Double-sided napping process of heating wool nitrile sticky fabric

A technology of fabrics and craftsmanship, applied in the field of double-sided napping technology, can solve the problems of softness not as good as cashmere, poor wearing comfort, and rigid velvet feel, etc., to achieve strong fluffy feeling of cloth surface, good dyeing fastness, and rich velvet surface Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

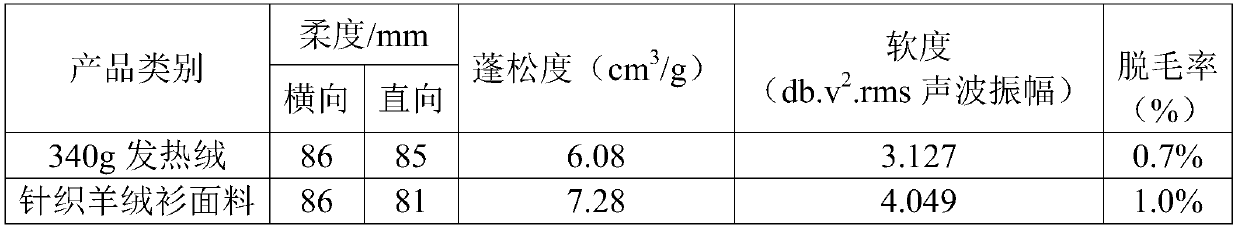

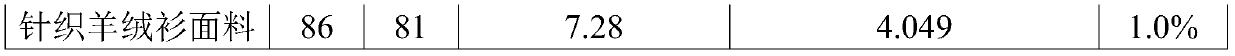

Embodiment 1

[0025] A double-sided napping process for heating velvet nitrile sticky fabrics, comprising the following steps:

[0026] (1) Softening treatment: Add 45g / L of Duff fatty acid type napping softener and 40g / L of Duff fatty acid type antistatic agent into the rolling groove of the sizing machine, mix evenly, wear the gray cloth on the leading cloth, and feed it to the sizing machine Cloth, set the liquid rolling rate to 75%, the oven temperature to 170°C, and the machine speed to 16m / min. The fabric can evenly absorb the softener and pass through each section of the oven at a uniform speed to ensure that the fluffy degree of the gray fabric reaches 6cm. 3 / g;

[0027] (2) First napping: The fabric in step (1) is napped on the reverse side within 0.5h, the gray cloth is put on the leading cloth, and the cloth is fed to the napping machine, and the front and back of the napping machine are continuously napped by 4 sets of 42 rollers, and the napping machine needle The speed gradu...

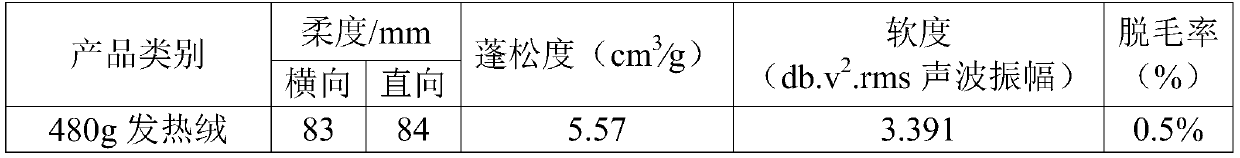

Embodiment 2

[0044] A double-sided napping process for heating velvet nitrile sticky fabrics, comprising the following steps:

[0045] (1) Softening treatment: Add 45g / L of Duff fatty acid type napping softener and 40g / L of Duff fatty acid type antistatic agent into the rolling groove of the sizing machine, mix evenly, wear the gray cloth on the leading cloth, and feed it to the sizing machine Cloth, set the liquid rolling rate to 78%, oven temperature to 175°C, and machine speed to 15m / min. The fabric can thoroughly absorb the softener and pass through each section of the oven at a uniform speed to ensure that the fluffy degree of the gray fabric reaches 6cm. 3 / g;

[0046] (2) First napping: The fabric in step (1) is napped on the reverse side within 1 hour, the gray cloth is put on the leading cloth, and the cloth is fed to the napping machine, and the front and back of the napping machine are continuously napped by 4 sets of 42 rollers, and the napping machine needle The speed gradual...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com