Cosmetic mask cloth and processing method thereof

A processing method and technology for cosmetics, which are applied in cosmetic preparations, chemical instruments and methods, and cosmetic preparations, etc., can solve the problems of easy tearing and poor liquid retention, and achieve the effects of easy identification and long-lasting liquid retention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] (2) Preparation of colored ordinary fiber layer: using colored short fibers formed by masterbatch or natural colored short fibers or dyed short fibers, and reinforced by opening-carding-laying-needling and / or spunlace into a colored non-woven fabric layer, or use colored staple fibers formed from masterbatches or natural colored staple fibers or yarns or filaments formed from dyed staple fibers for weaving, and weave into colored woven fabric layers or knitted fabric layers;

[0017] (3) Preparation of laminated fabric: The sea-island composite fiber web layer and the colored ordinary fiber layer prepared above are subjected to needle punching or spunlace processing, and then the processed two layers are placed in 6-10g / L, 90-98 After being treated in NaOH solution at ℃ for 0.5-2 hours, drying and heat setting are carried out to form a layer of laminated fabric containing a non-woven nanofiber layer;

[0018] (4) Preparation of the finished product: The laminated cloth ...

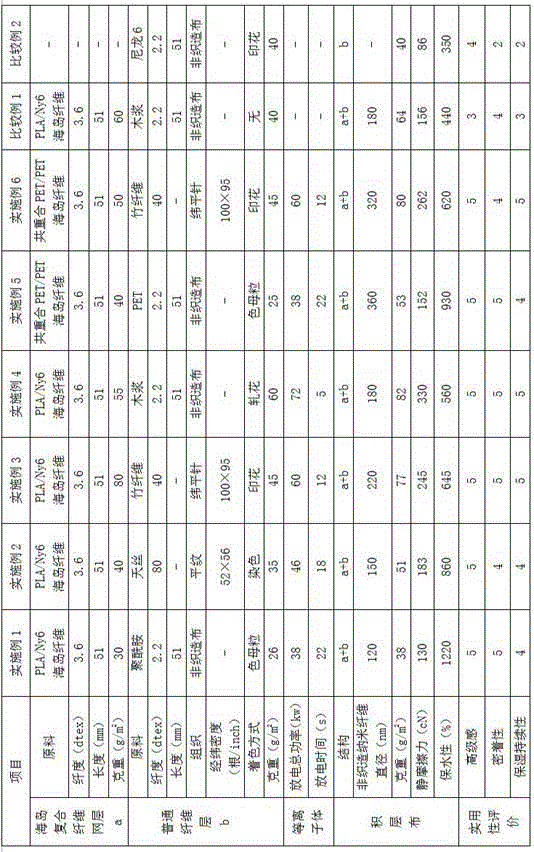

Embodiment 1

[0040] (1) Preparation of sea-island composite fiber web layer a: Put polylactic acid / polyamide 6 island-in-sea short fibers with a sea-island ratio of 60 / 40, a fineness of 3.6dtex, and a length of 51mm into the cotton mixing box for fiber opening-mixing-carding - Laying net - spunlace, to obtain a grammage of 30g / m 2 Polylactic acid / polyamide 6 island-in-the-sea composite fiber mesh layer a;

[0041] (2) Preparation of colored ordinary fiber layer b: Put the polyamide 6 original colored short fibers with a fineness of 2.2dtex and a length of 51mm into the cotton mixing box for fiber opening-cotton mixing-carding-laying-spunlace to obtain the grammage 26g / m 2 colored polyamide 6 nonwoven layer b;

[0042] (3) Preparation of laminated fabric: stack the sea-island composite fiber web layer a and the colored polyamide 6 nonwoven fabric layer b prepared above, and then feed them into the spunlace machine for spunlace compounding, and then process the two The layer was treated i...

Embodiment 2

[0045] (1) Preparation of sea-island composite fiber web layer a: Put polylactic acid / polyamide 6 island-in-sea short fibers with a sea-island ratio of 60 / 40, a fineness of 3.6dtex, and a length of 51mm into the cotton mixing box for fiber opening-mixing-carding - Laying net - spunlace, to obtain a grammage of 40g / m 2 Polylactic acid / polyamide 6 island-in-the-sea composite fiber mesh layer a;

[0046] (2) Preparation of colored ordinary fiber layer b: Weaving Tencel filaments with a fineness of 80 dtex into plain weave fabrics with warp and weft densities of 52×56 threads / inch respectively, and subjecting the plain weave fabrics prepared above to an environmentally friendly dyeing process, Get a grammage of 35 g / m 2 colored tencel woven fabric layer b;

[0047] (3) Preparation of laminated fabric: stack the sea-island composite fiber web layer a and the colored tencel woven fabric layer b prepared above, and then feed them into the spunlace machine for spunlace compounding, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Power | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com