Bamboo charcoal viscose facial mask base cloth and high moisture retention and moisturizing facial mask

A bamboo charcoal viscose and fiber technology, which is used in fiber processing, plant fibers, cosmetics, etc., can solve the problems of unsustainable liquid-holding and liquid-holding ability, loss and waste of effective ingredients, and user's sensory discomfort, and achieves a balance between liquid and liquid retention. Moisture release ability, antistatic comfort, effect of eliminating allergy risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

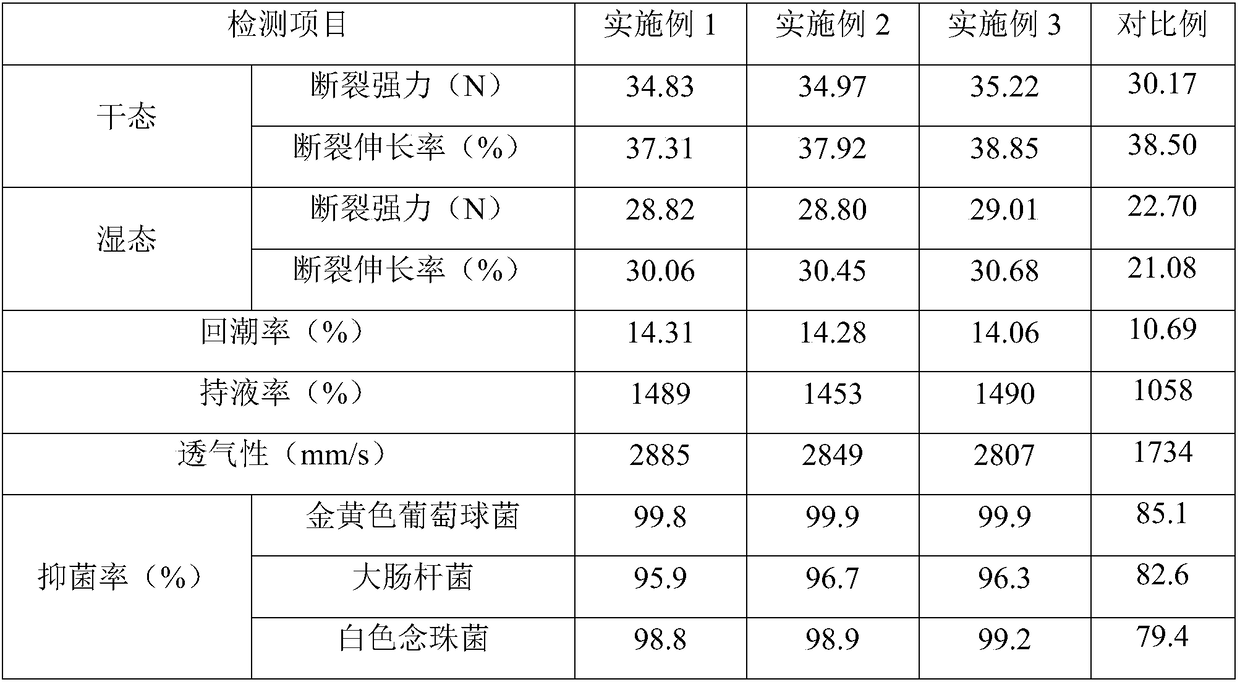

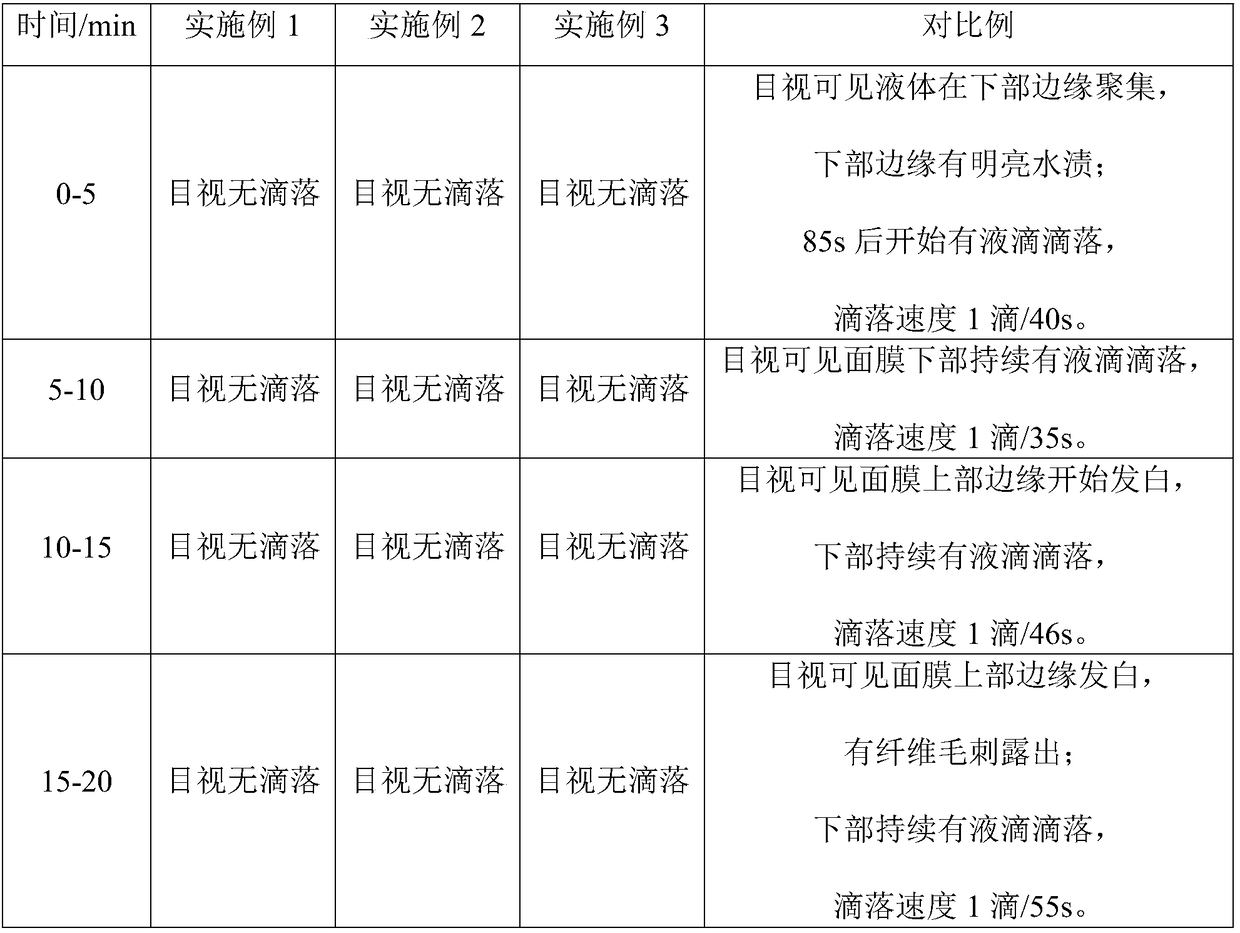

Examples

Embodiment 1

[0038] The bamboo charcoal viscose fiber mask base cloth of the present embodiment is prepared by the following method:

[0039] 1) dissolving the dispersant sodium polyacrylate in water to make a dispersion solution;

[0040] According to the mass ratio of nano-bamboo charcoal powder and sodium alginate as 8:0.5, take nano-bamboo charcoal powder and sodium alginate and add them to the dispersion solution obtained above, and make them disperse evenly through grinding and shearing emulsification to obtain bamboo charcoal with a mass content of 8 % bamboo charcoal slurry;

[0041] Wherein, the consumption of dispersant sodium polyacrylate is 10% of the quality of nanometer bamboo charcoal powder;

[0042] 2) Add the bamboo charcoal slurry obtained in step 1) into the viscose spinning solution, so that the mass ratio of the bamboo charcoal in the bamboo charcoal slurry to the cellulose in the viscose spinning solution is 0.8:30, stir to make it evenly dispersed, and filter , Va...

Embodiment 2

[0050] The bamboo charcoal viscose fiber mask base cloth of the present embodiment is prepared by the following method:

[0051] 1) dissolving the dispersant sodium polyacrylate in water to make a dispersion solution;

[0052] According to the mass ratio of nano-bamboo charcoal powder and sodium alginate being 9:0.7, get nano-bamboo charcoal powder and sodium alginate and add them to the dispersion solution obtained above, and make them dispersed evenly through grinding and shearing emulsification to obtain bamboo charcoal with a mass content of 9 % bamboo charcoal slurry;

[0053] Wherein, the consumption of dispersing agent sodium polyacrylate is 15% of nanometer bamboo charcoal powder quality;

[0054] 2) Add the bamboo charcoal slurry obtained in step 1) into the viscose spinning solution, so that the mass ratio of the bamboo charcoal in the bamboo charcoal slurry to the cellulose in the viscose spinning solution is 0.9:30, stir to make it evenly dispersed, and filter , ...

Embodiment 3

[0062] The bamboo charcoal viscose fiber mask base cloth of the present embodiment is prepared by the following method:

[0063] 1) dissolving the dispersant sodium polyacrylate in water to make a dispersion solution;

[0064] According to the mass ratio of nano-bamboo charcoal powder and sodium alginate as 10:0.8, take nano-bamboo charcoal powder and sodium alginate and add them to the dispersion solution obtained above, and make them disperse evenly through grinding and shearing emulsification to obtain bamboo charcoal with a mass content of 10 % bamboo charcoal slurry;

[0065] Wherein, the consumption of dispersant sodium polyacrylate is 13% of the quality of nanometer bamboo charcoal powder;

[0066] 2) Add the bamboo charcoal slurry obtained in step 1) into the viscose spinning solution, so that the mass ratio of the bamboo charcoal in the bamboo charcoal slurry to the cellulose in the viscose spinning solution is 1.0:30, stir to make it disperse evenly, and filter , V...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com