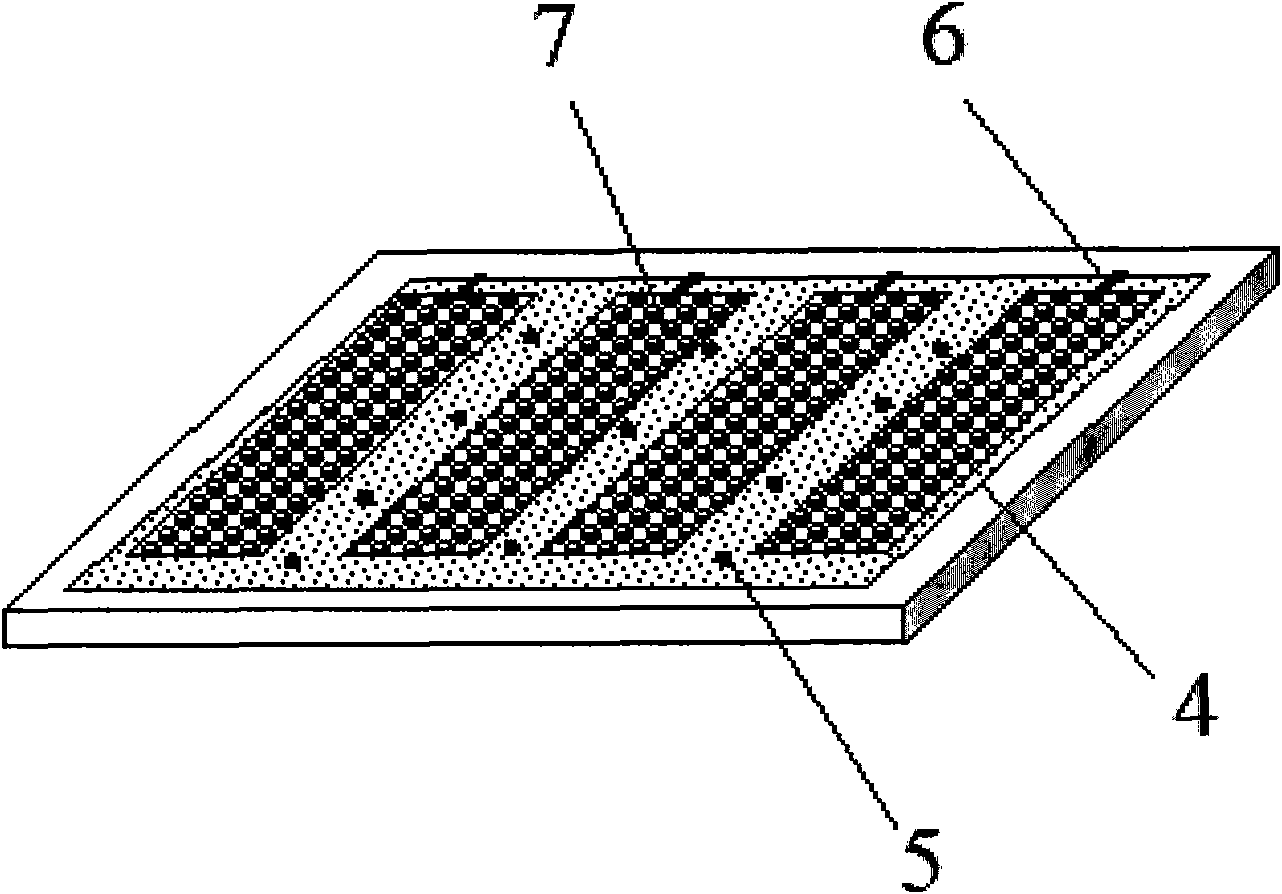

[0032] Screen printing TiO using a screen printer 2 Nanoparticles, the screen ...

Embodiment 2

[0038] The transparent conductive substrate adopts the FTO (F-doped tin oxide) conductive glass of Japan Nippon Sheet Glass Company. The conductive glass is cleaned in an ultrasonic water bath and then dried.

[0039] Preparation of TiO 2 Nanoparticle Slurry: Preparation of Nano-TiO by Sol-Gel Method 2 slurry. Prepare a certain concentration of triethylamine solution 50mL and 0.1mol / L titanium acetate solution 250mL. Under vigorous stirring, the triethylamine solution was added to the titanium acetate solution; in order to make TiO 2 The particles are uniform to prevent rapid agglomeration of the particles, and the triethylamine solution is slowly added to the titanium acetate solution using a dropping funnel. With the addition of triethylamine solution, white flocs were formed. Constantly stirring, after about 15h, it becomes a stable sol. Then filter to remove large particles of TiO 2 .

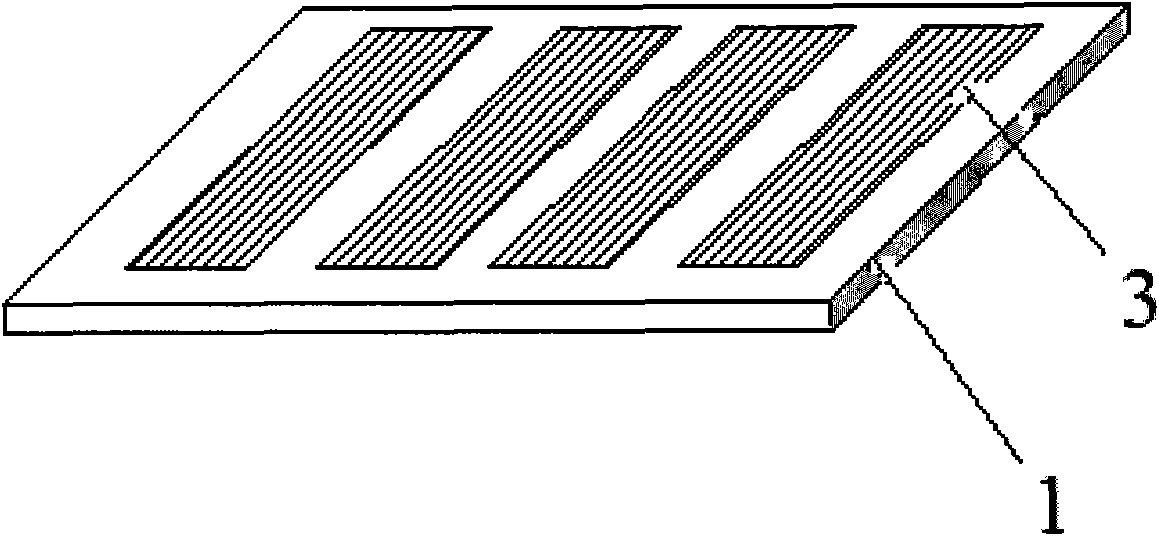

[0040] Screen printing TiO using a screen printer 2 Nanoparticles, the screen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com